Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Increase winding density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

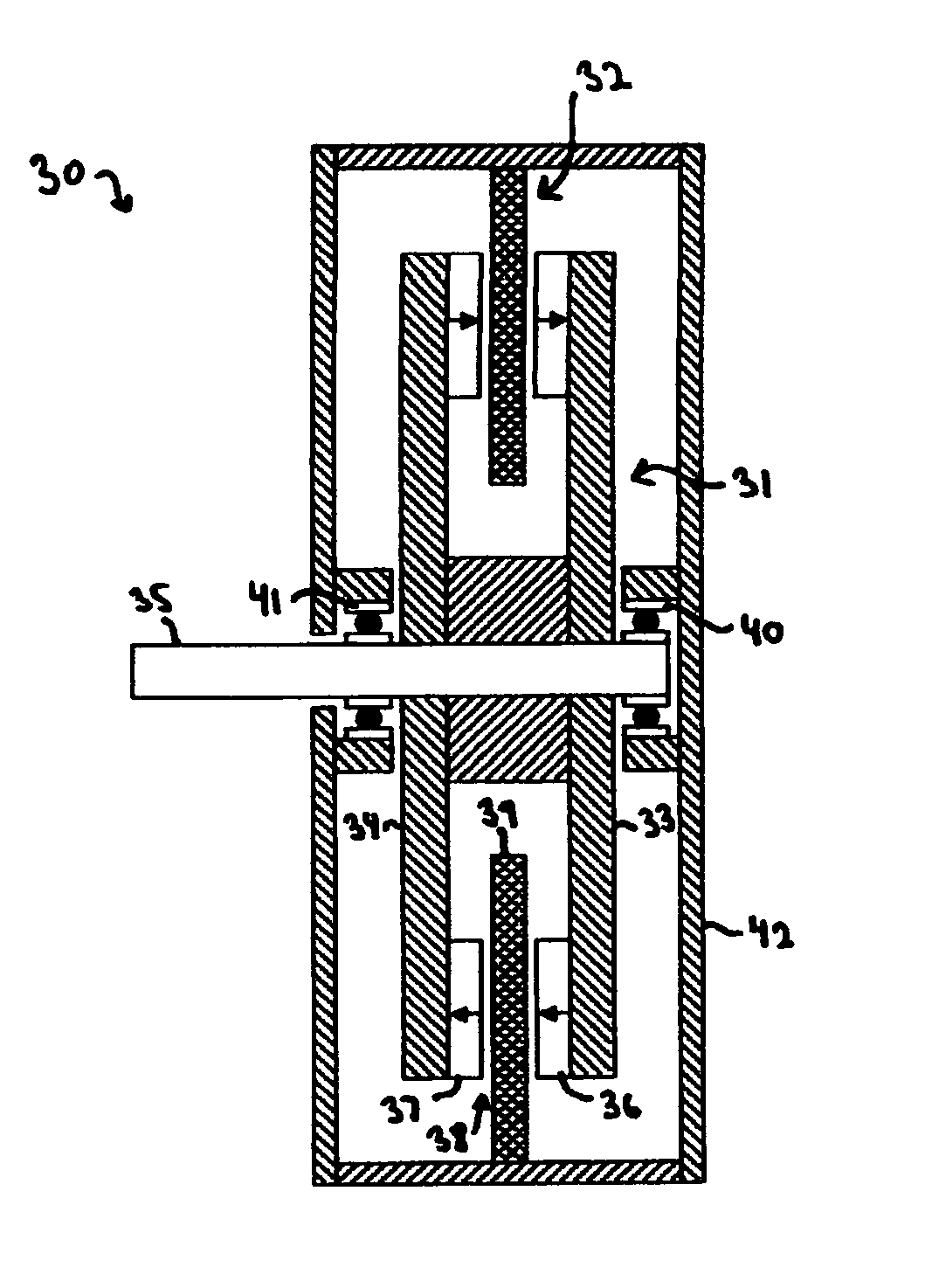

High performance air core motor-generator winding

InactiveUS7402934B1Long and reliable operating lifeIncrease winding densitySynchronous generatorsWindingsMagnetic polesRotational energy

A motor-generator for converting between electrical and rotational energy includes a rotor mounted for rotation about an axis of rotation relative to a stationary a stator that magnetically interacts with the rotor. The rotor has two spaced apart rotor portions that define therebetween an armature airgap. Magnetic poles on the rotor portions drive magnetic flux across the airgap. An air core armature is located in the airgap, such that opposite sides of the air core armature face the two opposed rotating surfaces of the rotor. The air core armature has windings in which AC voltage is induced as the rotor rotates. The windings are wound with multiple individually insulated strand conductor wire wrapped with a wrapping of a thin dielectric tape film over the multiple individually insulated strand conductor wire.

Owner:REVOLUTION ELECTRIC MOTOR

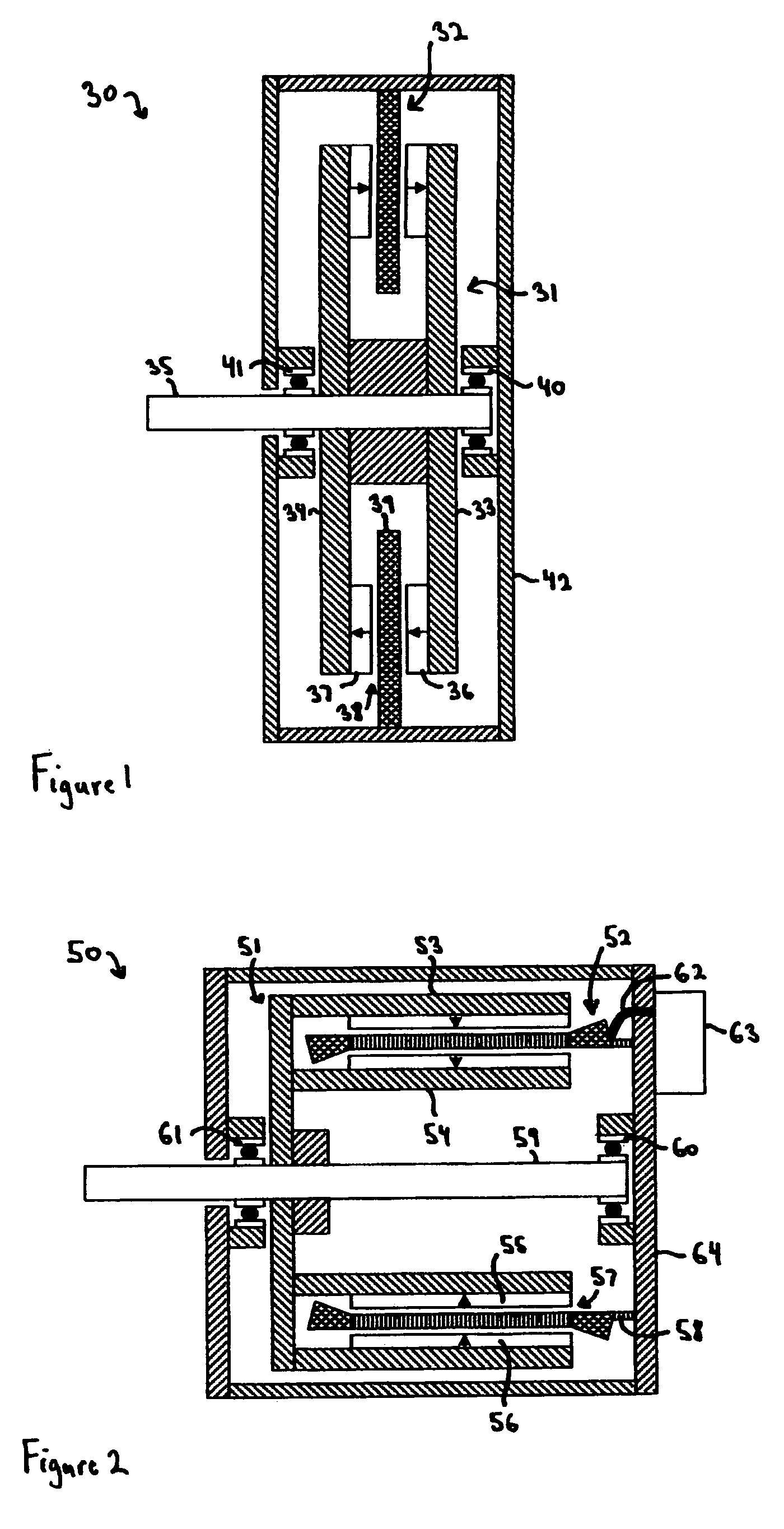

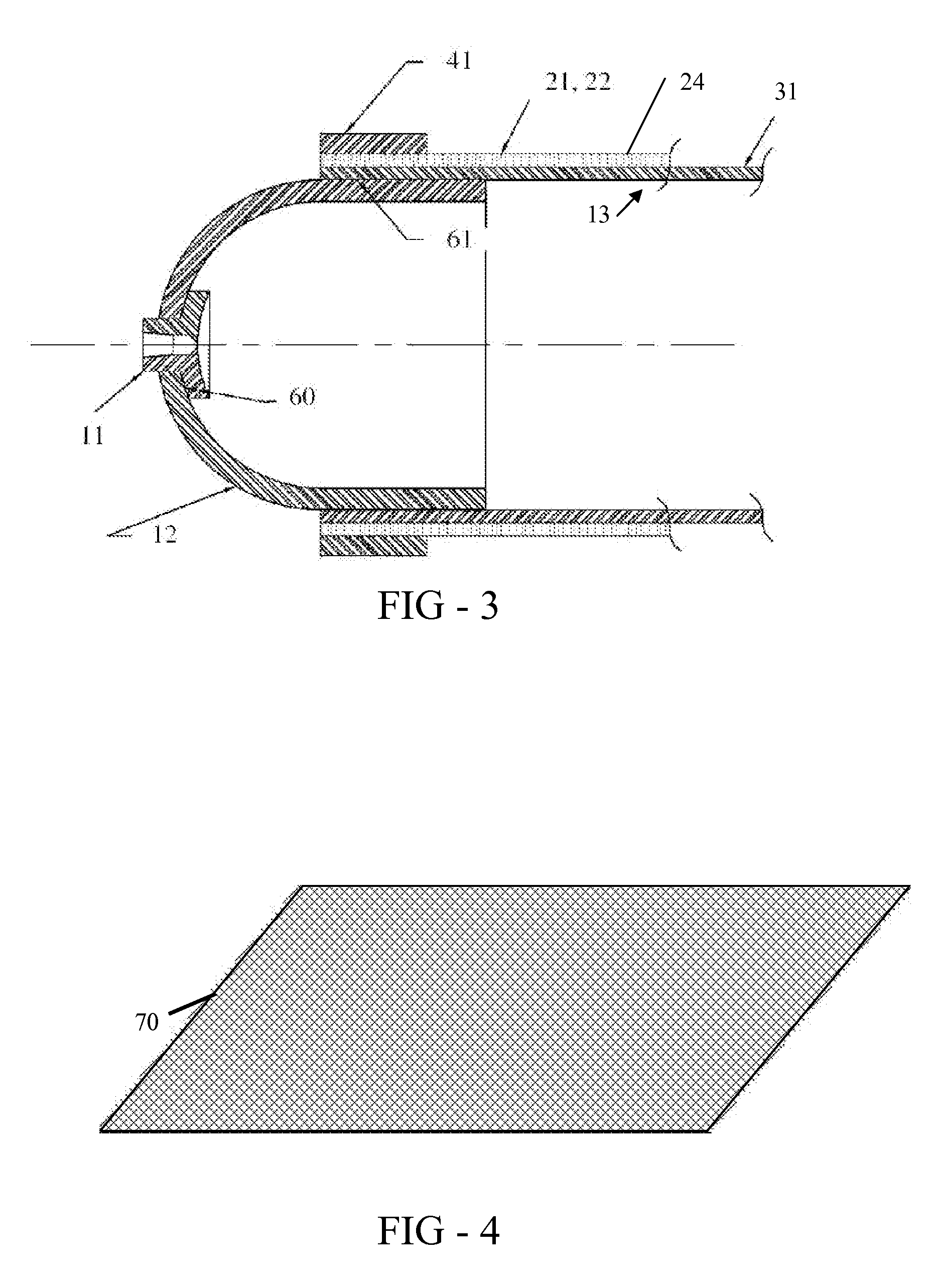

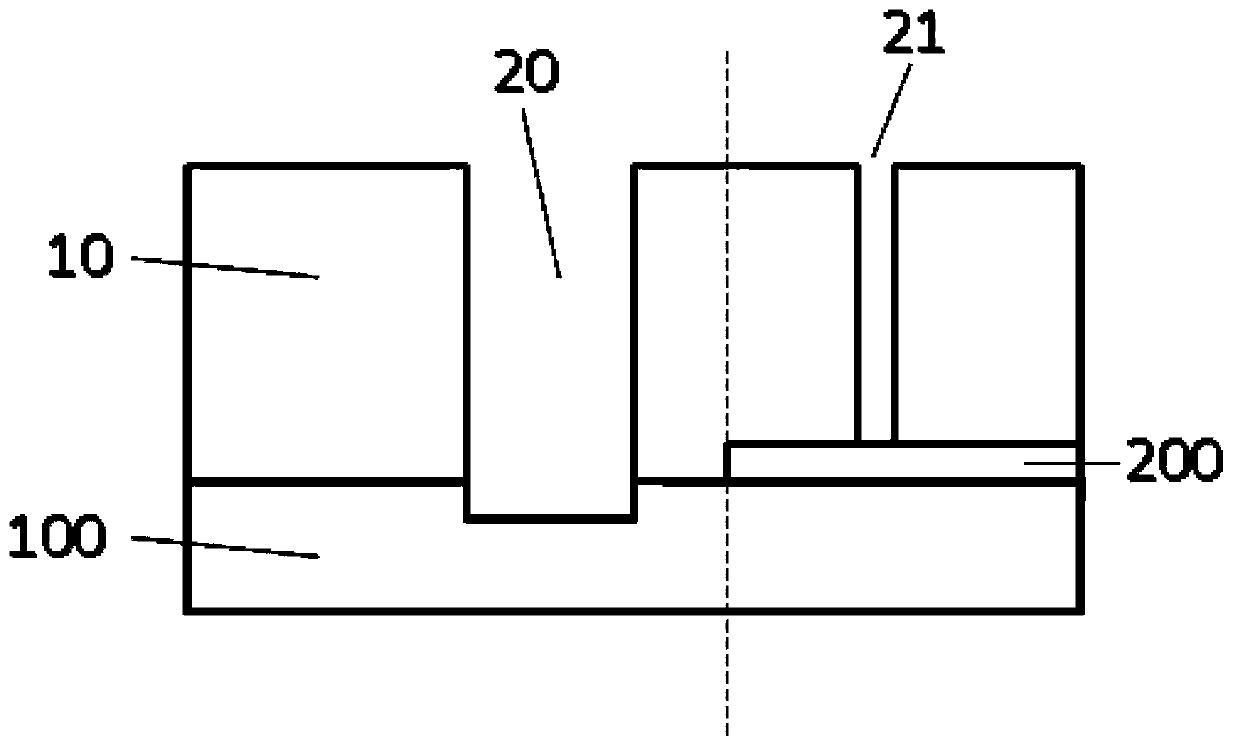

Wire wrapped pressure vessels

ActiveUS20090095796A1High strengthIncrease winding densityVessel manufacturingVessel geometry/arrangement/sizeGlass fiberWire rod

A pressure vessel (2) for the storage of fluid has a core (10) made of metal or polymer and is wrapped either completely or partially from outside with a high strength fibers (21, 22) for reinforcement wherein one of the reinforcing fibers is a metal wire (21) of a single filament or cables of multi filaments having strength from 2000 MPa to 6000 MPa. The wire has a plastic ductility of over 20% in reduction in area (RA) at tensile fracture. The metal wire (21) is made of steel or nickel or titanium or their respective alloys. The core (10) of the vessel (2) is first wrapped with a resin covered ceramic fibers such as carbon, fiberglass and subsequently wrapped with the metal wire (21) with or without other fibers (22). The metal wires (21) can be of different diameters in parallel or cabled forms.

Owner:WIRETOUGH CYLINDERS

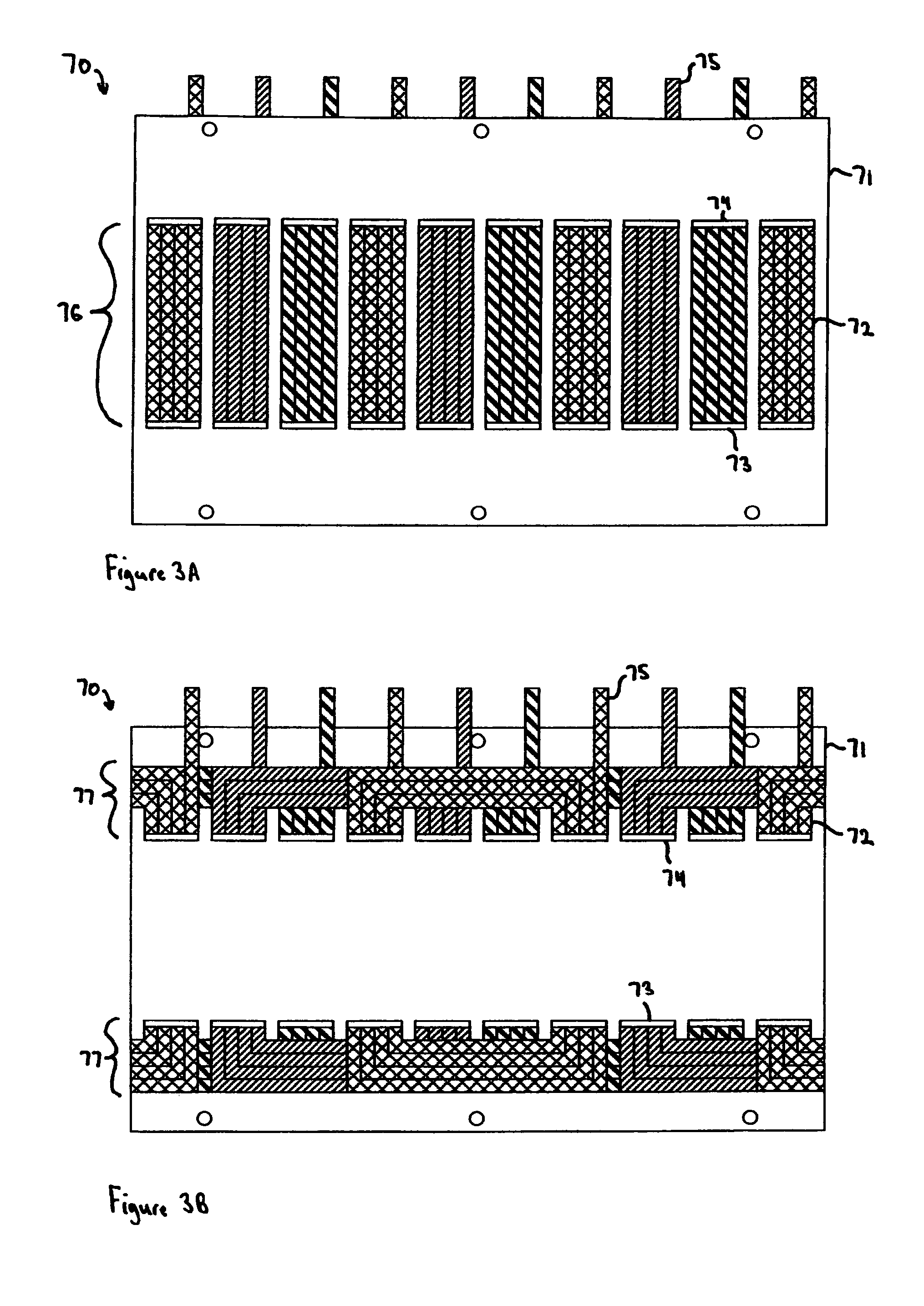

Double-layer coil for electromagnetic formation and manufacturing method of double-layer coil

InactiveCN104779029ASmall outer diameterIncrease the number of turnsCoils manufactureCoilsElectromagnetic formingBlind hole

The invention relates to a double-layer coil for electromagnetic formation and a manufacturing method of the double-layer coil. The double-layer coil comprises a casing; a circular groove where coils are arranged is formed in the front side of the casing; an upper layer coil body and a lower layer coil body are sequentially arranged in the groove from top to bottom; two rectangular through holes are respectively formed in two sides, close to the edge of the casing, in the groove; a step blind hole where a middle connector is arranged is formed in the middle of the groove; the middle connector is matched with the step blind hole; rectangular first blind holes are symmetrically formed in the two sides of the step blind hole; second blind holes corresponding to the first blind holes are formed in the back side of the casing; the first blind holes are communicated with the second blind holes; the beginning end of the upper layer coil body and the beginning end of the lower layer coil body are connected with the middle connector; the output end of the upper layer coil body and the output end of the lower layer coil body penetrate through the through holes and then are respectively connected with a power line in the second blind holes electrically. The double-layer coil has the advantage that the insulation and the mechanical strength of the coil are improved.

