Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1085results about "Hydrogen separation by diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

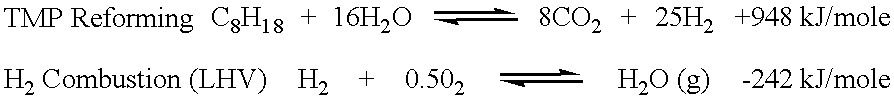

Method and system for supplying hydrogen for use in fuel cells

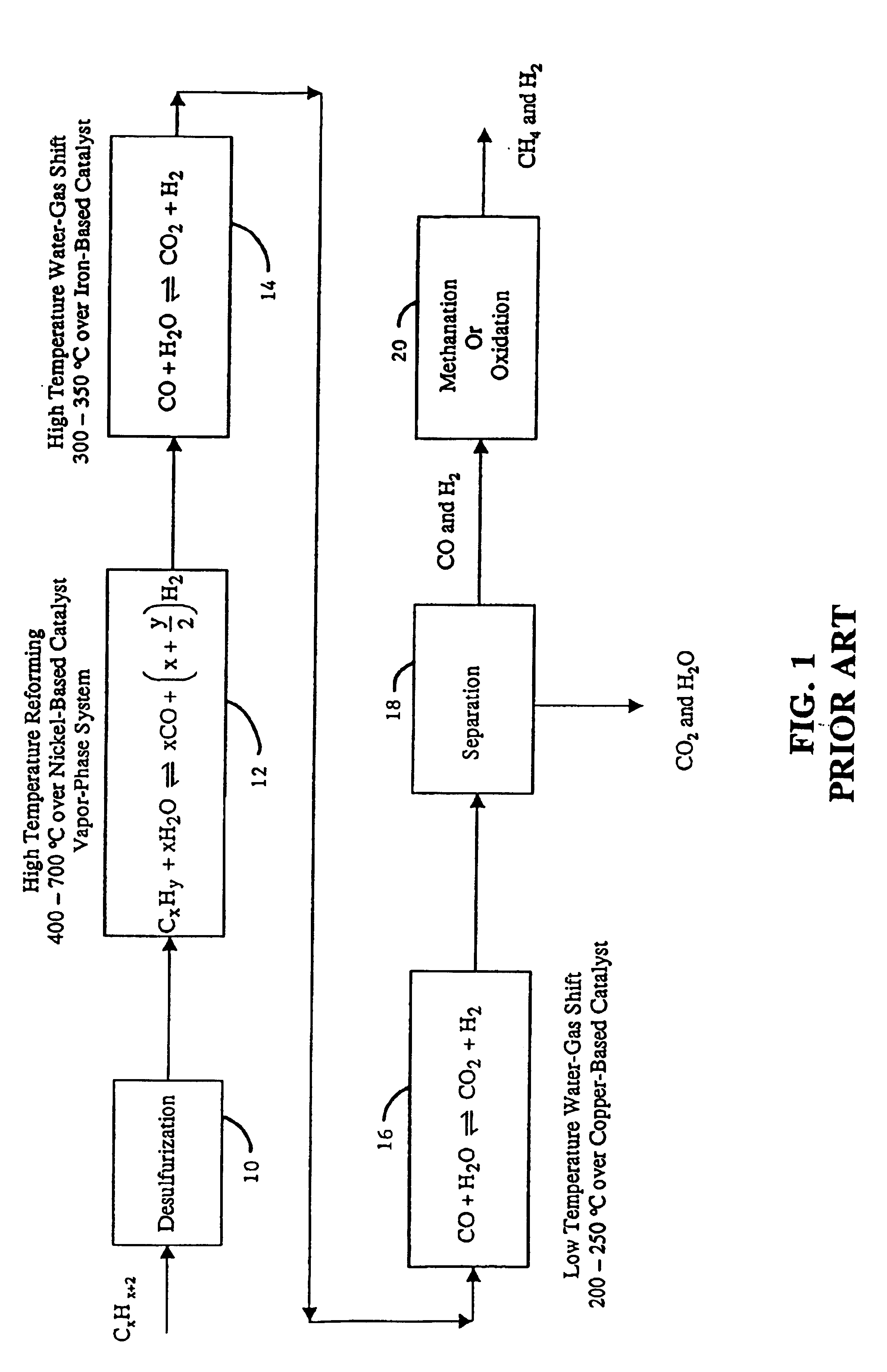

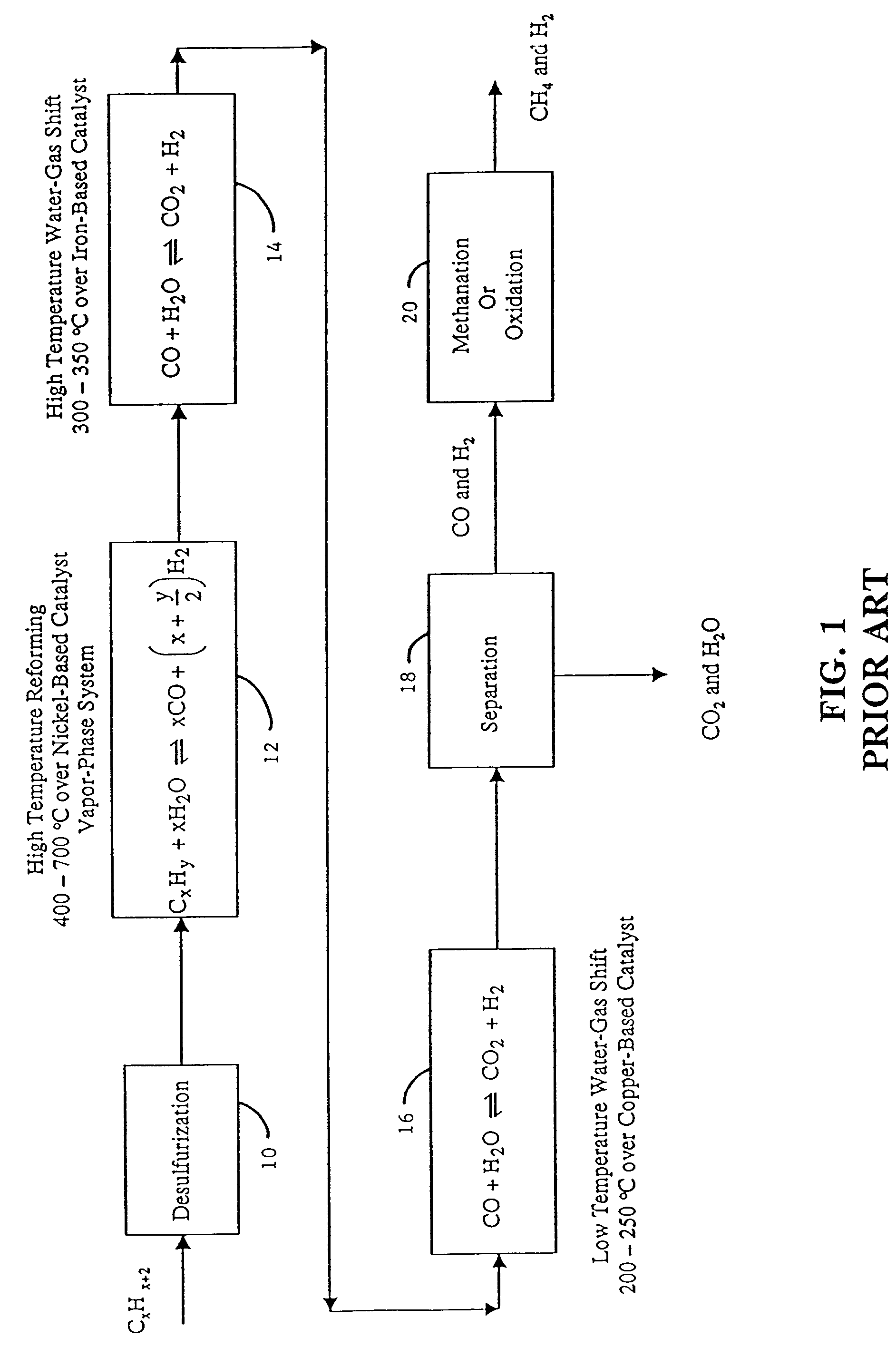

InactiveUS6348278B1Reduce hydrogen concentrationImprove concentrationElectricity cogenerationRegenerative fuel cellsHydrogenCombustor

The present invention provides a method and system for efficiently producing hydrogen that can be supplied to a fuel cell. The method and system of the present invention produces hydrogen in a reforming reactor using a hydrocarbon stream and water vapor stream as reactants. The hydrogen produced is purified in a hydrogen separating membrane to form a retentate stream and purified hydrogen stream. The purified hydrogen can then be fed to a fuel cell where electrical energy is produced and a fuel cell exhaust stream containing water vapor and oxygen depleted air is emitted. In one embodiment of the present invention, a means and method is provided for recycling a portion of the retentate stream to the reforming reactor for increased hydrogen yields. In another embodiment, a combustor is provided for combusting a second portion of the retentate stream to provide heat to the reforming reaction or other reactants. In a preferred embodiment, the combustion is carried out in the presence of at least a portion of the oxygen depleted air stream from the fuel cell. Thus, the system and method of the present invention advantageously uses products generated from the system to enhance the overall efficiency of the system.

