Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Hydrogen transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen pipeline transport is used to transport hydrogen from the point of production or delivery to the point of demand. Piping. Hydrogen has problems with both hydrogen embrittlement and corrosion. Hydrogen has an active electron, and therefore behaves somewhat like a halogen. For this reason, hydrogen pipes have to resist corrosion.

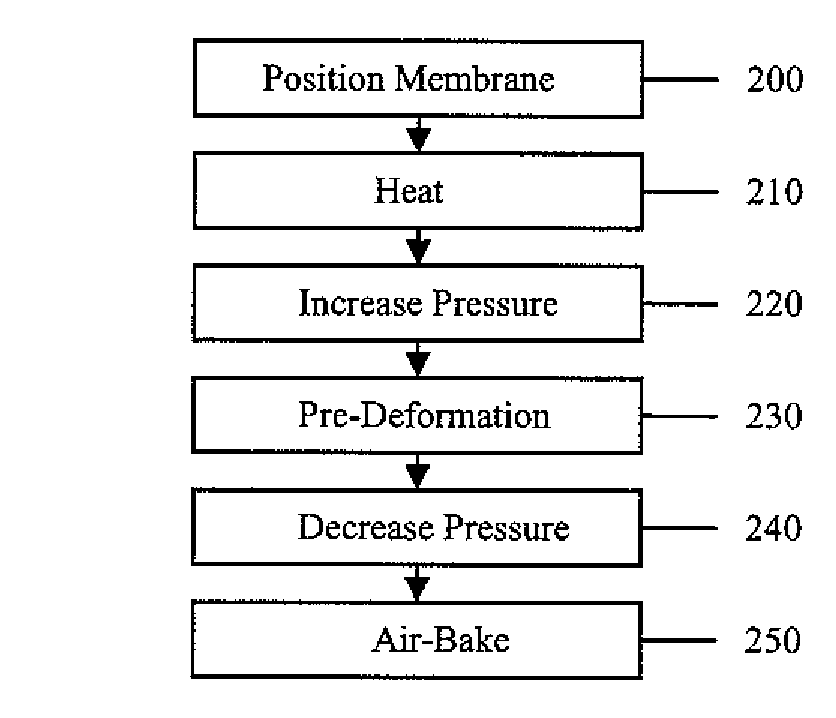

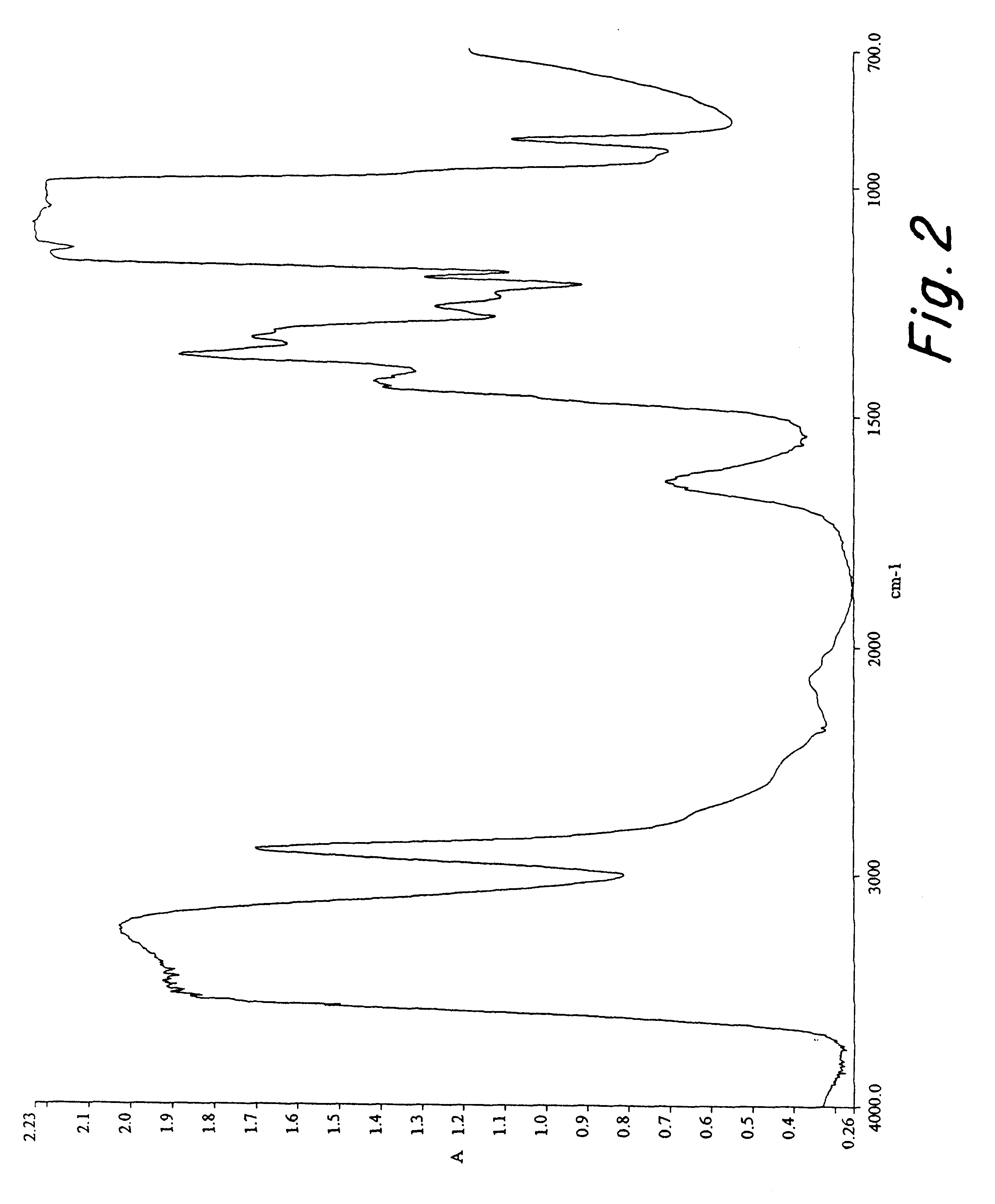

Hydrogen separation process

InactiveUS20080000350A1Isotope separationLoose filtering material filtersAmbient pressureInlet pressure