Owner:FUZHOU UNIV

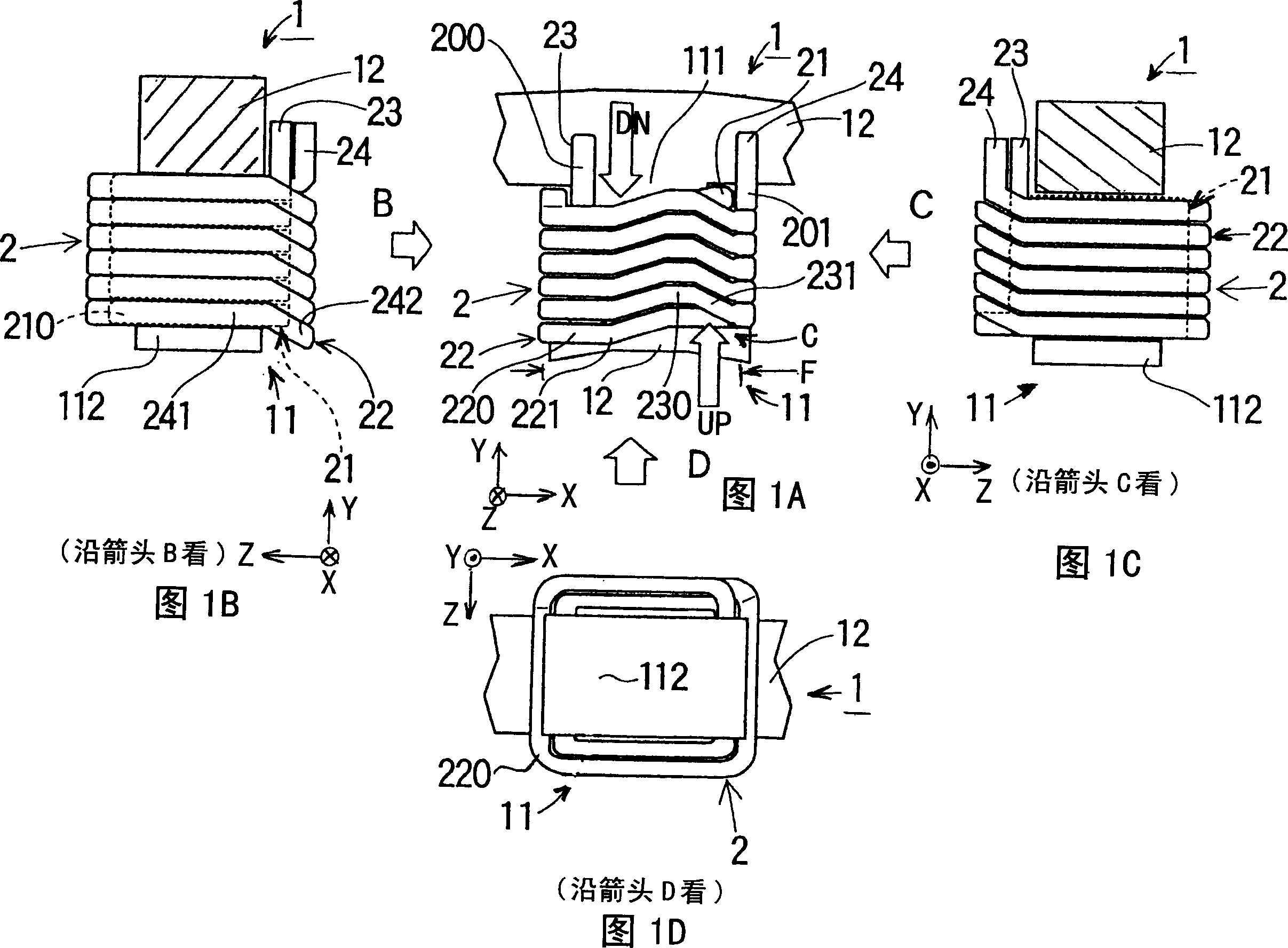

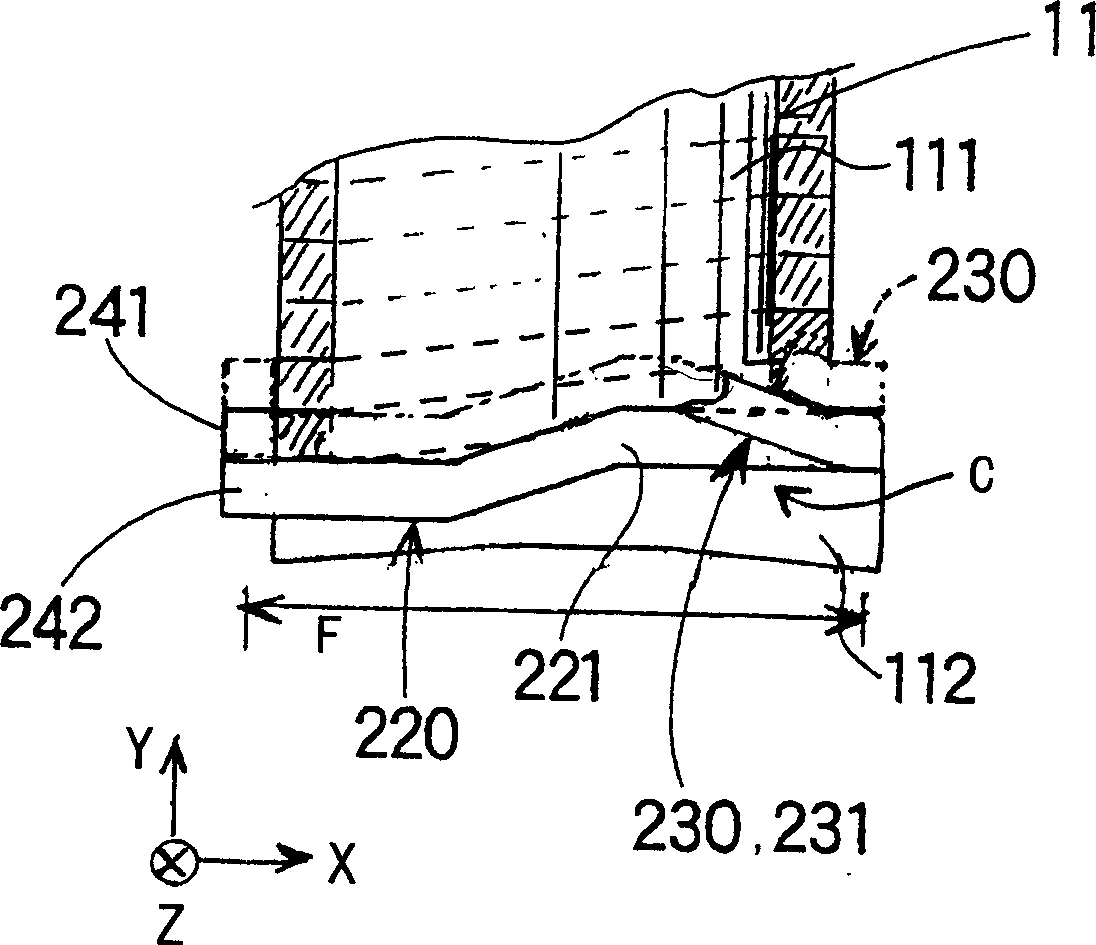

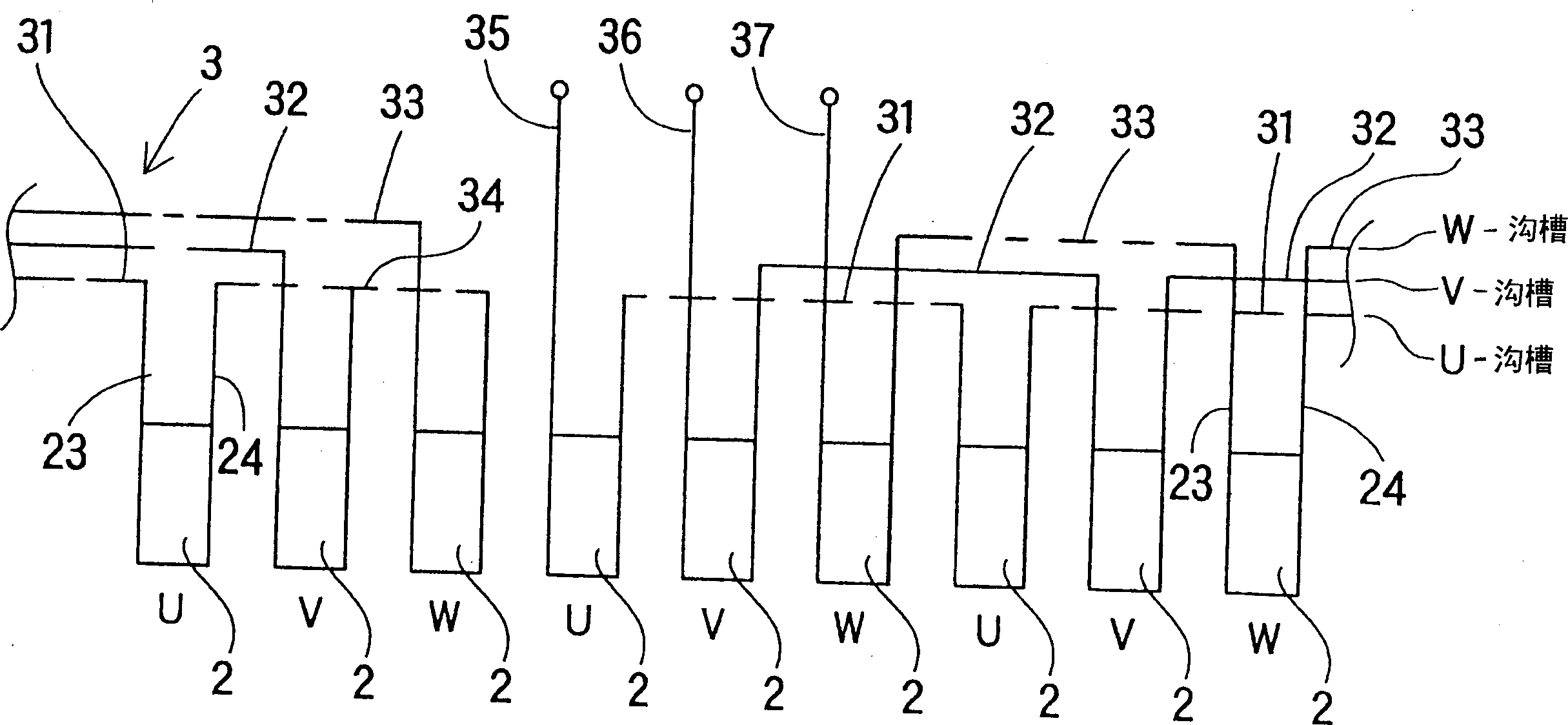

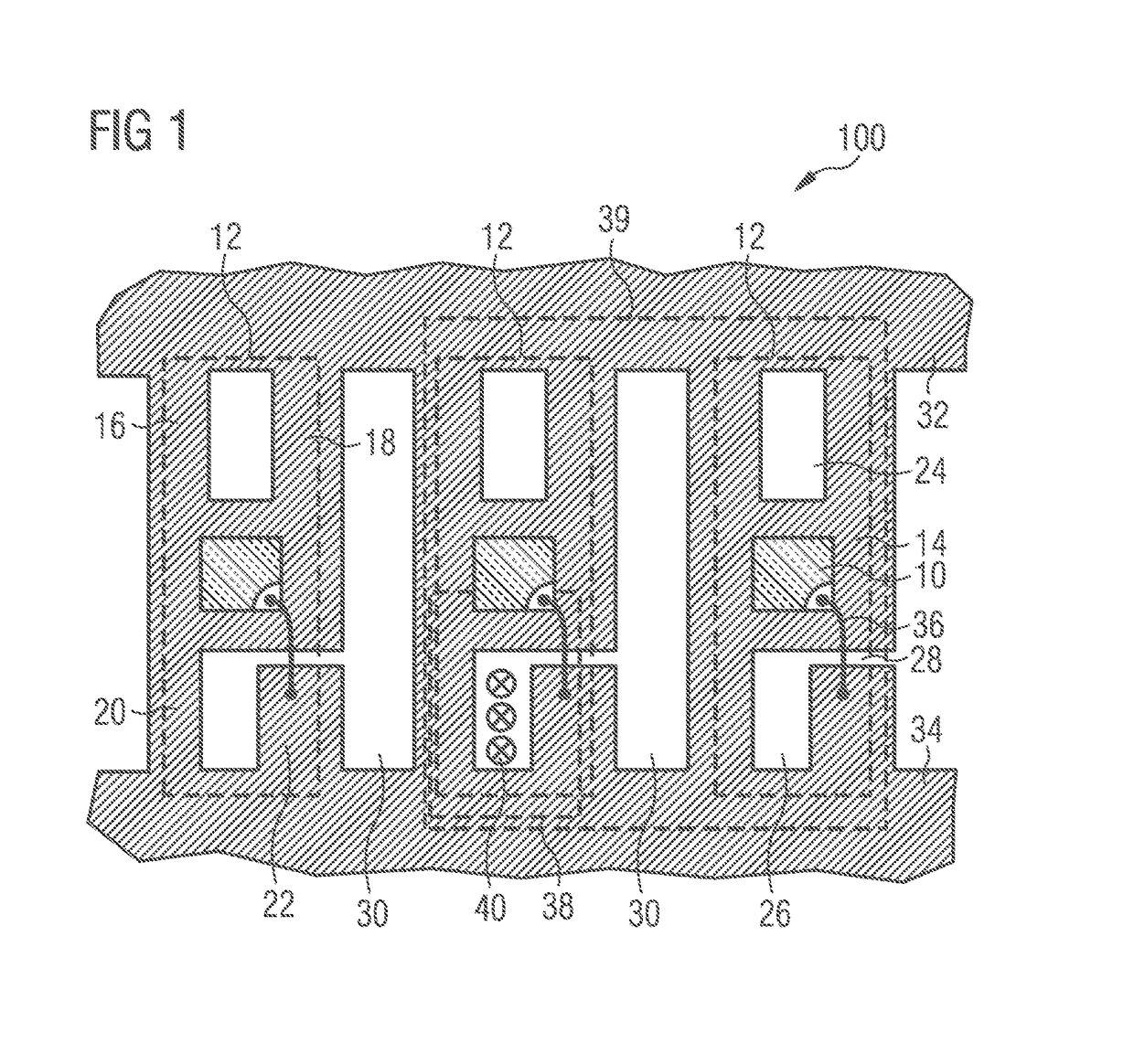

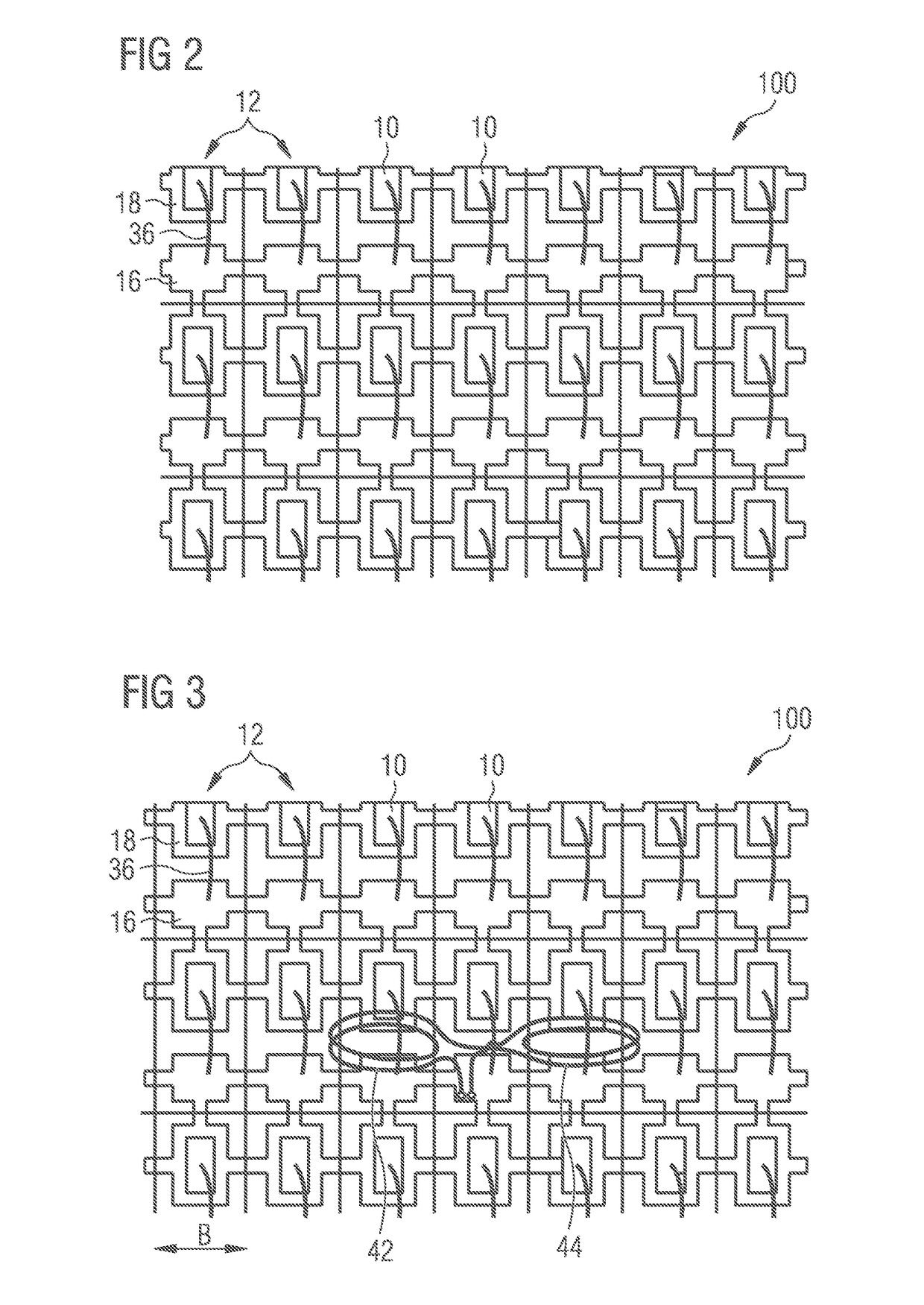

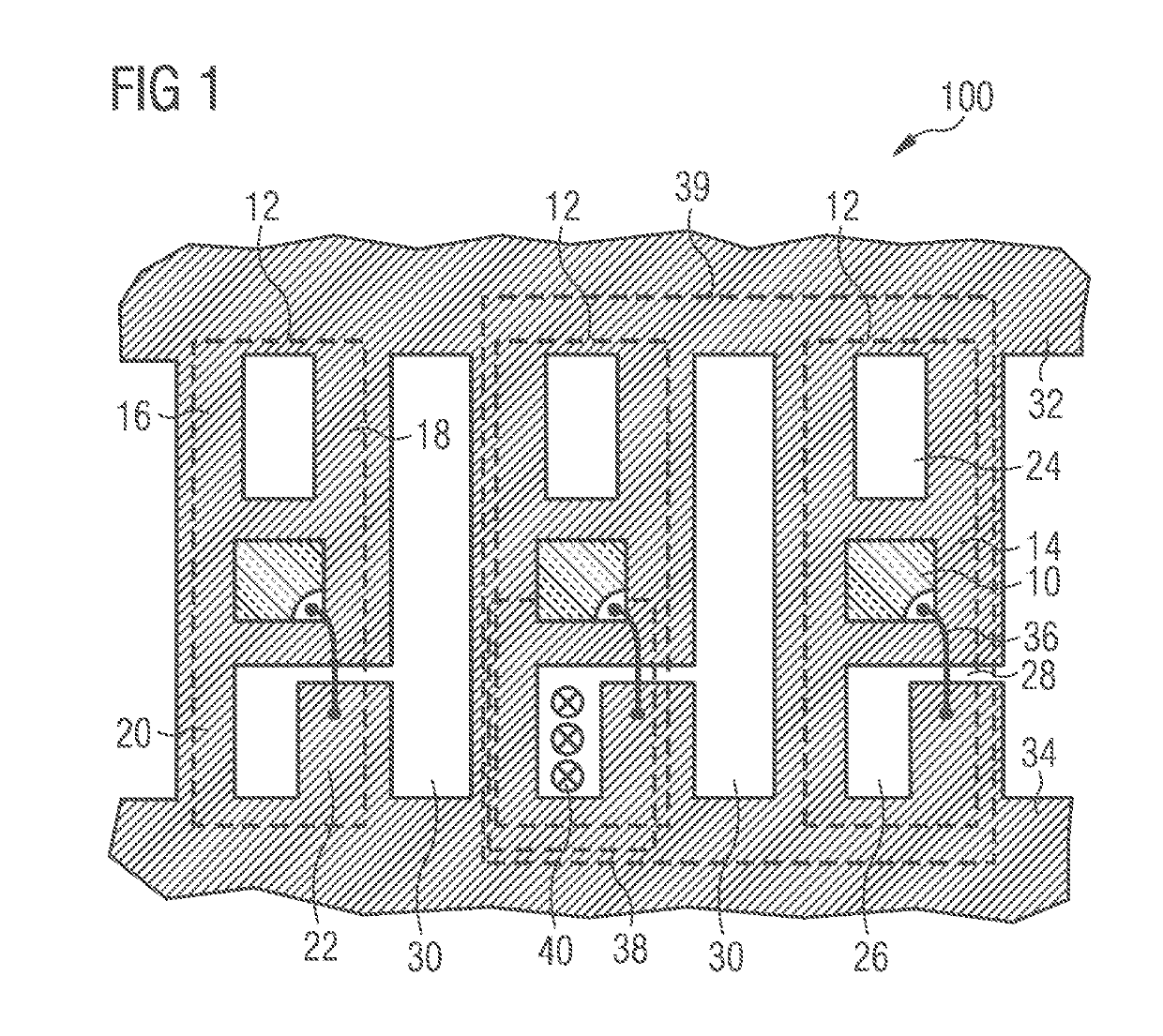

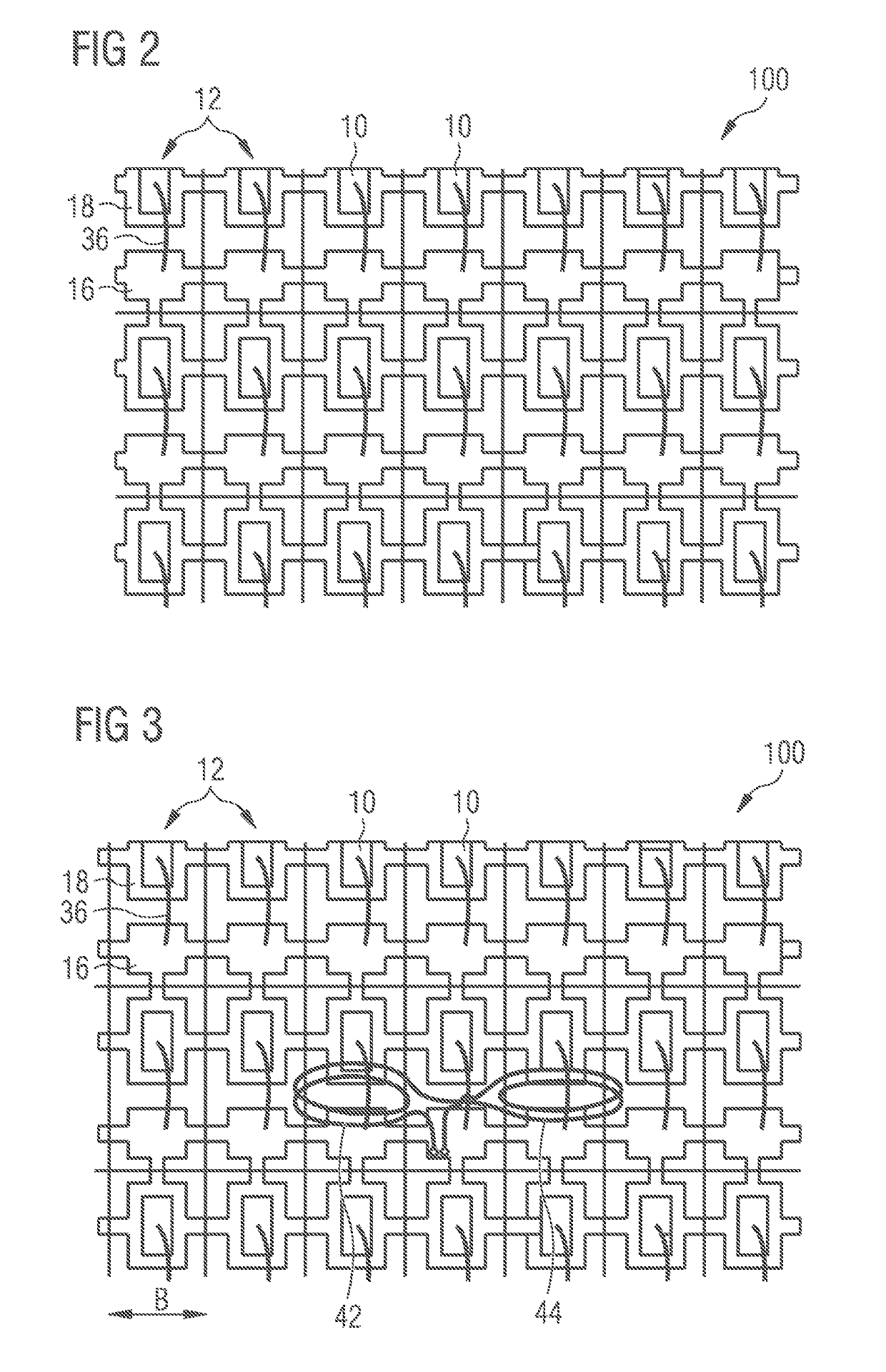

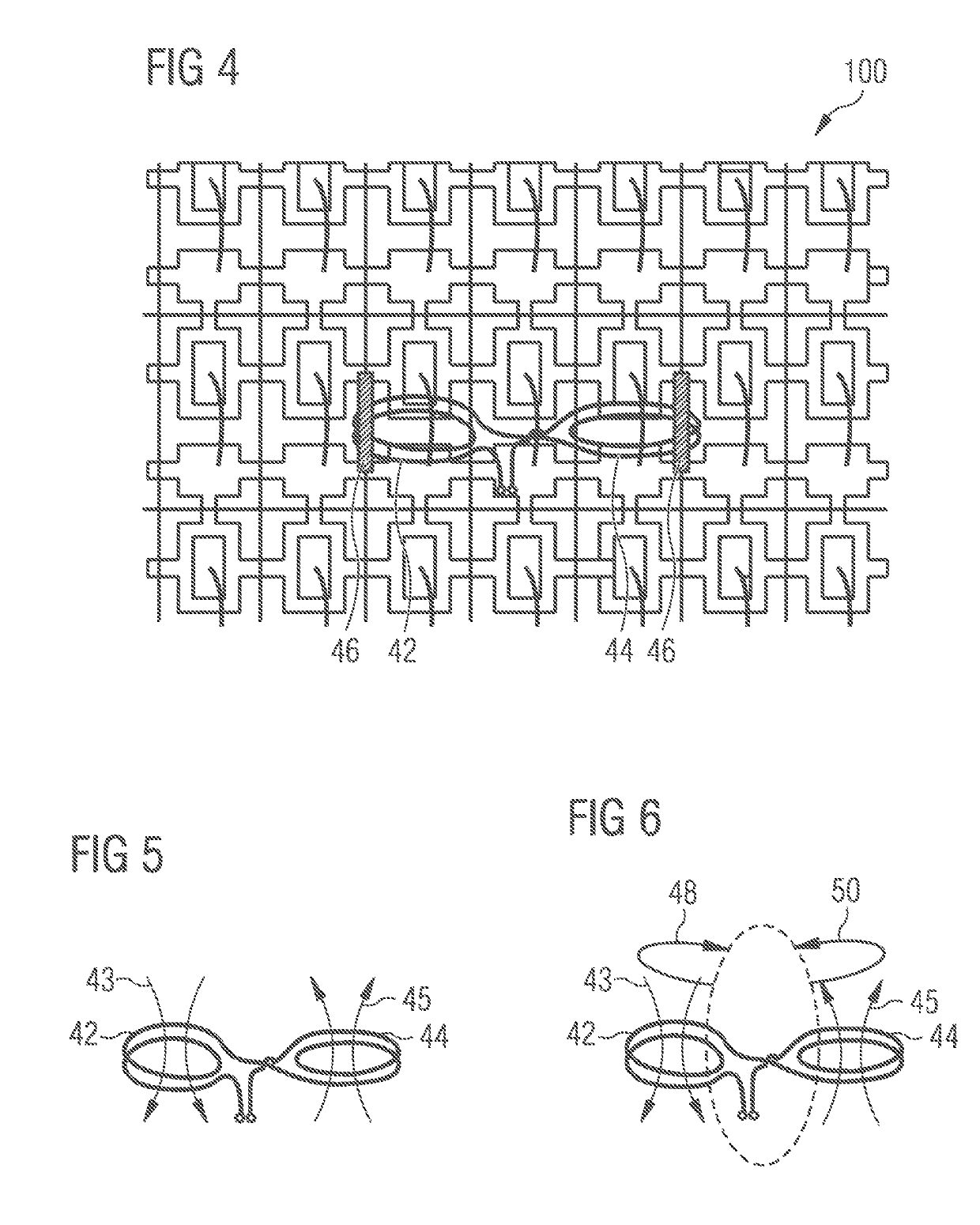

Integral winding stator coil assembly of rotating machine

InactiveCN1518191AAvoid contactAvoid interferenceManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric machineStator coil

A concentrated-winding type stator coil unit for a rotary electric machine is provided with a stator core having a core back and teeth protruding from the core back. Plural coils are wound around the teeth respectively. Each coil is composed of, for example, a first layered coil formed by winding a coil wire in a layer around each tooth to form plural turns arranged in parallel on each tooth and a second layered coil formed by winding the coil wire in a layer to from plural turns around the first layered coil wound around each tooth. The last turn of the first layered coil continues to the first turn of the second layered coil. Both ends of the coil wire are located at and on a base potion of each of the teeth as a winding-start end and a winding-finish end of each of the coils.

