Separator for electrochemical device, and electrochemical device

A technology for electrochemical components and diaphragms, which is applied in the field of diaphragms for electrochemical components and electrochemical components, can solve safety problems and other problems, and achieve excellent safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

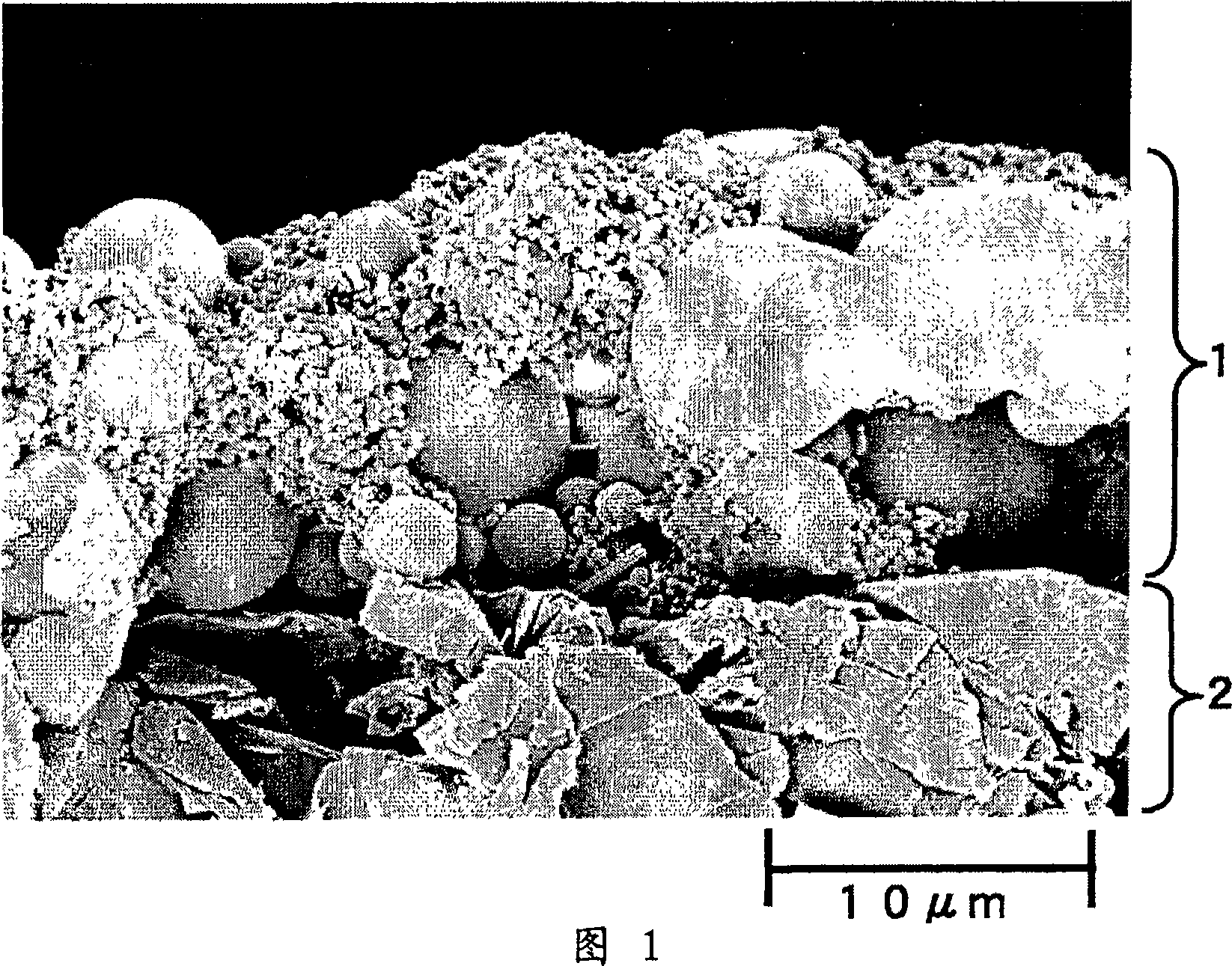

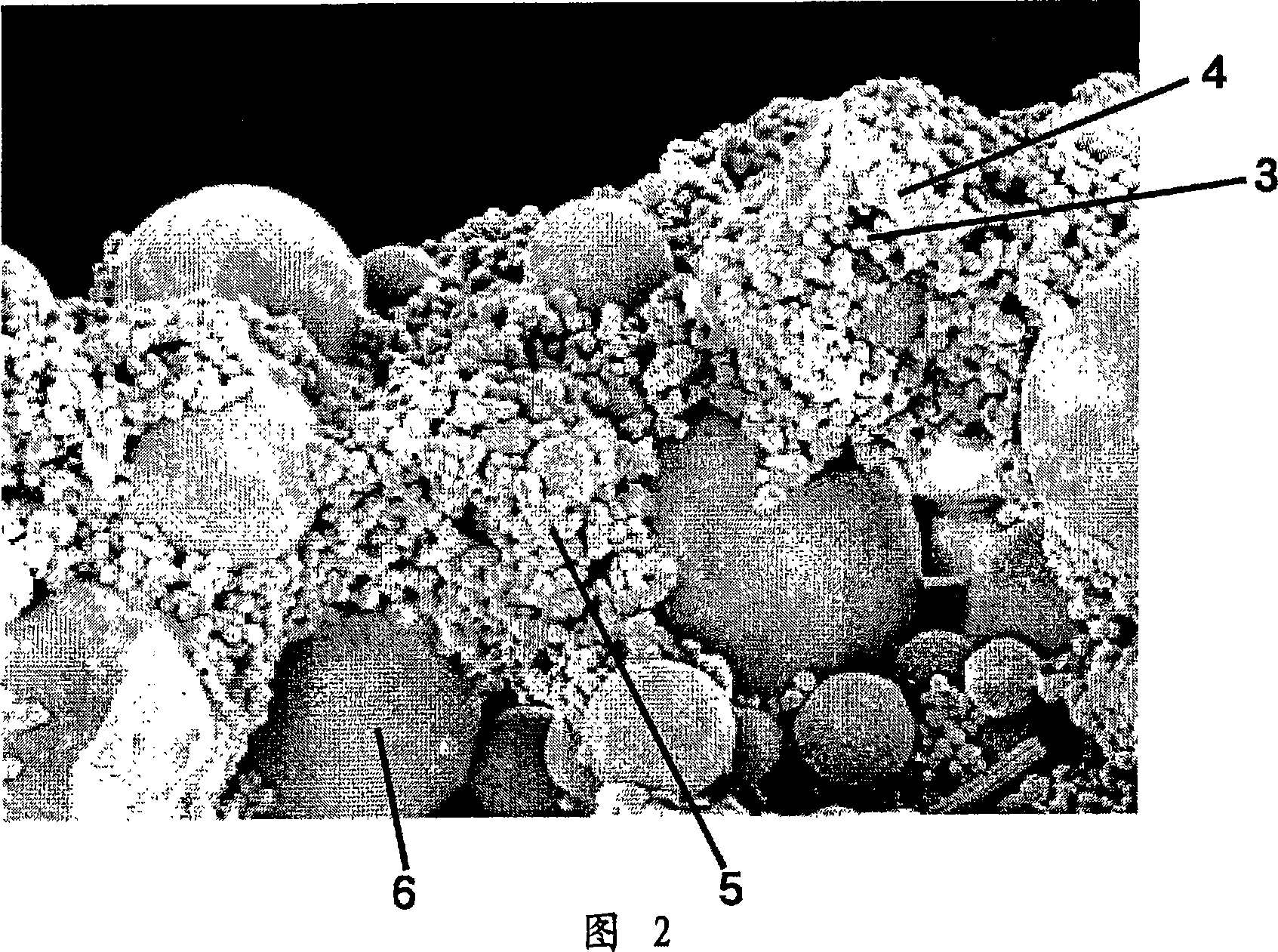

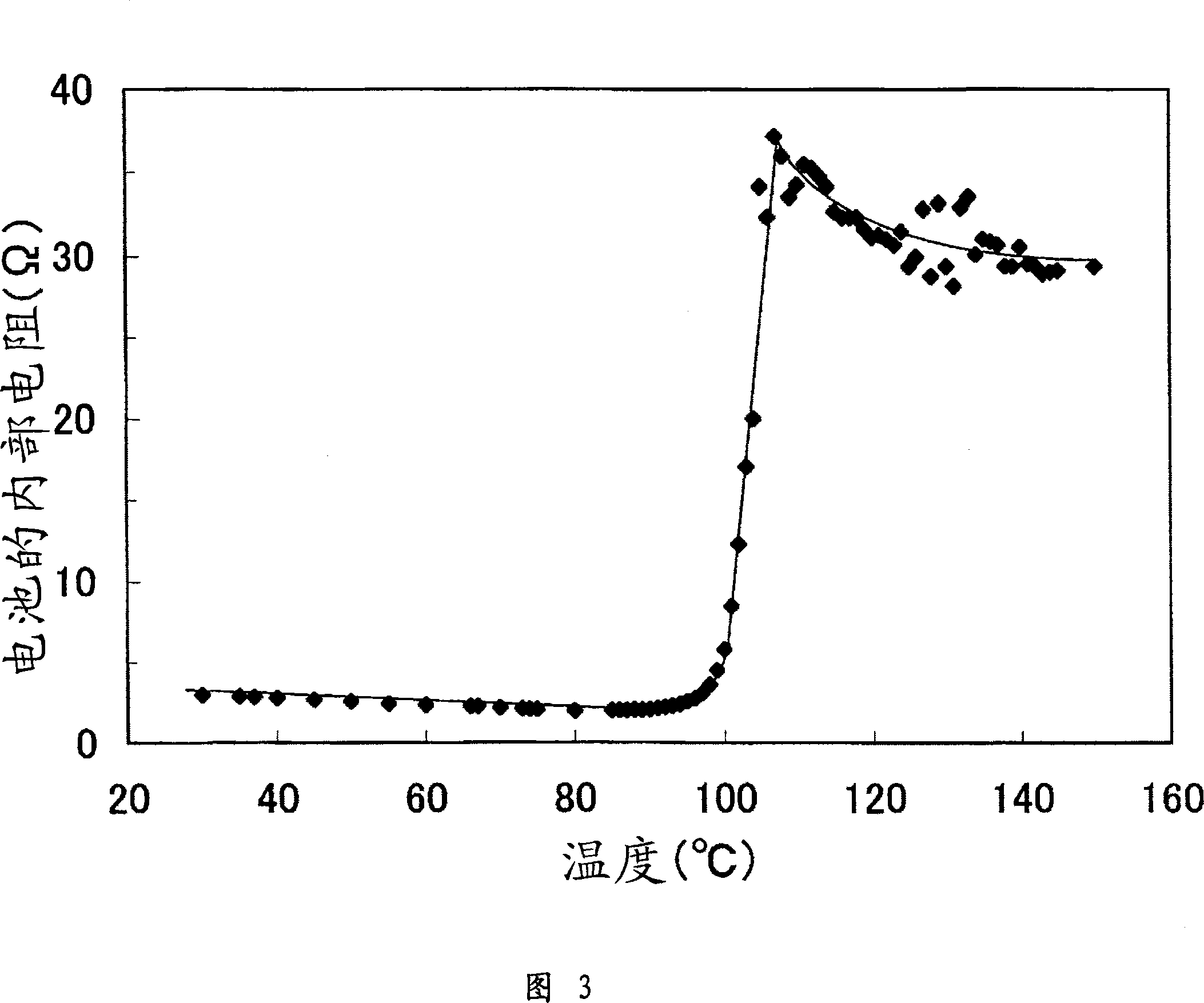

[0121] Put 2kg of polyethylene powder (resin A) aqueous dispersion (Mitsui Chemicals Co., Ltd. "Chemipal W-700" (trade name)) and 800g of ethanol in the container, using a disperser, under the condition of 2800r / min Stir for 1 hour to disperse. Add 300g of alumina (Al 2 o 3 ) microparticles (Sumitomo Chemical Co., Ltd. "Misu Corandam AA04" (trade name), heat-resistant temperature: 180° C. or higher, average particle diameter: 0.4 μm, particle size distribution: 0.3-0.7 μm), stirred for 3 hours to form a uniform slurry. A non-woven fabric made