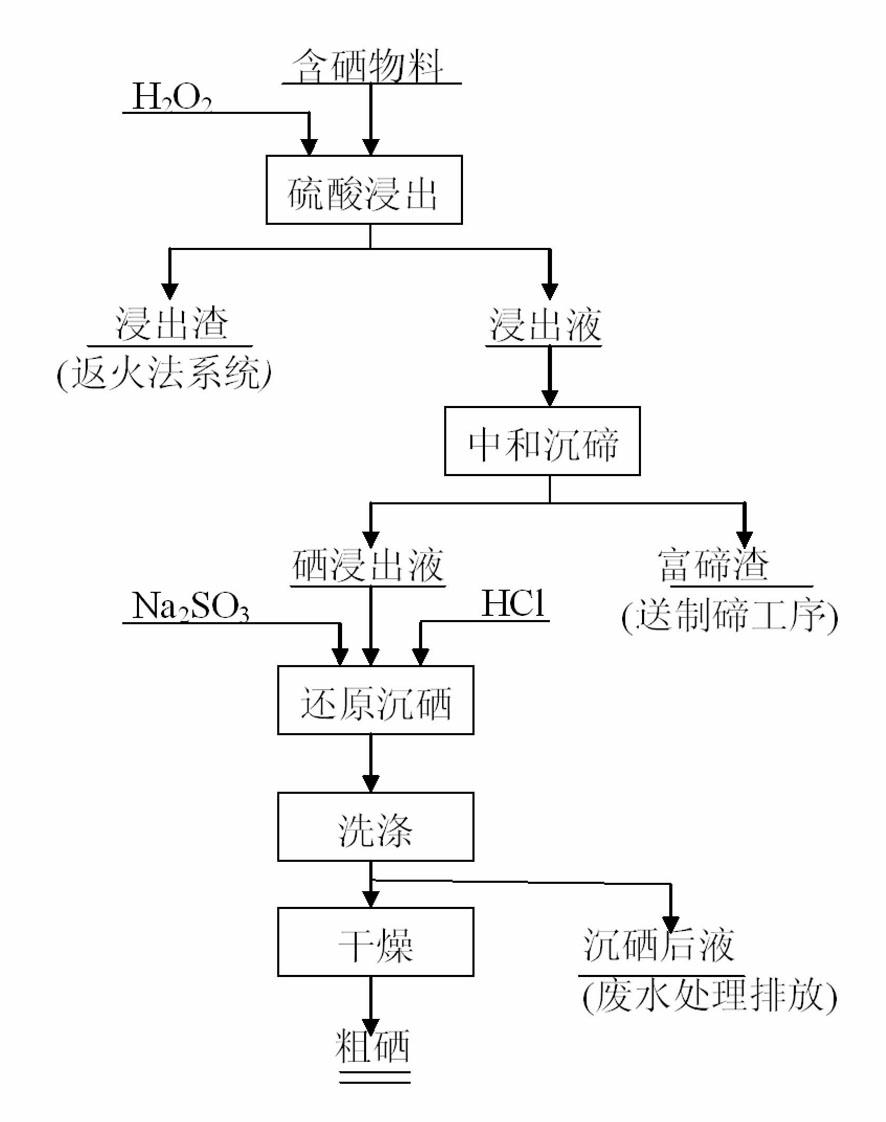

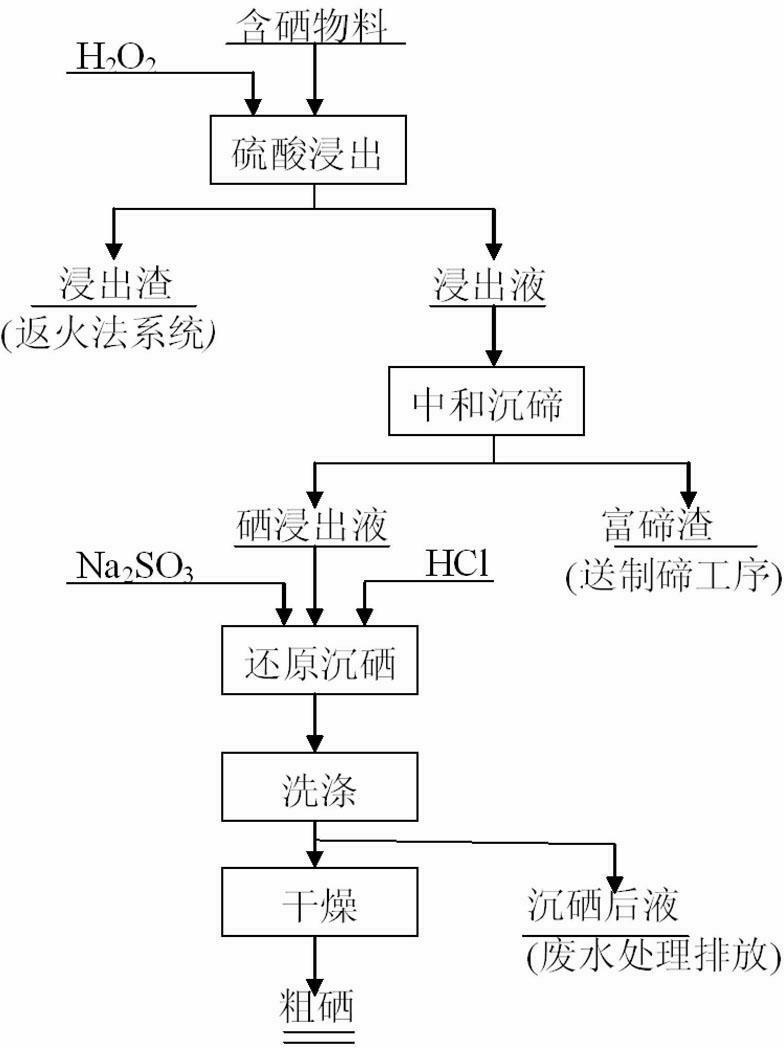

Process for separating and recovering selenium from selenium-containing material

A technology for recycling selenium and materials, applied in the direction of element selenium/tellurium, can solve the problems of low comprehensive utilization rate, long process flow, complicated process, etc., and achieve the effect of shortening production cycle, shortening process flow, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A process for separating and reclaiming selenium from selenium-containing materials, the implementation steps are as follows:

[0029] ① Oxidative leaching of selenium: Take 100g of dried selenium-containing material, and the selenium content in the analysis residue is 21.54%; lead 45.52%; tellurium 0.28%; silver 0.2%; Add 200% of the theoretical amount and 10% H by mass percentage 2 o 2 ; The concentration of sulfuric acid is controlled to 3mol / L, the liquid-solid ratio is 4:1, stirring at a constant speed, the reaction temperature is 85°C, and the oxidation time is 3 hours; solid-liquid separation, leaching slag containing 58.83% lead is sent to the pyrometallurgy system with known technology Extract silver, lead and copper; the recovery rate of lead can reach 98.12%; the concentration of selenium in the separated leachate can reach 43.28g / L;

[0030] ②Separation of selenium and tellurium: add sodium hydroxide with a mass percentage concentration of 10% to the leach...

Embodiment 2

[0035] A process for separating and reclaiming selenium from selenium-containing materials, the implementation steps are as follows:

