Biogas slurry concentrate and engineering preparation method

A technology of concentrated liquid and biogas liquid, which is applied in the field of resource utilization of biogas liquid, can solve problems such as difficult engineering and stable operation, inability to concentrate at a high rate, and easy clogging of the membrane, so as to improve the value of use, reduce the number of cleaning times of the membrane, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

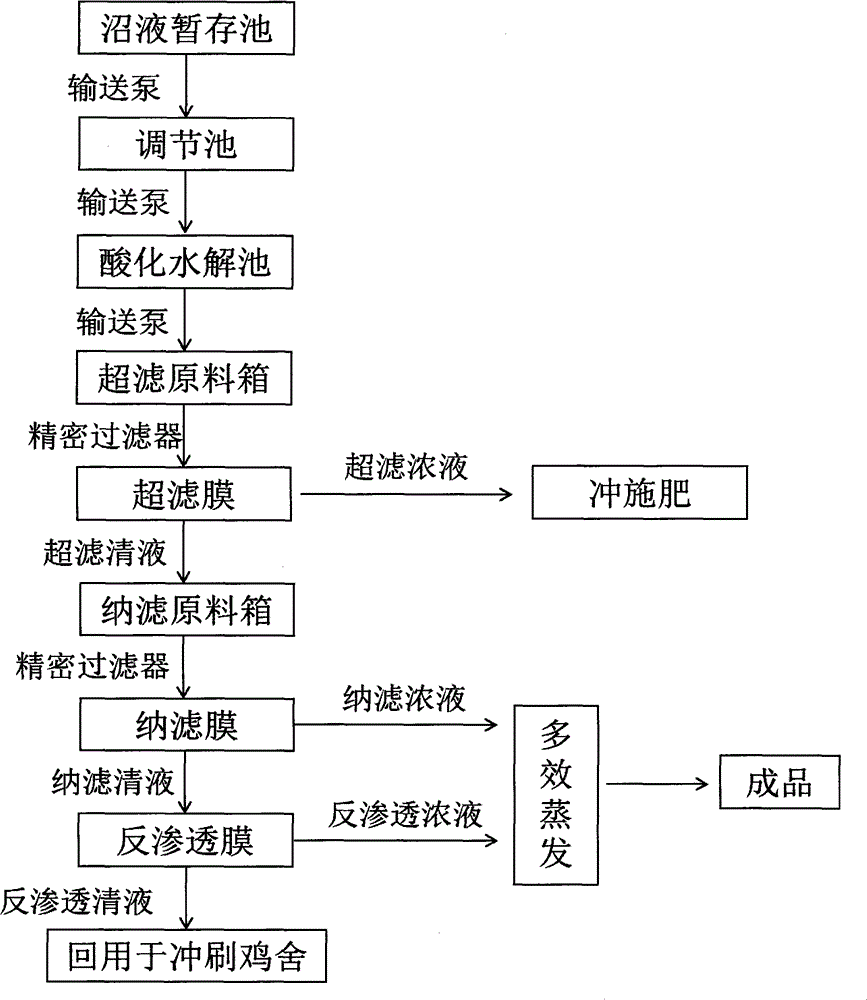

[0030] A kind of preparation method of biogas slurry concentrate comprises the following steps:

[0031] A. The raw biogas slurry is transported to the regulating tank, and is subjected to sedimentation and filtration to remove sand and impurities;

[0032] B. Transport the above-mentioned preliminary treated biogas slurry to the acidification hydrolysis tank for acidification and hydrolysis, and decompose the macromolecules in the original biogas slurry by controlling the amount of air and temperature and further precipitating and removing impurities;

[0033] C. The hydrolyzed biogas slurry is transported to the ultrafiltration raw material tank, first filtered through a precision filter, and then subjected to ultrafiltration treatment with an ultrafiltration membrane. The ultrafiltration membrane adopts an inorganic ceramic membrane with a pore size of 100-200nm. The flux is 60-65L / m 2 .h, the transmembrane pressure difference is 2010-0.20MPa, to obtain the ultrafiltration...