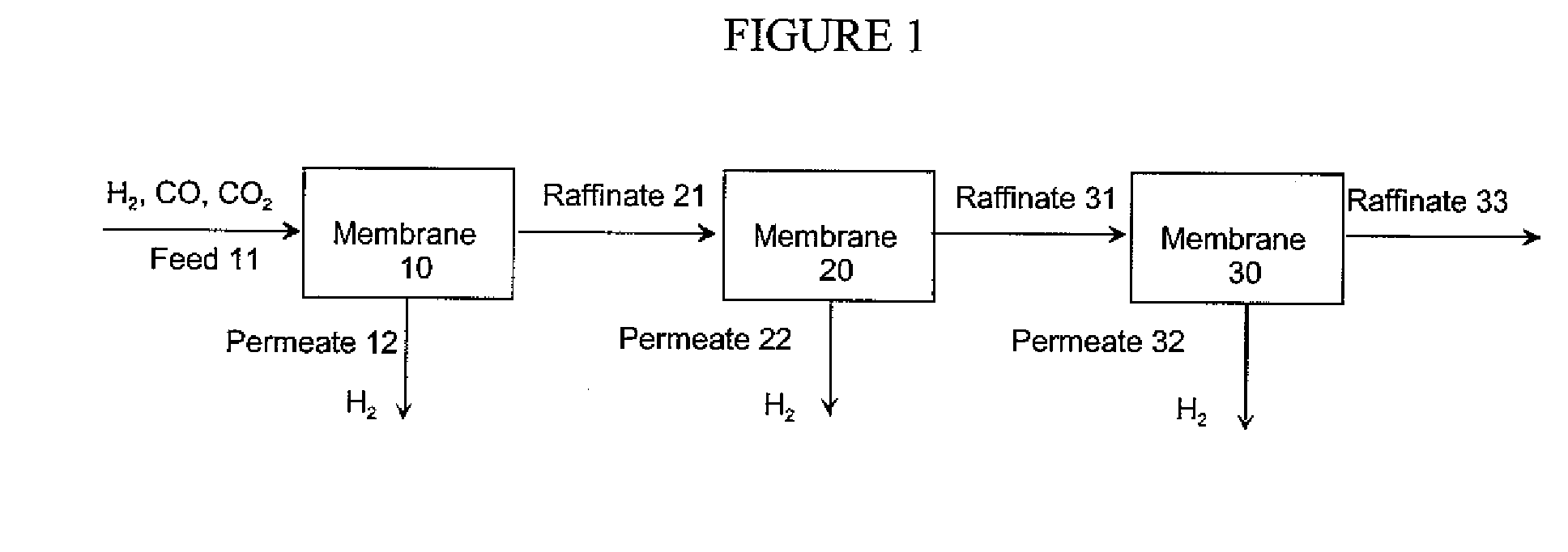

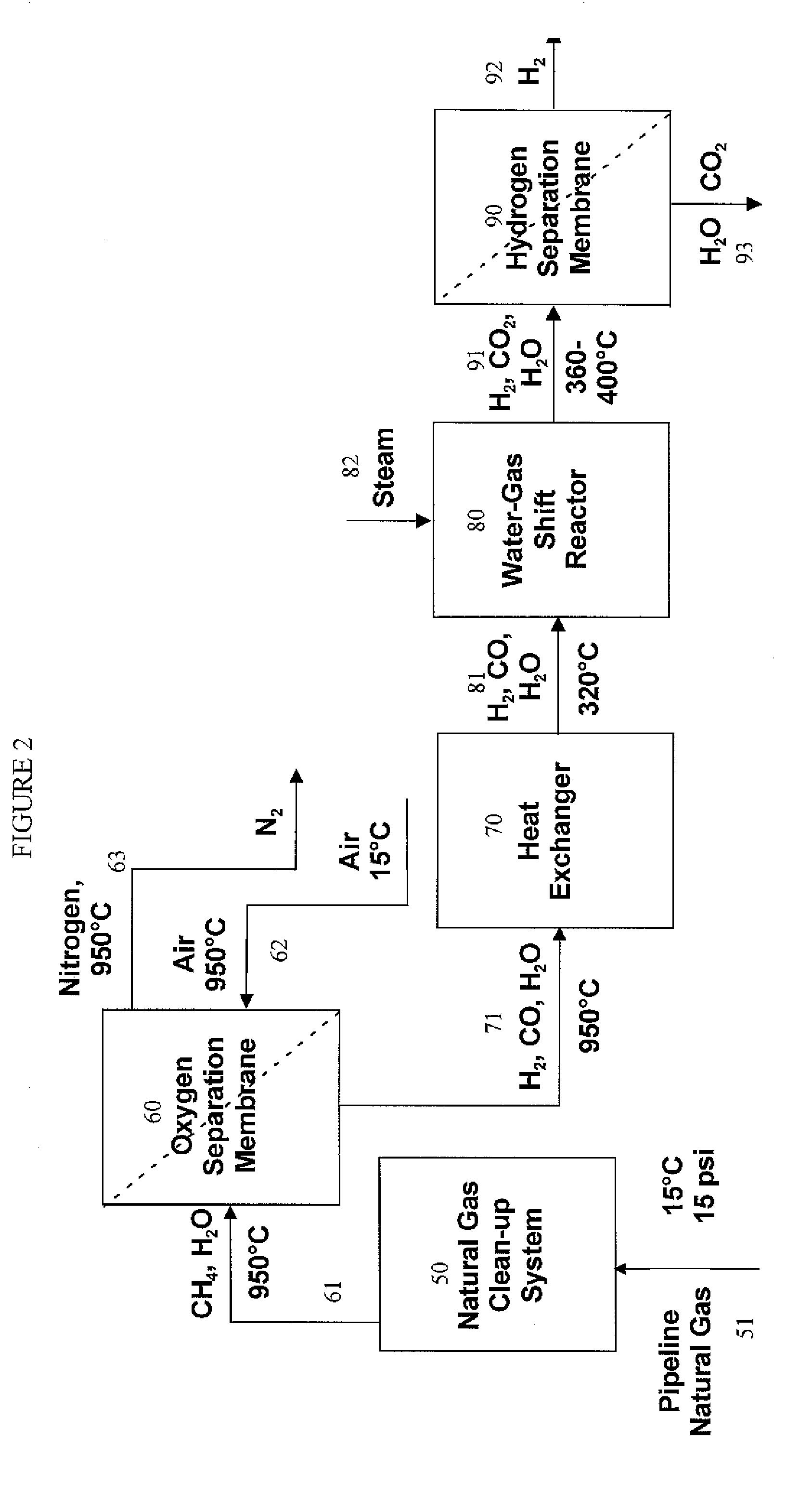

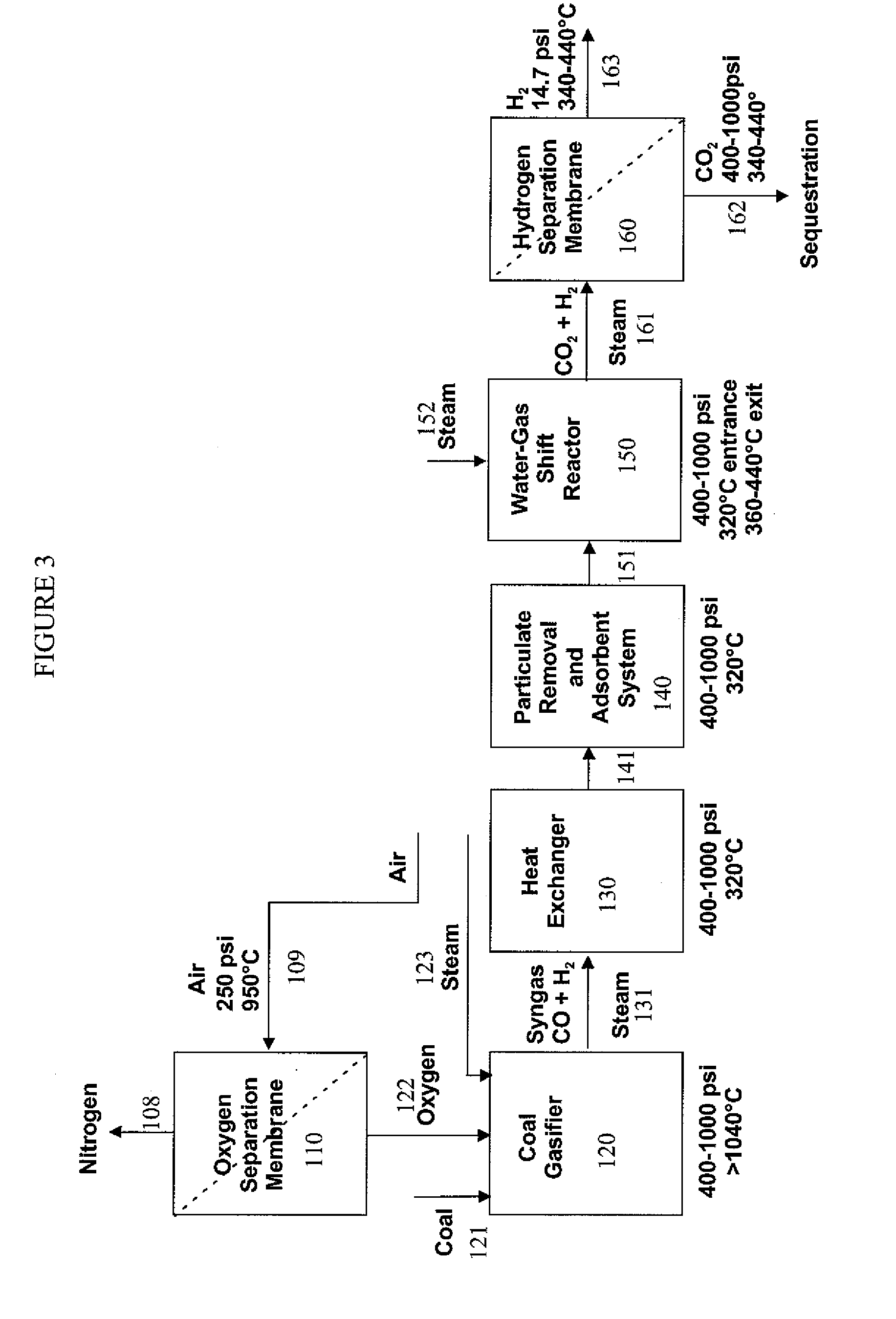

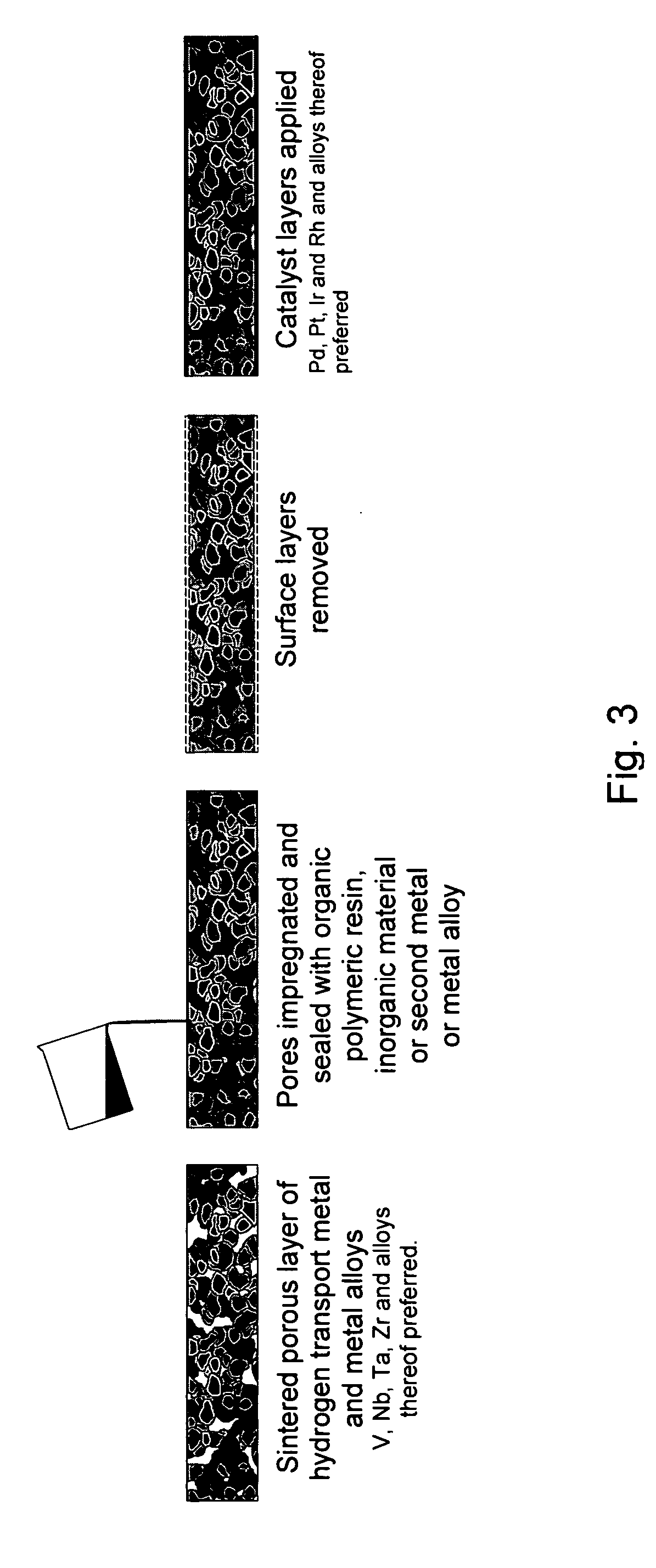

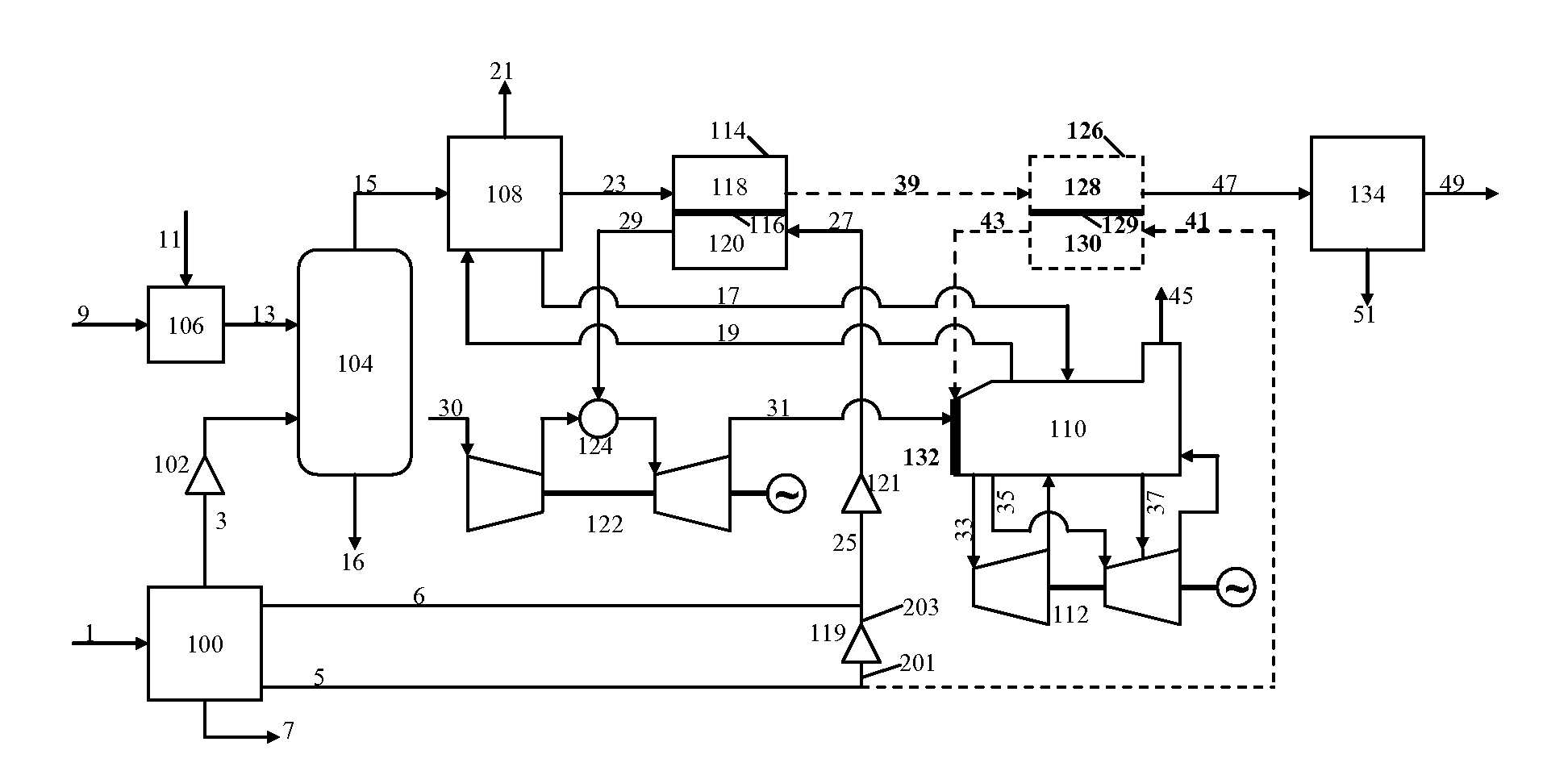

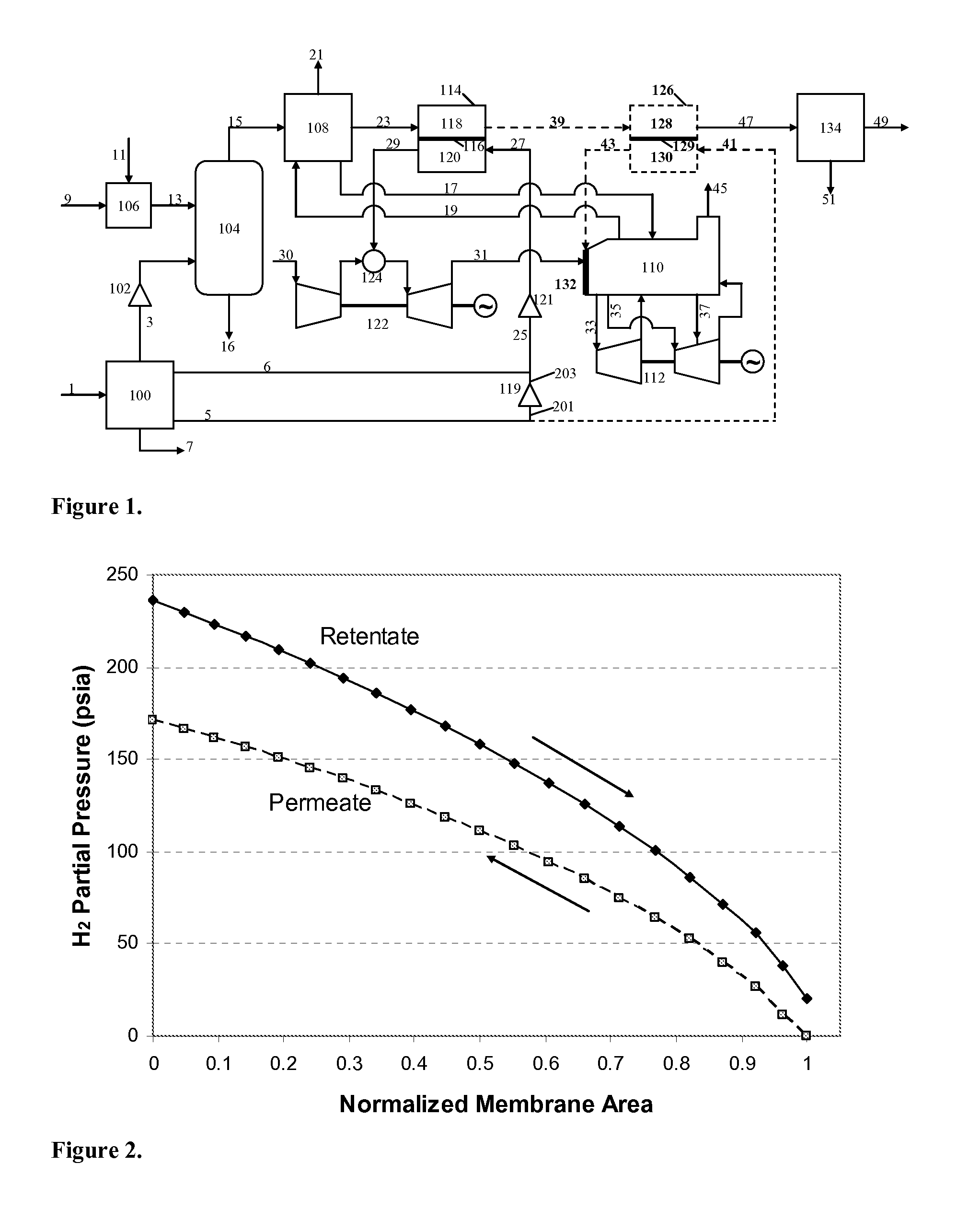

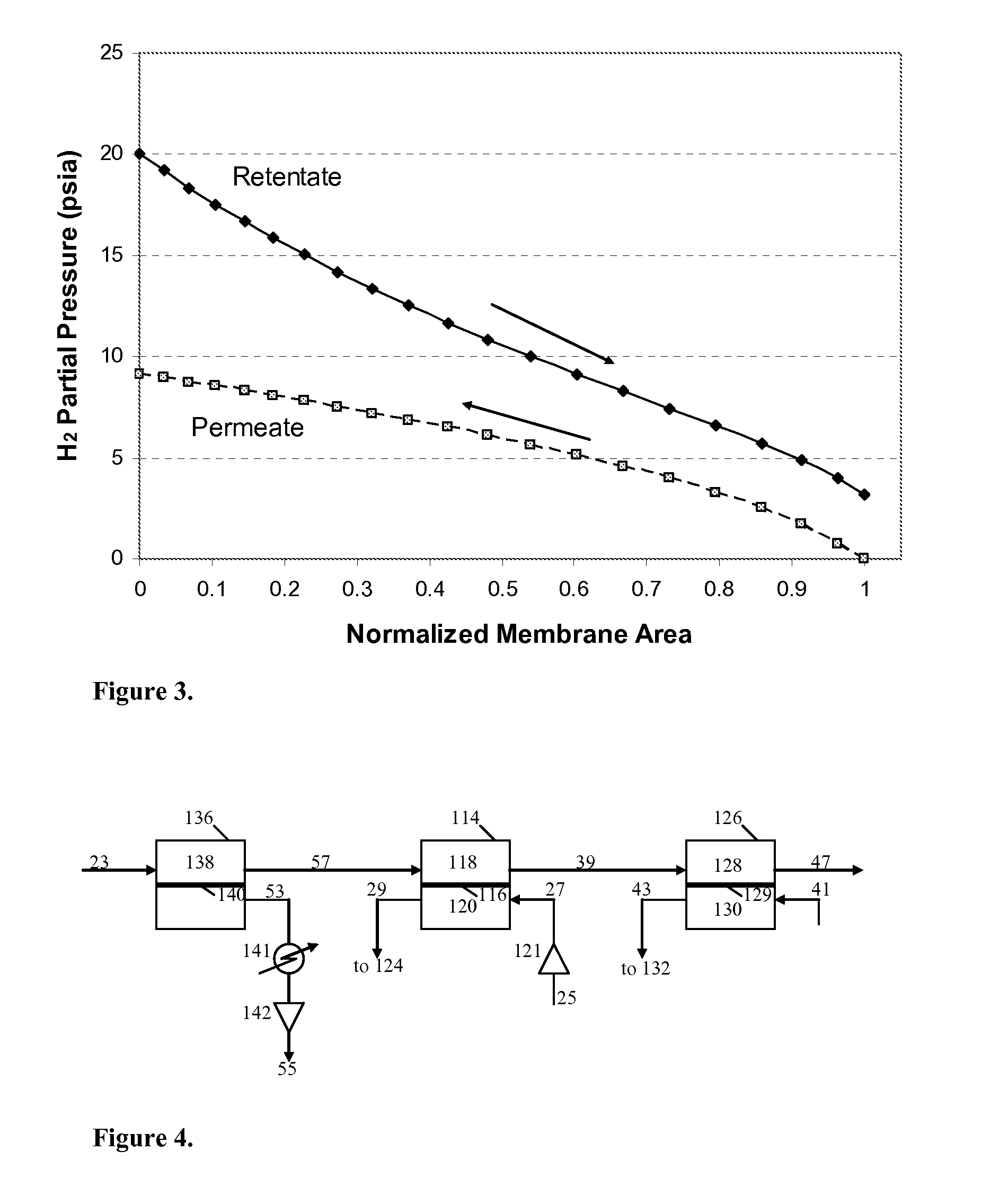

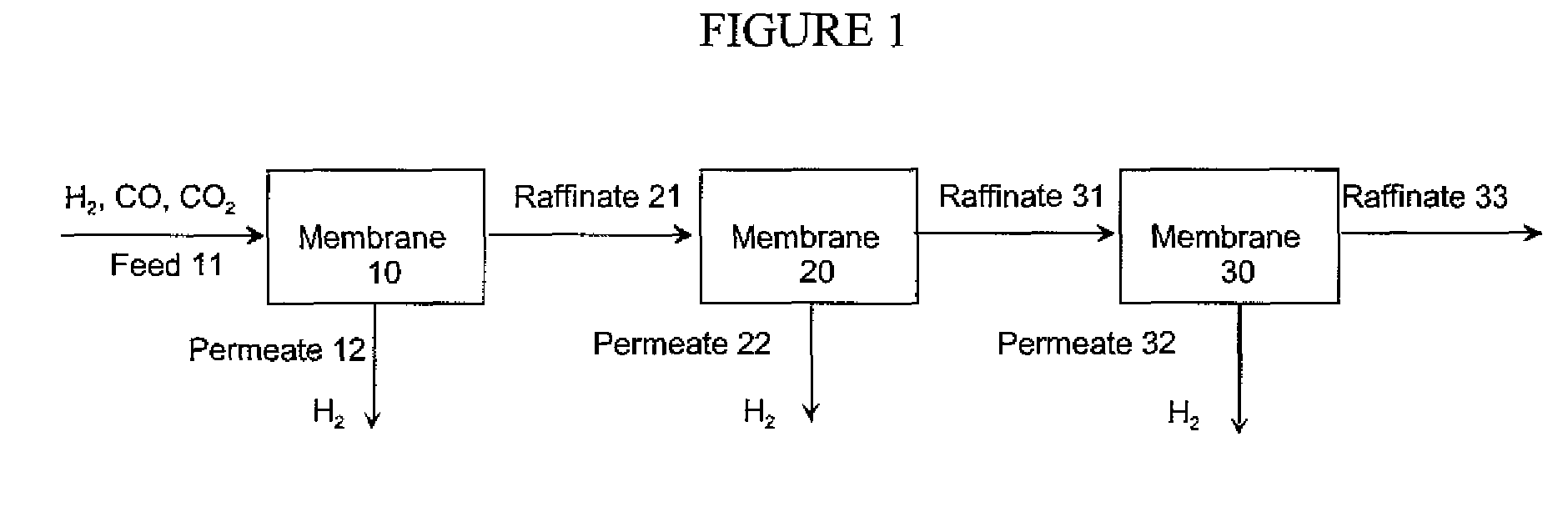

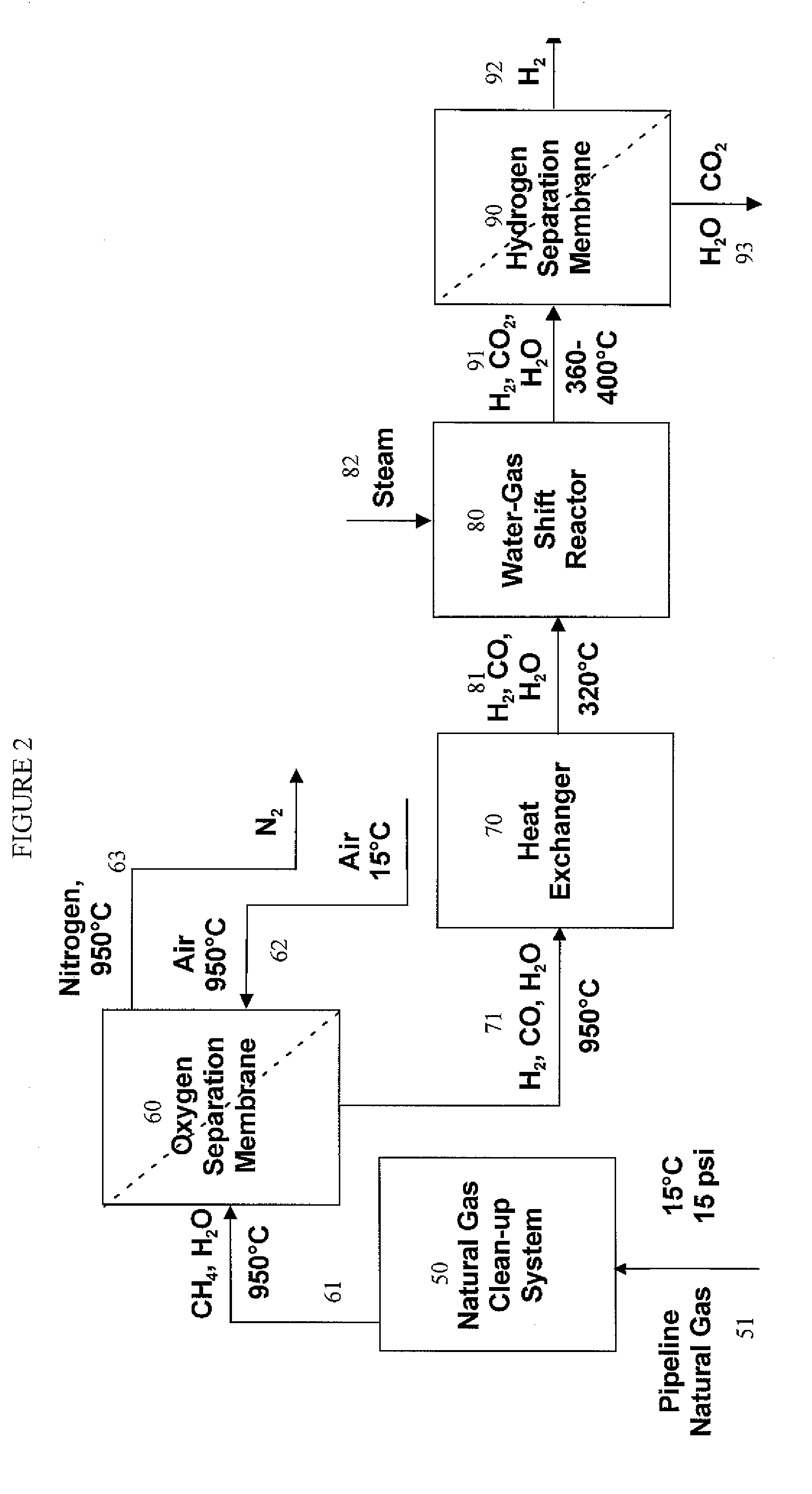

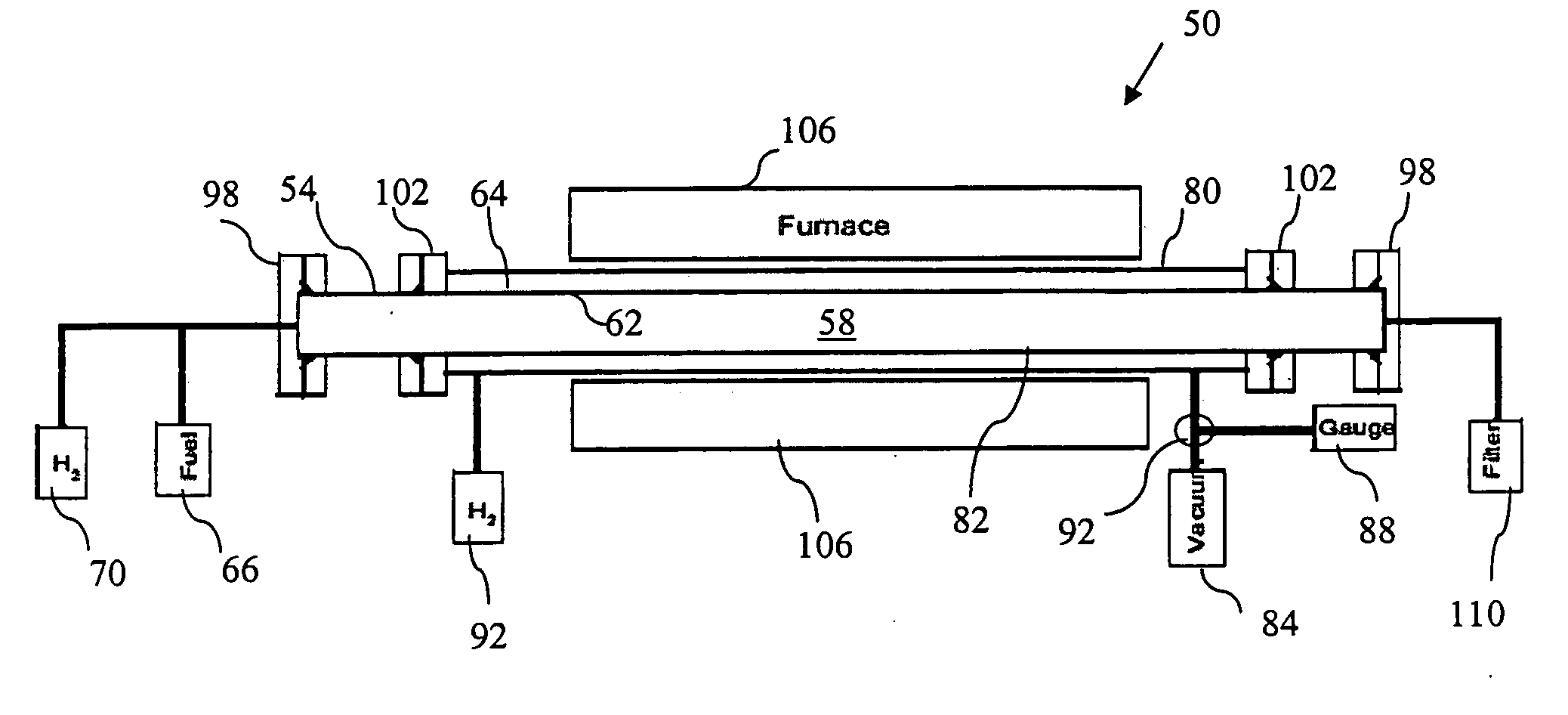

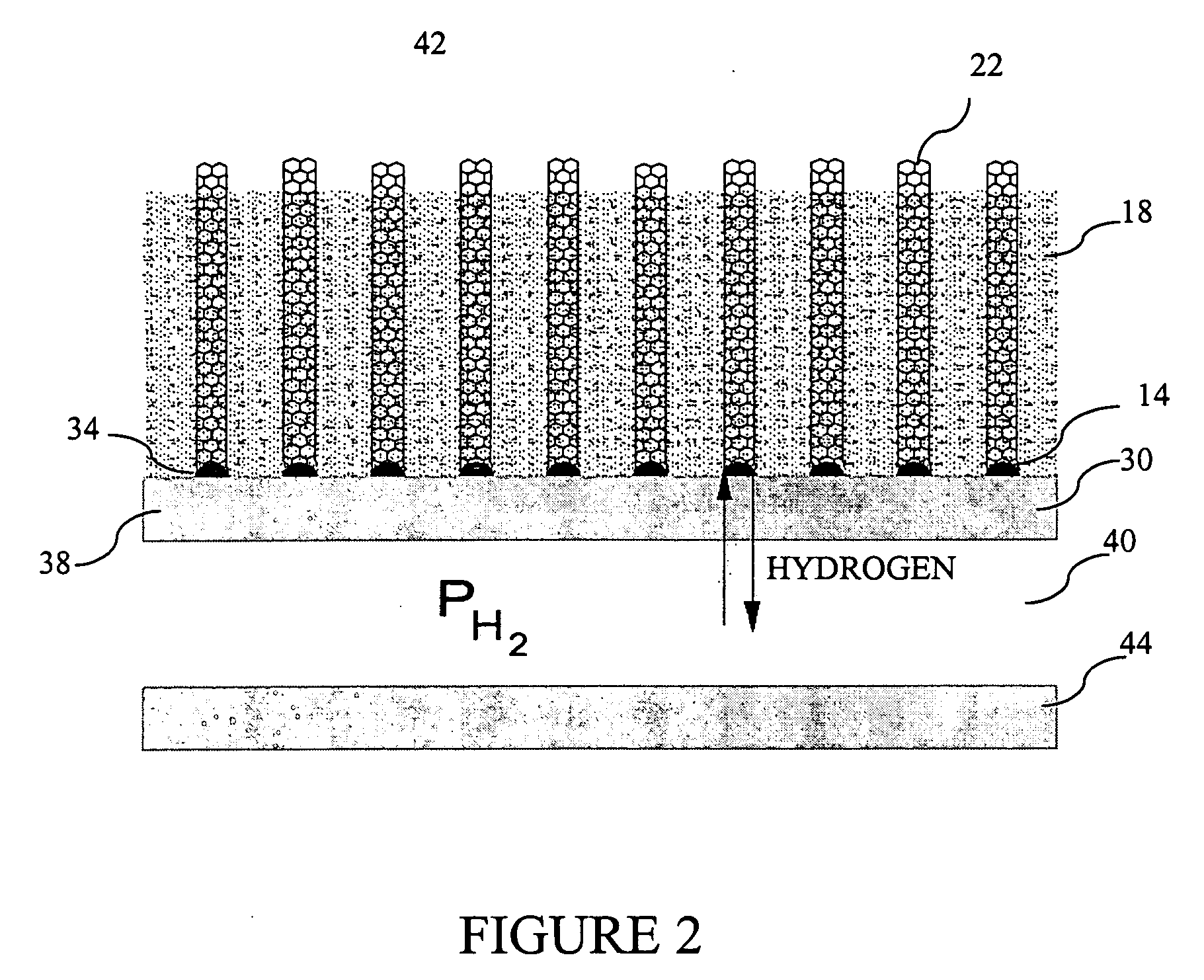

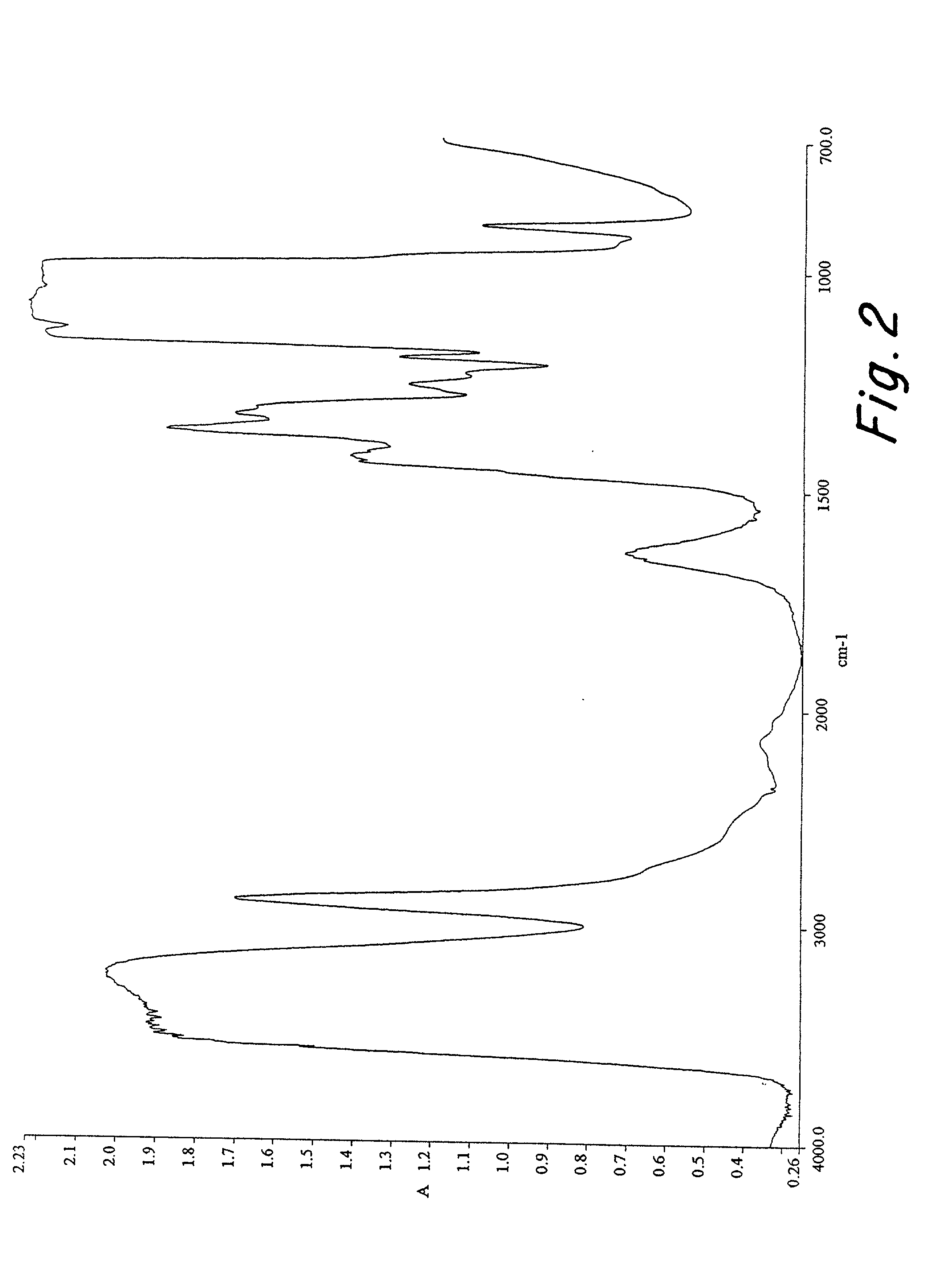

A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to a hydrogen separation membrane system comprising a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to an integrated water gas shift / hydrogen separation membrane system wherein the hydrogen separation membrane system comprises a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for pretreating a membrane, comprising: heating the membrane to a desired operating temperature and desired feed pressure in a flow of inert gas for a sufficient time to cause the membrane to mechanically deform; decreasing the feed pressure to approximately ambient pressure; and optionally, flowing an oxidizing agent across the membrane before, during, or after deformation of the membrane. A method of supporting a hydrogen separation membrane system comprising selecting a hydrogen separation membrane system comprising one or more catalyst outer layers deposited on a hydrogen transport membrane layer and sealing the hydrogen separation membrane system to a porous support.

