Process for separating ethandiol, mono methyl ether, isopropyl alcohol and water combined by extracting and axeotropy

A technology of ethylene glycol monomethyl ether and isopropanol, which is applied in the field of extraction and azeotropic separation, and can solve problems such as difficult regeneration, environmental problems, and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

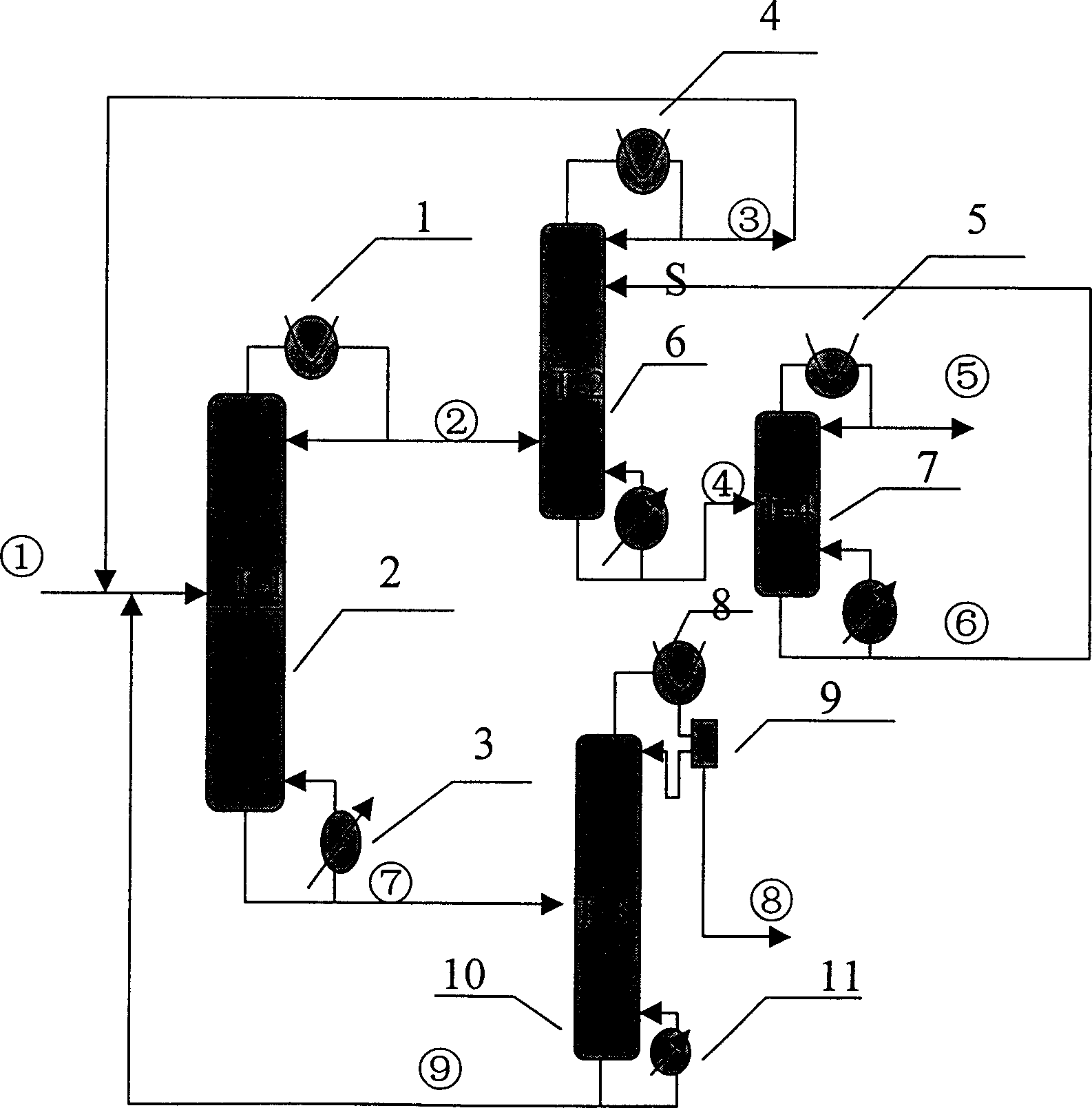

[0009] Extraction and azeotropic combination separation method of ethylene glycol monomethyl ether, isopropanol and water, refer to figure 1 Shown technology and parameter shown in table 2, raw material (F1) is ethylene glycol monomethyl ether+isopropanol+water mixed solution, the mass content of ethylene glycol monomethyl ether, isopropanol and water (Xf1, Xf2, Xf3 ) were 10%, 50%, and 40% respectively, and the flow rate was 4.1Kg / h. When the top and low temperatures of precision rectification tower T-1 were 80.4°C and 87.5°C respectively, the top and low flow rates were 2.7Kg / h, 1.4Kg / h, precision rectification ℃ The top reflux ratio (R1) is controlled at 4~6, the composition of the top and bottom of the tower (x Di , x wi )x D1 = 0.0000, x D2 =0.7592,x D3 =0.2407,x w1 =0.2929,x w2 =0.0000x w3 =0.7071; the top component is sent to the extractive distillation unit (T-2), the ratio of extractant (glycerin) to raw material S / F2=2.5:1, the top reflux ratio R2 is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com