Embodiment 2

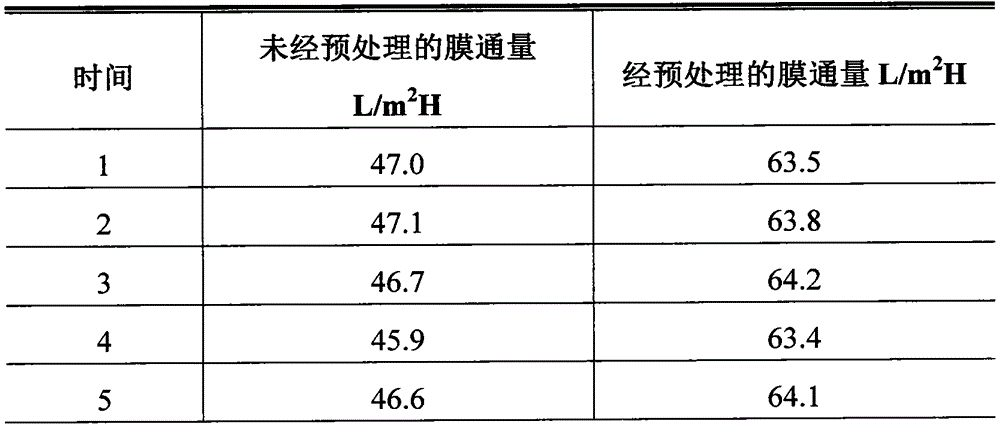

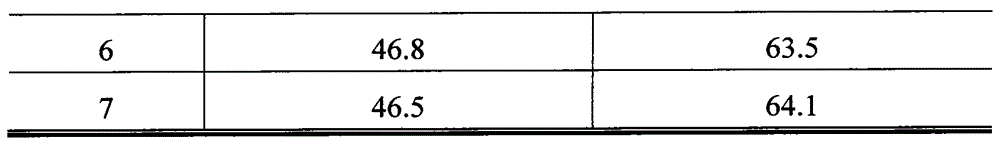

[0042] Test method: This test is carried out in a pilot plant. The raw biogas slurry after fermentation is continuous and stable, so as to ensure that the test effect is not affected by the material itself. The raw biogas slurry without pre-membrane pretreatment and the raw biogas slurry with pre-membrane pretreatment passed through the ultrafiltration membrane of the same pilot plant, and the membrane flux was measured every 10 minutes, and 7 sets of data were obtained respectively, and the measurement was carried out continuously for 3 days . The data statistics are shown in Table 1-3 below:

[0043] Table 1. Membrane flux on the first day

[0044]

[0045]

[0046] Table 2. Membrane flux on the second day

[0047]

[0048] Table 3. Membrane flux on the third day

[0049]

[0050] The results show that the addition of pre-membrane pretreatment processes, including precipitation, filtration, and acidification hydrolysis processes, facilitates the subsequent mem...

Embodiment 3

[0052] Test site: Vegetable Test Base in Muping District

[0053] Soil for testing: All soil types are brown soil with good irrigation and drainage conditions.

[0054] The soil conditions are as follows:

[0055] Table 4. Soil nutrient status of the test field

[0056]

[0057] Fertilizer for test: biogas slurry concentrate

[0058] Test varieties and cultivation methods

[0059] Celery, a variety of glass green, transplanted for seedling cultivation, and planted in borders after planting.

[0060] experiment method:

[0061] Three treatments were set up in the experiment, repeated three times, and the plot area was 20 square meters.

[0062] Treatment 1: Regular fertilization

[0063] Treatment 2: conventional fertilization + equal amount of water

[0064] Treatment 3: conventional fertilization + biogas slurry concentrate

[0065] Table 5. Celery yield result table

[0066]

[0067] Experimental results:

[0068] Field observation showed that treatment 3 spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com