Owner:MOBIL OIL CORP

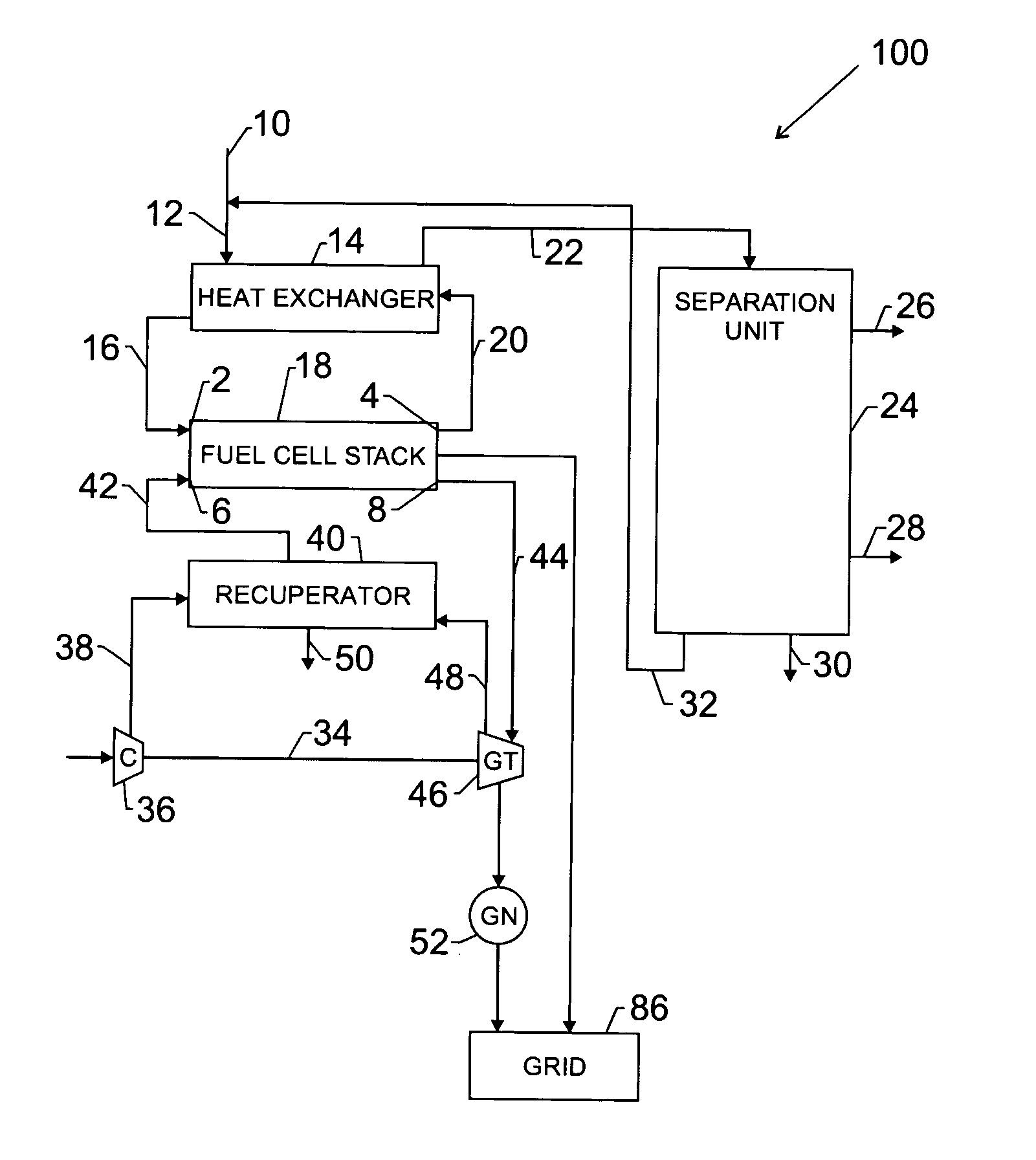

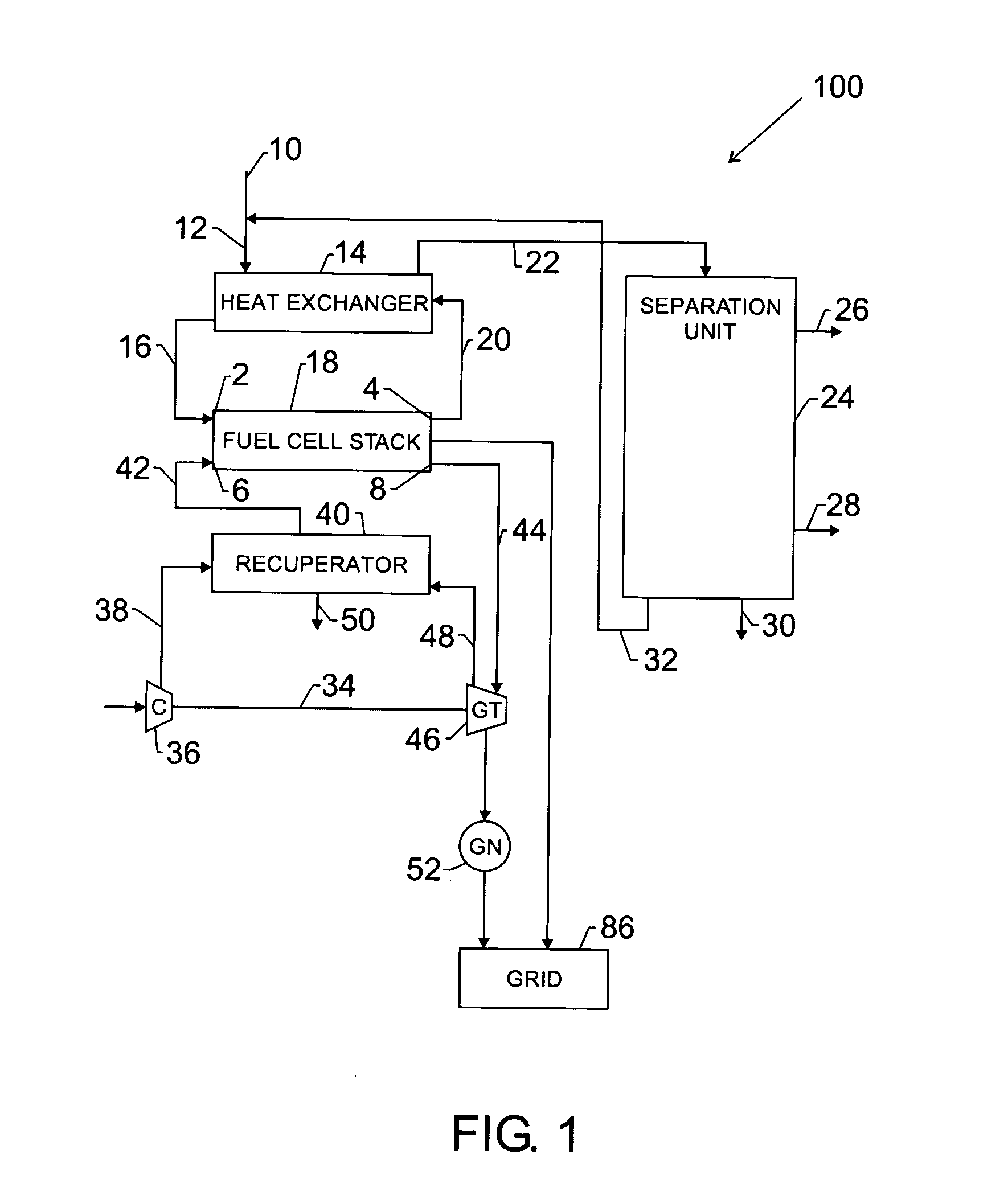

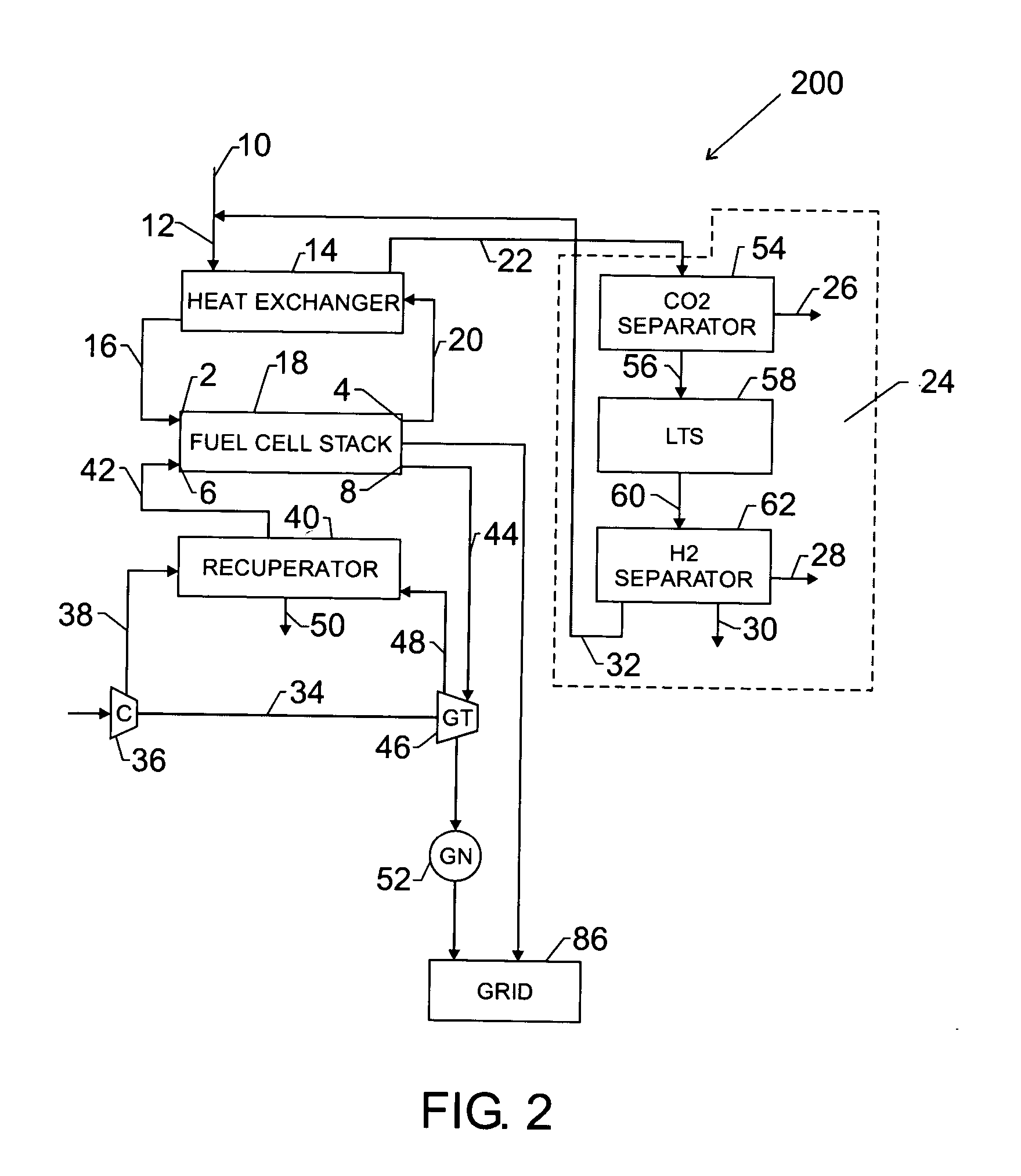

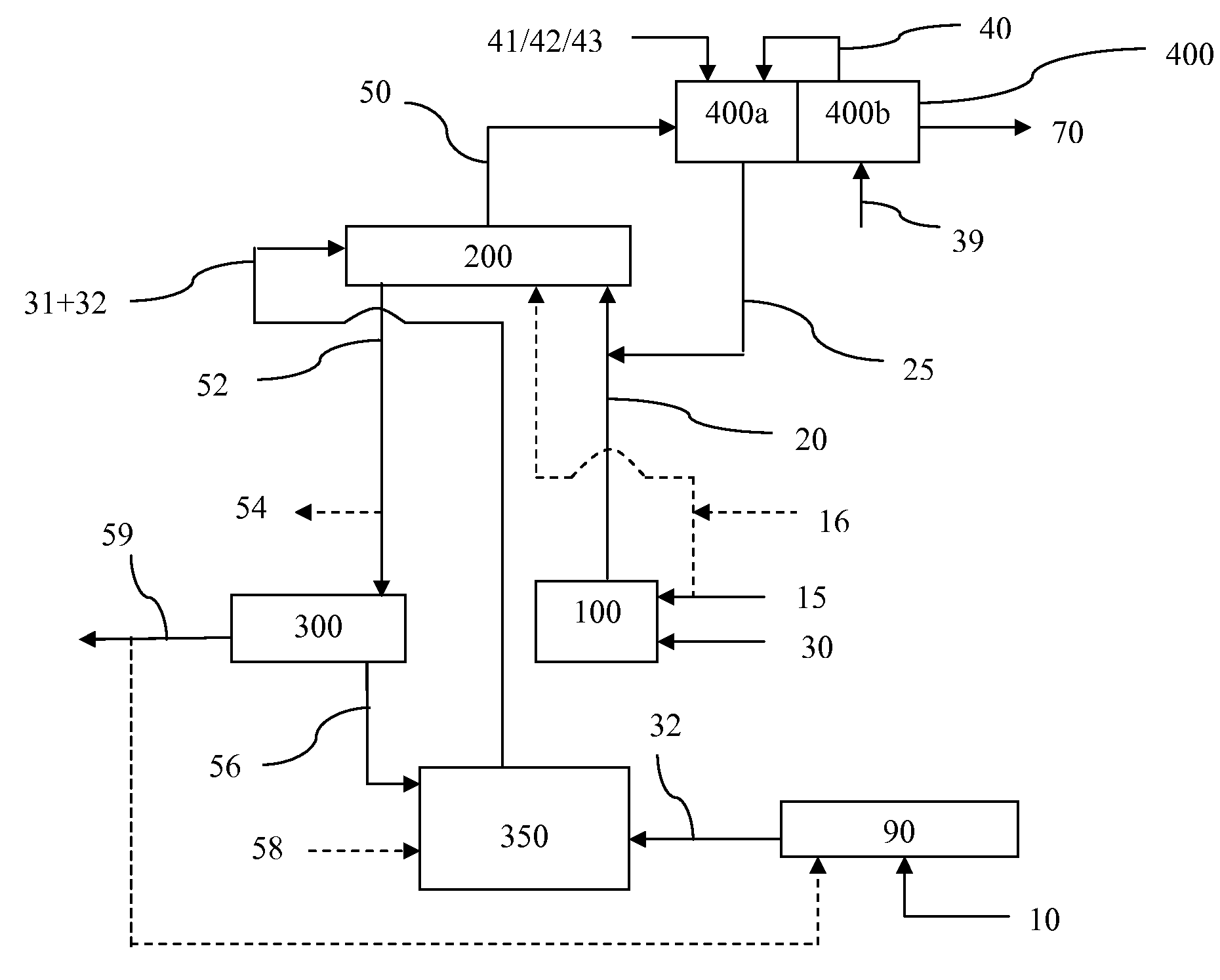

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

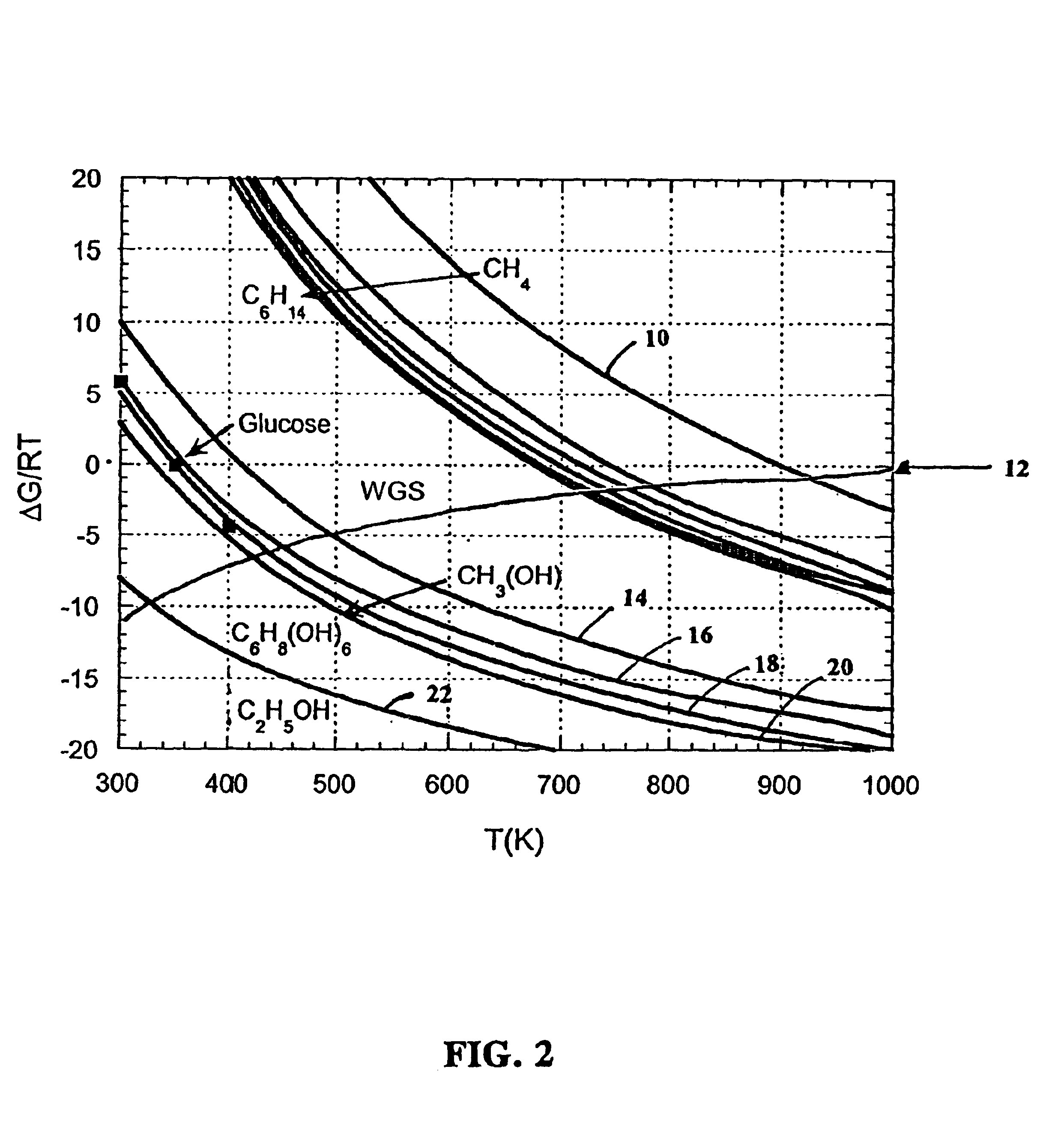

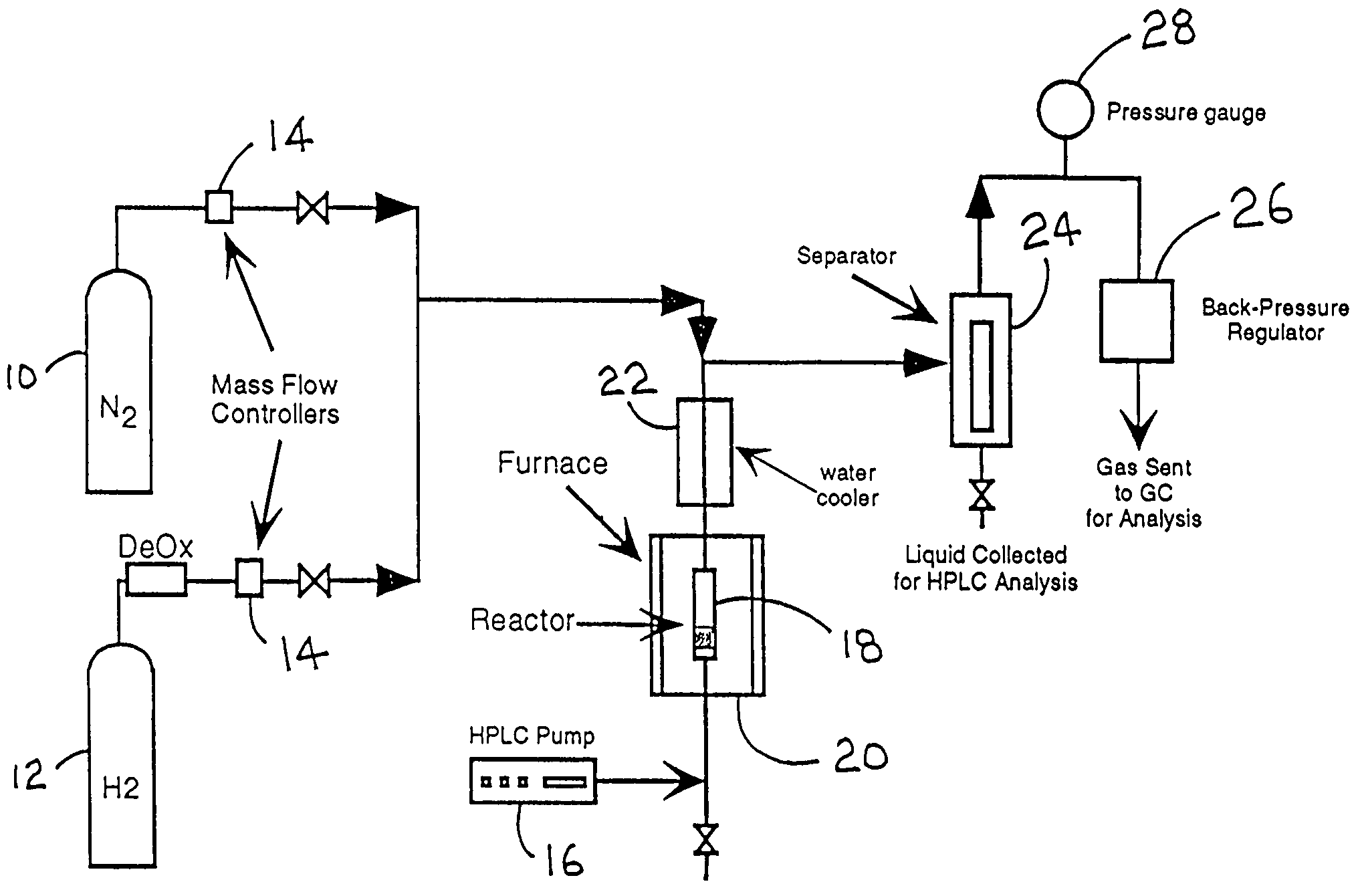

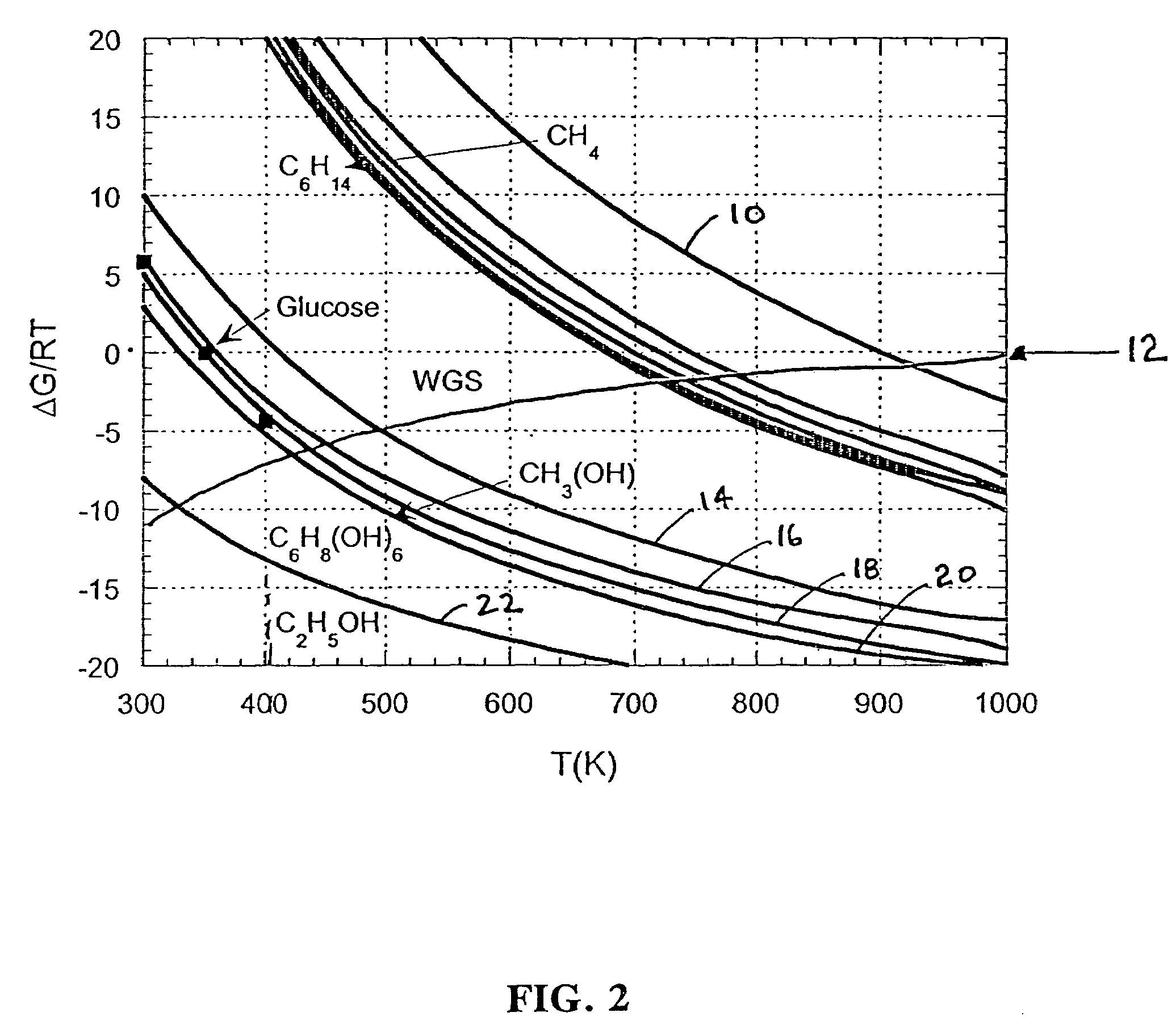

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

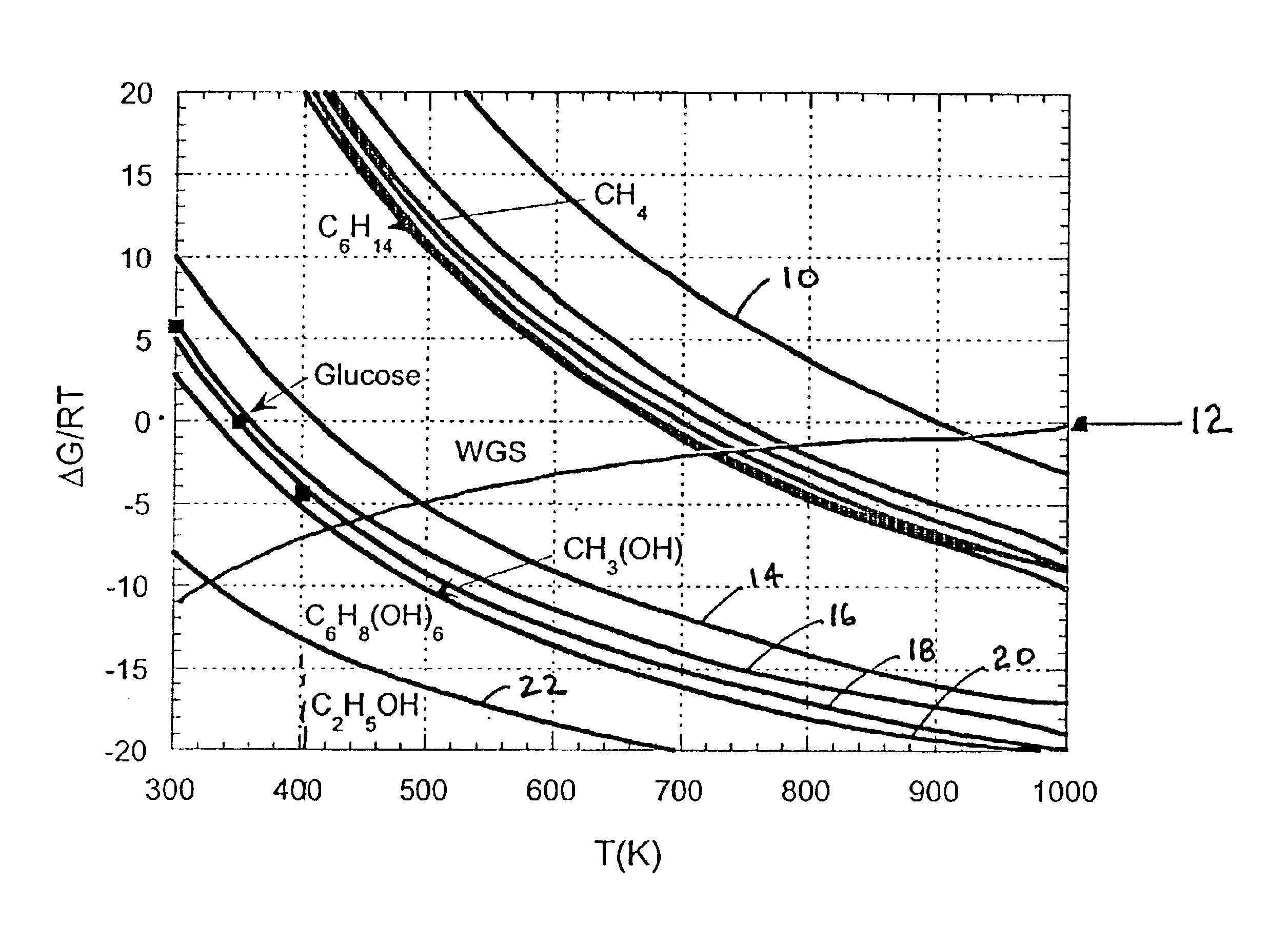

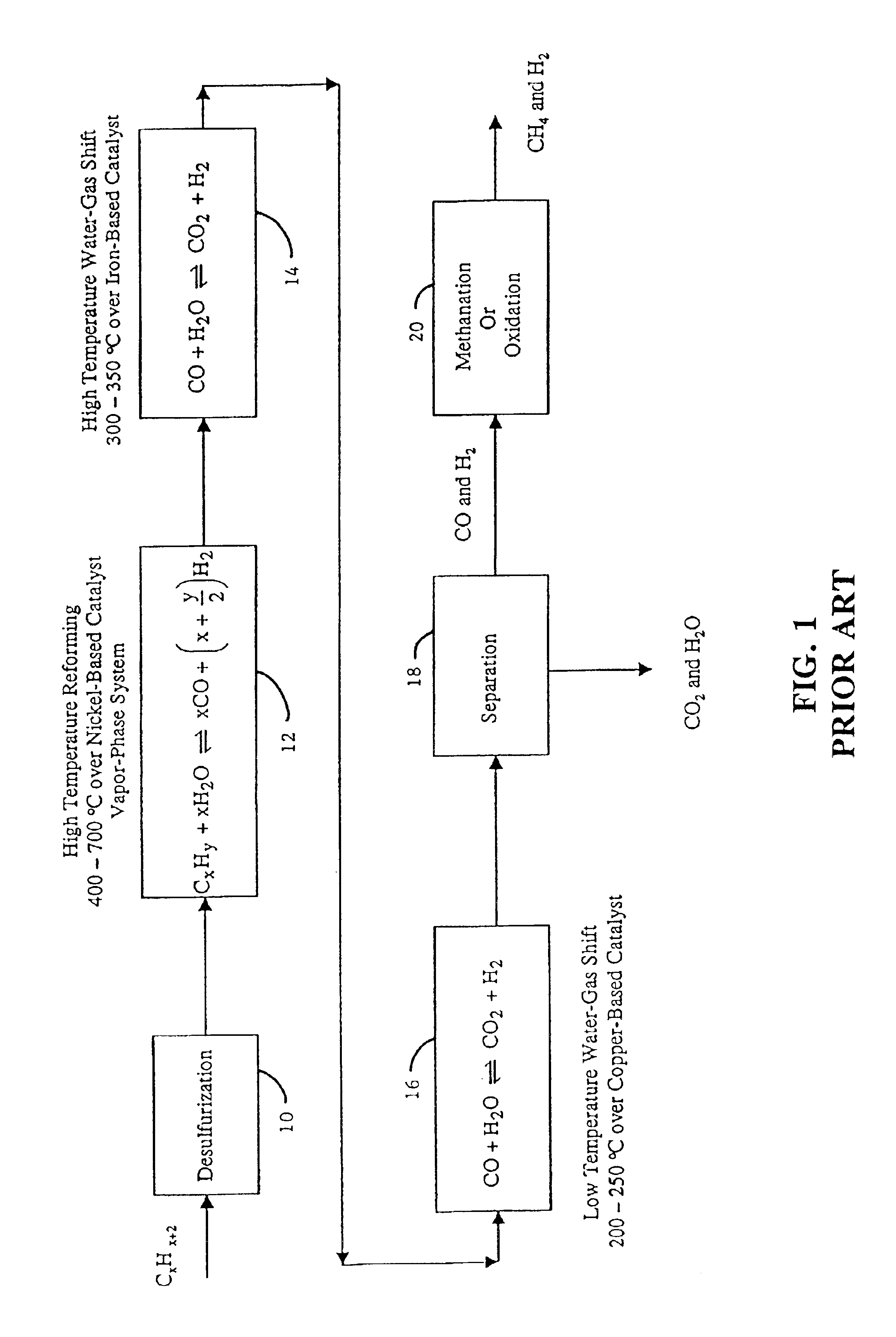

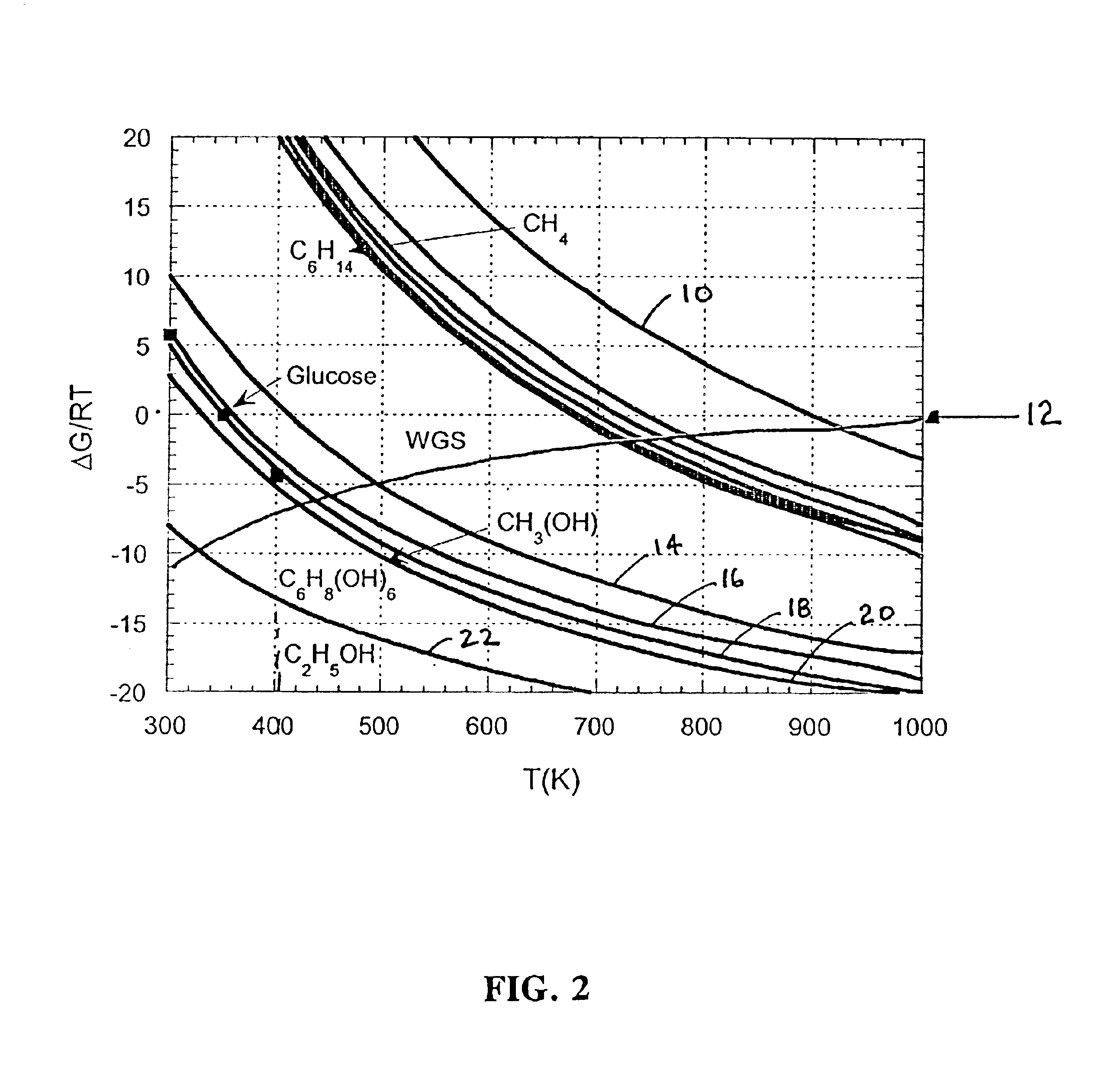

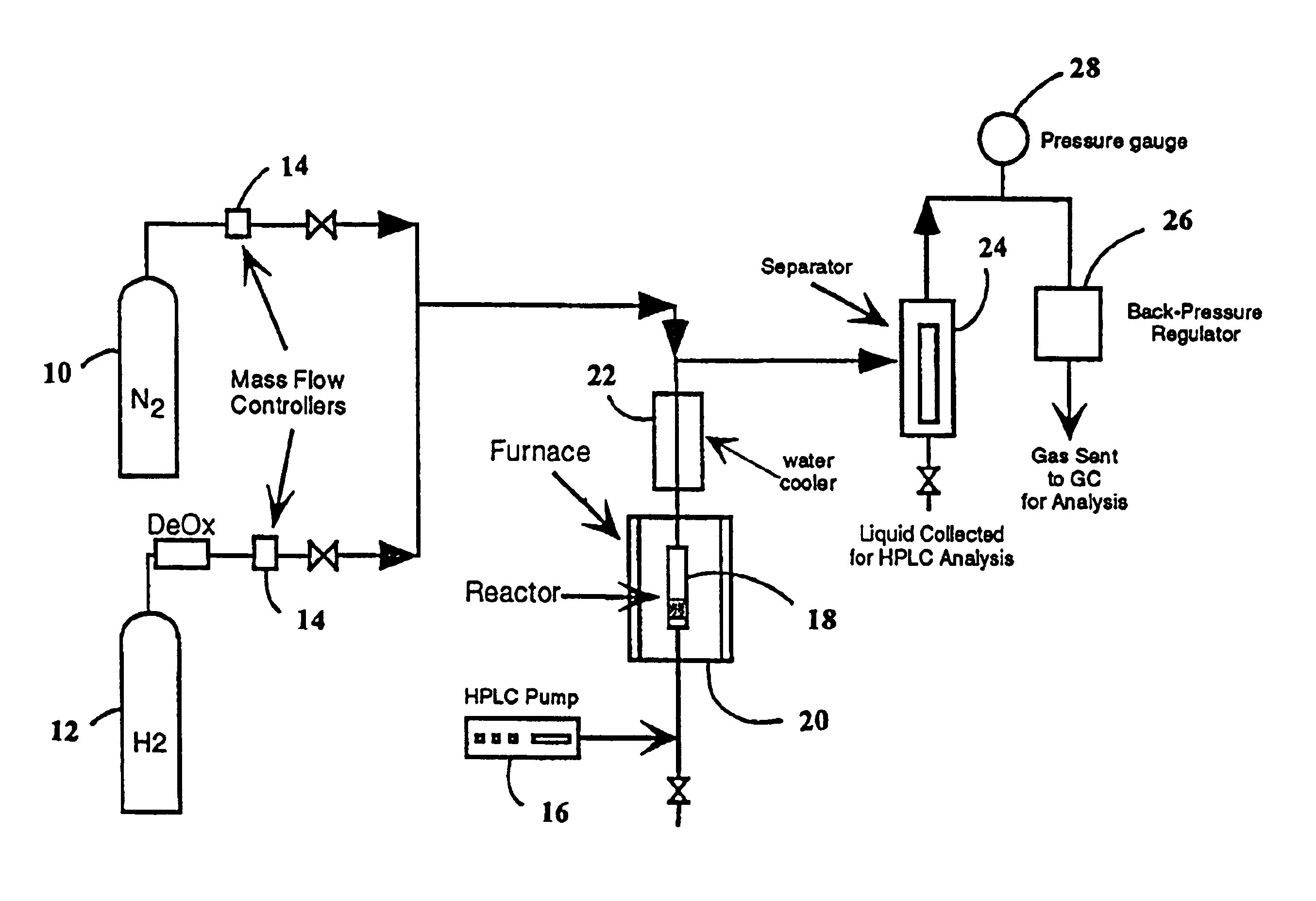

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964758B2High energy costWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIII transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

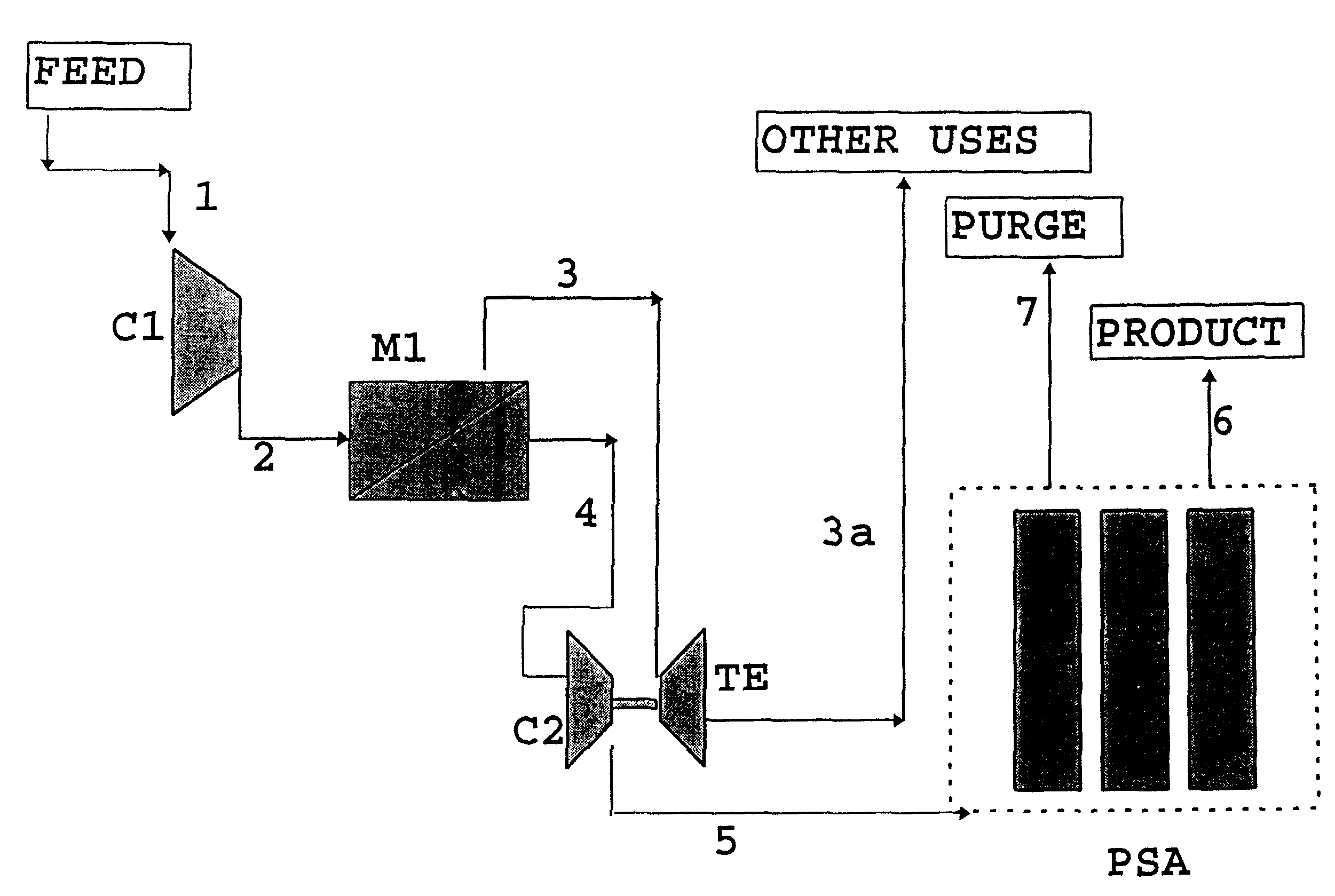

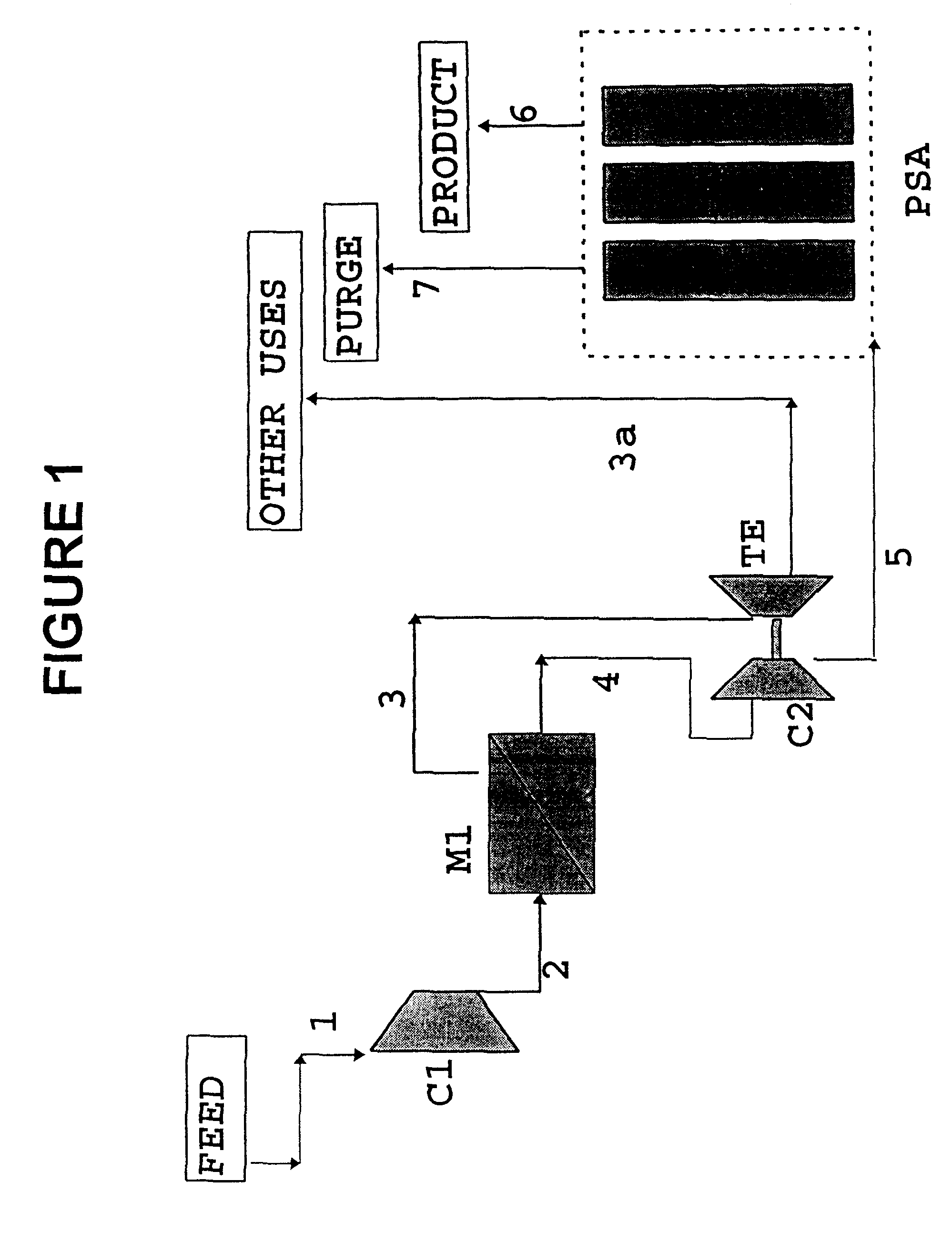

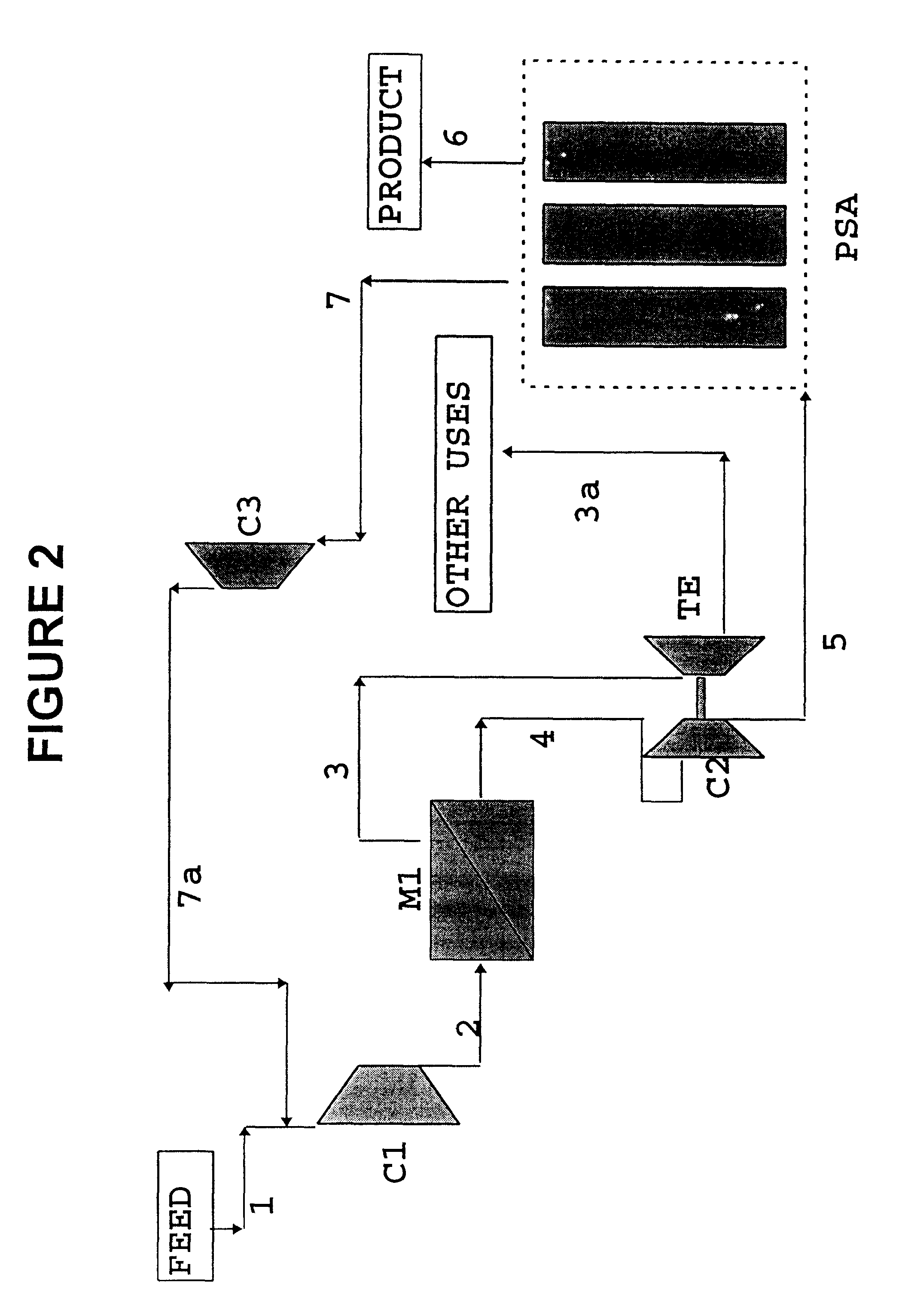

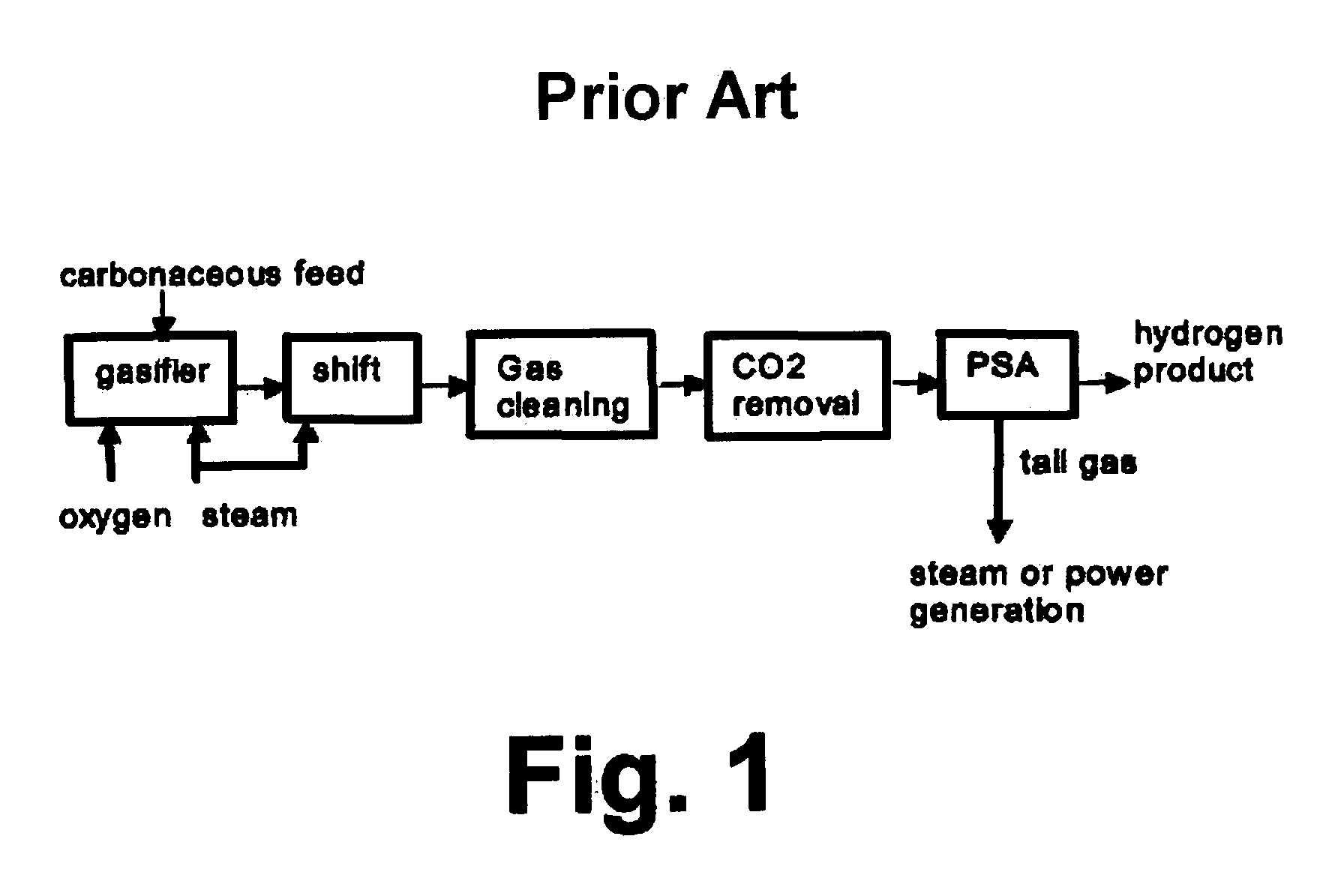

Process for the separation/recovery of gases

InactiveUS6179900B1Low costHigh purityNitrogen purification/separationGas treatmentHydrogenHigh pressure

A process for the separation / recovery of gases is described where the desired component to be separated from the gaseous mixture is present in low / very low molar amount and / or low / moderate pressure, the process comprising contacting the gaseous mixture with a separation membrane unit containing high permeability / medium selectivity membranes which separate the feed stream into a permeate stream, enriched in the desired component and at a lower pressure and a retentate stream lean in the desired component and at a higher pressure. The retentate stream is made to convey its pressure to the permeate stream which then is directed to an adsorption PSA unit for further purification of the permeate stream so that the effluent stream from the PSA unit which contains the purified component has a purity of up to 99.90%. The process is useful for separating hydrogen from refinery off gases such as FCC gases and can also be applied to other gases such as helium and any other valuable gases present in gaseous streams in low to very low molar contents and low to moderate pressures.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH +1

