Heating device and heating method for heating sample before flat plate impact experiment

A heating device and pre-experimental technology, applied in the direction of electric heating devices, heating elements, measuring devices, etc., can solve problems such as inability to achieve the use effect, achieve the effect of controllable temperature rise and rate, small overall structure, and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

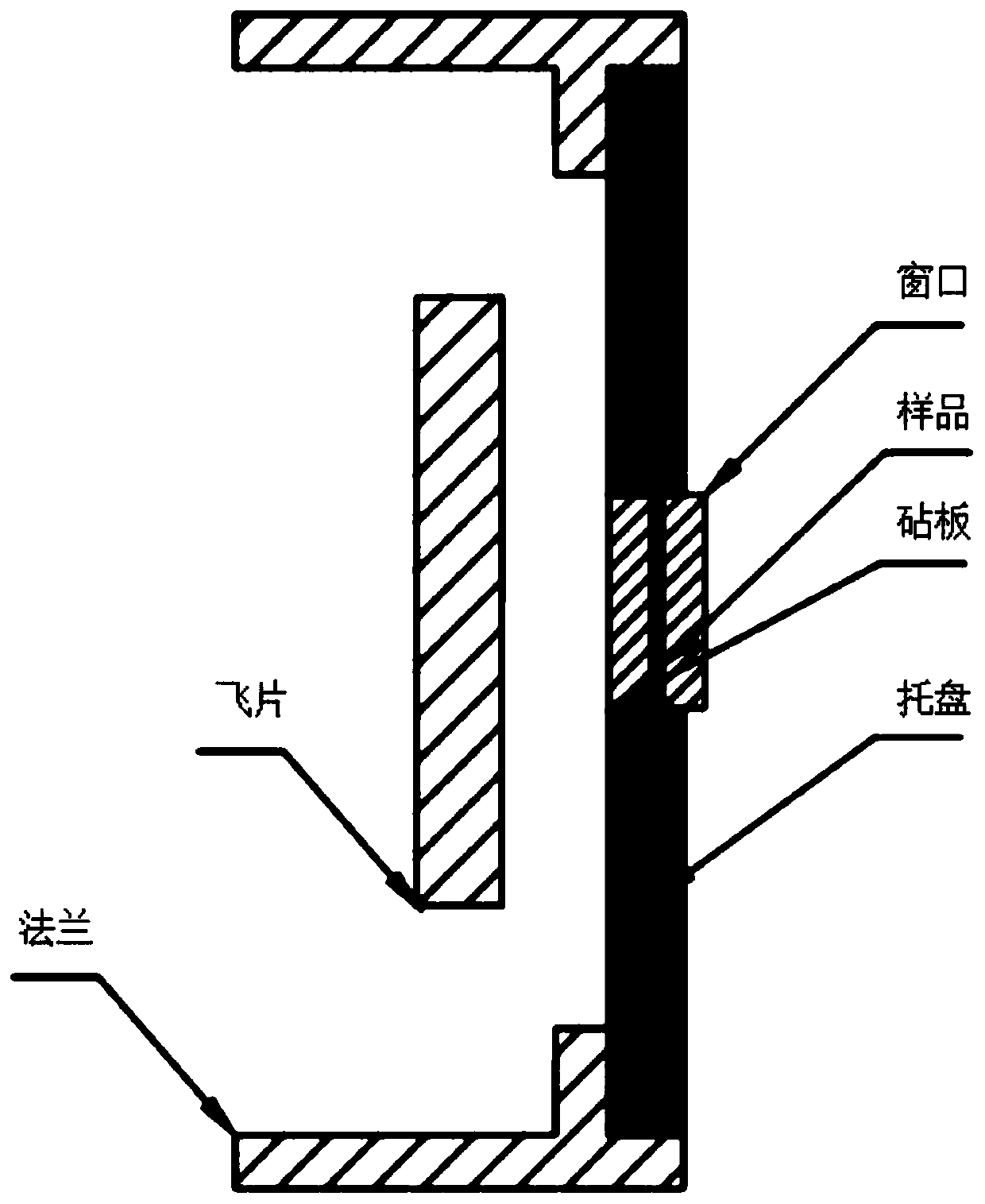

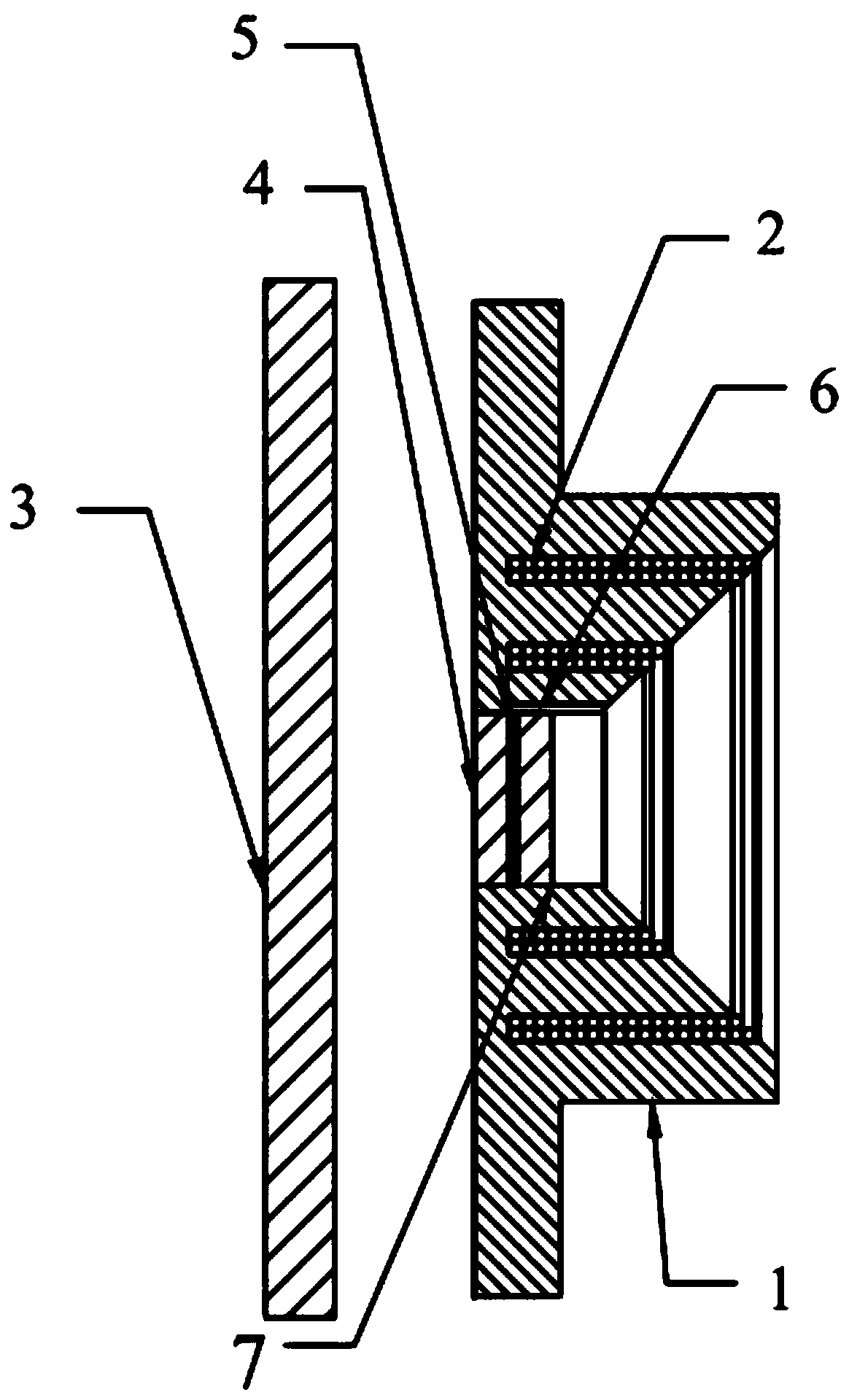

[0032] This embodiment provides a heating device for heating the sample before the plate impact test, which can heat the sample and change the initial temperature of the sample without affecting the progress of the plate impact test.

[0033] Considering the use environment of the heating device, the heating device must be simple in structure, small in size, and able to cooperate with the flange of the target plate chamber to meet the required heating power; to meet a certain heating power, a certain heating coil needs to be wound, and the heating structure requires Sufficient section length. Considering that the thickness of the sample is thin, the effective heating area is small, and the test system device is close to the flange of the target plate chamber, the heating structure cannot hinder the test system, so the section length should not be too long. Therefore, the designed heating device needs to effectively heat the sample under the premise of meeting the above conditi...

Embodiment 2

