Multifunctional textile finishing agent, preparation method thereof and cotton textile finishing method

A fabric finishing agent and multi-functional technology, applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of poor fixation effect, insufficient anti-wrinkle durability, etc., and achieve convenient processing, good anti-wrinkle effect and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0040] The preparation steps of ecological multifunctional fabric finishing agent are as follows:

[0041] (1) Boil silk into 0.5% Na by weight 2 CO 3 Degumming in the solution for 3 times, 30 minutes each time, rinsing with hot water for 3 times, then drying at 55°C and cutting into pieces, the amount of silk used is 0.5% Na 2 CO 3 1.5% of the solution.

[0042] (2) According to the molar ratio, anhydrous calcium chloride: ethanol: water = 1:2:8 to make a ternary solution, and dissolve the silk fiber obtained in step (1) in the above ternary solution at 75°C After 180 minutes, filter the fibroin solution, put it into a dialysis bag, place it in clean water for dialysis, change the water every 2 hours, and concentrate it after 3 days of dialysis to obtain a silk fibroin solution. The amount of the above ternary solution is 15 times the dosage.

[0043] (3) Add 3.0mol / L hydrochloric acid solution to the silk fibroin solution in step (2), hydrolyze at 60°C for 150 minutes, ...

Embodiment example 2

[0047] The preparation steps of ecological multifunctional fabric finishing agent are as follows:

[0048] (1) Boil silk into 0.5% Na by weight 2 CO 3 Degumming in the solution 3 times, 30 minutes each time, rinsing 3 times with hot water, then drying and cutting at 65 °C, the amount of silk is 0.5% Na 2 CO 3 3% of the solution.

[0049](2) According to the molar ratio, anhydrous calcium chloride: ethanol: water = 1:2:8 to make a ternary solution, and dissolve the silk fiber obtained in step (1) in the above ternary solution at 75°C After 120 minutes, filter the silk fibroin solution, put it into a dialysis bag, place it in clean water for dialysis, change the water every 3 hours, and get the silk fibroin solution after 3 days of dialysis. The amount of the above ternary solution is the amount of silk 20 times.

[0050] (3) Add 3.0mol / L hydrochloric acid solution to the silk fibroin solution in step (2), hydrolyze at 70°C for 120 minutes, titrate to neutral with 3mol / L so...

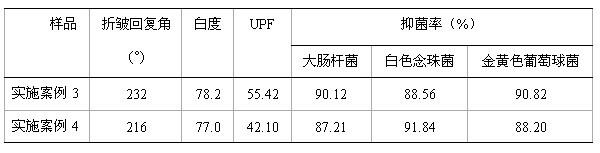

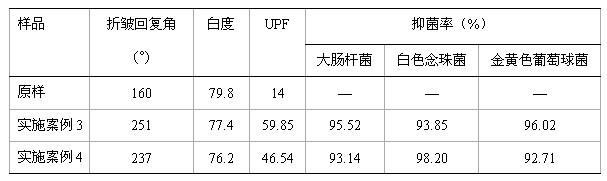

Embodiment example 3

[0054] The steps of finishing the cotton fabric with the ecological multifunctional fabric finishing agent containing silk fibroin and chitosan are as follows:

[0055] (1) plain weave cotton fabric (150g / m 2 ) soaked in a sodium hydroxide solution with a concentration of 21% by mass, soaked at room temperature for 30 minutes, took it out, washed with water until neutral, and wrung out to obtain an alkali-treated cotton fabric. The consumption of sodium hydroxide solution is 40 times of cotton fabric weight.

[0056] (2) The alkali-treated cotton fabric obtained in step (1) was dipped twice and rolled twice in the ecological multifunctional fabric finishing agent of Example 1. The ecological multi-functional fabric finishing agent is 30 times the weight of cotton fabric, the soaking time is 40 minutes, and the squeeze rate is 85%.

[0057] (3) The cotton fabric obtained by padding in step (2) was pre-baked at 80°C for 60 minutes, and then baked at 130°C for 3 minutes to comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com