Slotless stator single-phase AC asynchronous motor composed of sinusoidal hollow cup windings

A single-phase AC, asynchronous motor technology, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of single-phase AC asynchronous motor volume reduction, adverse effects on motor performance, and increased motor loss, etc. Easy and smooth starting, improved motor performance, improved motor performance effect

Inactive Publication Date: 2014-04-16

XIAN AEROSPACE PROPULSION TESTING TECH RES INST

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The torque fluctuation and high-order harmonics generated by the cogging form of the AC motor usually have a negative impact on the performance of the motor, for example, it will increase the motor loss, start difficulty, torque fluctuation, etc.

If the number of slots is increased, this effect will be reduced, but increasing the slots will cause difficulty in inserting wires, especially for motors with smaller sizes.

In addition, this kind of stator structure with cogging also makes it impossible to greatly reduce the volume of single-phase AC asynchronous motors, which has become an obstacle restricting the development of miniature AC asynchronous motors to some extent.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

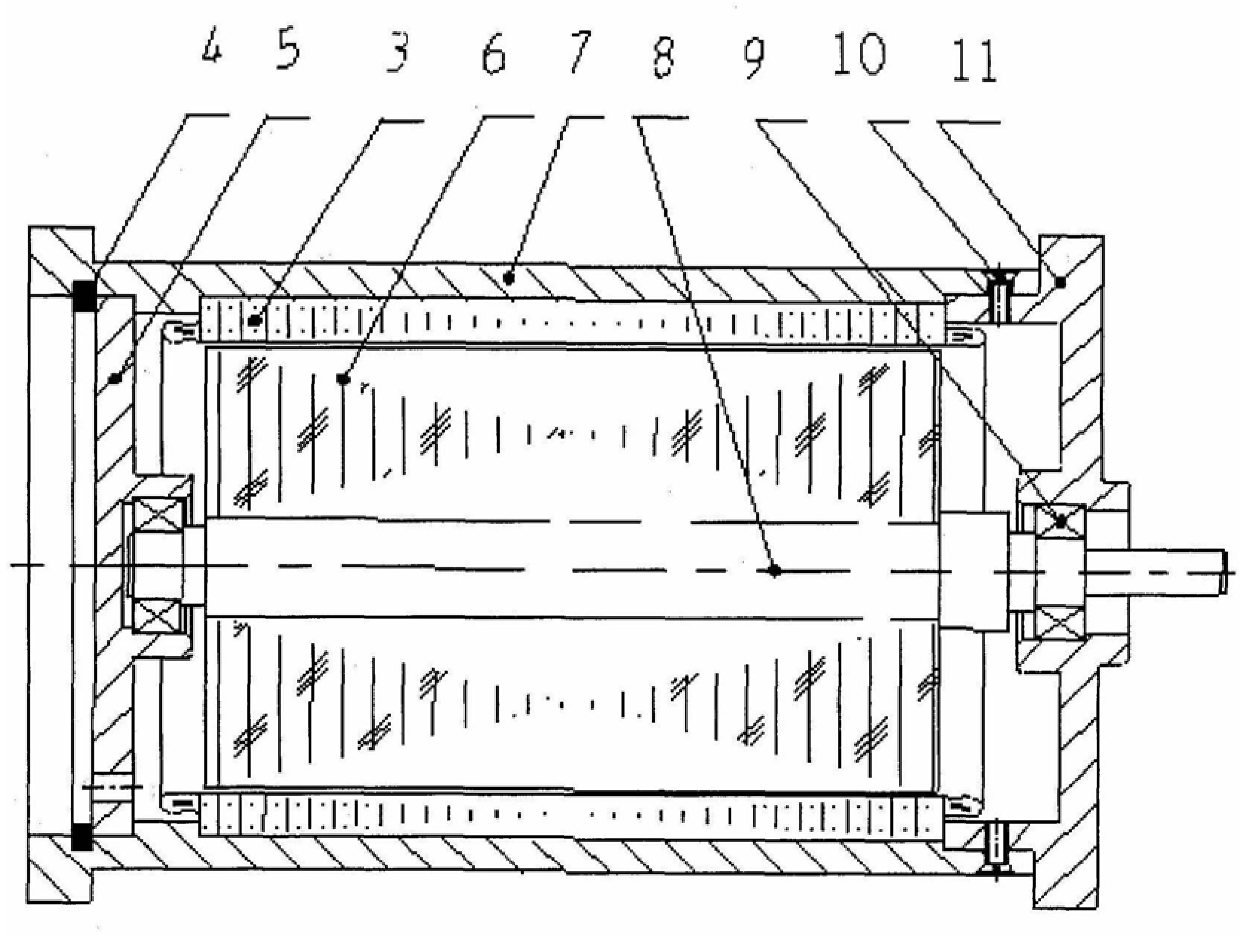

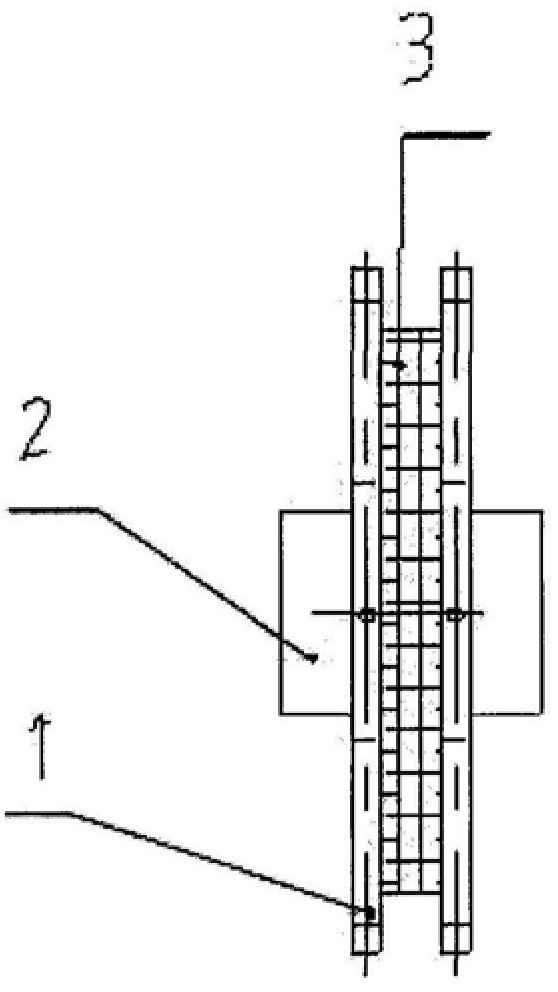

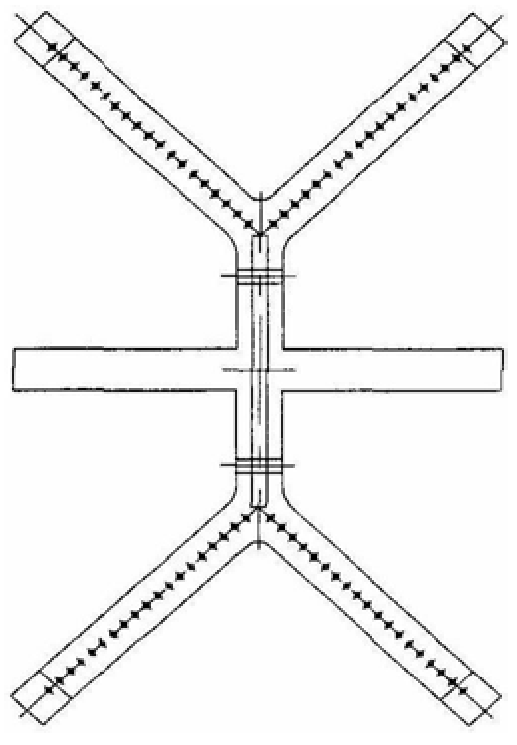

The invention discloses a slotless stator single-phase AC asynchronous motor composed of sinusoidal hollow cup windings. The stator of the AC motor is directly composed of sinusoidal hollow cup windings, so that the stator has a slotless structure. The sinusoidal winding constituting the slotless stator is made on the winding tool, which is composed of two splints and inserting plates. The two splints are fixed together by the inserting plate and fastened with screws to form the winding