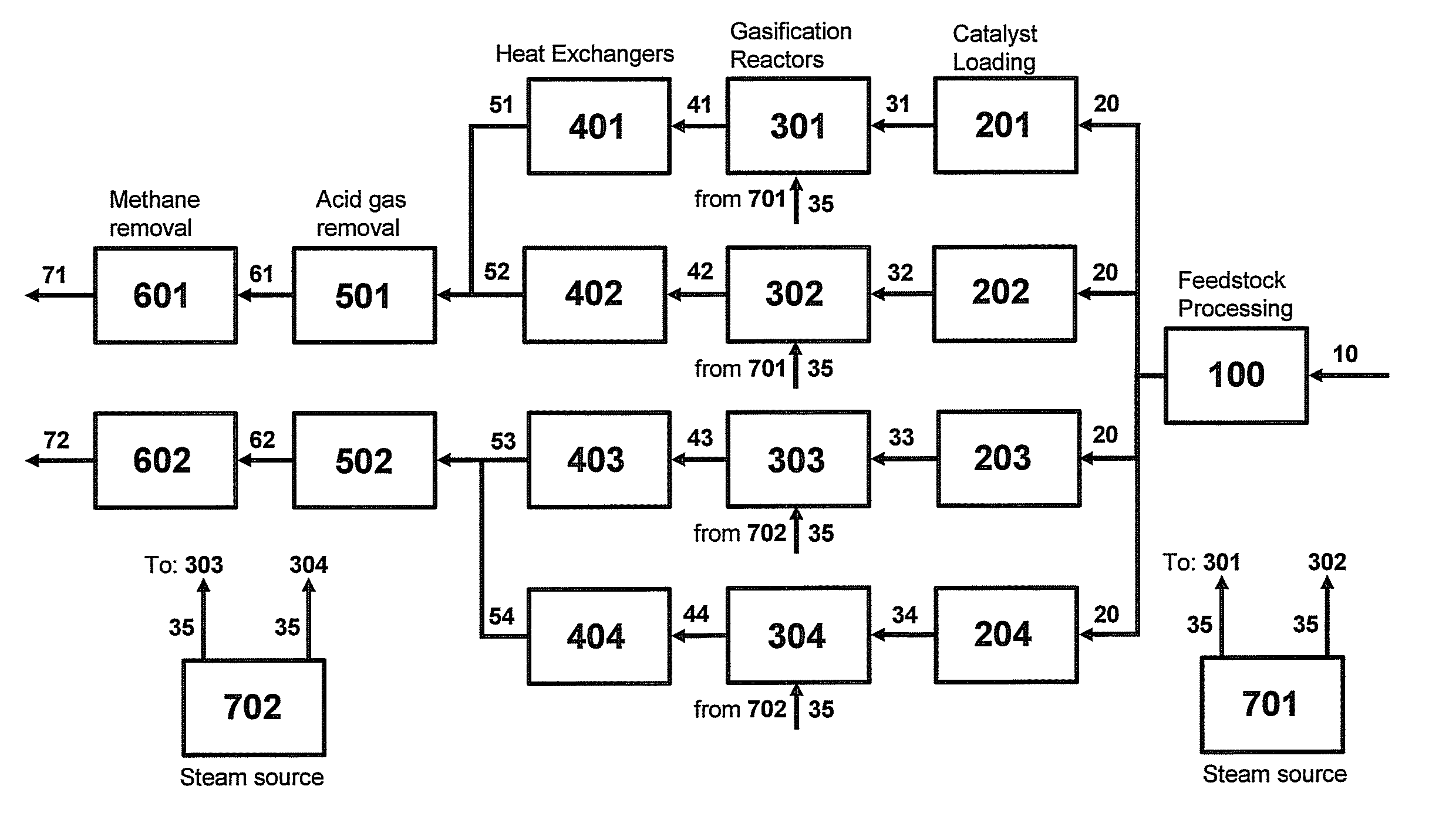

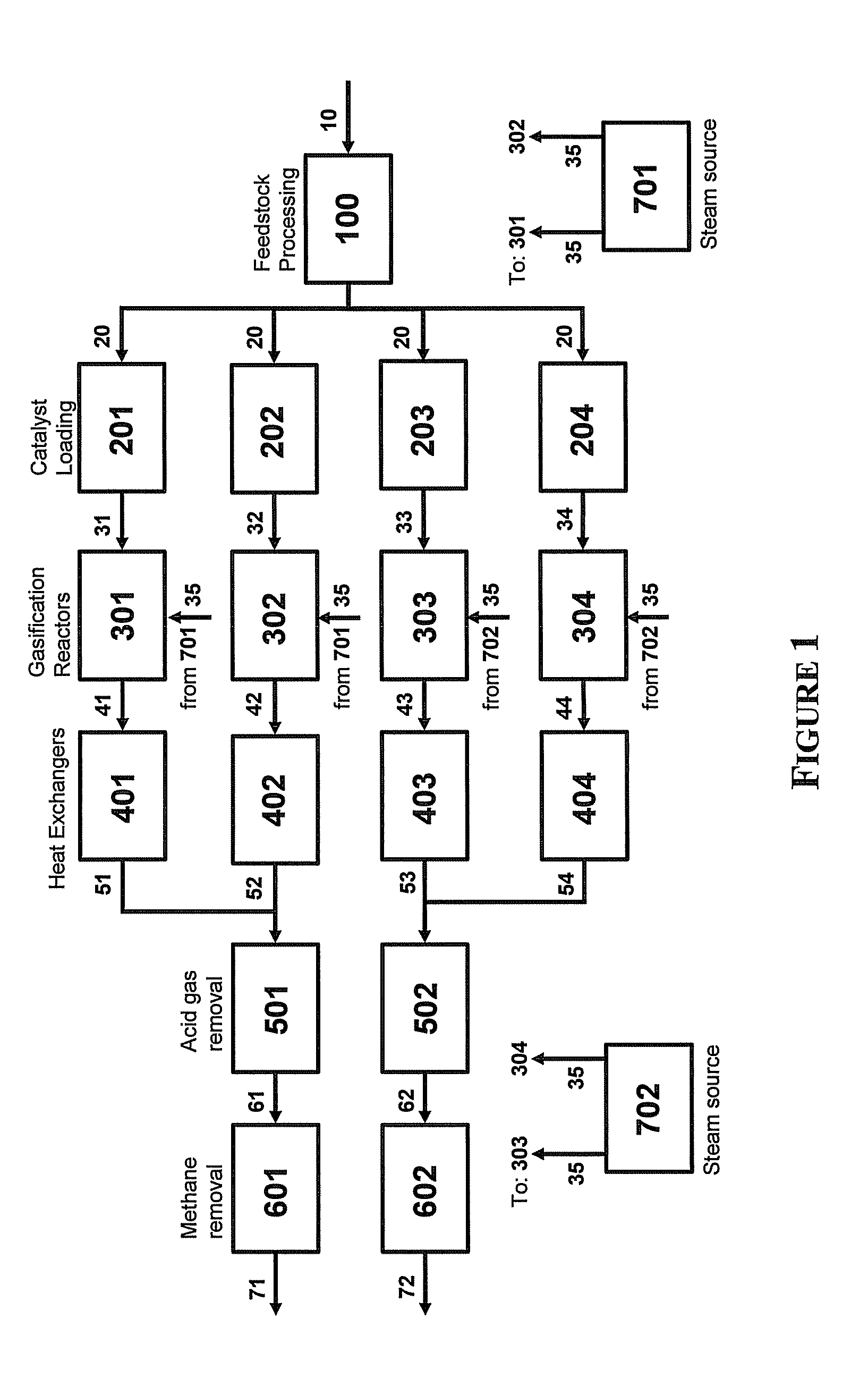

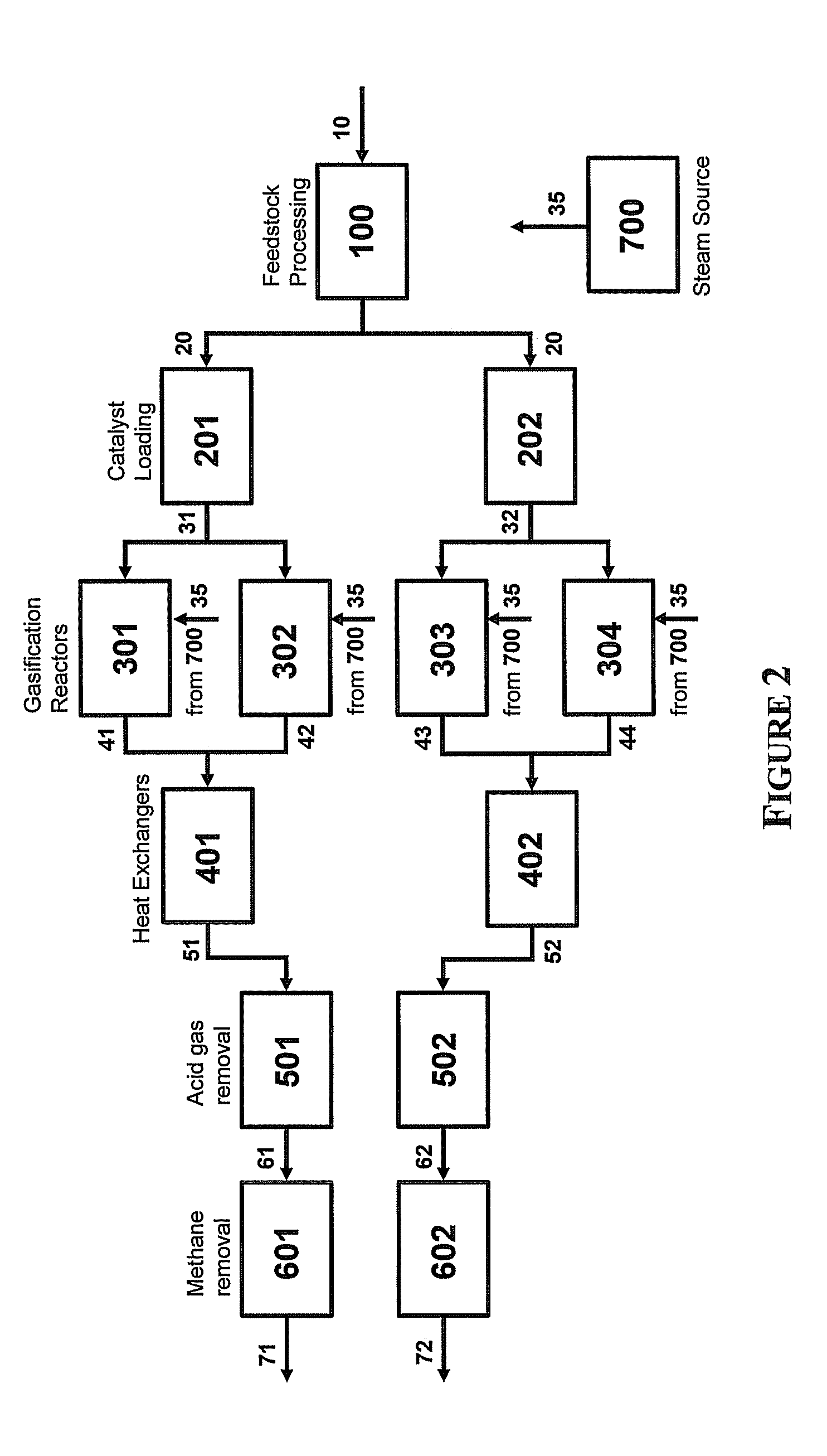

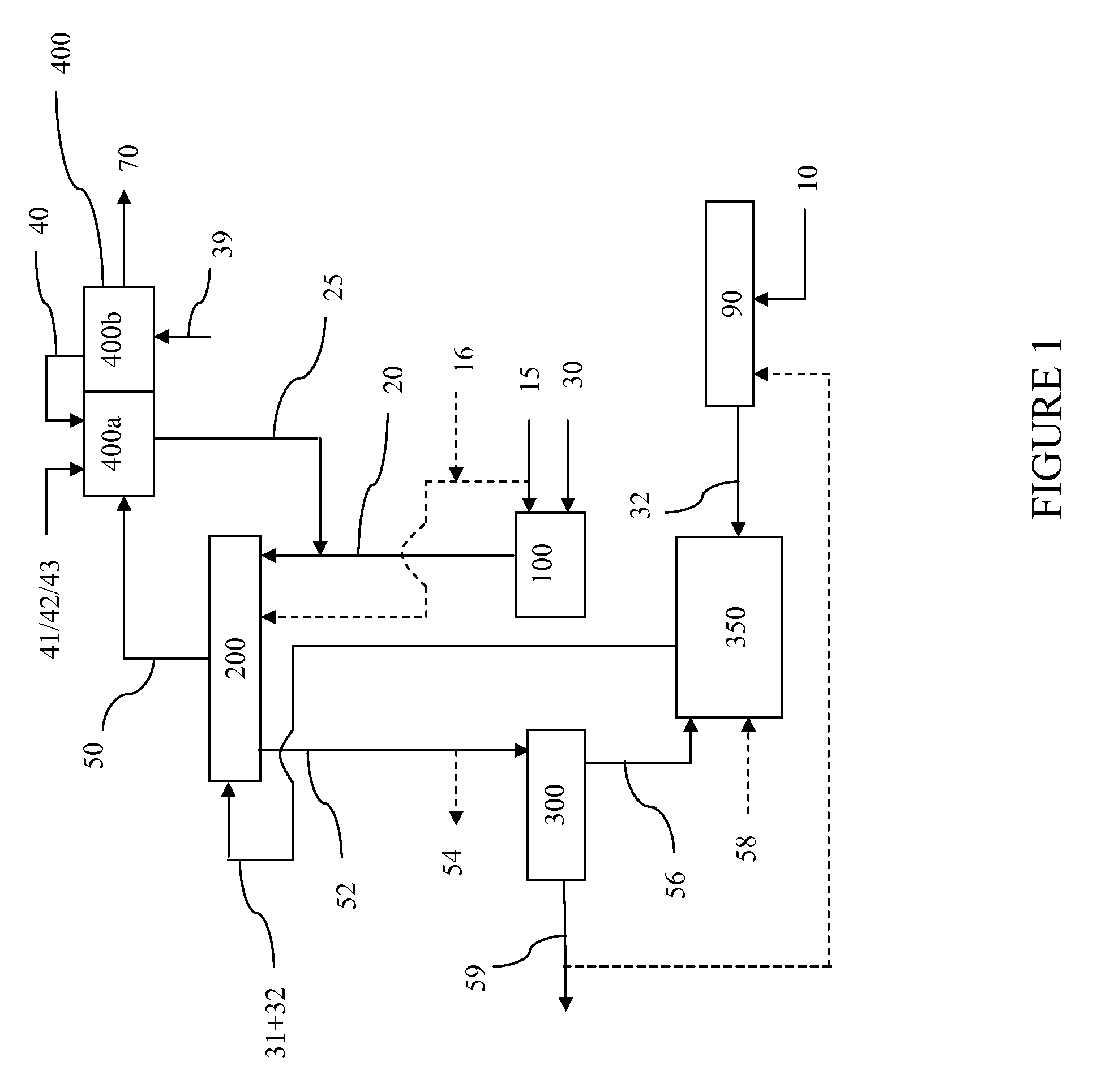

Four-Train Catalytic Gasification Systems

InactiveUS20090324460A1Reduce moisture contentHydrogen separation at low temperatureHydrogen separation using liquid contactUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

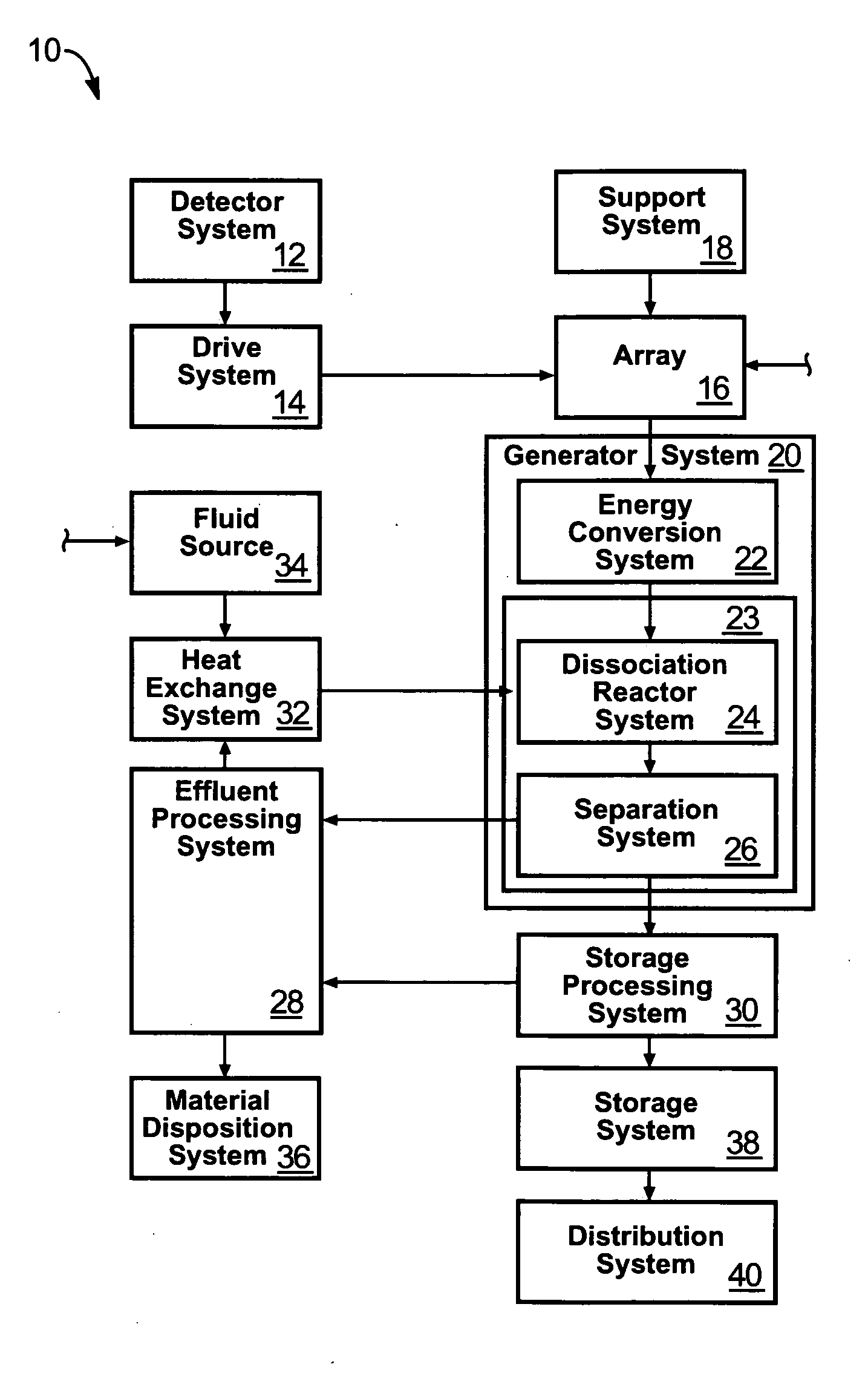

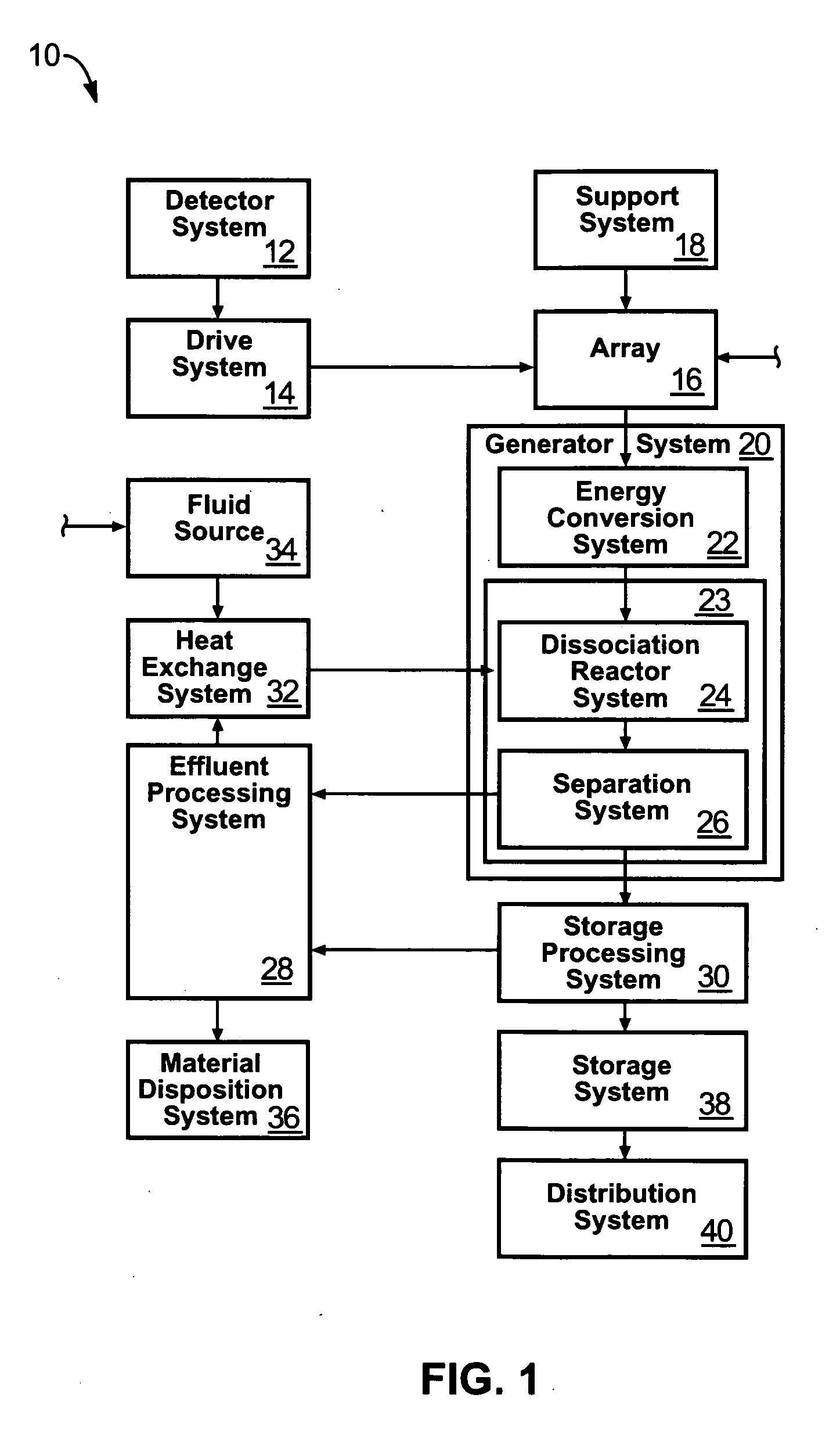

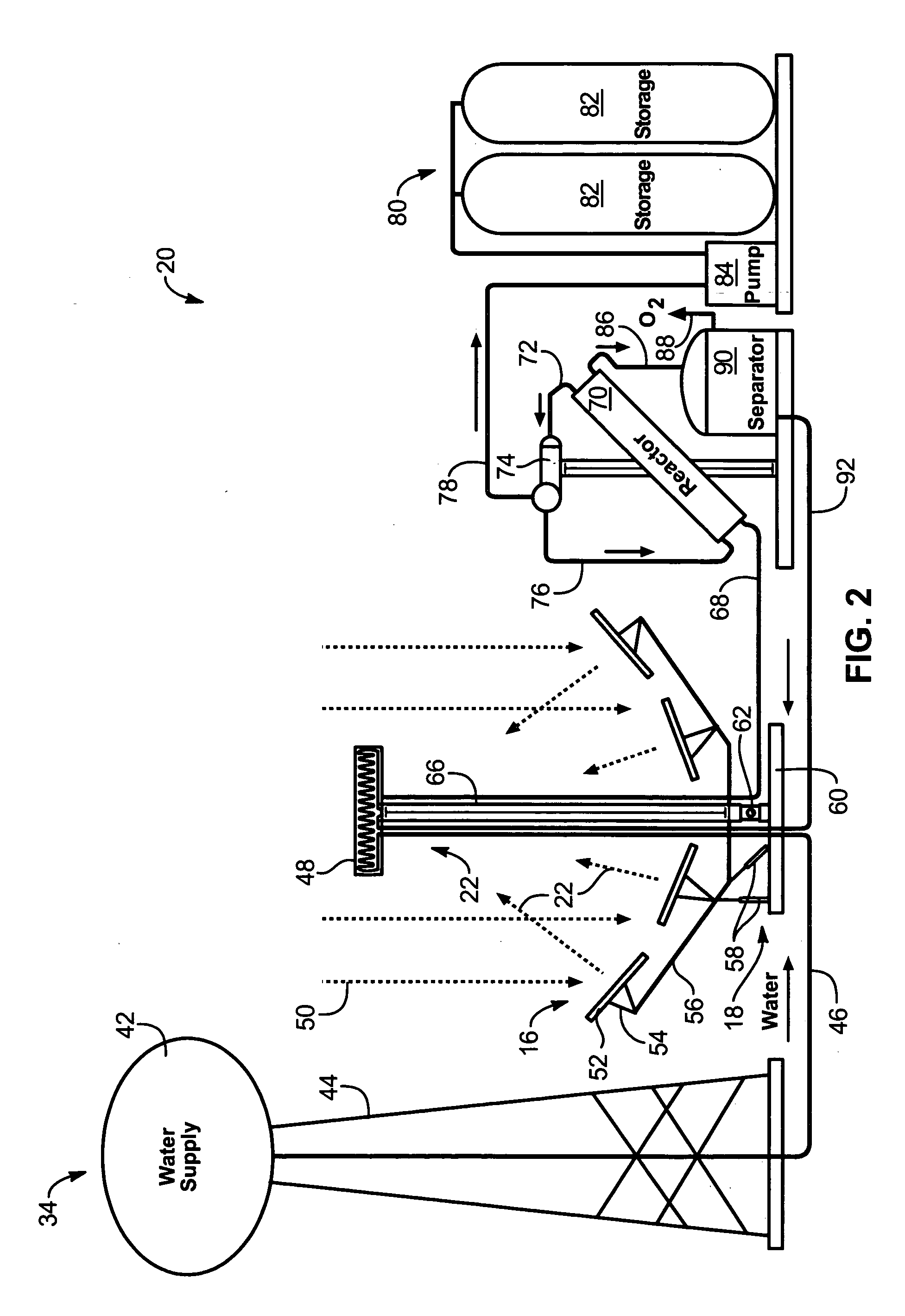

Solar, catalytic, hydrogen generation apparatus and method

InactiveUS20060048808A1High thermodynamic availabilityLoss in efficiencySolar heating energySolar heat collector controllersThermal energyPorosity

An apparatus for producing hydrogen may include a collector of radiation to concentrate solar radiation on a converter having an absorptivity to convert the solar radiation to thermal energy to drive a chemical process using a feedstock to dissociate into an output chemical and a byproduct. A separator separates the output and byproduct, after which a reactor reacts the output to form a storage chemical, reactive to produce energy but sufficiently stable for safe handling outside designation as an energetic material. The separator may have a porosity to substantially pass hydrogen and block oxygen and water. A sweep gas may sweep hydrogen away from the separation barrier to change equilibrium. Catalysts may reduce temperature of dissociation and a subsequent reaction to combine it in a more stable, storable form.

Owner:PURESCI

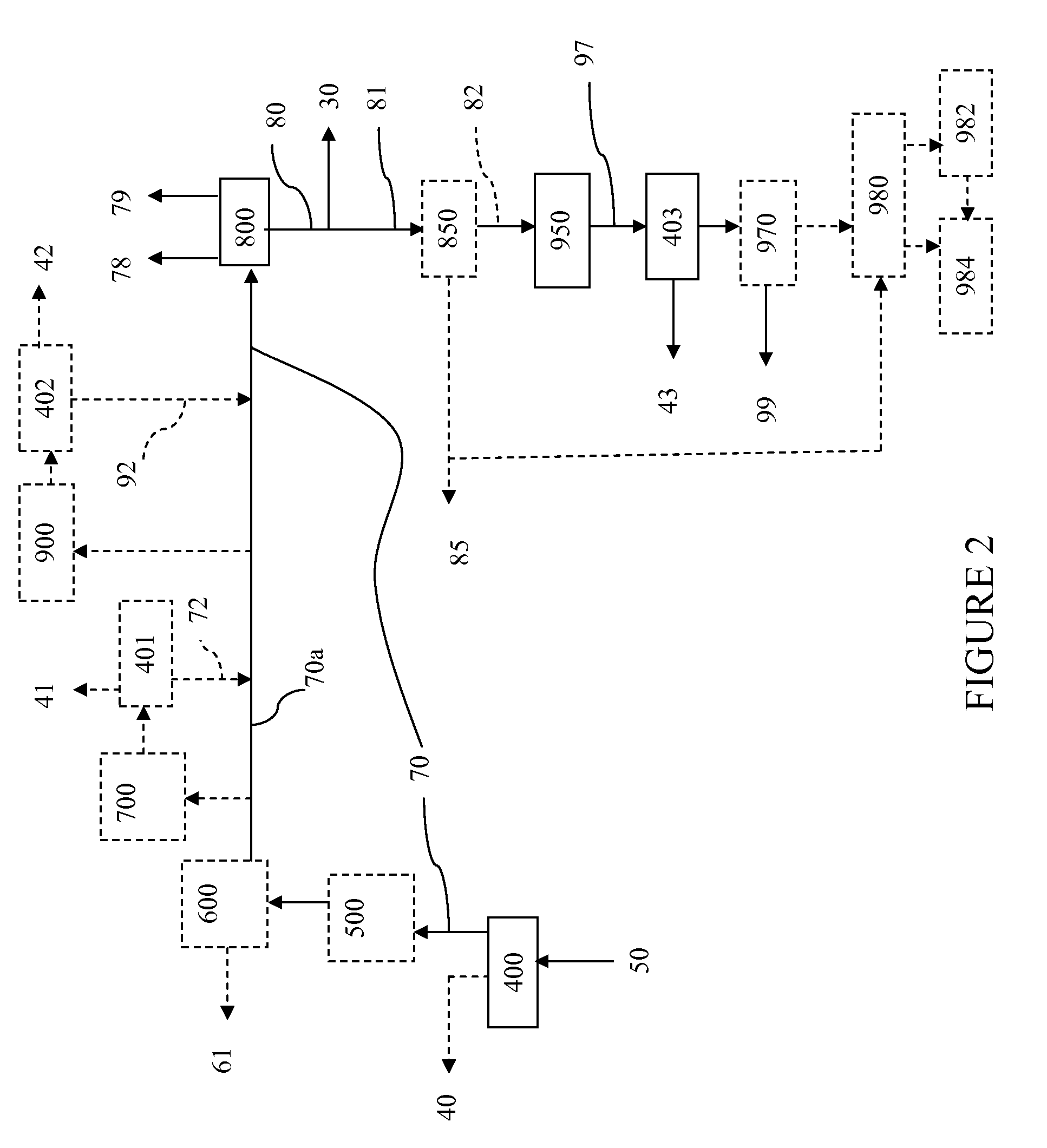

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287836A1Hydrogen separation at low temperatureCarbon compoundsMethanationHydromethanation

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of carbonaceous feedstocks in the presence of steam, carbon monoxide, hydrogen and a hydromethanation catalyst.

Owner:SURE CHAMPION INVESTMENT LTD

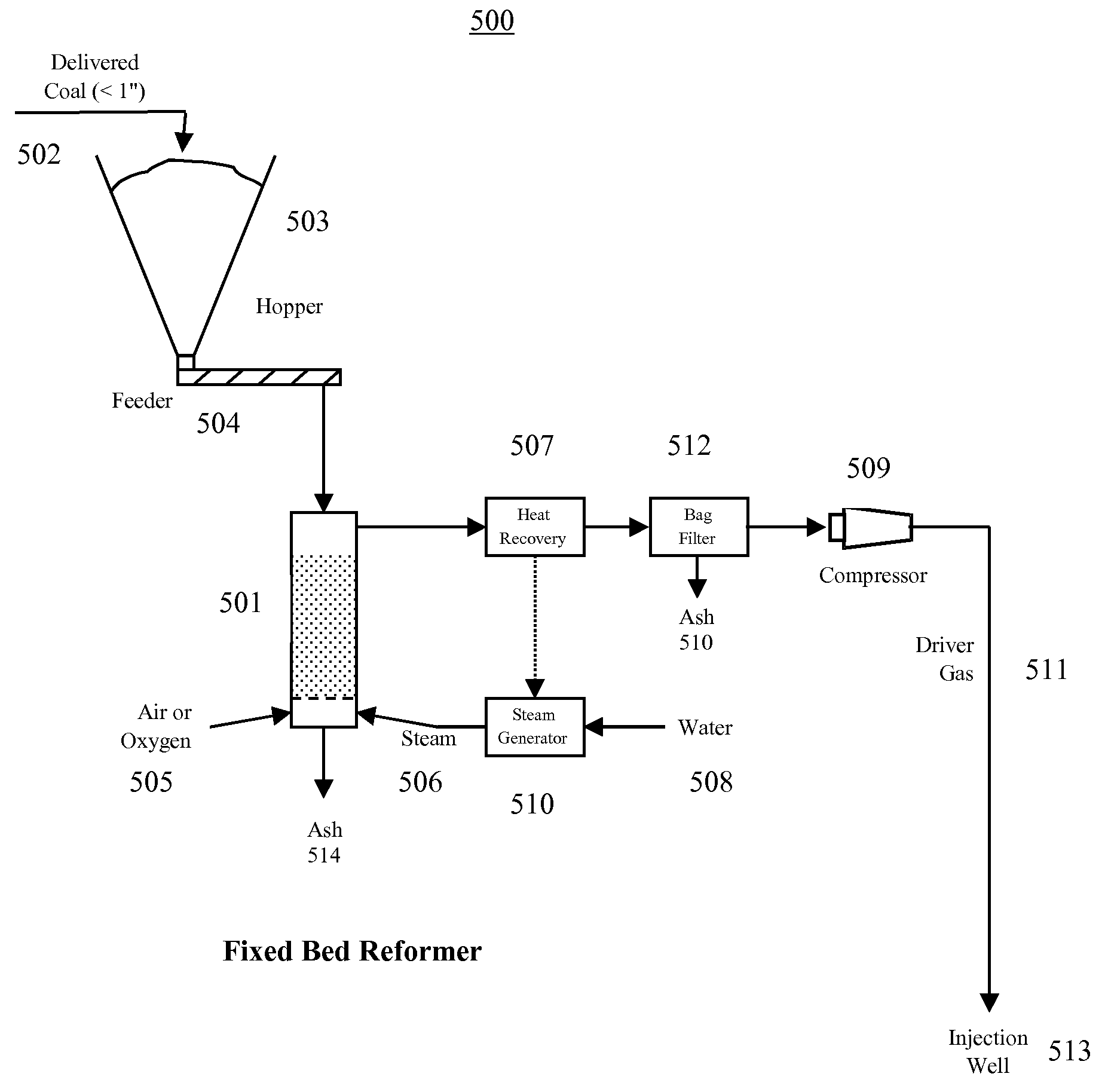

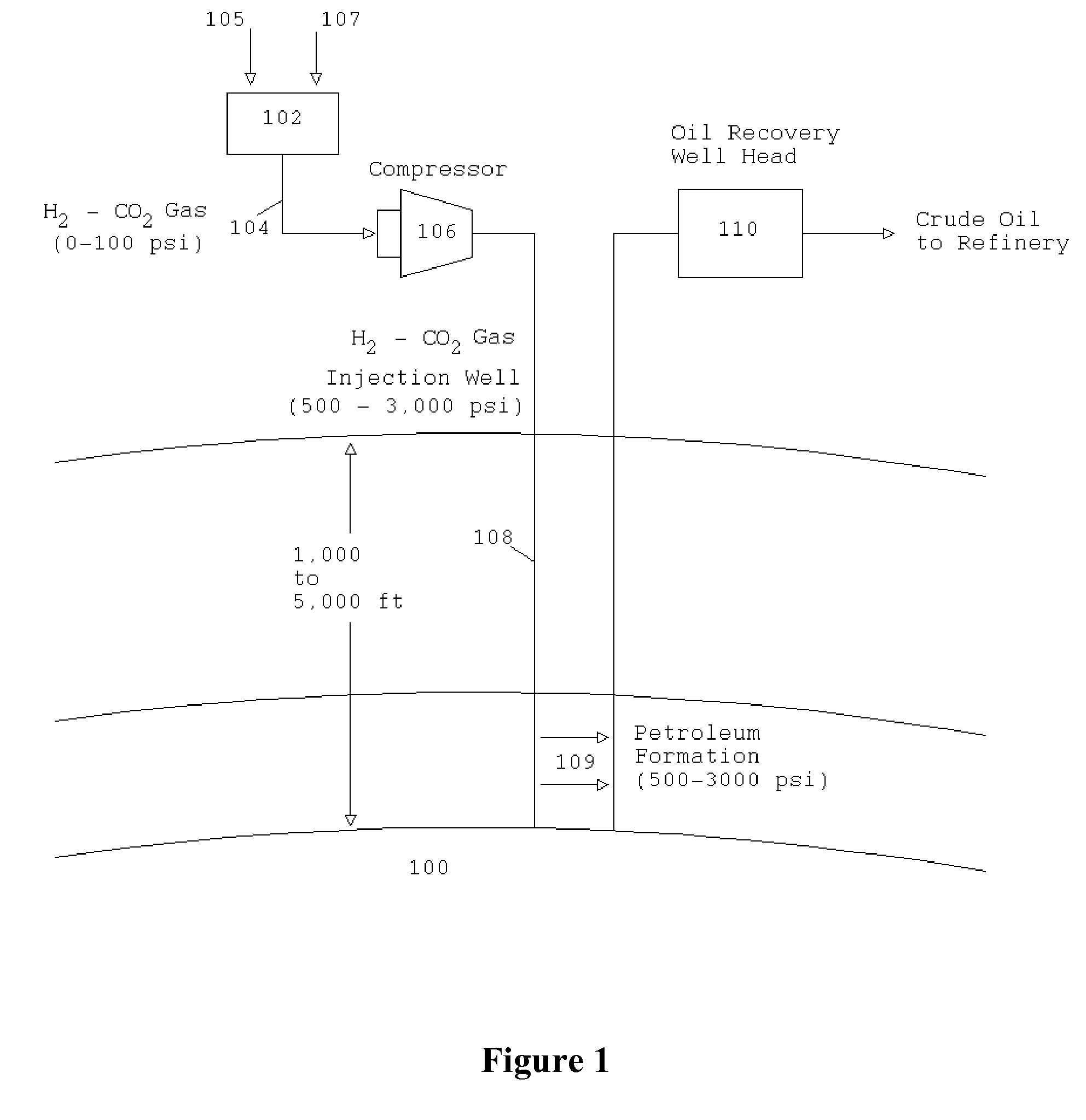

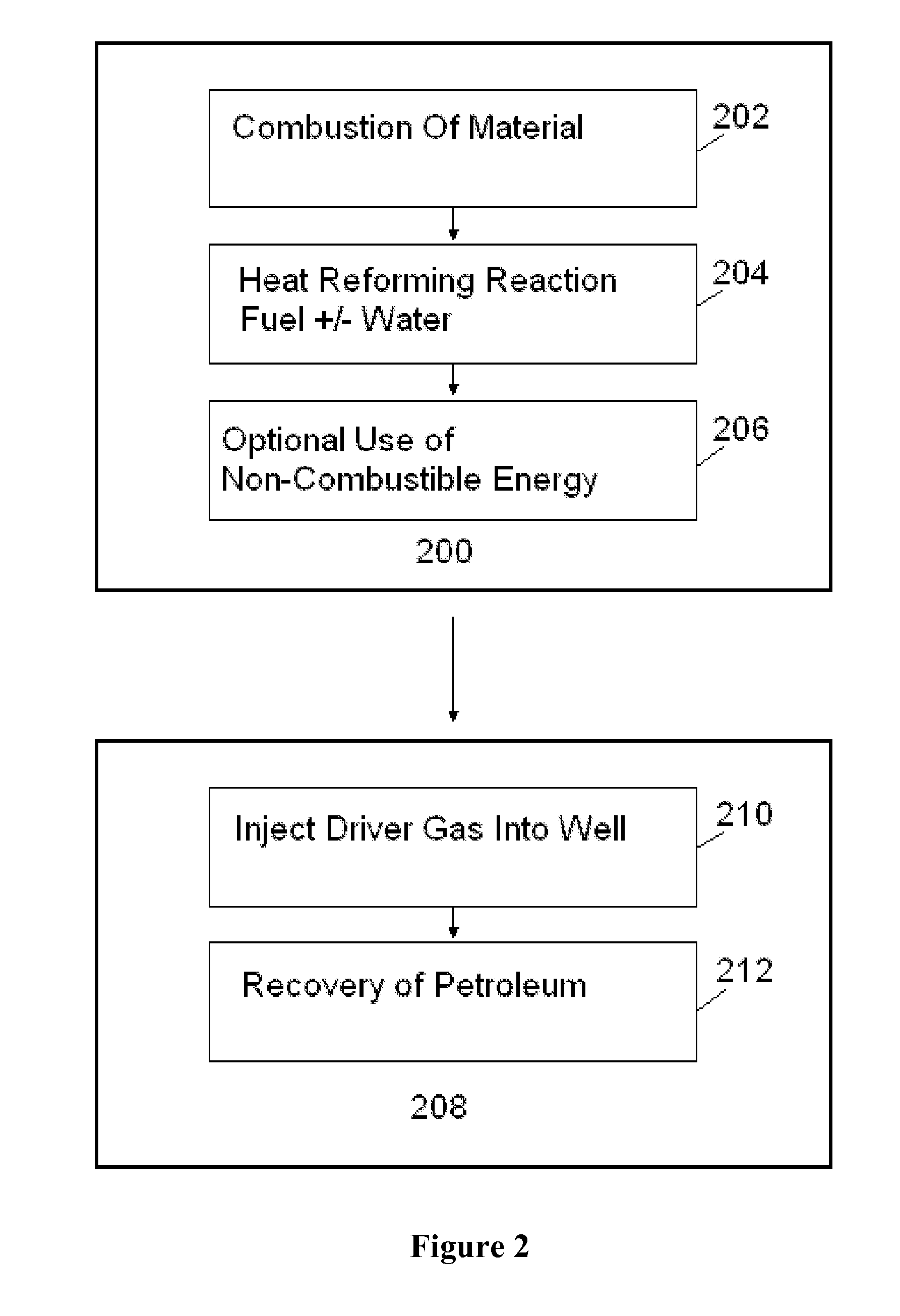

Apparatus, methods, and systems for extracting petroleum using a portable coal reformer