Owner:DENSO CORP

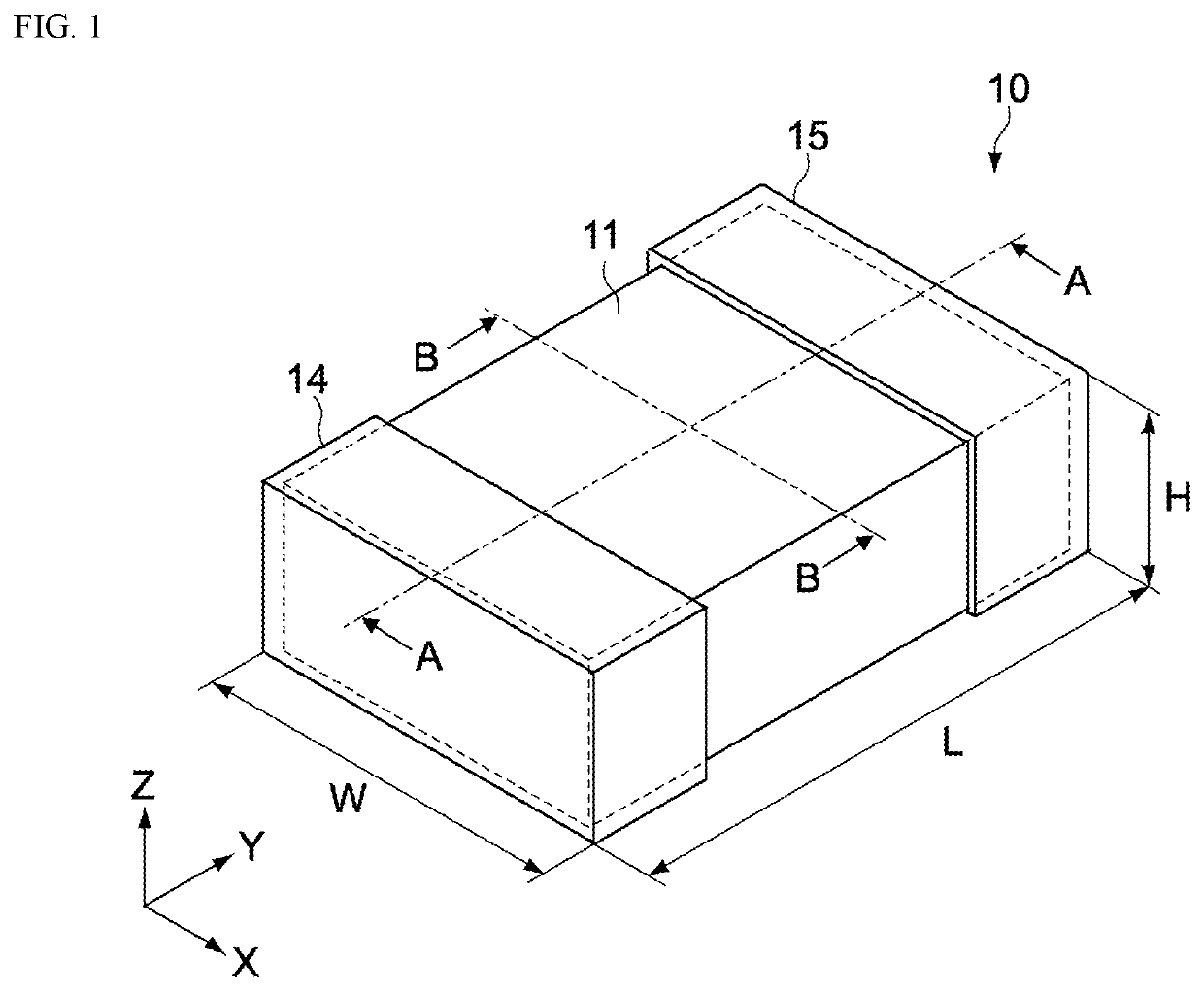

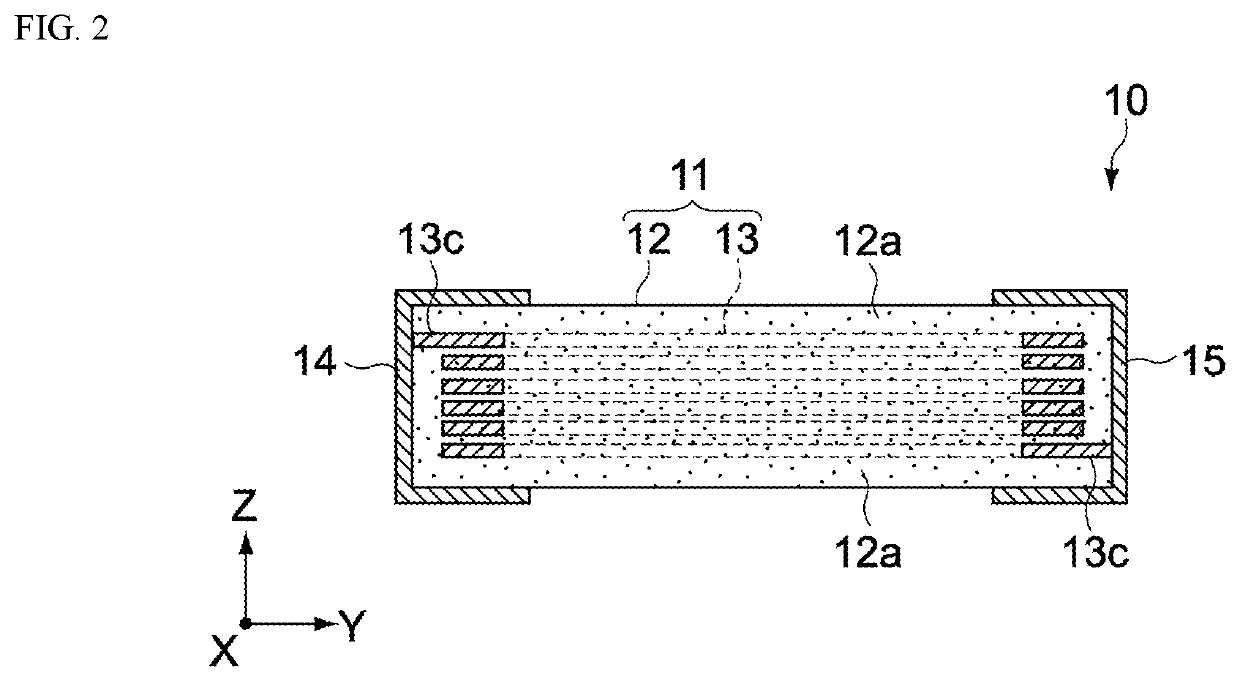

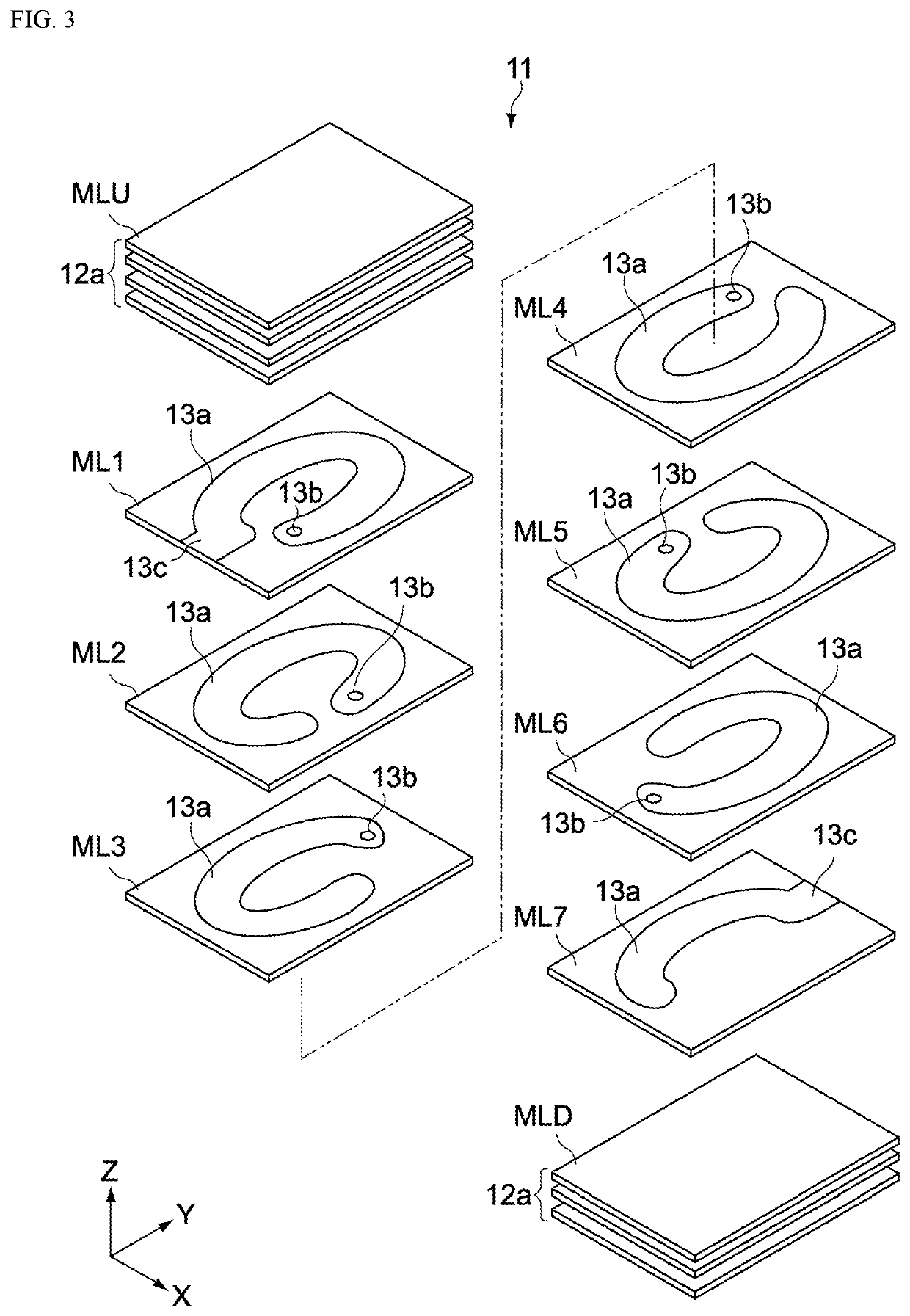

Coil component

ActiveUS20180166199A1Improve performanceAdditional componentTransportation and packagingTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

A coil component includes a magnetic body part and a coil part. The magnetic body part has first and second magnetic layers stacked together alternately in one axis direction, and cover parts covering the first and second magnetic layers from the one axis direction. The coil part has conductor patterns provided on the second magnetic layers. The magnetic body part includes: oblate soft magnetic grain-containing layers extending over the entire range of the magnetic body part in the direction perpendicular to the one axis direction, exposed in the direction perpendicular to the one axis direction, and formed by oblate soft magnetic grains whose thickness direction is oriented in the one axis direction; and spherical grain-containing layers adjoining the oblate soft magnetic grain-containing layers in the one axis direction, and formed by insulative spherical grains.

Owner:TAIYO YUDEN KK

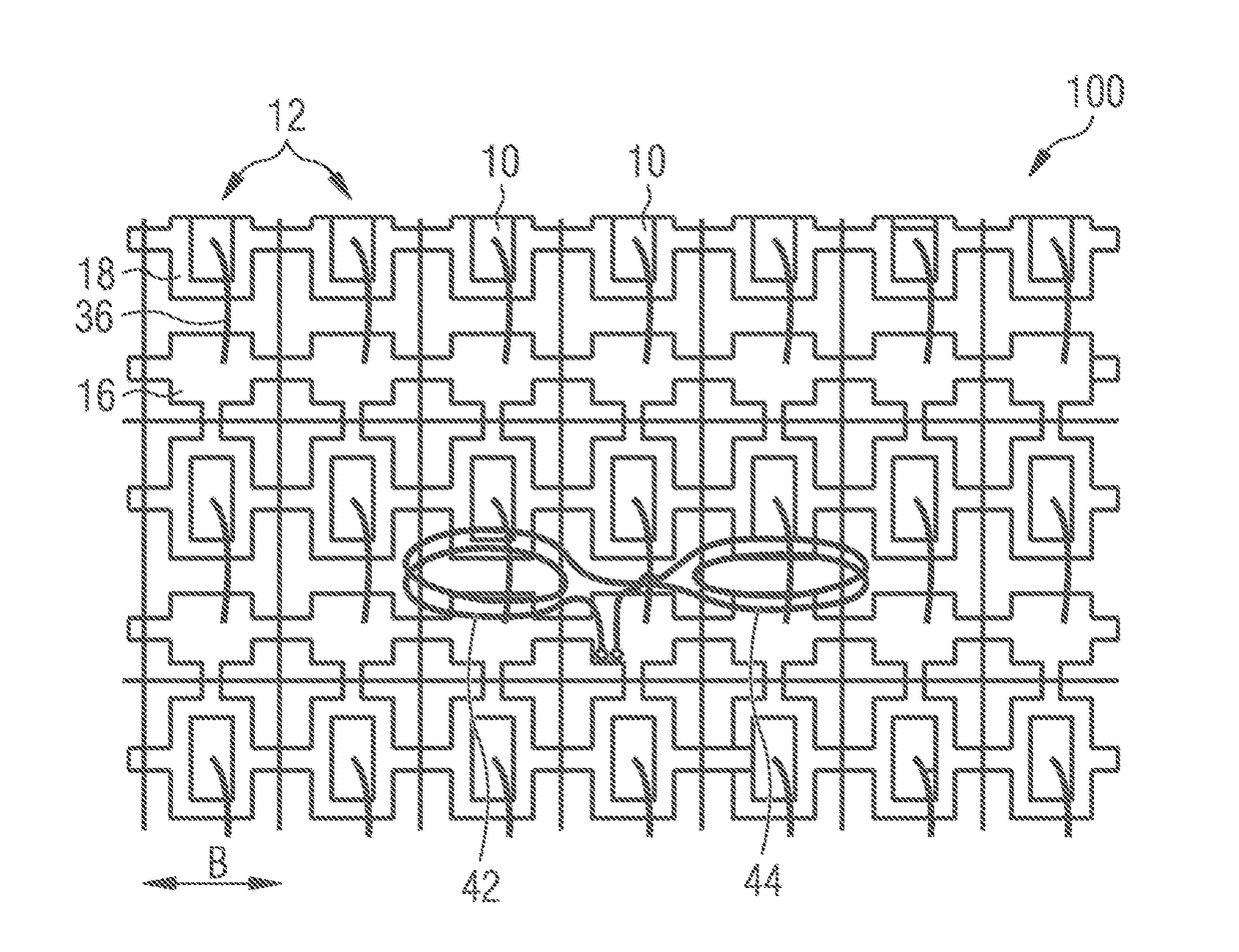

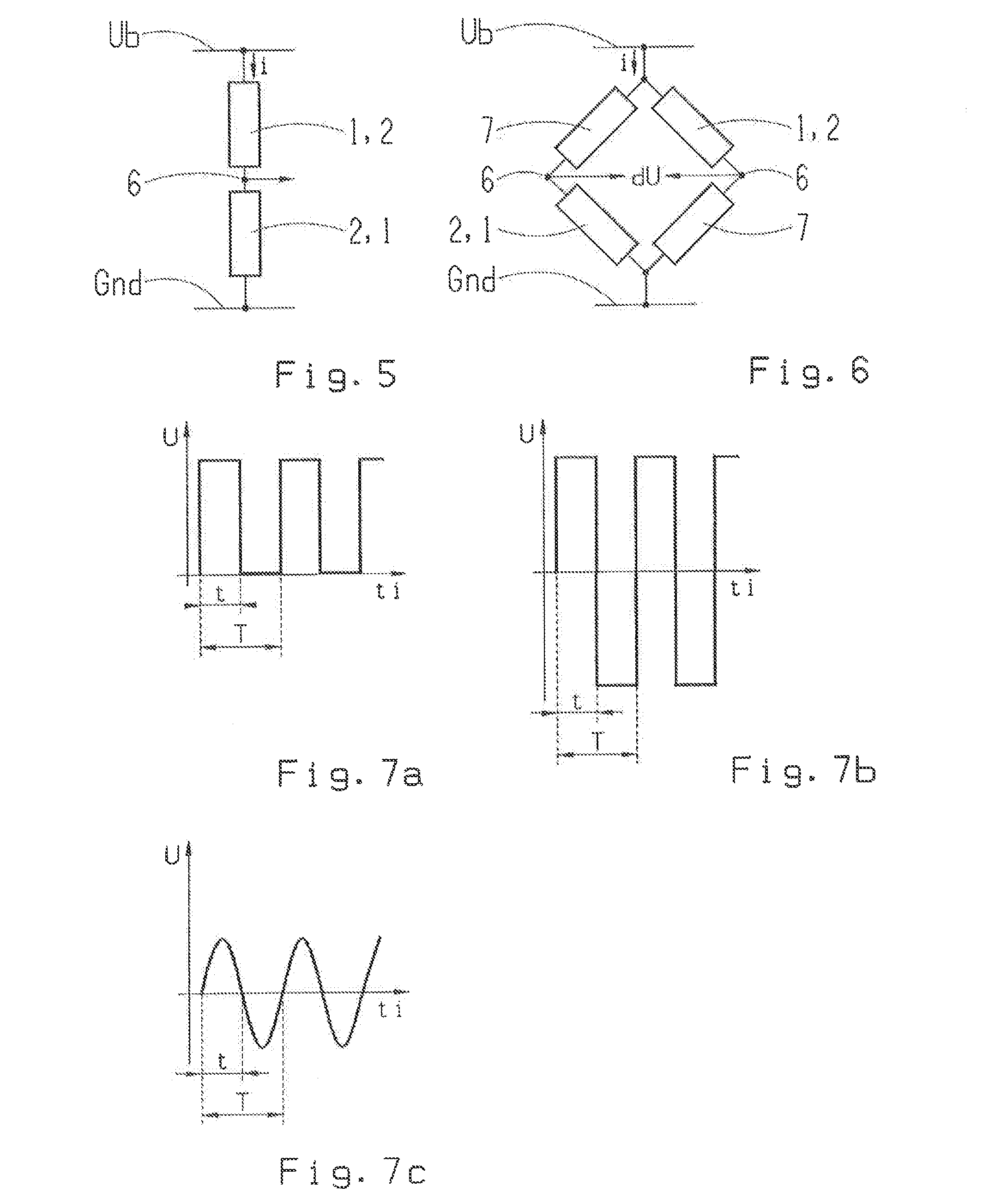

Method and Device for Inspecting an Optoelectronic Component

A method and a device for inspecting an optoelectronic component are disclosed. In an embodiment, the method includes exciting at least one electromagnetic resonant circuit, formed by the at least one optoelectronic component and the connection board, such that the at least one optoelectronic component emits electromagnetic radiation, wherein exciting the electromagnetic resonant circuit comprises applying an electrical alternating voltage in the electromagnetic resonant circuit by generating a temporally variable electromagnetic alternating field by a first coil and a second coil, wherein the first coil and the second coil are movable with respect to the connection board.

Owner:OSRAM OLED

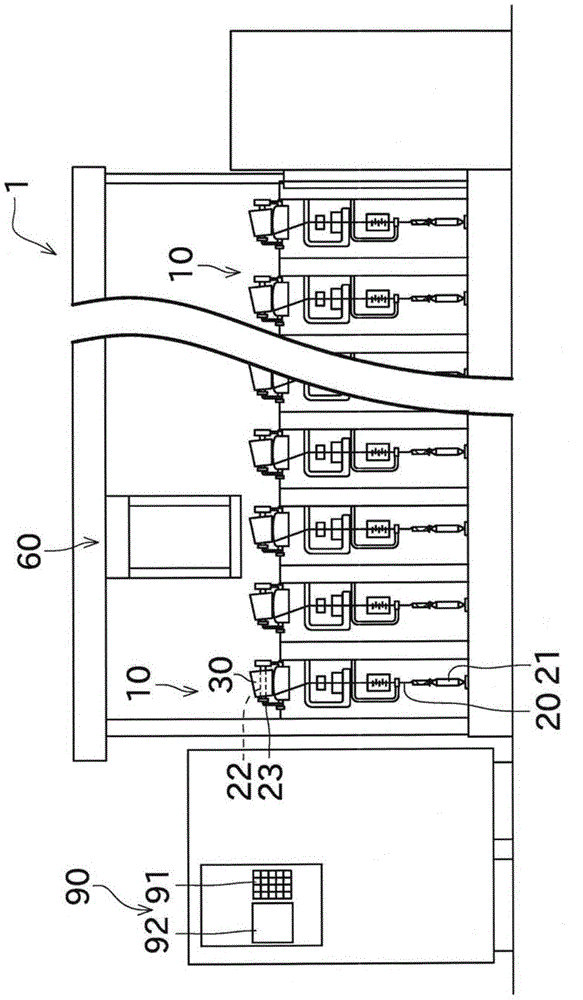

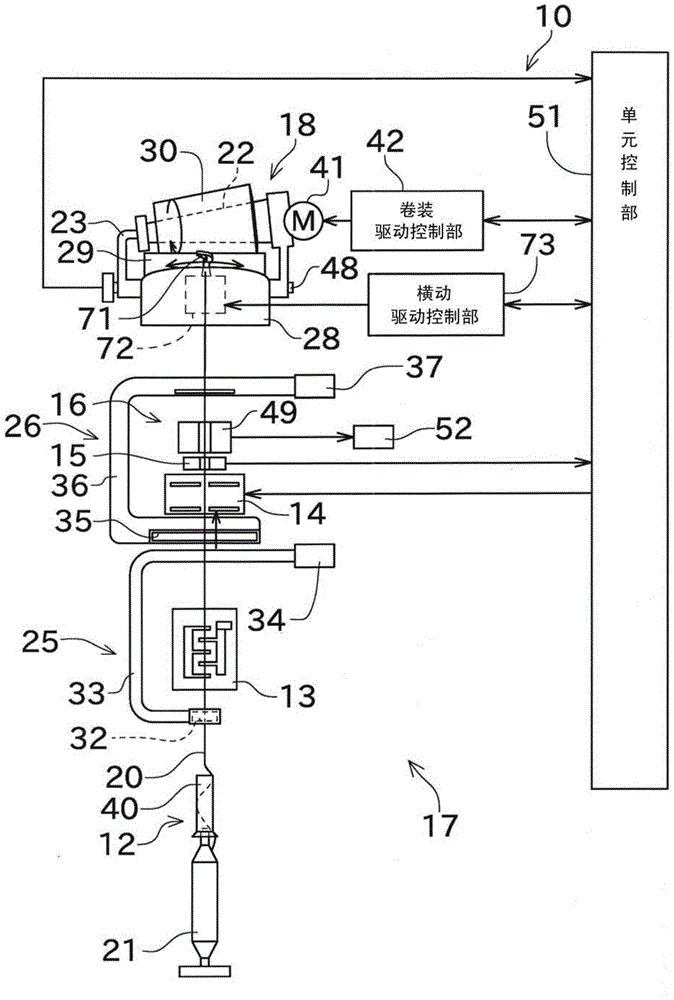

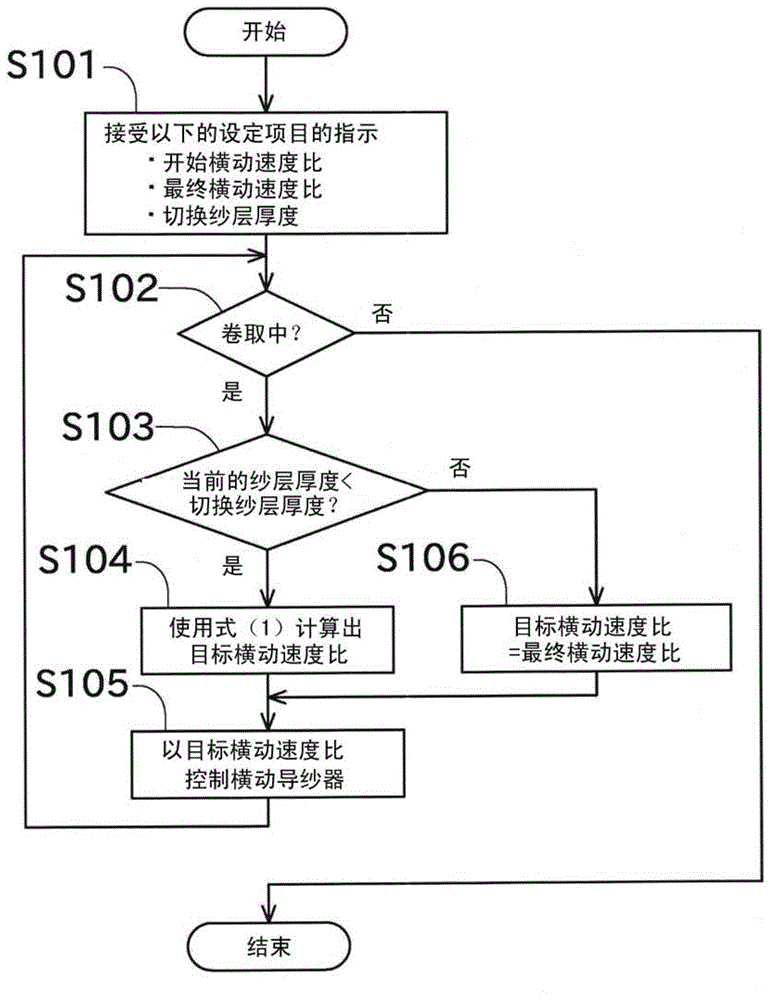

Yarn winder and winding method

The invention provides a yarn winder and a winding method. An automatic winder (1) includes a cross arm (71) and a unit control section (51). The cross arm (71) makes yarn (20) winding on a conical winding device (30) move transversely. During the winding, the unit control section (51) makes the transverse moving speed of the cross arm (71) in a small-diameter side area increase relative to the transverse moving speed ratio, namely the transverse moving speed ratio, of the cross arm (71) in a large-diameter side area.

