Straw component separation and straw component full utilization method

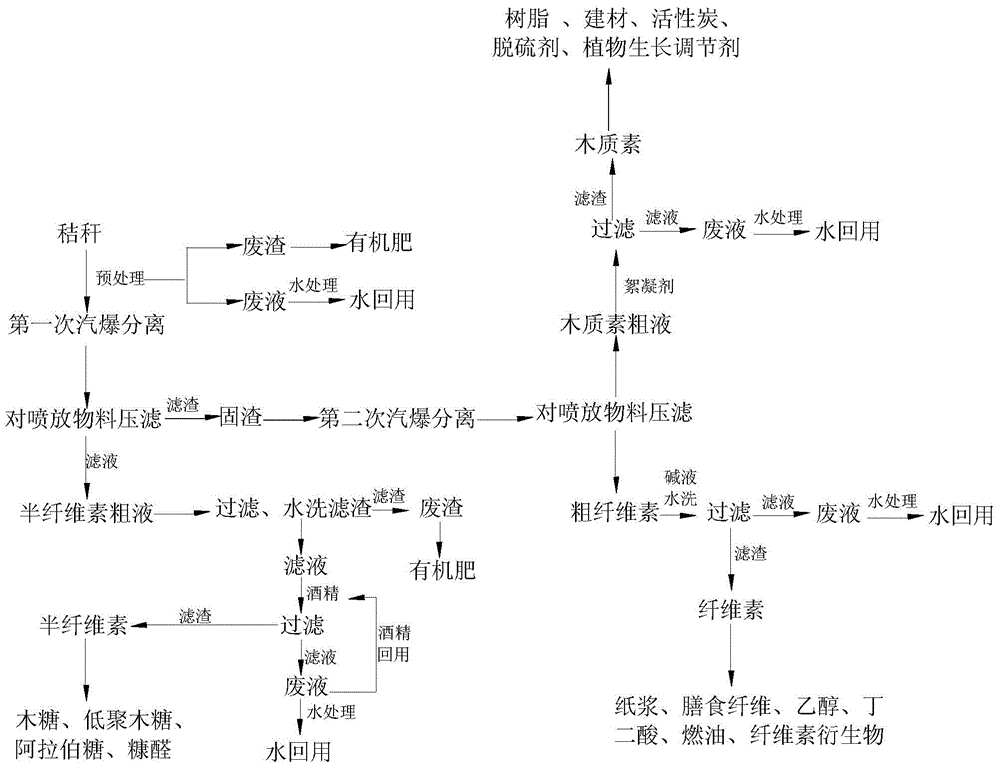

A technology for separation of straw and steam explosion, applied in the direction of raw material separation, etc., can solve the problems of complex separation process, high energy consumption, low yield of extract, etc., and achieve the effect of comprehensive utilization, thorough separation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for separating straw components and fully utilizing straw components comprises the following steps:

[0039] 1) Straw pretreatment

[0040] Weigh 500kg of rice stalks, and then cut, dedust and wash the stalks;

[0041] 2) Extraction of hemicellulose

[0042] Put the straw pretreated in step 1) into the steam explosion separator, add 60kg of sodium hydroxide solution with a mass fraction of 3% to the steam explosion separator, close the steam explosion separator and feed steam, and conduct The first steam explosion; the conditions for the first steam explosion are: temperature 120°C, pressure 1.2MPa, time 40min; after the first steam explosion is completed, press filter the sprayed material, and the clear liquid obtained after the press filter is Hemicellulose crude liquid, collect solid residue;

[0043] 3) Extraction of cellulose and lignin

[0044] Put the solid slag obtained in step 2) in a steam explosion separator, add 60kg of sodium hydroxide soluti...

Embodiment 2

[0053] The method for separating straw components and fully utilizing straw components comprises the following steps:

[0054] 1) Straw pretreatment

[0055] Weigh 500kg of wheat straw, cut, dust and wash the straw respectively;

[0056] 2) Extraction of hemicellulose

[0057] Put the straw pretreated in step 1) into the steam explosion separator, add 80kg of sodium hydroxide solution with a mass fraction of 5% to the steam explosion separator, close the steam explosion separator and feed steam, and conduct The first steam explosion; the conditions for the first steam explosion are: temperature 200°C, pressure 1.8MPa, time 40min; after the first steam explosion is completed, press filter the sprayed material, and the clear liquid obtained after the press filter is Hemicellulose crude liquid, collect solid residue;

[0058] 3) Extraction of cellulose and lignin

[0059] Place the solid slag obtained in step 2) in a steam explosion separator, add 90kg of sodium hydroxide sol...

Embodiment 3

[0068] The method for separating straw components and fully utilizing straw components comprises the following steps:

[0069] 1) Straw pretreatment

[0070] Weigh 500kg corn stalks, cut, dust and wash the stalks respectively;

[0071] 2) Extraction of hemicellulose

[0072] Put the straw pretreated in step 1) into the steam explosion separator, add 50kg of sodium hydroxide solution with a mass fraction of 10% to the steam explosion separator, close the steam explosion separator and feed steam, and conduct The first steam explosion; the conditions for the first steam explosion are: temperature 200°C, pressure 2.0MPa, time 20min; after the first steam explosion is completed, press filter the sprayed material, and the clear liquid obtained after the press filter is Hemicellulose crude liquid, collect solid residue;

[0073] 3) Extraction of cellulose and lignin

[0074] Put the solid slag obtained in step 2) in a steam explosion separator, add 50kg of sodium hydroxide soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com