InactiveUS7654330B2Highly economicalVast supplyDrilling rodsHydrogen separation using solid contactPetroleumCoal

Apparatus, methods, and systems for extracting oil or natural gas from a well using a portable coal reformer. In one example, the method may include reforming coal by reaction with water to generate driver gas (comprising carbon dioxide and hydrogen gas), and injecting the driver gas into the well. The driver gas reduces the viscosity and pressurizes the oil to help extract the oil from the oil well. The coal reforming operation may include combusting coal or other combustible material with ambient oxygen to release energy, and heating coal and water with the energy released to a temperature above that required for the coal reforming reaction to proceed, thereby reforming coal and water into driver gas. The driver gas may be purified by filtering out particles and sulfur before injecting into the well. A portion of the hydrogen gas may be separated from the driver gas and used to generate electrical power.

Owner:PIONEER ENERGY

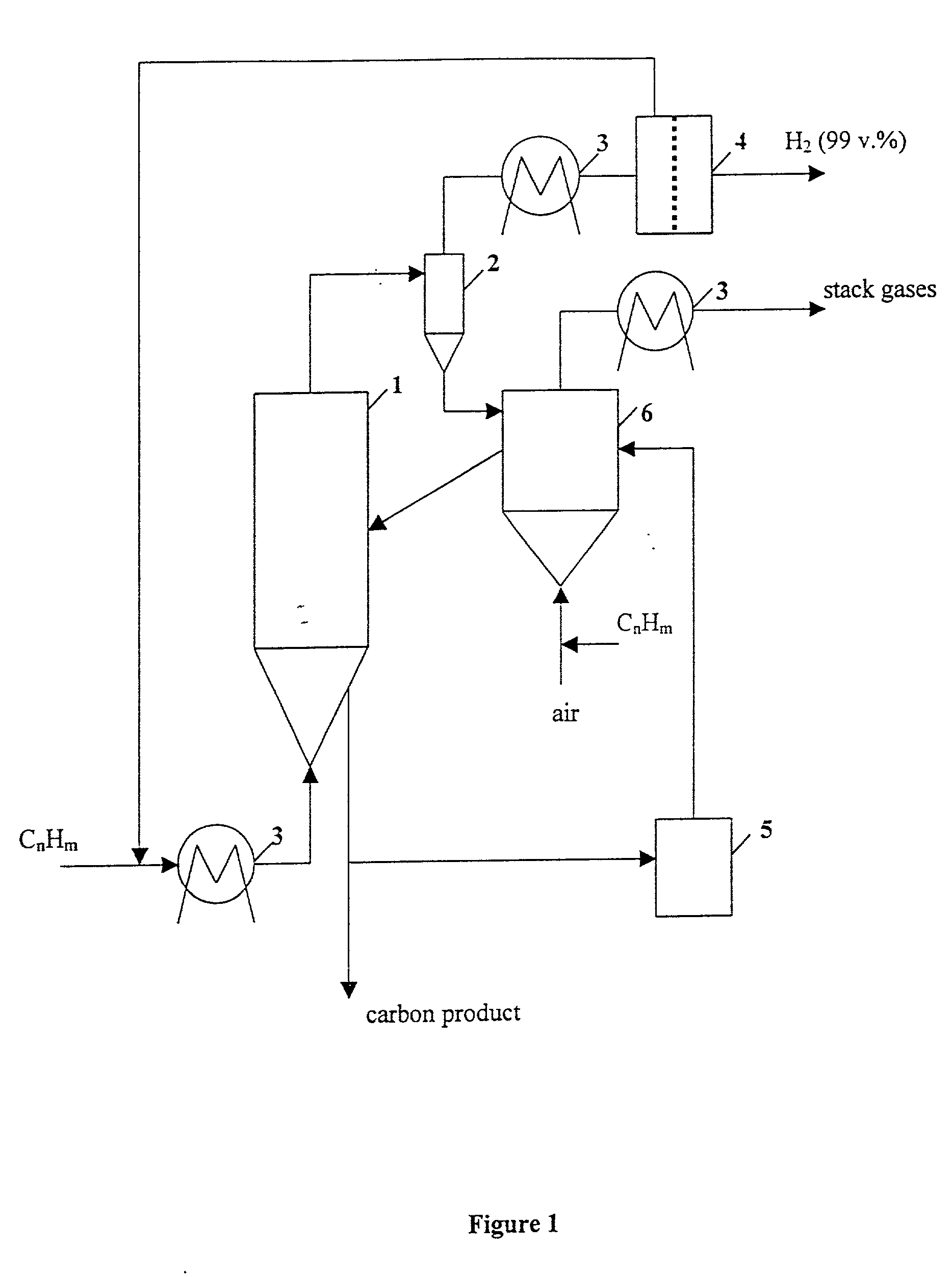

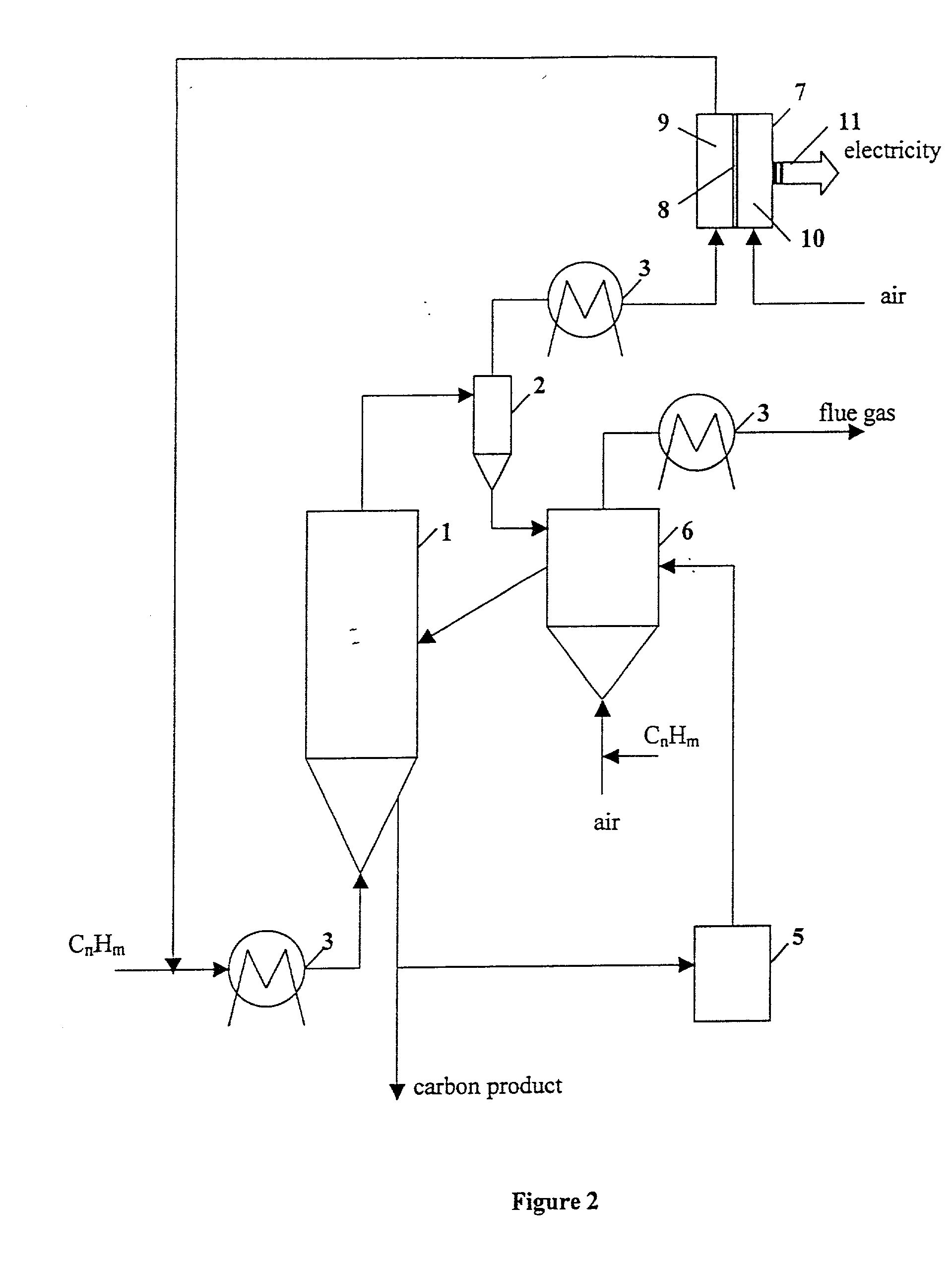

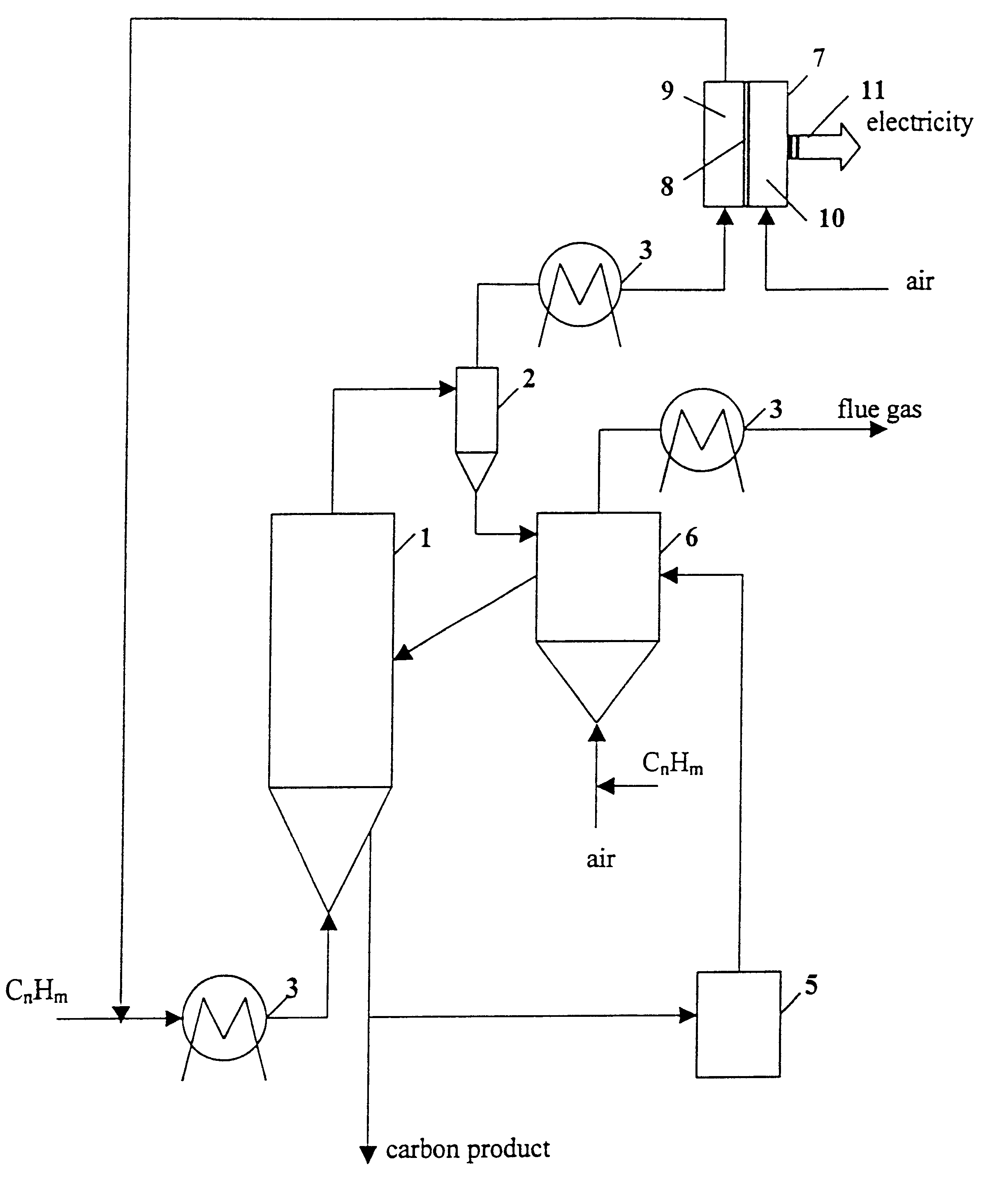

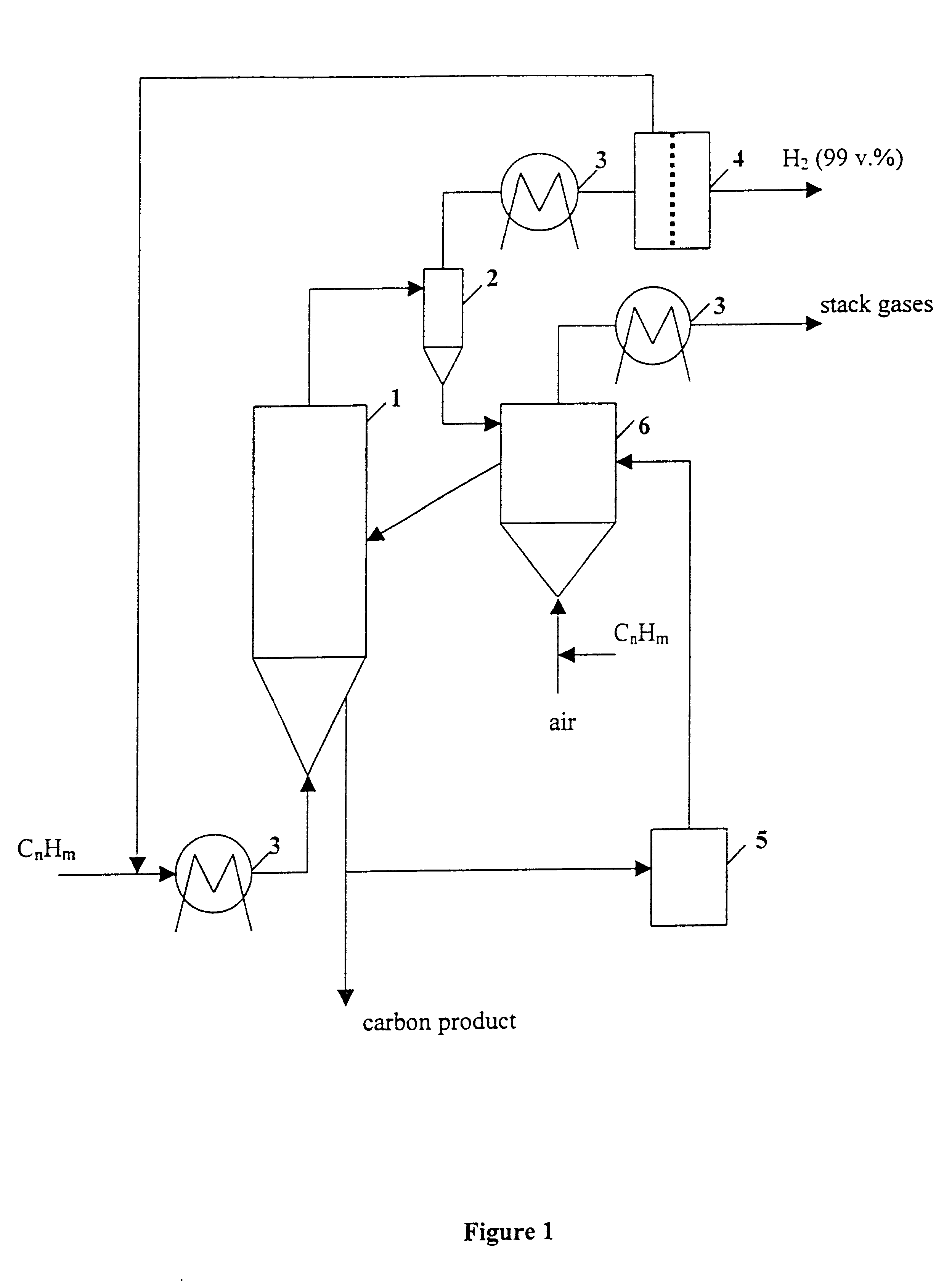

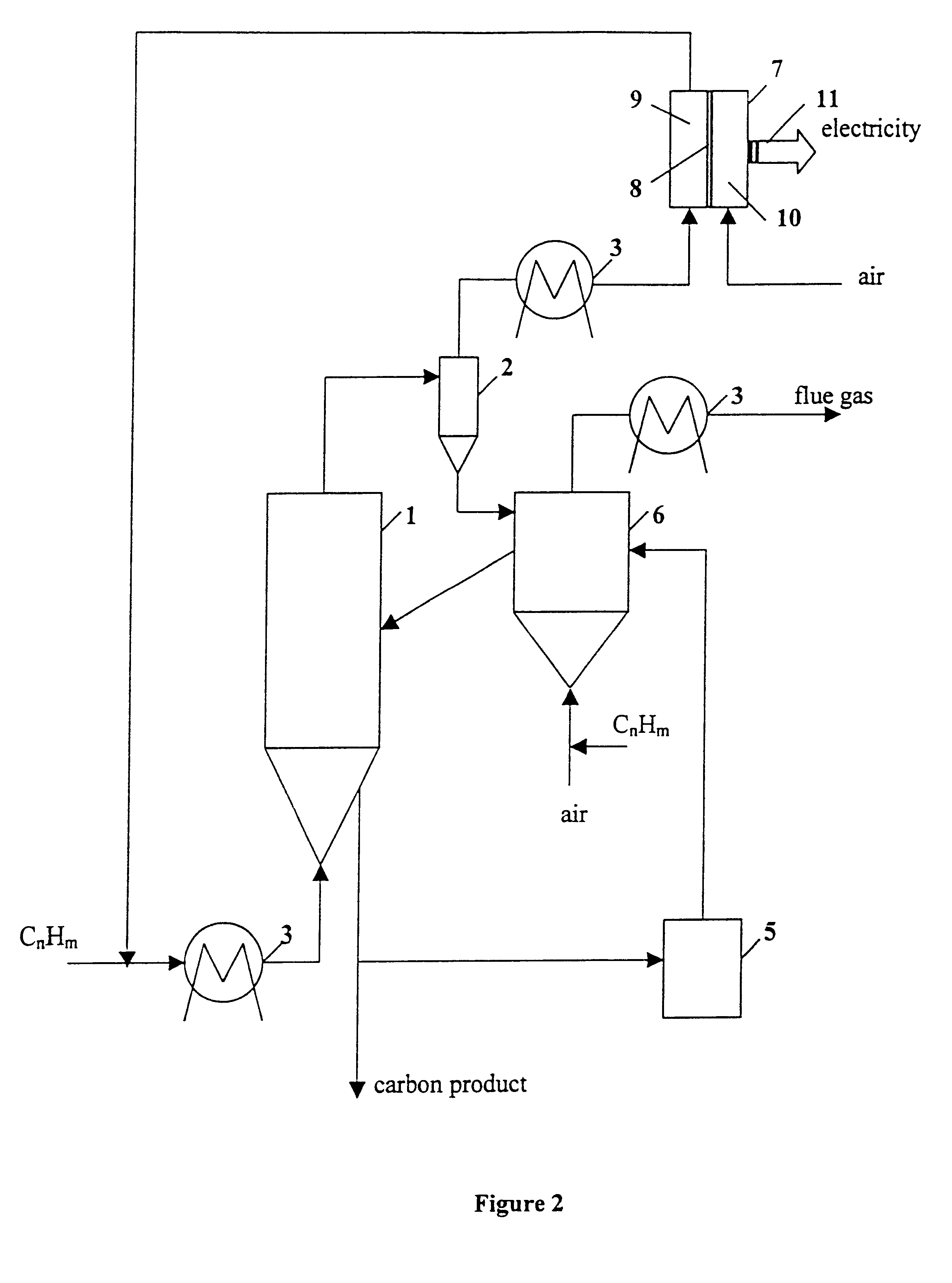

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS7618612B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

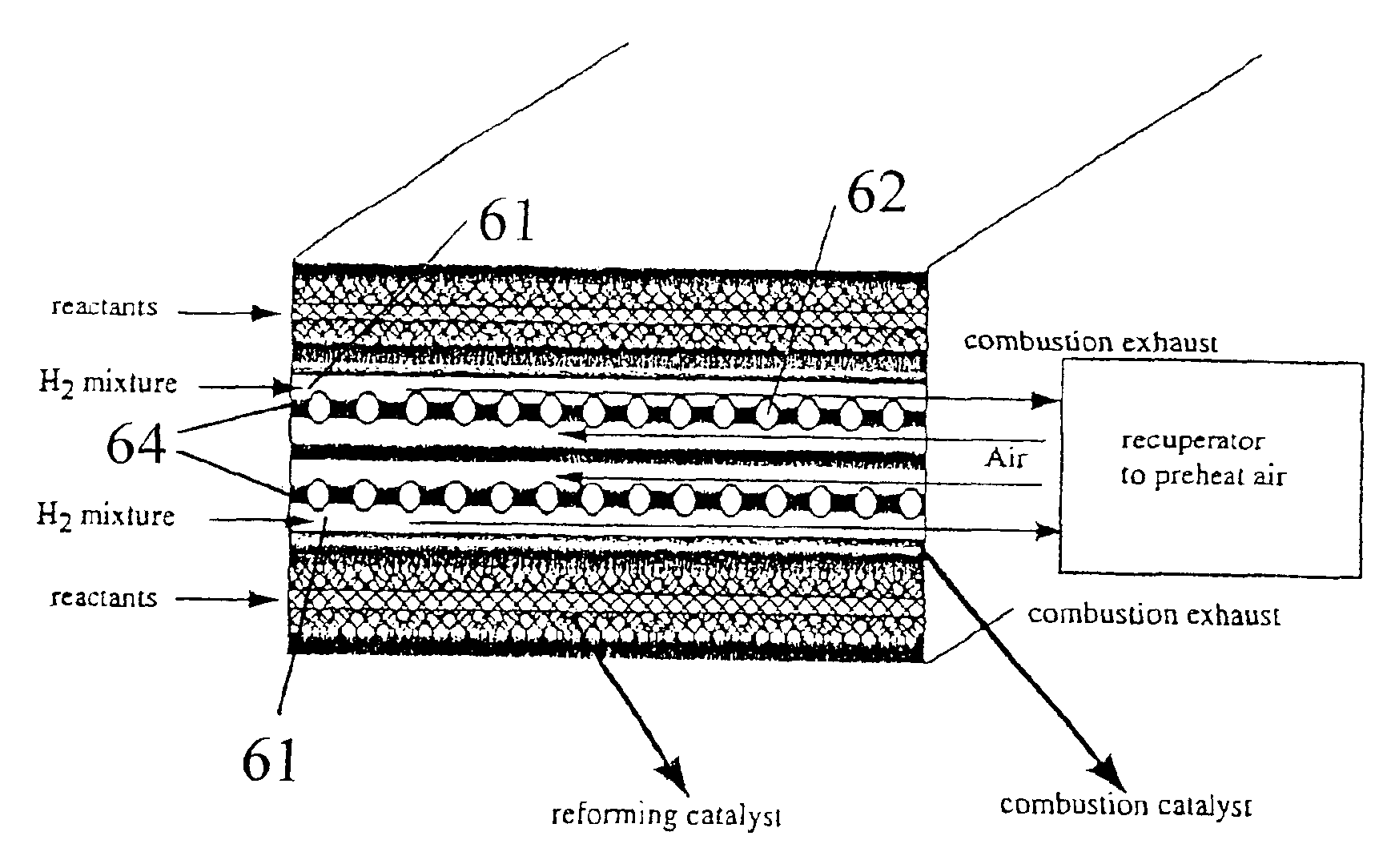

Methods of conducting simultaneous exothermic and endothermic reactions

InactiveUS6969506B2High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberEngineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for free flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

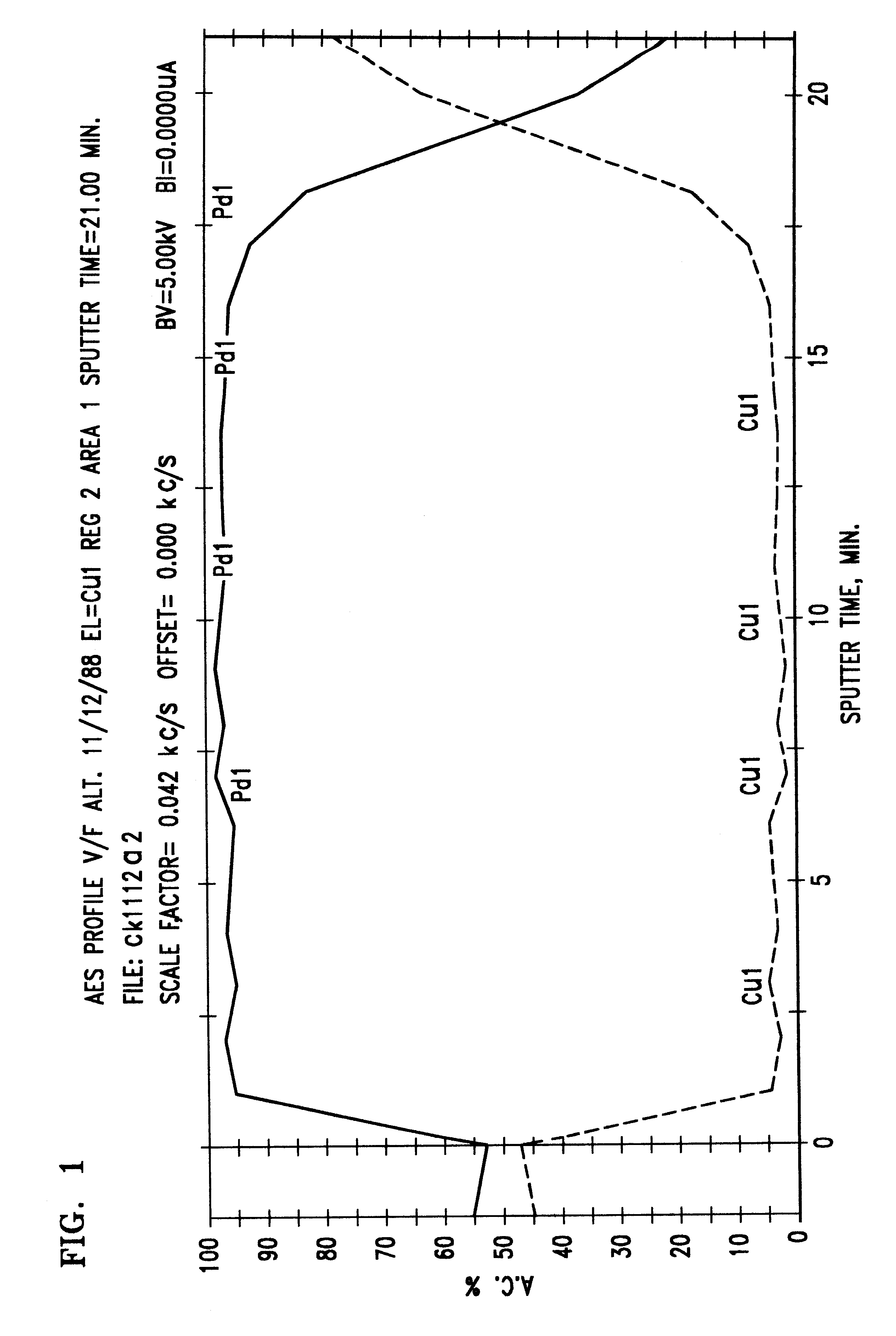

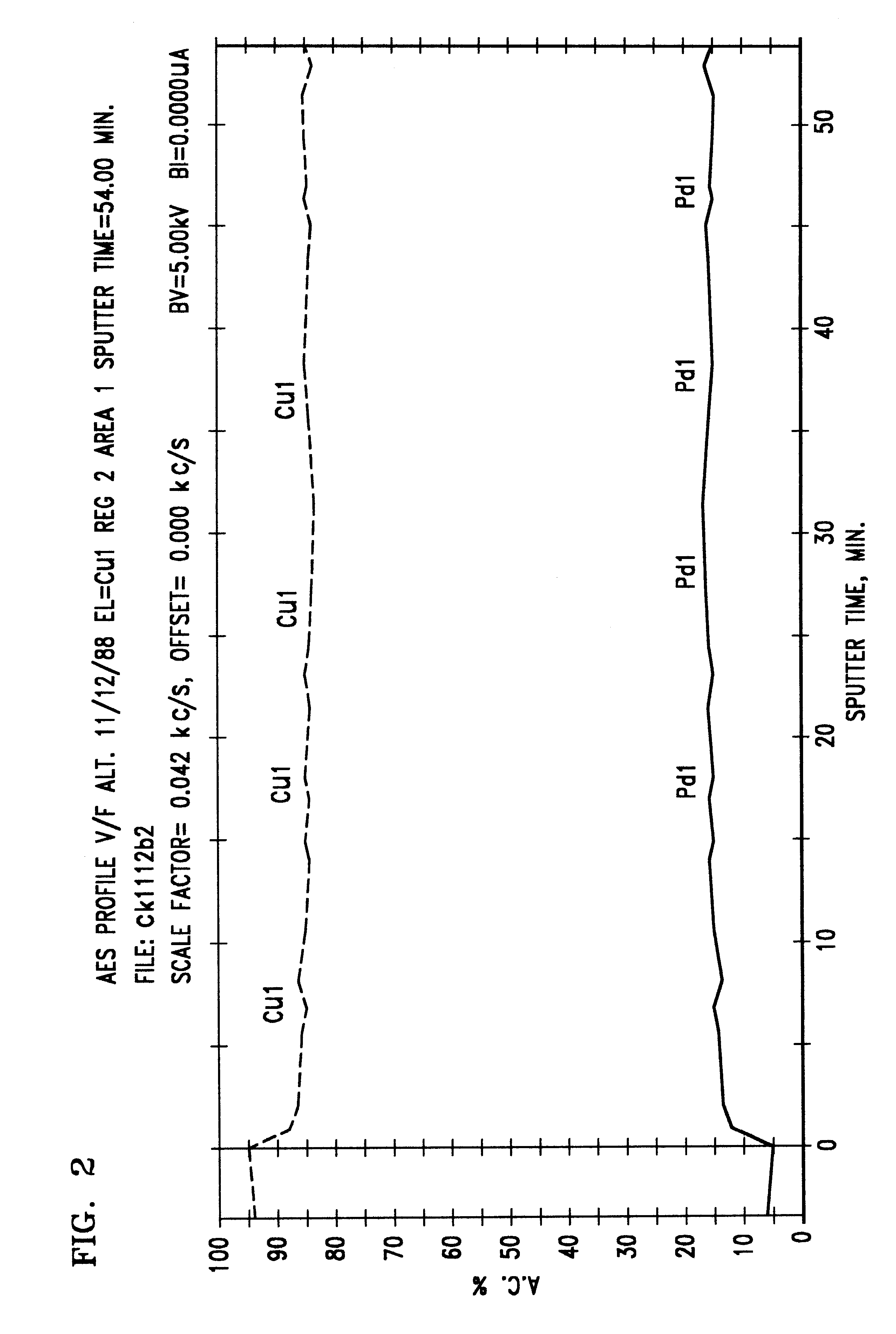

Method of producing thin palladium-copper and the like, palladium alloy membranes by solid-solid metallic interdiffusion, and improved membrane

InactiveUS6238465B1Improve facilitiesImprove performanceSemi-permeable membranesMembranesHydrogenSufficient time

A novel method of producing an improved thin hydrogen-selective palladium-alloy membrane, through solid-solid interdiffusion of thin films or layers of palladium and a palladium-enhancing metal, such as copper, subjected in the presence of a reducing agent, such as hydrogen, to an elevated temperature below the melting point of both metals, for a sufficient time to effect substantially complete interdiffusion of the metals.