[0041] On the basis of Example 1, in order to effectively heat the sample 5 to the set initial temperature, a thermocouple keyway 6 is provided at the position corresponding to the sample 5 in the axial through hole of the heat conduction tray 1; The probe of the thermocouple is in contact with the sample 5, and the temperature of the sample 5 is detected and fed back by the thermocouple. Control the power module of the heating coil 2 according to the temperature of the sample 5 fed back by the thermocouple. When the temperature of the sample 5 fed back by the thermocouple is consistent with the set initial temperature, disconnect the power module of the heating coil 2; When the temperature of the sample 5 fed back is lower than the set initial temperature, the power supply module of the heating coil 2 is turned on, so that the sample 5 can be kept at a constant initial temperature.

[0042] Since the initial temperature during the experiment is generally below 200°C, the heat...

Embodiment 3

[0044] On the basis of embodiment 2, the concrete installation, working process of heating device are illustrated:

[0045] A. Wind the heating coil 2 in the annular groove of the heat conduction tray 1: wind the heating coil 2 from the inner annular groove to the outer annular groove in sequence. Considering that the heating coil 2 will burn out if the temperature is too high, the winding coil is two layers;

[0046] B. First place the heat conduction tray 1 wrapped with the heating coil 2 on the horizontal reference platform, then put the cutting board 4 into the round hole section of the heat conduction tray 1, and use heat-resistant glue to laterally bond the cutting board 4 to the round hole section Inside, stick sample 5 on the cutting board 4 with heat-resistant glue, place a thermocouple in the thermocouple keyway 6 so that the thermocouple probe contacts sample 5, fix the thermocouple with heat-resistant glue, and then glue it on sample 5 with heat-resistant glue wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com