Highlight-dark-bubble-resistance white wood lacquer and preparation method and application thereof

A wood lacquer and white technology, which is applied in the field of high-gloss anti-foaming white wood lacquer and its preparation, can solve the problem that the drying performance of the paint film is difficult to guarantee, and achieve the prevention of damage and carcinogenicity, good compatibility and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

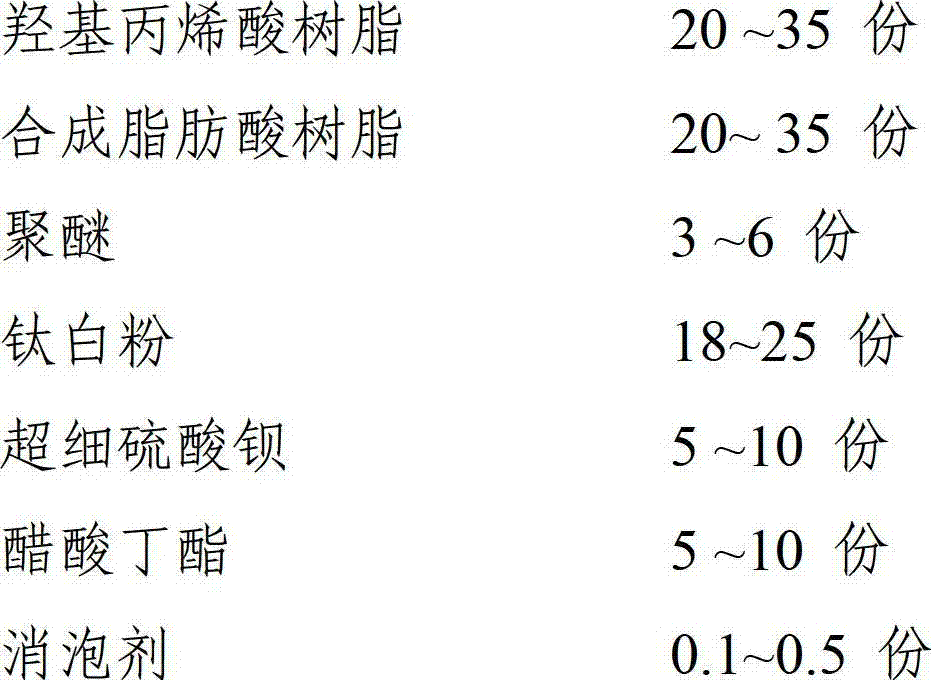

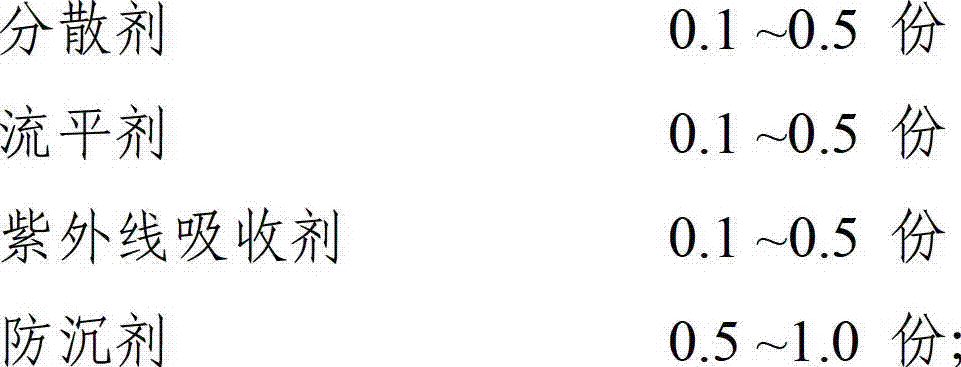

[0122] Prepare high-gloss anti-foaming white wood paint according to the following ratio:

[0123] A component: ACR6606 30kg, 3755-X-80 30kg, N-210 3kg, titanium dioxide 25kg, superfine barium sulfate 5kg, butyl acetate 6kg, DeuRheo2290.5kg, Defom5300 0.2kg, EFKA-E4061 0.5kg, BYK- 306 0.4kg, TINUVIN-328 0.1kg;

[0124] Component B: BAYERN-75 10kg, Desmodur HL 60kg, butyl acetate 25kg;