Owner:HYDRIP LLC

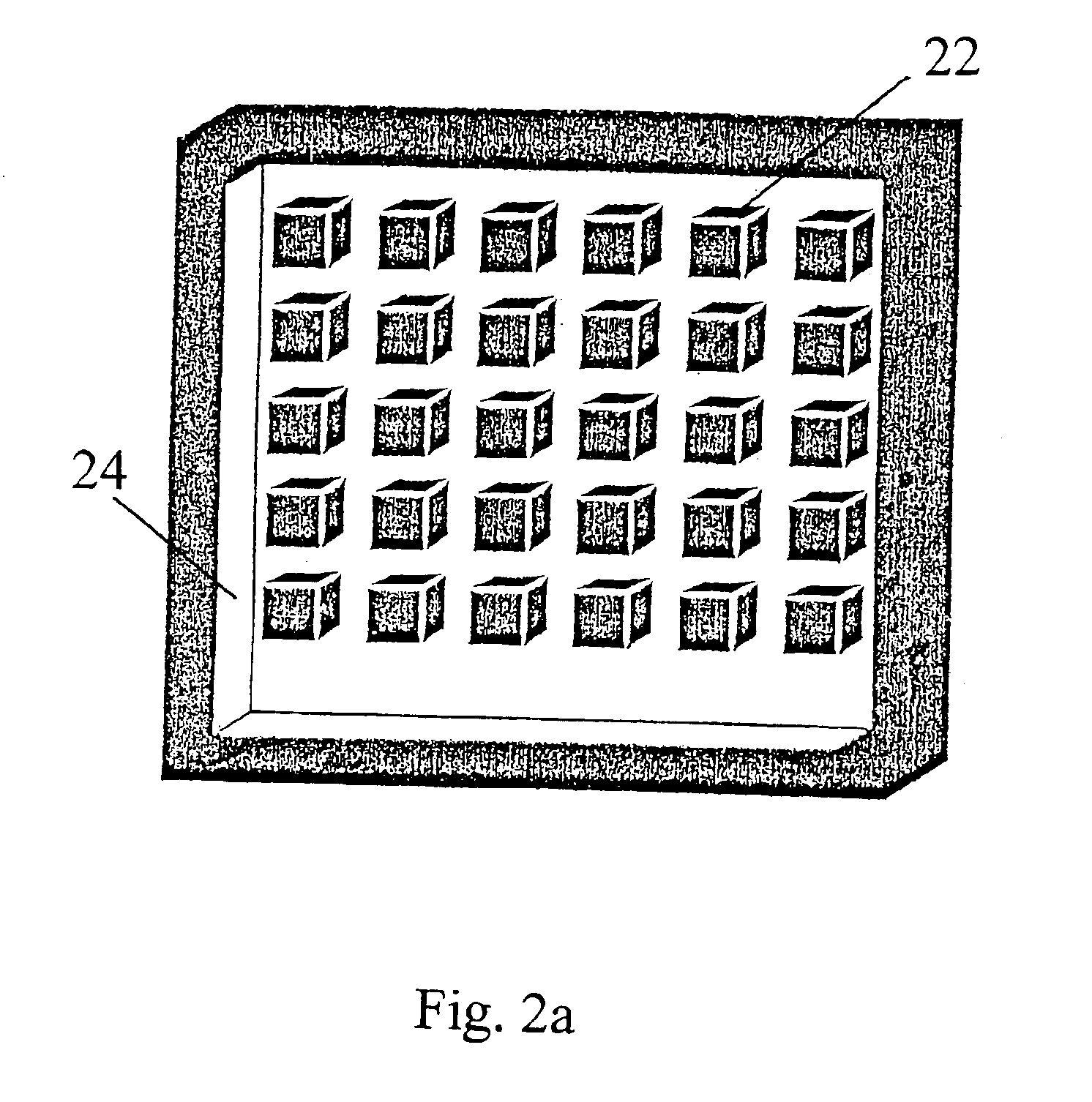

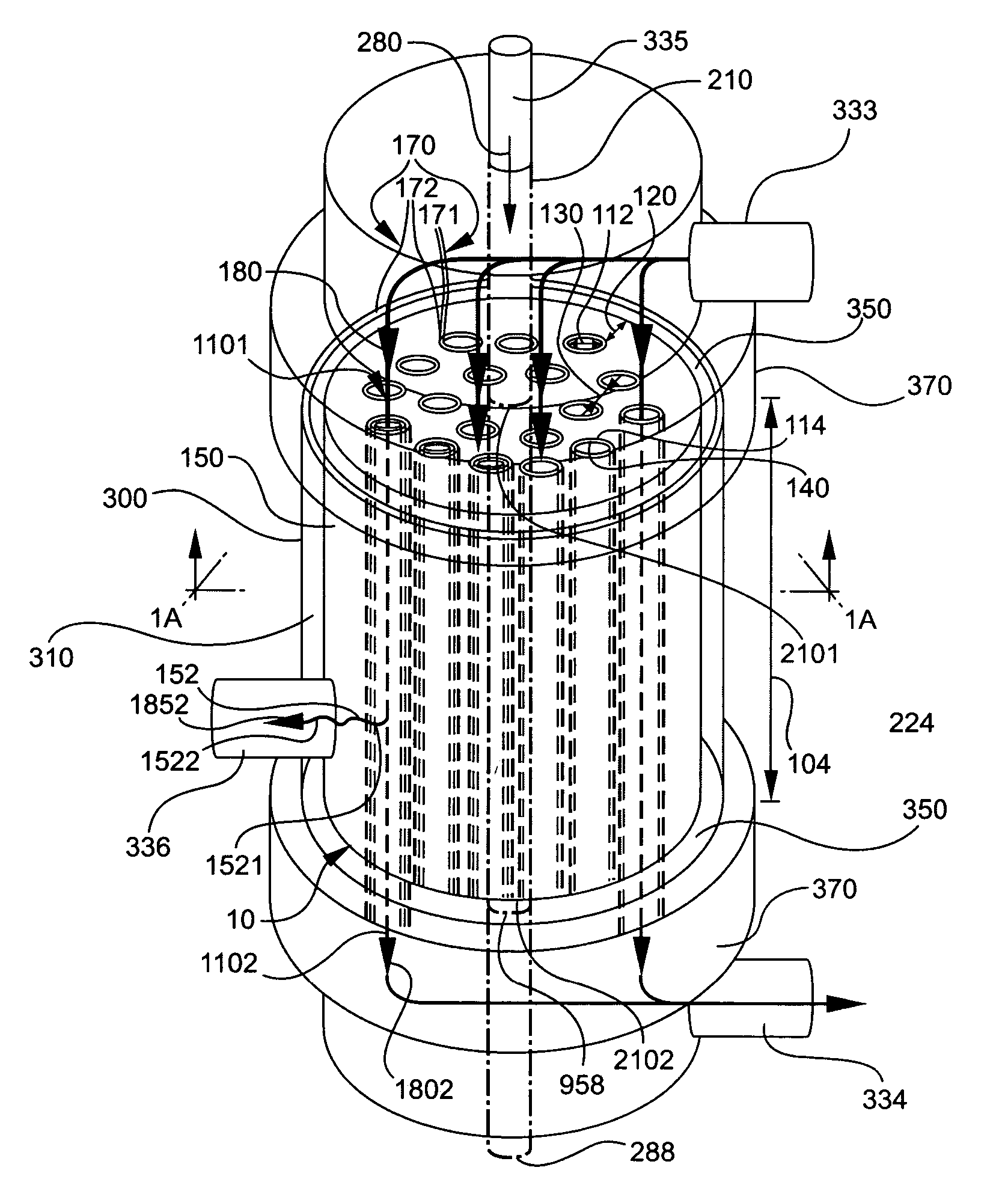

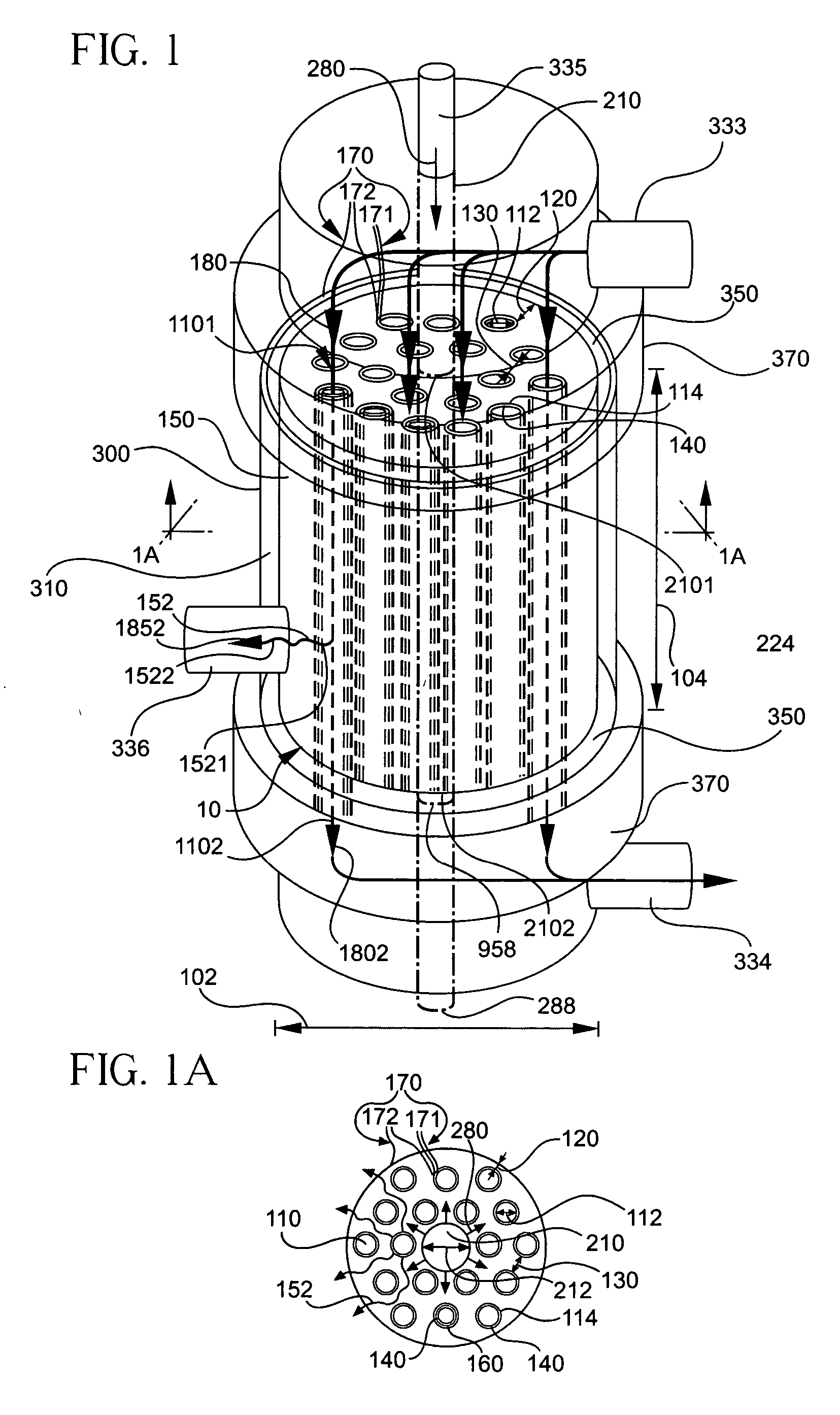

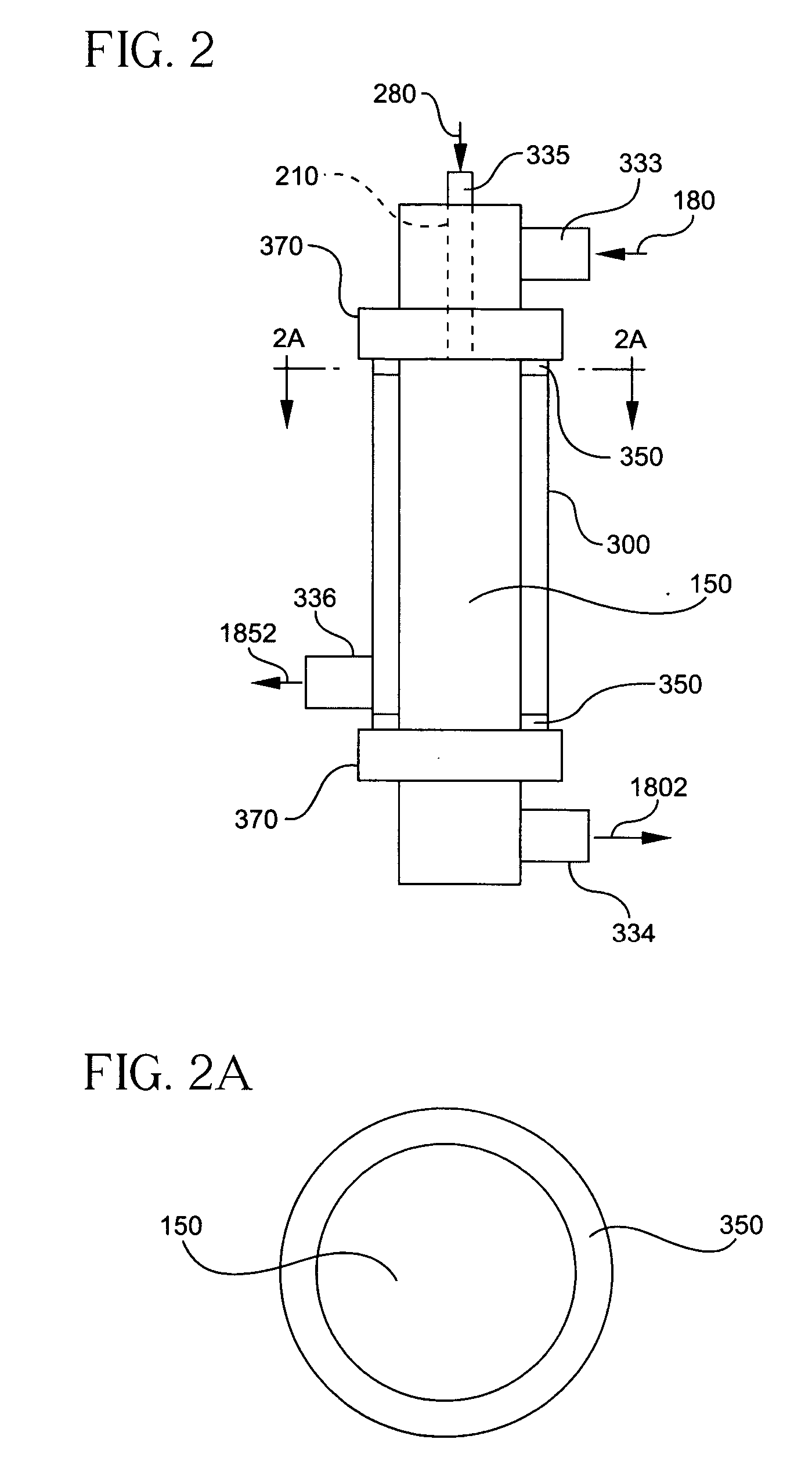

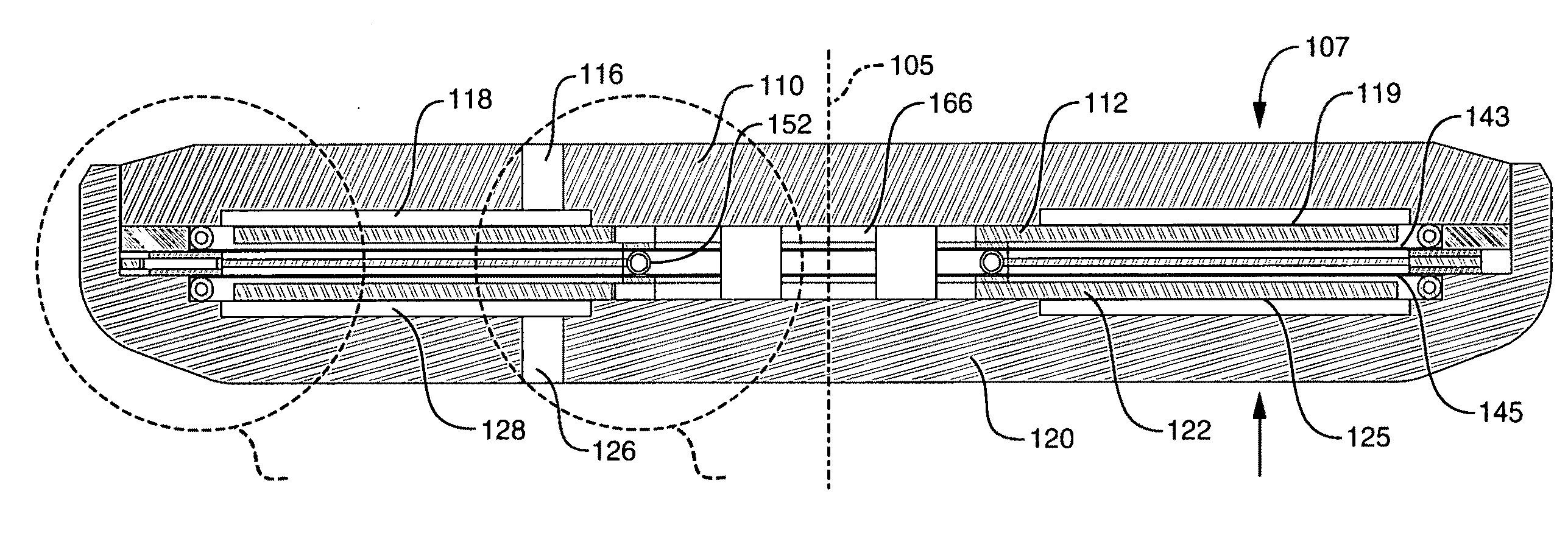

Multi-channel cross-flow porous device

InactiveUS20060090651A1Dispersed particle filtrationTransportation and packagingStream flowEngineering

A multi-channel modular device (10) processes between two fluid streams of different compositions. The device (10) includes a porous body (150) having a first plurality of feed-flow pathways (110) disposed in the body (150) for transporting a first stream (180). A pathway wall (114) surrounds each of the first plurality of feed-flow pathways (110) for processing the first stream (180) into a first composition (1852) and a second composition (1802). At least one feed-flow inlet (1101) is disposed in the body (150) for introducing the first stream (180) into the first plurality of feed-flow pathways (110). At least one feed-flow outlet (1102) is disposed in the body (150) for discharging the remaining first stream containing the second composition (1802). At least one second pathway (210) is disposed in the body (150) for transporting a second stream (280) having a second inlet (2101) and a second outlet (2102). A networked plurality of fluid conduits (152) formed in the porous body (150) provides the flow-conduit for the second stream (280) to sweep the first composition (1852) from each of the first plurality of the feed-flow pathways (110) to the second outlet (2102). A vessel (300) ports the inlets (1101 and 2101) and outlets (1102 and 2102) to provide a second stream flow access and for spacing the body within and away from the inner surfaces of the vessel (300) to provide a gap (310) for access. A partition (350) is disposed in the gap between the body and the vessel for diverting the flow within the gap (310).

Owner:CORNING INC

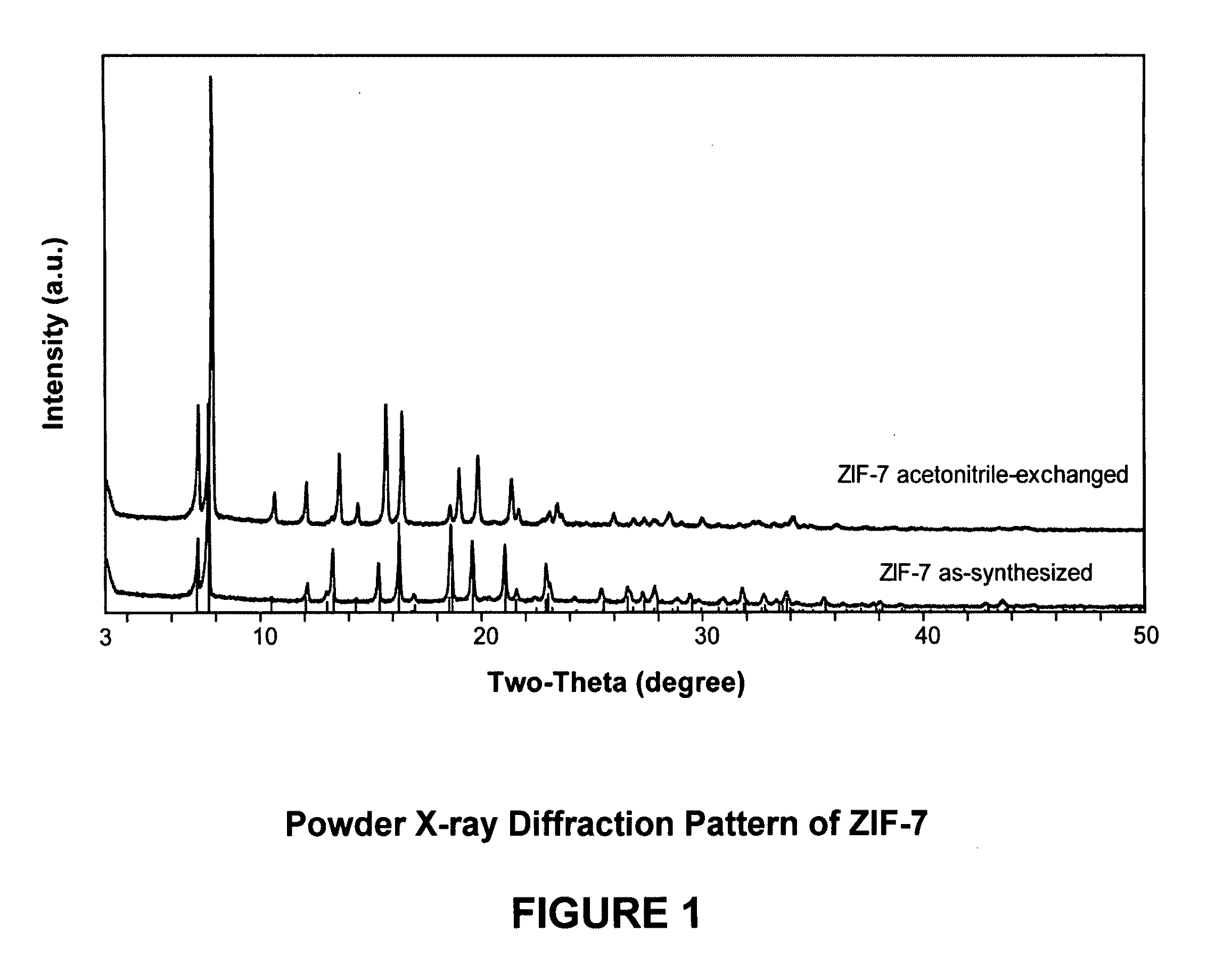

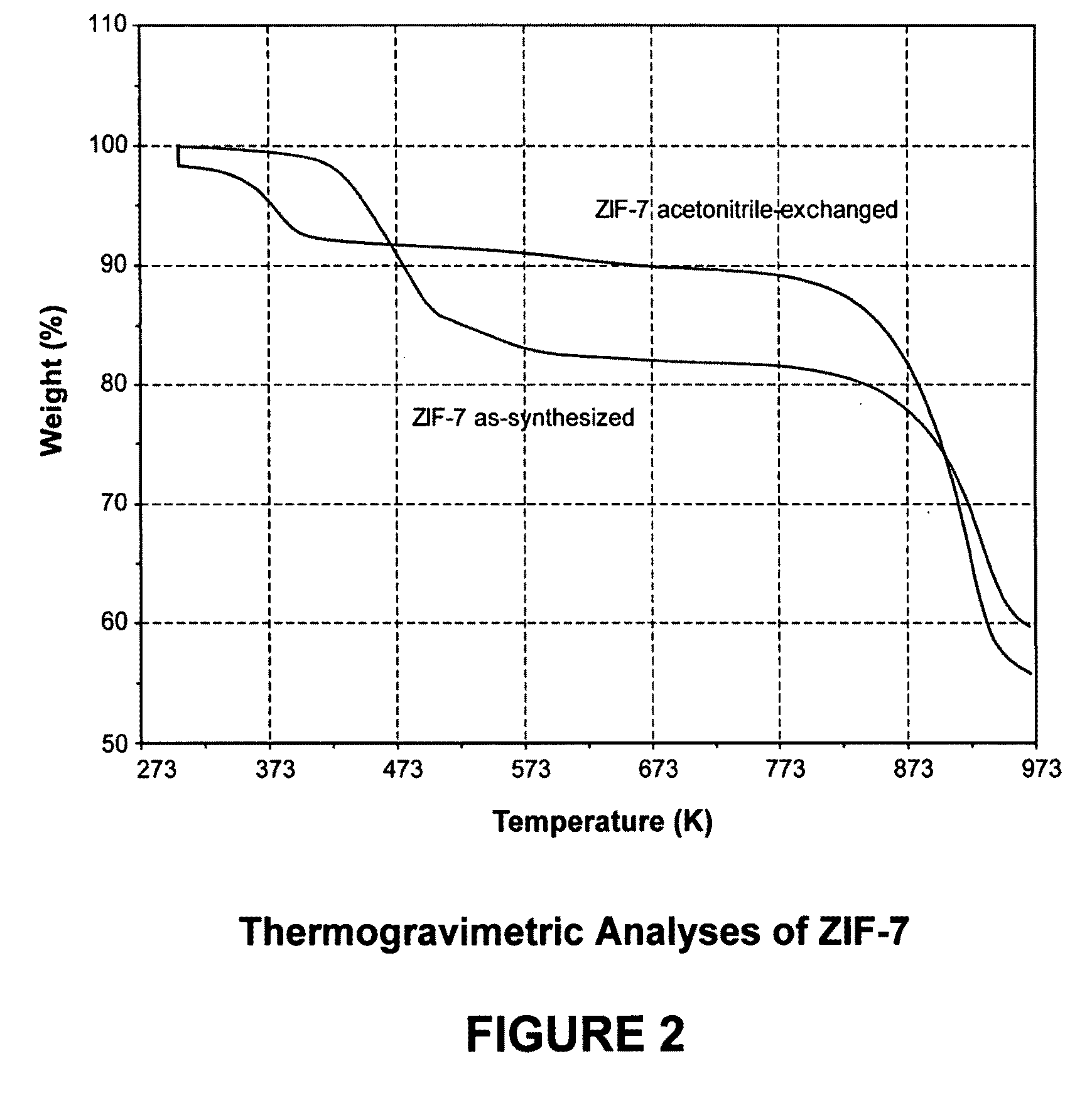

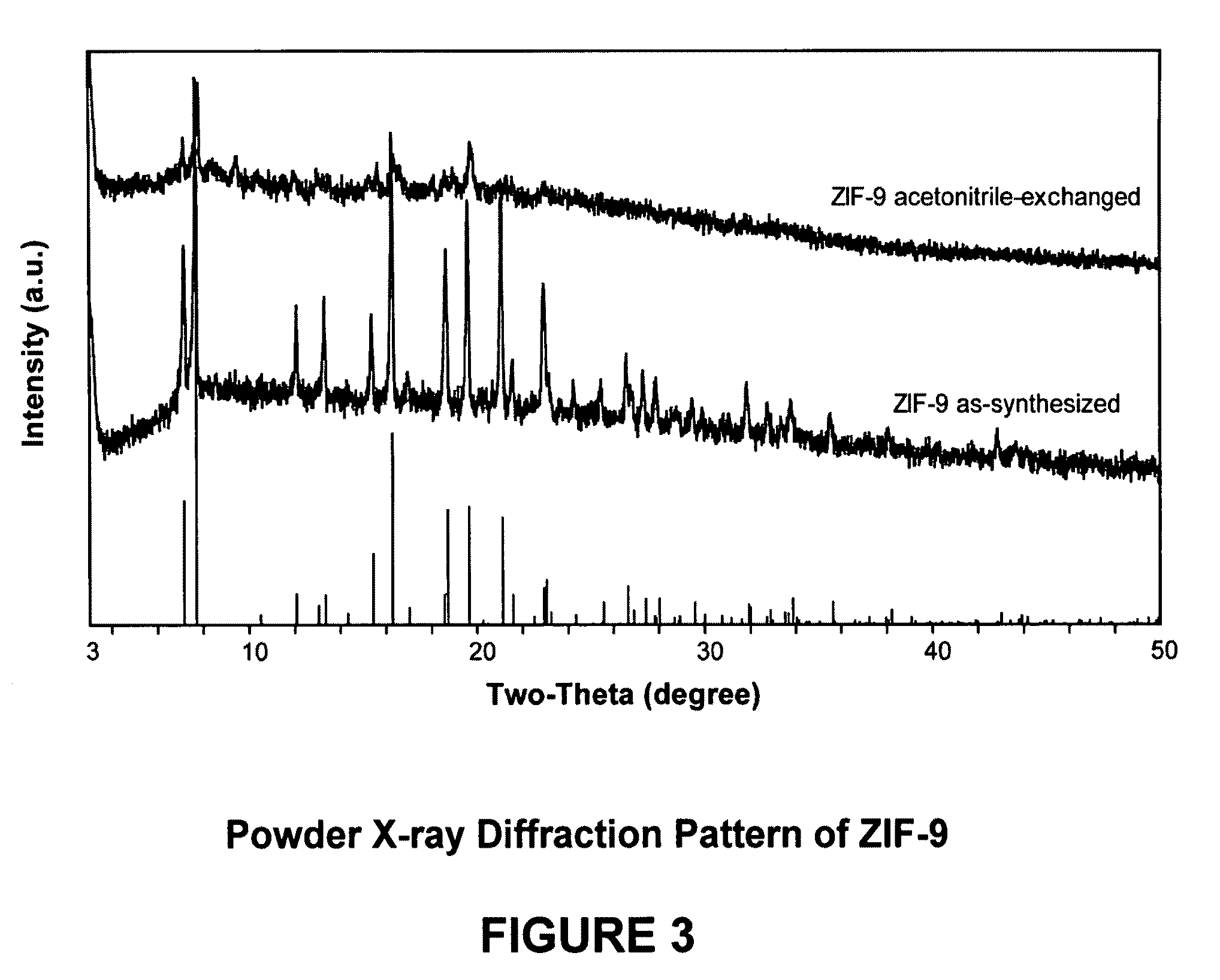

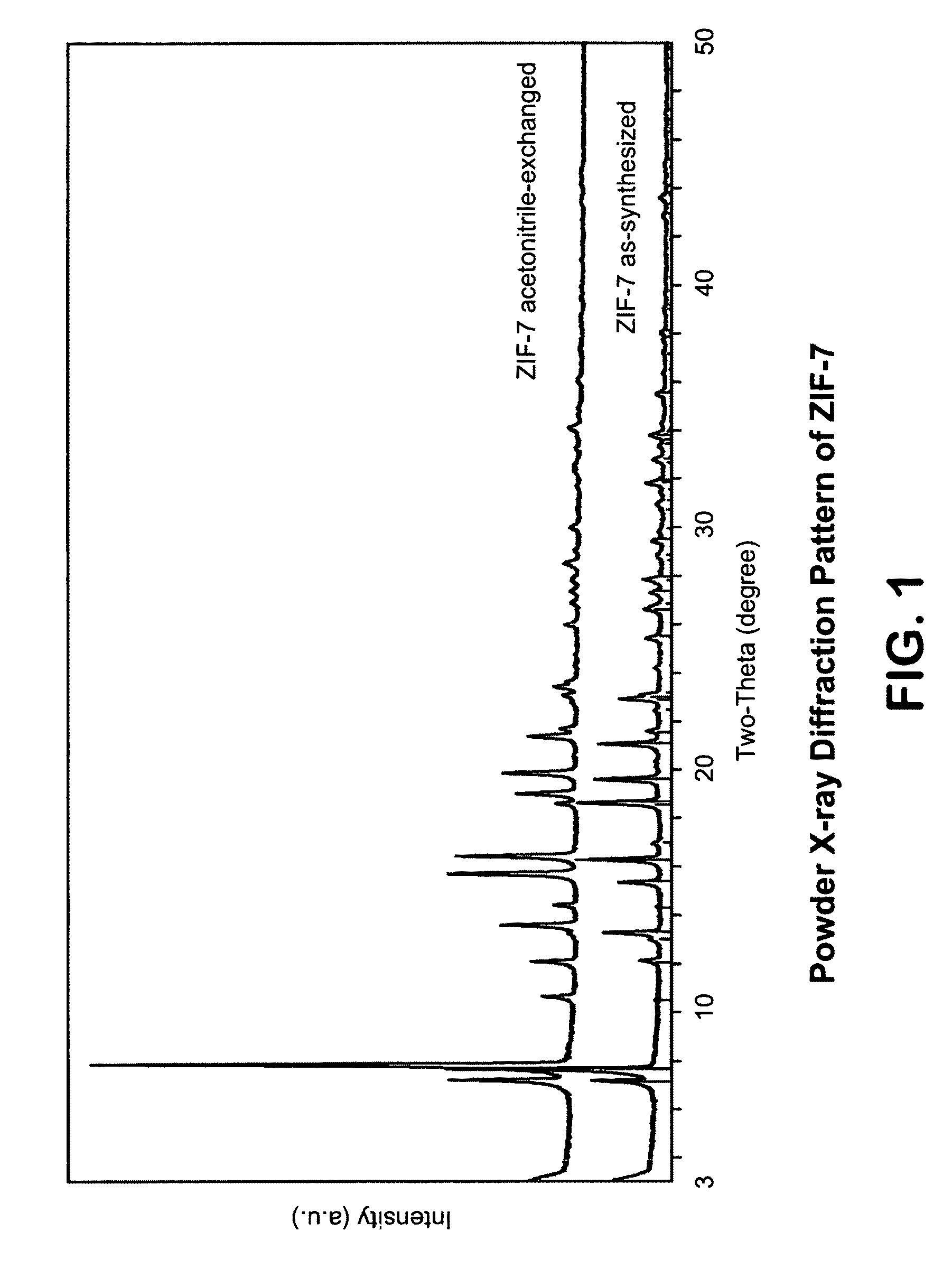

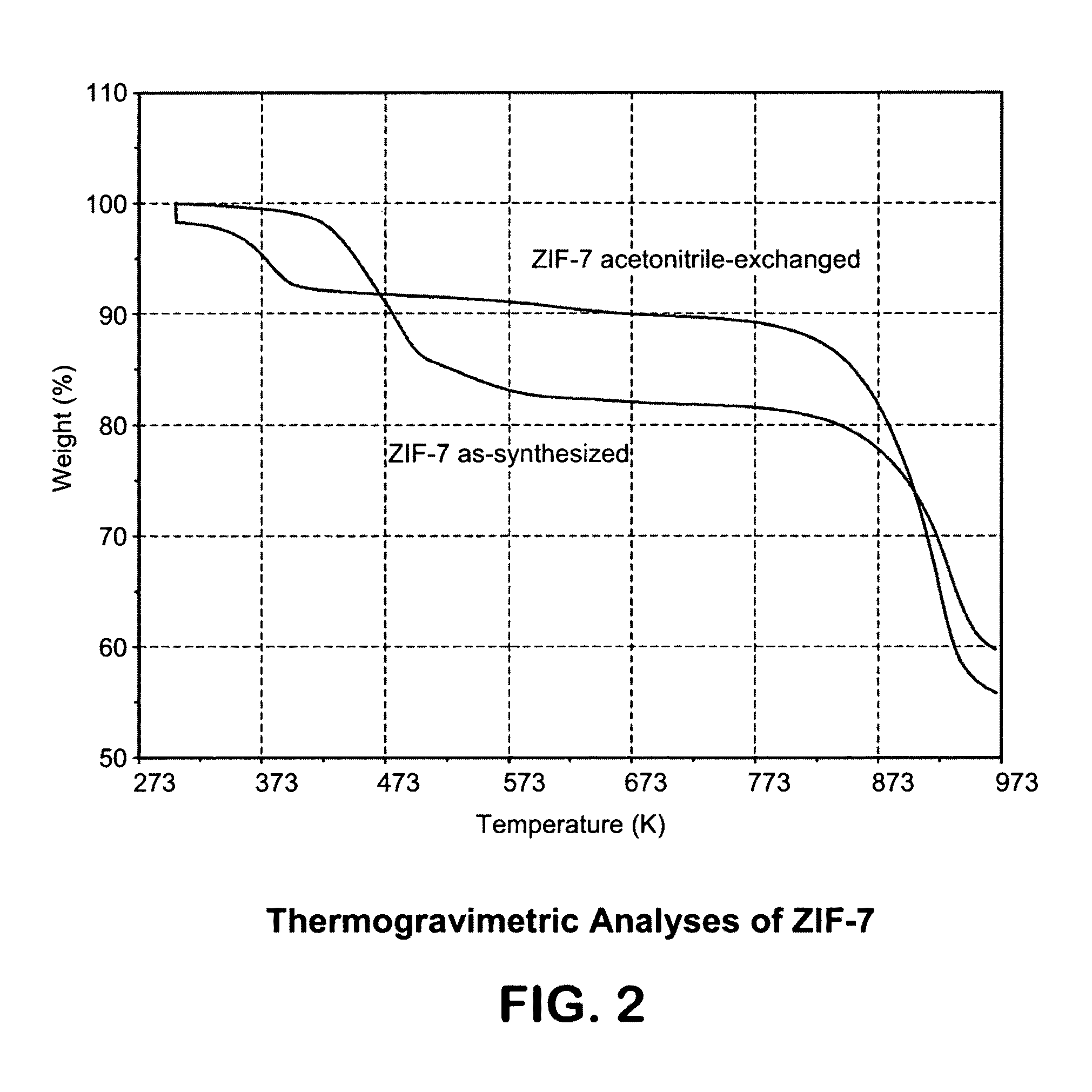

Separation of carbon dioxide from methane utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from methane (“CH4”) in streams containing both carbon dioxide and methane utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from natural gas streams preferably for sequestration of at least a portion of the carbon dioxide present in the natural gas.

