Integrated treatment method for malodorous VOCs gas of refining devices

A gas and refining technology, which is applied in the field of integrated treatment of malodorous VOCs gas in refining and chemical equipment, can solve the problems of ineffective treatment of VOCs odorous gas, catalyst deactivation in catalytic oxidation process, and inability to effectively remove organic components, etc., to achieve Low equipment investment and operating costs, reduced operating costs, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

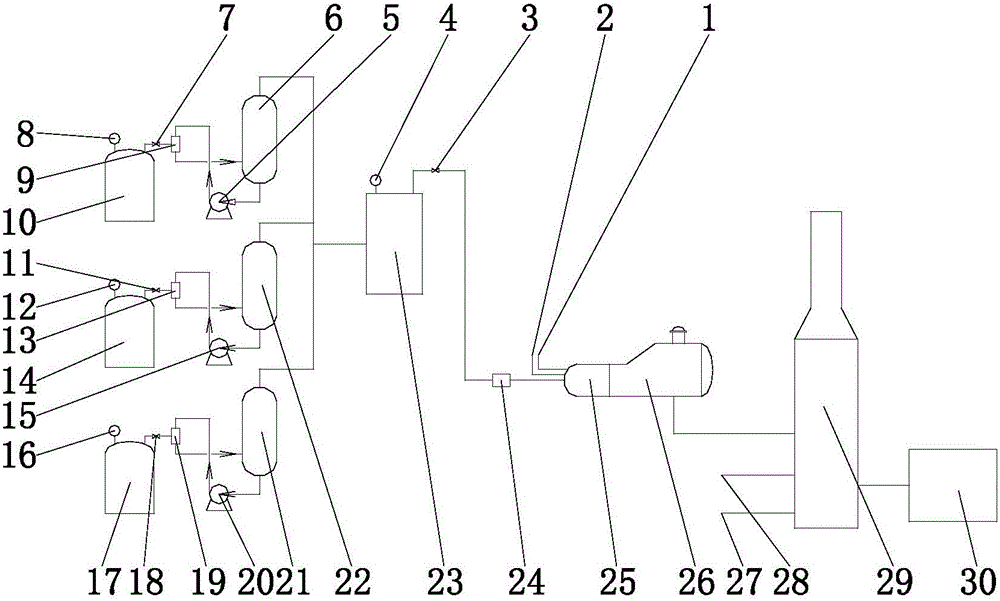

[0028] The acid water tank, intermediate product tank and residual oil tank of a refining unit shall be figure 1 Process construction VOCs treatment system, the volume of the three storage tanks is 5000m 3 , and the pressure is controlled to 15kPag. Acid water tank discharge 150Nm 3 / h malodorous gas, where H 2 S concentration is 42100mg / Nm 3 , the total non-methane hydrocarbon concentration is 41300mg / Nm 3 (calculated as methane); 200Nm of malodorous gas discharged from the residue oil tank 3 / h, where H 2 S concentration is 2000mg / Nm 3 , the total non-methane hydrocarbon concentration is 38000mgN / m 3 ;The odorous gas discharged from the intermediate product tank is 200Nm 3 / h, where H 2 S concentration is 1270mg / Nm 3 , the total non-methane hydrocarbon concentration is 41600mg / Nm 3 (as methane). After passing through the gas-liquid separation device, the above-mentioned gas is passed into the gas storage buffer tank, and the pressure in the tank is controlled to ...

Embodiment 2

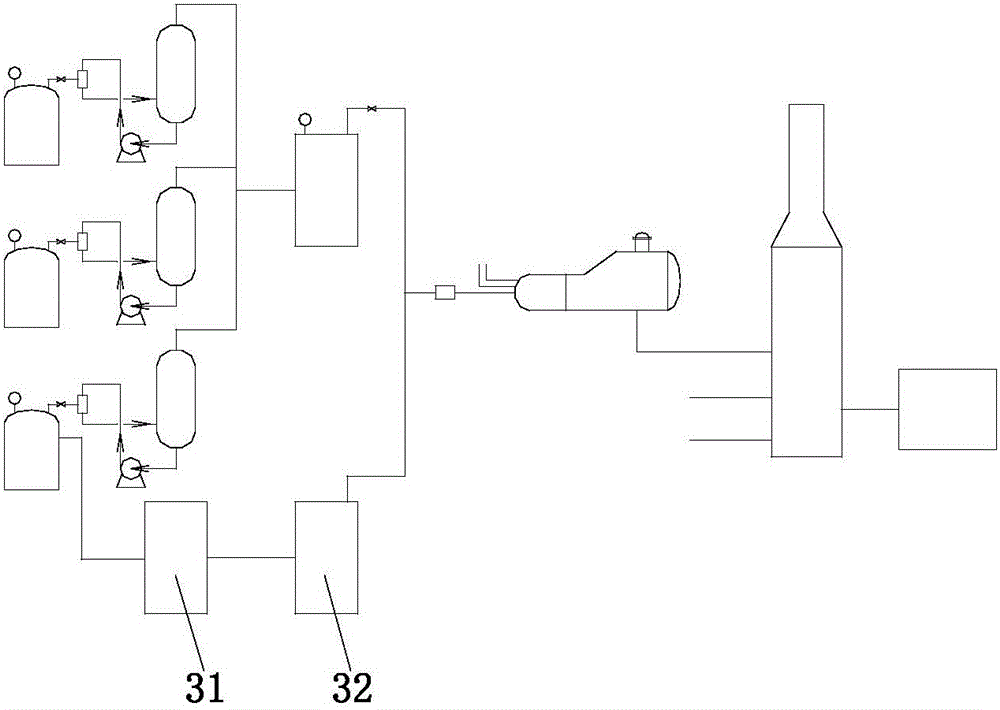

[0030] There are acid water stripping devices, sulfur recovery devices, incineration and waste heat recovery systems and ammonia desulfurization systems in the refinery. figure 2 The shown process builds a VOCs treatment system. The volume of the acid water tank is 4600m 3 , the volume of the intermediate product tank and the residual oil tank is 4800m 3 , the pressure of the three storage tanks are controlled to 14kPa. Acid water tank discharge 120Nm 3 / h malodorous gas, where H 2 S concentration is 31200mg / Nm 3 , the total non-methane hydrocarbon concentration is 28000mg / Nm 3 (calculated as methane); 100Nm of malodorous gas discharged from the residue tank 3 / h, where H 2 S concentration is 800mg / Nm 3 , the total non-methane hydrocarbon concentration is 25000mg / Nm 3 (in terms of methane); 165Nm of malodorous gas discharged from the intermediate product tank 3 / h, where H 2 S concentration is 650mg / Nm 3 , the total non-methane hydrocarbon concentration is 22600mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com