Method of preparing synthetic natural gas by coke oven gas

A technology for synthesizing natural gas and coke oven gas, which can be used in gas fuel, petroleum industry, fuel and other directions, and can solve the problems of low calorific value and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

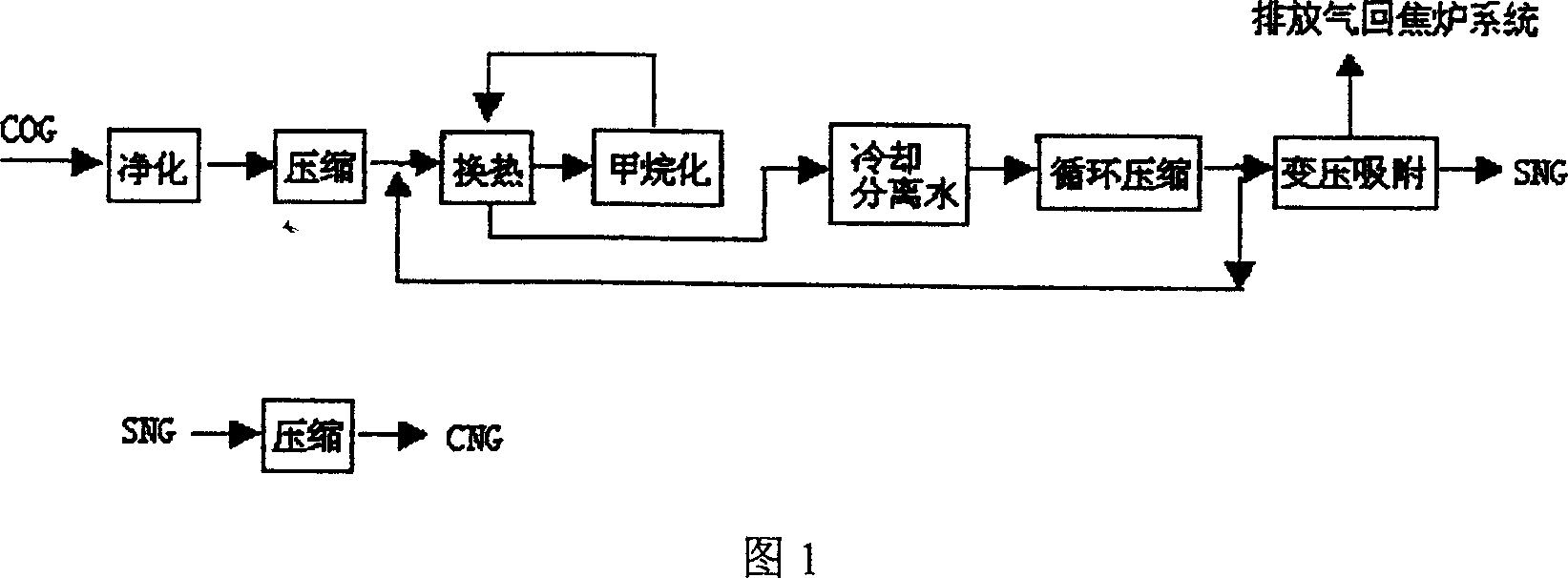

[0026] In this embodiment, the method for preparing synthetic natural gas by using coke oven gas is as follows, and the flow diagram is shown in Figure 1:

[0027] First, the coke oven gas is purified to remove benzene, naphthalene, heavy hydrocarbons, and sulfides, and the composition (vol%) of the purified coke oven gas is: H 2 58.6, CH 4 26,N 2 4, O 2 0.4, CO 7, CO 2 2,C m h n 2; the purified coke oven gas is treated with SiO 2 Under the action of the Ni catalyst system as the carrier, the methanation reaction is carried out to generate methane, and a mixed gas mainly composed of methane is obtained. The pressure of the methanation reaction is about 1.0MPa, and the temperature at the reactor inlet is about 250°C; part of the mixed gas is returned to To the feed gas before the methanation reaction to dilute CO and CO 2 concentration, the circulation ratio is about 1:1, and the raw material gas composition (vol%) after dilution is: H 2 50.4, CH 4 37.64,N 2 ...

Embodiment 2

[0032] In this embodiment, the method for preparing synthetic natural gas by using coke oven gas is as follows, and the flow diagram is shown in Figure 1:

[0033] First, the coke oven gas is purified to remove benzene, naphthalene, heavy hydrocarbons, and sulfides, and the composition (vol%) of the purified coke oven gas is: H 2 58.6, CH 4 26,N 2 4, O 2 0.4, CO 7, CO 2 2,C m h n 2; the coke oven gas after this purification, in Al 2 o 3 Under the action of the Ni catalyst system as the carrier, the methanation reaction is carried out to generate methane, and a mixed gas mainly composed of methane is obtained. The pressure of the methanation reaction is about 1.0MPa, and the temperature at the reactor inlet is about 250°C; part of the mixed gas is returned to To the feed gas before the methanation reaction to dilute CO and CO 2 concentration, the circulation ratio is about 2:1, and the raw material gas composition (vol%) after dilution is: H 2 48.23, CH 4 40.8...

Embodiment 3

[0038] In this embodiment, the method for preparing synthetic natural gas by using coke oven gas is as follows, and the flow diagram is shown in Figure 1:

[0039] First, the coke oven gas is purified to remove benzene, naphthalene, heavy hydrocarbons, and sulfides, and the composition (vol%) of the purified coke oven gas is: H 2 58.6, CH 4 26,N 2 4, O 2 0.4, CO 7, CO 2 2,C m h n 2; the purified coke oven gas is treated with SiO 2 Under the action of the Ni catalyst system as the carrier, the methanation reaction is carried out to generate methane, and a mixed gas mainly composed of methane is obtained. The pressure of the methanation reaction is about 3.0MPa, and the temperature at the reactor inlet is about 250°C; part of the mixed gas is returned to To the feed gas before the methanation reaction to dilute CO and CO 2 concentration, the circulation ratio is about 2:1, and the raw material gas composition (vol%) after dilution is: H 2 48.23, CH 4 40.82,N 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com