Owner:ELTRON RES

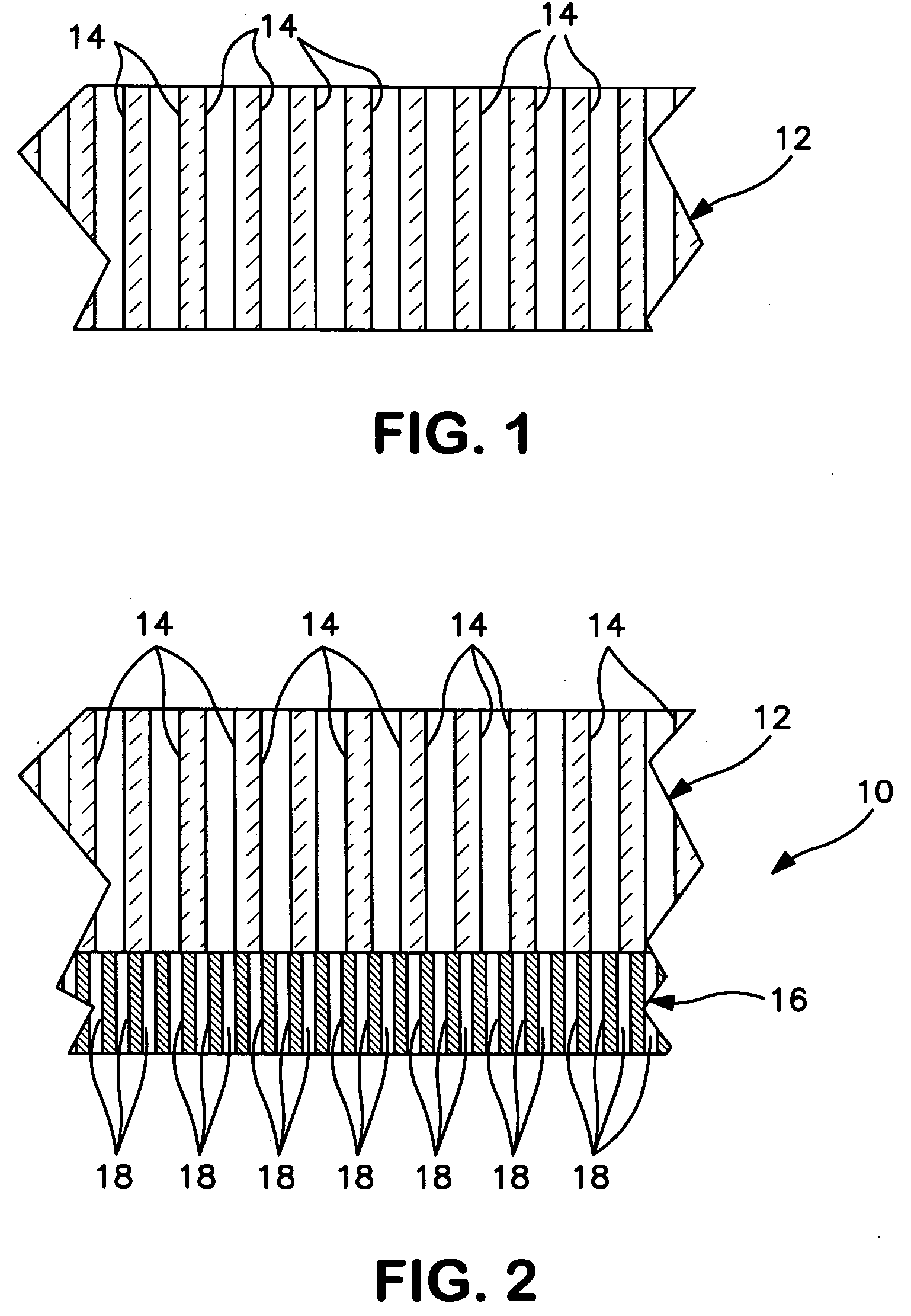

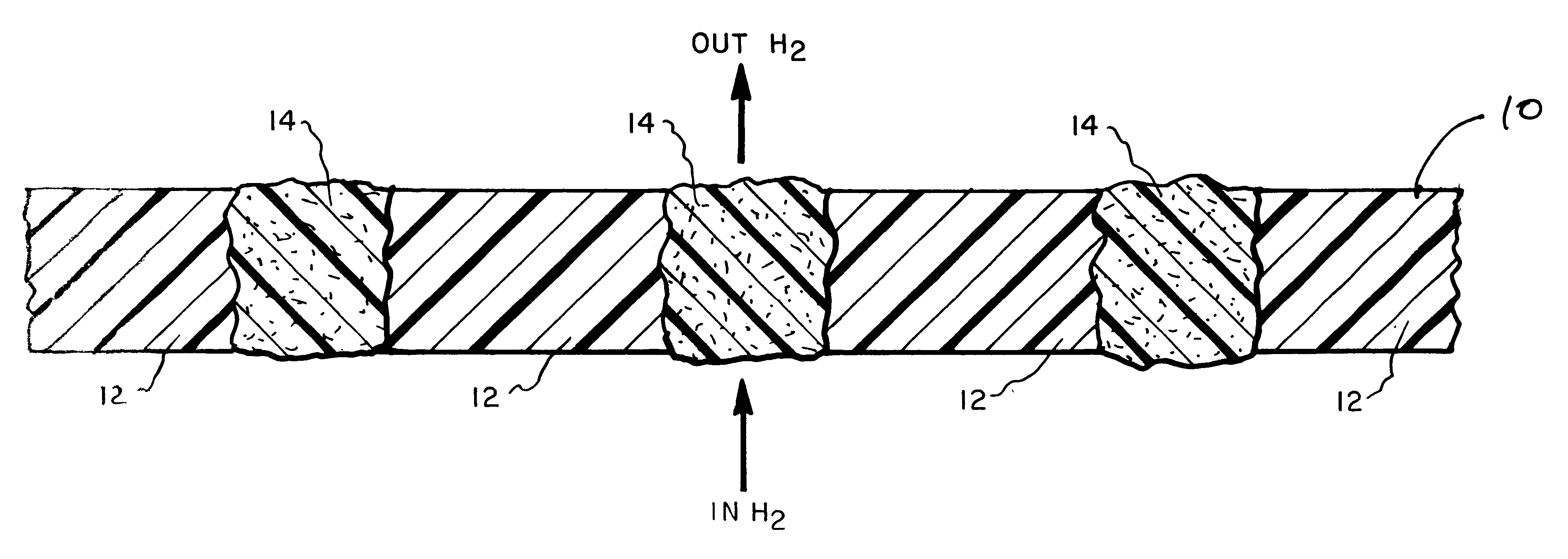

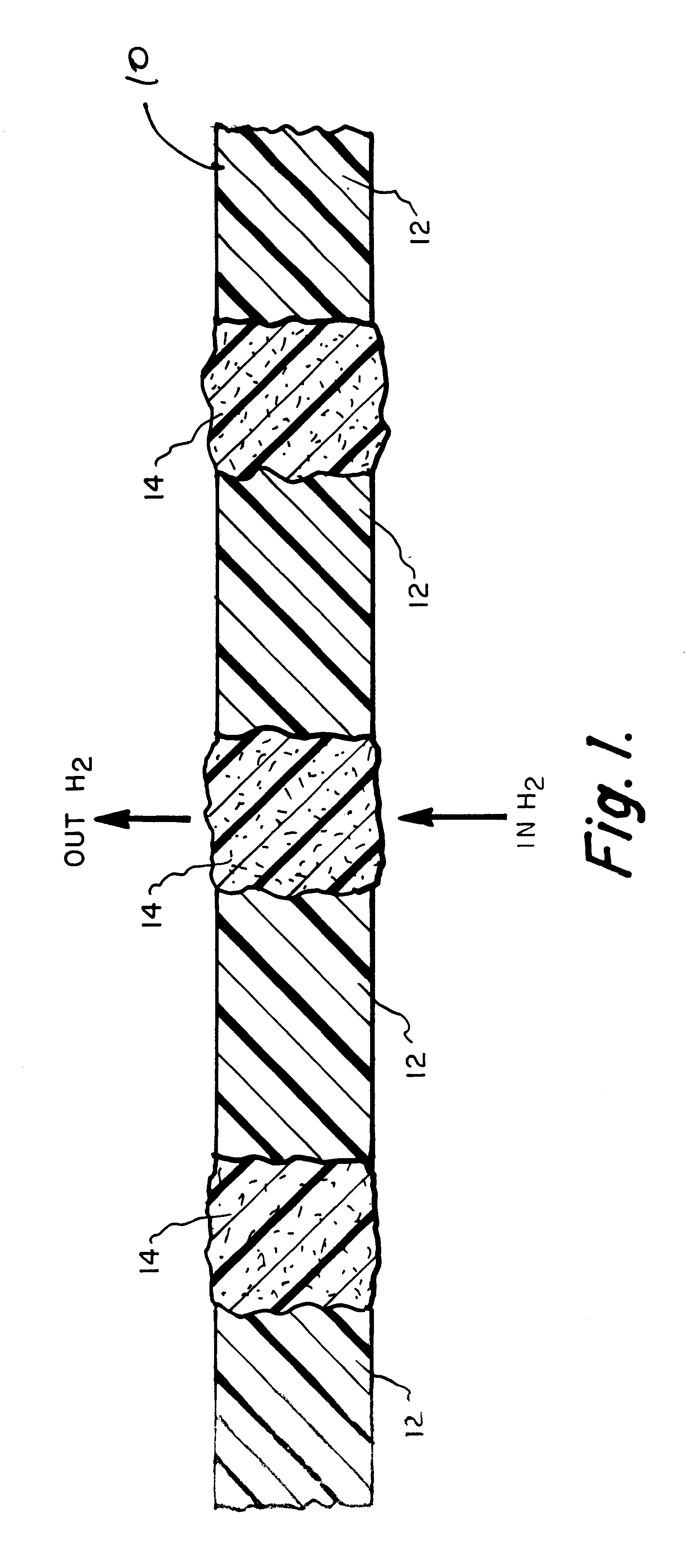

Hydrogen transport membranes

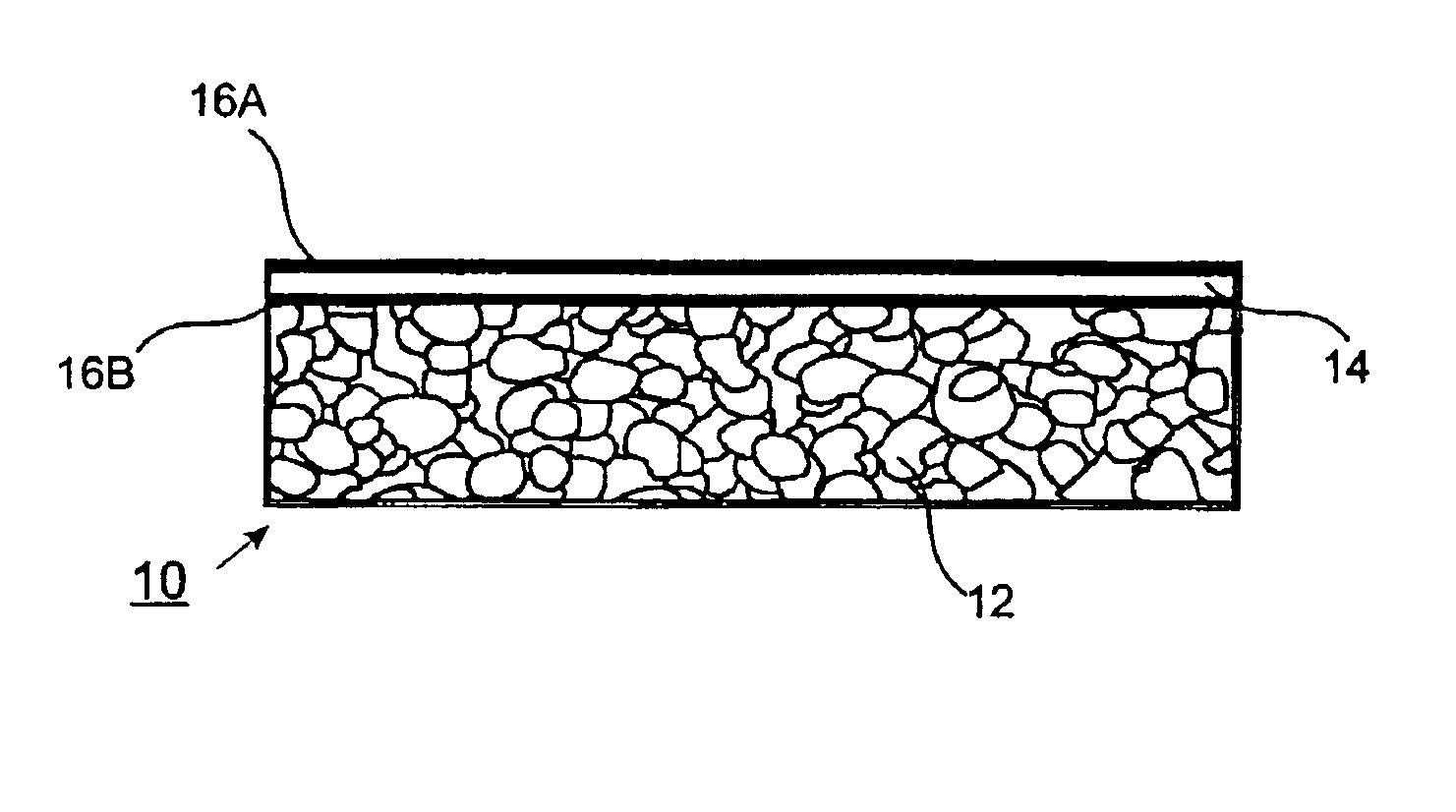

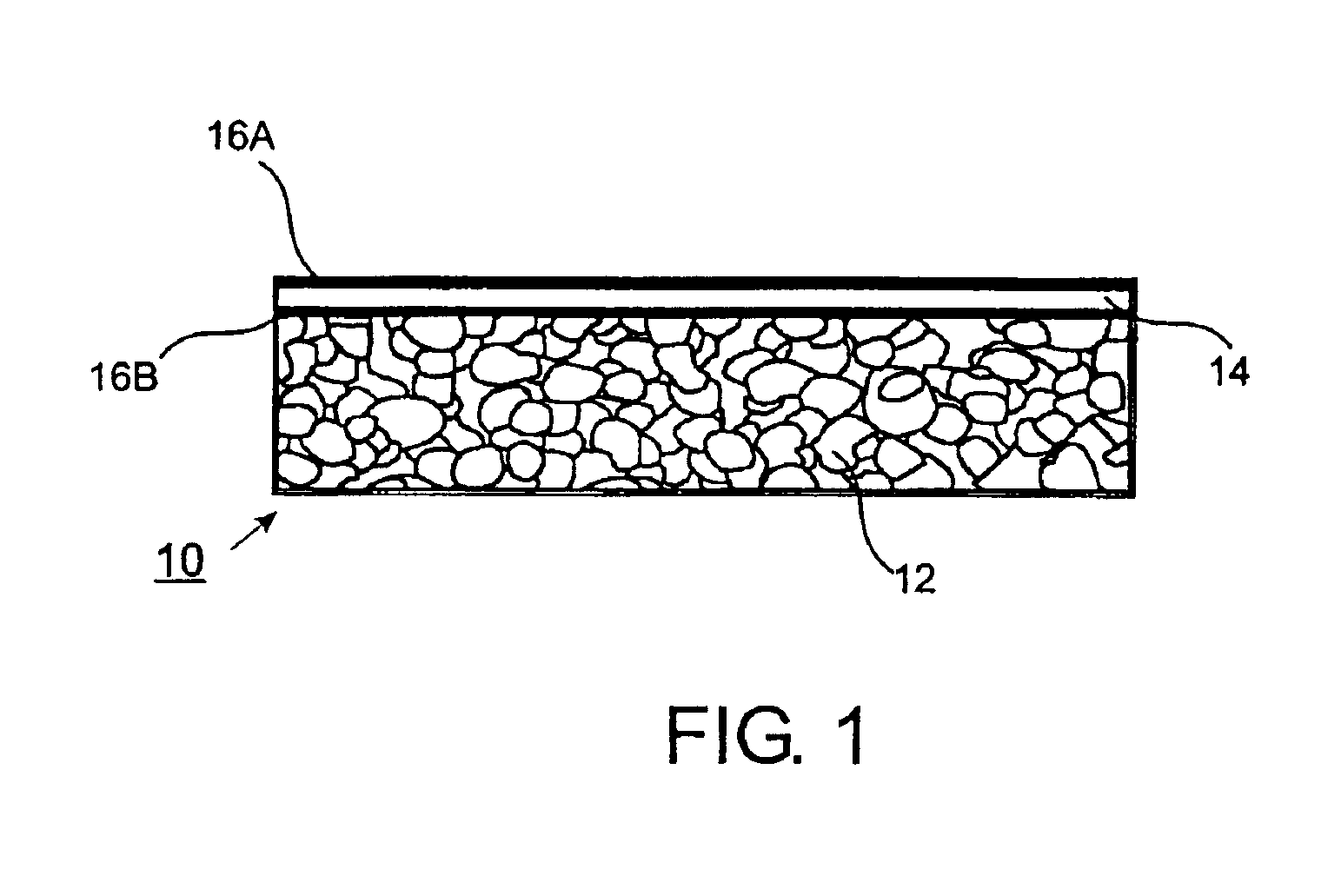

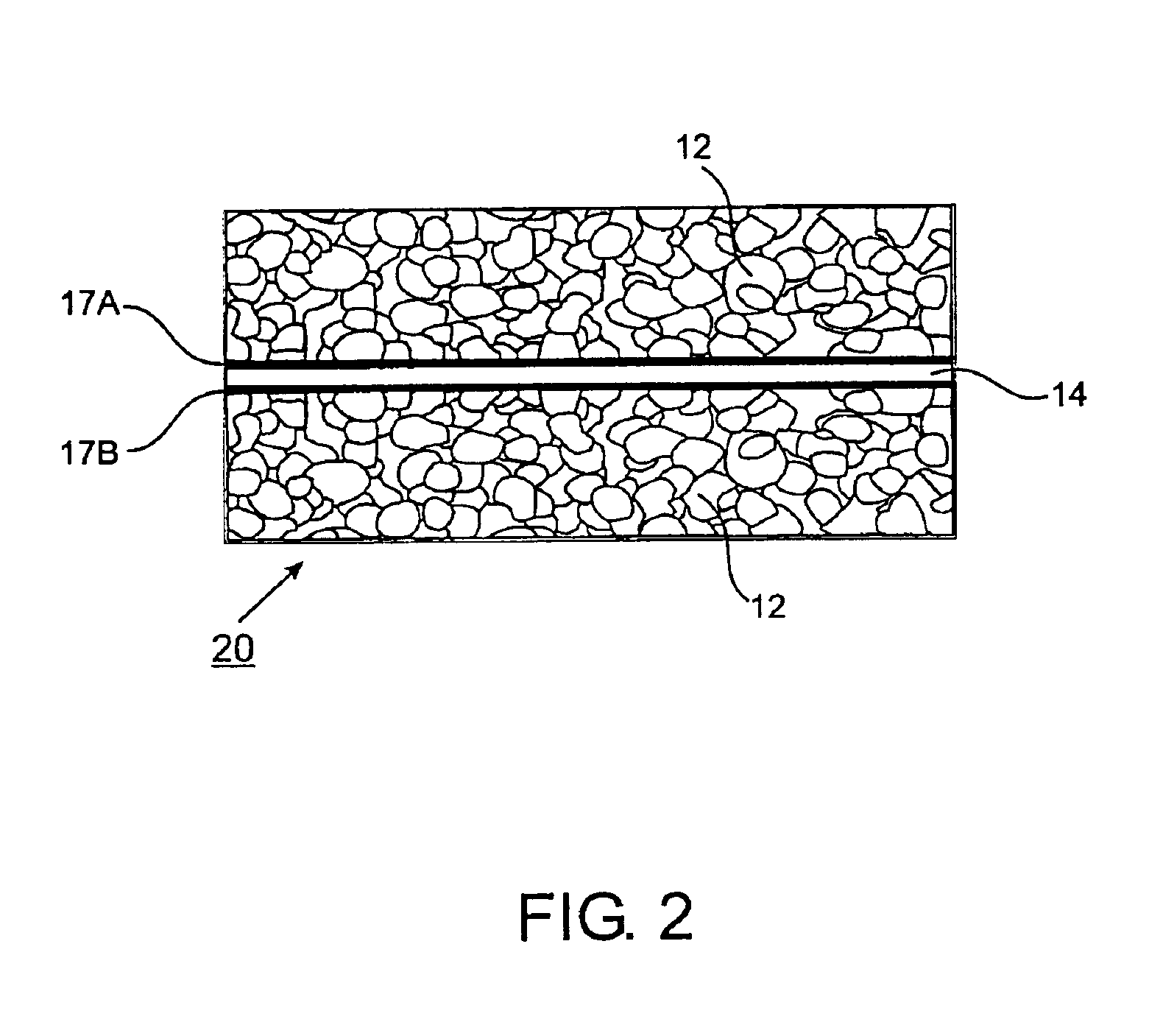

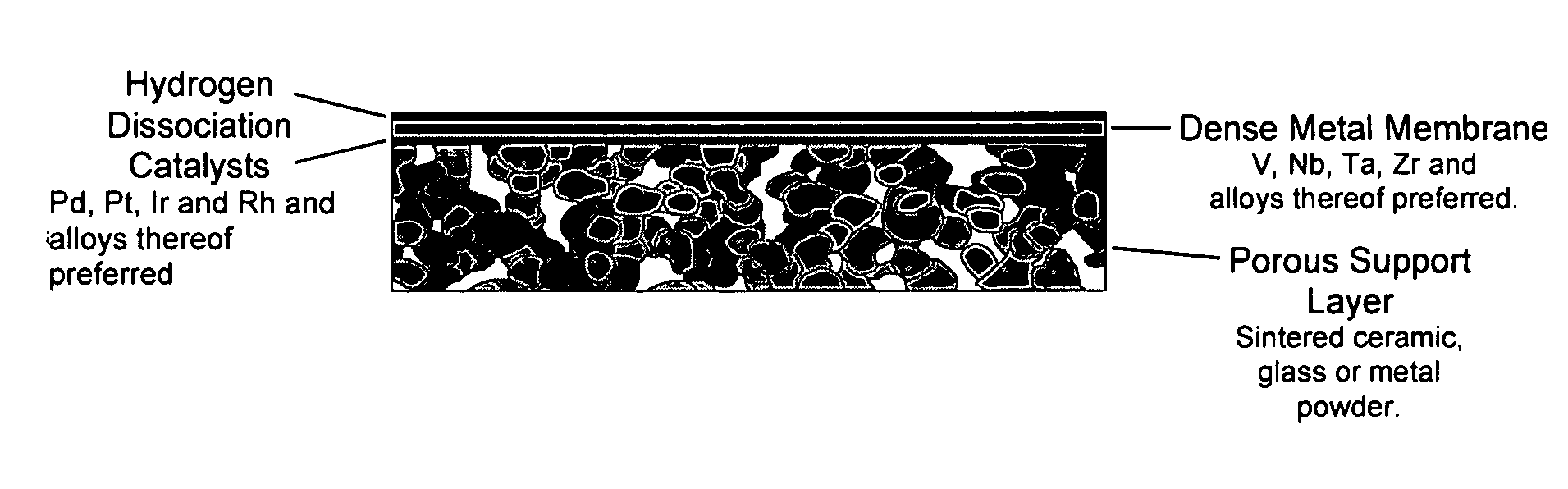

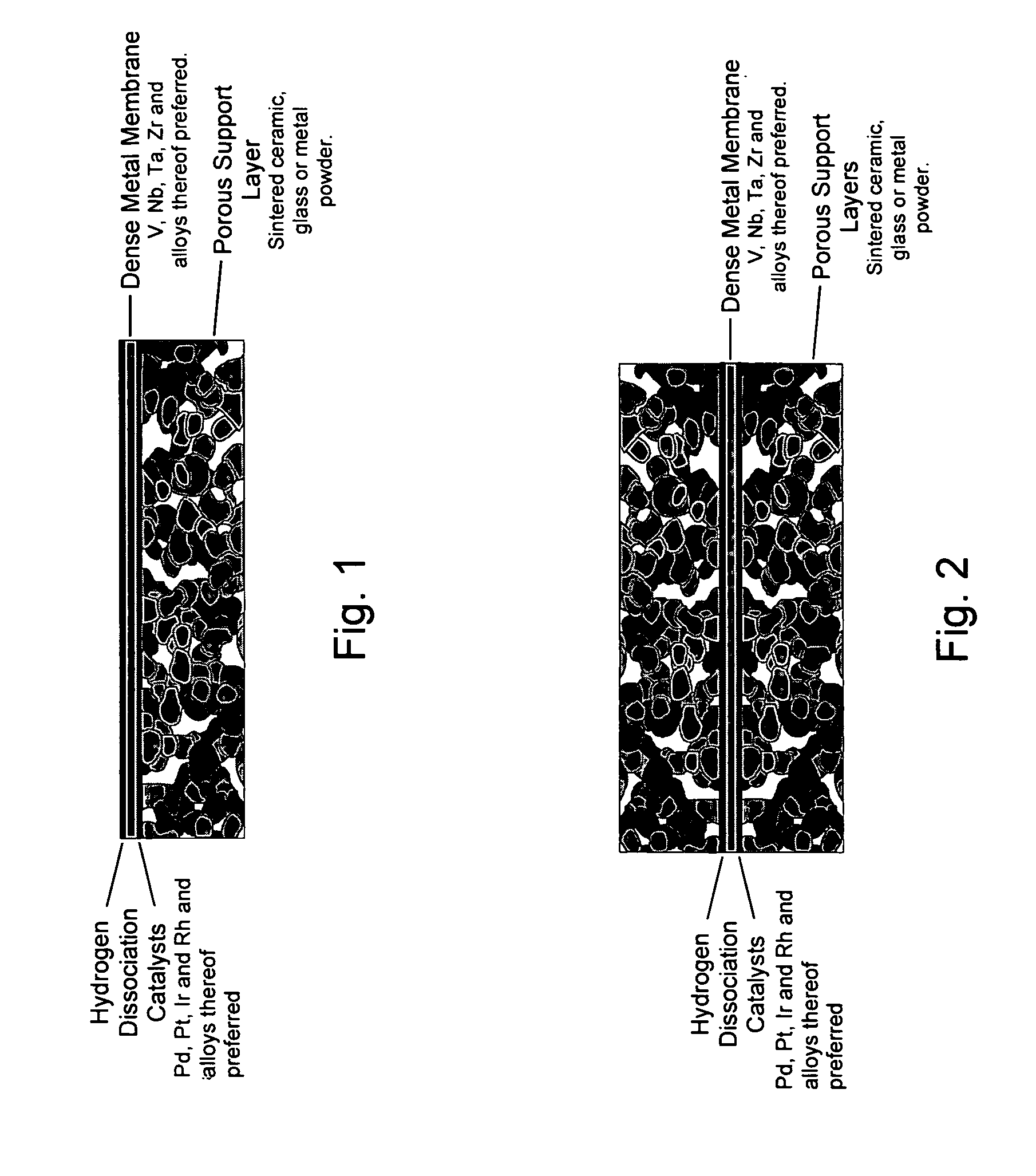

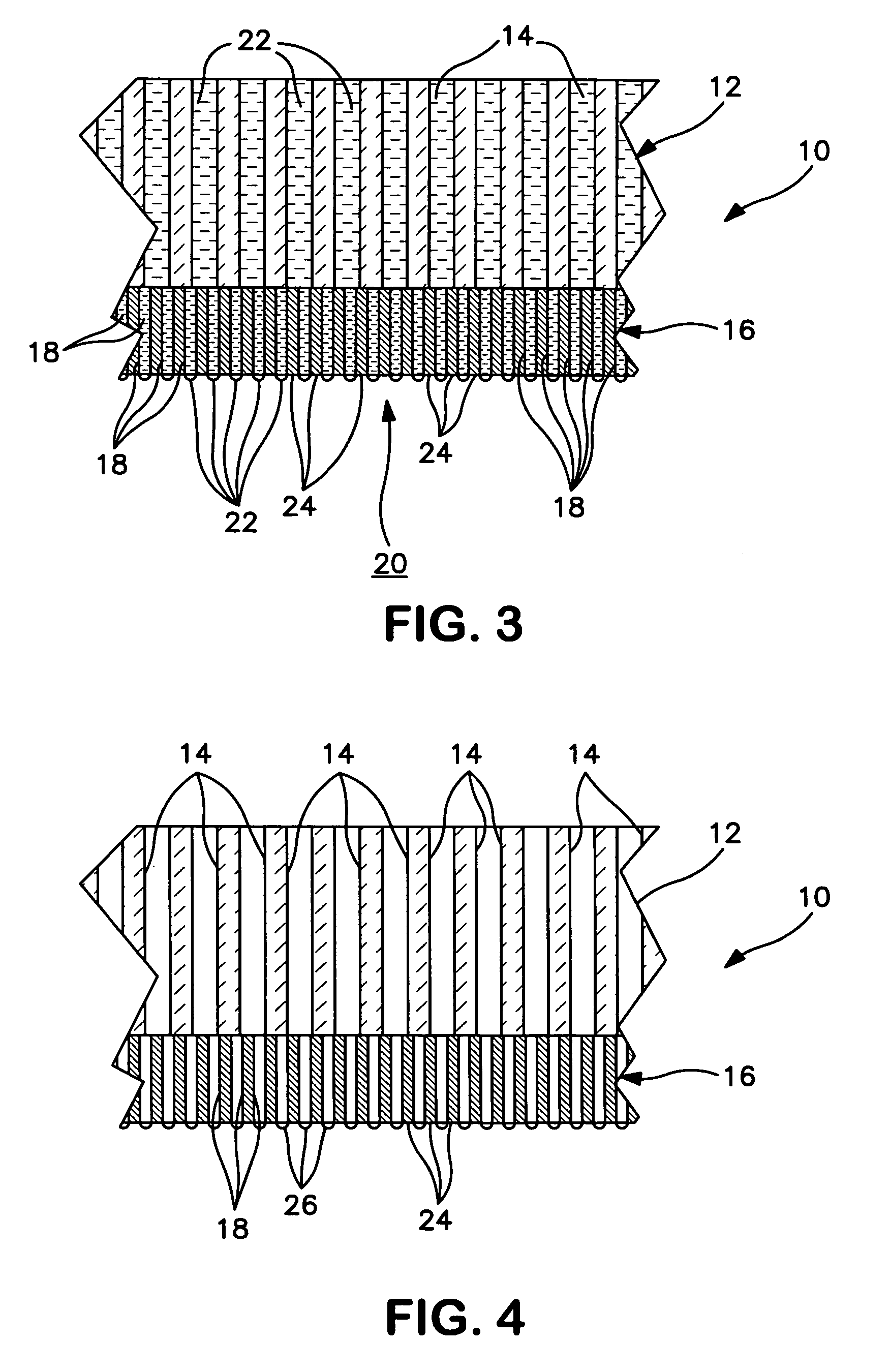

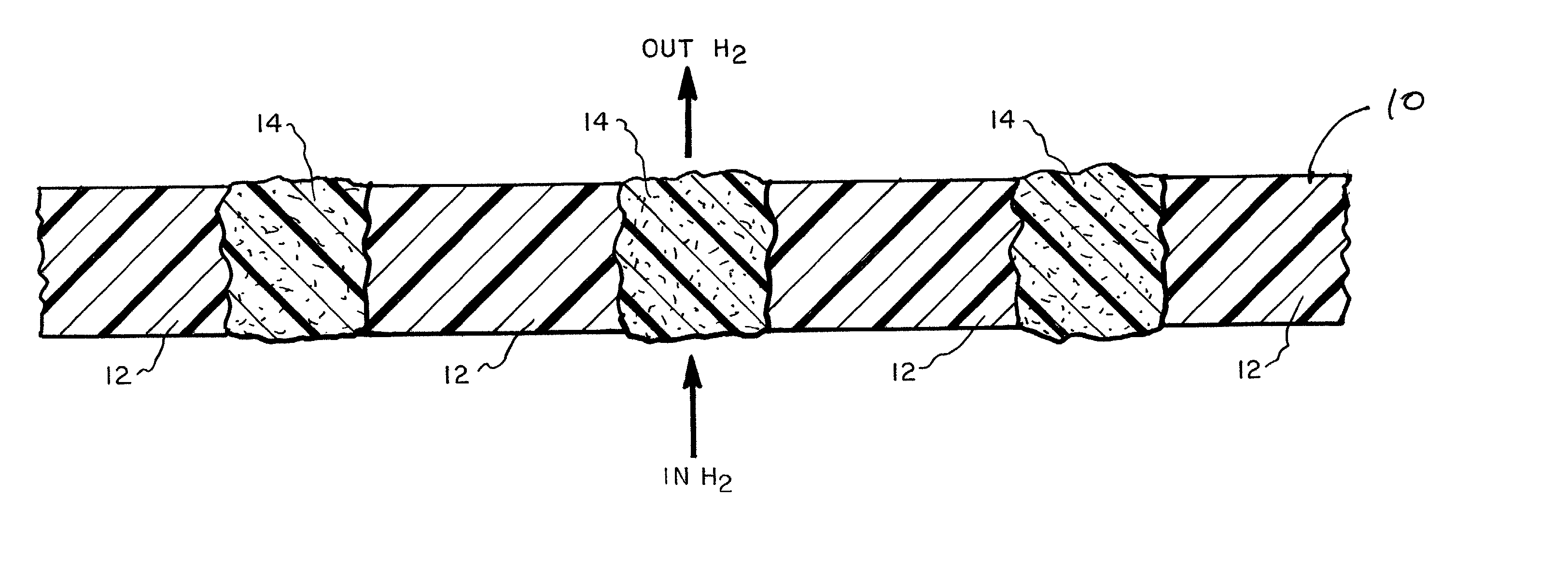

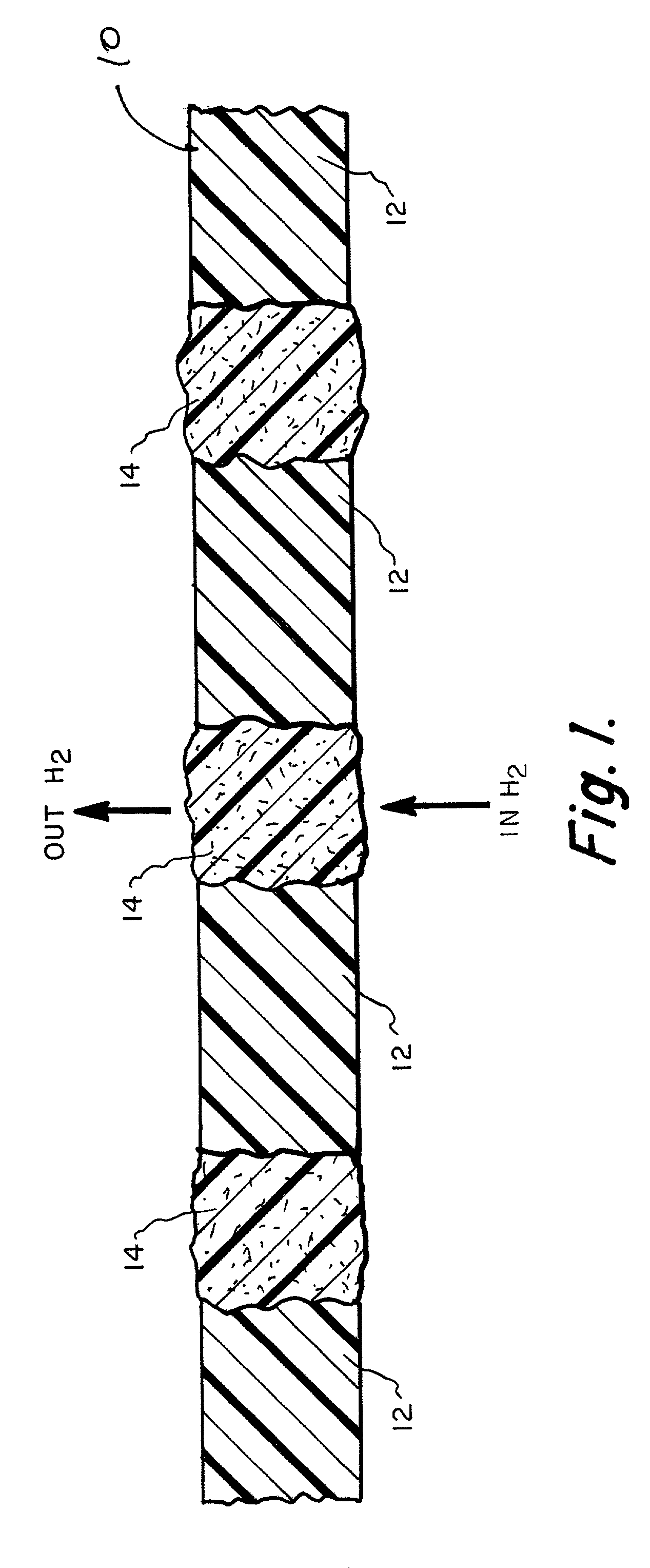

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

Hydrogen transport membranes

InactiveUS20050241477A1Thickness minimizationImprove permeabilitySemi-permeable membranesMembranesDifferential pressureMetal alloy

Composite hydrogen transport membranes used for extraction of hydrogen from gas mixtures are provided. Membranes are described comprising metals and metal alloys which exhibit high hydrogen permeability and which exhibit resistance to differential pressures across the membrane and wherein the metals and alloys are protected from embrittlement by hydrogen. Support materials of the membranes are selected in some cases to be lattice matched to the metals and alloys. In specific embodiments, membranes useful in the invention contain binary, ternary or quaternary alloys of vanadium which exhibit high hydrogen permeability and improved strength and / or longevity in application.

Owner:ELTRON RES

Asu nitrogen sweep gas in hydrogen separation membrane for production of hrsg duct burner fuel

InactiveUS20100077766A1Minimize NO productionDecrease H permeate partial pressureGas treatmentDispersed particle separationSyngasCombustor

The present invention relates to the use of low pressure N2 from an air separation unit (ASU) for use as a sweep gas in a hydrogen transport membrane (HTM) to increase syngas H2 recovery and make a near-atmospheric pressure (less than or equal to about 25 psia) fuel for supplemental firing in the heat recovery steam generator (HRSG) duct burner.

Owner:PRAXAIR TECH INC

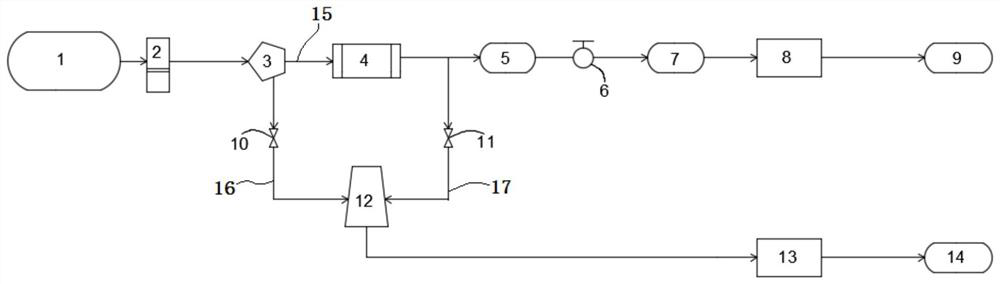

Electric methanol hydrogen transporting tool

InactiveCN104986051AEmission reductionSolve the energy crisisFinal product manufactureFuel cell auxillariesSteam reformingWater vapor

The invention discloses an electric methanol hydrogen transporting tool. The tool comprises a methanol-to-hydrogen system, a hydrogen generating system and an electric engine, wherein the methanol-to-hydrogen system, the hydrogen generating system and the electric engine are connected with each other in sequence. The methanol-to-hydrogen system is used for preparing hydrogen through methanol steam reforming; the hydrogen passes through a membrane separation device plated with a palladium silver alloy to obtain a high-purity hydrogen; the obtained hydrogen is used for generating power through the hydrogen generating system; and the generated electric power is provided to the electric engine to work. The hydrogen generating system comprises a fuell cell, wherein the fuell cell comprises a plurality of sub fuel cell modules; and each sub fuel cell module comprises at least one super-capacitor. According to the electric methanol hydrogen transporting tool disclosed by the invention, the methanol can be used as energy for the transporting tool so that problems of energy crisis and vehicle emission are solved. The electric methanol hydrogen transporting tool disclosed by the invention is advantaged in that the volume of a hydrogen preparation device is small; the prepared hydrogen is rapid, stable and highly purified because the hydrogen is purified by using a special catalyst formula and a palladium membrane; and stable input energy can be provided to the transporting tool.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

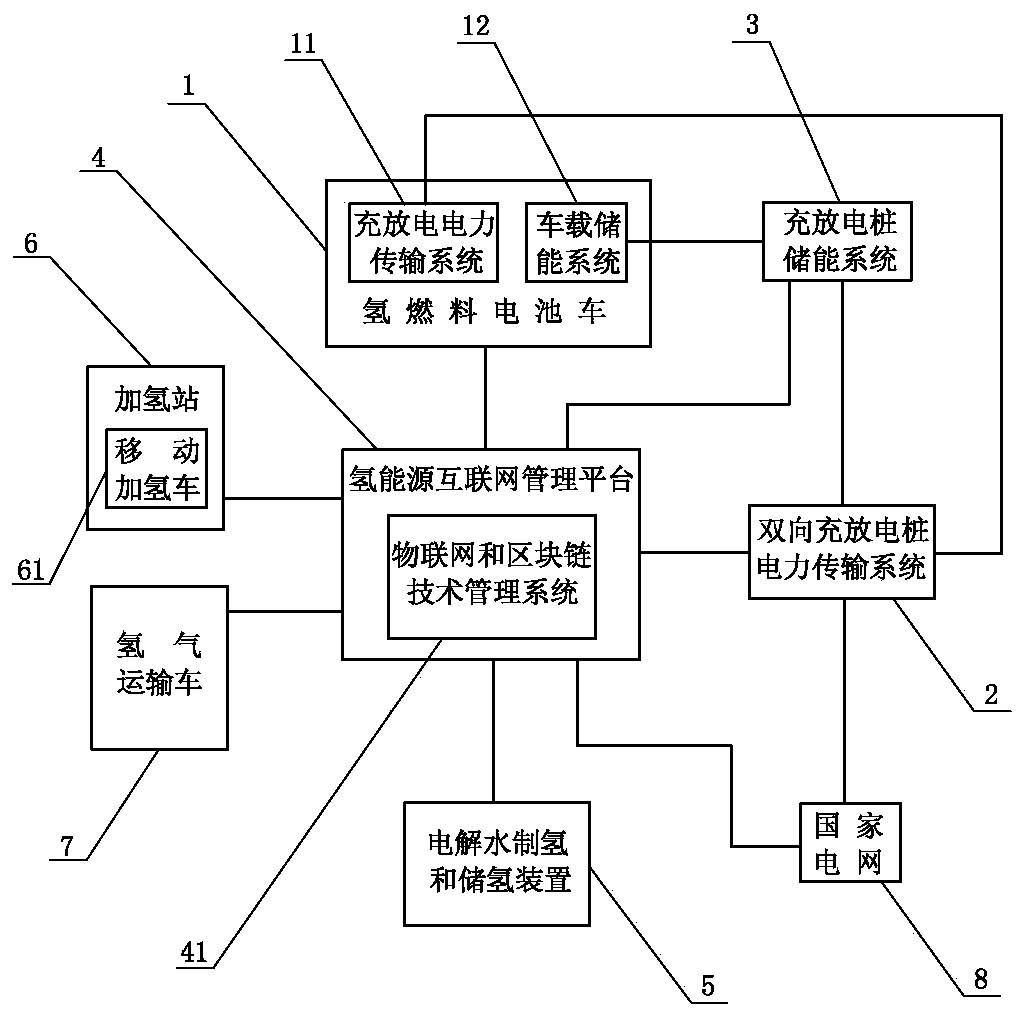

Distributed power generation and energy storage system based on hydrogen fuel cell car

PendingCN108928254AClean thoroughlyAchieve recyclingSingle network parallel feeding arrangementsEnergy storageElectric powerDistributed power generation

A distributed power generation and energy storage system based on a hydrogen fuel cell car comprises a hydrogen energy internet management platform network connection hydrogen fuel cell car, a charging and discharging power transmission system, a vehicle-mounted energy storage system, a two-way charging and discharging pile power transmission system, a charging and discharging pile energy storagesystem, a hydrogen energy internet management platform, an internet of things and a block chain technology management system, a water-electrolytic hydrogen production, photoelectric combined hydrogenproduction and electric energy consuming compound hydrogen production and hydrogen storage device, a hydrogen refueling station, a mobile hydrogen refueling station, a hydrogen transporting vehicle and a power grid; and the matching between a power generation time of the social hydrogen fuel cell car and a power grid peak demand is intelligently managed and adjusted. The distributed power generation and energy storage system based on the hydrogen fuel cell car has the advantages that complete cleaning and zero emission of traffic energy can be realized, the energy is effectively recycled and utilized, the investments of the power grid and a power station are saved, the safety and energy utilization efficiency of the power grid are enhanced, the national power grid is balanced, natural distribution of virtual distributed energy storage power stations is realized, incomes are brought to assets and owners, shared investment of green traveling is realized, social resources are sufficientlyutilized, and popularization and application of green traffic are promoted.