Owner:MURATA MASCH LTD

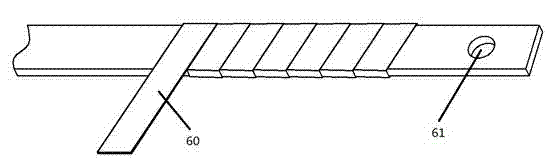

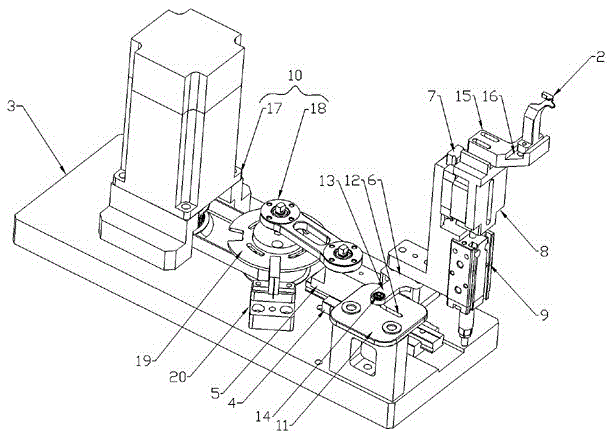

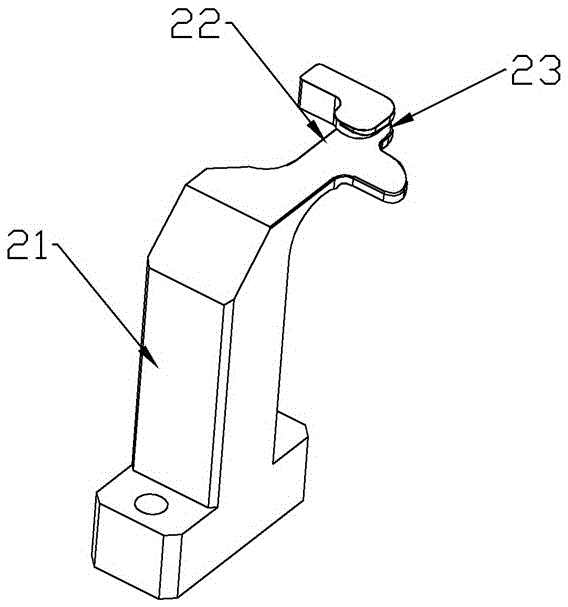

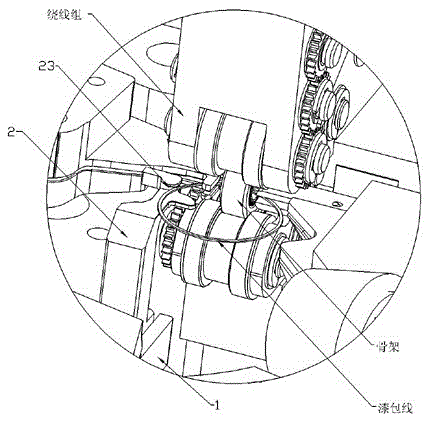

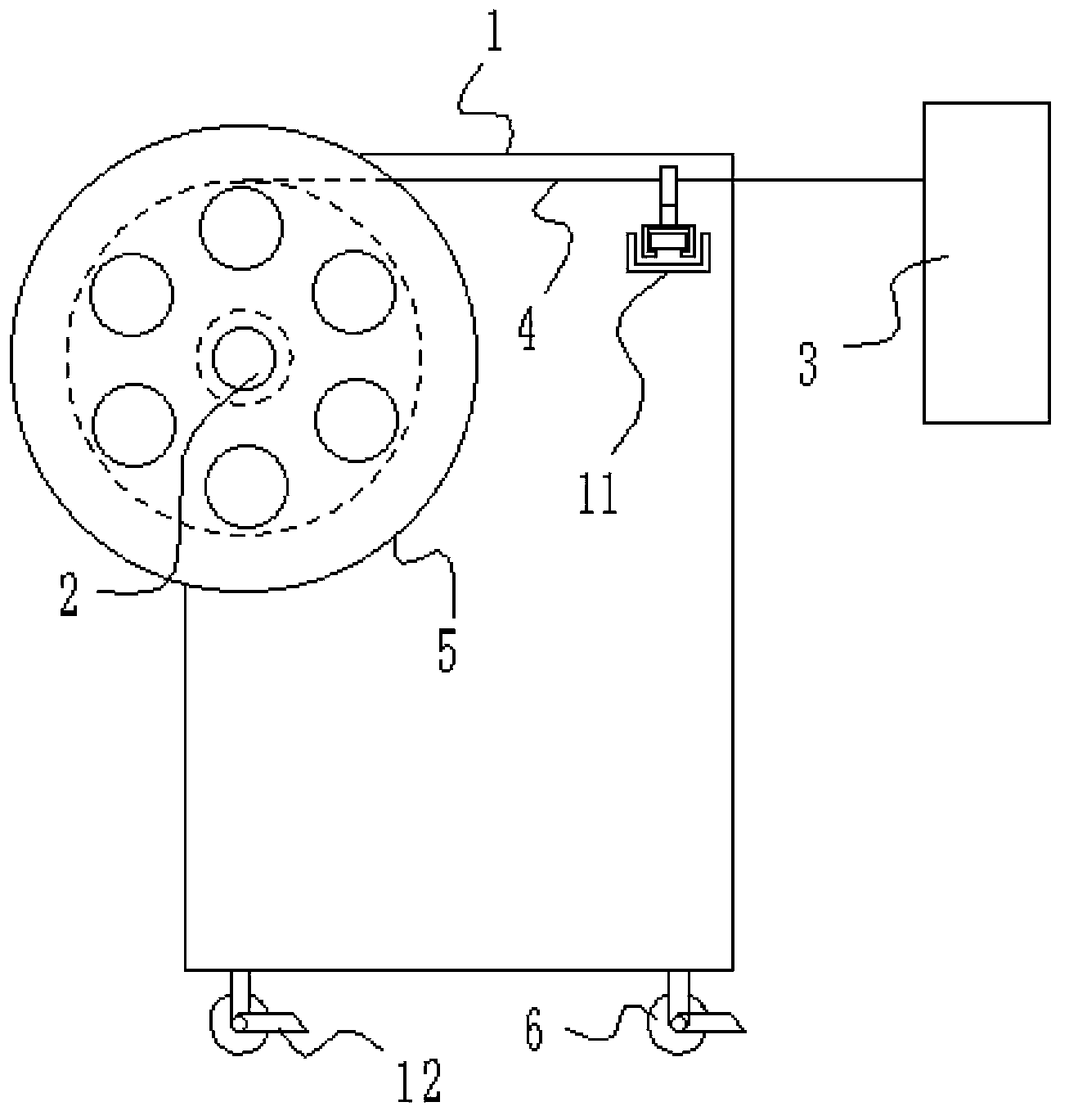

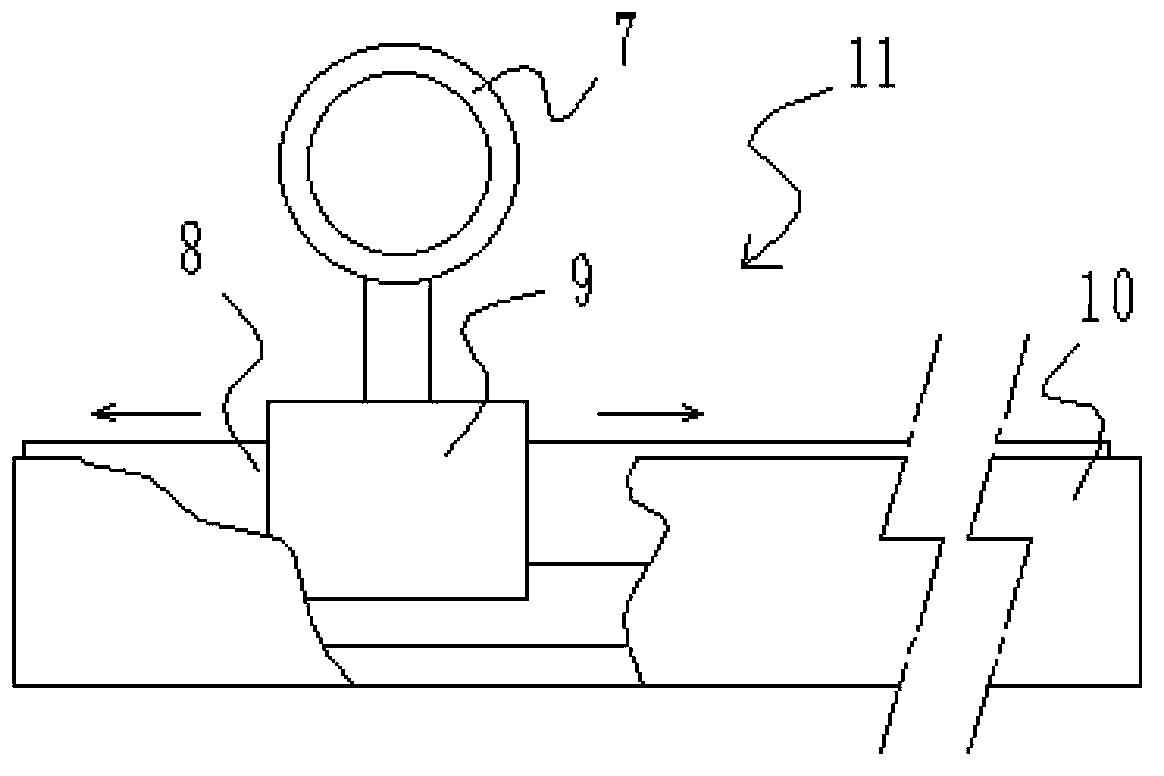

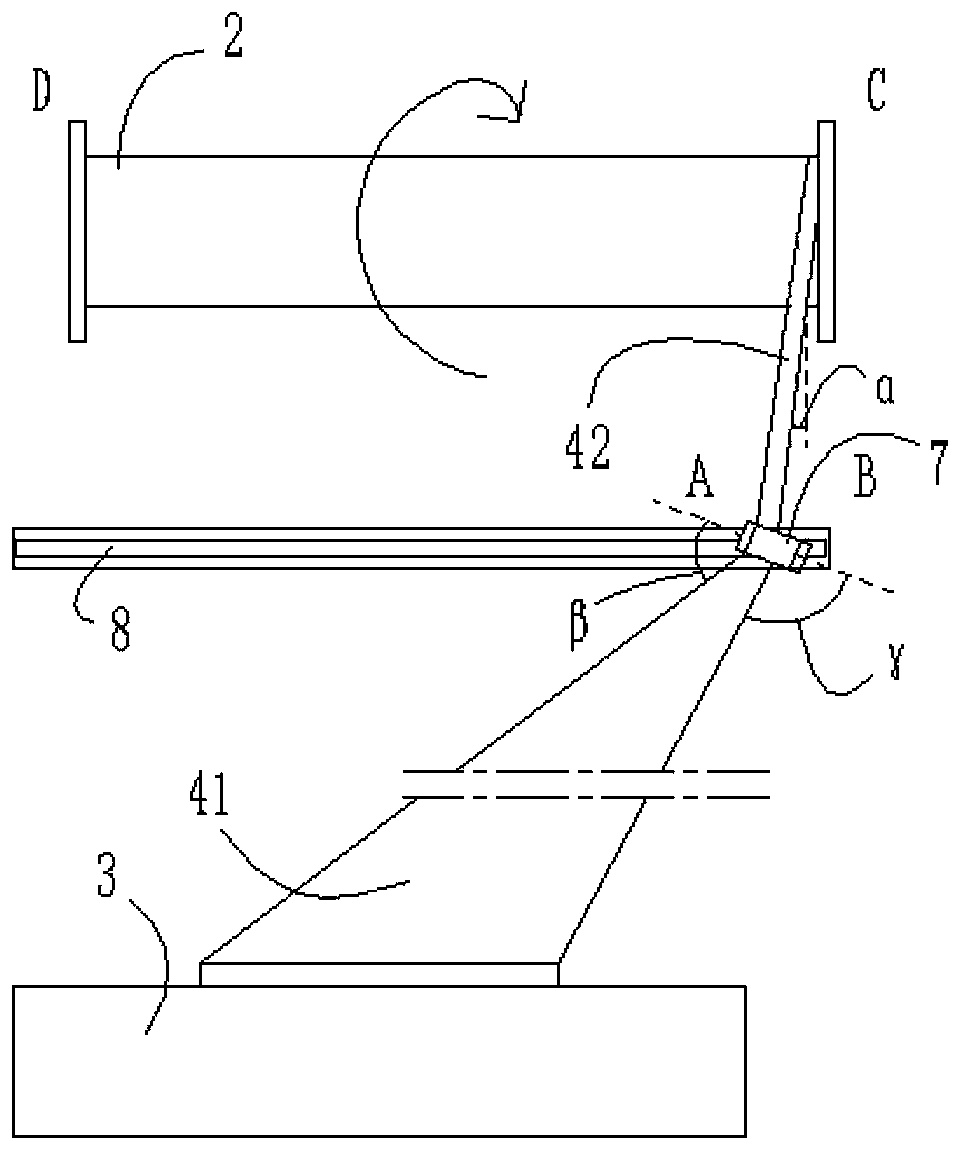

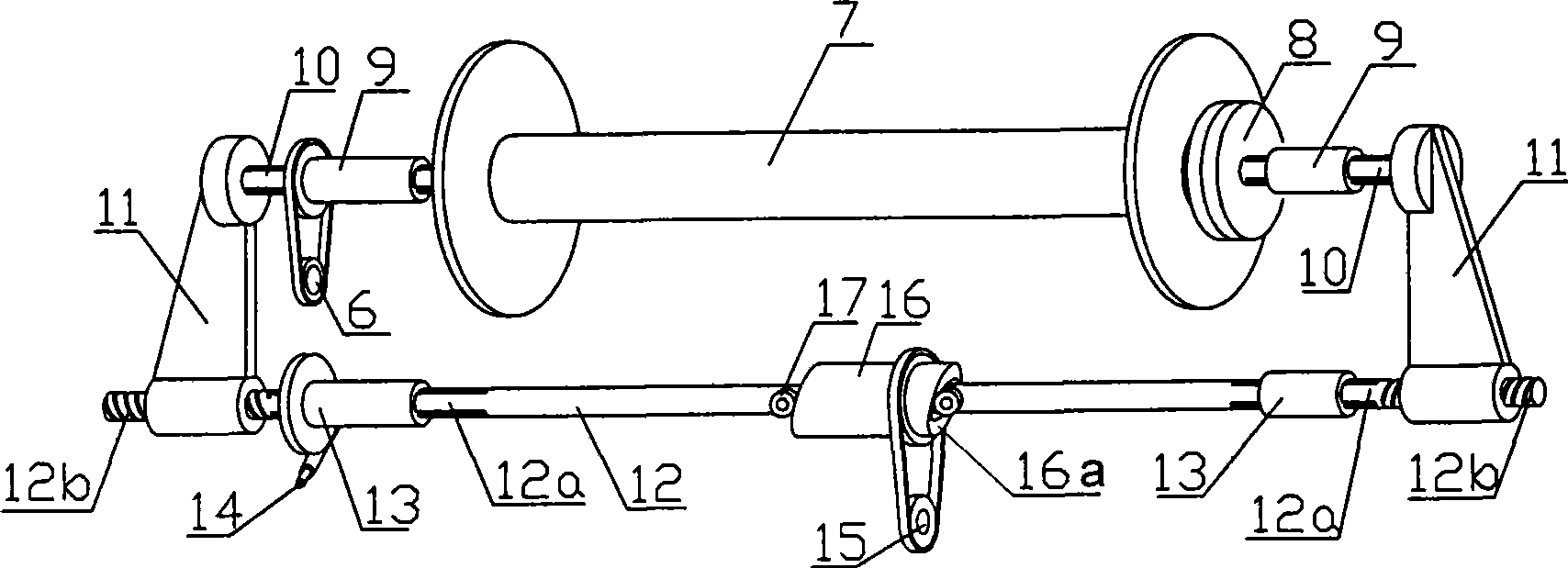

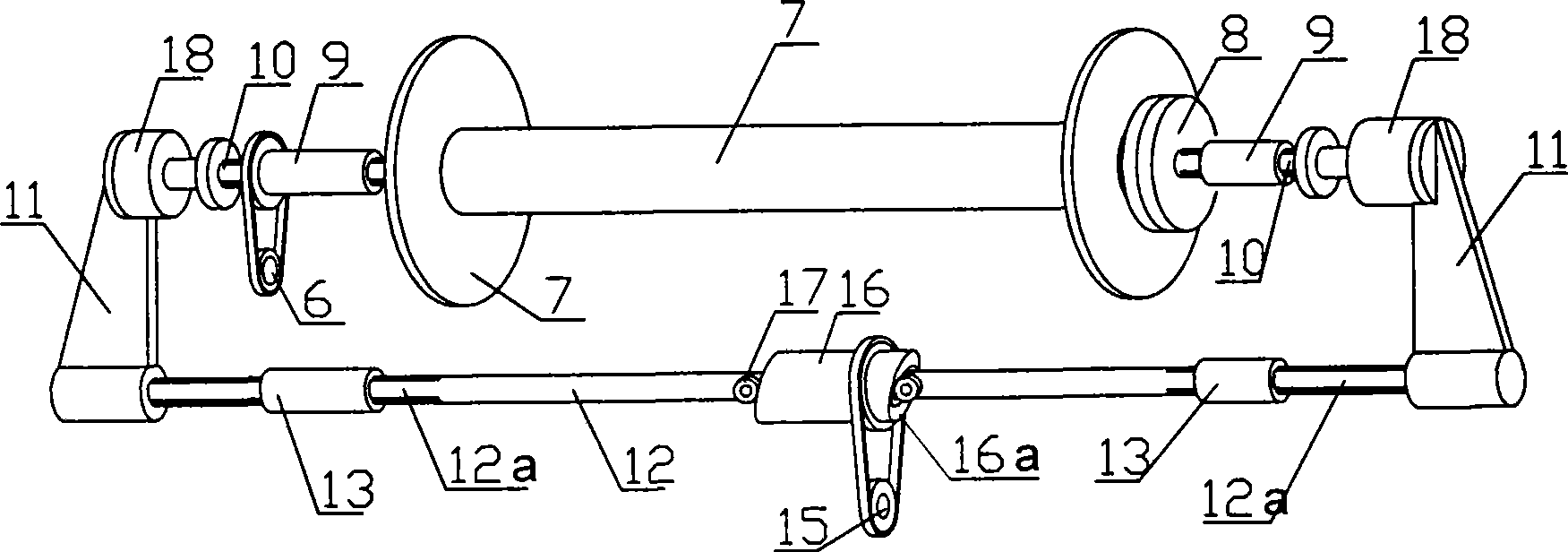

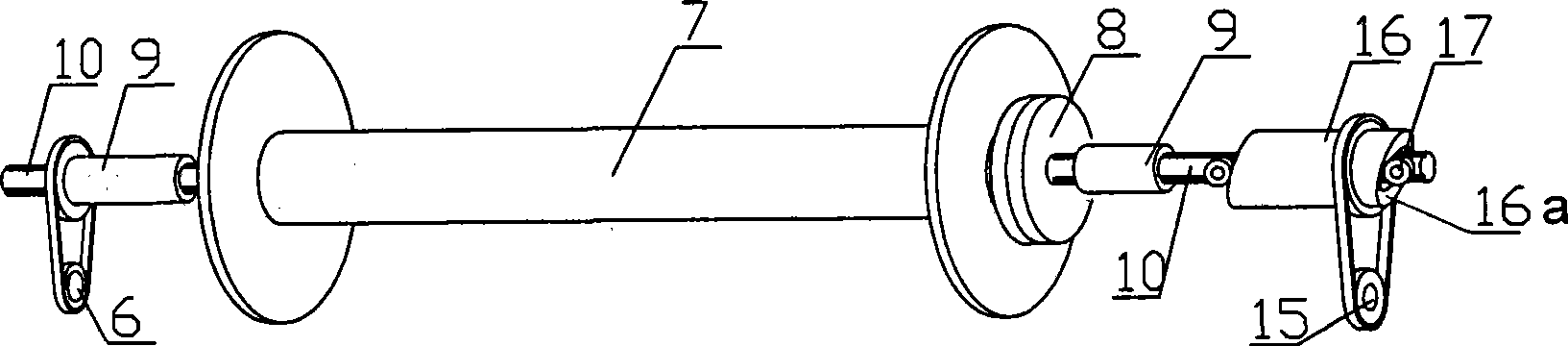

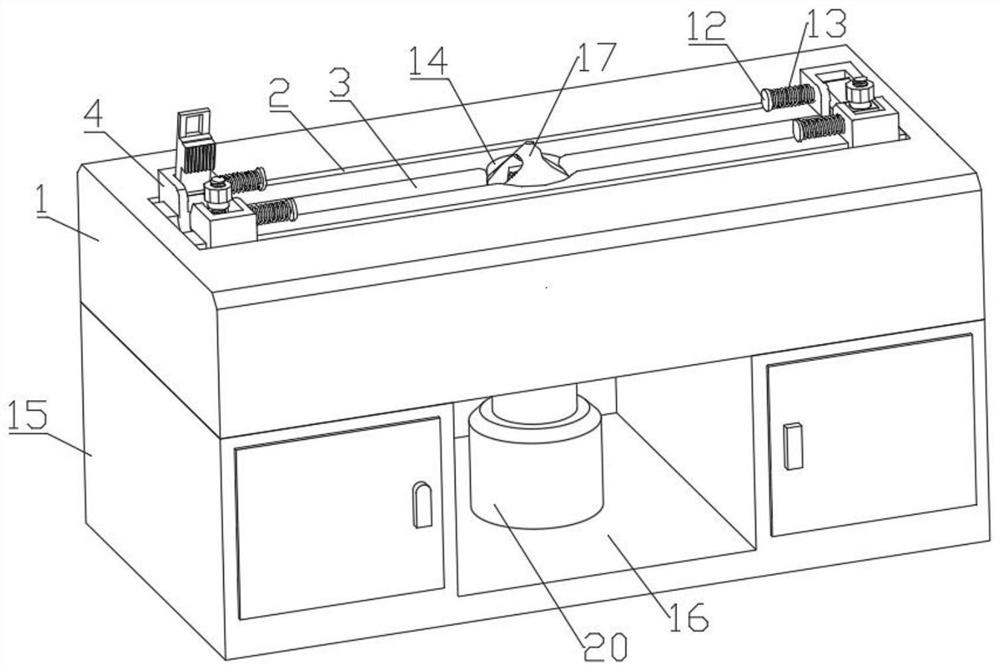

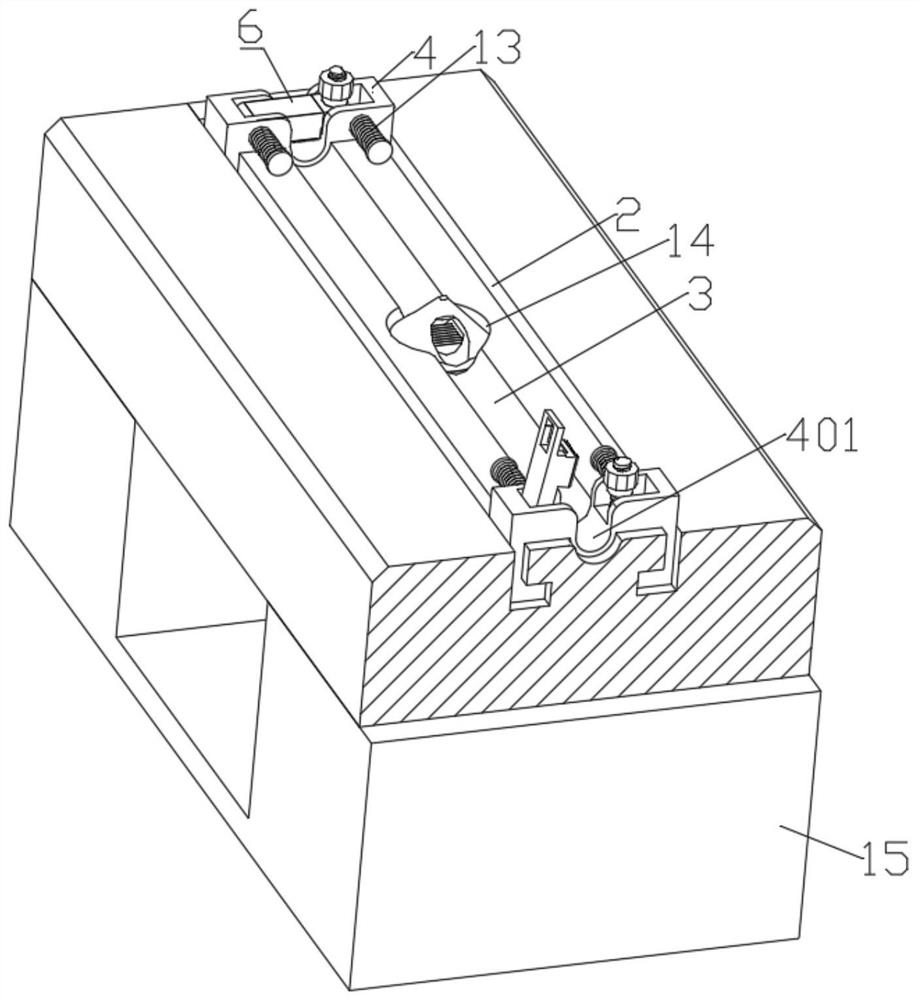

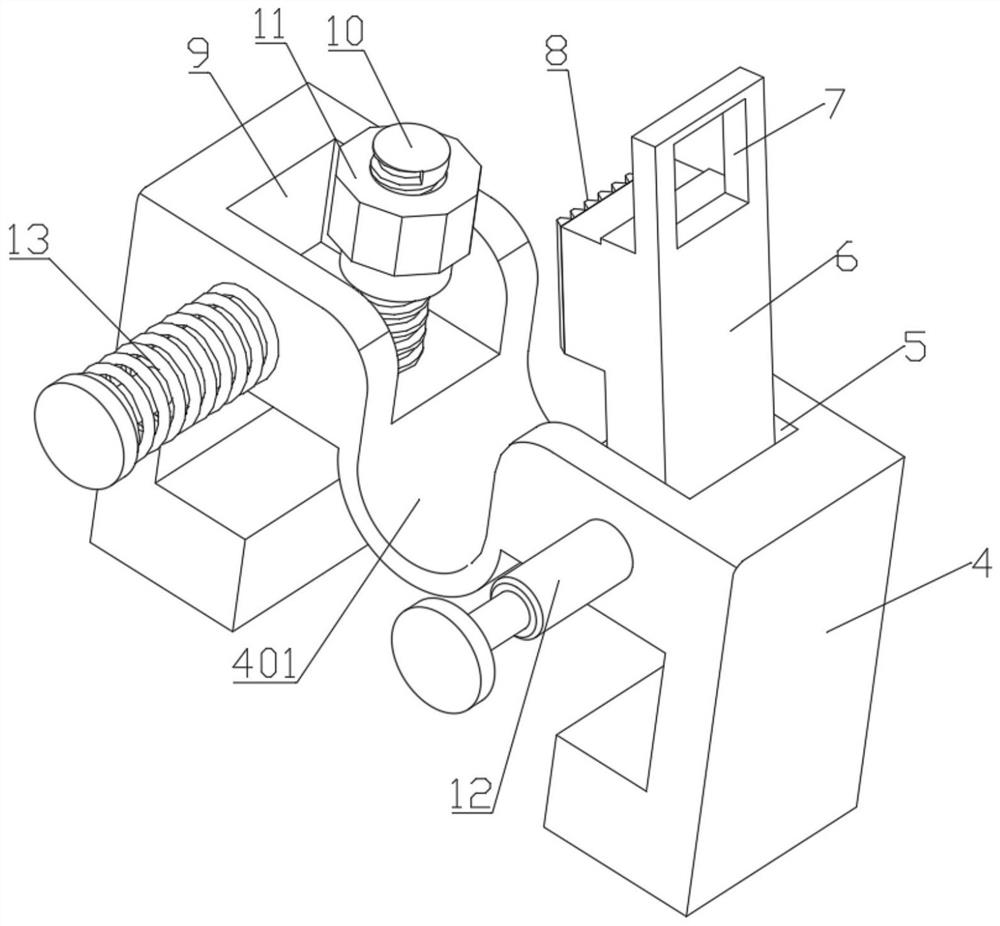

Auxiliary wire arranging and drawing mechanism and automatic winding machine

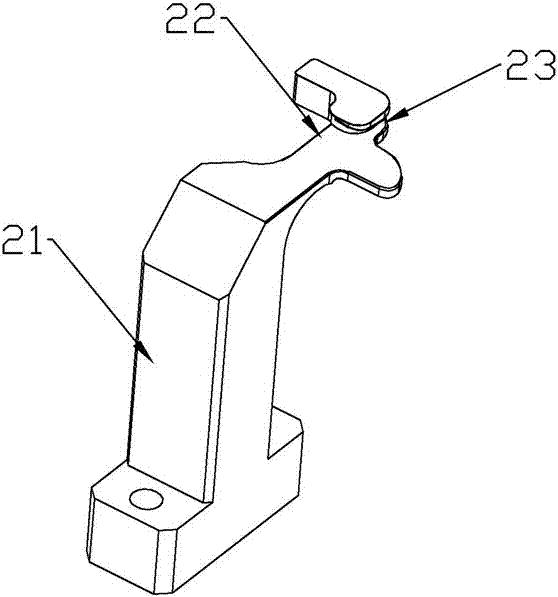

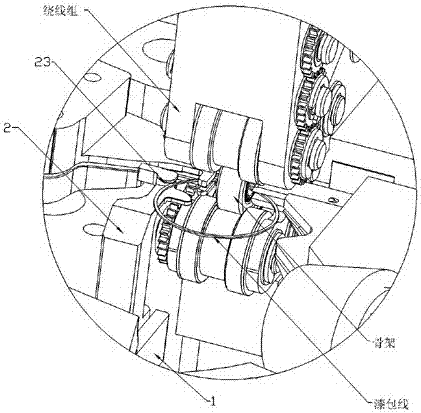

ActiveCN105632754ASimple structureProvides winding capabilityInductances/transformers/magnets manufactureWinding machineEngineering

The invention discloses an auxiliary wire arranging and drawing mechanism and an automatic winding machine, and aims at providing the auxiliary wire arranging and drawing mechanism which is simple in structure and conducive to improvement of the product winding density and can effectively improve the winding capability of the winding machine. Meanwhile, the invention further provides the automatic winding machine which is high in winding capability, high in production efficiency and good in product quality. The auxiliary wire arranging and drawing mechanism comprises a drive mechanism and a wire wiping head, wherein the wire wiping head is arranged on the drive mechanism; and an auxiliary wire arranging and drawing design is adopted by the automatic winding machine. The auxiliary wire arranging and drawing mechanism is applied to the technical field of the winding machine.

Owner:ZHUHAI KLES MACHINE TECH

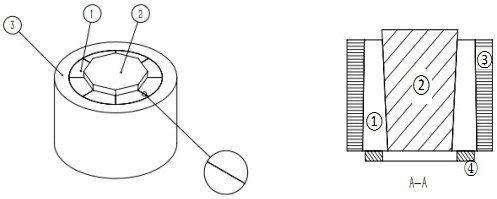

Stator winding iron core and winding method thereof

InactiveCN110571966ASolve the complex problem of winding manufacturingSolve the problem that multi-strand parallel winding cannot be carried outWindings insulation shape/form/constructionManufacturing dynamo-electric machinesEngineeringPower equipment

The invention discloses a stator winding iron core and a winding method thereof, and belongs to the field of power equipment. The stator winding iron core comprises an iron core and a winding, whereinthe iron core comprises a core body and an insulating framework which are connected with each other; a plurality of winding areas which are sequentially distributed in the direction from a first endto a second end are defined in the core body; the insulating framework is provided with a wire inlet and a wire outlet; the winding comprises a plurality of wires in one-to-one correspondence with theplurality of winding areas, the starting winding section of each wire in the plurality of wires jointly forms a wire inlet end matched with the wire inlet, and the ending winding section of each wirein the plurality of wires jointly forms a wire outlet end matched with the wire outlet. The stator winding iron core in the embodiment of the invention adopts a multi-strand parallel winding mode, and the production efficiency and quality can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Leftover material wrapuping device capable of realizing parallel winding

ActiveCN103381980AAchieving Parallel WindingSave electricityFilament handlingEngineeringConductor Coil

The invention relates to leftover waster material winding and recycling equipment, in particular to a leftover material wrapuping device capable of realizing parallel winding. The leftover material wrapuping device comprises a winding mechanism, a power mechanism and a hauling mechanism, wherein the winding mechanism is used for winding leftover materials; the power mechanism is used for driving the winding mechanism to run; the hauling mechanism is arranged on a passing zone of the leftover materials and used for enabling the width of the leftover materials to be decreased and used for enabling the leftover materials to be winded in parallel in the winding mechanism. According to the leftover material wrapuping device capable of realizing parallel winding, the hauling mechanism is arranged in addition, the position of a winding device is not changed, the parallel winding of the leftover materials on the winding mechanism is realized; the hauling mechanism drives the leftover materials moves in the direction of a shaft line parallel a wind up roll, so the regulation control to winding and feeding direction of the leftover materials on the winding mechanism is realized further, the parallel winding of adjacent winding rings with equal diameter in the length direction of the winding mechanism is realized, the maximization of the winding density is realized, and the recycling and utilization efficiency of the winding is high.

Owner:HUANGSHAN NOVEL

Coil component

ActiveUS10930420B2Increase inductanceImprove performanceTransportation and packagingTransformers/inductances coils/windings/connectionsElectrical conductorMagnetic layer

Owner:TAIYO YUDEN KK

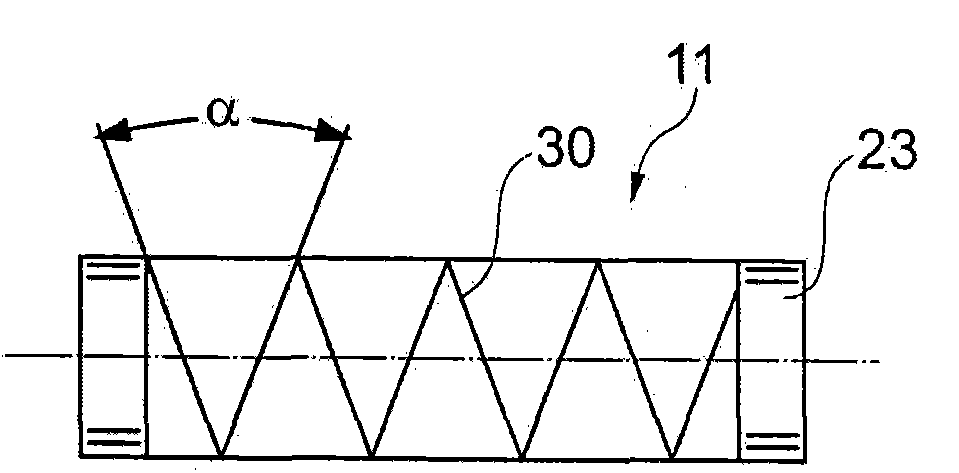

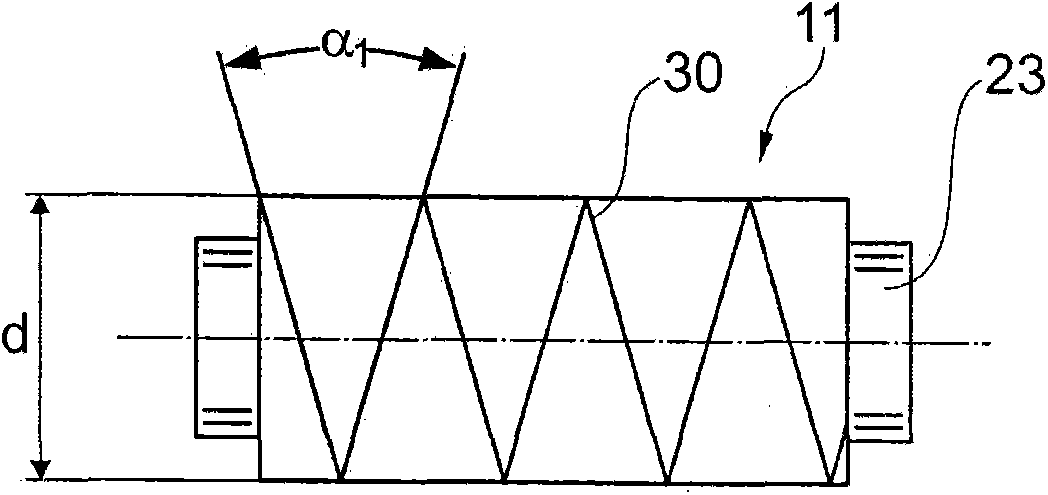

Method for manufacturing dye bobbin in the form of cross-wound spool

The invention relates to a method for manufacturing a dye bobbin in the form of a cross-wound spool. According to the method, the cross-wound spool is supported in a bobbin creel of a coil winder of an automatic winder by utilization of a spool. The coil winder is provided with a device for rotating the cross-wound spool, and a device for allowing transverse movement of the yarn wound on the surface of the cross-wound spool. A random winding manner is adopted at the beginning of the dye bobbin (11) for winding, wherein inner yarn layers are wound with a large first cross angle (alpha) for producing good dye liquor, and the spool is switched to a small second cross angle (alpha 1) when reaching of a predetermined diameter (d) of the dye bobbin (11) and rewound in a random winding manner.

