Azeotropic rectification device and method for separating propylene glycol monomethyl ether and water

A technology of propylene glycol methyl ether and azeotropic rectification, applied in azeotropic distillation, ether separation/purification, ether preparation and other directions, can solve problems such as personnel health effects and serious benzene pollution, achieve good social benefits and improve market competition power, reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

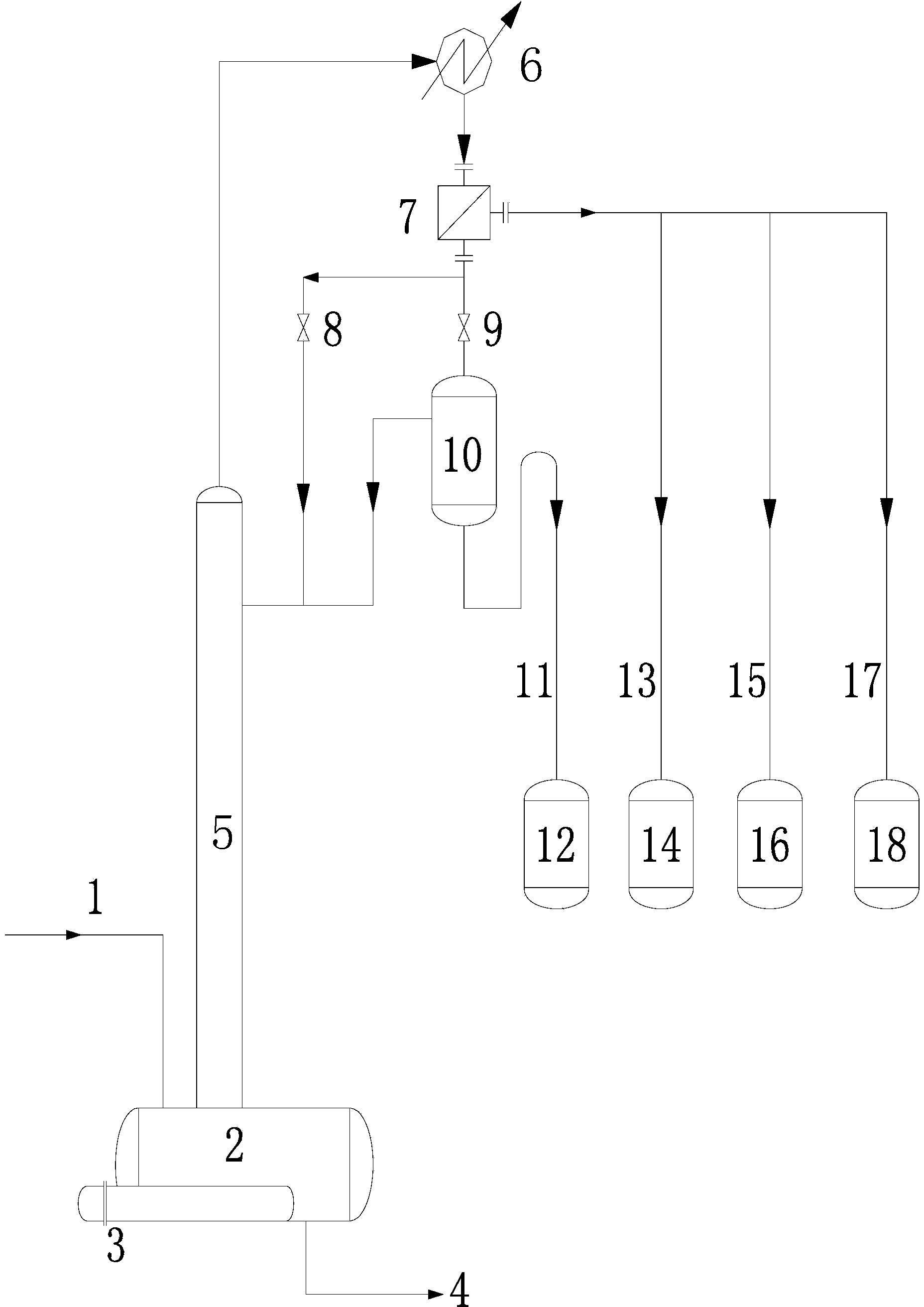

Image

Examples

Embodiment 1

[0033] Feed composition:

[0034] Make up

Heavy component

Water

Content (wt%)

35%~40%

5%

55%~60%

[0035] Intermittent distillation operation, processing one kettle of waste liquid per day, the processing capacity of each kettle is 5 tons, the processing time of each kettle is 20 hours, and the waste liquid 1 added with cyclohexane is added to the distillation at one time according to the processing volume of each kettle. In kettle 2, the material in distillation kettle 2 is heated to steam by kettle reboiler 3 and then rises to the top of distillation tower 5. The theoretical plate number of the distillation tower is 75, the operating pressure is normal pressure, and the reflux ratio is 2. ~8, the temperature at the top of the tower is 65℃~125℃, and the temperature of the tower bottom is 90℃~140℃. The gas phase at the top of the rectification tower 5 is condensed into a liquid phase by the top condenser 6 of the rectification tower, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com