Owner:黄竹磬

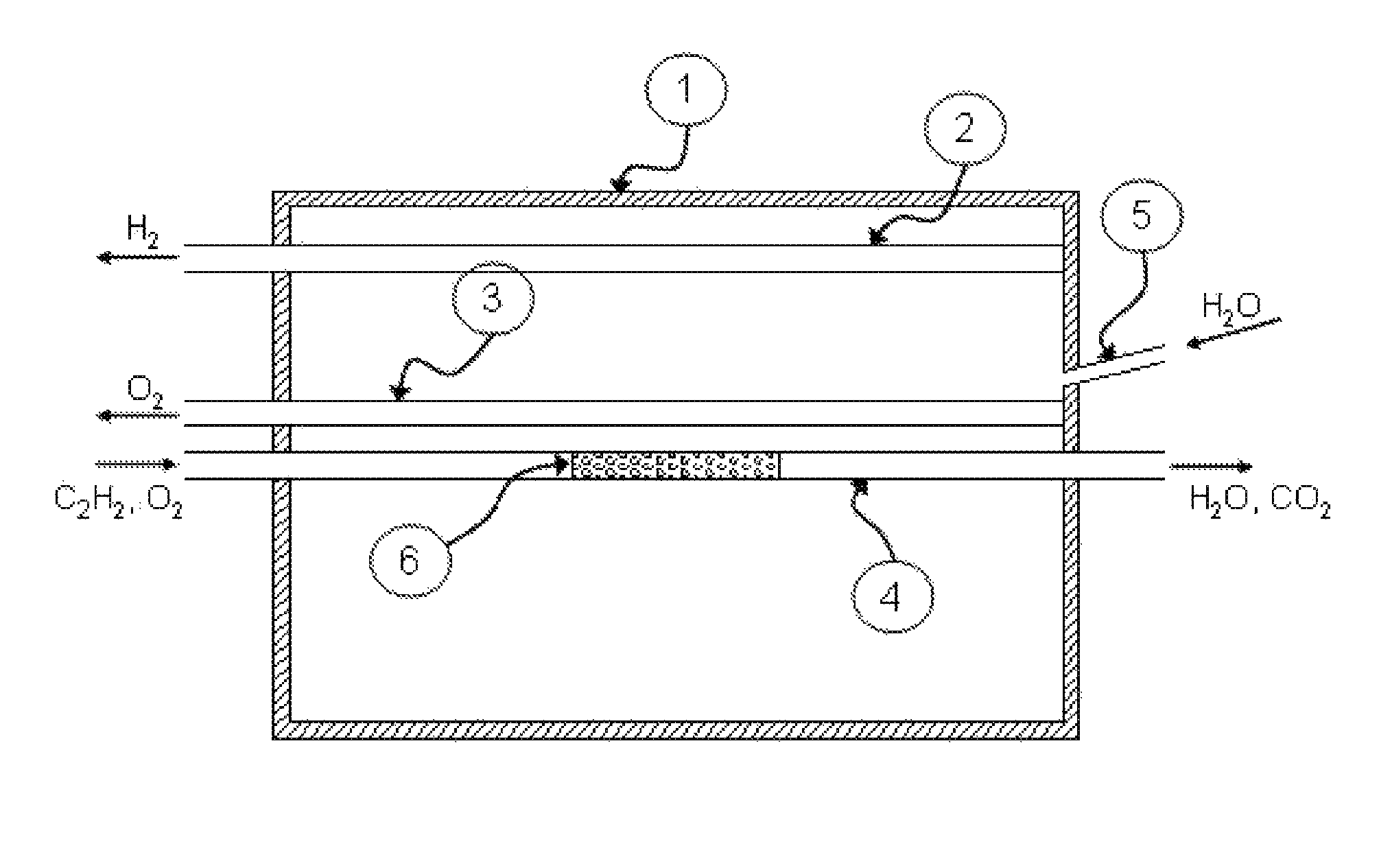

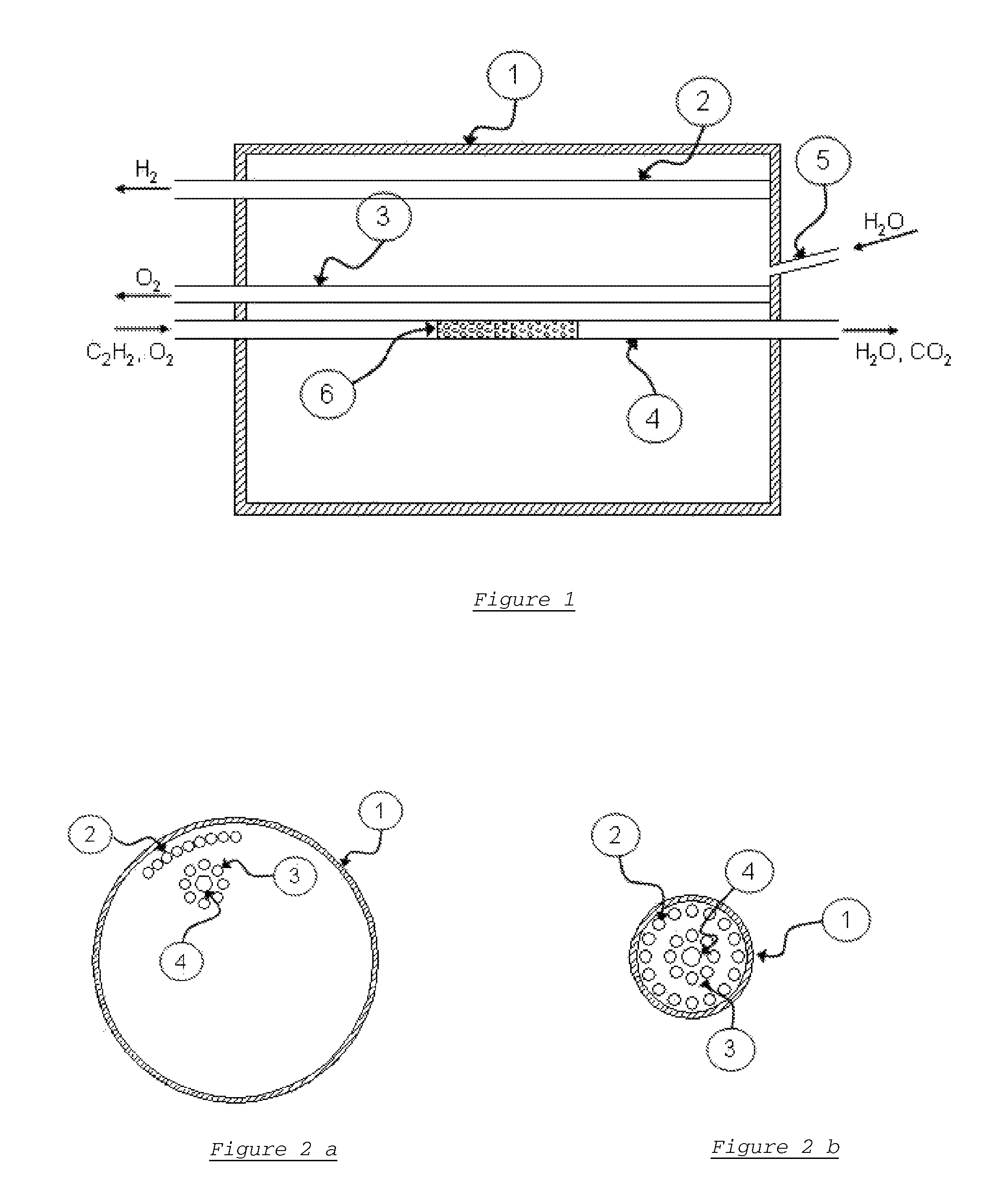

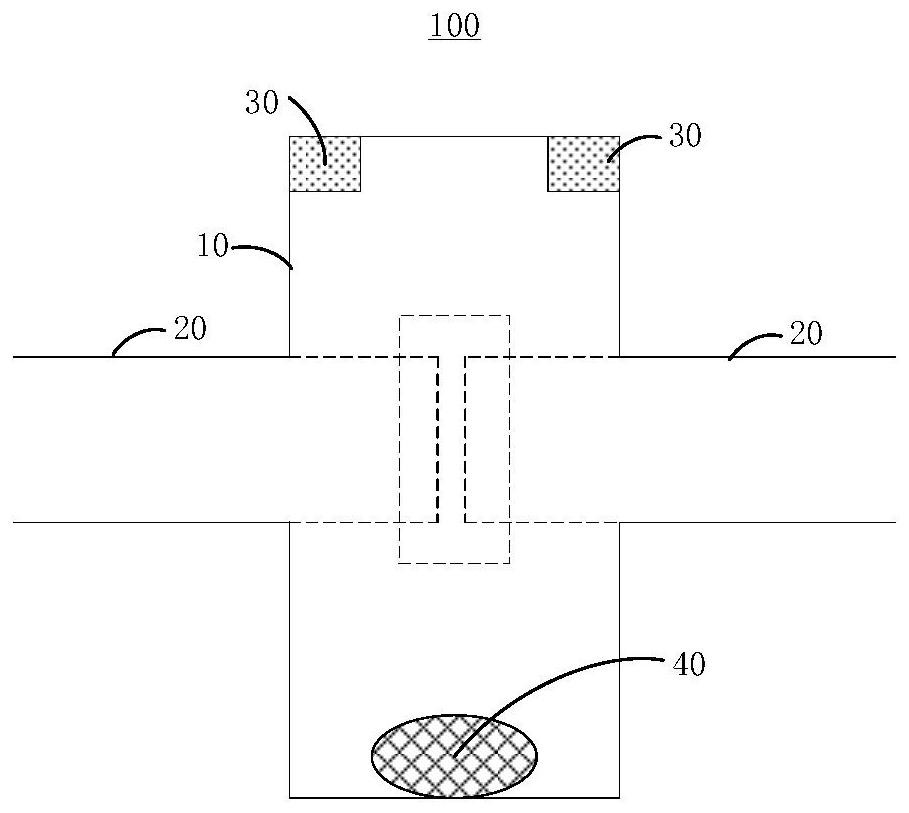

Reactor for simultaneous separation of hydrogen and oxygen from water

InactiveUS7935254B2Reduce needIncreasing introductionRegenerative fuel cellsIsotope separationWater useOxygen

We disclose a device for the production of hydrogen from water using heat. The device employs thermal water splitting and works essentially without electricity. It is based on the concept of a membrane reactor with two kinds of membranes allowing the separation of hydrogen and oxygen simultaneously in stoichiometric quantities from the reactor volume. The device has a special geometry resulting in a temperature distribution inside the reaction chamber to accommodate the use of hydrogen selective membranes. The device will help to reduce the need for hydrogen transport and storage as it will be rather compact for on-site use in households, small factories or gas stations. The use of the device in mobile applications is conceivable. The heat source of the device as described is combustion of a hydrocarbon using porous burner technology; however the device can be modified to exploit any other heat source, especially solar radiation.

Owner:H2 POWER SYST

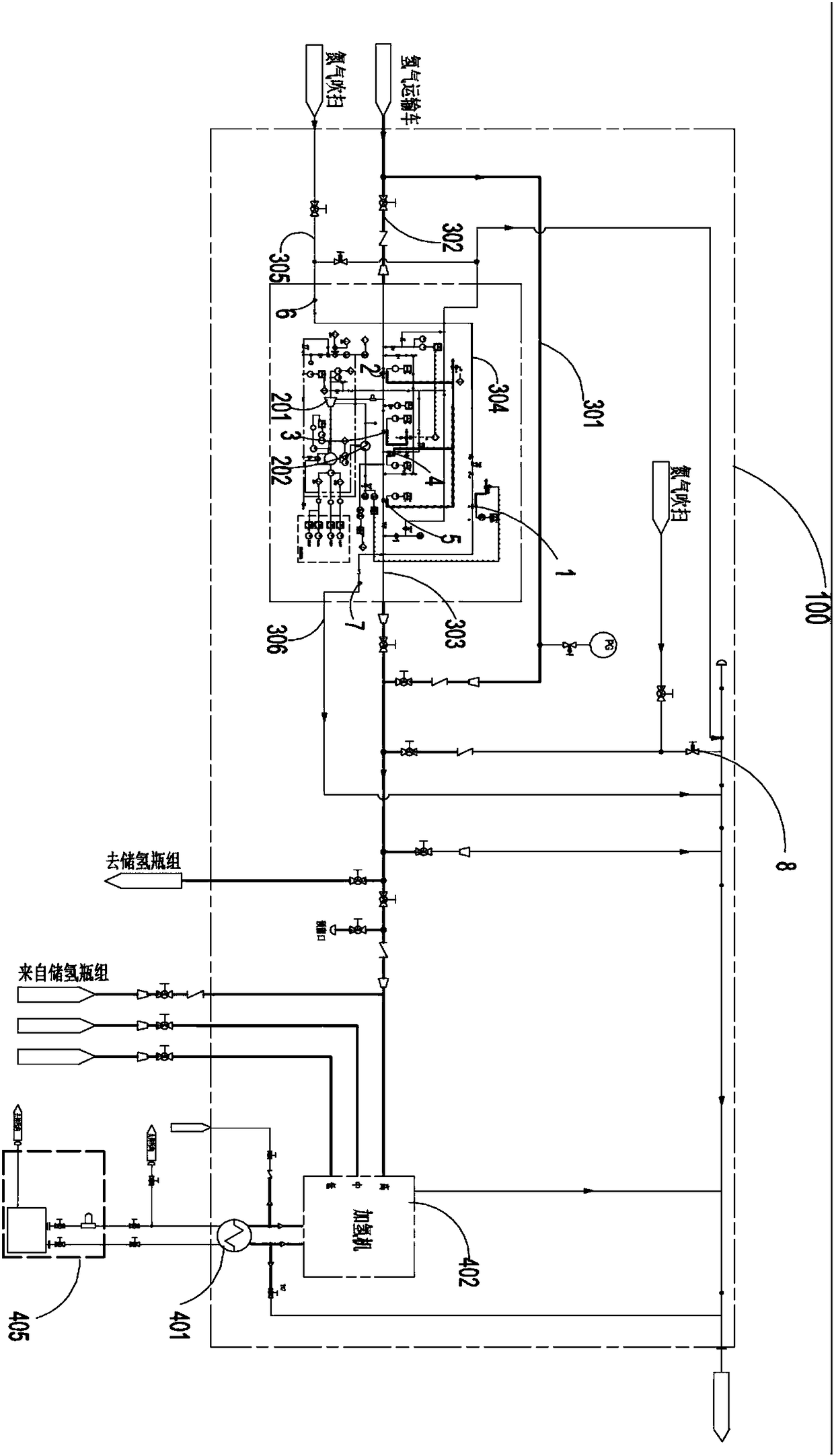

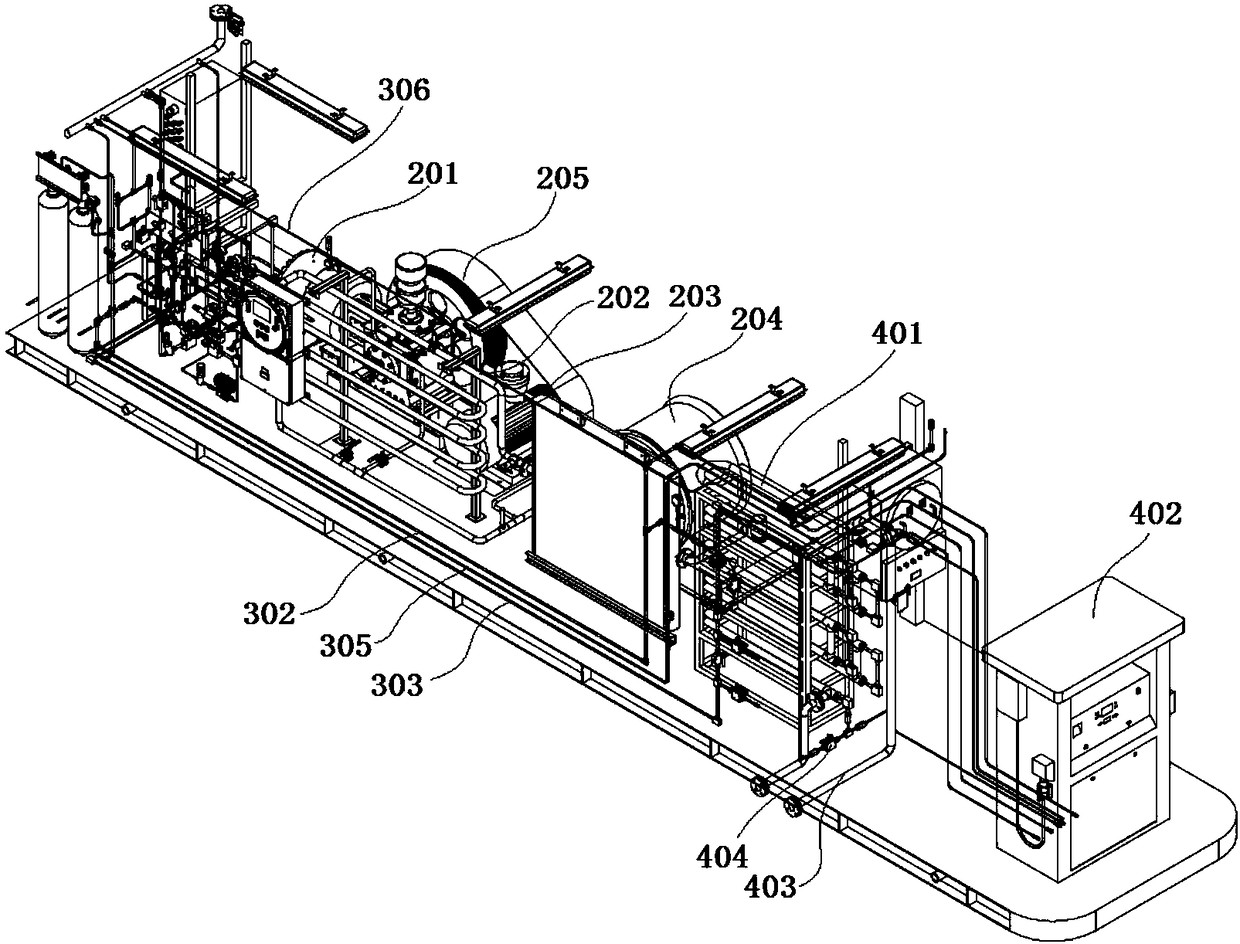

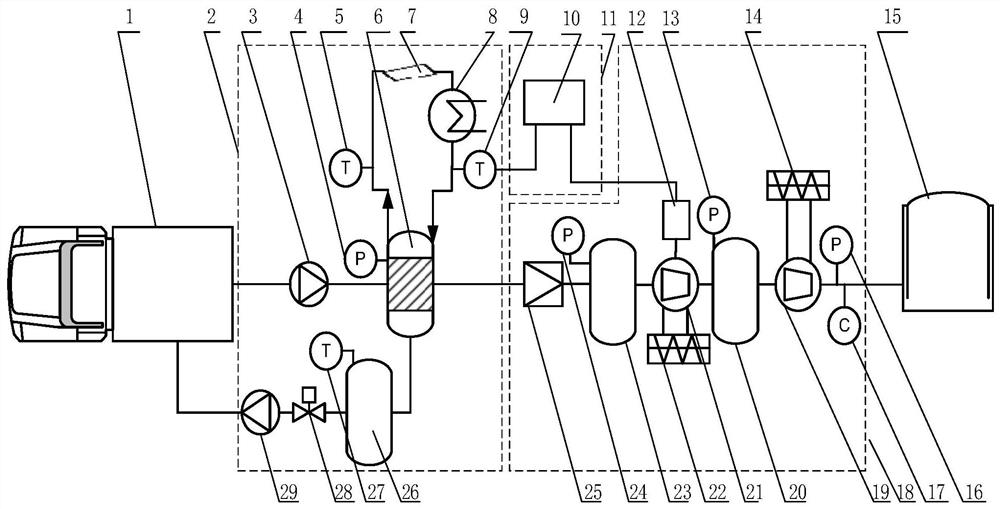

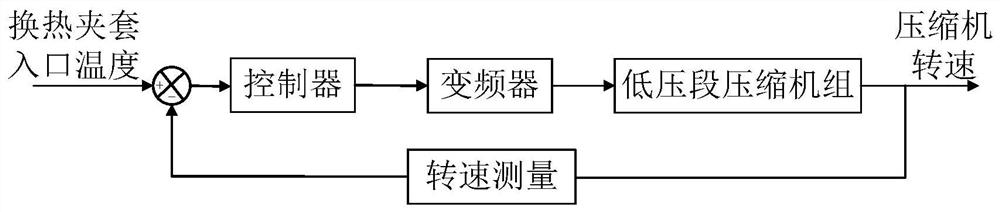

Hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and hydrogeneration method thereof

ActiveCN108361546ACompact structureSmall footprintVessel geometry/arrangement/sizeSecondary cellsProcess engineeringSmall footprint

The invention provides a hydrogeneration system of hydrogen compressor skid-mounted hydrogeneration equipment and a hydrogenation method. The system comprises the following components arranged insidea skid-mounted shell: a pressurizing component, a hydrogen dispenser, a circulation loop and a controller, wherein a gas inlet of a diaphragm compressor in the pressurizing component is connected witha hydrogen inlet pipe, the end of the hydrogen inlet pipe is provided with an input end connected with a gas outlet of a hydrogen transporting truck, a gas outlet of the diaphragm compressor is connected with a hydrogen outlet pipe, and hydrogen in the hydrogen outlet pipe is cooled when flowing through a first cooling heat exchange element; a gas inlet pipeline of the hydrogen dispenser is connected with the hydrogen outlet pipe, and hydrogen in the gas inlet pipeline is cooled when flowing through a second cooling heat exchange element; one end of the circulation loop communicates with thehydrogen inlet pipe, and the other end of the circulation loop communicates with the hydrogen outlet pipe; and a first control valve, a second control valve and a third control valve which are used for controlling on and off of the pipelines are arranged on the hydrogen inlet pipe, the hydrogen outlet pipe and the circulation loop correspondingly, and are all connected with the controller. The whole hydrogeneration system is compact in structural arrangement, small in occupied area, and large in hydrogeneration capacity.