Owner:EXXON RES & ENG CO

Hydrogen extraction unit

A hydrogen extraction unit has reformed gas flow channel plates, hydrogen separation plates, and purge gas flow channel plates, which are designed as thin metal plate members. The hydrogen extraction unit is constructed by laminating these thin plate members and then bonding them together by diffusion bonding. Each of reformed gas flow channel holes formed in the reformed gas flow channel plates constitutes a flow channel for reformed gas together with a correspondingly adjacent one of the hydrogen separation plates. Each of purge gas flow channel holes formed in the purge gas flow channel plates constitutes, together with a correspondingly adjacent one of the hydrogen separation plates, a flow channel for purge gas with which hydrogen extracted from reformed gas is mixed.

Owner:TOYOTA JIDOSHA KK

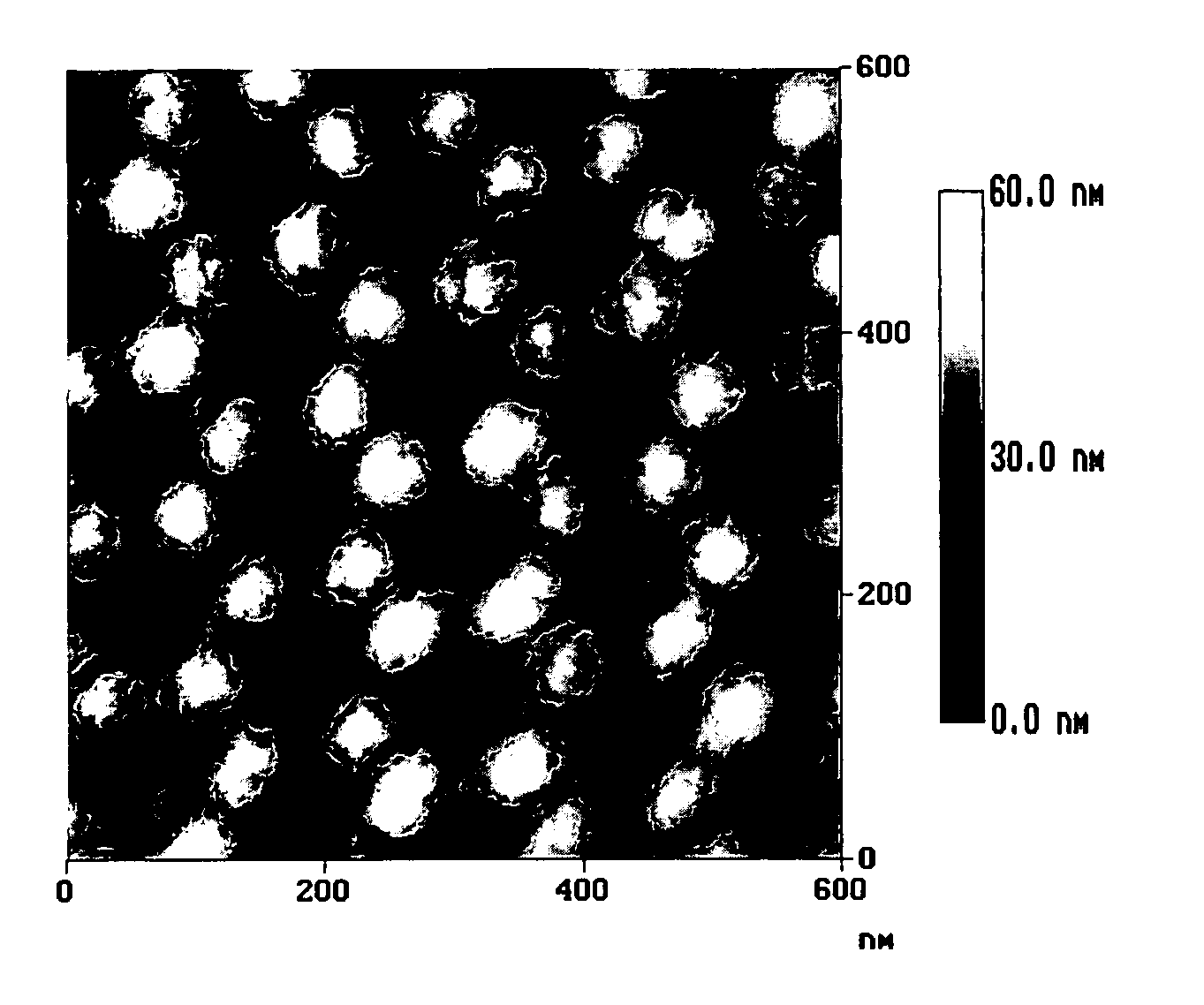

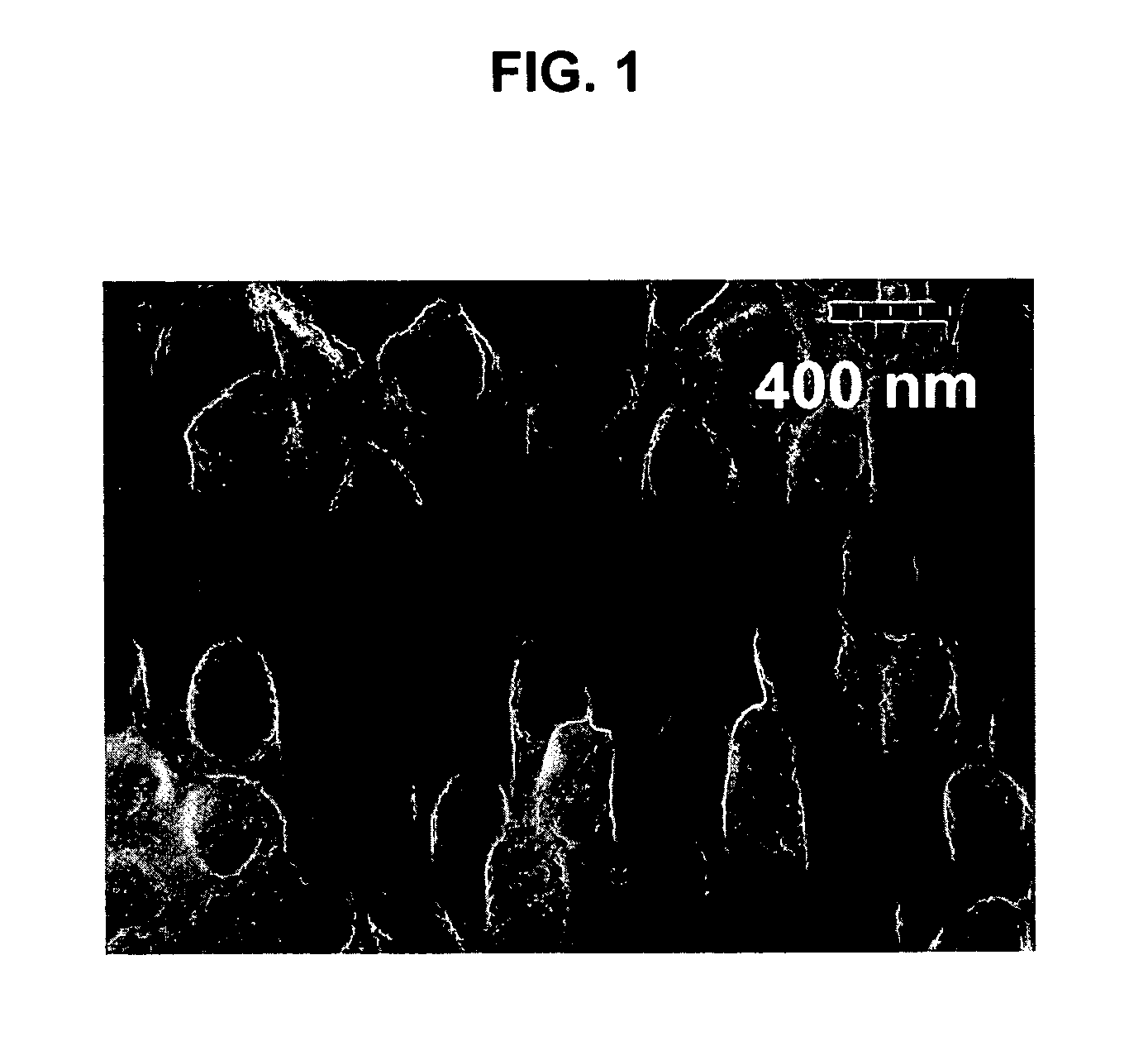

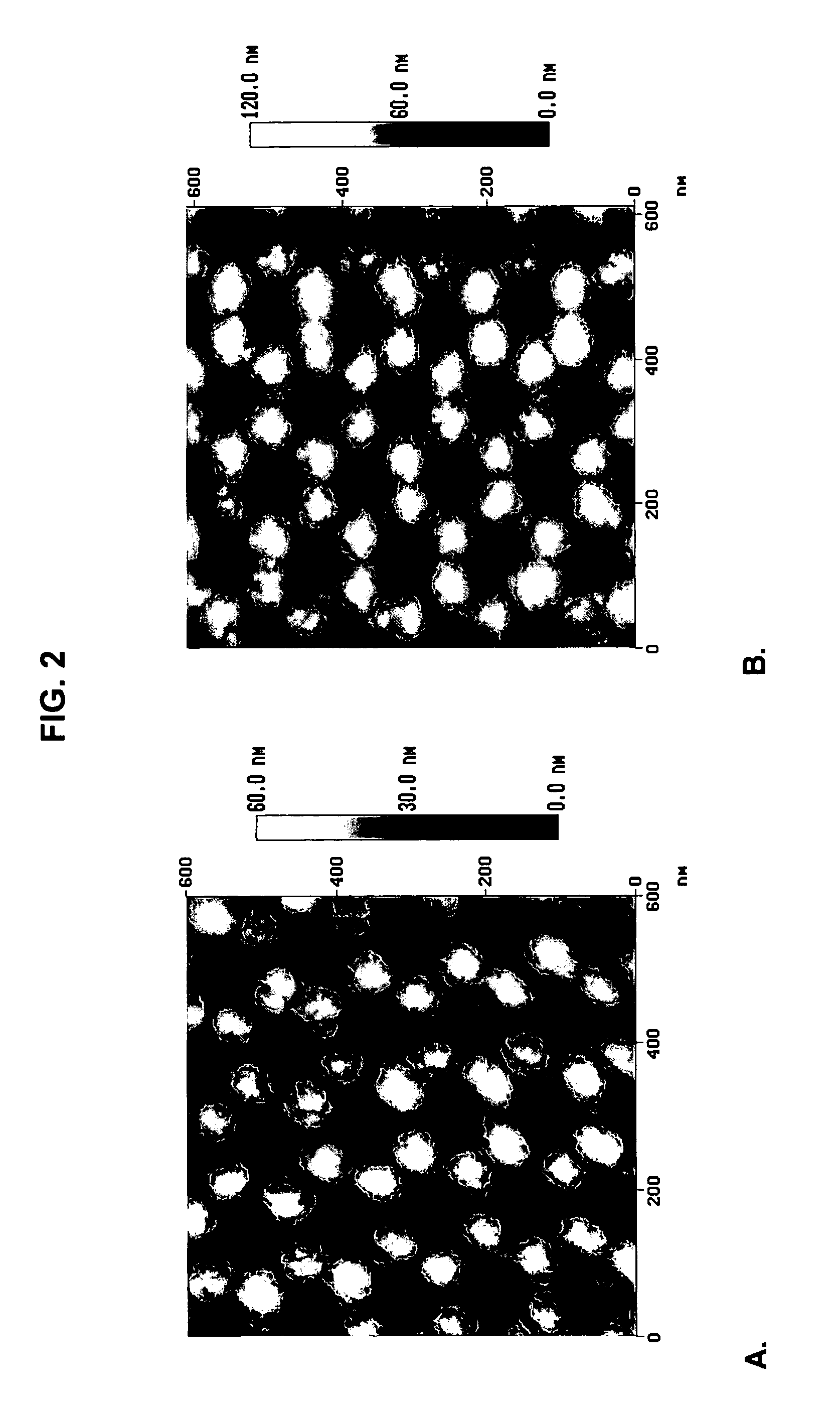

Nanostructures synthesized using anodic aluminum oxide

InactiveUS20060289351A1Simple methodEasy to makeMaterial nanotechnologyCoatingsHydrogen sensorNanostructure

This invention provides ways to fabricate nanotubes and nanobead arrays by utilizing nanopores in anodic aluminum oxide (AAO) membranes. Nanotubes of bismuth and other low melting point metals with controlled diameters and lengths can be fabricated by sintering AAO coated with appropriate metals at temperatures above their melting points. Carbon nanotubes may also be readily formed by carbonizing a polymer on the interior walls of the nanopores in AAO membranes. Palladium nanobead arrays which can be used as ultrafast hydrogen sensors are fabricated by coating the flat surface of AAO membranes with controlled pore-wall ratios.

Owner:UCHICAGO ARGONNE LLC

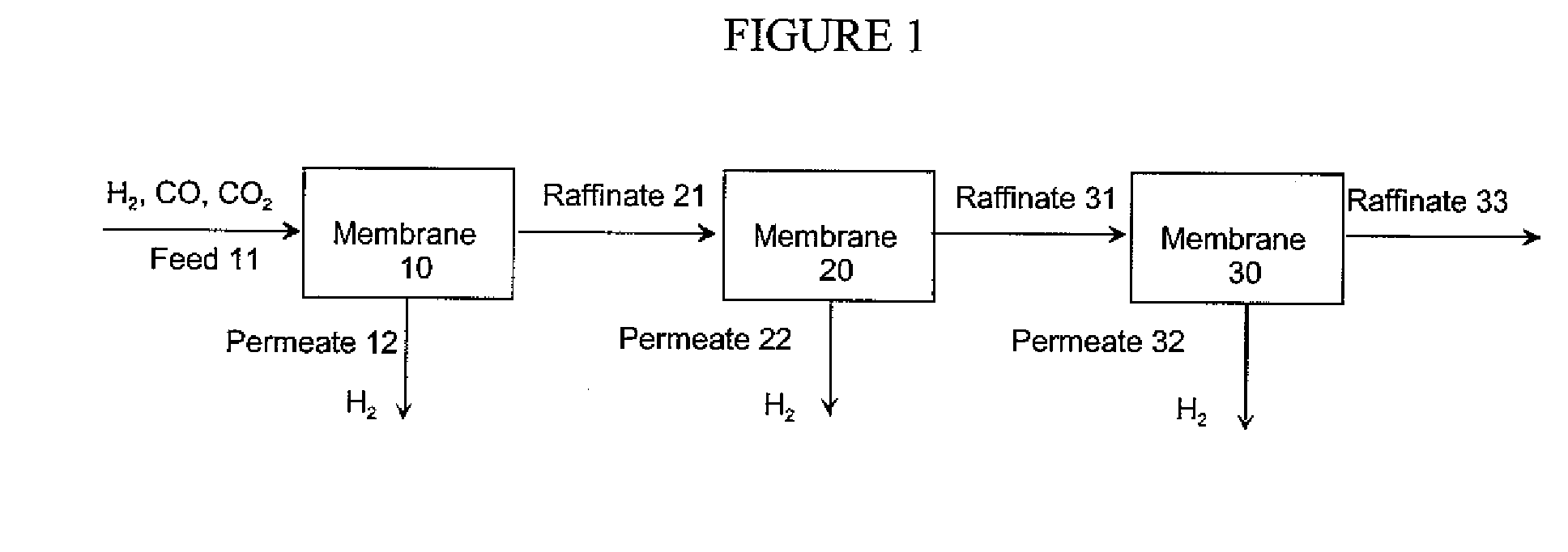

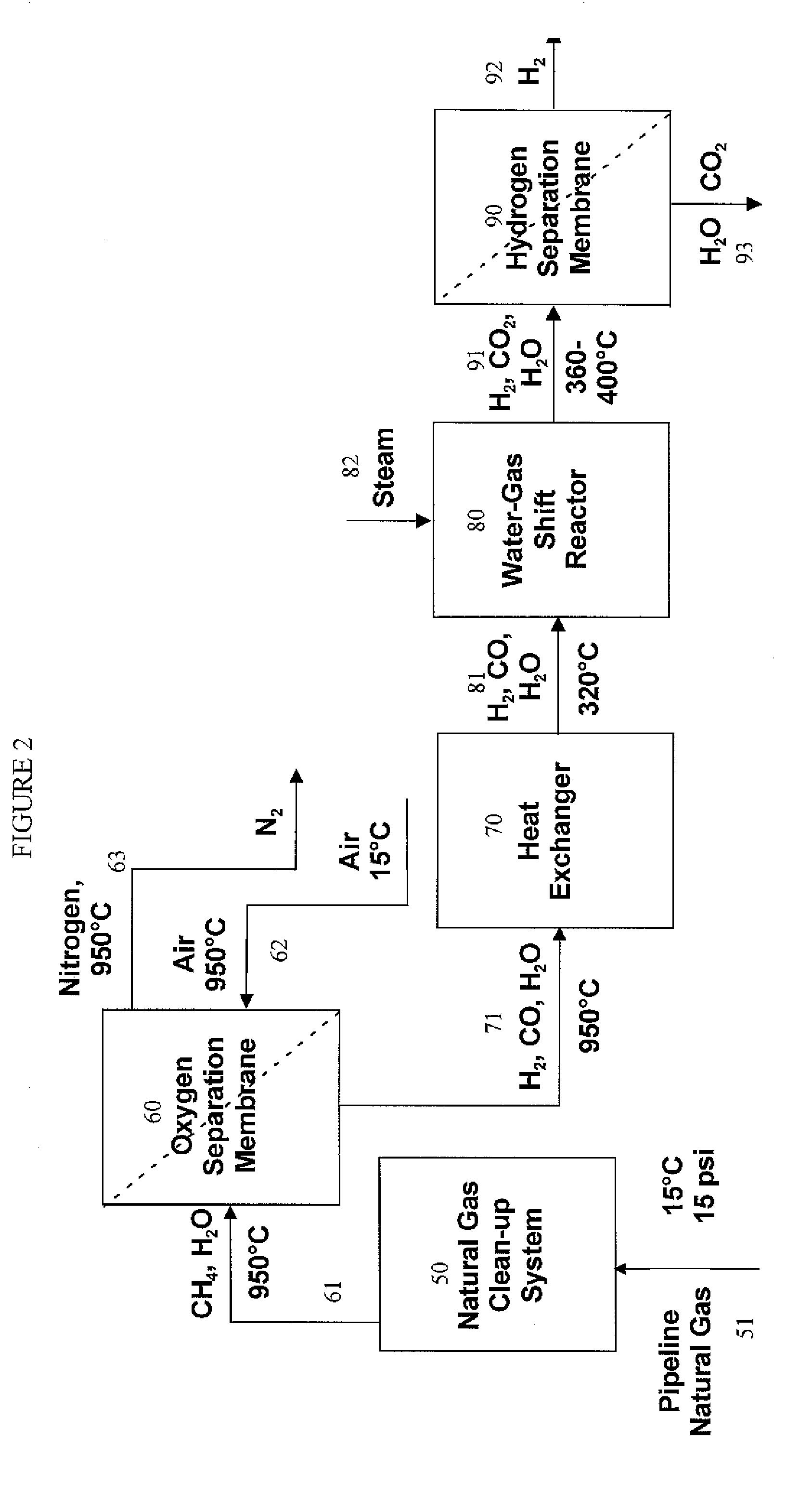

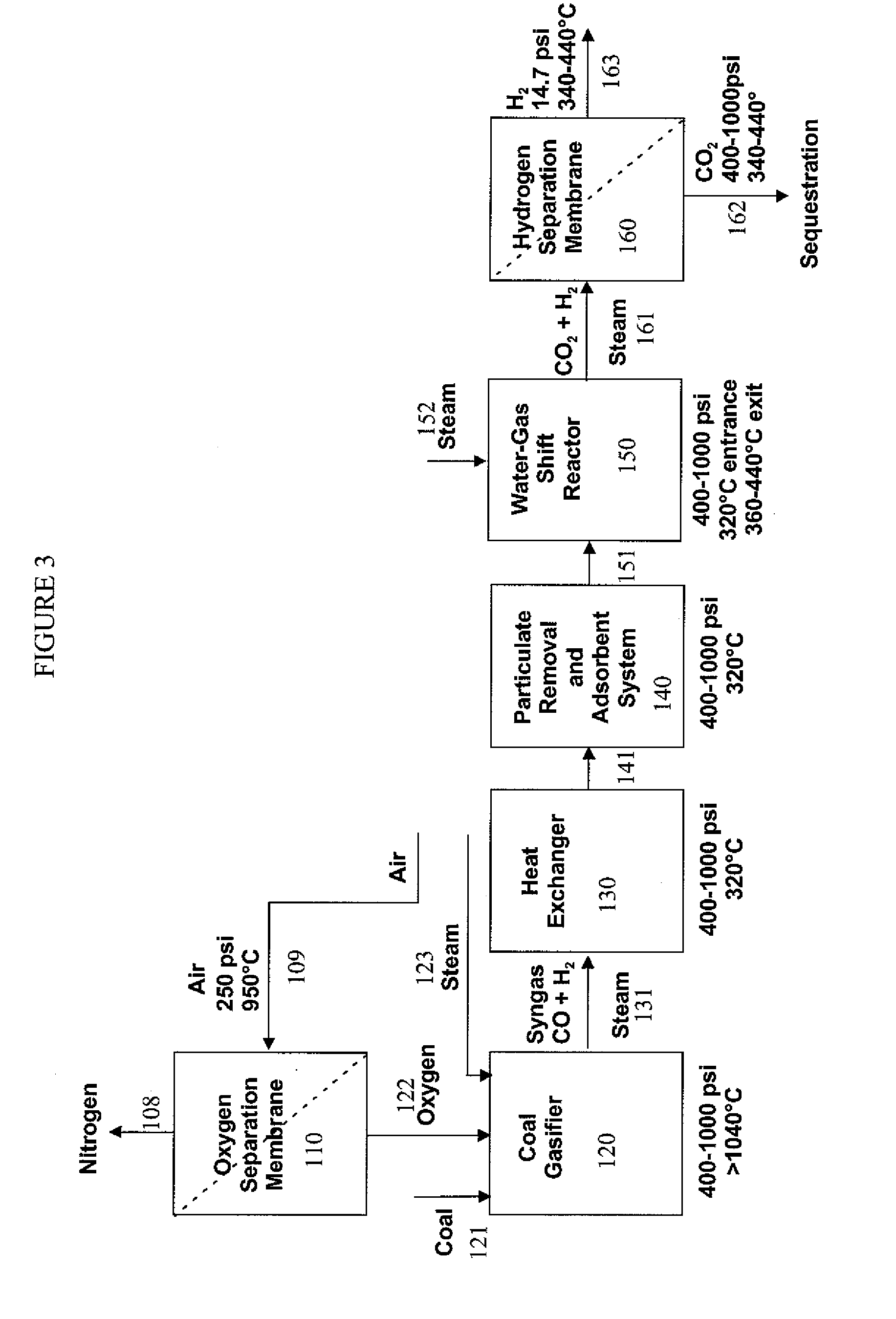

Hydrogen separation process

InactiveUS20080000350A1Isotope separationLoose filtering material filtersAmbient pressureInlet pressure

A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to a hydrogen separation membrane system comprising a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to an integrated water gas shift / hydrogen separation membrane system wherein the hydrogen separation membrane system comprises a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for pretreating a membrane, comprising: heating the membrane to a desired operating temperature and desired feed pressure in a flow of inert gas for a sufficient time to cause the membrane to mechanically deform; decreasing the feed pressure to approximately ambient pressure; and optionally, flowing an oxidizing agent across the membrane before, during, or after deformation of the membrane. A method of supporting a hydrogen separation membrane system comprising selecting a hydrogen separation membrane system comprising one or more catalyst outer layers deposited on a hydrogen transport membrane layer and sealing the hydrogen separation membrane system to a porous support.

Owner:ELTRON RES

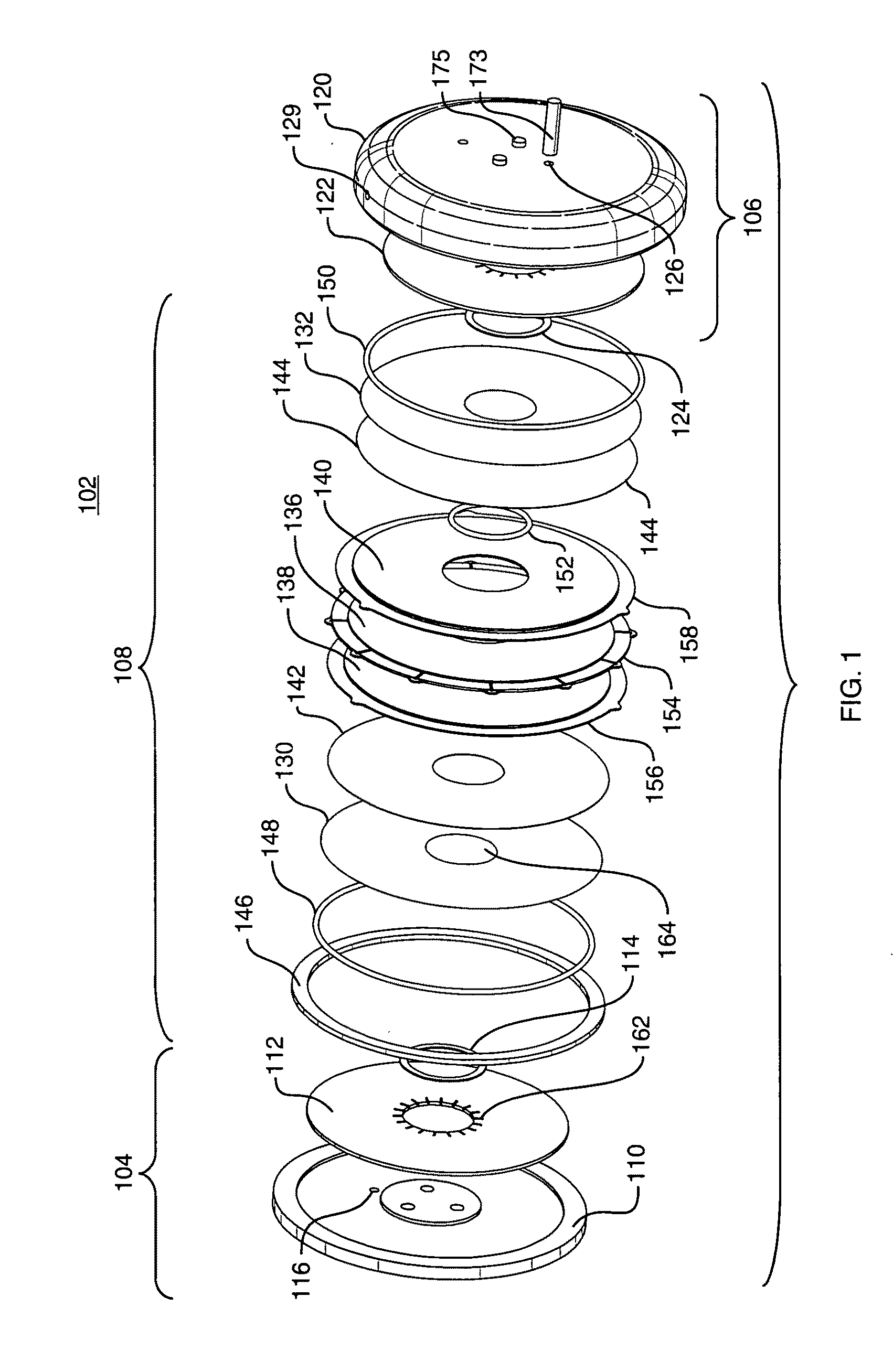

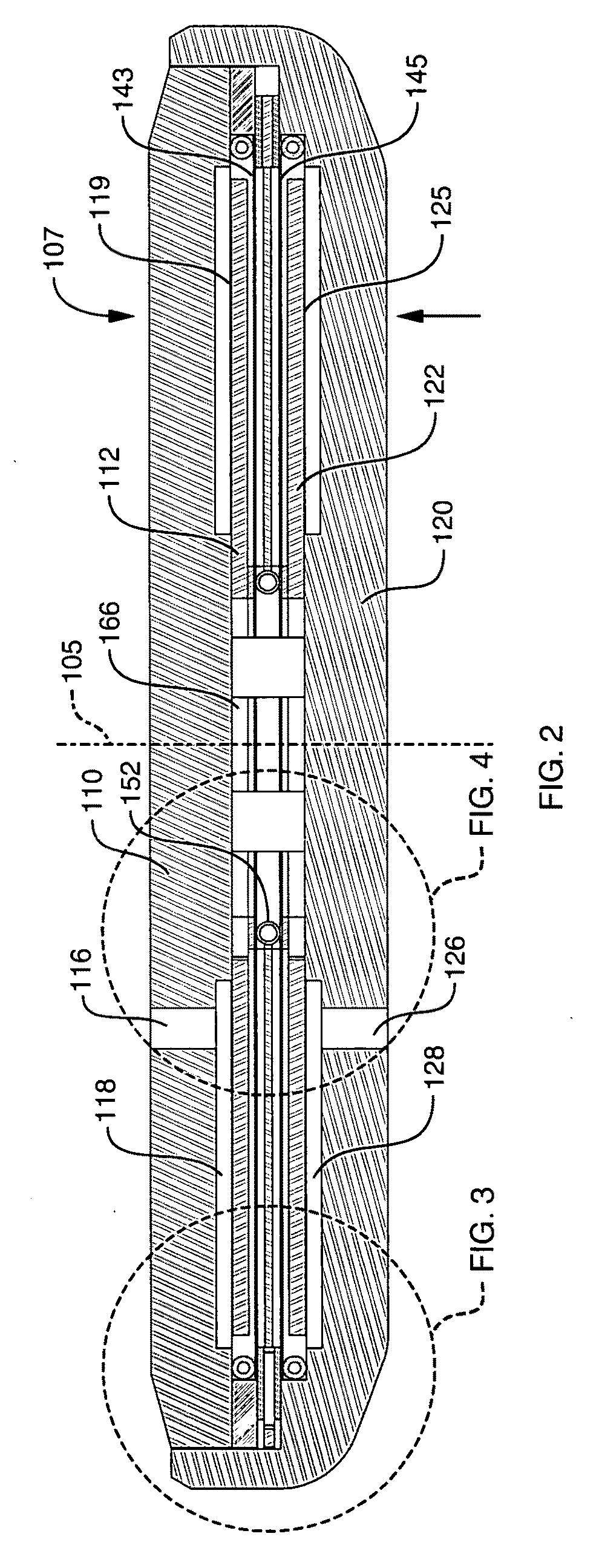

Membrane support module for permeate separation in a fuel cell

ActiveUS20100064887A1Simple structureAvoid breakingMembranesSemi-permeable membranesFuel cellsMembrane configuration

A gas separation unit 102, 200, 300 for permeating a gas out from a pressurized feed mixture includes an input manifold 104, 204, an exhaust manifold, 106, 206 and a permeate assembly 108, 208, 303. The permeate assembly supports one or more permselective foils 130, 132, 218, 232, 318 over a hollow cavity 134, 272, 306 supported by a microscreen element 142, 144, 228, 230, 326. The microscreen element includes non-porous perimeter walls 190, 192, 278 supported on a frame surface and a porous central area 194, 280 supported over the hollow cavity. A porous spacer 138, 140, 174, 234 disposed inside the hollow cavity structurally supports the entire microscreen surface spanning the hollow cavity while also providing a void volume for receiving fluid passing through the porous central area and for conveying the fluid through the hollow cavity.

