Ultrasonic signal receiving and detecting circuit and application

A signal receiving and detection circuit technology, applied in the field of ultrasonic applications, can solve problems such as damage to the atomizer, detection failure, corrosion and oxidation, and achieve the effects of low cost, long life and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be described in further detail below in conjunction with the drawings:

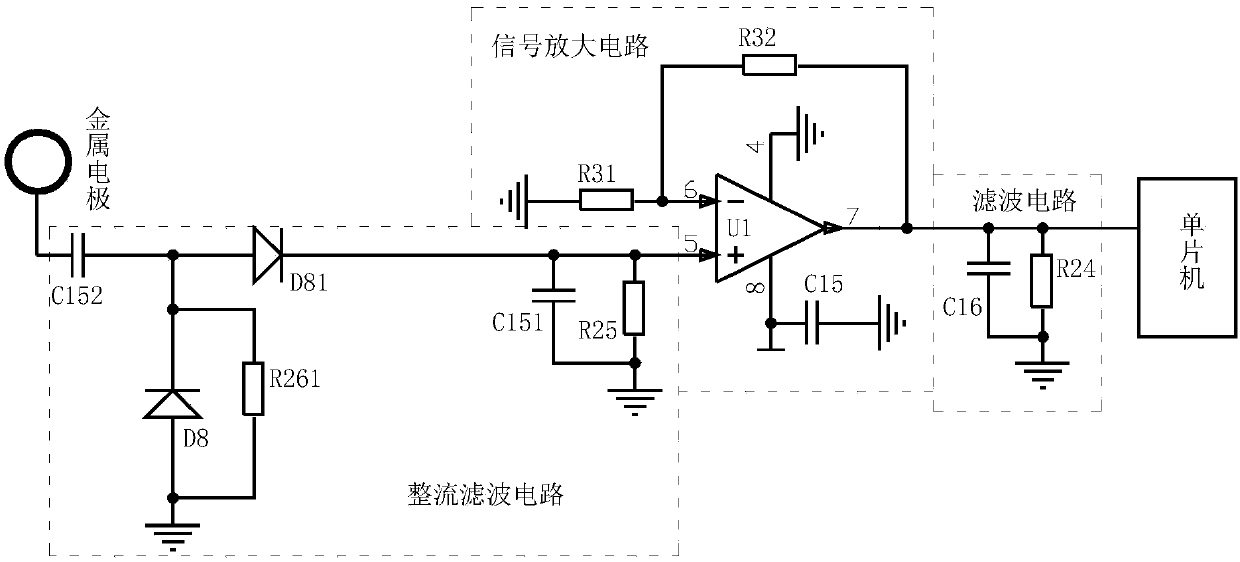

[0017] The present invention is an ultrasonic signal receiving and detecting circuit and its application. Common ultrasonic signal receiving in the market generally uses ultrasonic sensors, but ultrasonic sensors are expensive. The invention is based on the characteristics of good beamability and directivity of ultrasonic wave propagating along a straight line within a certain distance, and adopts metal electrodes to receive and process ultrasonic signals. At the same time, since the energy attenuation of ultrasonic waves in air is significantly greater than that in water compared with those in water, an ultrasonic wave detection circuit can be used to achieve anhydrous detection of ultrasonic atomizers.

[0018] An ultrasonic signal receiving and detecting circuit includes a metal electrode for receiving ultrasonic signals and a signal processing circuit connected with the metal elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com