Owner:SAURER GERMANY GMBH & CO KG

Method and device for inspecting an optoelectronic component arranged on a connection board

ActiveUS10288671B2Reduce areaIncrease winding densityElectronic circuit testingDiode testingElectricityElectromagnetic radiation

A method and a device for inspecting an optoelectronic component are disclosed. In an embodiment, the method includes exciting at least one electromagnetic resonant circuit, formed by the at least one optoelectronic component and the connection board, such that the at least one optoelectronic component emits electromagnetic radiation, wherein exciting the electromagnetic resonant circuit comprises applying an electrical alternating voltage in the electromagnetic resonant circuit by generating a temporally variable electromagnetic alternating field by a first coil and a second coil, wherein the first coil and the second coil are movable with respect to the connection board.

Owner:OSRAM OLED

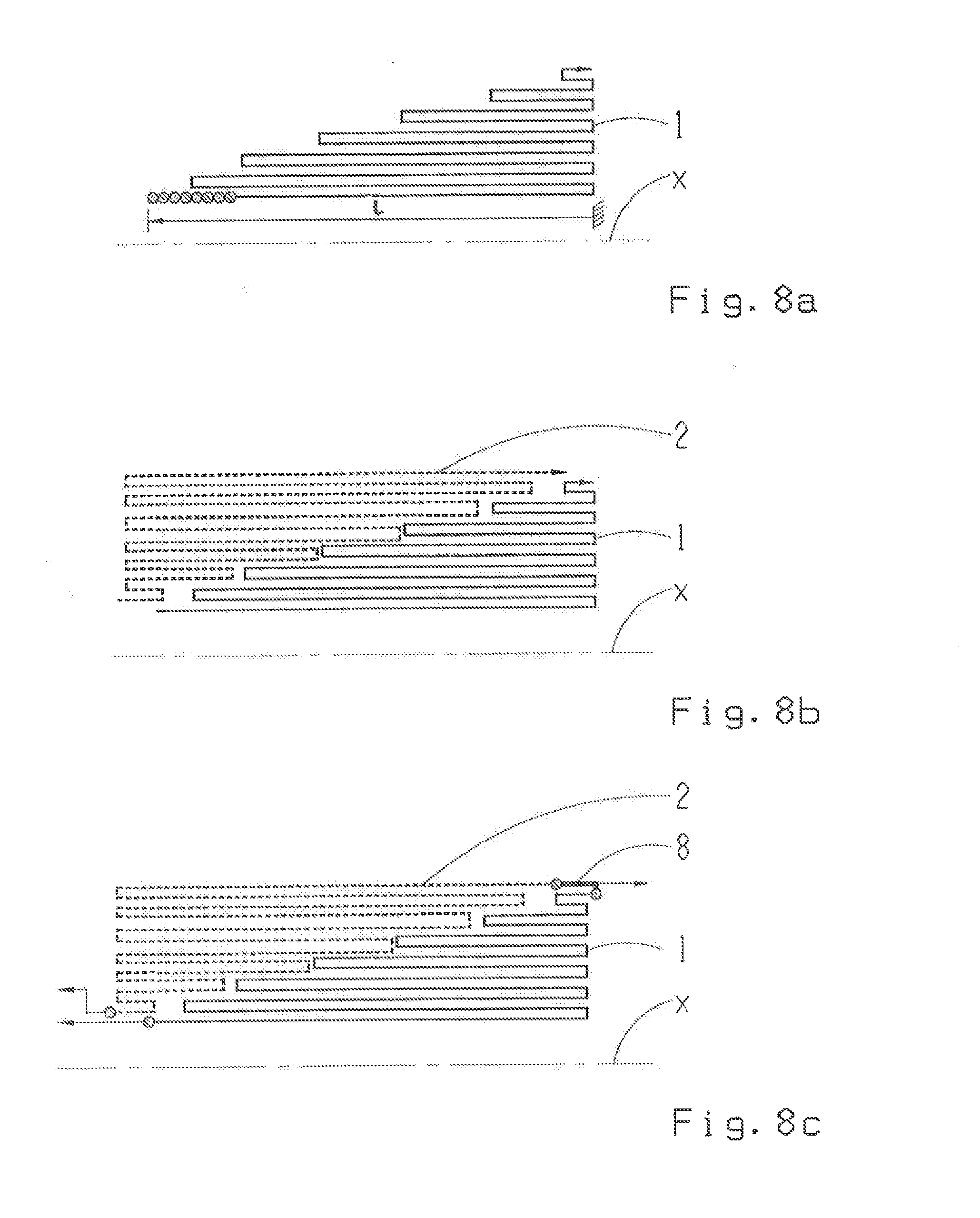

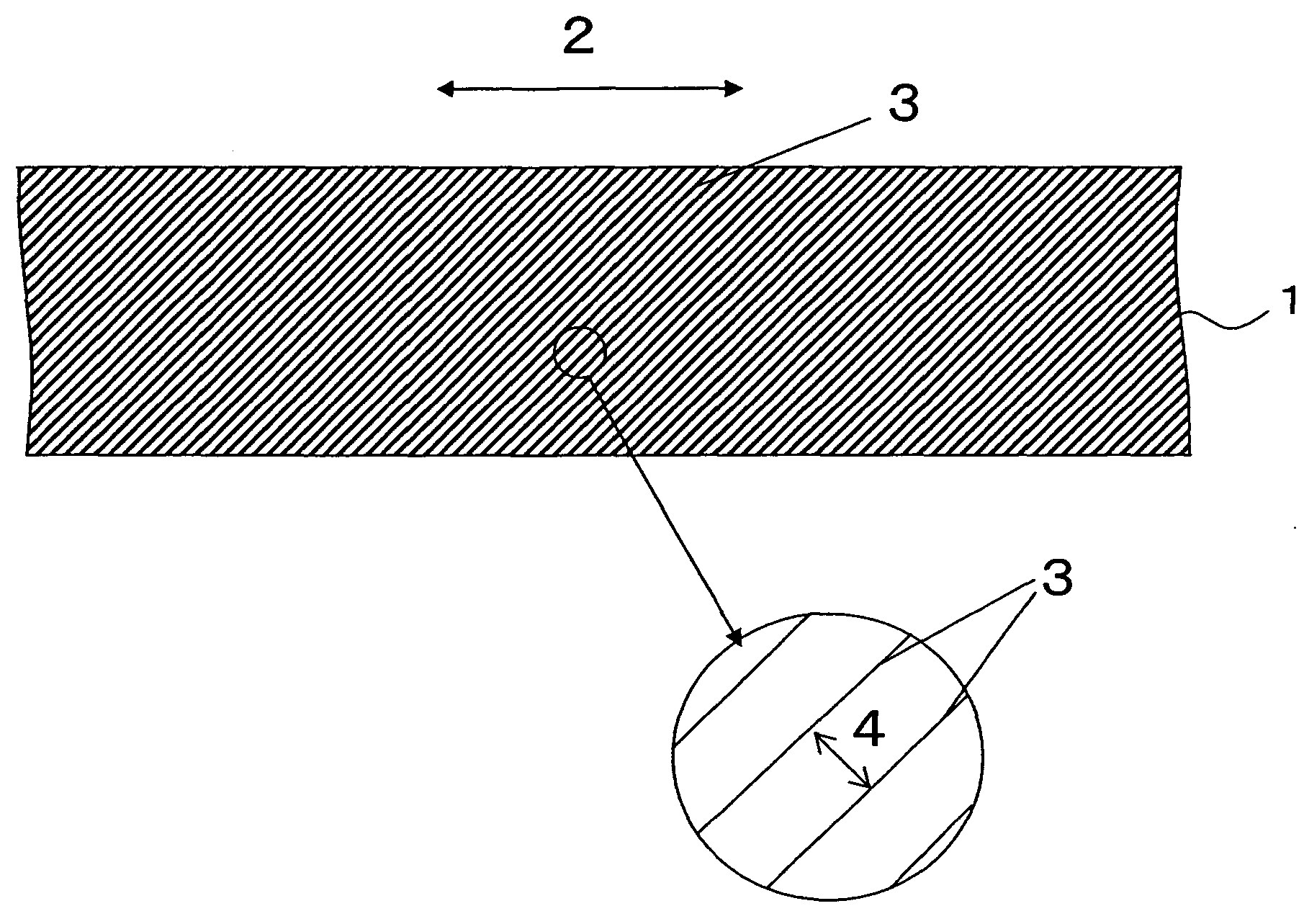

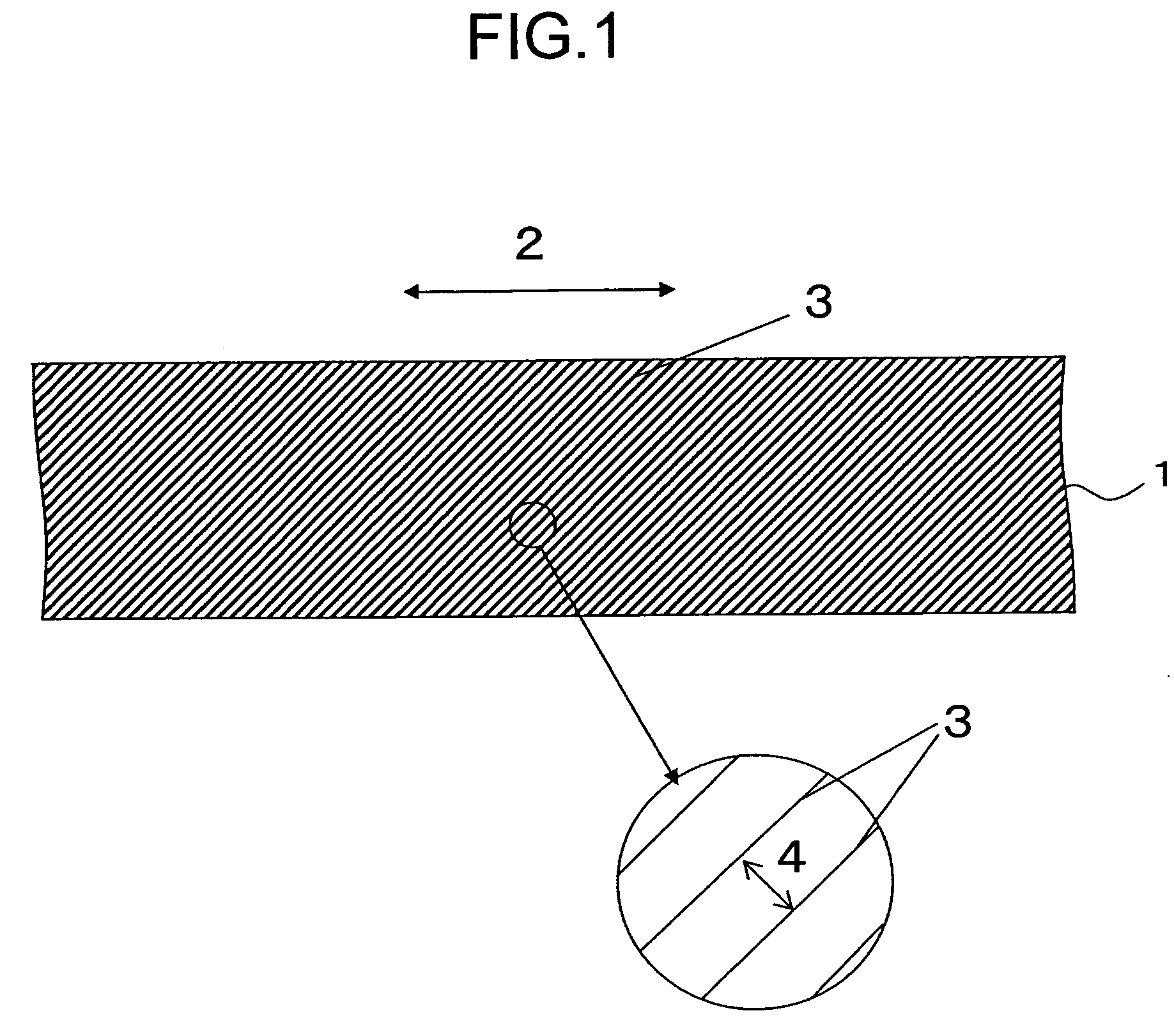

Coil arrangement having two coils

InactiveUS20150354991A1Simple and cost-effective productionReduce gapUsing electrical meansConverting sensor output electrically/magneticallyEngineeringPosition sensor

A cod arrangement, in particular for a position sensor, has a first coil (1) and a second coil (2) which are electrically connected to one another and disposed substantially coaxially relative to one another. The first coil (1) has a winding density that increases in the longitudinal direction (X) of the coil arrangement, and the second coil (2) has a winding density that decreases in the longitudinal direction (X) of the coil arrangement. In addition, the invention relates to a position sensor having such a coil arrangement and a production method for such a coil arrangement.

Owner:ZF FRIEDRICHSHAFEN AG

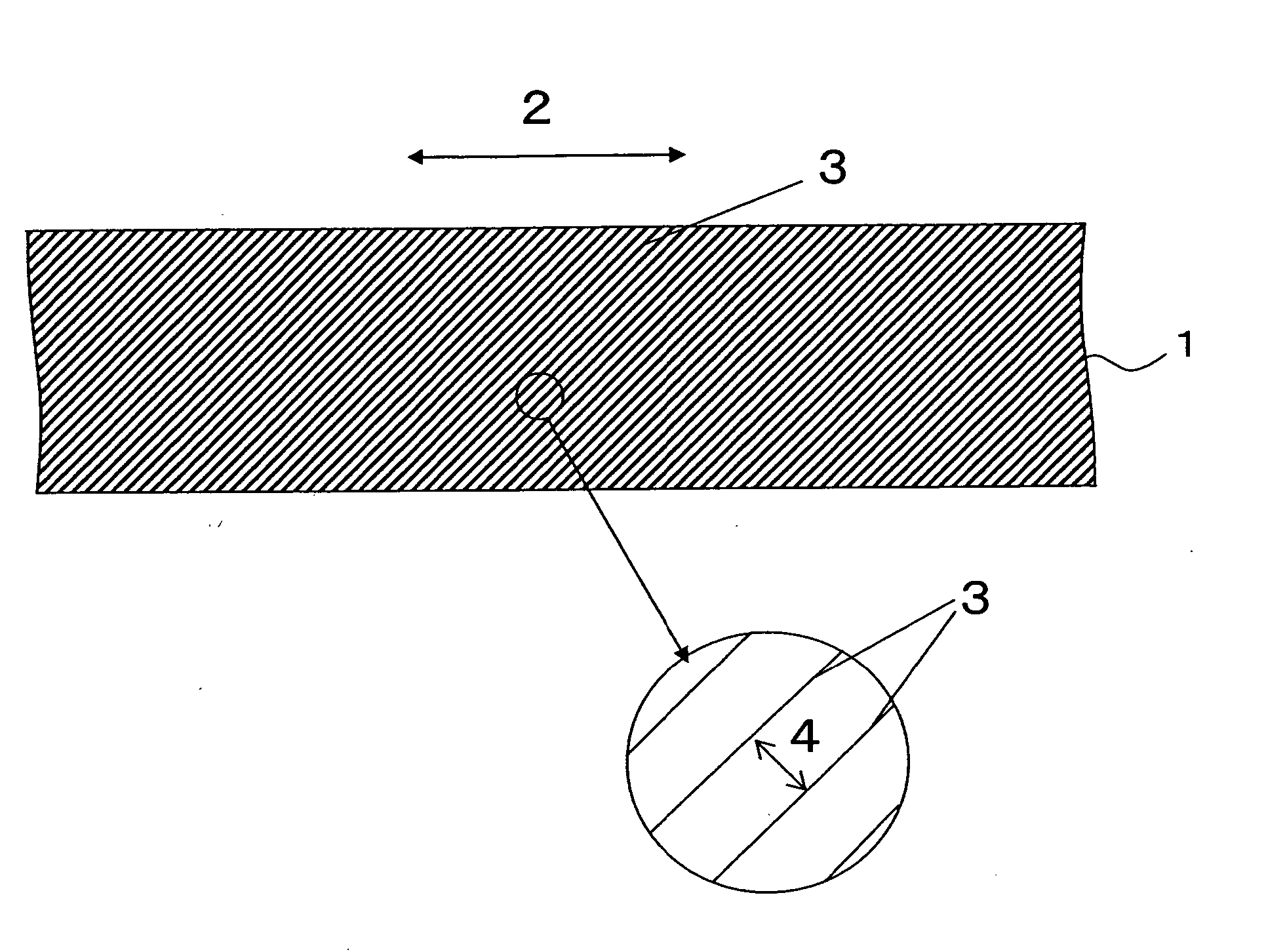

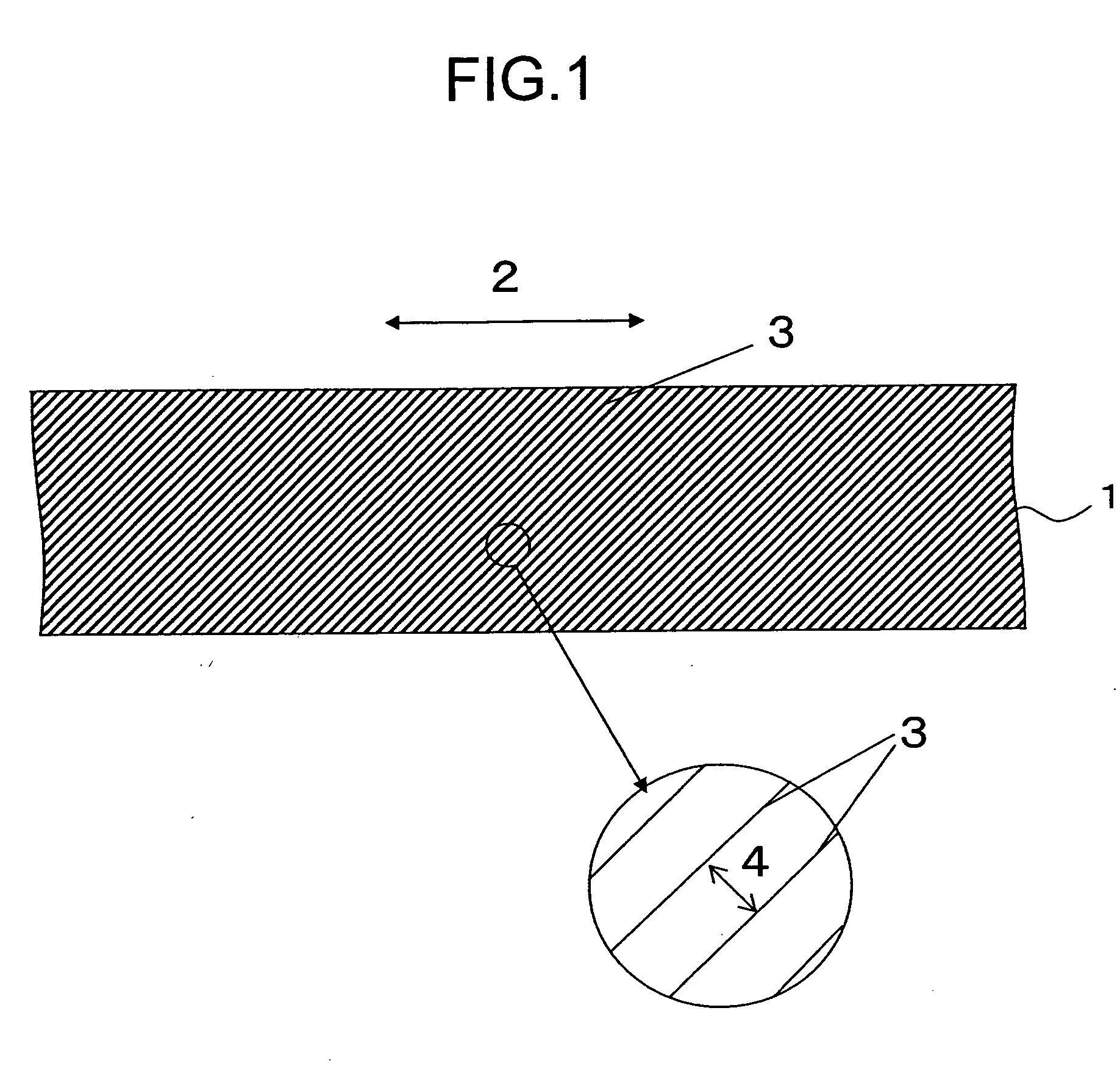

Method of producing an electrode plate for a nonaqueous electrolyte secondary battery

InactiveUS7854773B2Improve permeabilityImprove quality stabilityElectrode manufacturing processesPrimary cellsHigh densityEngineering

There is disclosed an electrode plate for a nonaqueous electrolyte secondary battery, which comprises a collector and an active material layer provided on at least one side of the collector, in which the active material layer has one or more slits. Such an electrode plate can facilitate infiltration of a liquid electrolyte even when wound at high density and can have high stability of quality. There is also disclosed a nonaqueous electrolyte secondary battery with high capacity and high quality, which is constructed using the above-mentioned electrode plate.

Owner:DAI NIPPON PRINTING CO LTD

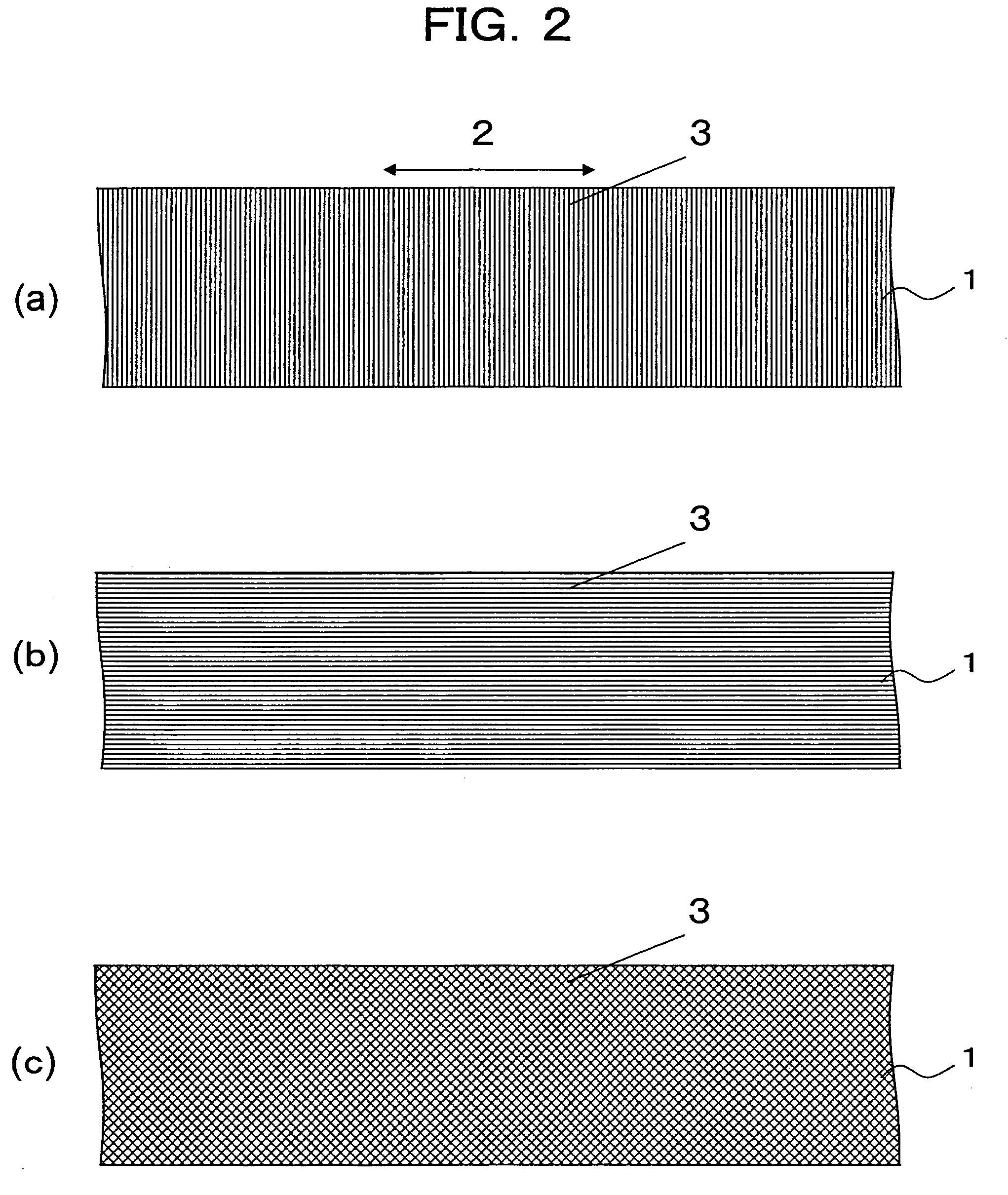

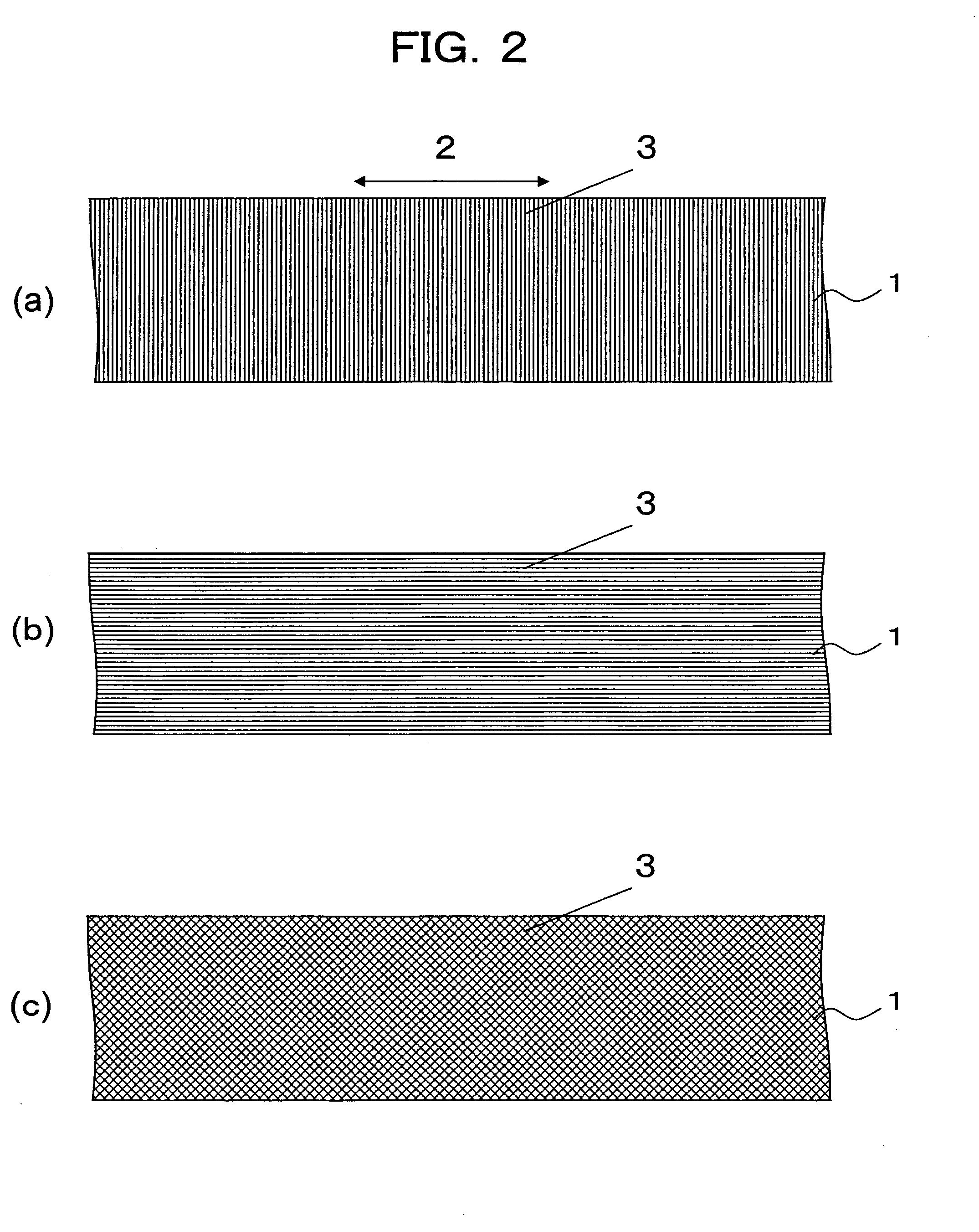

Electrode plate for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20080113265A1Improve permeabilityImprove quality stabilityActive material electrodesNon-aqueous electrolyte accumulator electrodesHigh densityEngineering

There is disclosed an electrode plate for a nonaqueous electrolyte secondary battery, which comprises a collector and an active material layer provided on at least one side of the collector, in which the active material layer has one or more slits. Such an electrode plate can facilitate infiltration of a liquid electrolyte even when wound at high density and can have high stability of quality. There is also disclosed a nonaqueous electrolyte secondary battery with high capacity and high quality, which is constructed using the above-mentioned electrode plate.