Owner:SILICON VALLEY BANK

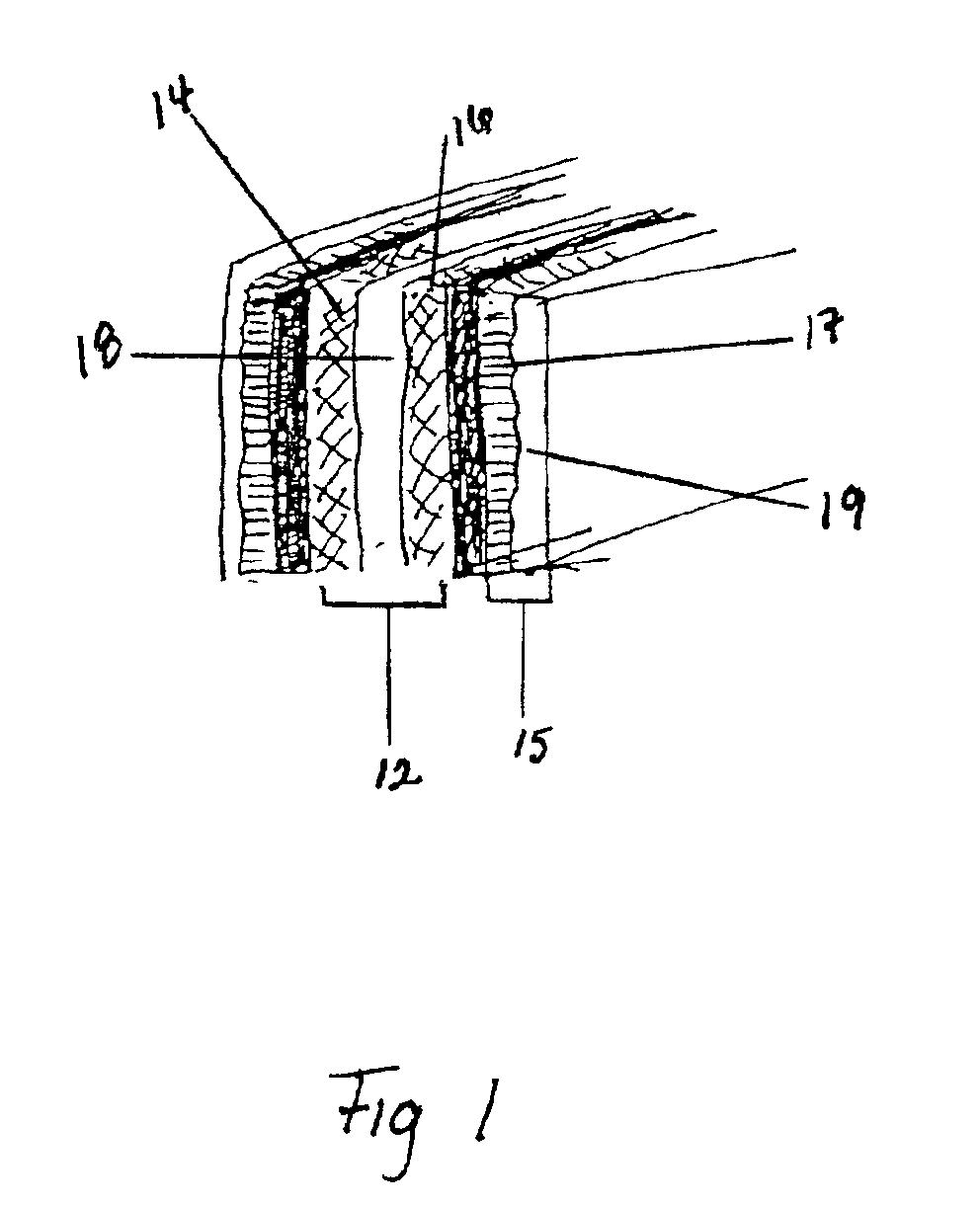

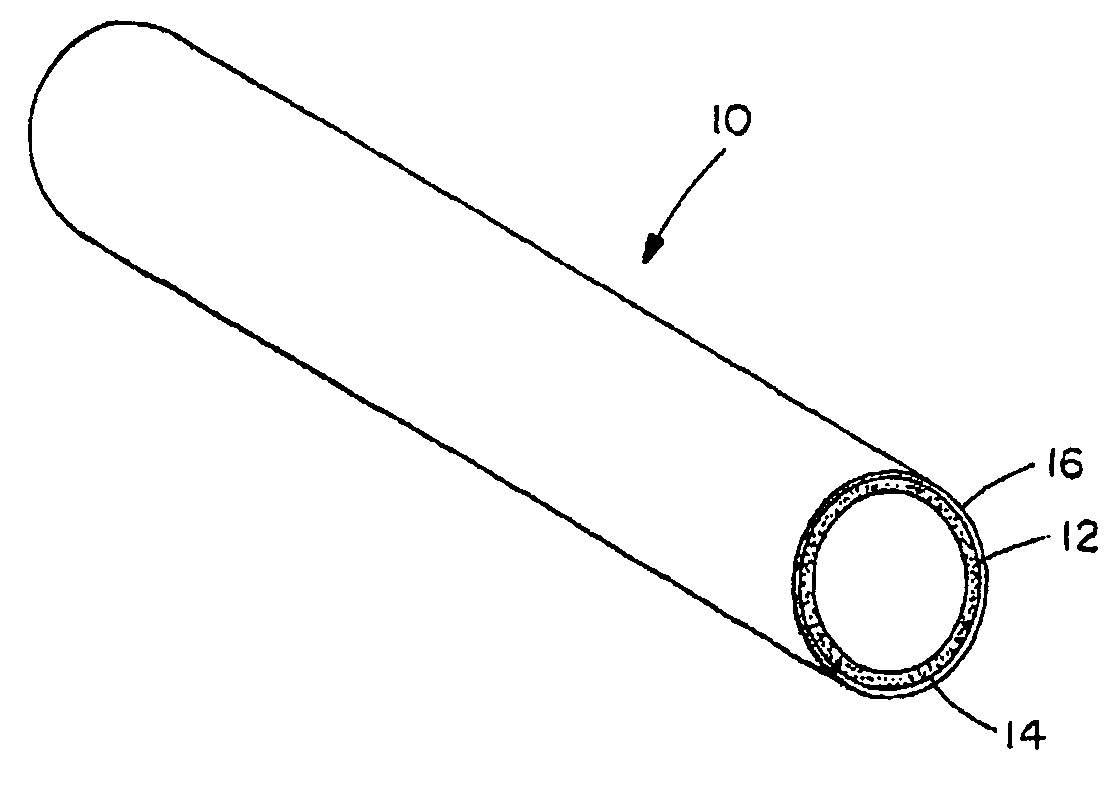

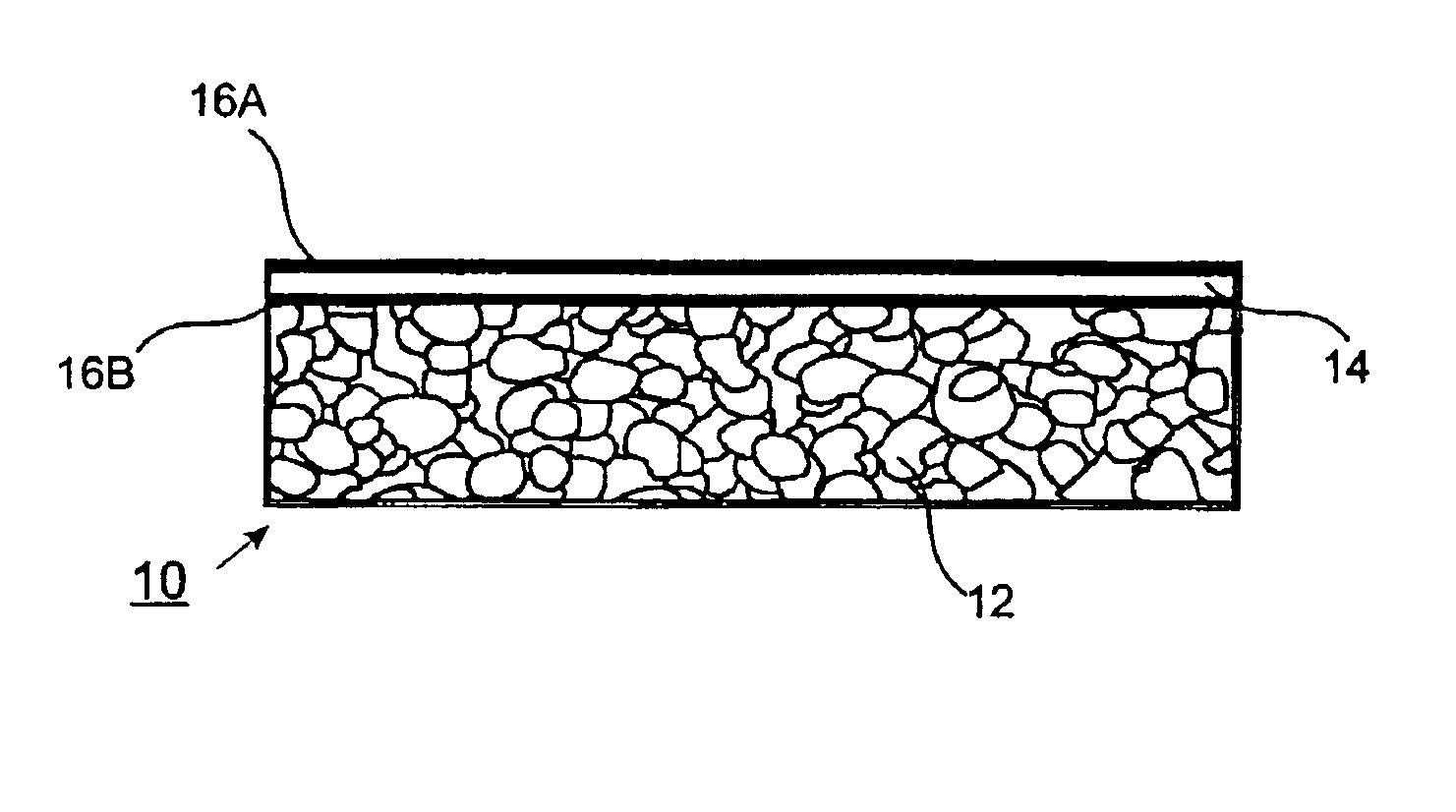

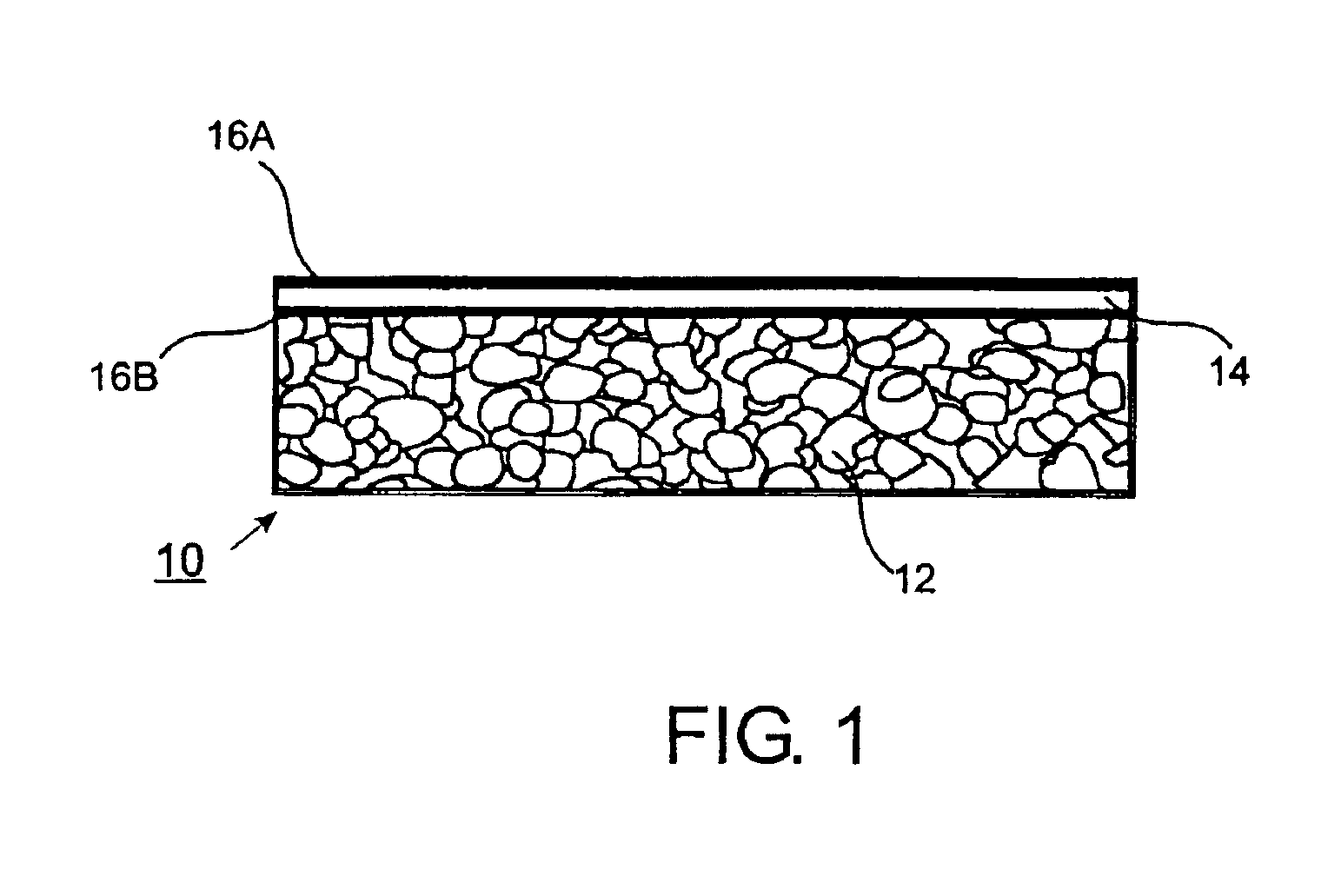

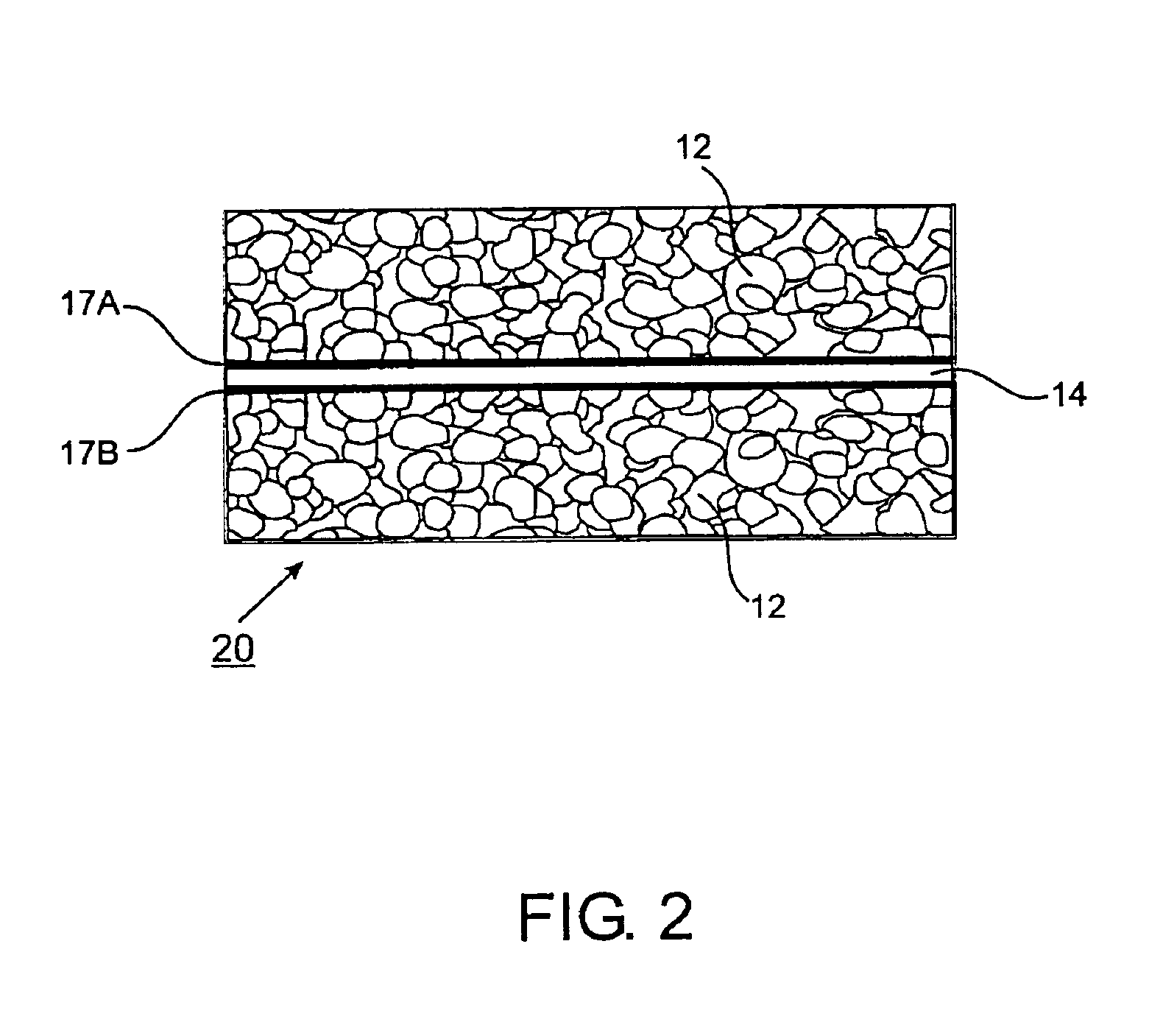

Composite gas separation modules having intermediate porous metal layers

InactiveUS7175694B2Reduce fluxControl performanceMembranesSemi-permeable membranesHydrogenProduct gas

The present invention relates to a composite gas separation module and to methods for fabricating a composite gas separation module. The present invention also relates to methods for selectively separating hydrogen gas from a hydrogen gas-containing gaseous stream. In one embodiment, the composite gas separation module includes a porous metal substrate; an intermediate porous metal layer, wherein the intermediate porous metal layer overlies the porous metal substrate; and a dense hydrogen-selective membrane, wherein the dense hydrogen-selective membrane overlies the intermediate porous metal layer. The intermediate porous metal layer can include palladium and a Group IB metal. For example, the intermediate porous metal layer can contain alternating layers of palladium and a Group IB metal.

Owner:WORCESTER POLYTECHNIC INSTITUTE

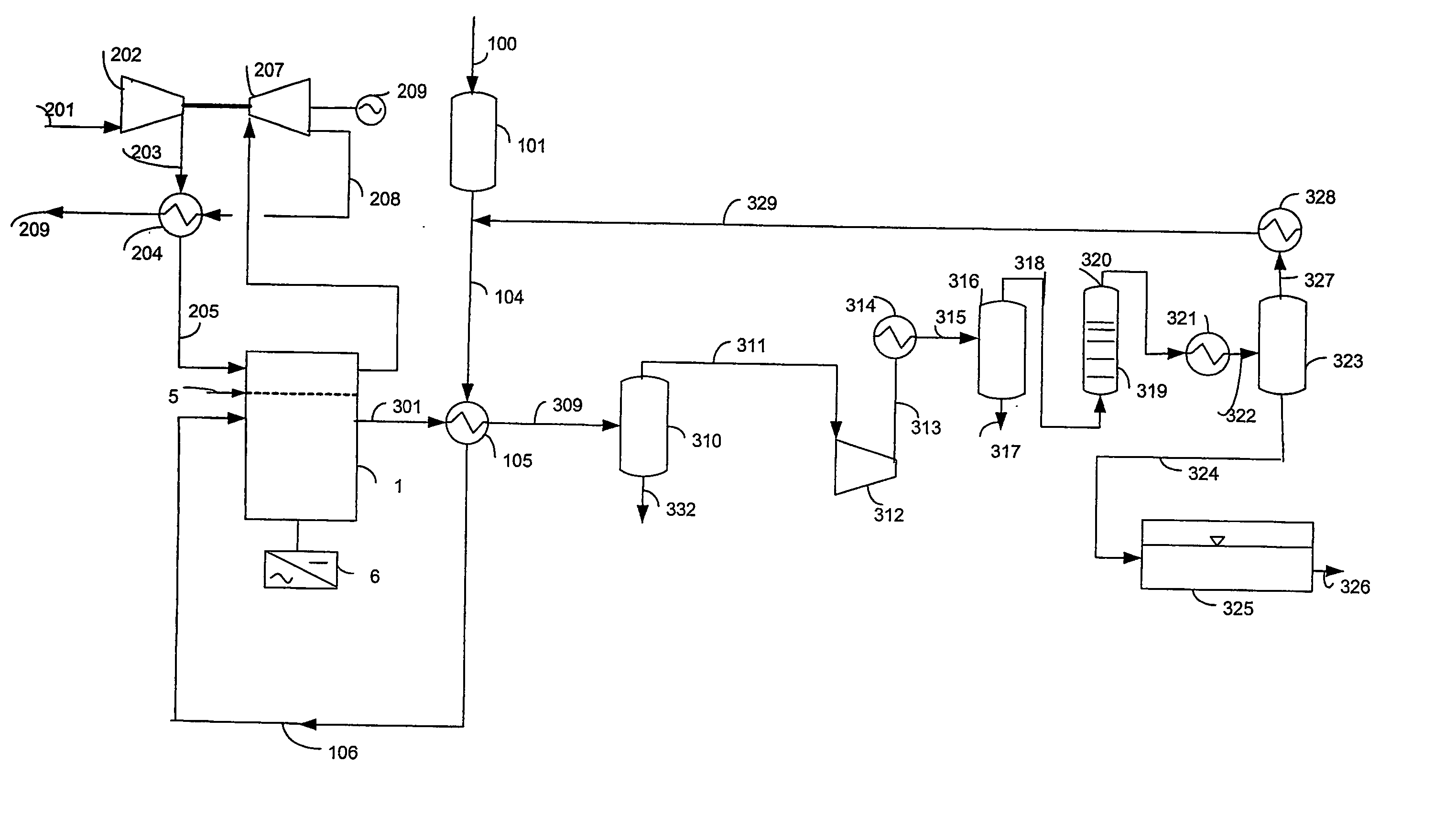

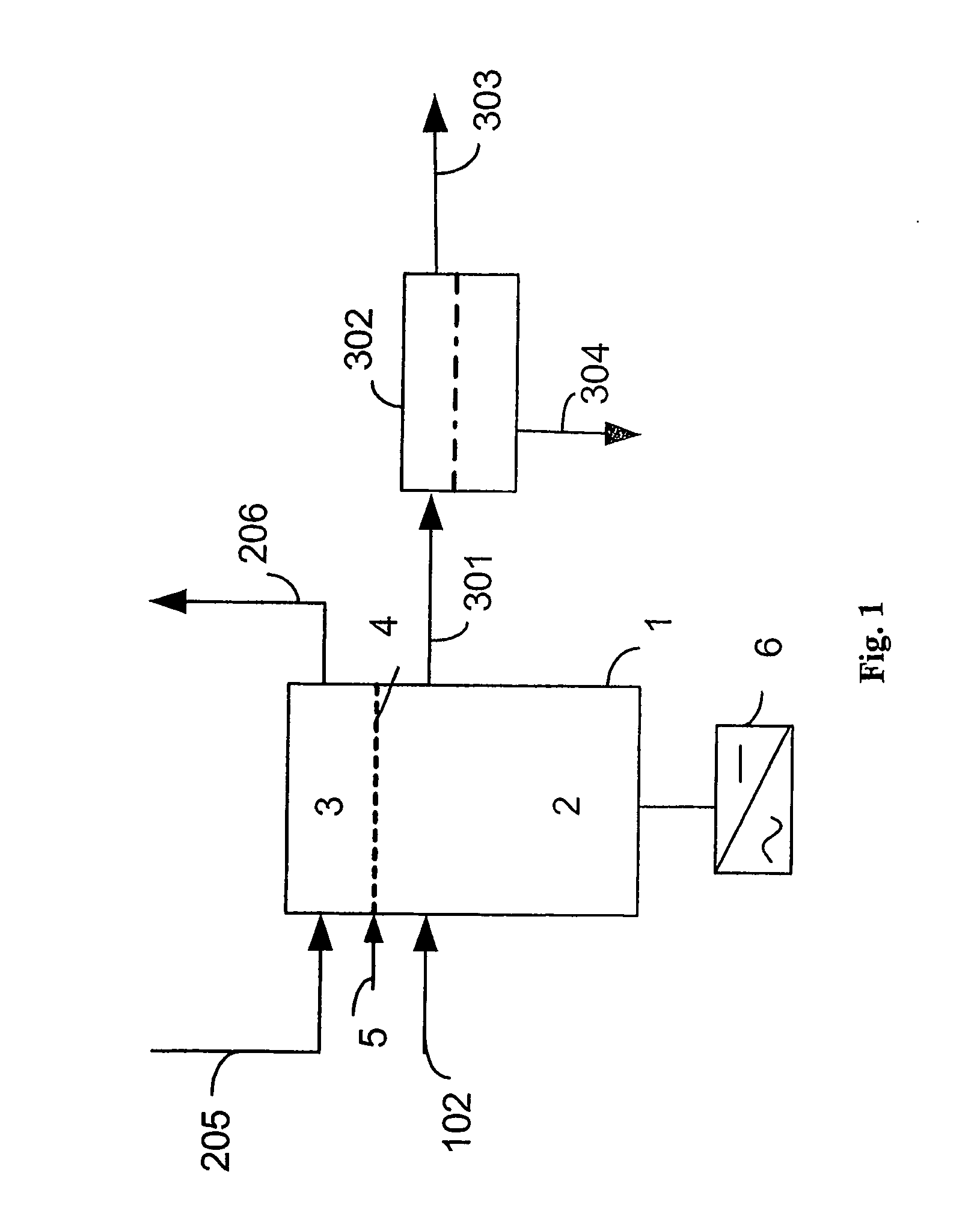

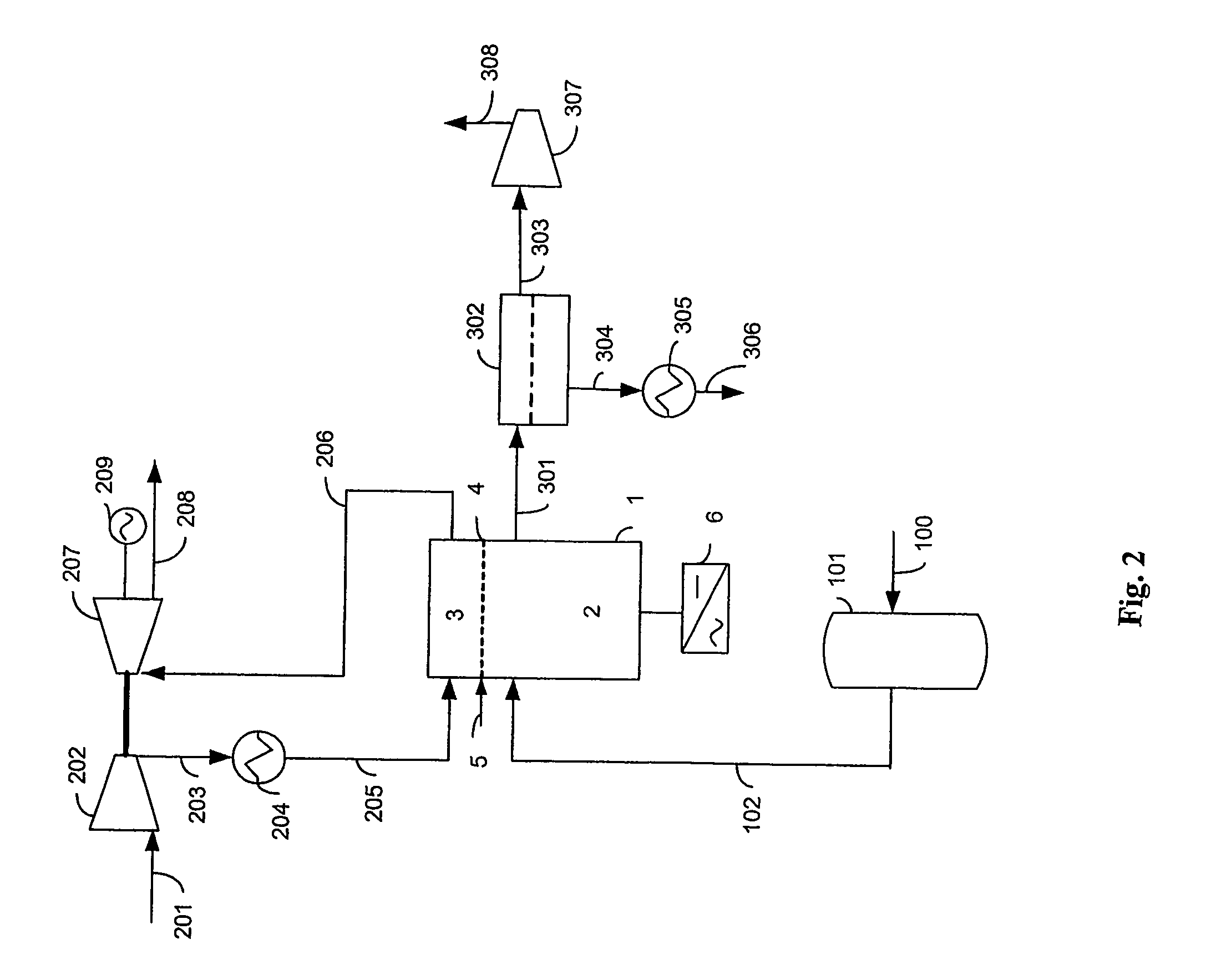

Method for exhaust gas treatment in a solid oxide fuel cell power plant

InactiveUS20060115691A1Improve electricity efficiencySimple and preferably cheapSolidificationLiquefactionFuel cellsPower station

The invention relates to anode exhaust gas treatment methods for solid oxide fuel cell power plants with CO2 capture, in which the unreacted fuel in the anode exhaust (301) is recovered and recycled, while the resulting exhaust stream (303) consists of highly concentrated CO2. It is essential to the invention that the anode fuel gas (102) and the cathode air (205) are kept separate throughout the solid oxide fuel cell stacks (1). A gas turbine (202,207) is included on the air side in order to maximise the electrical efficiency.

Owner:AKER KVRNER ENG & TECH

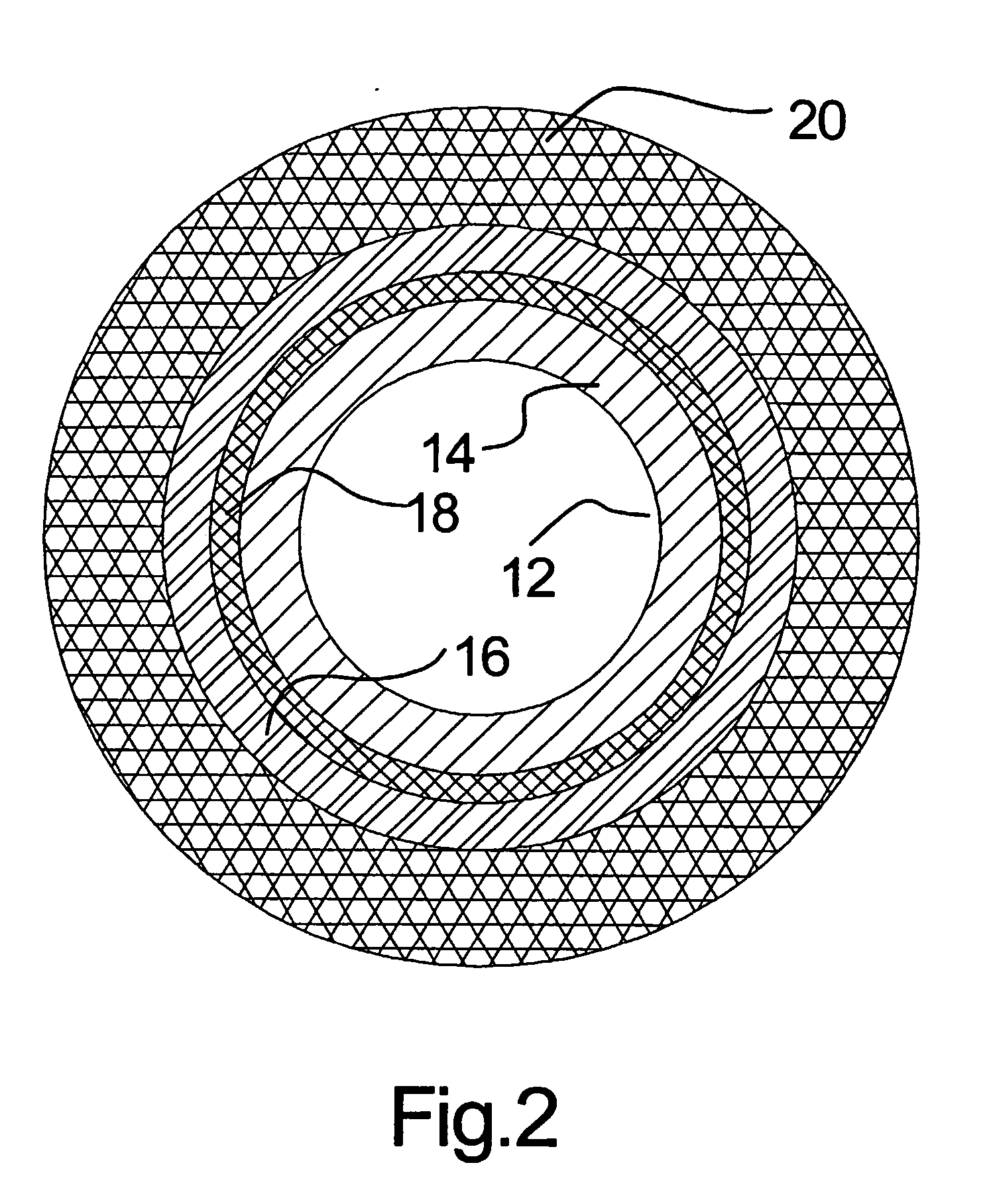

Dense, layered membranes for hydrogen separation

InactiveUS7001446B2Detrimental interdiffusionMinimize interdiffusionMembranesSemi-permeable membranesReactor systemProduct gas

This invention provides hydrogen-permeable membranes for separation of hydrogen from hydrogen-containing gases. The membranes are multi-layer having a central hydrogen-permeable layer with one or more catalyst layers, barrier layers, and / or protective layers. The invention also relates to membrane reactors employing the hydrogen-permeable membranes of the invention and to methods for separation of hydrogen from a hydrogen-containing gas using the membranes and reactors. The reactors of this invention can be combined with additional reactor systems for direct use of the separated hydrogen.