tooling. , install the winding tool on the winding machine, and wind the sinusoidal winding sheet. Glue the sides of the four-pole pair of sinusoidal winding sheets into one group to make two groups of windings; stagger the two groups of windings at one-eighth of the length of one group of windings and glue them together; roll the bonded two groups of windings into a circle Cylinder, insert the centering tool into the cylinder, and then fasten it with the solid tooling to make a slotless stator. The invention breaks through the traditional mode of the cogged stator in the field of AC motors, effectively improves and enhances the performance of the motor; the size of the AC motor can be reduced to φ24mm or even smaller.

Description

Slotless stator single-phase AC asynchronous motor composed of sinusoidal hollow cup winding technical field The invention belongs to the technical field of hollow motors, and relates to a single-phase AC asynchronous motor with a slotless stator structure composed of sinusoidal hollow cup windings. Background technique The stator structure of the existing single-phase AC asynchronous motor is usually in the form of slots, and the windings are embedded in the slots of the stator to form the stator. The cogging form of the AC motor produces torque fluctuations and high-order harmonics due to the cogging effect, which usually has a negative impact on the performance of the motor, for example, it will increase the motor loss, start difficulties, and torque fluctuations. If the number of slots is increased, this effect will be reduced, but increasing the number of slots will cause difficulty in inserting wires, especially for motors with smaller sizes. In addition, the stator...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K17/04H02K17/16

Inventor 许选年李博宋剑晓

Owner XIAN AEROSPACE PROPULSION TESTING TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com