Owner:DAI NIPPON PRINTING CO LTD

Large-density cotton yarn spinning technology

InactiveCN105386166AEasy to twistIncrease winding densityDrafting machinesContinuous wound-up machinesYarnEngineering

The invention discloses a large-density cotton yarn spinning technology comprising the working procedures of blowing, carding, drawing, roving and spinning. According to the technical scheme adopted for solving the technical problems, in the roving working procedure, the twist degree of technology gears arranged on a roving machine is improved, the tooth number of the roving twist degree technology gear Z1 is decreased, and the tooth number of the roving twist degree technology gear Z2 is increased; meanwhile, the winding density of the roving machine is increased, the tooth number of the winding technology gear Z10 is decreased, and the tooth number of the winding technology gear Z11 is increased. The twist degree of the technology gears in the roving working procedure during ring spinning is creatively improved, meanwhile, the winding density of the roving machine is improved, so that yarns with the twist degree matched with that of the yarns in the spinning working procedure are spun on the roving machine in the roving working procedure, and the yarns have the large density larger than 194 tex.

Owner:SHANDONG XIANGRUIXIANG TEXTILE CO LTD

Support connection device for warp beam of warping machine

InactiveCN101435124ALight in massIncreased axial stabilityWarping machinesOther manufacturing equipments/toolsYarnReciprocating motion

The invention relates to a warp beam supporting and connecting device of a warper, comprising a warp beam, a winding and driving chain for driving the warp beam, connecting discs, a spline housing, spline shafts and a reciprocating shaft moving and driving mechanism. The two spline shafts are arranged at two ends of the warp beam and have coaxial line with the warp beam, the inner side end of each spline shaft is connected with the connecting discs, the two connecting discs are respectively connected with the warp beam into a whole by tightly pressing on the corresponding end of the warp beam or a connecting piece, the spline housing is bushed on the spline shafts in a sliding way, the winding and driving chain is connected on the spline housing, and the reciprocating shaft moving and driving mechanism is connected with the outer side end of the spline shafts, and drives the warp beam to carry out axial reciprocating movement by the spline shafts. The warp beam supporting and connecting device has the advantages that: the warp beam can carry out axial reciprocating motion of small stroke simultaneously when winding to lead adjacent upper and lower layers of yarns to form cross winding, so as to solve the problem that dyeing liquor rushes the yarns to be disorderly often occurring in warp beam dyeing and improve the warp beam dyeing quality; and the yarns have good axial stability and can achieve smaller winding density, the dyeing liquor is easy to penetrate, and the pumping power of the dyeing liquor is reduced.

Owner:姜一

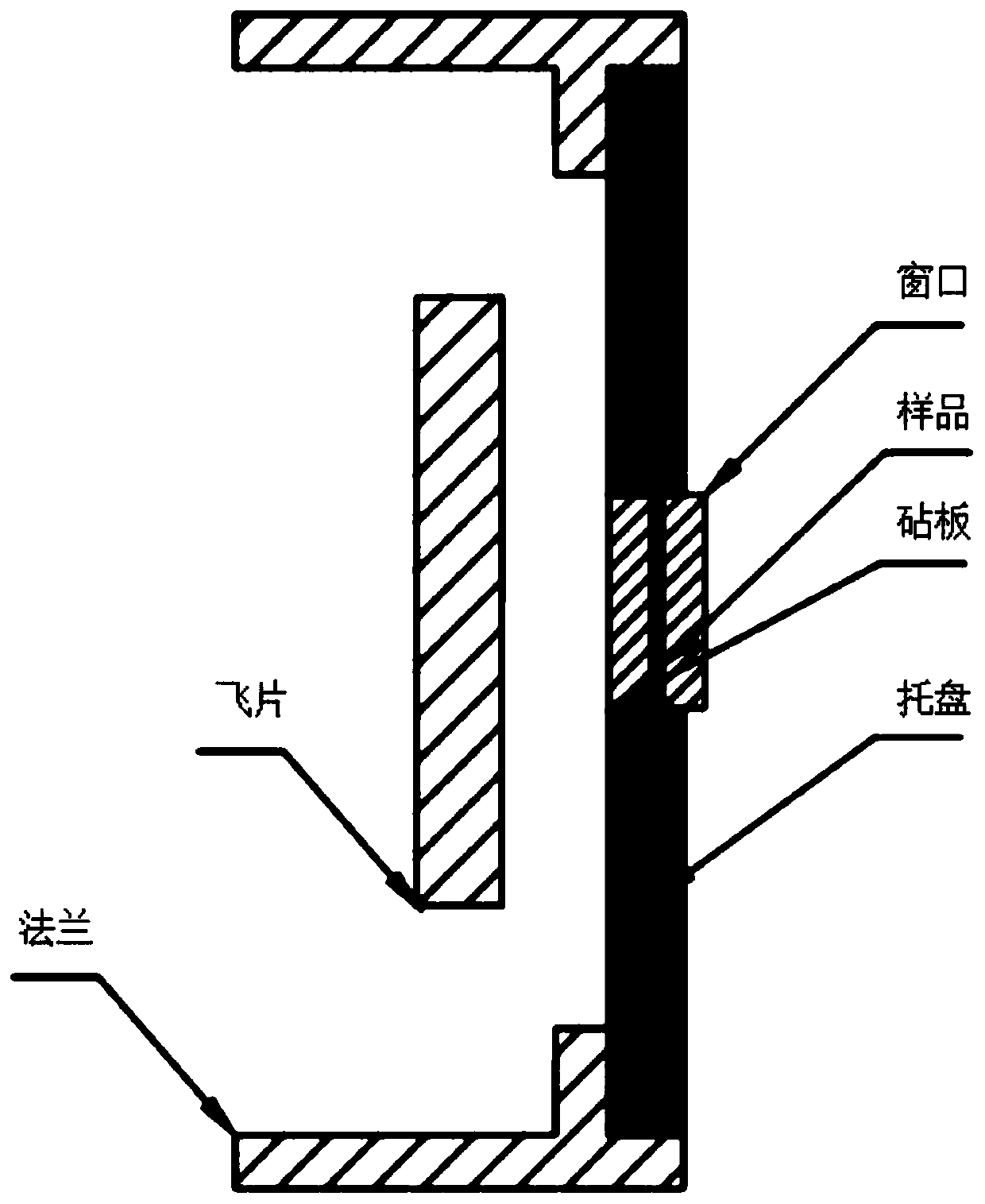

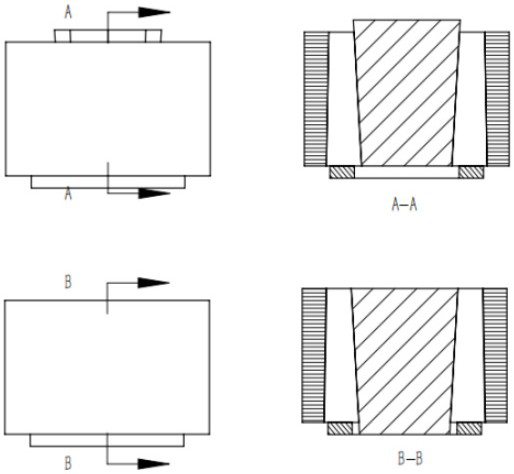

Heating device and heating method for heating sample before flat plate impact experiment

ActiveCN110784947ASmall overall structureImprove heating efficiencyHeater elementsHeating element shapesPhysicsEngineering

The invention relates to the technical field of flat plate impact experiments, in particular to a heating device and method, and provides a heating device and a heating method for heating a sample before a flat plate impact experiment. The heating device comprises a heat conducting tray and a heating coil. The heat conducting tray is provided with a through hole along the axis. The heat conductingtray is also provided with an annular groove coaxial with the through hole. The heating coil is wound in the annular groove. The heating coil is connected with a temperature regulating circuit. The sample area is heated by the heating coil before the flat plate impact experiment is performed. The device can effectively heat the sample and perform the flat plate impact experiment and has a small overall structure and a simple structure and can effectively heat the sample without affecting the flat plate impact experiment and the use of the velocity measuring system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

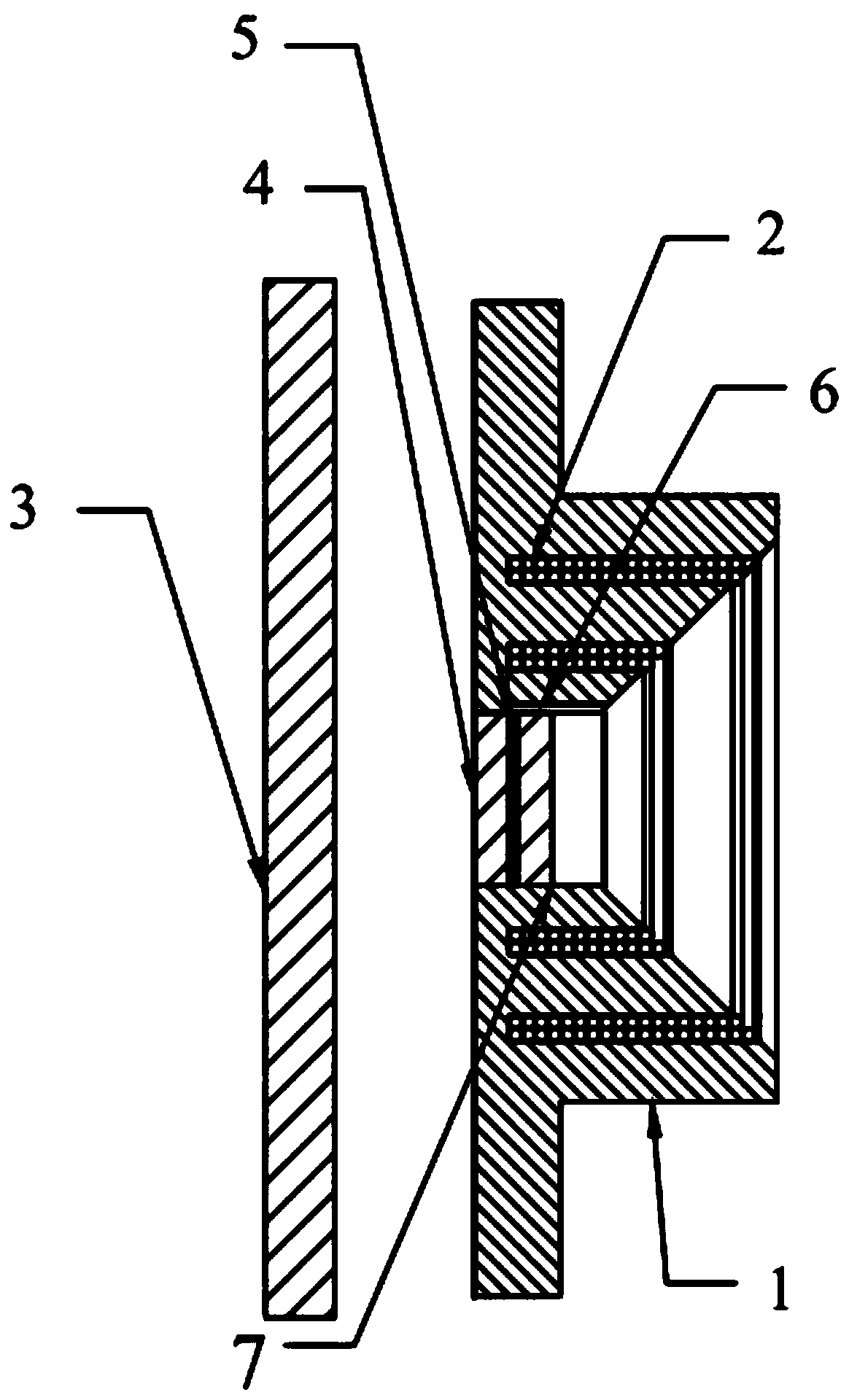

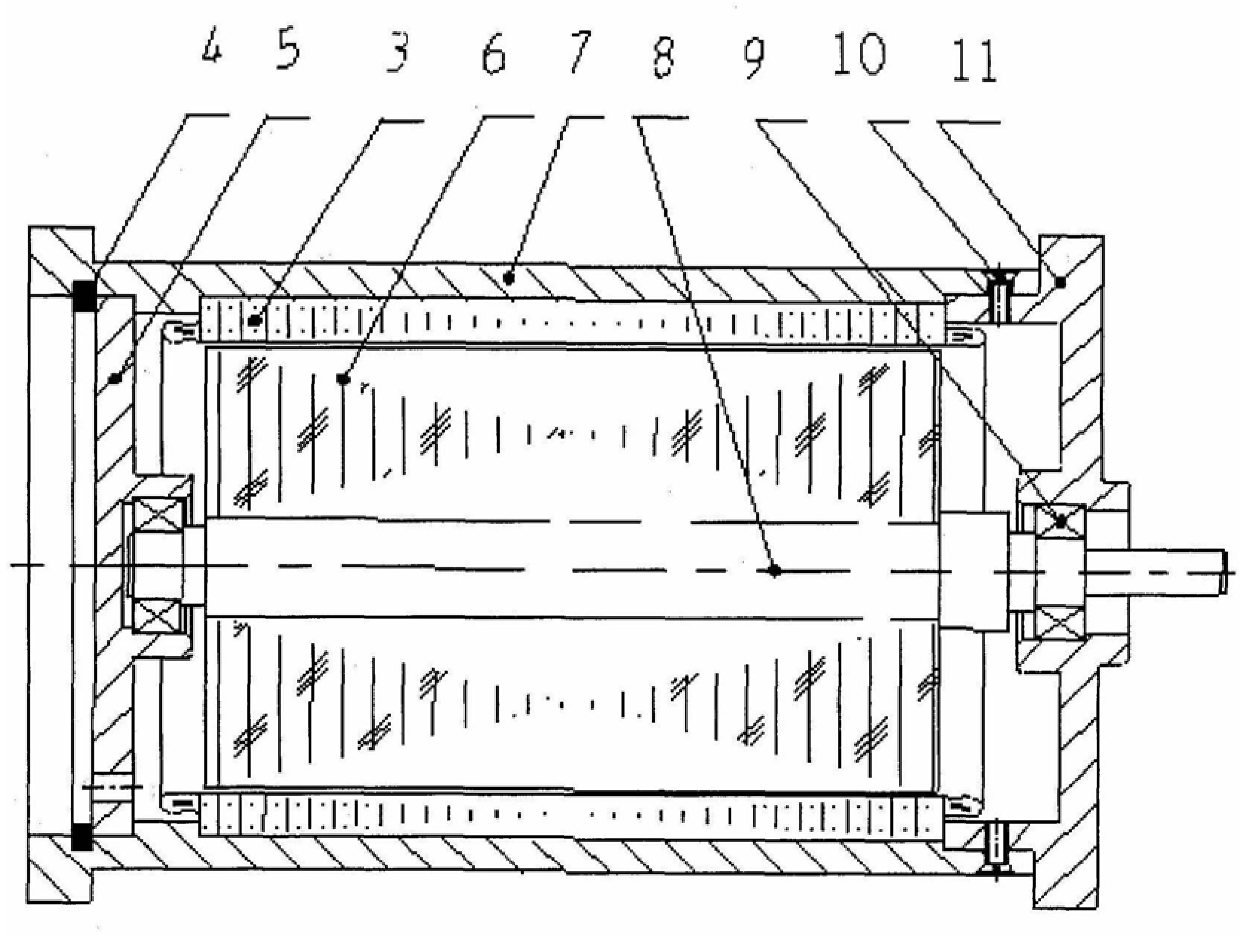

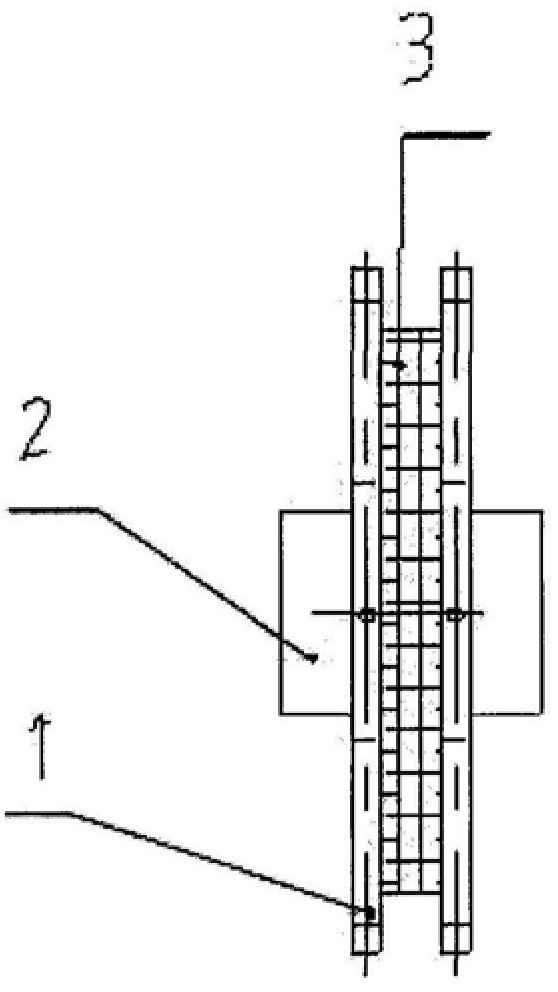

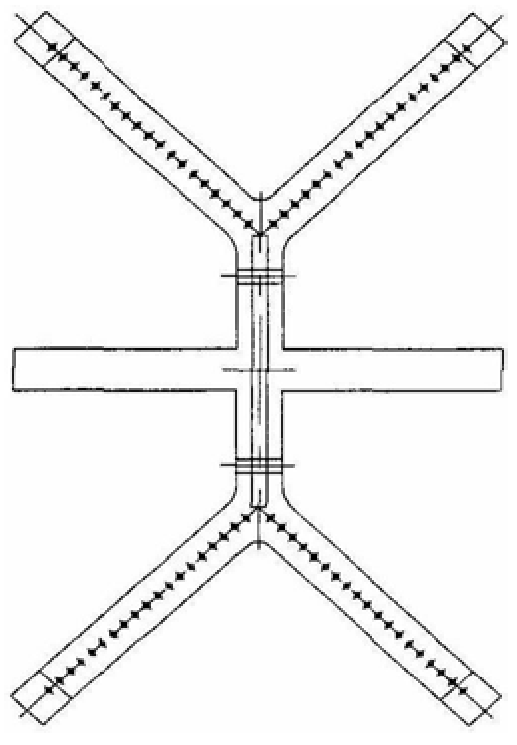

Slotless stator single-phase AC asynchronous motor composed of sinusoidal hollow cup windings

InactiveCN106342387BTorque ripple eliminationEasy and smooth startAsynchronous induction motorsSingle phaseWinding machine

The invention discloses a slotless stator single-phase AC asynchronous motor composed of sinusoidal hollow cup windings. The stator of the AC motor is directly composed of sinusoidal hollow cup windings, so that the stator has a slotless structure. The sinusoidal winding constituting the slotless stator is made on the winding tool, which is composed of two splints and inserting plates. The two splints are fixed together by the inserting plate and fastened with screws to form the winding tooling. , install the winding tool on the winding machine, and wind the sinusoidal winding sheet. Glue the sides of the four-pole pair of sinusoidal winding sheets into one group to make two groups of windings; stagger the two groups of windings at one-eighth of the length of one group of windings and glue them together; roll the bonded two groups of windings into a circle Cylinder, insert the centering tool into the cylinder, and then fasten it with the solid tooling to make a slotless stator. The invention breaks through the traditional mode of the cogged stator in the field of AC motors, effectively improves and enhances the performance of the motor; the size of the AC motor can be reduced to φ24mm or even smaller.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

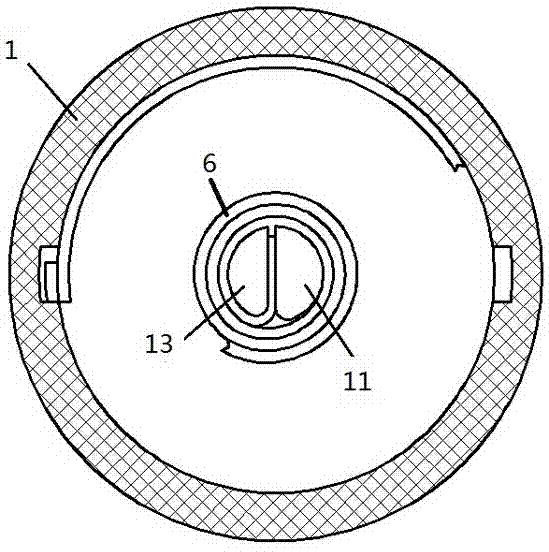

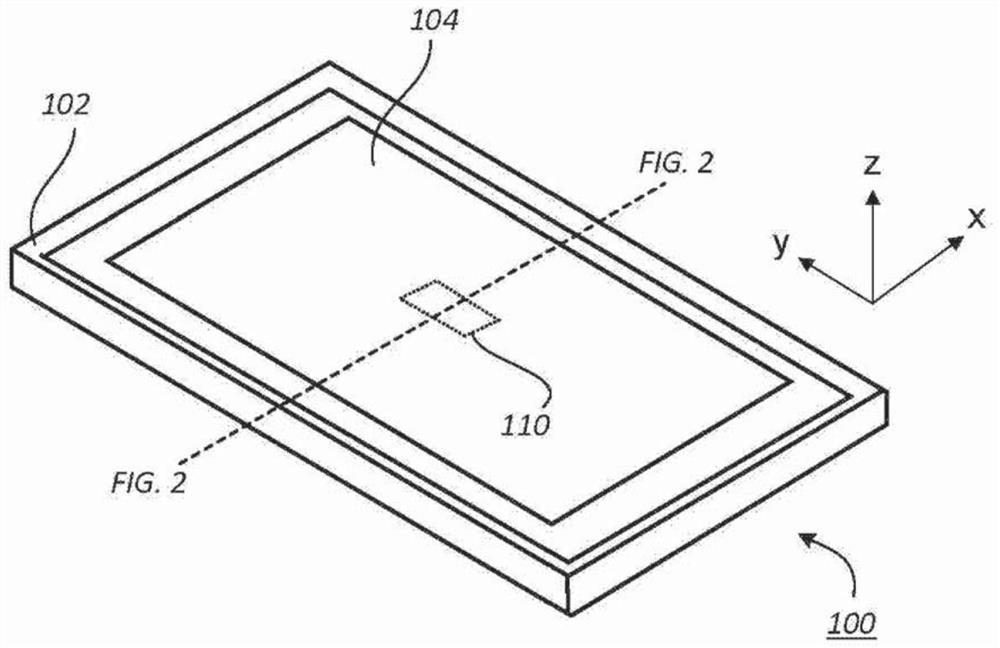

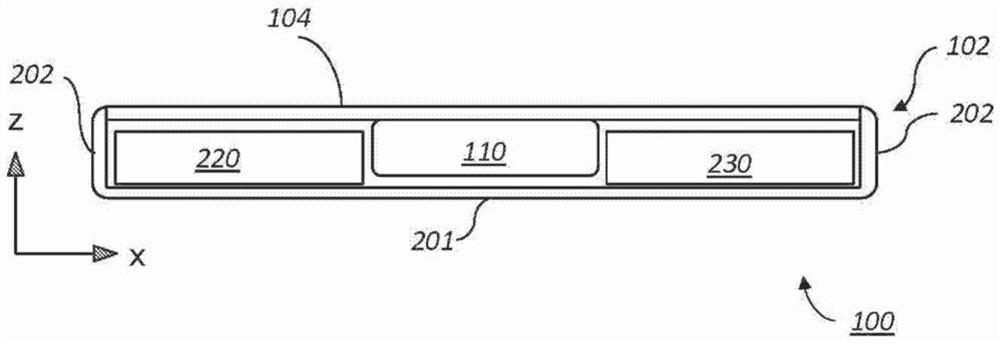

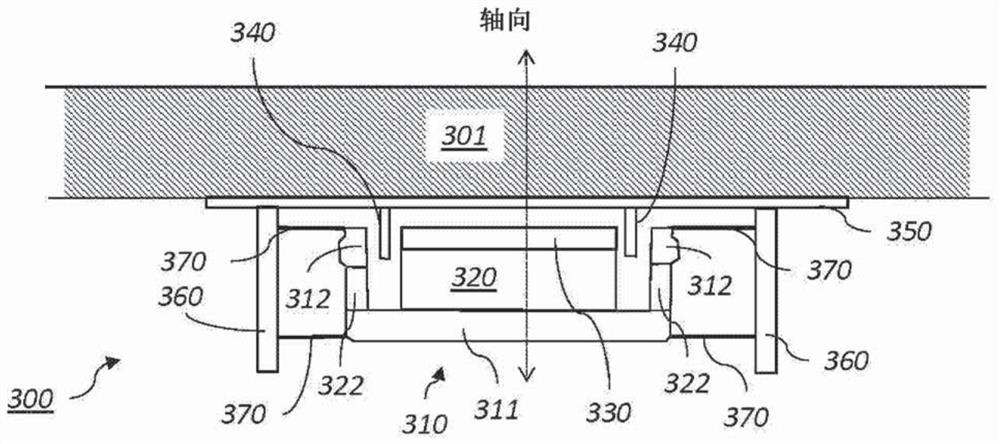

Coil-equipped moving magnet actuator for panel audio speaker

ActiveCN112868246AHigh winding densityImprove robustnessLoudspeaker transducer fixingPlane diaphragmsEngineeringActuator

A panel audio speaker includes a panel and an actuator rigidly coupled to a surface of the panel. The actuator includes: a magnet assembly including a permanent magnet disposed within a cup, wherein there is an air gap between a sidewall of the cup and the permanent magnet; and, a coil rigidly connected to the panel, the coil including a length of conductive wire wound therein and extending along an axis. The coil includes a first region having a first winding density and a second region having a second winding density higher than the first winding density, the second region extending at least partially into the air gap of the magnet assembly.