Owner:ELTRON RES

Hydrogen transport membranes

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

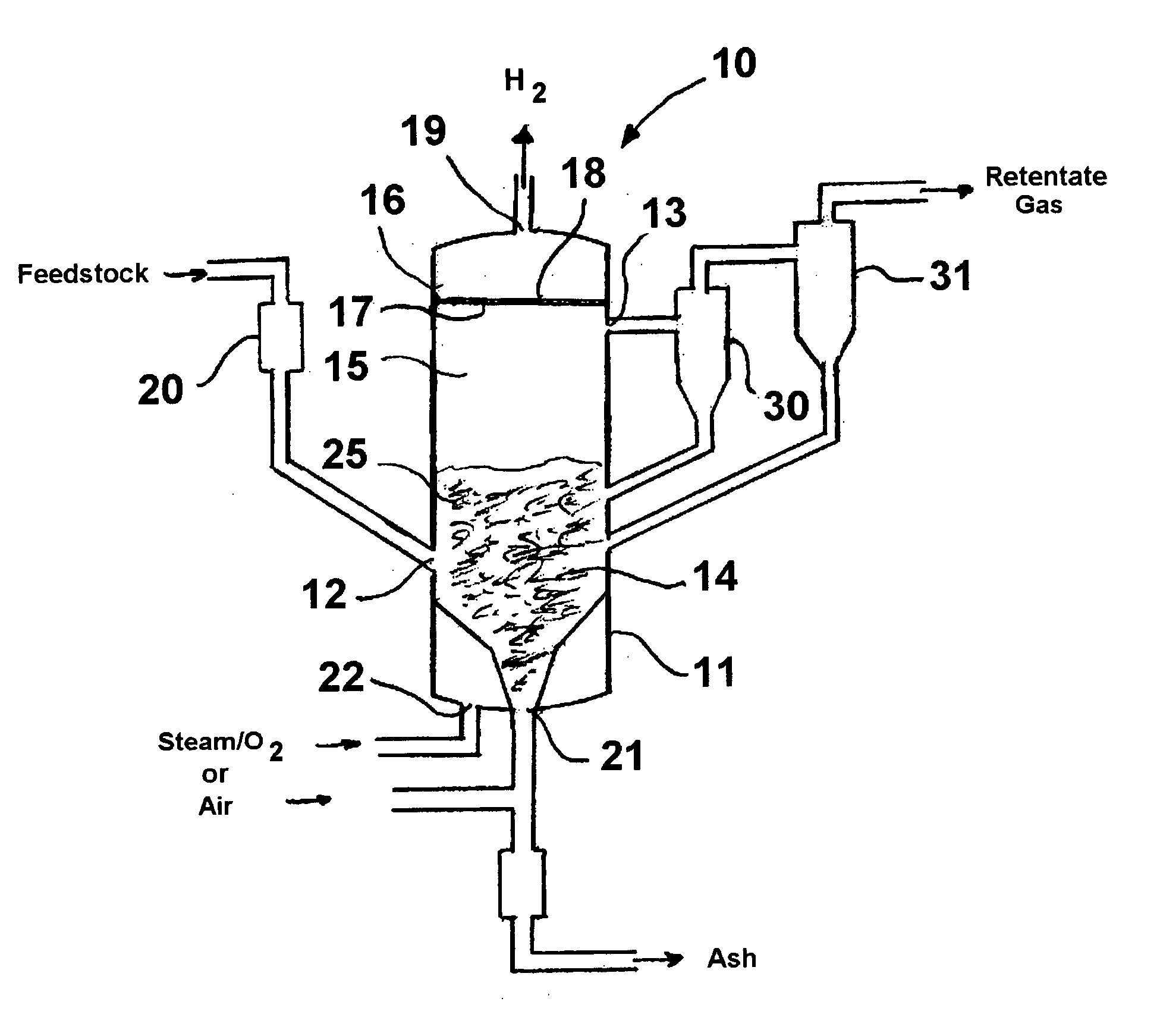

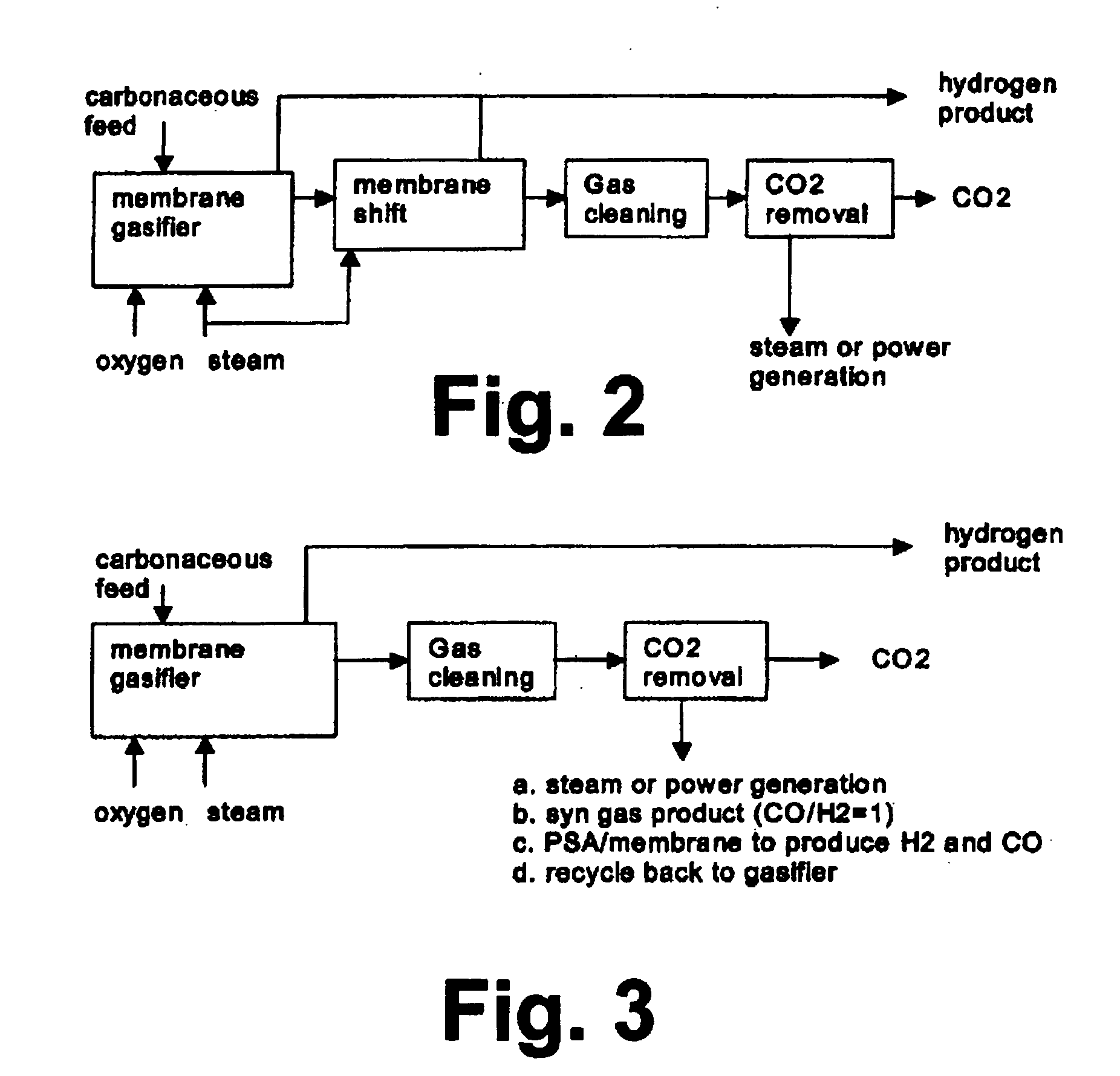

Hydrogen production process from carbonaceous materials using membrane gasifier

InactiveUS20050039400A1Improve thermal efficiencySmall sizeGasifier mechanical detailsHydrogen/synthetic gas productionPermeationThermal efficiency

A method and apparatus for producing hydrogen from carbonaceous materials using a hydrogen-selective permeation membrane incorporated into a carbonaceous material reactor, as a result of which, hydrogen production rate from the reactor is increased, downstream gas cleaning and purification units of conventional systems are eliminated or substantially reduced in size, and the thermal efficiency of producing hydrogen from carbon-containing materials is increased and its production cost is reduced.

Owner:GAS TECH INST

Tubular solid oxide fuel cell stack

This invention relates to a stack comprising a continuous solid-phase matrix and tubular fuel cells embedded in the matrix. Each fuel cell comprises an inner electrode layer, an outer electrode layer, and an electrolyte layer sandwiched between the inner and outer electrode layers. The matrix is sufficiently porous to allow a first reactant to flow through the matrix and to the outer electrode of each fuel cell, and have sufficient mechanical strength to support the fuel cells in the stack. The fuel cells are embedded such that a second reactant may be flowed through the inside of each tubular fuel cell and to the inner electrode thereof. Alternatively, a stack of tubular separation membranes or a stack of tubular membrane reactors may be embedded in the matrix. The matrix material may comprise solid state foam, metal filament, or metal, cermet, or ceramic wool.

Owner:INNOTECH ALBERTA INC

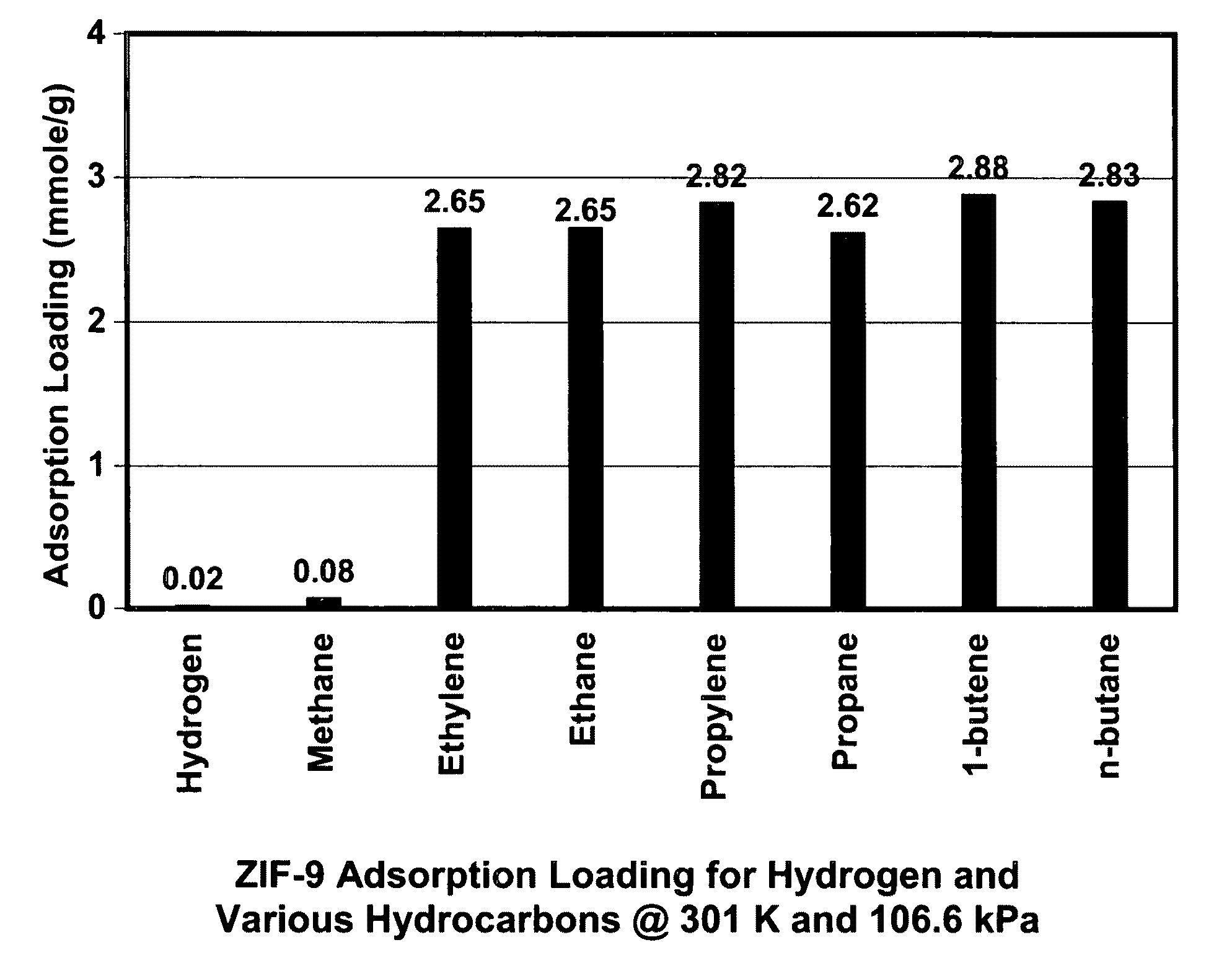

Separation of hydrogen from hydrocarbons utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of hydrogen (“H2”) hydrocarbons in streams containing both hydrogen and hydrocarbons (e.g. methane, ethylene, ethane, propylene, propane, etc.) utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in either a pressure swing adsorption process, a temperature swing adsorption process, or a membrane separations process to separate hydrogen from hydrocarbons present in hydrogen production streams or petrochemical / petroleum refining product streams and intermediate streams.

Owner:EXXON RES & ENG CO

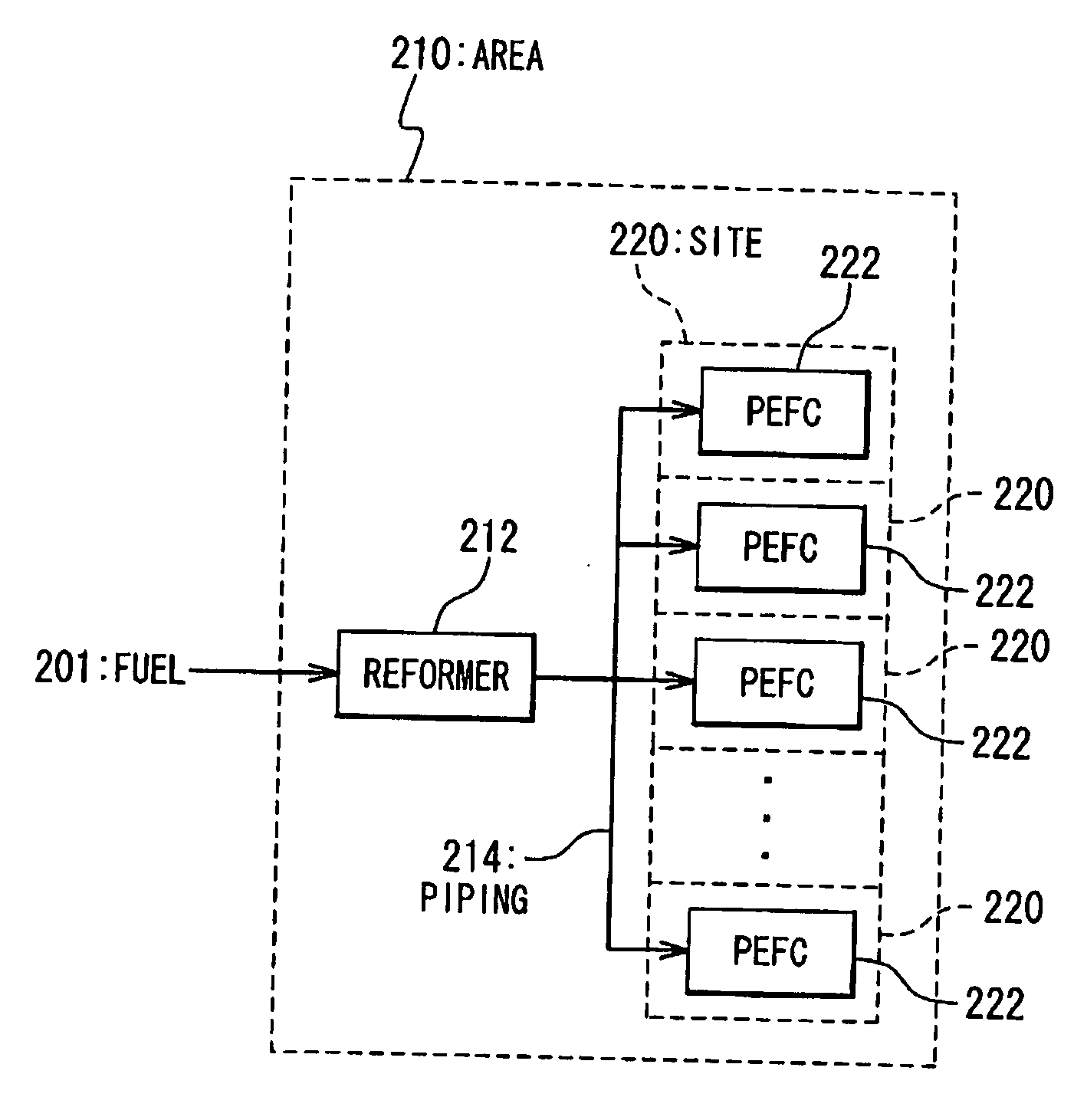

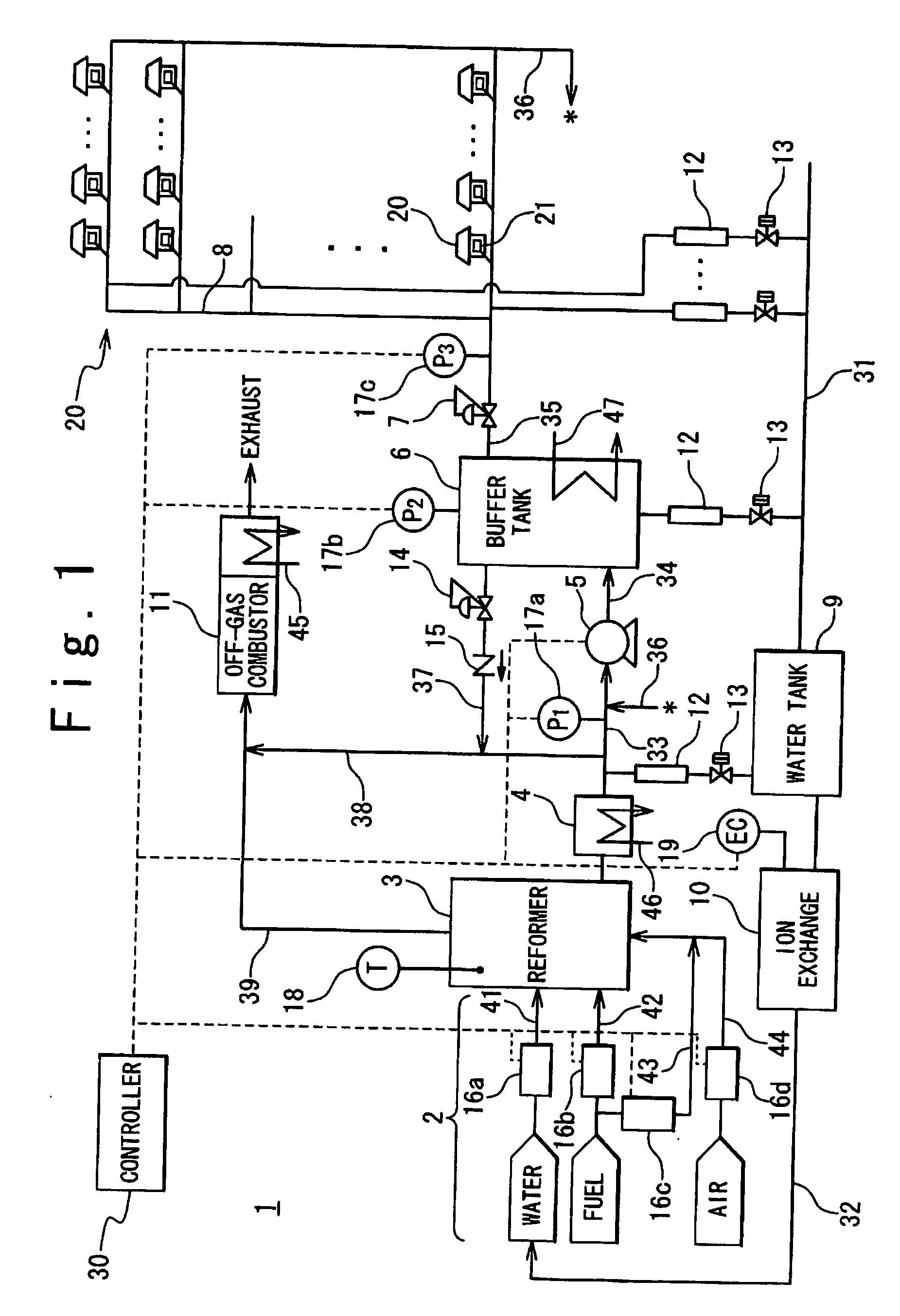

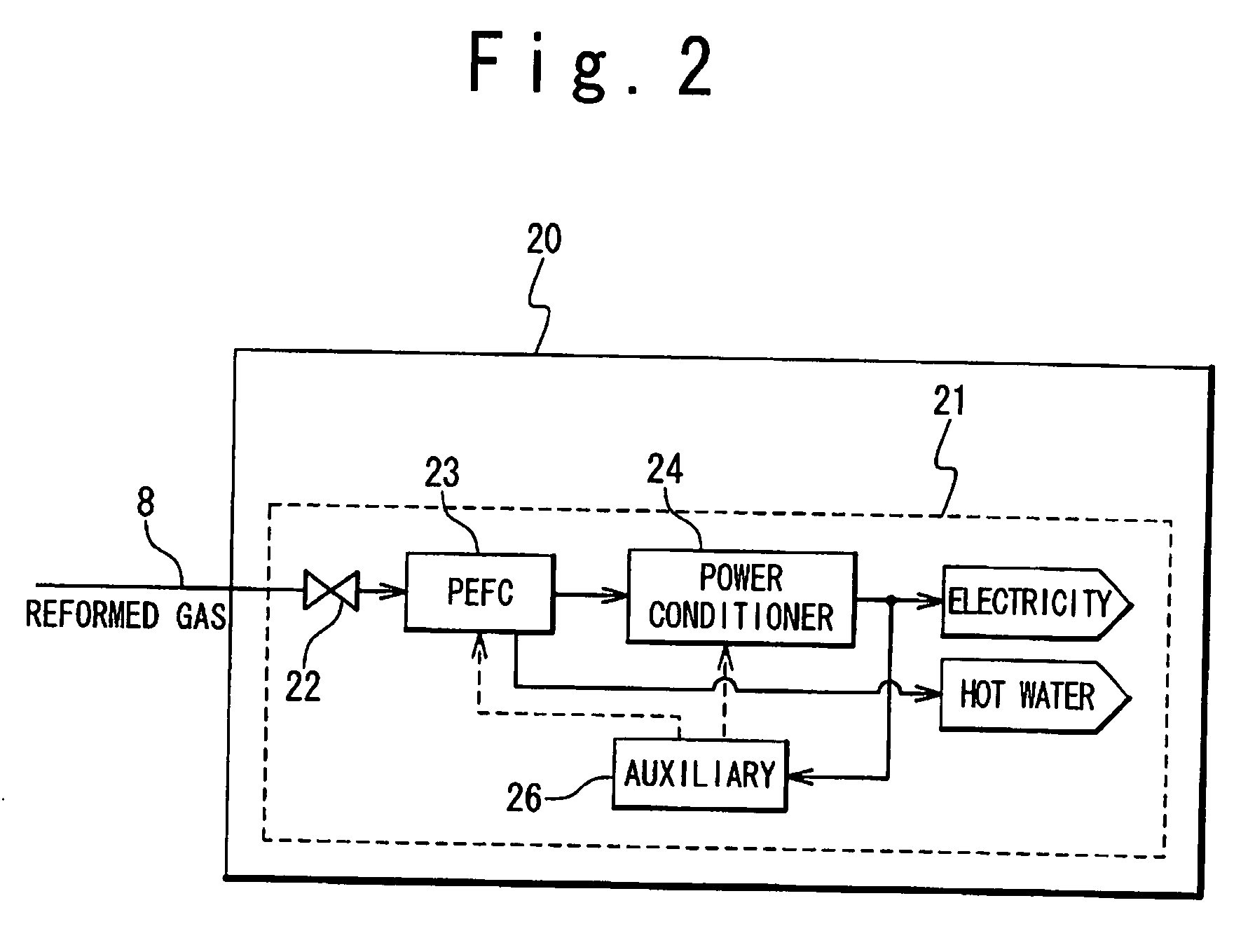

Gas supplying system and gas supplying method

A gas supplying system for fuel cell includes a reformer generating a reformed gas by reforming a mixed raw material including a fuel and a first water, a piping network distributing the reformed gas to fuel cell systems each of which is installed in different rooms or buildings, a drain recovery unit recovering a water condensed from the reformed gas in the piping network. The piping network has a circulating route. By the circulation route, the reformed gas does not stay in the piping network so that the water condensation in the piping is suppressed. The water in the piping is removed by the drain recovery unit. According to this configuration, the clogging and corrosion of the piping caused by the condensed water is avoided.

Owner:MITSUBISHI HEAVY IND LTD

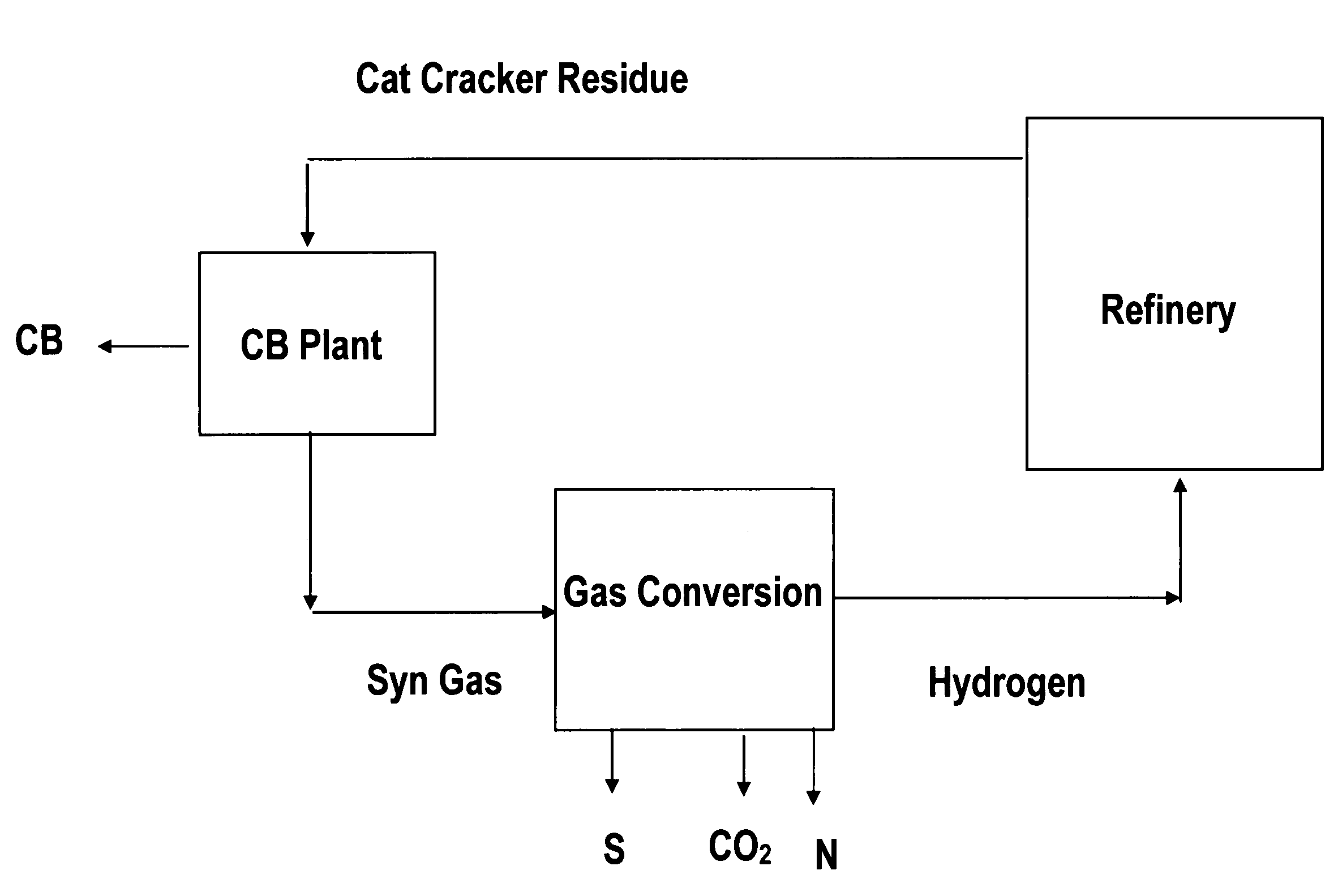

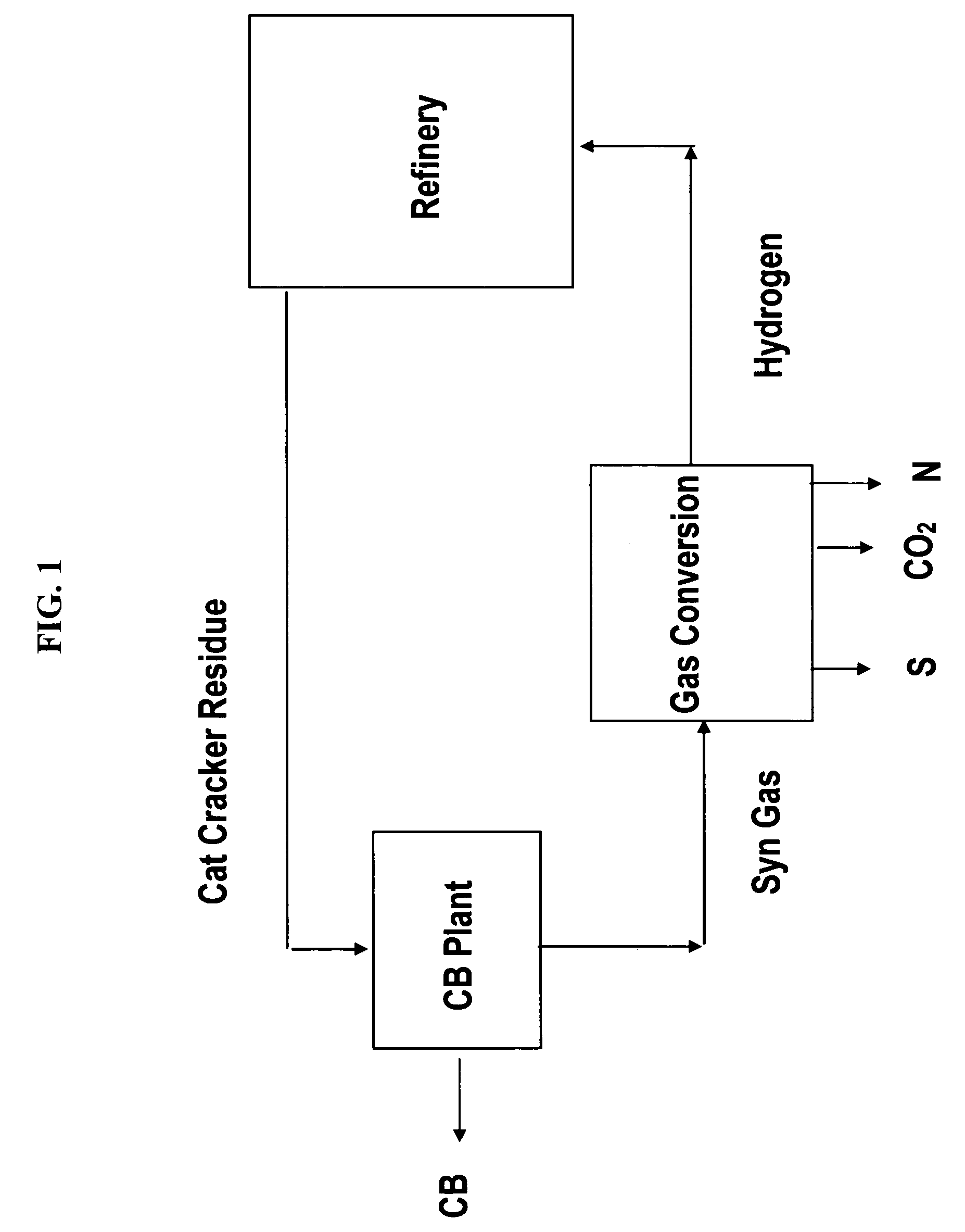

Method to produce hydrogen or synthesis gas and carbon black

InactiveUS7666383B2Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenOil refinery

Owner:CABOT CORP

Popular searches

Solid electrolyte fuel cells Motive system fuel cells Hydrogen separation by diffusion Evaporation apparatus Iron oxides/hydroxides Chemical industry Chemical/physical/physico-chemical stationary reactors Liquid-gas reaction processes Transportation fuel cell technology Transportation hydrogen technology

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com