Owner:上海氢枫能源技术有限公司

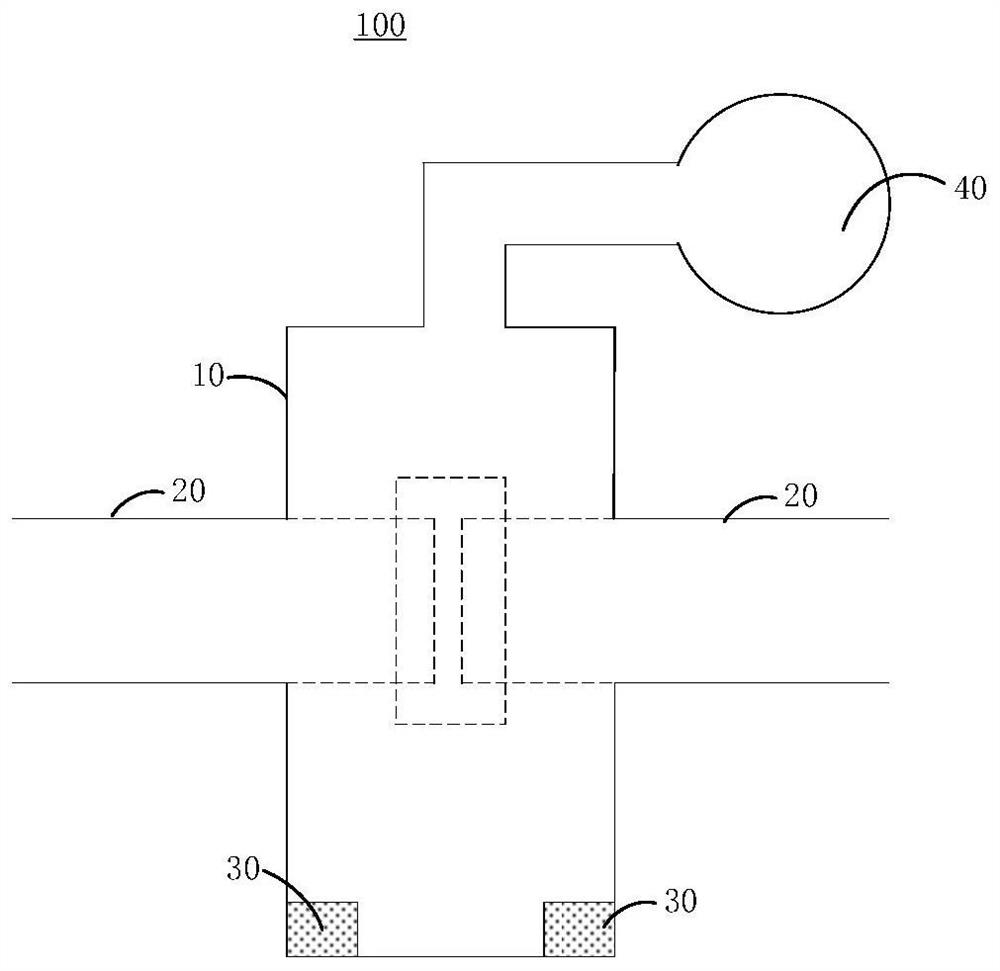

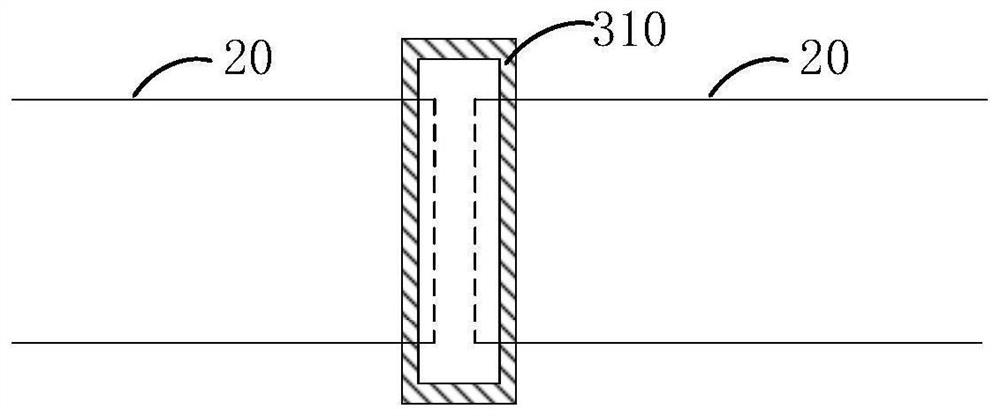

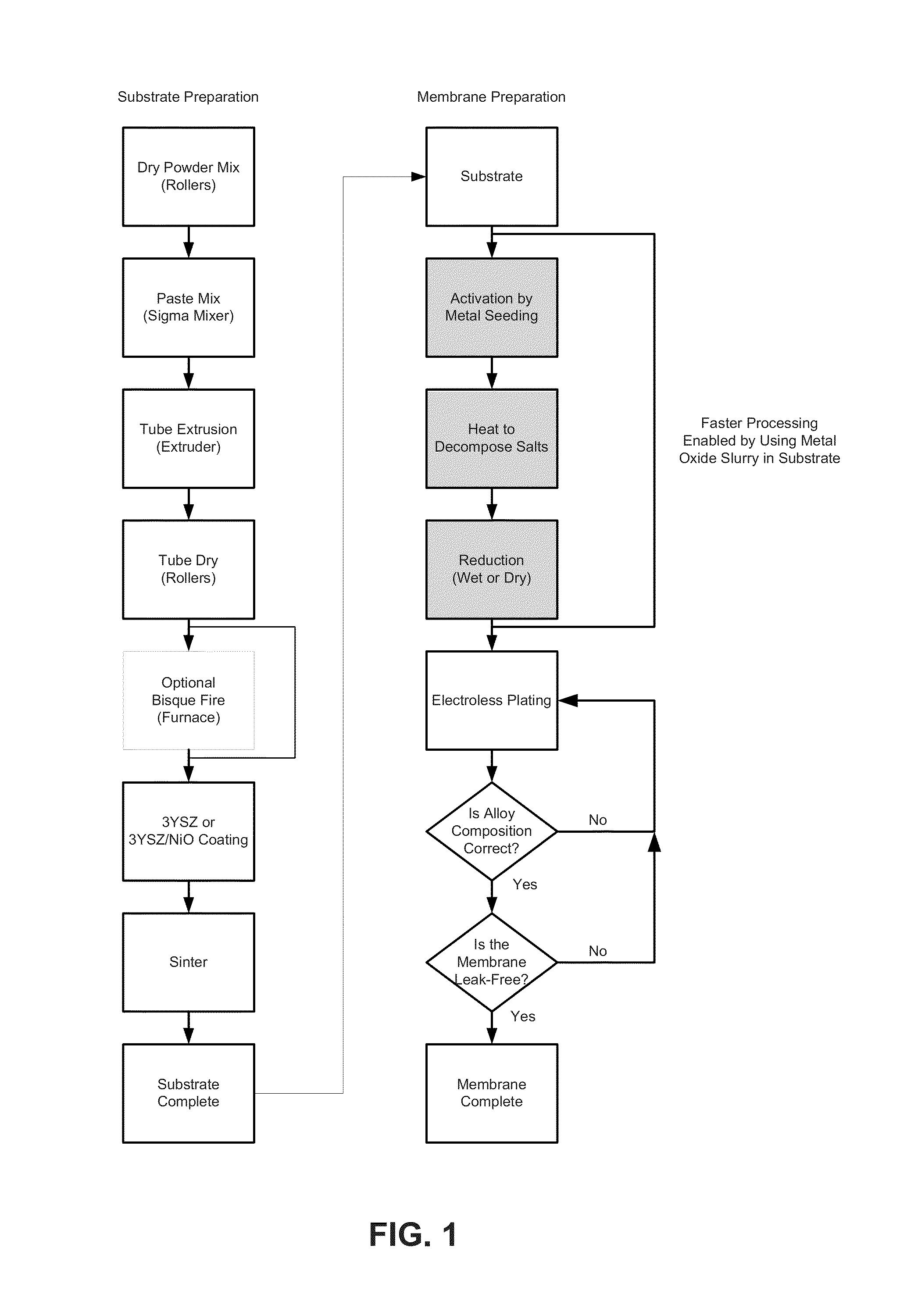

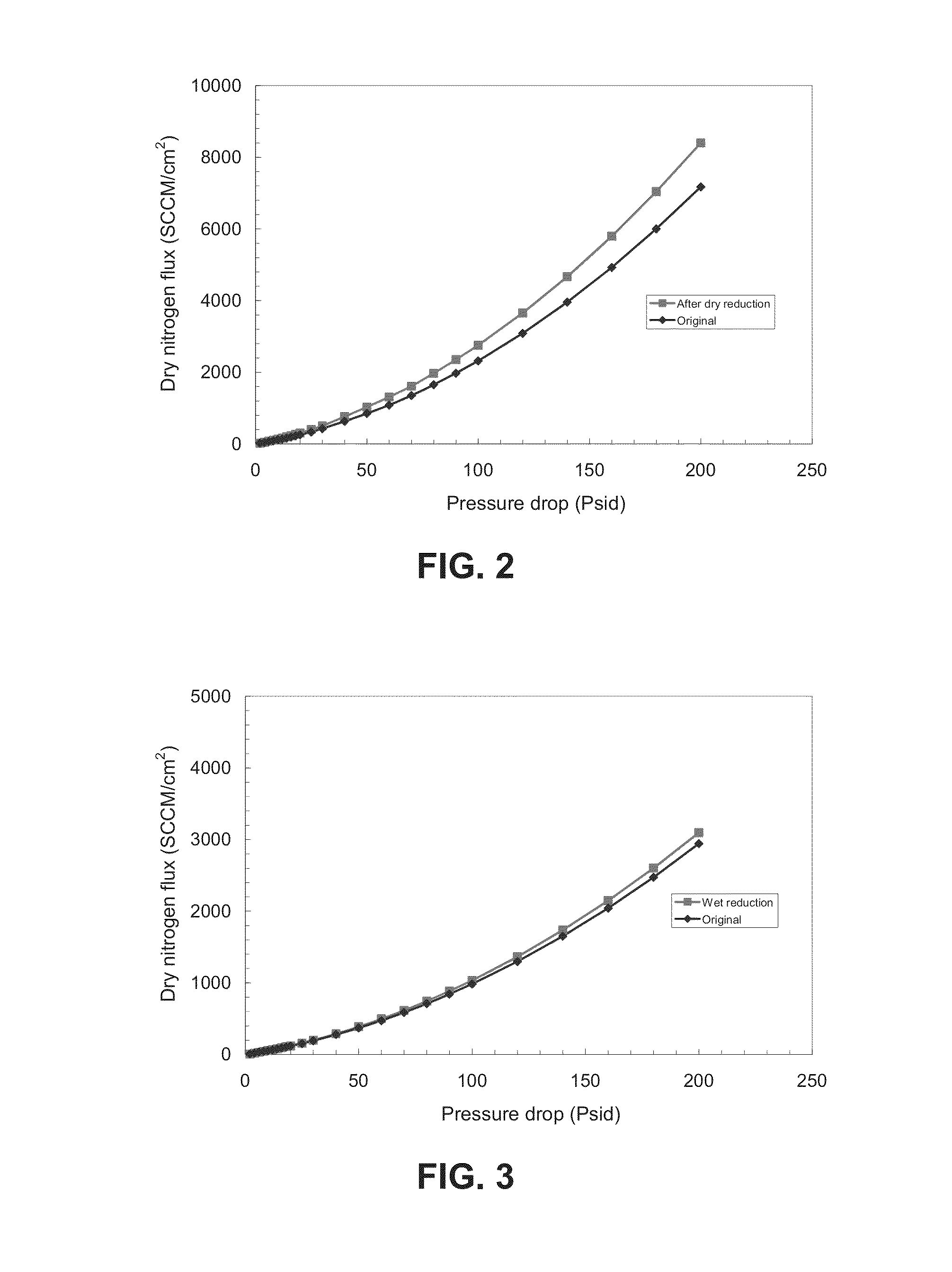

Hydrogen transport membrane fabrication method

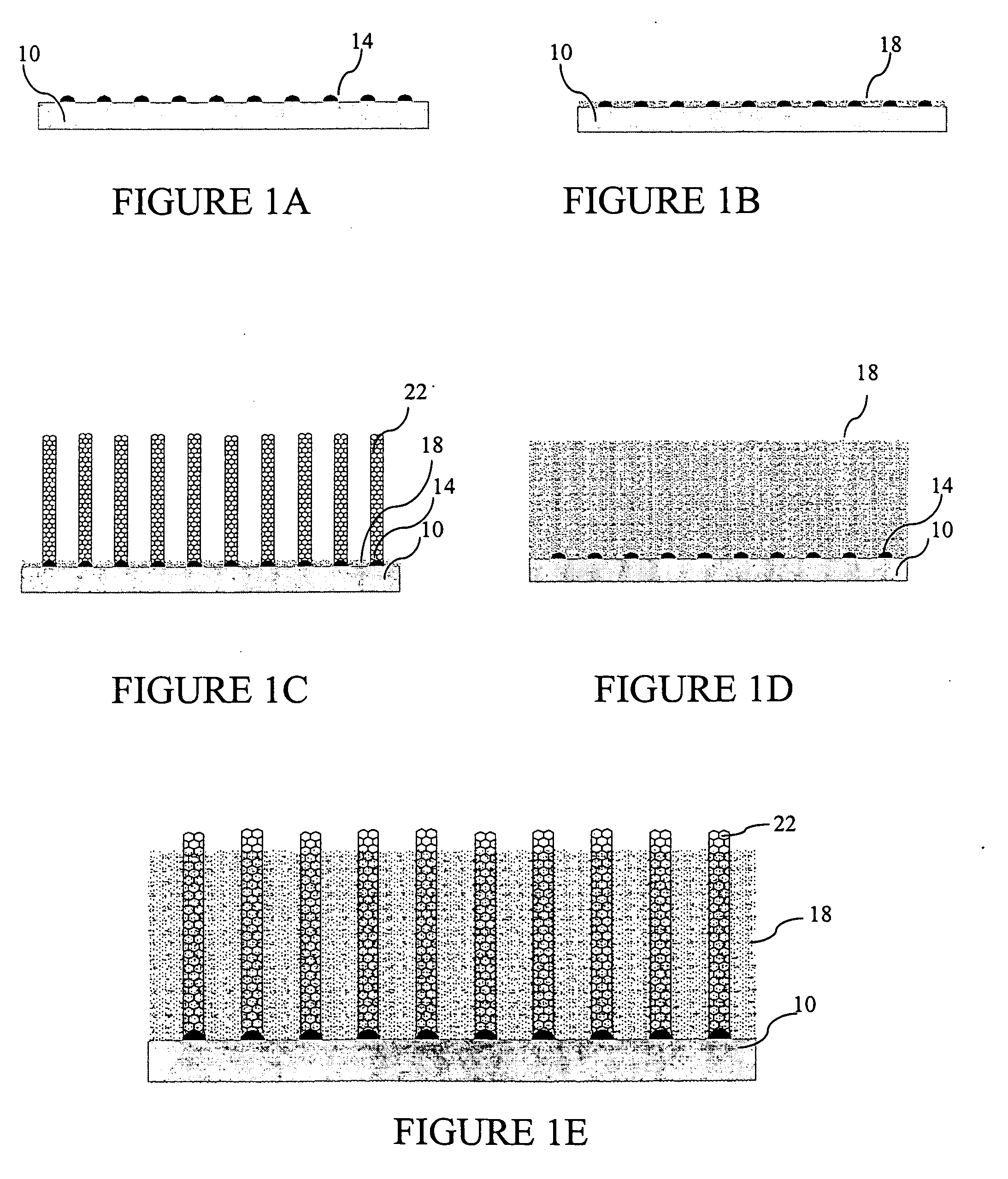

InactiveUS20070110991A1Inhibits the formation of defectsMembranesSemi-permeable membranesAlloySalt solution

A method of forming a hydrogen transport membrane to separate hydrogen from a hydrogen containing feed in which a porous ceramic support is formed to support a dense layer of palladium or an alloy of palladium serving as a hydrogen transport material. Isolated deposits of palladium, a palladium alloy or a component of such alloy are produced on a surface of the porous ceramic support that bridge pores within the porous ceramic support without penetrating the pores and without bridging regions of the surface defined between the pores. The isolated deposits of the metal are produced by an electroless plating process that involves contacting the porous ceramic support with a precipitating agent so that the precipitating agent fills the pores but does not seep out of the pores onto the regions of the surfaces defined between the pores. The surface is then contacted with a salt solution containing a salt of the metal so that said metal precipitates and produces the isolated deposits of the metal. Thereafter, the dense layer is formed on the surface having the isolated deposits.

Owner:PRAXAIR TECH INC

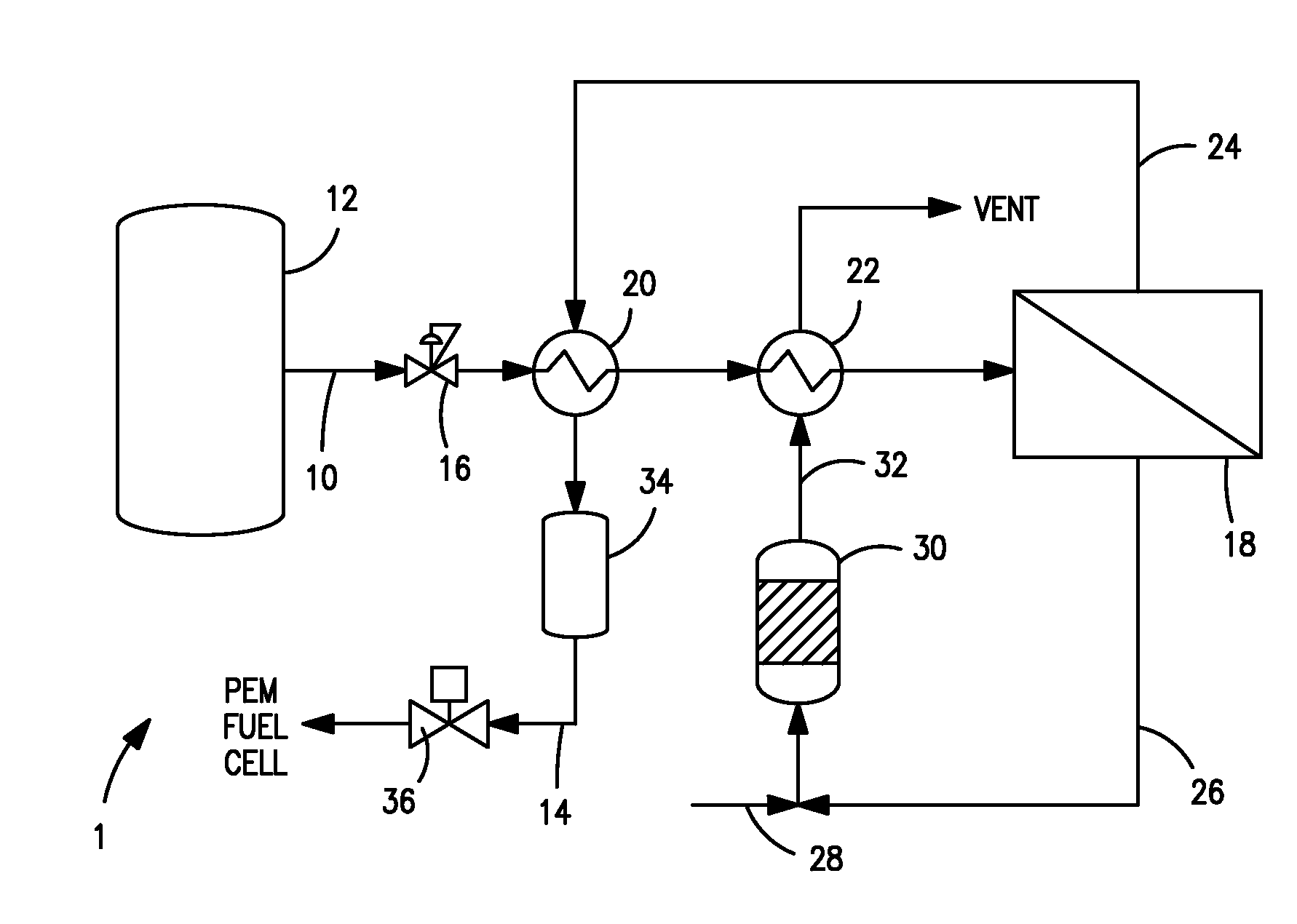

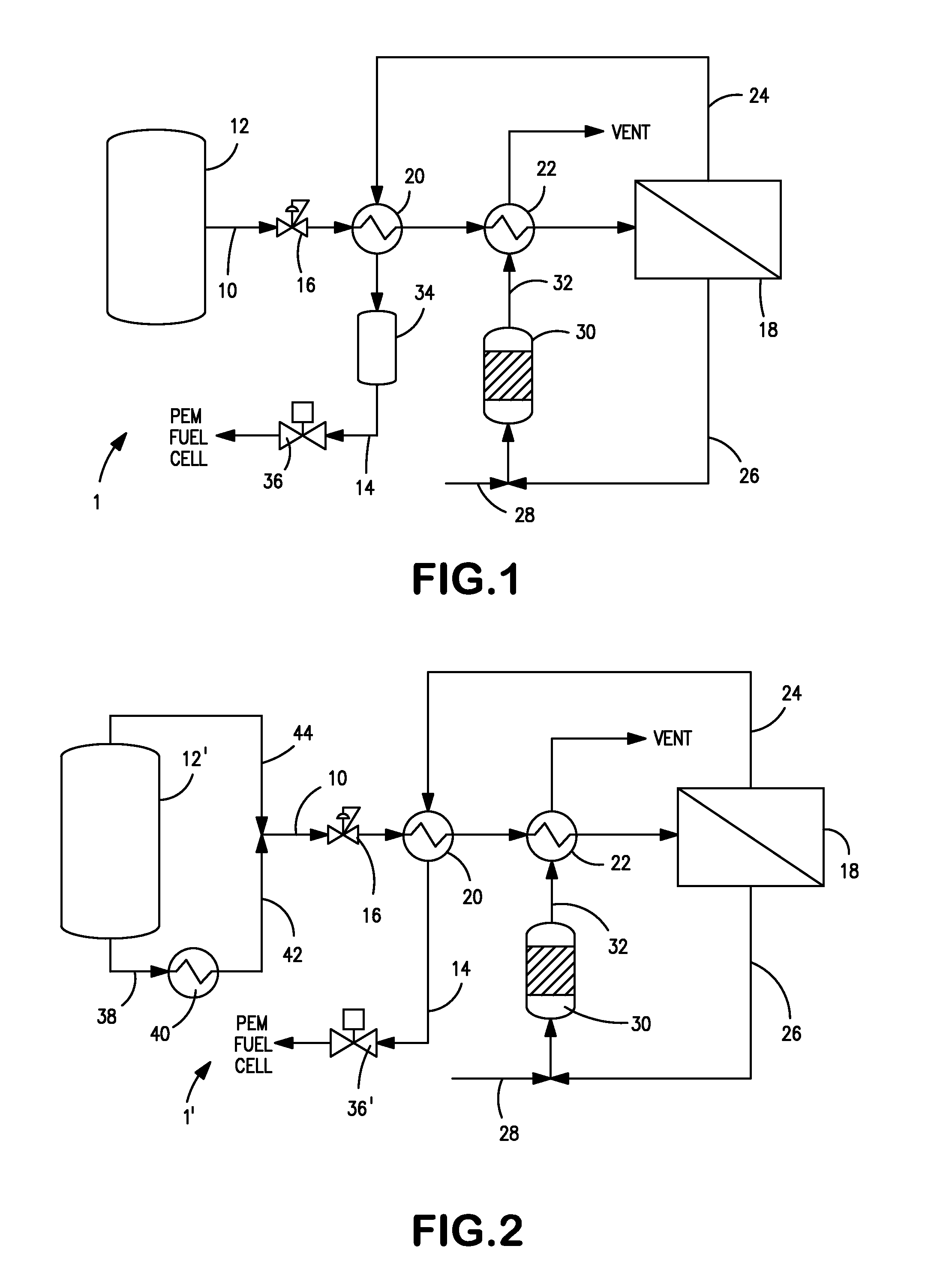

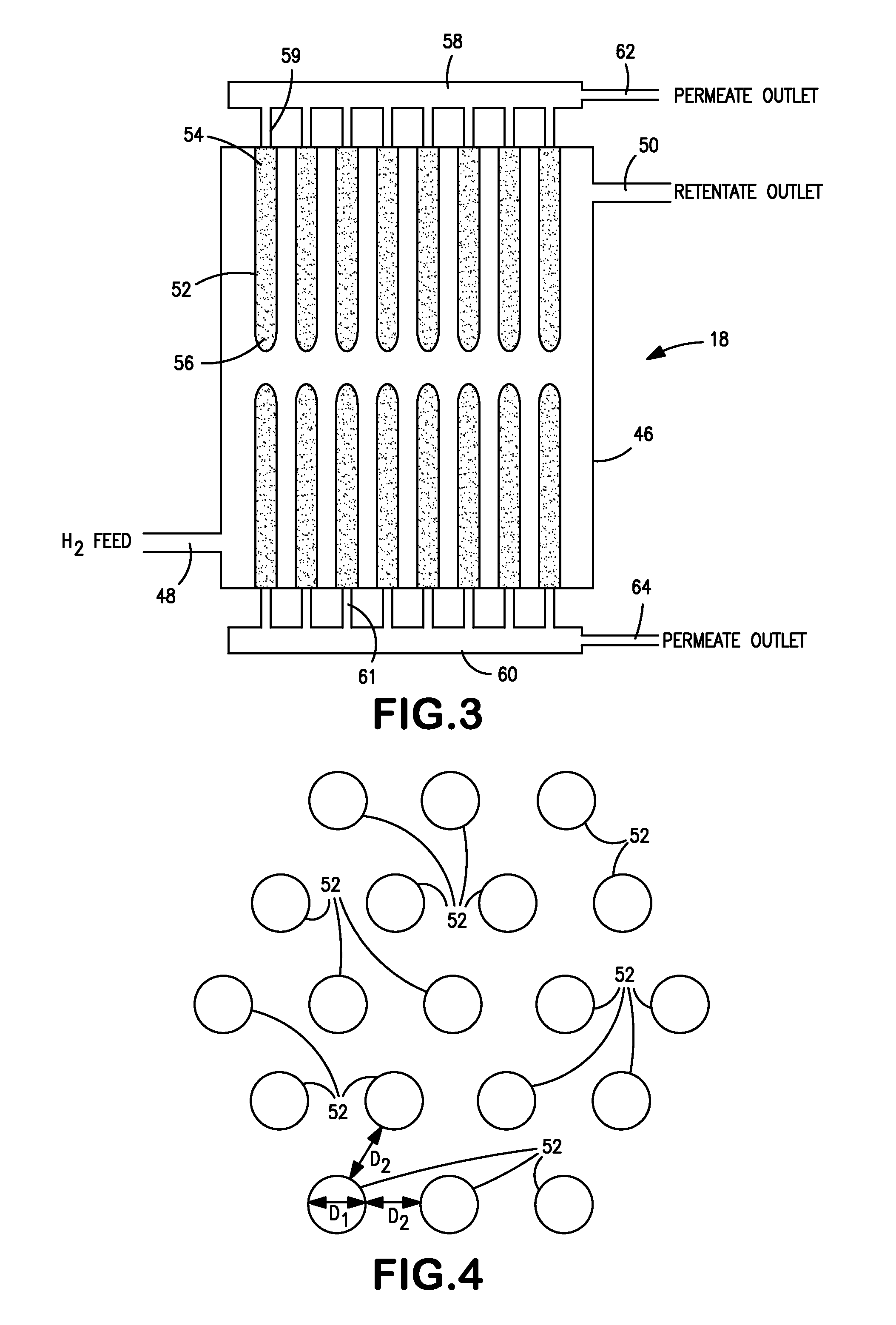

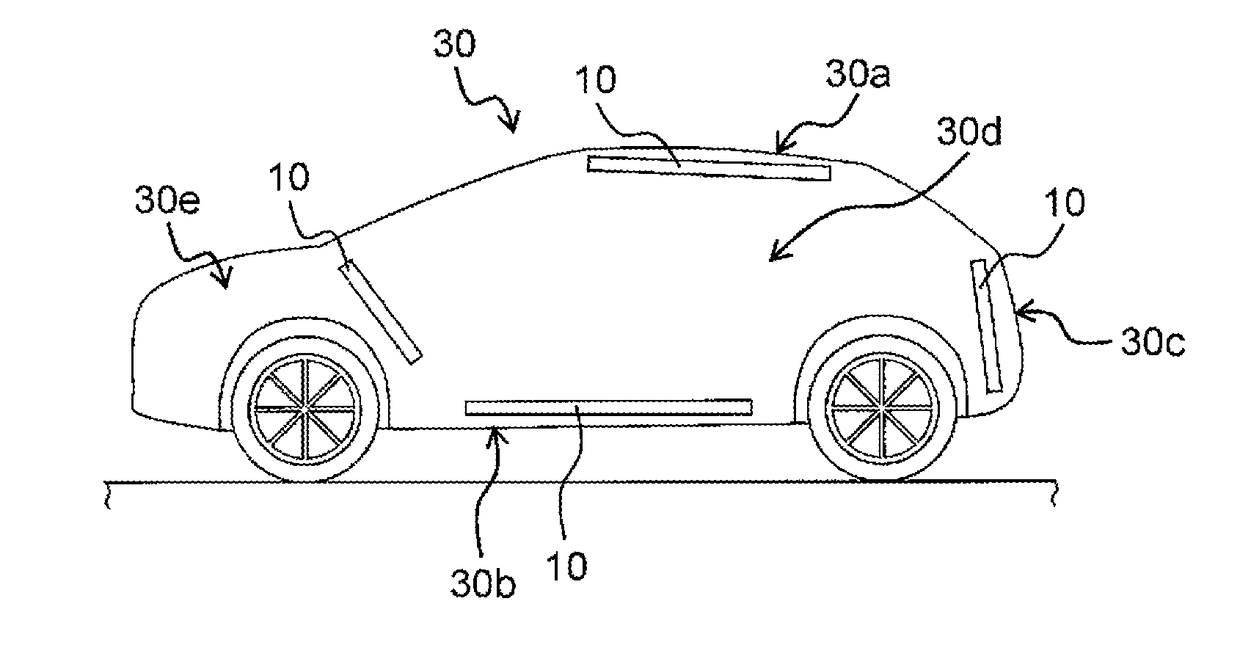

Hydrogen purification for fuel cell vehicle

InactiveUS7628842B2Fuel cell heat exchangeReactant parameters controlProcess engineeringHydrogen permeation

A purification system and method for purifying a hydrogen stream supplied from a storage tank mounted in a vehicle to produce a purified hydrogen stream for use in a PEM fuel cell system that is utilized within the vehicle. The hydrogen is purified within a membrane separator having hydrogen transport membrane elements having a dense metallic layer such as palladium to separate the hydrogen from the impurities. The separated hydrogen is supplied to the PEM fuel cell. In order to heat the membrane to its operational temperature, heat is recovered from the hydrogen permeate stream of the membrane system in a first heat exchanger and heat is generated by combusting the retentate stream containing residual hydrogen and impurities.

Owner:PRAXAIR TECH INC

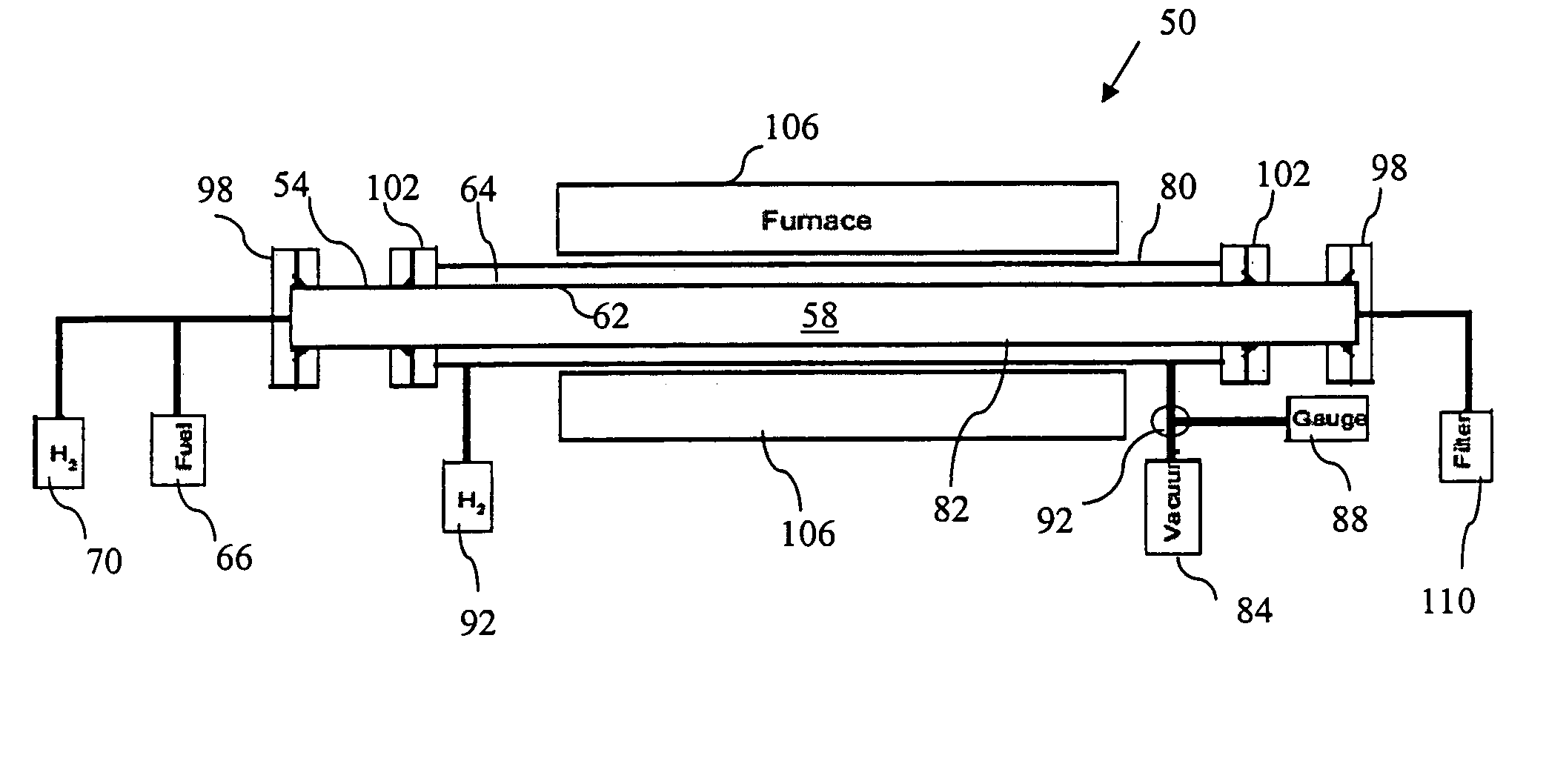

Hydrogen separation process

A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to a hydrogen separation membrane system comprising a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to an integrated water gas shift / hydrogen separation membrane system wherein the hydrogen separation membrane system comprises a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for pretreating a membrane, comprising: heating the membrane to a desired operating temperature and desired feed pressure in a flow of inert gas for a sufficient time to cause the membrane to mechanically deform; decreasing the feed pressure to approximately ambient pressure; and optionally, flowing an oxidizing agent across the membrane before, during, or after deformation of the membrane. A method of supporting a hydrogen separation membrane system comprising selecting a hydrogen separation membrane system comprising one or more catalyst outer layers deposited on a hydrogen transport membrane layer and sealing the hydrogen separation membrane system to a porous support.