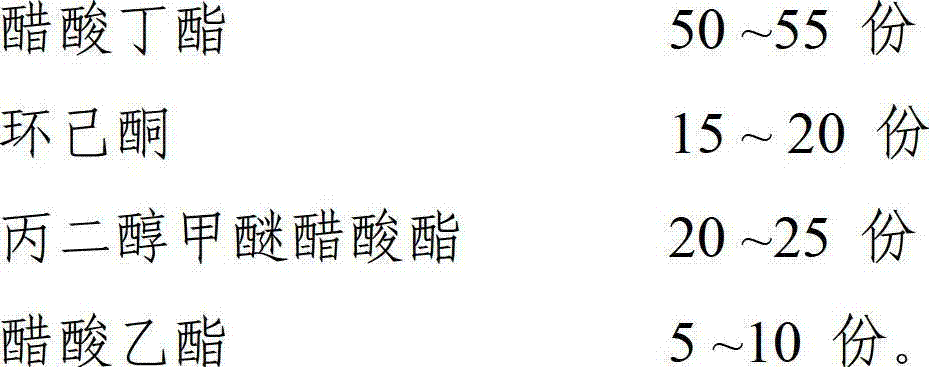

[0125] C component: butyl acetate 25kg, cyclohexanone 10kg, propylene glycol methyl ether acetate 10kg, ethyl acetate 5kg;

[0126] The weight ratio of component A, component B and component C is 100:80:50.

[0127] The preparation method comprises the following steps:

[0128] (1) Preparation of component A:

[0129] 1) Put the 3755-X-80, ACR6606, N-210, butyl acetate and EFKA-E4061 in the above ratio into the reactor, and stir at a speed of 600r / min for 30min to obtain a resin mixture;

[0130] 2) Slowly add the titanium dioxide, ultra-fine barium sulfate, and DeuRheo229 in the above rat...

Embodiment 2

[0138] Prepare high-gloss anti-foaming white wood paint according to the following ratio:

[0139] A component: ACR6606 20kg, 3755-X-80 35kg, N-210 5kg, titanium dioxide 23kg, superfine barium sulfate 10kg, butyl acetate 5kg, DeuRheo2290.6kg, BYK-065 0.1kg, EFKA-4010 0.4kg, BYK-333 0.5kg, 2-(2-hydroxy-5-methylphenyl)benzotriazole 0.2kg;

[0140] B component: BAYER N-75 20kg, Desmodur HL 40kg, butyl acetate 20kg;

[0141] Component C: butyl acetate 15kg, cyclohexanone 6kg, propylene glycol ether acetate 6kg, ethyl acetate 3kg;

[0142] The weight ratio of component A, component B and component C is 100:100:30.

[0143] The preparation method comprises the following steps:

[0144] (1) Preparation of component A:

[0145] 1) Put ACR6606, 3755-X-80, N-210, butyl acetate and EFKA-4010 in the above ratio into the reactor, and stir at 800r / min for 20min to obtain the resin mixture;

[0146] 2) Slowly add titanium dioxide, ultra-fine barium sulfate, and DeuRheo229 into the reactor...

Embodiment 3

[0154] Prepare high-gloss anti-foaming white wood paint according to the following ratio:

[0155] A component: ACR6606 35kg, 3755-X-80 20kg, N-210 6kg, titanium dioxide 18kg, superfine barium sulfate 8kg, butyl acetate 10kg, DeuRheo2291kg, Defom5300 0.5kg, EFKA-E4061 0.2kg, BYK-306 0.1 kg, TINUVIN-328 0.5kg;

[0156] B component: BAYER N-75 15kg, Desmodur HL 50kg, butyl acetate 30kg;

[0157] Component C: 27.5kg butyl acetate, 7.5kg cyclohexanone, 12.5kg propylene glycol methyl ether propionate, 2.5kg ethyl acetate;

[0158] The weight ratio of component A, component B and component C is 100:85:40.

[0159] The preparation method comprises the following steps:

[0160] (1) Preparation of component A:

[0161] 1) Put ACR6606, 3755-X-80, N-210, butyl acetate and EFKA-E4061 in the above ratio into the reactor, and stir at a speed of 700r / min for 25min to obtain a resin mixture;

[0162] 2) Slowly add titanium dioxide, ultra-fine barium sulfate, and DeuRheo229 into the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com