of PBT with a thickness of 28 μm (made by Tapil Co., Ltd.) as a porous substrate was passed through the slurry, and the slurry was coated by pull-up coating, and then dried to obtain resin A in the voids of the non-woven fabric. and a 35 μm thick separator of filler particles.

Embodiment 2

[0123] 100g of ethylene-vinyl acetate copolymer (EVA) (the structural unit from vinyl acetate is 34mol%, manufactured by Japan Unika Co., Ltd.) is put into a container together with 6kg of toluene as a solvent, and stirred at room temperature until it is evenly dissolved , to obtain a binder solution. In this binder solution, 1 kg of polyethylene powder ("Fロ-ビ-ズ LE1080" (trade name) manufactured by Sumitomo Seika Co., Ltd., manufactured by Sumitomo Seika Co., Ltd., melting point: 107° C., average particle diameter: 6 μm, particle size distribution: 2 to 15 μm), using a disperser, stirring for 1 hour under the condition of 2800r / min to disperse. 1 kg of polypropylene powder ("PPW-5" (trade name) manufactured by Seishin Co., Ltd.) was added as filler particles, and stirred at 2800 r / min for 3 hours using a disperser to form a uniform slurry. A gap of 50 μm was formed, and the slurry was filled onto a 25 μm thick paper (manufactured by Nippon Advanced Paper Co., Ltd.) and flatte...

Embodiment 3

[0125] 750 g of the same polyethylene powder aqueous dispersion as in Example 1, 200 g of isopropyl alcohol (IPA) and 375 g of polyvinyl butyral (PVB) as a binder (manufactured by Sekisui Chemical Co., Ltd. KX-5" (trade name)), using a disperser, stirred for 1 hour under the condition of 2800r / min to disperse. 300 g of platy boehmite fine particles ("BMM" (trade name) manufactured by Kawai Lime Co., Ltd.) were added as filler particles, and stirred for 3 hours to form a uniform slurry. A nonwoven fabric made of PP with a thickness of 15 μm (manufactured by Nitupon Advanced Paper Co., Ltd.) was passed through the slurry, coated by pull-up coating, and then dried to obtain a separator with a thickness of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com