Owner:ELTRON RES INC

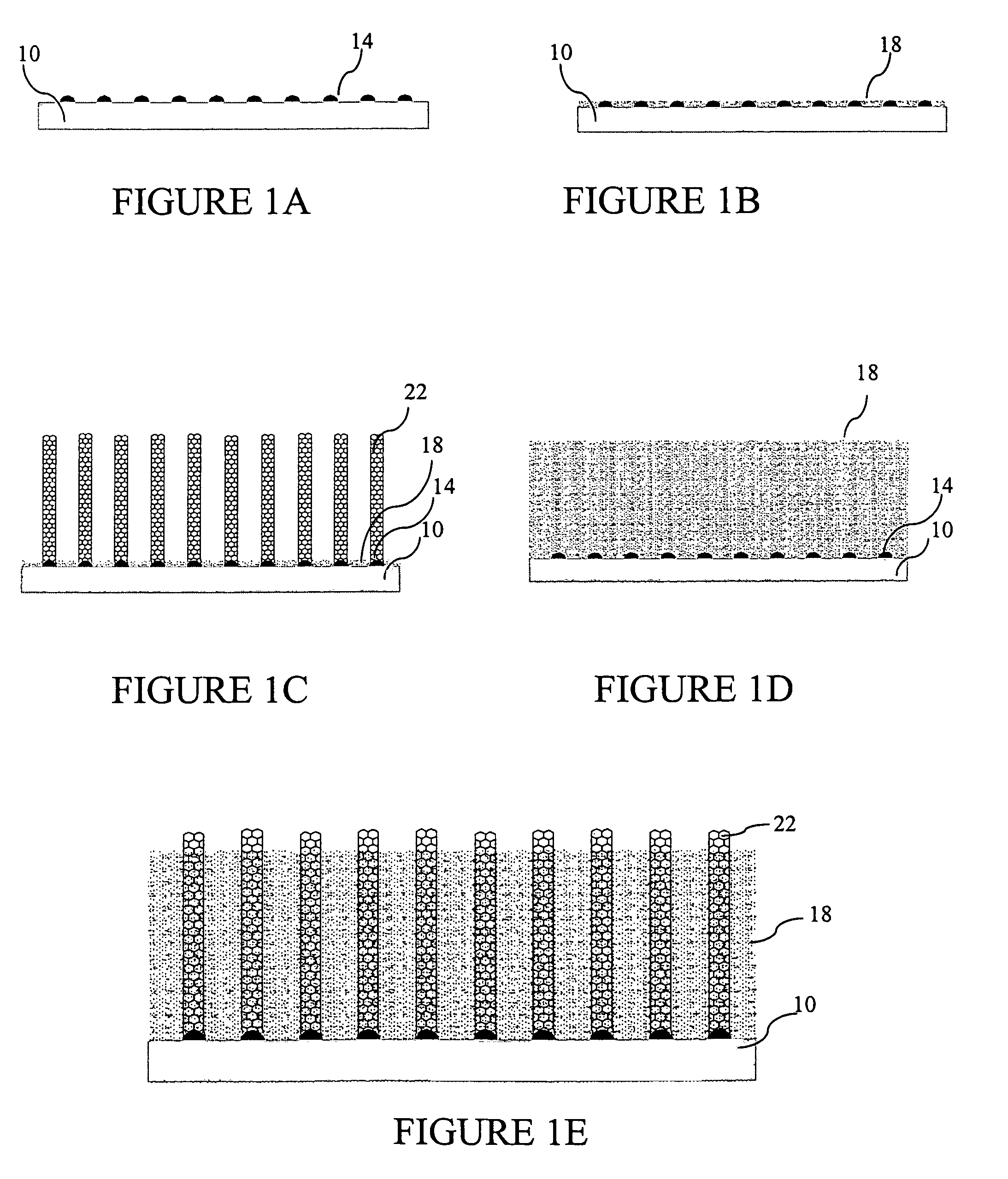

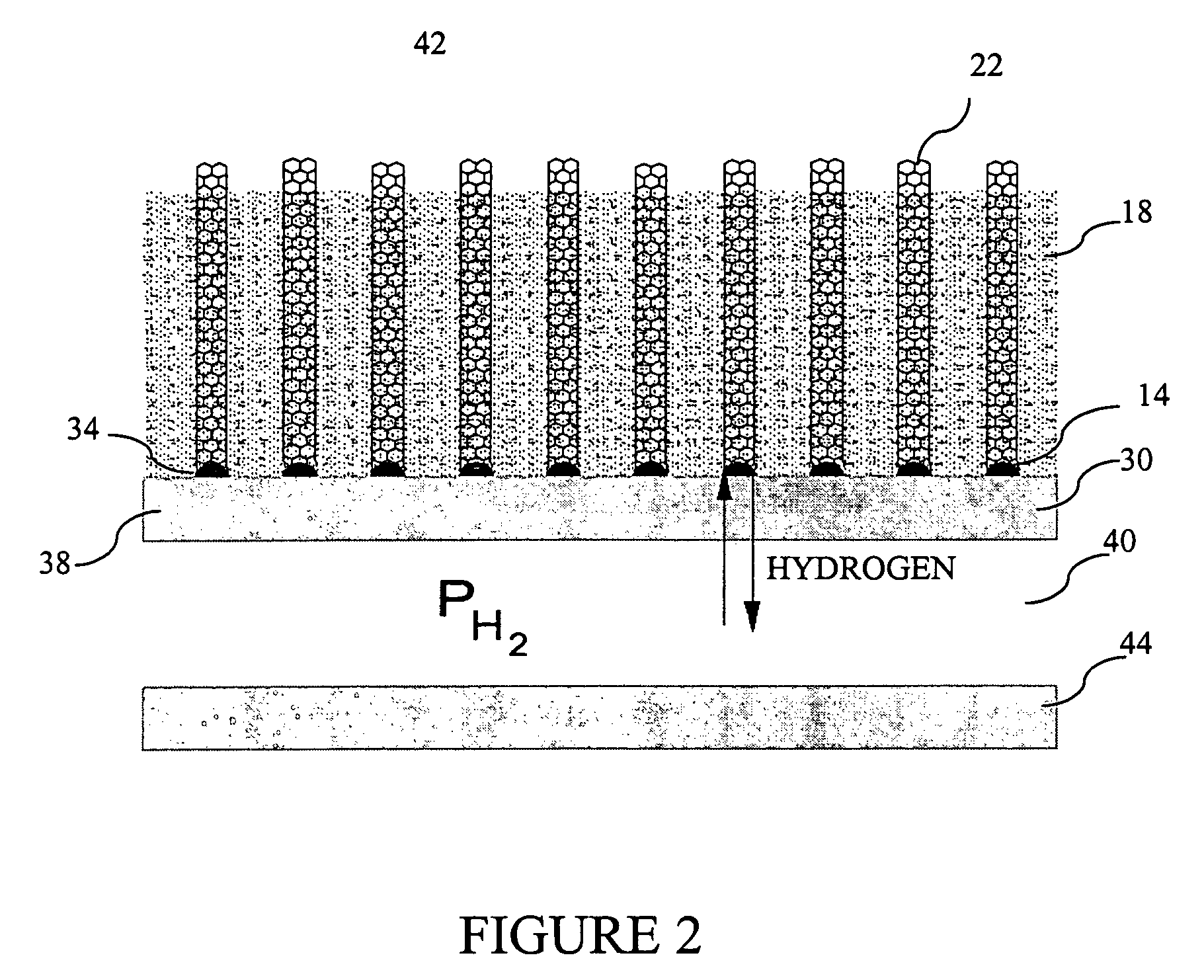

System and method for controlling hydrogen elimination during carbon nanotube synthesis from hydrocarbons

InactiveUS20070048210A1Material nanotechnologyPhysical/chemical process catalystsGas phaseHydrocotyle bowlesioides

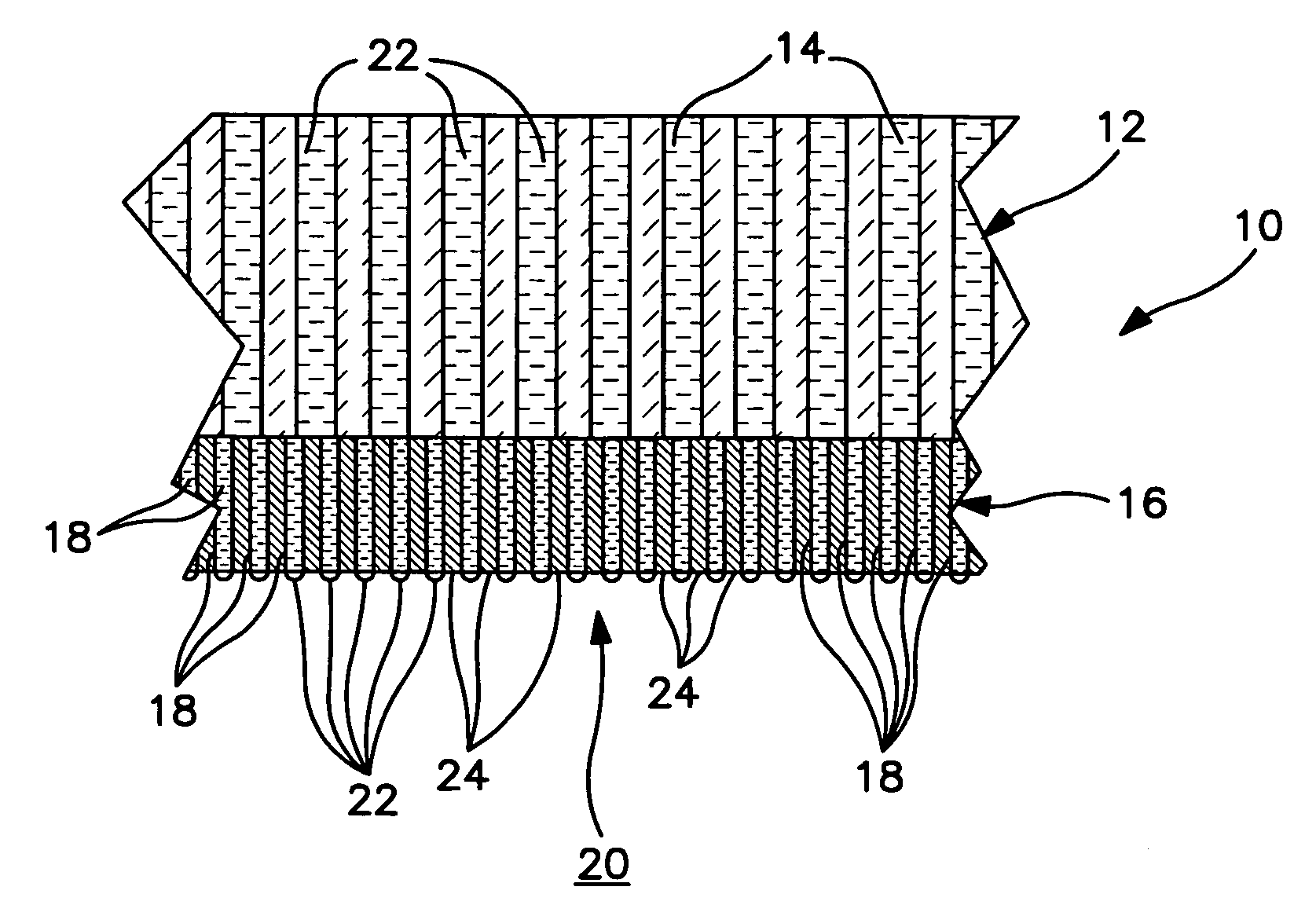

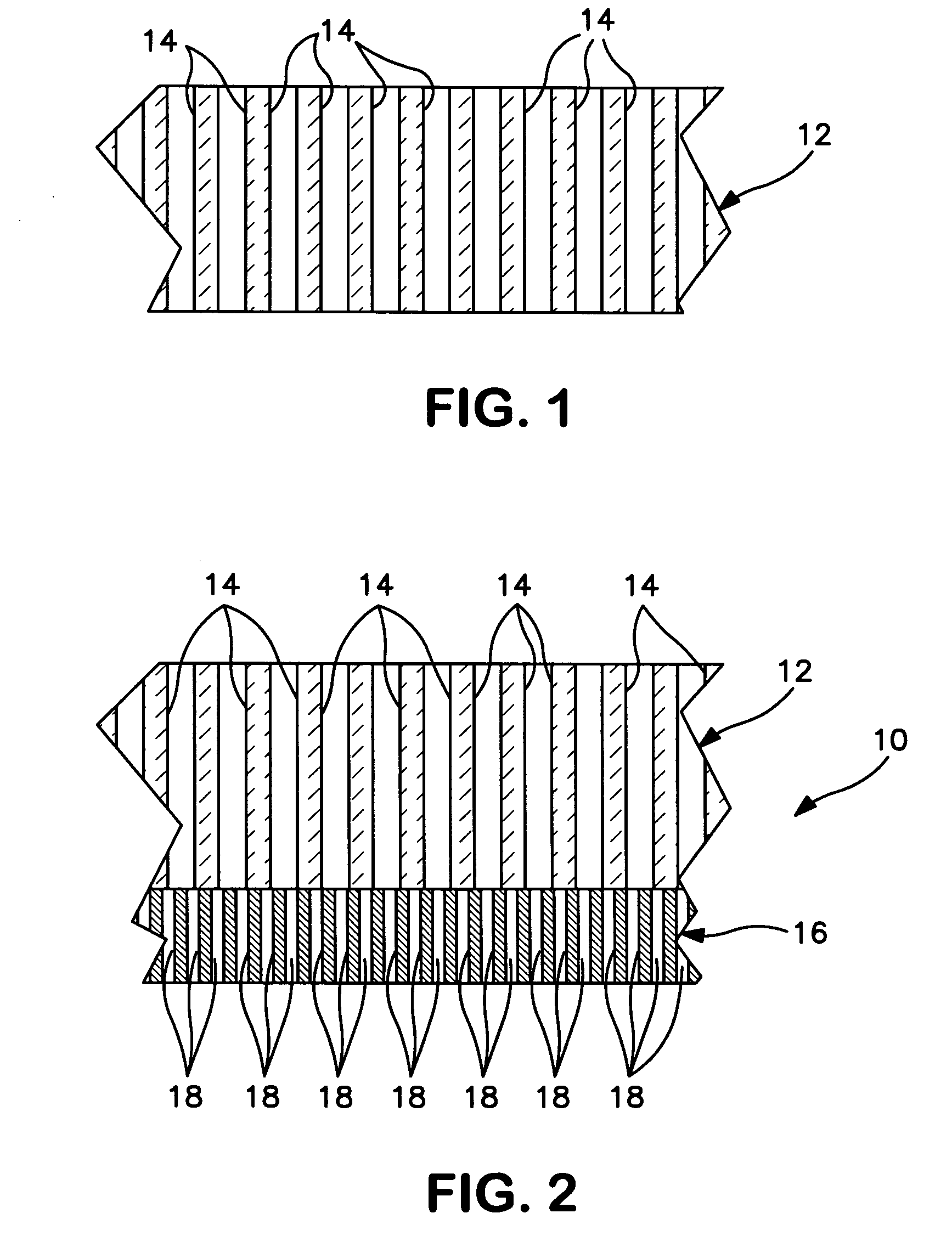

A system and method for producing carbon nanotubes by chemical vapor deposition includes a catalyst support having first and second surfaces. The catalyst support is capable of hydrogen transport from the first to the second surface. A catalyst is provided on the first surface of the catalyst support. The catalyst is selected to catalyze the chemical vapor deposition formation of carbon nanotubes. A fuel source is provided for supplying fuel to the catalyst.

Owner:UT BATTELLE LLC

Hydrogen transport membrane fabrication method

InactiveUS7531215B2Inhibits the formation of defectsMembranesSemi-permeable membranesAlloyPorous ceramics

A method of forming a hydrogen transport membrane to separate hydrogen from a hydrogen containing feed in which a porous ceramic support is formed to support a dense layer of palladium or an alloy of palladium serving as a hydrogen transport material. Isolated deposits of palladium, a palladium alloy or a component of such alloy are produced on a surface of the porous ceramic support that bridge pores within the porous ceramic support without penetrating the pores and without bridging regions of the surface defined between the pores. The isolated deposits of the metal are produced by an electroless plating process.

Owner:PRAXAIR TECH INC

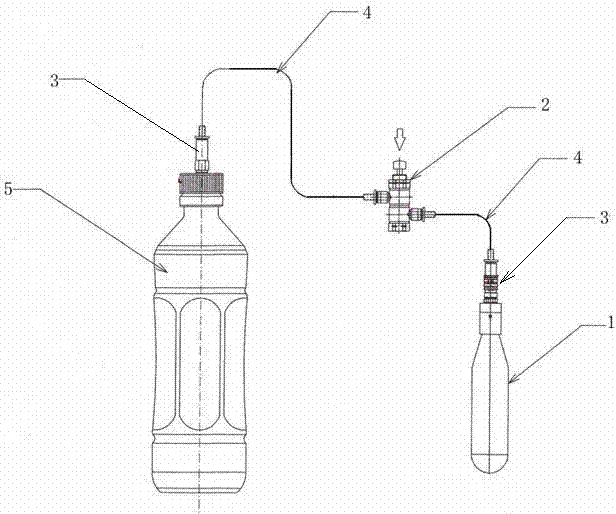

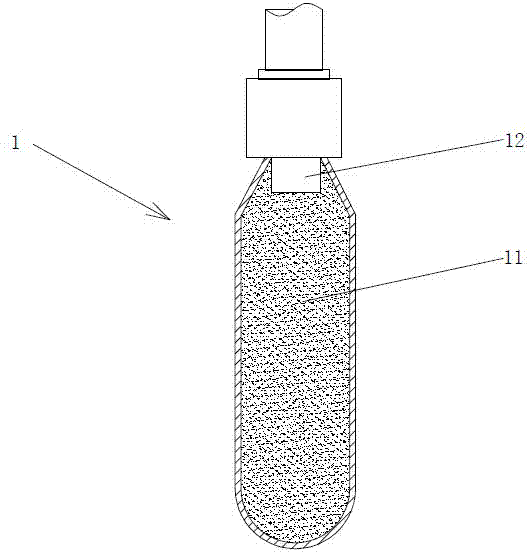

Portable preparation method capable of immediately preparing hydrogen ionized water when being required and apparatus thereof

ActiveCN104761040AEasy to carryGive full play to health careWater/sewage treatment by substance additionEnvironmental chemistryHydrogen transport

The invention discloses a portable preparation method capable of immediately preparing hydrogen ionized water when being required, which is characterized in that a hydrogen storage alloy is filled in a hydrogen storage tank, hydrogen transport elements are prepared for the hydrogen storage tank in order to form a hydrogen ionized water preparation apparatus, the hydrogen transport elements comprise a vent valve, a connecting pipe and a seal joint, so that the hydrogen ionized water preparation apparatus and a drinking water container port are sealed and connected; a container with the port capable of cooperating with the seal joint of the hydrogen ionized water preparation apparatus is used for filling the drinking water, air in the drinking water container is evacuated, then the port of the drinking water container and the seal joint are sealed and connected; the vent valve of the hydrogen ionized water preparation apparatus is opened, and a proper amount of hydrogen is injected in drinking water in the container, then the vent valve is closed, the container is shaken, hydrogen is fully dissolved in water to generate saturated or supersaturated hydrogen ionized water which is the hydrogen ionized water capable of being immediately prepared and drunk. The invention also discloses an apparatus adapted to the method. The method is not restricted to environment and operation condition, the hydrogen ionized water is capable of being immediately prepared and drunk, and the method can develop health care and treatment effect of the hydrogen ionized water in a convenient and maximum degree.

Owner:叶小剑

Liquid hydrogen storage type hydrogen refueling station mixed filling system

ActiveCN113483259AGood filling effectReduce energy consumptionHydrogen technologiesContainer discharging methodsHigh pressure hydrogenLiquid hydrogen

The invention discloses a liquid hydrogen storage type hydrogen refueling station mixed filling system. The system comprises a 35 MPa hydrogen filling unit and a 70 MPa hydrogen filling unit which are connected with a liquid hydrogen storage tank, each of the two filling units comprises a liquid hydrogen pump communicating with the liquid hydrogen storage tank, a fluid separator for changing the flow direction and flow of hydrogen and a high-pressure vaporizer, the 35MPa hydrogen filling unit further comprises a 90MPa buffer bottle group, a 45MPa buffer bottle group and a first hydrogen filling machine, and the 70MPa hydrogen filling unit further comprises a second liquid hydrogen conveying pipe, a high-pressure hydrogen conveying pipe, a gas-liquid mixer and a second hydrogen adding machine. The system has the advantages that the hydrogen storage capacity is large, the energy consumption is low, and the filling requirements of different forms of hydrogen can be met.

Owner:SOUTHEAST UNIV

Recombinant separator

A heterogeneous, cellulose battery separator made of a mixture of cellulose and a polymer with hydrogen permeability for use in zinc-based batteries exhibiting increased hydrogen transport through the membrane while maintaining low electrical impedance and exhibiting resistance to zinc ion transport preventing zinc dendrite formation.

Owner:ZPOWER LLC

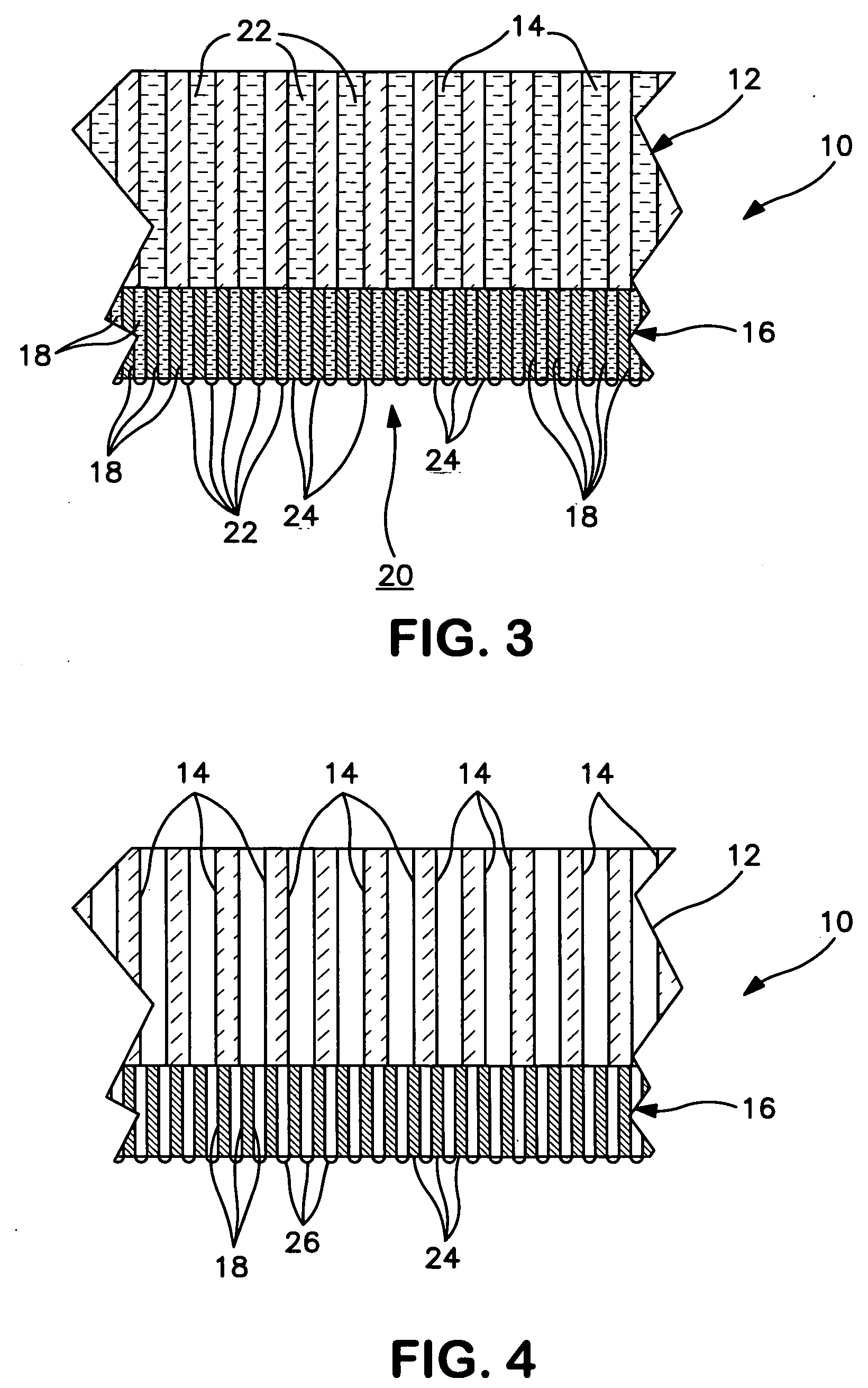

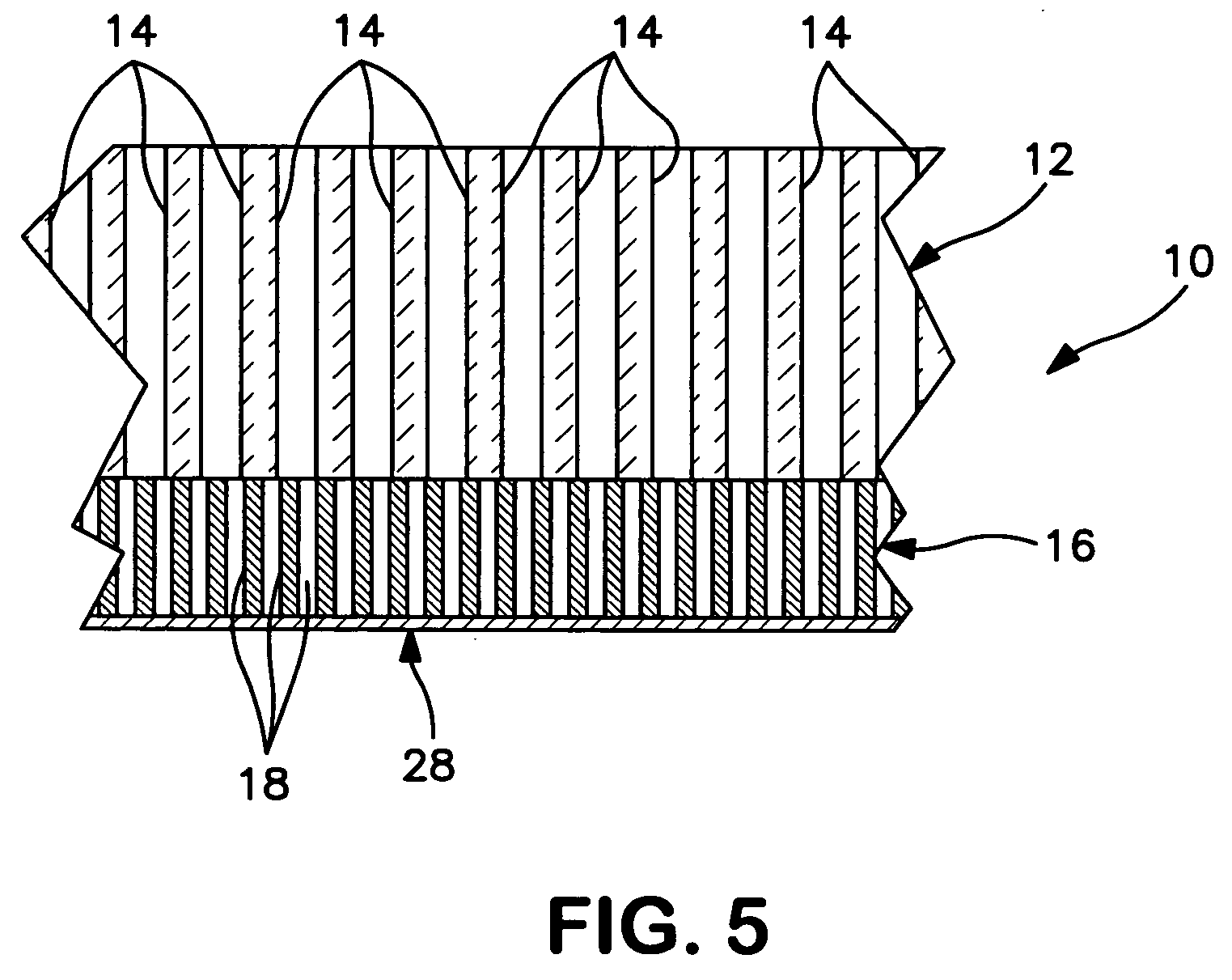

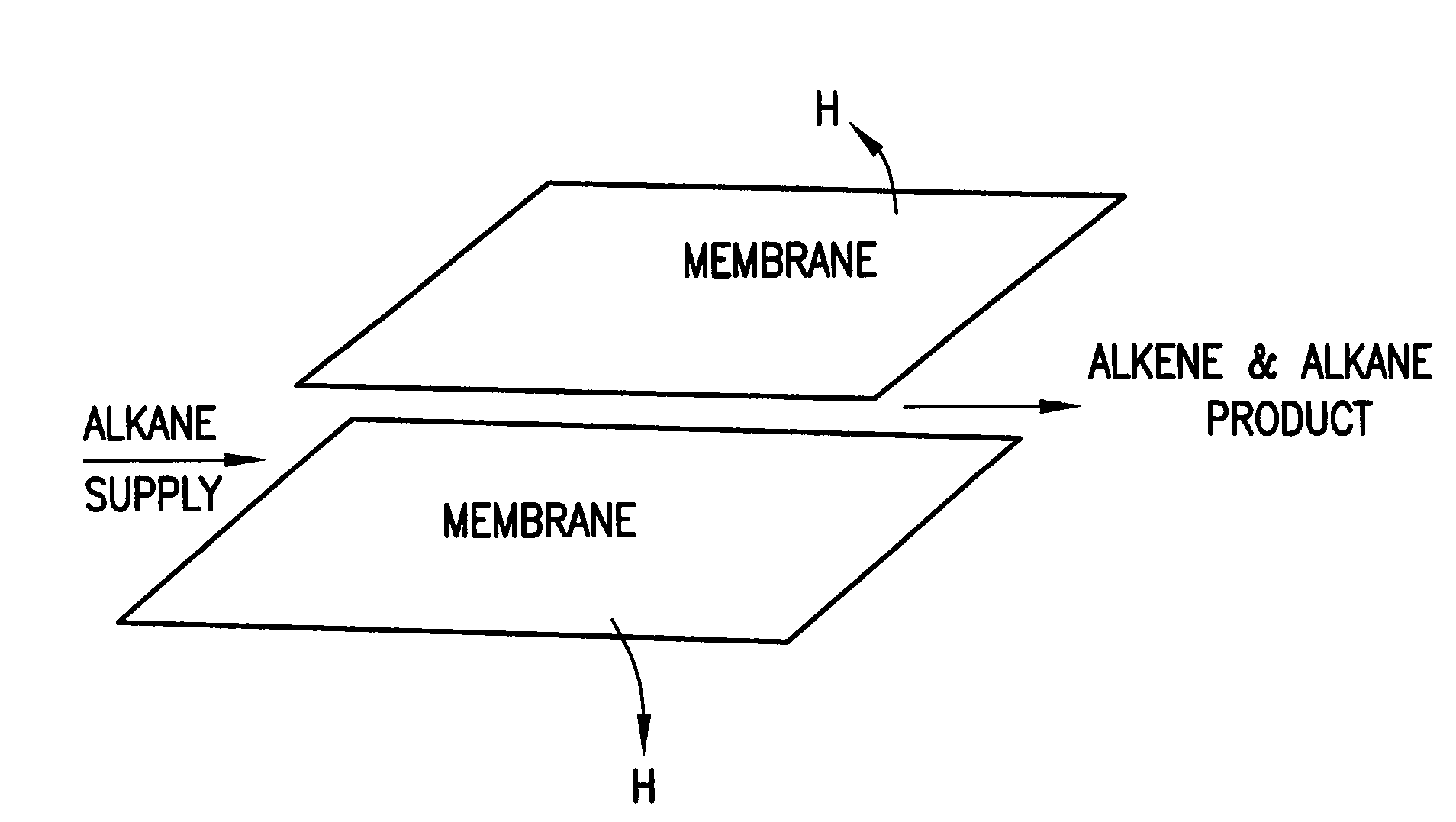

Hydrogen transport membranes for dehydrogenation reactions

InactiveUS7329791B2High yieldGood choiceCatalystsHydrocarbon preparation catalystsOxide ceramicHigher alkanes

A method of converting C2 and / or higher alkanes to olefins by contacting a feedstock containing C2 and / or higher alkanes with a first surface of a metal composite membrane of a sintered homogenous mixture of an Al oxide or stabilized or partially stabilized Zr oxide ceramic powder and a metal powder of one or more of Pd, Nb, V, Zr, Ta and / or alloys or mixtures thereof. The alkanes dehydrogenate to olefins by contact with the first surface with substantially only atomic hydrogen from the dehydrogenation of the alkanes passing through the metal composite membrane. Apparatus for effecting the conversion and separation is also disclosed.