[0036] ① Oxidative leaching of selenium: Take 100g of dried selenium-containing material, and the selenium content in the analysis residue is 18.22%; lead 48.66%; tellurium 0.31%; silver 0.32%; Add 150% of the theoretical amount, 10% H in mass percent concentration 2 o 2 ; Control the concentration of sulfuric acid to 2.5mol / L, liquid-solid ratio 3:1, constant speed stirring, reaction temperature is 65 ℃, oxidation time 1 hour; Technology to extract silver, lead and copper; the recovery rate of lead can reach 97.23%; the concentration of selenium in the separated leachate can reach 40.05g / L;

[0037] ②Separation of selenium and tellurium: add sodium hydroxide with a mass percentage concentration of 10% to the leaching solution separated in step ① to adjust the pH to 5.5, so that tellurium forms a tellurite precipitate, and the sulfur remainin...

Embodiment 3

[0042] A process for separating and reclaiming selenium from selenium-containing materials, the implementation steps are as follows:

[0043] ① Oxidative leaching of selenium: Take 100g of dried selenium-containing material, and the selenium content in the analysis residue is 28.774%; lead 40.13%; tellurium 0.25%; silver 0.14%; Add 180% of the theoretical amount, 10% H by mass percentage 2 o 2 ; The concentration of sulfuric acid is controlled to 3.5mol / L, the liquid-solid ratio is 6:1, the constant speed is stirred, the reaction temperature is 95°C, and the oxidation time is 2 hours; solid-liquid separation, the leaching slag containing 55.64% of lead is sent to the pyrometallurgy system with known Technology to extract silver, lead and copper; the recovery rate of lead can reach 97.85%; the concentration of selenium in the separated leachate can reach 45.92g / L;

[0044] ②Separation of selenium and tellurium: Add sodium hydroxide with a mass percentage concentration of 10% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com