Owner:GOOGLE LLC

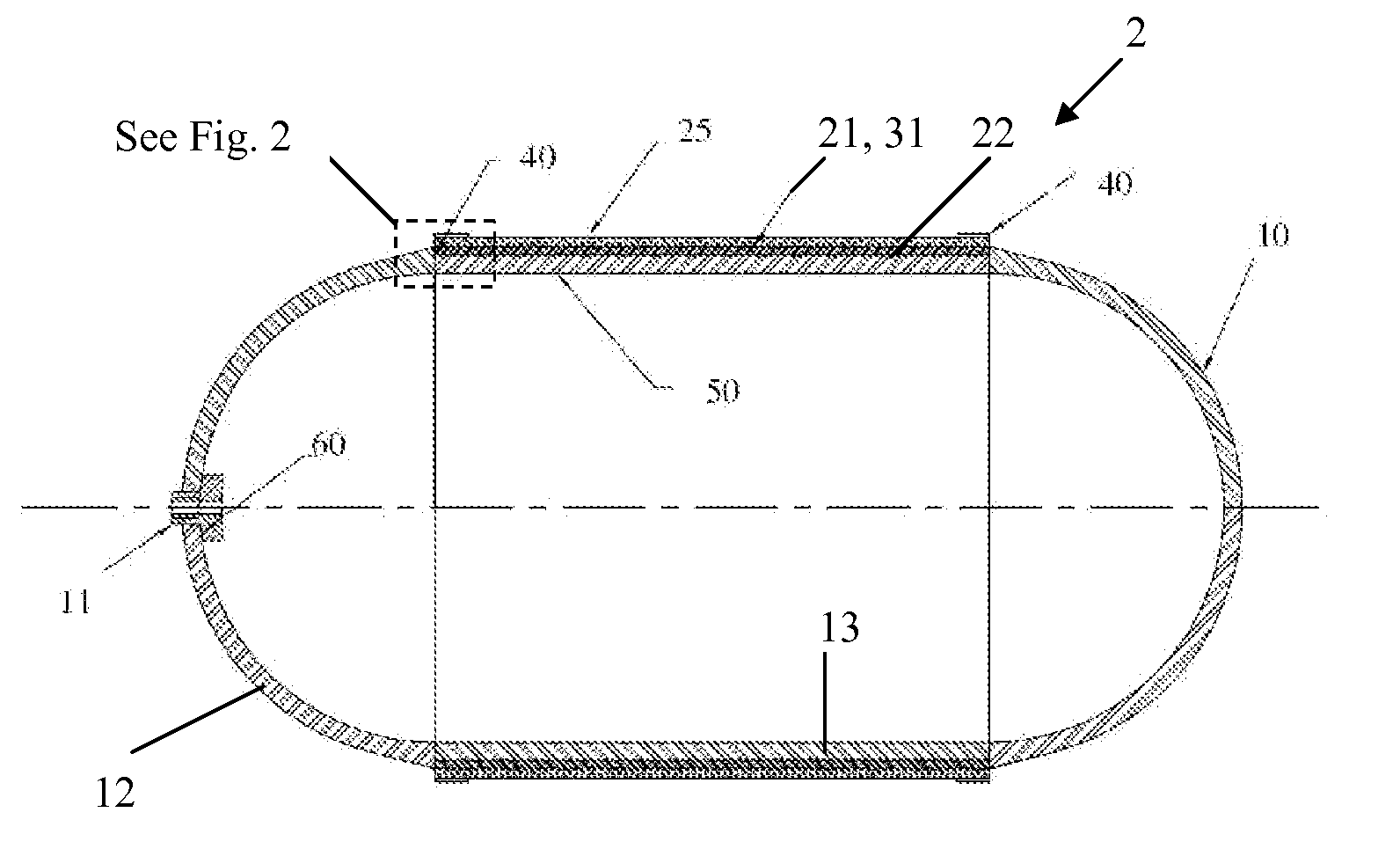

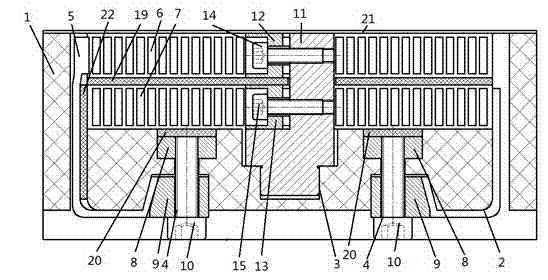

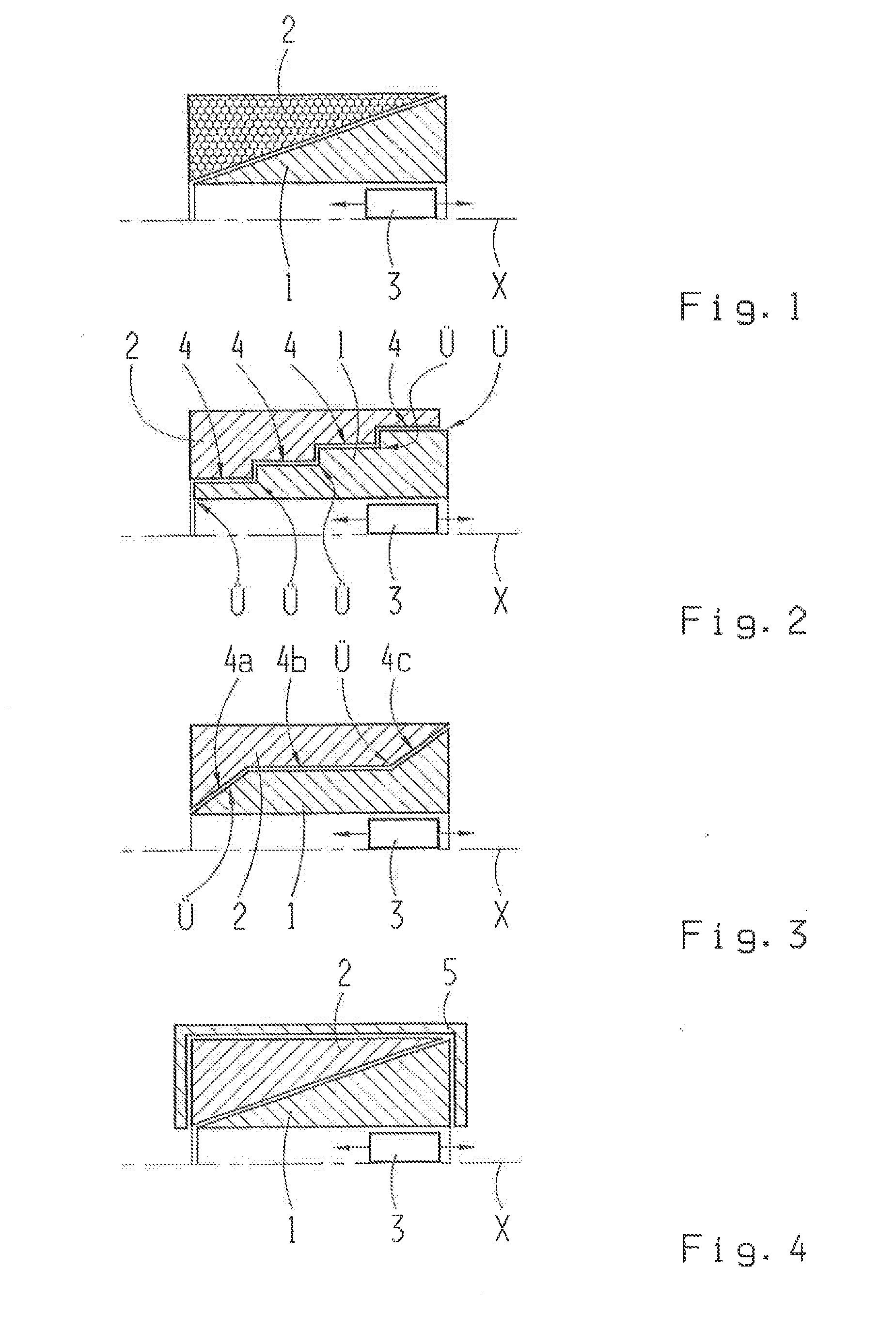

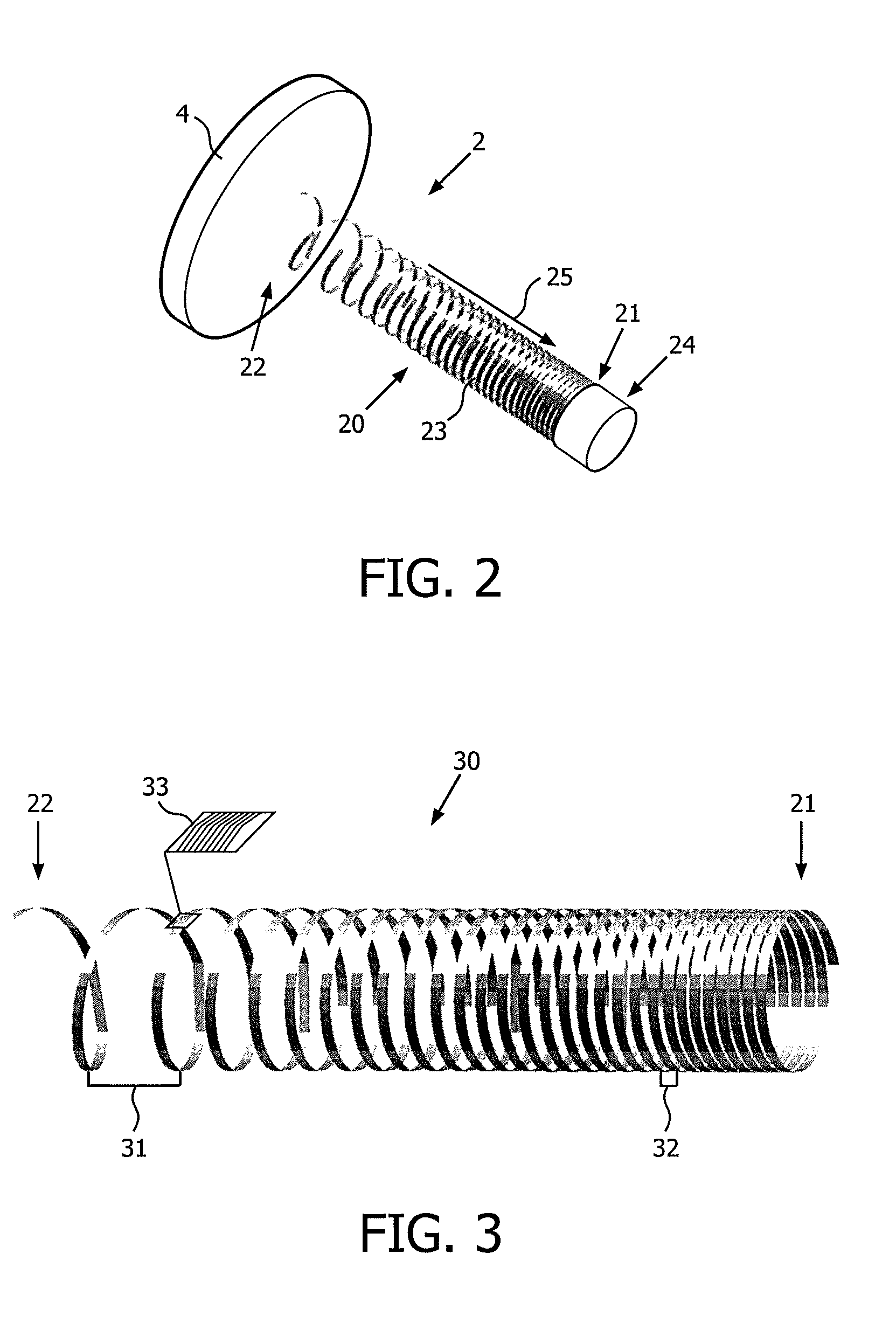

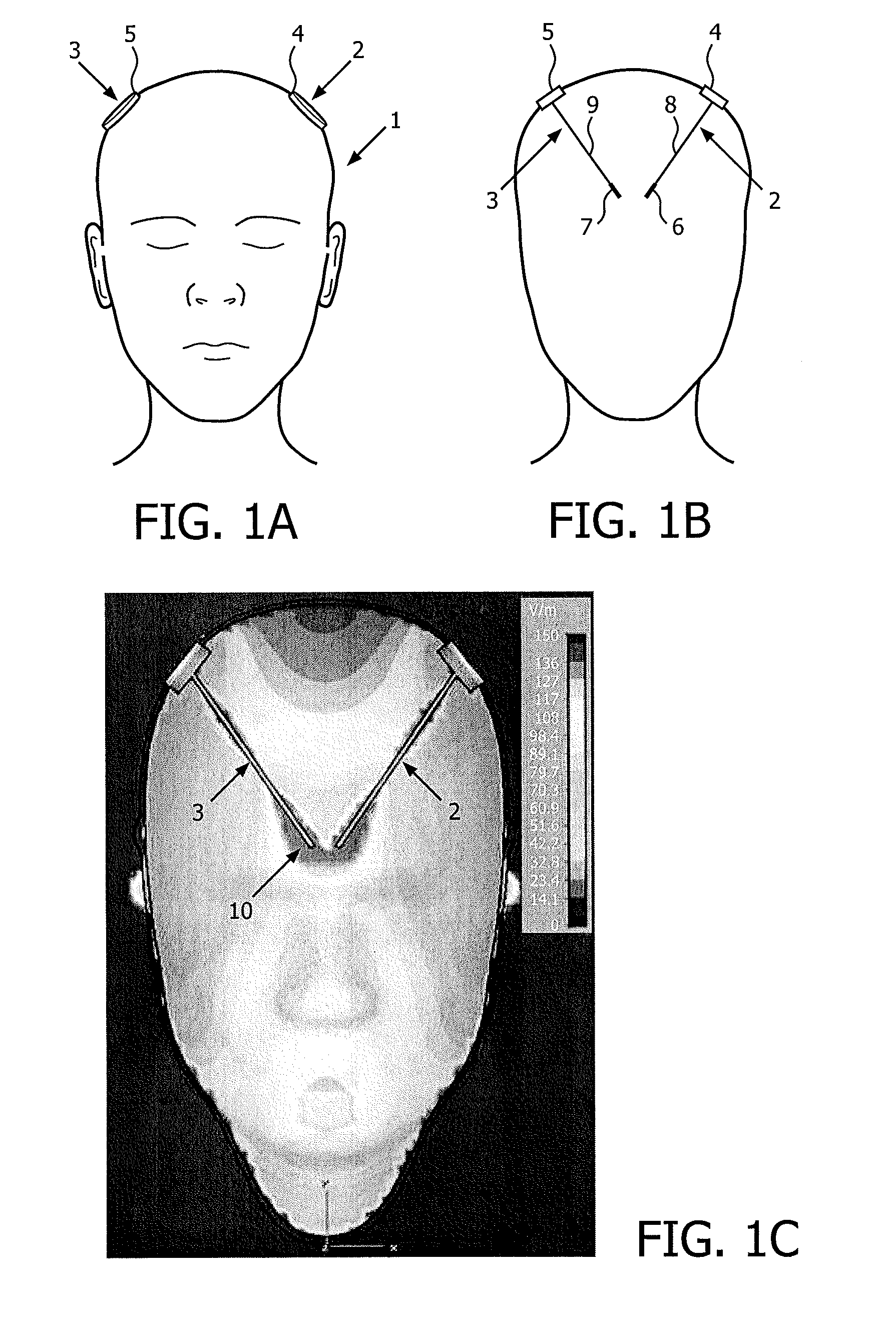

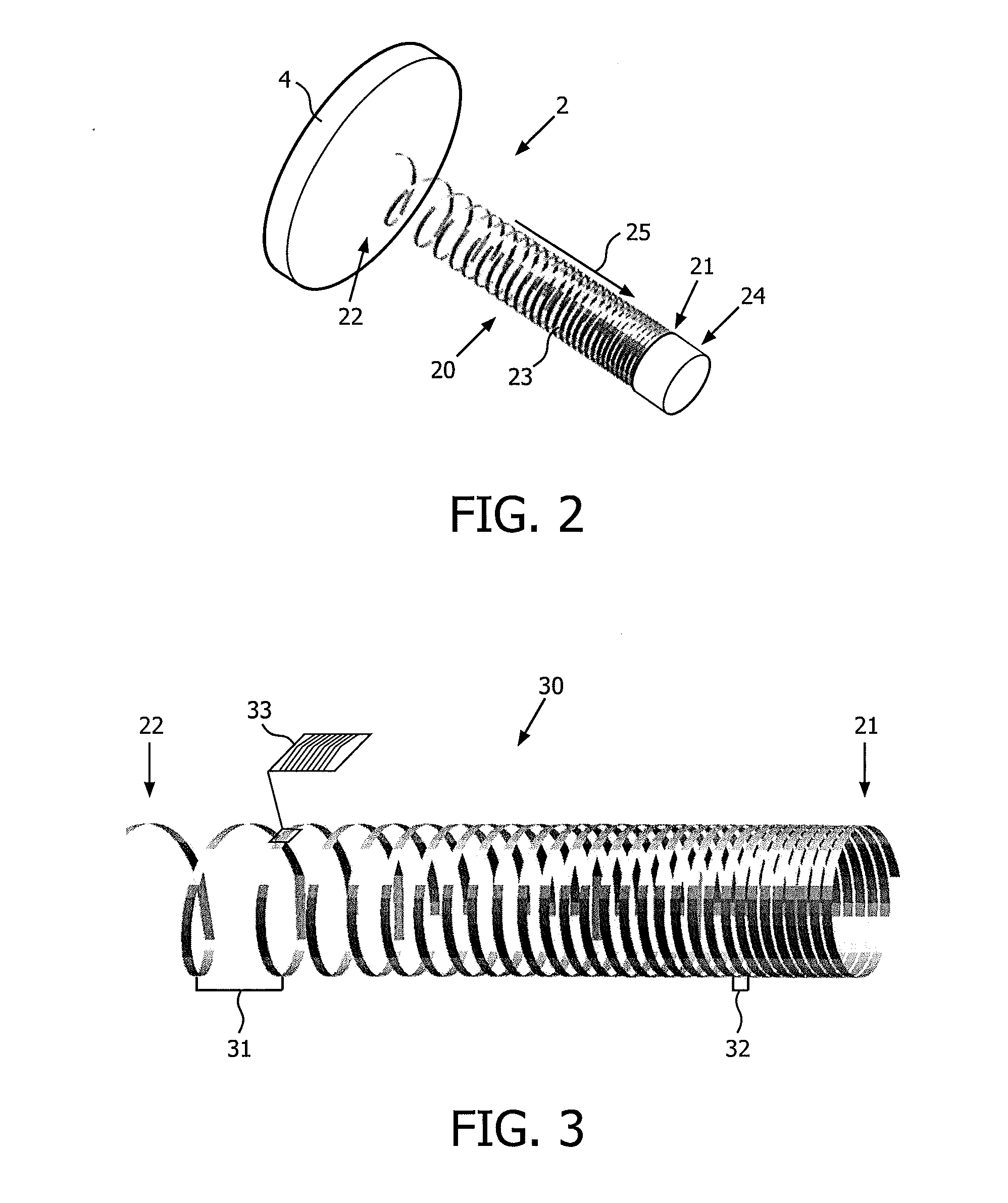

Medical device for electrical stimulation

ActiveUS9205252B2Mitigate, alleviate or eliminate oneImproving impedanceHead electrodesExternal electrodesElectricityElectrical conductor

The present invention relates to a medical device (2) for electrical stimulation. The device comprising an implantable elongated lead system (20) having a distal end (21) and a proximal end (22), the lead system comprises one or more electrical conductors (23) for connection to one or more electrodes (24). The one or more electrical conductors are wound along a length axis (25) of the lead system with a plurality of windings, and wherein the density of windings is non-uniformly distributed along the length axis. In an embodiment, the medical device is in the form of a deep brain stimulation (DBS) device.

Owner:MEDTRONIC BAKKEN RES CENT

Medical Device for Electrical Stimulation

ActiveUS20120191168A1Mitigate, alleviate or eliminate oneImproving impedanceHead electrodesExternal electrodesElectricityElectrical conductor

The present invention relates to a medical device (2) for electrical stimulation. The device comprising an implantable elongated lead system (20) having a distal end (21) and a proximal end (22), the lead system comprises one or more electrical conductors (23) for connection to one or more electrodes (24). The one or more electrical conductors are wound along a length axis (25) of the lead system with a plurality of windings, and wherein the density of windings is non-uniformly distributed along the length axis. In an embodiment, the medical device is in the form of a deep brain stimulation (DBS) device.

Owner:MEDTRONIC BAKKEN RES CENT

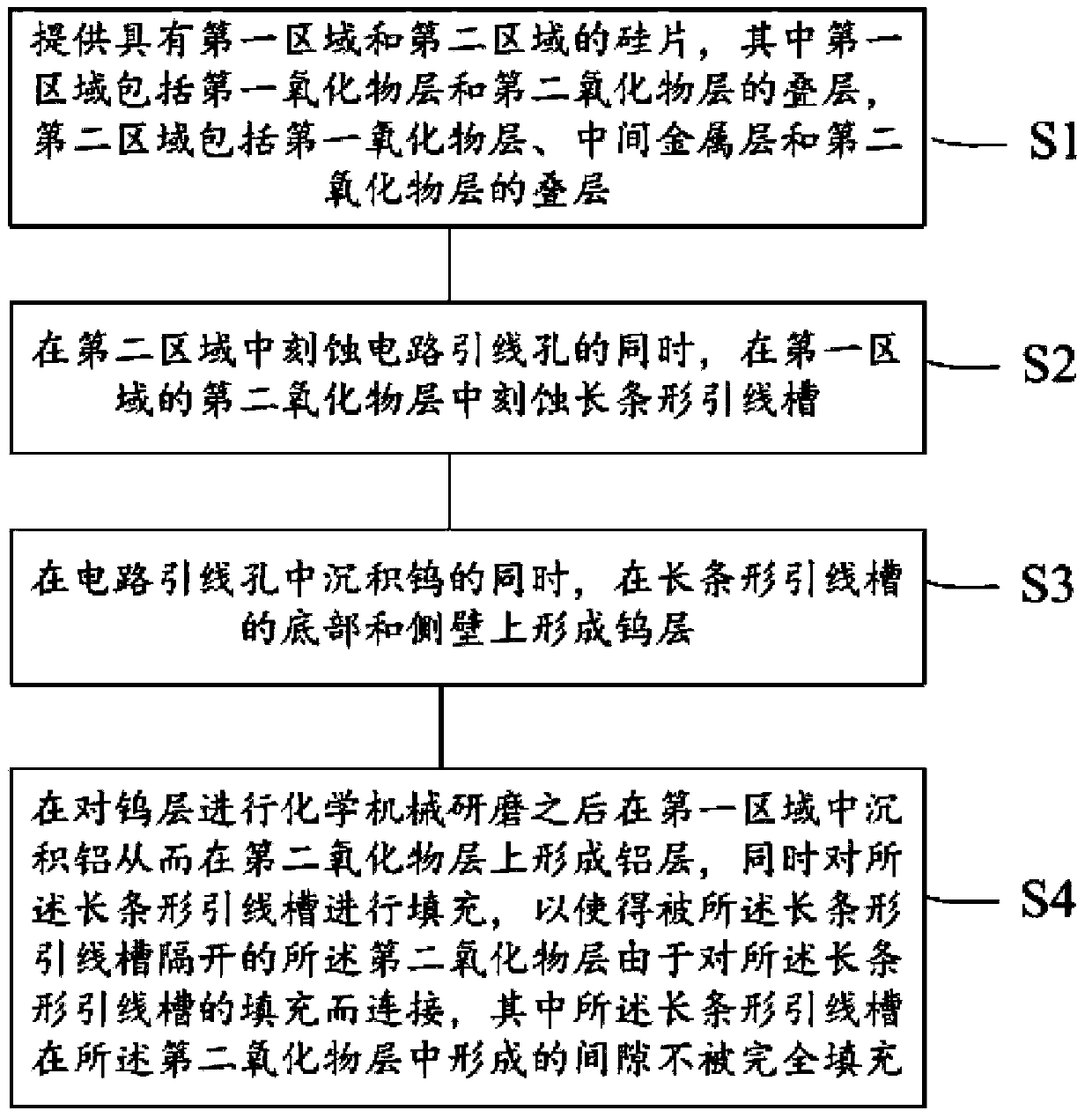

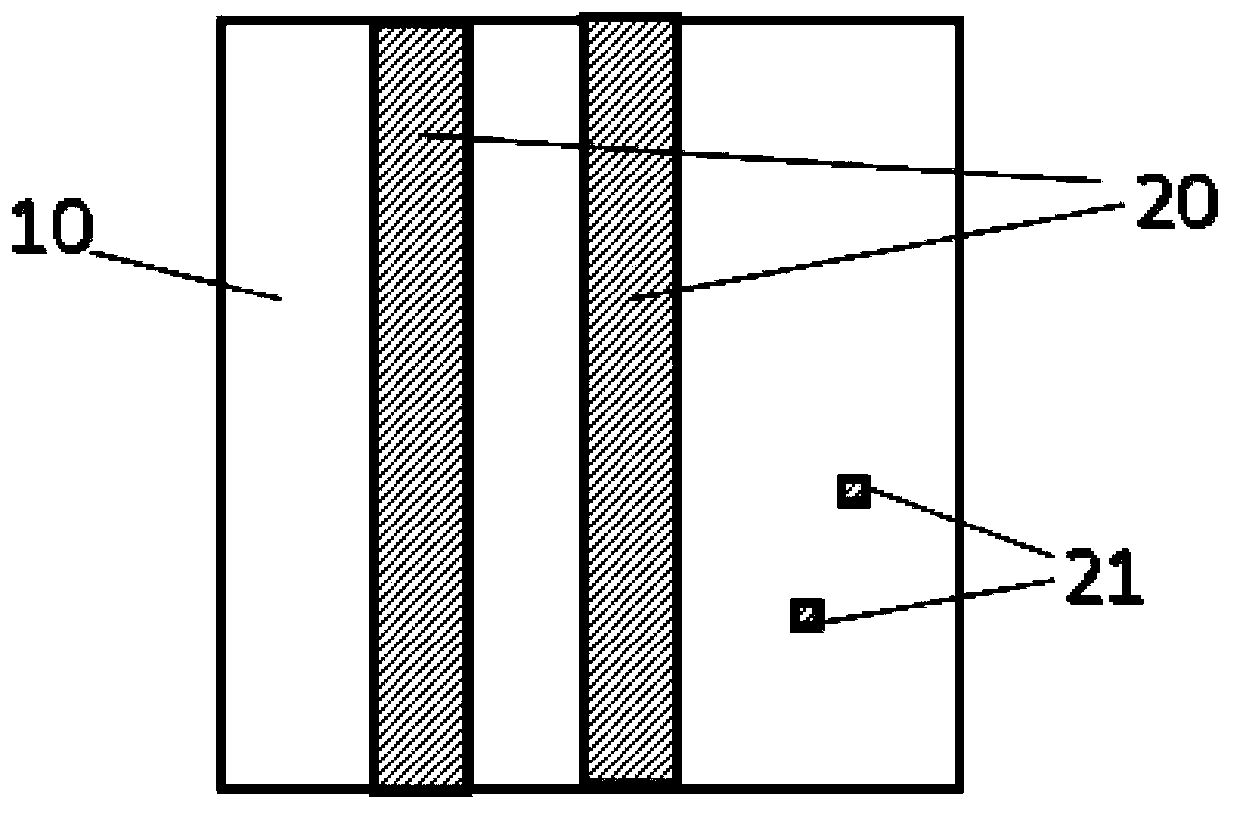

Method for increasing surface area of inductor

ActiveCN103390543AImprove performanceIncrease the effective surface areaSemiconductor/solid-state device manufacturingInductorTungsten

The invention discloses a method for increasing a surface area of an inductor. The method comprises the steps that a silicon wafer with a first area and a second area is provided, wherein the first area comprises a lamination layer of a first oxide layer and a second oxide layer, and the second area comprises lamination layers of the first oxide layer, a middle metal layer and the second oxide layer; strip-shaped wire lead grooves are etched in the second oxide layer of the first area when circuit wire lead holes are etched in the second area; tungsten layers are formed at the bottoms and on side walls of the strip-shaped lead wire grooves when tungsten is settled in the circuit wire lead holes; aluminum is settled after the tungsten layers are subjected to chemical-mechanical grinding, so that an aluminum layer is formed on the second oxide layer; the strip-shaped lead wire grooves are filled, so that the second oxide layer isolated by the strip-shaped lead wire grooves is connected due to the fact that the strip-shaped lead wire grooves are filled; and gaps formed by the strip-shaped lead wire grooves in the second oxide layer are not filled completely.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