Owner:UCHICAGO ARGONNE LLC

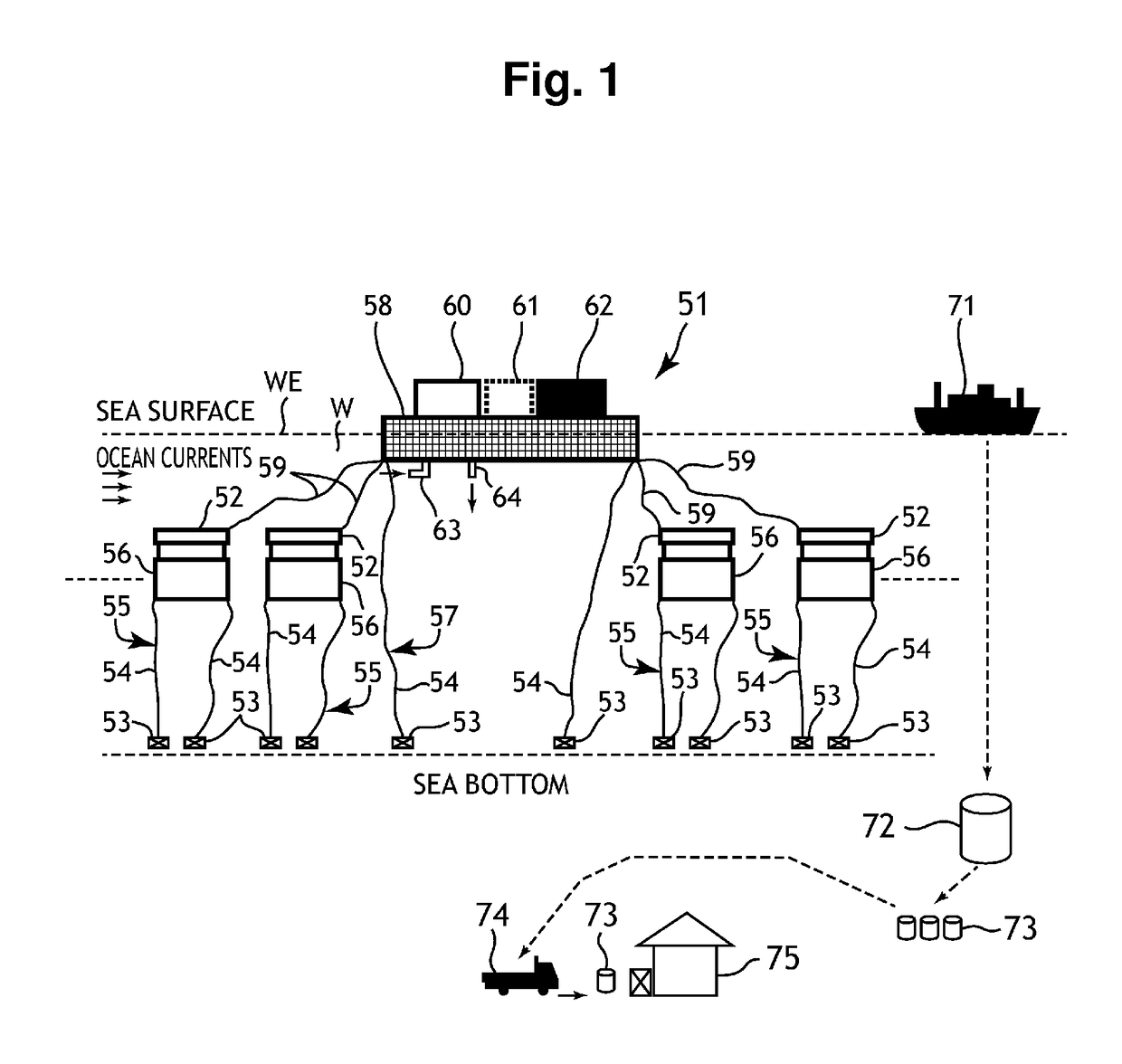

Seawater hydrogen production conveying system and method based on existing offshore wind plant

InactiveCN112161196AReduce the cost of hydrogen productionGas handling applicationsGas handling/storage effectsEnvironmental engineeringAtmospheric sciences

The invention belongs to the field of offshore wind power, and particularly relates to a seawater hydrogen production conveying system and method based on an existing offshore wind power plant. The system comprises a wind driven generator, a seawater electrolytic tank device and a hydrogen conveying unit, wherein the wind driven generator is used for converting wind energy to electric energy, theseawater electrolytic tank device is used for electrolyzing seawater by utilizing electric energy supplied by the wind driven generator, and the hydrogen conveying unit is used for conveying hydrogenprepared by the seawater electrolytic tank device to the land. According to the seawater hydrogen production conveying system and method based on the existing offshore wind power plant, offshore windpower and seawater hydrogen production are combined, the resource advantages of an offshore wind power plant are fully utilized, the seawater hydrogen production cost is reduced, and finally coordinated development of offshore green wind energy and seawater hydrogen production is achieved.

Owner:ZHEJIANG UNIV

Hydrogen transport membranes for dehydrogenation reactions

InactiveUS20050222479A1High yieldGood choiceCatalystsHydrocarbon preparation catalystsOxide ceramicHigher alkanes

A method of converting C2 and / or higher alkanes to olefins by contacting a feedstock containing C2 and / or higher alkanes with a first surface of a metal composite membrane of a sintered homogenous mixture of an Al oxide or stabilized or partially stabilized Zr oxide ceramic powder and a metal powder of one or more of Pd, Nb, V, Zr, Ta and / or alloys or mixtures thereof. The alkanes dehydrogenate to olefins by contact with the first surface with substantially only atomic hydrogen from the dehydrogenation of the alkanes passing through the metal composite membrane. Apparatus for effecting the conversion and separation is also disclosed.

Owner:UCHICAGO ARGONNE LLC

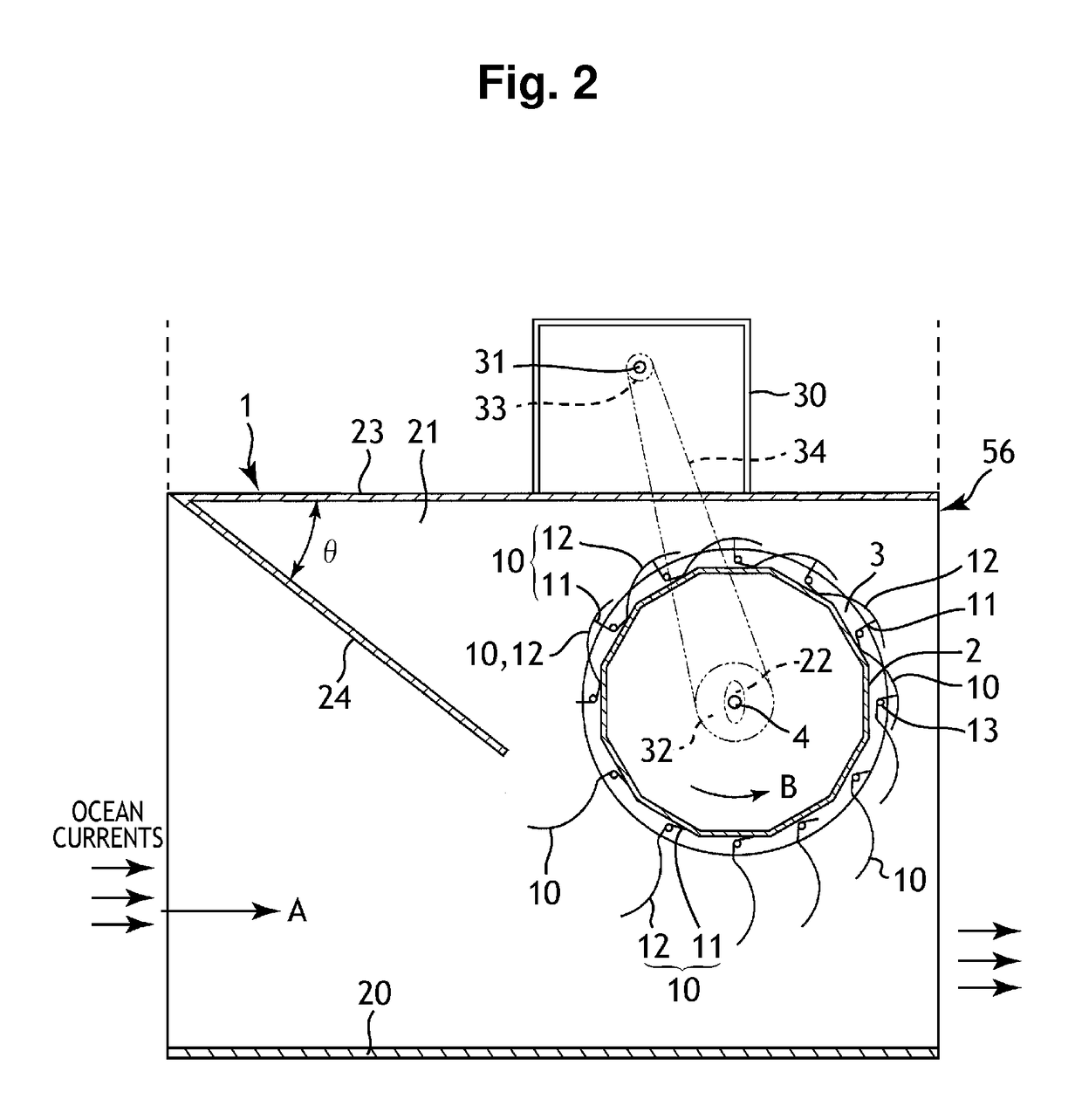

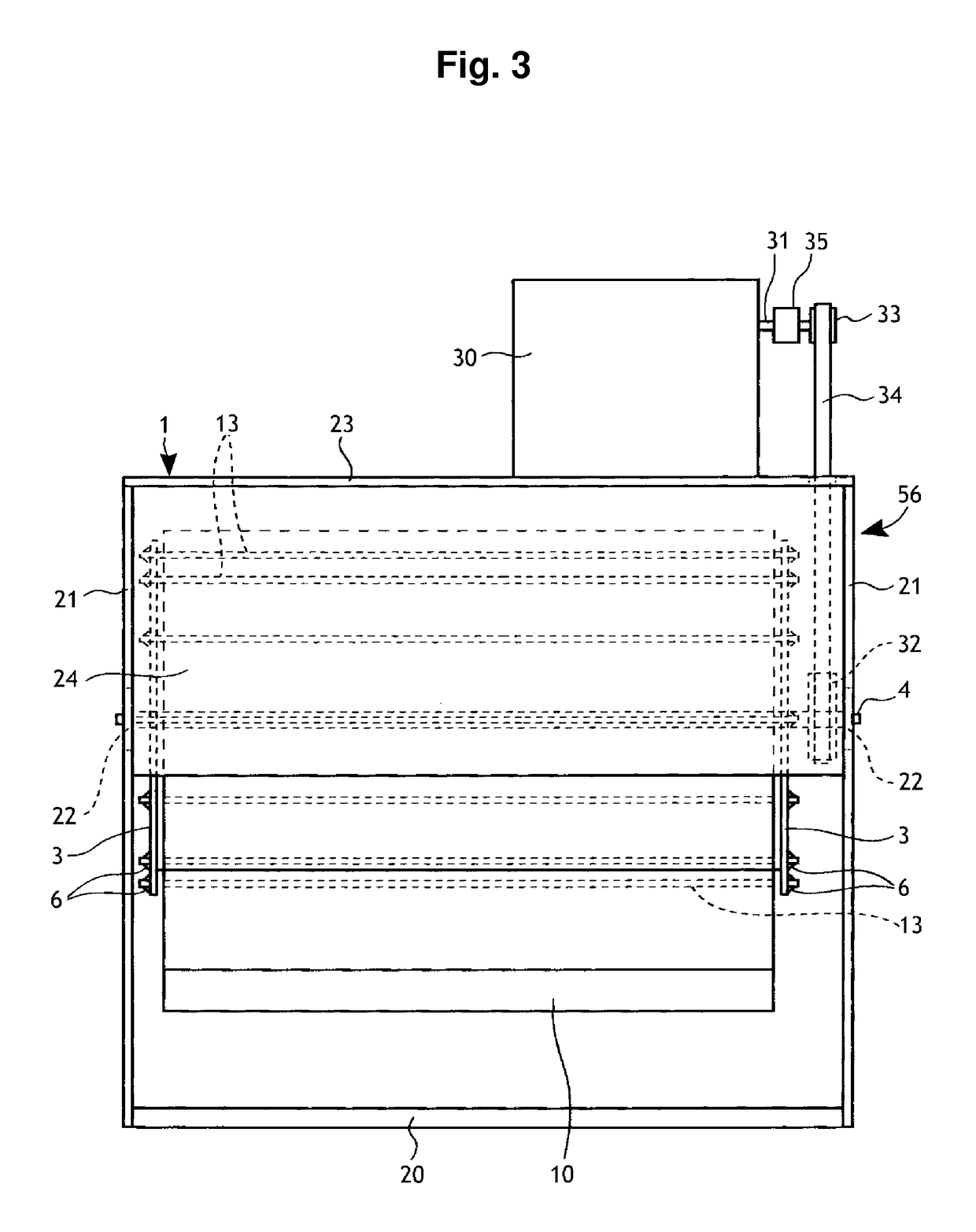

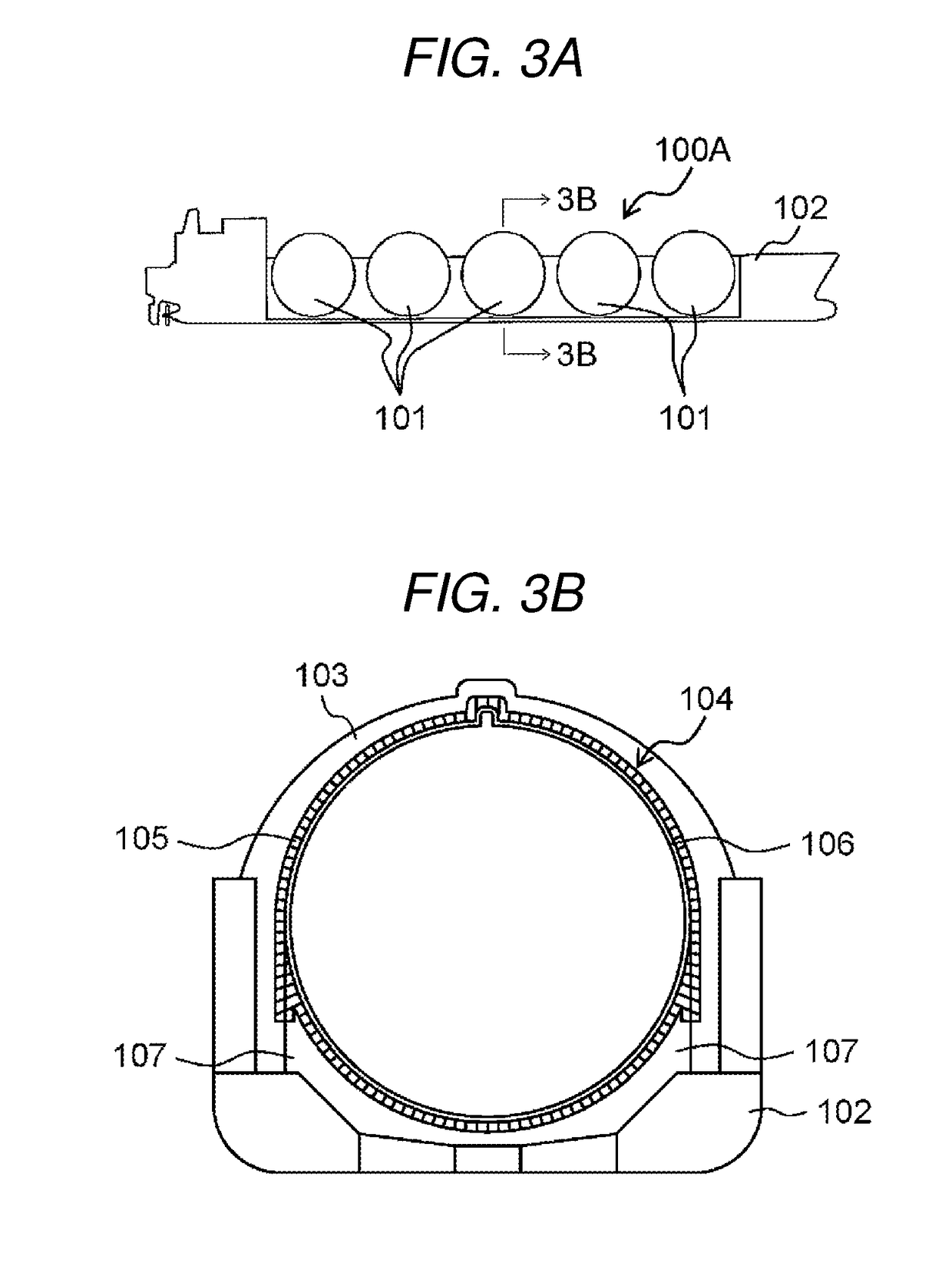

Hydrogen energy supply system using ocean current power generation

ActiveUS10138563B2Meet cost performance requirementsValid conversionCellsHydrogenImpellerElectrolysis

A hydrogen energy supply system including 10 or more water wheel impeller type power generation devices that are supported to float in water by first floating bodies and generate electric power by using ocean currents; a second floating body on which a seawater electrolysis device, a hydrogen liquefaction device, and a liquid hydrogen tank are arranged; a hydrogen transporting ship that accommodates the liquid hydrogen stored in the liquid hydrogen tank and transports it by sea to land; an overland liquid hydrogen tank that stores the liquid hydrogen supplied from the hydrogen transporting ship; a small cylinder that accommodates the liquid hydrogen supplied from the overland liquid hydrogen tank; and a hydrogen transporting vehicle that transports the small cylinder to a consumer on land.

Owner:JAPAN SYST PLANNING

Recombinant separator

A heterogeneous, cellulose battery separator made of a mixture of cellulose and a polymer with hydrogen permeability for use in zinc-based batteries exhibiting increased hydrogen transport through the membrane while maintaining low electrical impedance and exhibiting resistance to zinc ion transport preventing zinc dendrite formation.

Owner:ZPOWER LLC

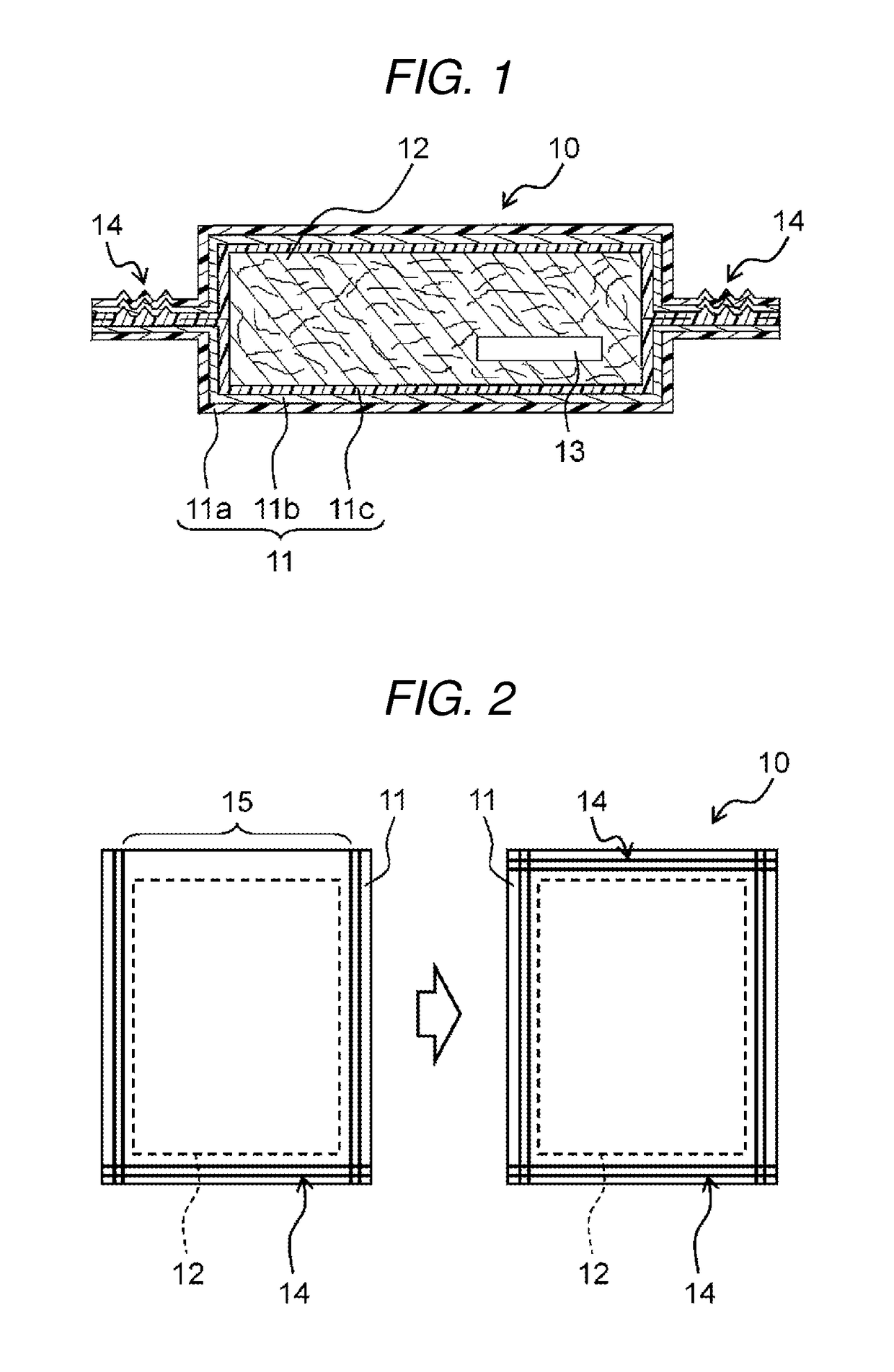

Vacuum heat-insulating material, and heat-insulating container, dwelling wall, transport machine, hydrogen transport tanker, and LNG transport tanker equipped with vacuum heat-insulating material

InactiveUS20170234487A1Improve reliabilityReduce controlThermal insulationVessel wallsEngineeringLinear expansion coefficient

A vacuum heat-insulating material includes: an outer cover material; and a core material which is sealed in a tightly closed and decompressed state on the inside of the outer cover material. Outer cover material has gas barrier properties and satisfies at least one of a condition that a linear expansion coefficient is 80×10−5 / ° C. or lower when a static load is 0.05 N within a temperature range of −130° C. to 80° C., inclusive, a condition that an average value of a linear expansion coefficient is 65×10−5 / ° C. or higher when a static load is 0.4 N within a temperature range of −140° C. to −130° C., inclusive, a condition that an average value of a linear expansion coefficient is 20×10−5 / ° C. or higher when a static load is 0.4 N within a temperature range of −140° C. to −110° C., inclusive, and a condition that an average value of a linear expansion coefficient is 13×10−5 / ° C. or higher when a static load is 0.4 N within a temperature range of +50° C. to +65° C., inclusive.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

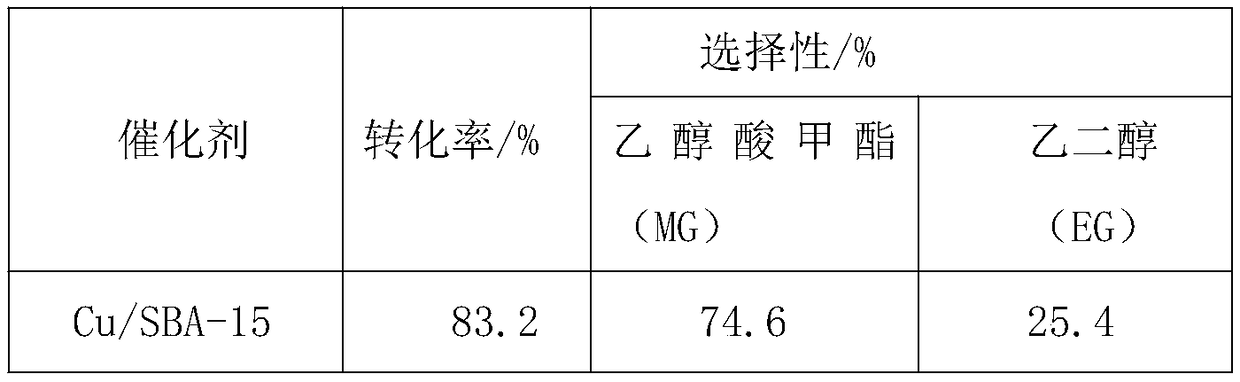

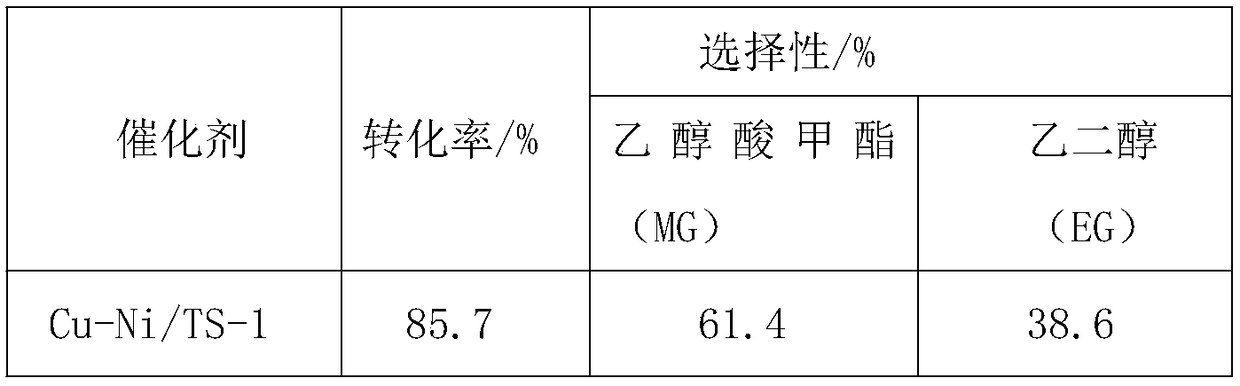

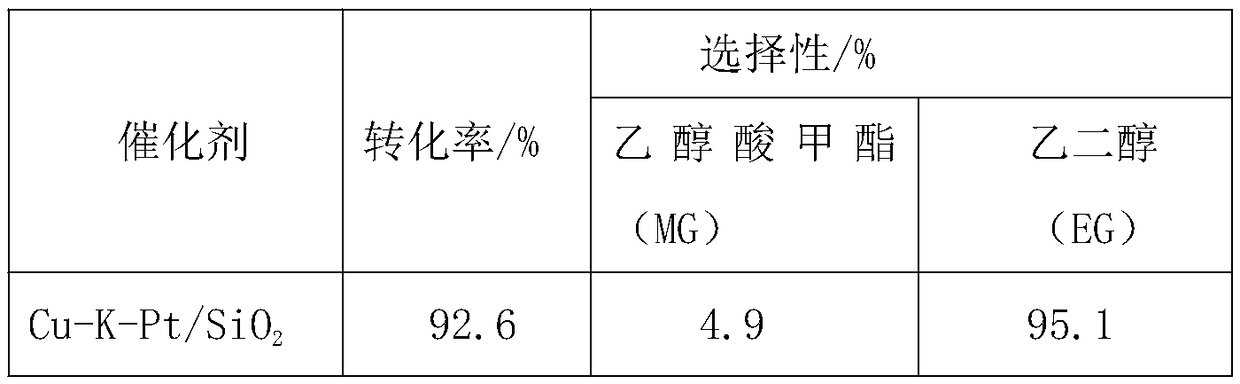

Method for transforming dimethyl oxalate into ethylene glycol by one-pot process under hydrogen-free condition

ActiveCN109232185AImprove hydrogenation performanceActivation of hydrogenation capacityOrganic compound preparationHydroxy compound preparationAlkaline earth metalOxygen vacancy

The invention provides a method for transforming dimethyl oxalate into ethylene glycol by a one-pot process under a hydrogen-free condition. The method comprises the following steps: (1) preparing a Cu-based catalyst, wherein the Cu-based catalyst comprises a reactive metal Cu and a carrier, a second metallic element is introduced into the Cu-based catalyst, the auxiliary metallic elements refer to alkali metal or / and alkaline-earth metal elements; the reactive metal Cu comprises Cu<+> and Cu0, and oxygen vacancy is enriched on the surface of the Cu-based catalyst; (2) weighing dimethyl oxalate, the Cu-based catalyst and a hydrogen-donor solvent, sequentially adding into a micro high-pressure reactor, filling N2, and reacting under the condition of 180-300 DEG C for 0.5-10 hours, thereby obtaining the ethylene glycol. According to the method disclosed by the invention, alcoholic hydrogen production and dimethyl oxalate hydrogenation reaction can be successfully coupled in the one-stepprocess, supply of exogenous hydrogen is not needed, equipment for performing hydrogenation conversion on the dimethyl oxalate to obtain ethylene glycol in the traditional process and hydrogen transport input can be greatly reduced, and the potential safety hazards in the production process are reduced.

Owner:EAST CHINA NORMAL UNIVERSITY

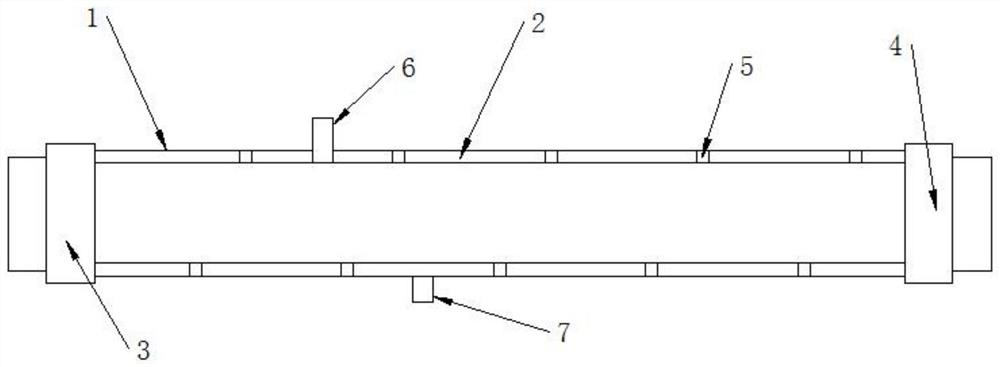

Liquid hydrogen vacuum conveying pipe

InactiveCN112128483AAchieving reduced gasificationQuick connectionThermal insulationFlexible pipesEngineeringLiquid hydrogen

The invention discloses a liquid hydrogen vacuum conveying pipe, and relates to the technical field of liquid hydrogen conveying tools. The conveying pipe comprises a flexible adapter pipe, and a vacuum interlayer is arranged on the pipe wall of the flexible adapter pipe. The problems that in the prior art, an existing hard transfer pipe is limited by the structure of the hard transfer pipe, a storage and transportation tank and a containing container are inconvenient to connect, operation wastes time and labor, and due to the fact that the low-temperature condition of liquid hydrogen cannot be guaranteed through the transfer pipe, the phenomenon that the liquid hydrogen is gasified in the conveying process is easily caused are solved.

