Method for separating ethyl ether, ethyl alcohol and acid water by combining rectifying and azeotropic distilling

A technology of azeotropic distillation and ethanol, applied in the separation/purification of hydroxyl compounds, separation/purification of carboxylic acid compounds, ether separation/purification, etc., can solve the problems of high energy consumption, incomplete separation, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

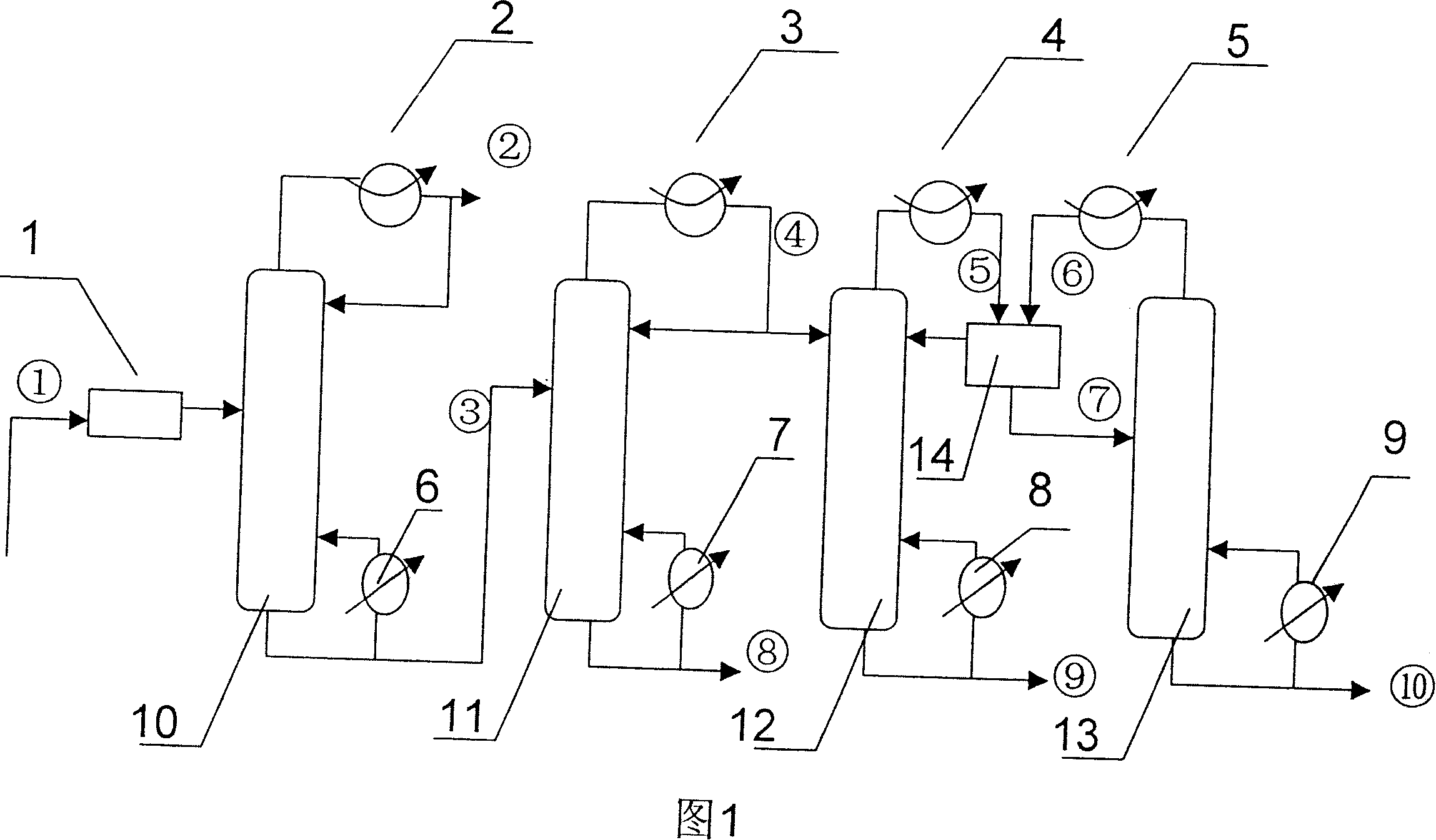

[0021] With reference to the technique shown in Figure 1 and the parameters shown in Table 2, the raw material (F1) is ether+ethanol+acid water mixed solution, the mass content (Xf1, Xf2, Xf3) are 2%, 93%, 5% respectively, pH=1~2, flow rate is 110Kg / h, through preheating to 33 ℃, precision rectifying tower T-1 top, low temperature are respectively 34.5 ℃ and 78- At 81°C, the top and low flows are 2.24Kg / h and 107.76Kg / h respectively, the pH values are 5-6 and 1-2 respectively, and the reflux ratio (R1) at the top of the precision distillation column is controlled at 2-3. Bottom composition (x Di , x wi )x D1 =0.9810,x D2 =0.0055,x D3 =0.0135,x w1 = 0.0000, x w2 =0.9485,x w3 =0.0515; the tower bottom components are sent to the deacidification rectification unit T-2 for treatment, the top reflux ratio (R2) is controlled at 3 to 4, and 95.12% ethanol can be obtained at the top of the rectification tower, and the pH value is 5 to 6. The bottom is rich in acid aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com