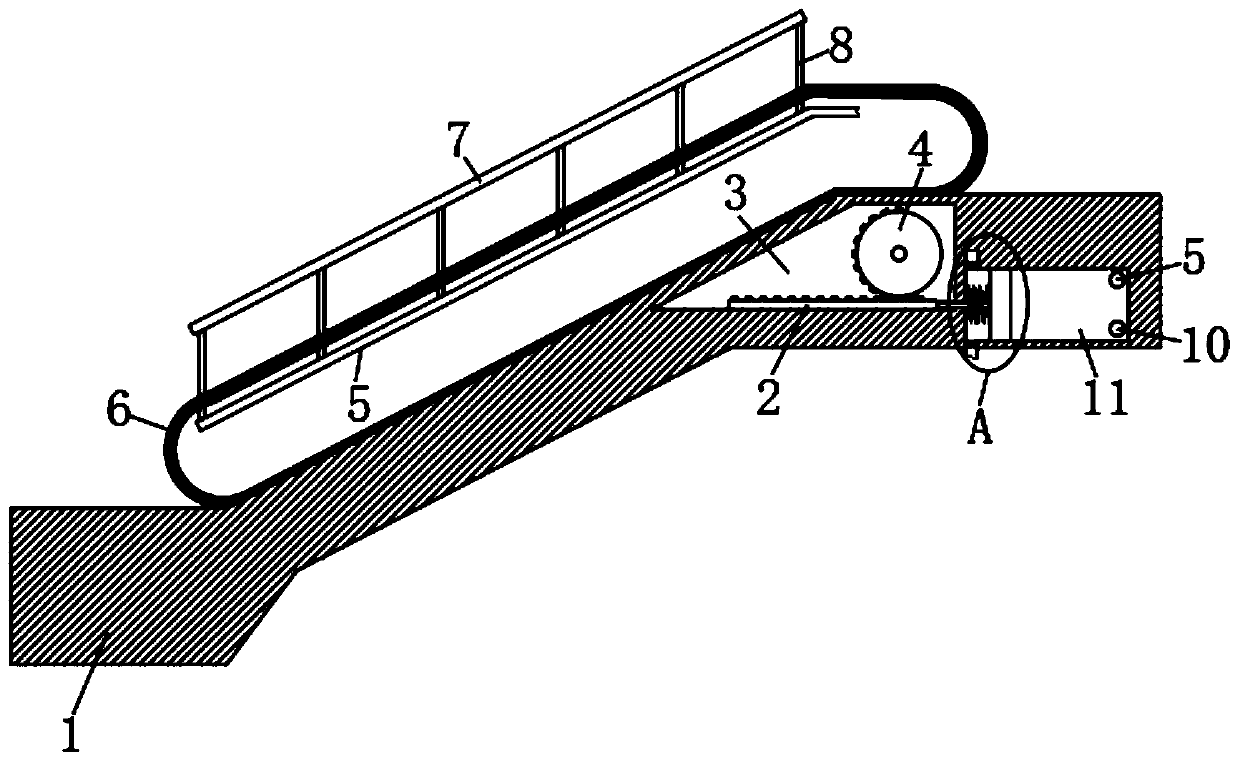

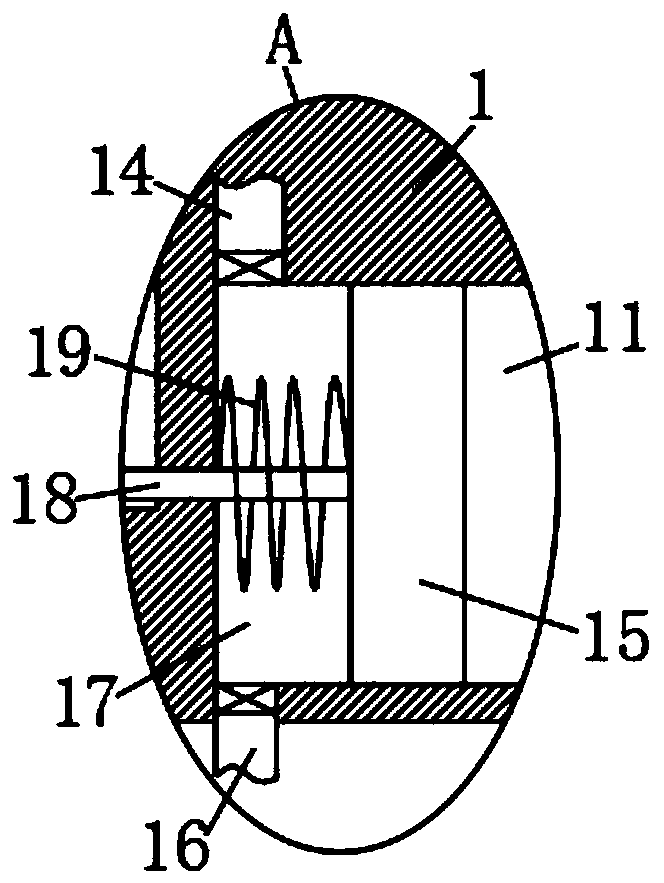

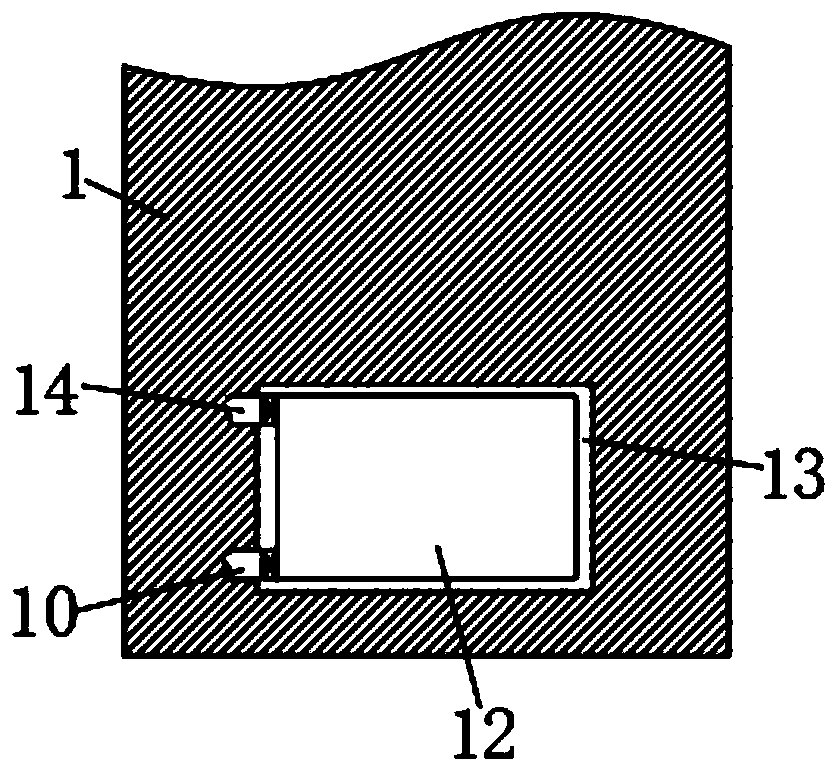

Pedestrian cooling device of induction escalator

The invention discloses a pedestrian cooling device of an induction escalator. The pedestrian cooling device comprises an elevator pedestal and an escalator body, wherein a device cavity and a cavityare arranged in the upper end of the elevator pedestal; the output shaft of an escalator body drive motor extends into the device cavity and is fixed with an incomplete gear; the bottom in the devicecavity is in sliding connection with a rack; the rack is engaged with the incomplete gear; the tail end of the rack is fixedly connected with an abutting-against rod which extends into the cavity; oneend, in the cavity, of the abutting-against rod is fixed with a piston for dividing the cavity into a first cavity and a second cavity; a spring is arranged on a position, between the piston and theinner wall of the cavity, on the abutting-against rod; a placing slot is formed in one side of the cavity; a refrigerating cabinet is placed in the placing slot; and the first cavity communicates withthe refrigerating cabinet through a first gas sucking tube. The pedestrian cooling device is reasonable in structure, can automatically output cool air while the escalator is used on hot summer days,and greatly improves taking comfort.

Owner:王立强 +2

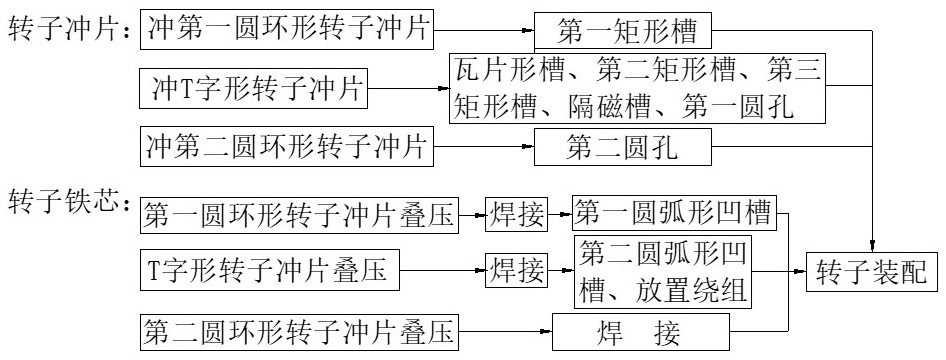

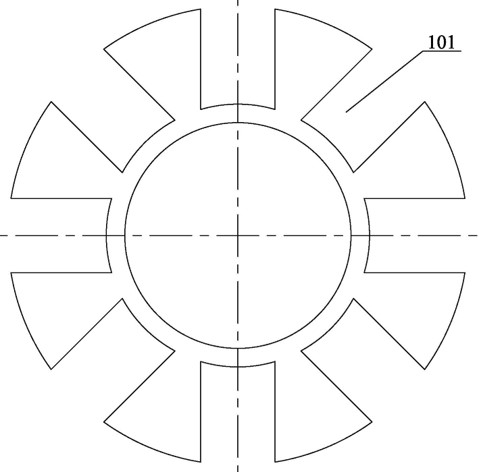

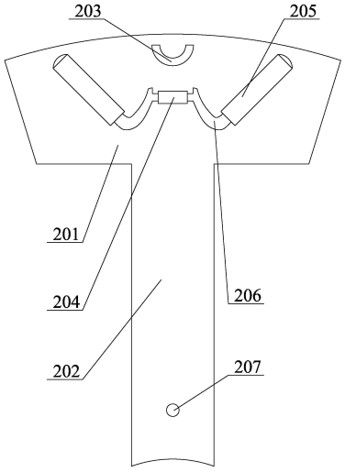

Locking ring type modular double excitation drive motor rotor production method

ActiveCN112600371BReduce manufacturing costEasy to manufactureManufacturing stator/rotor bodiesElectric machineWire cutting

The invention provides a locking ring type modular double excitation drive motor rotor production method, which belongs to the technical field of automobile motors and electrical appliances. The locking ring-type modular double-excitation drive motor rotor core punching is easy to process, and the wire cutting path is less complicated; the off-line winding is easy to machine operation, convenient and fast, and the third rotor core is used as a locking ring, which can be used as A part of the magnetic circuit can realize the axial fixation of the modular rotor, and the effect of multi-winding and multi-permanent magnets can be achieved in the limited space inside the motor, thereby improving the power density of the motor; the magnet in the rotor structure adopts three layers The structure, the second permanent magnet steel and the third permanent magnet steel combined with the magnetic isolation groove can better play the role of magnetic circuit blocking, the first permanent magnet steel can play its magnetic attraction role, and weaken the high-order harmonic content of the back electromotive force of the drive motor , to improve the performance of the motor.

Owner:SHANDONG UNIV OF TECH

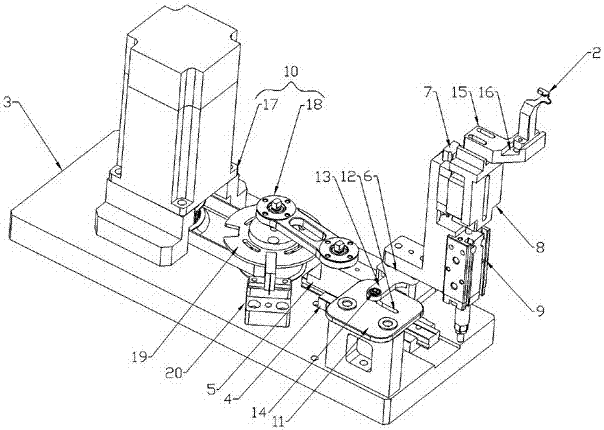

An auxiliary wire arrangement, wire pulling mechanism and automatic winding machine

ActiveCN105632754BSimple structureImprove the winding effectInductances/transformers/magnets manufactureWinding machineConductor Coil

The invention discloses an auxiliary wire arranging and pulling mechanism and an automatic winding machine, aiming to provide an auxiliary wire arranging and pulling mechanism which is simple in structure, helps to improve the winding density of products, and can effectively improve the winding capacity of the winding machine. mechanism, and also provide an automatic winding machine with strong winding capacity, high production efficiency and good product quality. The auxiliary wire-drawing and wire-drawing mechanism includes a driving mechanism and a wire-drawing head arranged on the driving mechanism. The automatic winding machine adopts the design of auxiliary wire arranging and pulling. The invention is applied to the technical field of winding machines.

Owner:ZHUHAI KLES MACHINE TECH

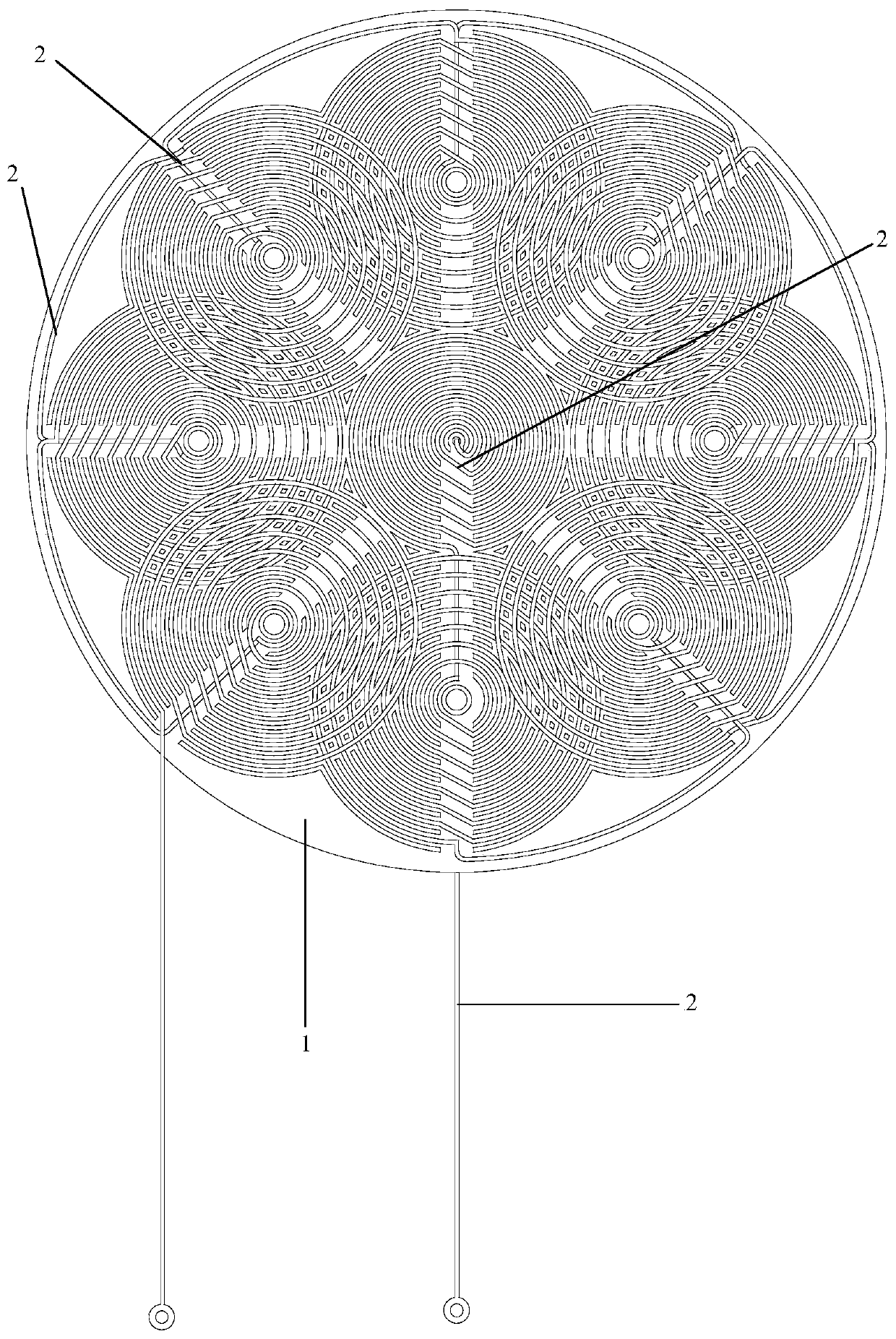

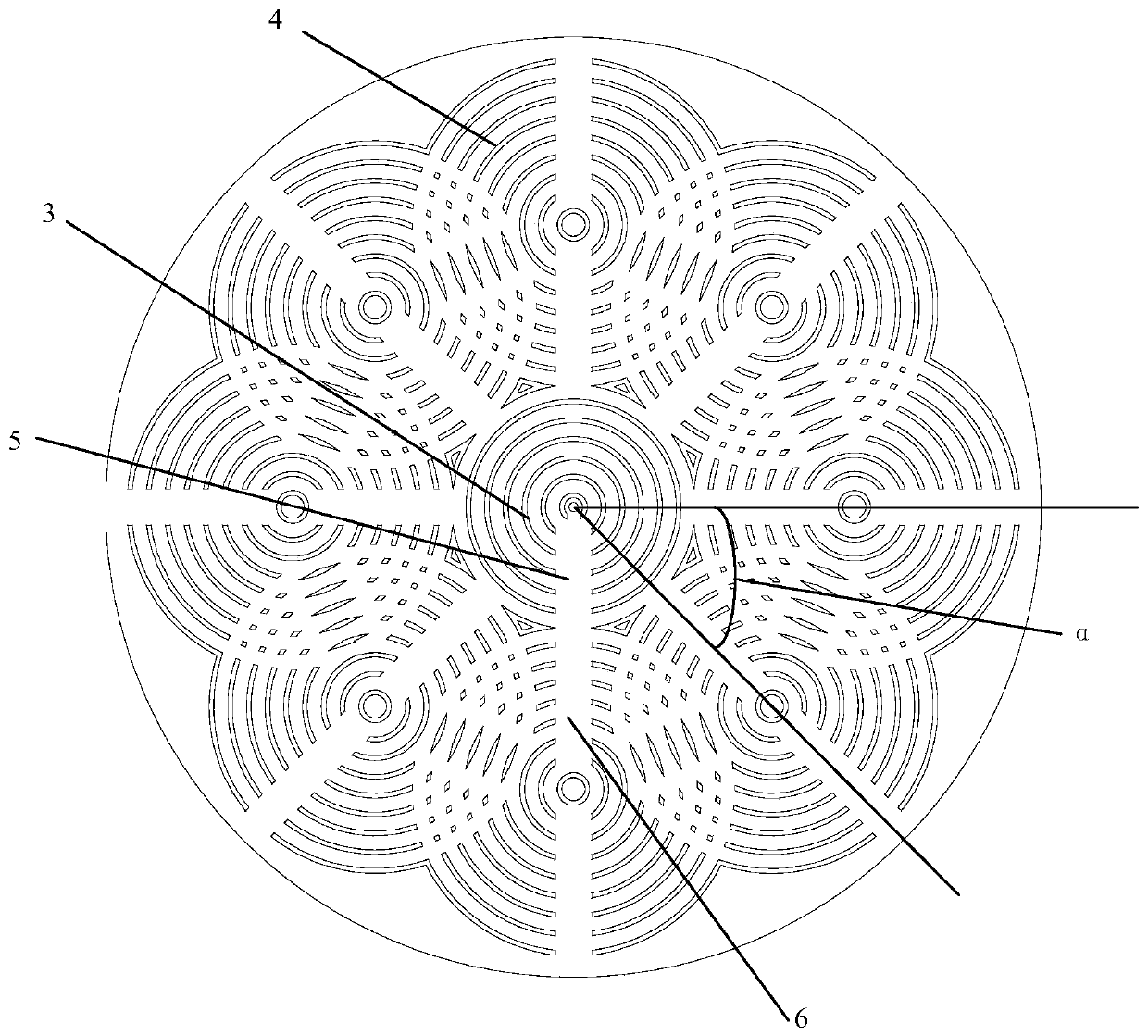

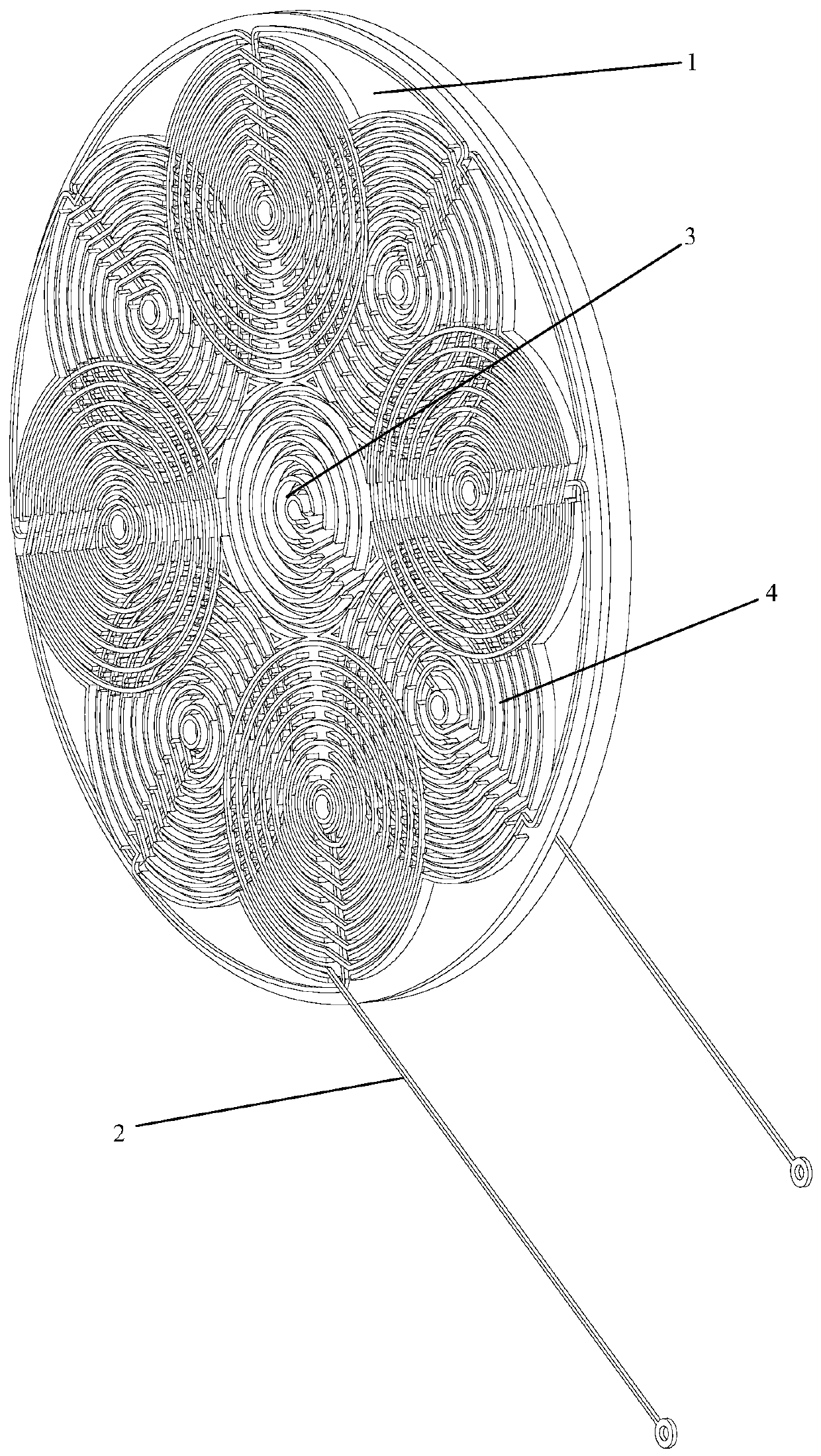

Coil panel of induction cooker and winding method thereof

PendingCN110225610AThin wire coil thicknessIncrease coil winding densityDomestic stoves or rangesCoil arrangementsCookerEngineering

The invention relates to a coil panel of an induction cooker, comprising a coil panel base and enameled wires. The coil panel is characterized in that the coil panel base is provided with wire slots for coiling the enameled wires; the wire slots include a central wire slot and a plurality of circumferential wire slots uniformly arranged around the central wire slot; the central wire slot includesa plurality of annular wire slots centered around the center of the coil panel base; and each annular wire slot includes a plurality of annular wire slots having a common center, and the adjacent annular wire slots overlap with each other. There is no blind area of heating, and the heating is uniform. Especially when fried food is heated, the degree of heating is consistent in different areas, andno part of the food will be burnt.

Owner:大红鹰商业管理(中山)有限公司

Carbon-carbon composite material ring for hot pressed sintering and preparation method thereof

The invention discloses a carbon-carbon composite material ring for hot pressed sintering and a preparation method thereof. Firstly, high-strength carbon fiber yarn impregnated with phenolic resin is wound on the outer side of a steel mold core with the taper of 1-5 degrees, after winding is conducted by 2-10 mm, carbon fiber cloth impregnated with phenolic resin is wound by 1-3 mm, the breadth of the carbon fiber cloth is the same as the height of the mold, and the carbon fiber cloth and the carbon fiber yarn are wound repeatedly and alternately. After winding to a preset thickness, the mold is heated and cured. The cured carbon fiber reinforced phenolic resin material ring is taken down from the steel mold and sleeves on an expanding and inner diameter expanding mold, then is put into a hot-pressing sintering furnace, slowly heated and carbonized to 600 DEG C or above in the presence of flowing nitrogen, and slowly pressurized while slowly heated and carbonized, the maximum pressure is increased to 25-35 Mpa and is kept until the carbonization is finished; and after cooling, discharging from the furnace, the carbon-carbon composite material ring is taken down, dipped in the phenolic resin again, and heated and cured after dipping so as to obtain the carbon-carbon composite material ring for hot pressed sintering.

Owner:福州赛瑞特新材料技术开发有限公司

High-toughness electric wire connecting machine and working method thereof

PendingCN113964552ARealize positioning stuckRealize the effect of rotating windingCoupling device detailsElectric connection structural associationsStructural engineeringElectric wire

The invention discloses a high-toughness electric wire wiring machine and a working method thereof. The high-toughness electric wire wiring machine comprises a wiring table, a base frame and sliding line clamping mechanisms. The wiring table is symmetrically provided with two sets of sliding line clamping mechanisms, and the inner side surfaces of the two sets of sliding line clamping mechanisms are symmetrically provided with elastic extrusion mechanisms for tensioning lines during winding; meanwhile, a wiring hole is formed in the middle of the wiring table, a rotary wiring shuttle with a conical top is mounted in the wiring hole, horizontal wire insertion through holes for inserting two ends of a wiring wire are formed in the conical part of the top of the rotary wiring shuttle, and a telescopic wire clamping mechanism for clamping a wire end is mounted on the rotary wiring shuttle; the bottom of the rotary wiring shuttle is provided with the rotary winding wiring mechanism, and meanwhile, the rotary wiring shuttle, the telescopic wire clamping mechanism and the rotary winding wiring mechanism are all installed on the hydraulic telescopic mechanism, so that rapid wiring of high-toughness lines is realized through the structure, and the winding compactness of rotary wiring is improved; and a high-strength combination effect of high-toughness line rotary wiring is achieved.

Owner:HANGZHOU ELECTRIC EQUIP MFG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com