Owner:WEIFANG XINLIMENG AQUATIC TECHN

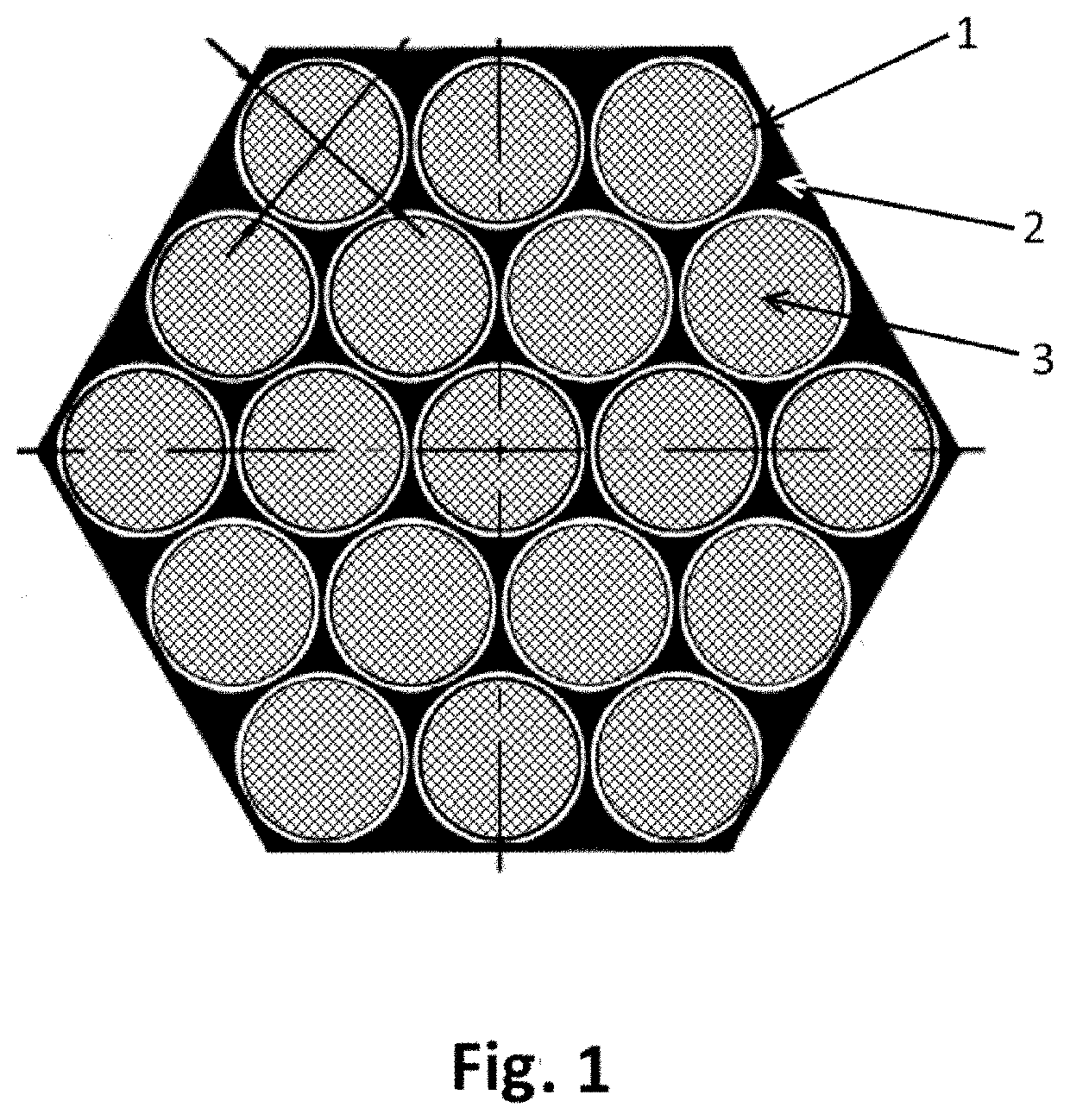

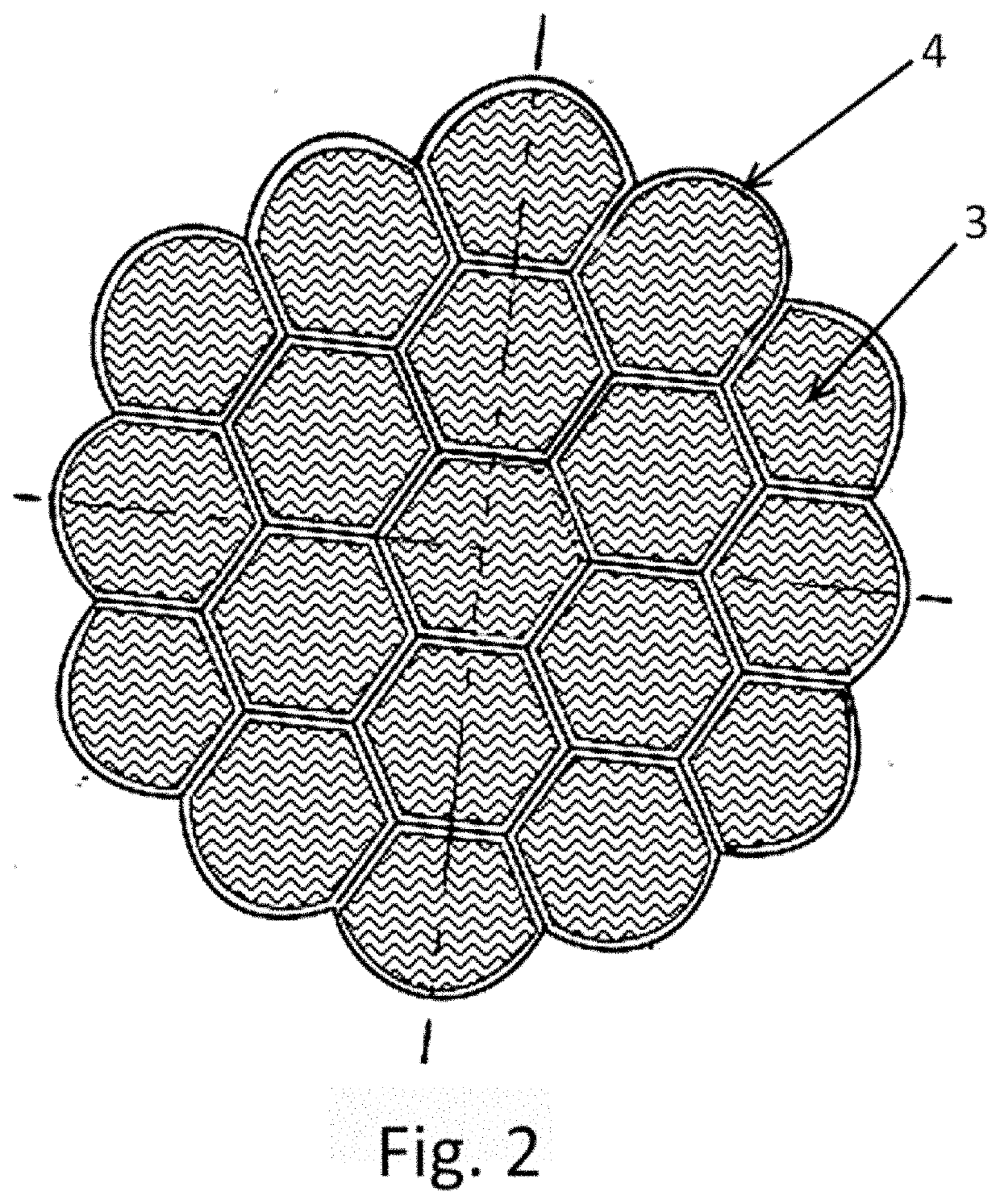

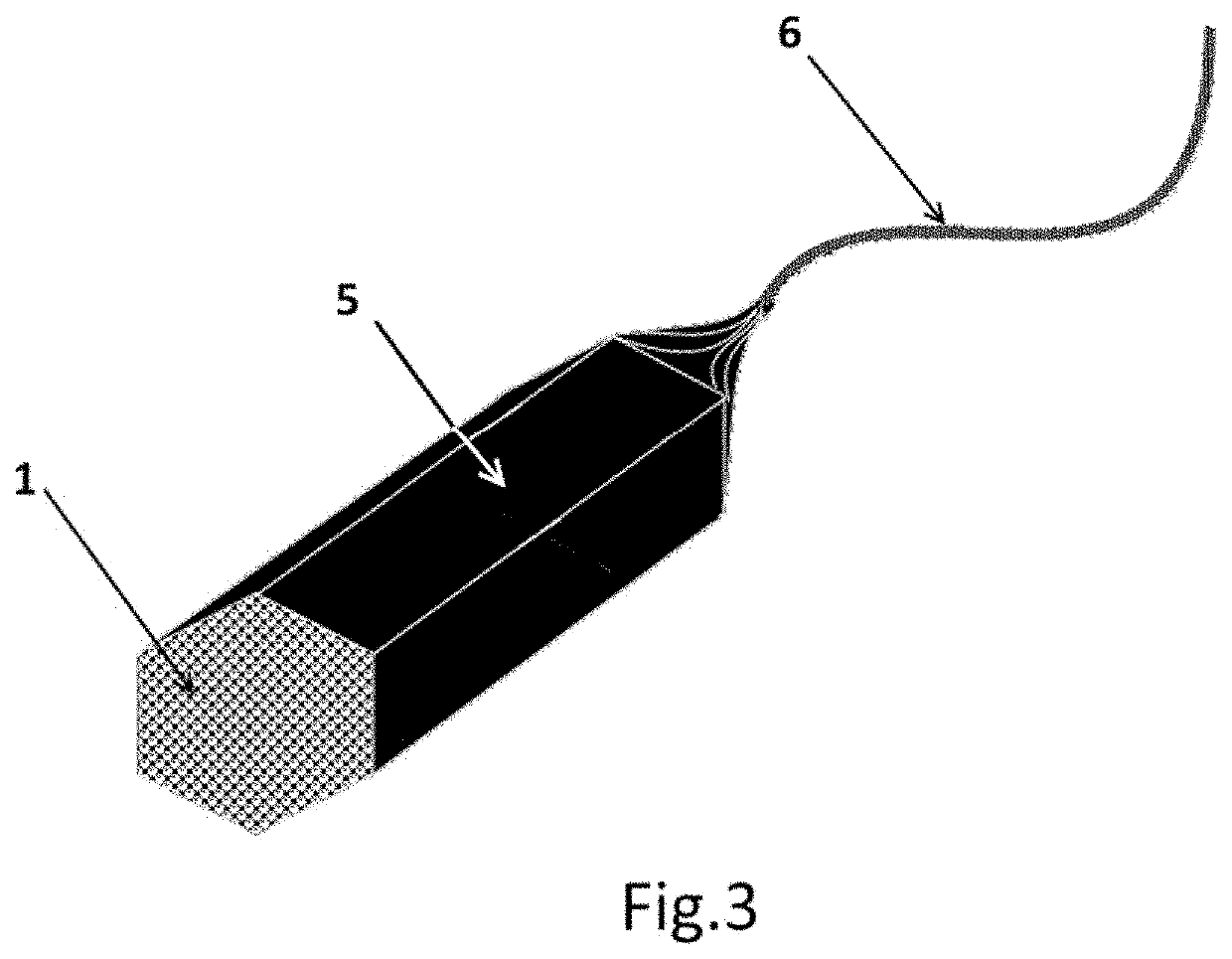

System for the storage of fuel gases

ActiveUS20200158285A1Improve securityOvercomes drawbackVessel mounting detailsVessel manufacturingThermodynamicsCapillary Tubing

Disclosed is a gas storage, preferably of hydrogen, and is in the form of a multi-capillary structure. The multi-capillary structure has a constant section over a certain length, which section then reduces sharply, down to a value at which the multi-capillaries become sufficiently flexible. The area of flexibility of the multi-capillaries has a length sufficient for the transportation of hydrogen to a fuel element. In this way, a flexible multi-capillary gas pipeline is created, which pipeline is integrated with a volume of stored hydrogen, the function of which pipeline is to supply hydrogen to the fuel element. The technical result consists of the provision of rapid priming of a micro-capillary vessel with high pressure gas and the regulated release of the gas from the vessel into a collector, where a moderate pressure (<1 MPa), required for operation of the fuel element, is maintained.

Owner:H2 ENERGY LLC

Active safety protection system and method for hydrogen leakage

ActiveCN111156423BReduce security risksPipeline systemsFixed capacity gas holdersProcess engineeringEnvironmental engineering

The invention relates to an active safety protection system and method for hydrogen leakage. The active safety protection system for hydrogen leakage can be applied to the hydrogen transporting and storing process, and can effectively and actively prevent the problem of ignition or explosion caused by hydrogen leakage. According to the active safety protection system for hydrogen leakage, leaked hydrogen is collected through a collecting chamber, and the equivalent weight of the hydrogen in the collecting chamber is detected in real time through a detection device. An active protection deviceis used for taking active safety protection measures when the equivalent weight of the hydrogen reaches to a preset hydrogen equivalent weight threshold value, so that hydrogen in the environment is not accumulated continuously. The active safety protection system for hydrogen leakage can actively operate the leaked hydrogen, so that the potential safety hazard brought by hydrogen leakage is reduced.

Owner:TSINGHUA UNIV

Method of making a hydrogen transport membrane, and article

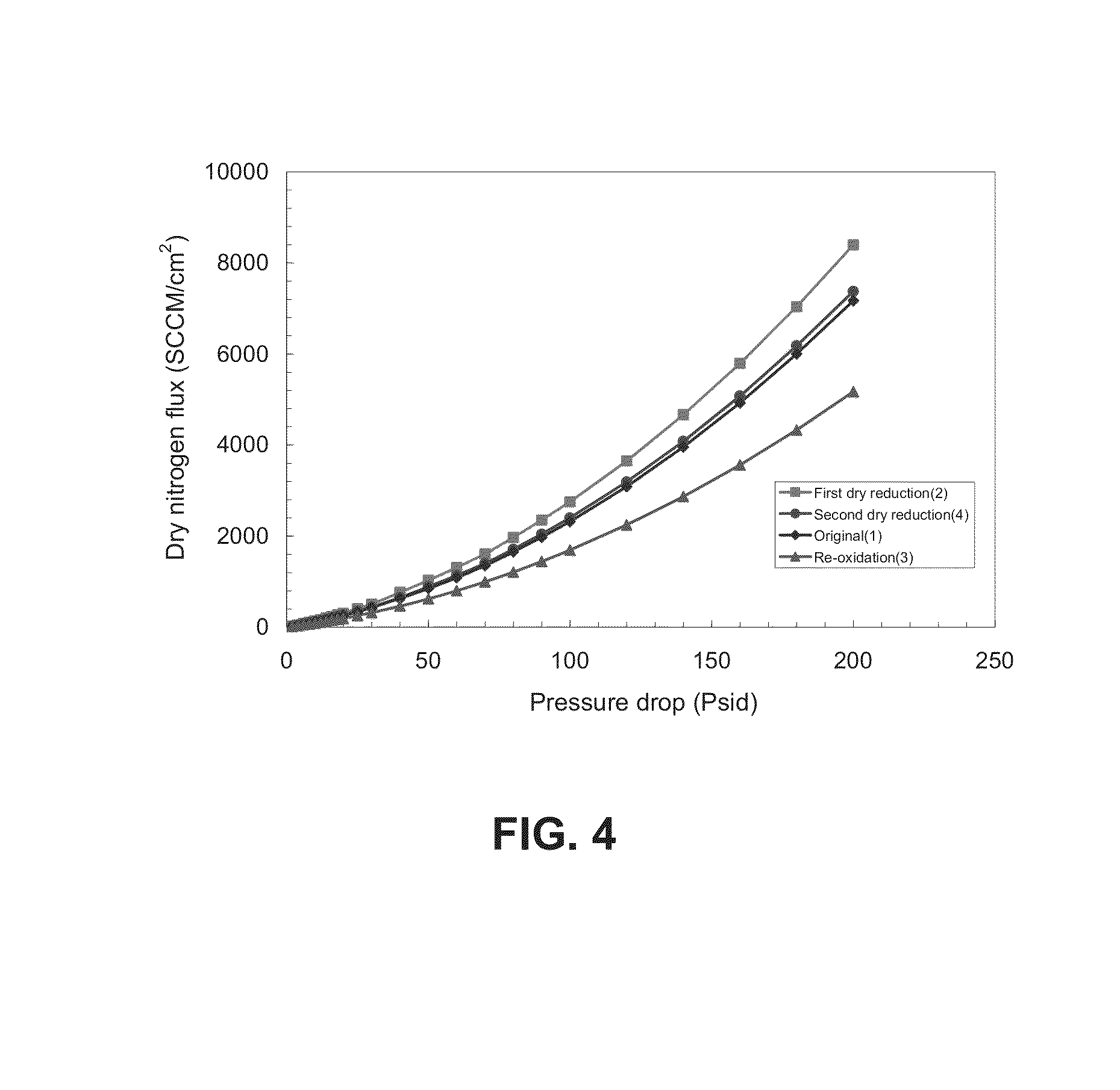

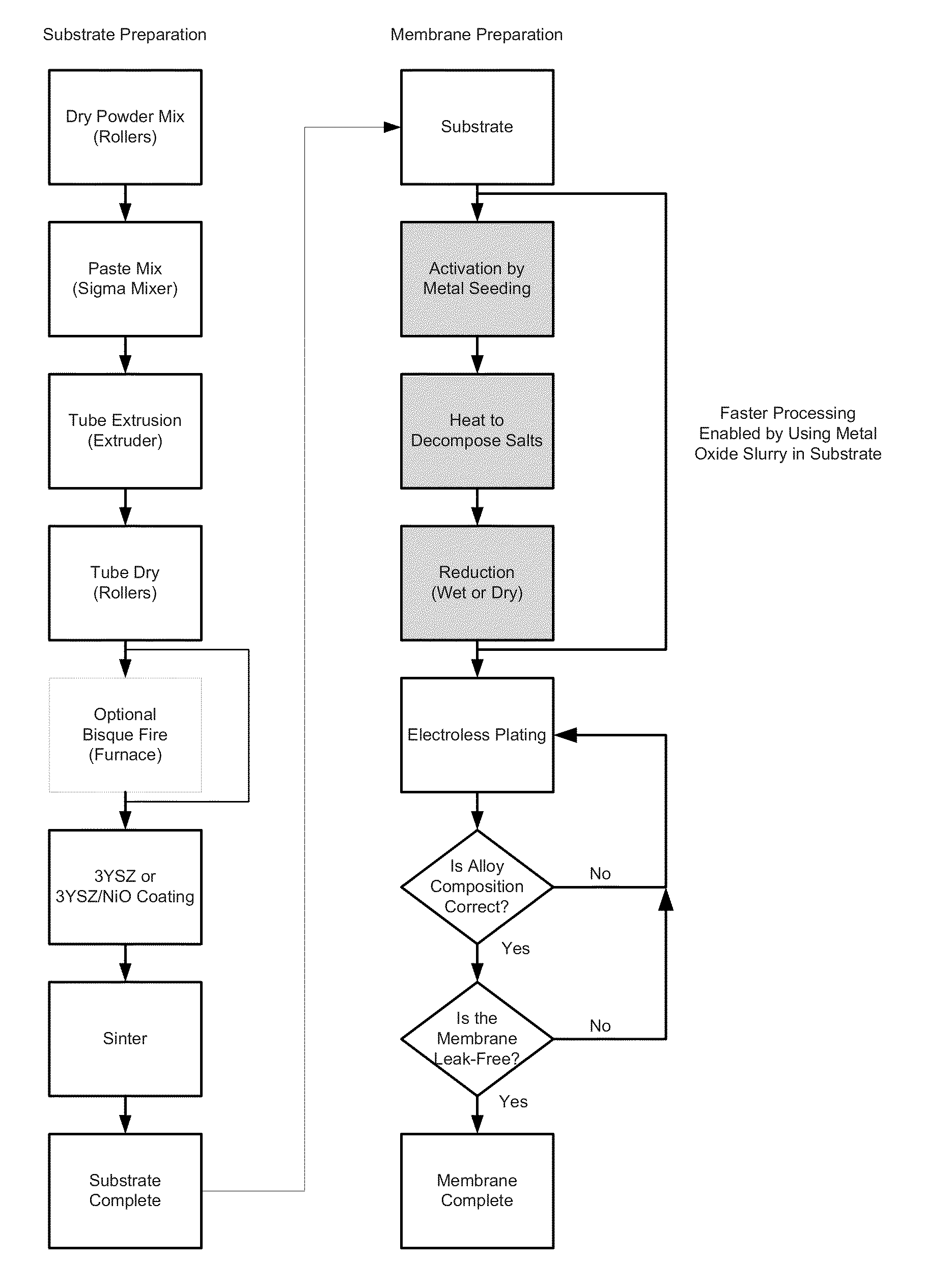

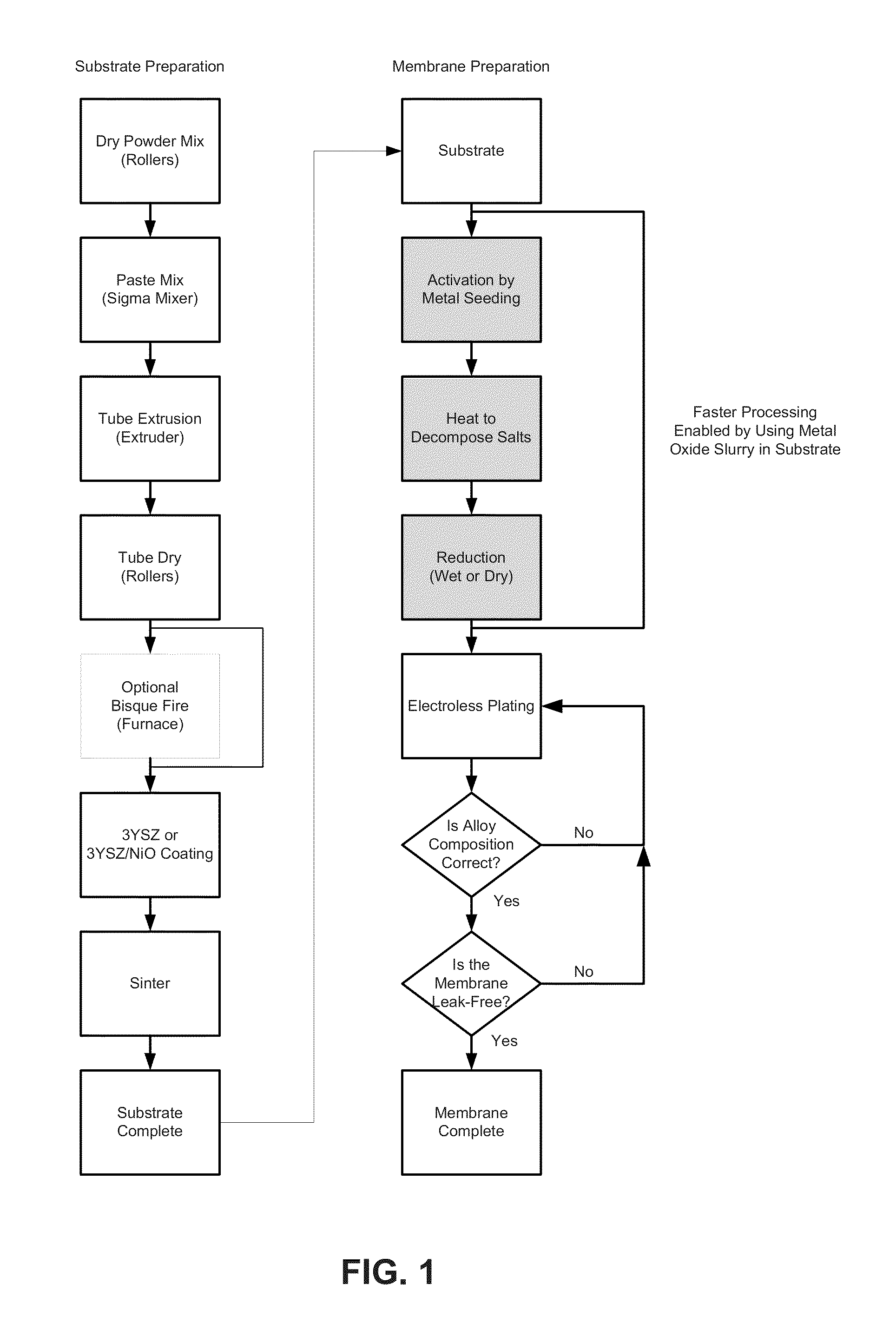

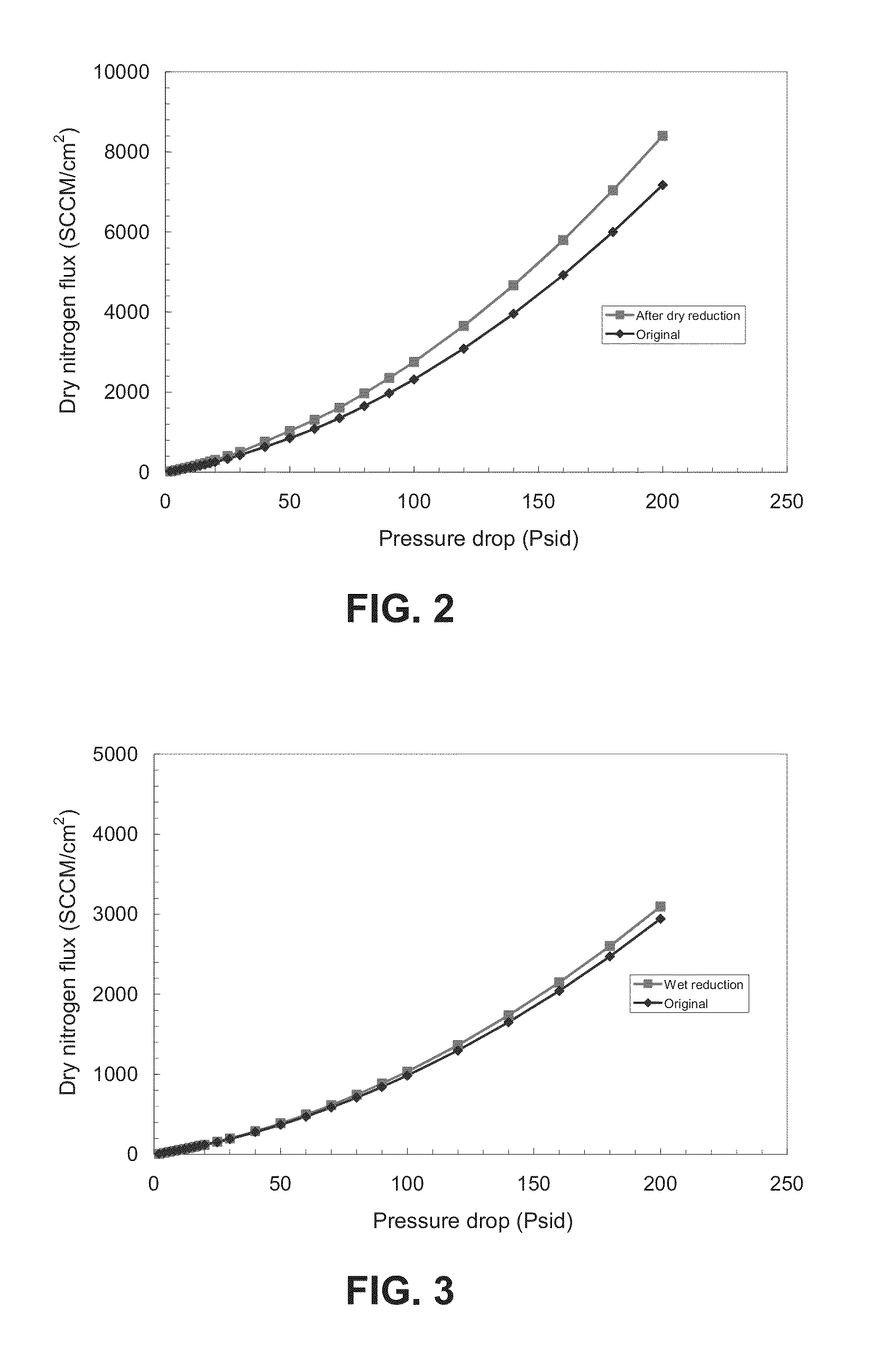

The present invention relates to a method of manufacturing a hydrogen transport membrane and the composite article itself. More specifically, the invention relates to producing a membrane substrate, wherein the ceramic substrate is coated with a metal oxide slurry, thereby eliminating the need for an activation step prior to plating the ceramic membrane through an electroless plating process. The invention also relates to modifying the pore size and porosity of the substrate by oxidation or reduction of the particles deposited by the metal oxide slurry

Owner:PRAXAIR TECH INC

Method of making a hydrogen transport membrane, and article

The present invention relates to a method of manufacturing a hydrogen transport membrane and the composite article itself. More specifically, the invention relates to producing a membrane substrate, wherein the ceramic substrate is coated with a metal oxide slurry, thereby eliminating the need for an activation step prior to plating the ceramic membrane through an electroless plating process. The invention also relates to modifying the pore size and porosity of the substrate by oxidation or reduction of the particles deposited by the metal oxide slurry.

Owner:PRAXAIR TECH INC

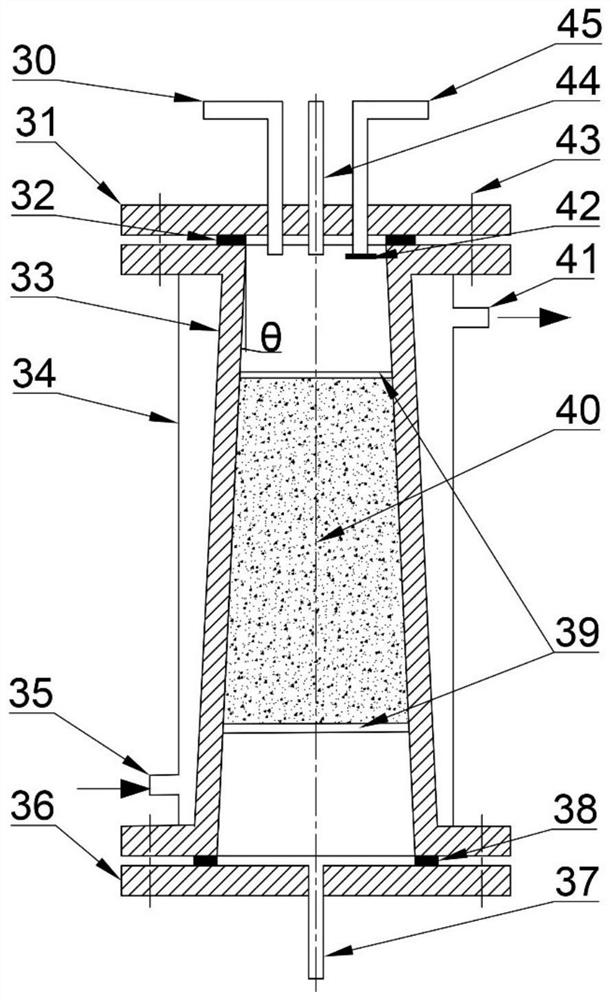

High-pressure gaseous hydrogen refueling station fuel supplementing device for hydrogen transportation of organic liquid hydrogen storage material

PendingCN112125278AExpanding Hydrogen SourcesAchieve convergenceHydrogen separation using solid contactPipeline systemsThermodynamicsHeat management

The invention discloses a high-pressure gaseous hydrogen refueling station fuel supplementing device for hydrogen transportation of an organic liquid hydrogen storage material, and belongs to the field of hydrogen energy storage and transportation. The high-pressure gaseous hydrogen refueling station fuel supplementing device comprises a hydrogen transport tanker, a hydrogen desorption module, a hydrogen pressurization module and a control module; a hydrogen-rich organic liquid hydrogen storage material in the hydrogen transport tanker releases low-pressure hydrogen through the hydrogen desorption module, and the low-pressure hydrogen is increased to the pressure of a high-pressure gaseous hydrogen refueling station through the hydrogen pressurization module and enters the high-pressure gaseous hydrogen refueling station; hydrogen can be provided for the high-pressure gaseous hydrogen refueling station through mutual cooperation of the hydrogen transportation tank car, the hydrogen desorption module, the hydrogen pressurization module and the control module. According to the device, connection between hydrogen transportation with an organic liquid hydrogen storage material and thehigh-pressure gaseous hydrogen refueling station is achieved, good heat management is provided for the desorption reactor, the purposes of high efficiency and energy conservation are achieved, hydrogen away from a hydrogen using place can be utilized in a centralized mode, the hydrogen source of the high-pressure gaseous hydrogen refueling station is expanded, and large-scale use and development of hydrogen energy are facilitated.

Owner:陕西集智氢源科技有限公司

System and method for controlling hydrogen elimination during carbon nanotube synthesis from hydrocarbons

InactiveUS7682453B2Material nanotechnologyPhysical/chemical process catalystsGas phaseCarbon nanotube

A system and method for producing carbon nanotubes by chemical vapor deposition includes a catalyst support having first and second surfaces. The catalyst support is capable of hydrogen transport from the first to the second surface. A catalyst is provided on the first surface of the catalyst support. The catalyst is selected to catalyze the chemical vapor deposition formation of carbon nanotubes. A fuel source is provided for supplying fuel to the catalyst.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com