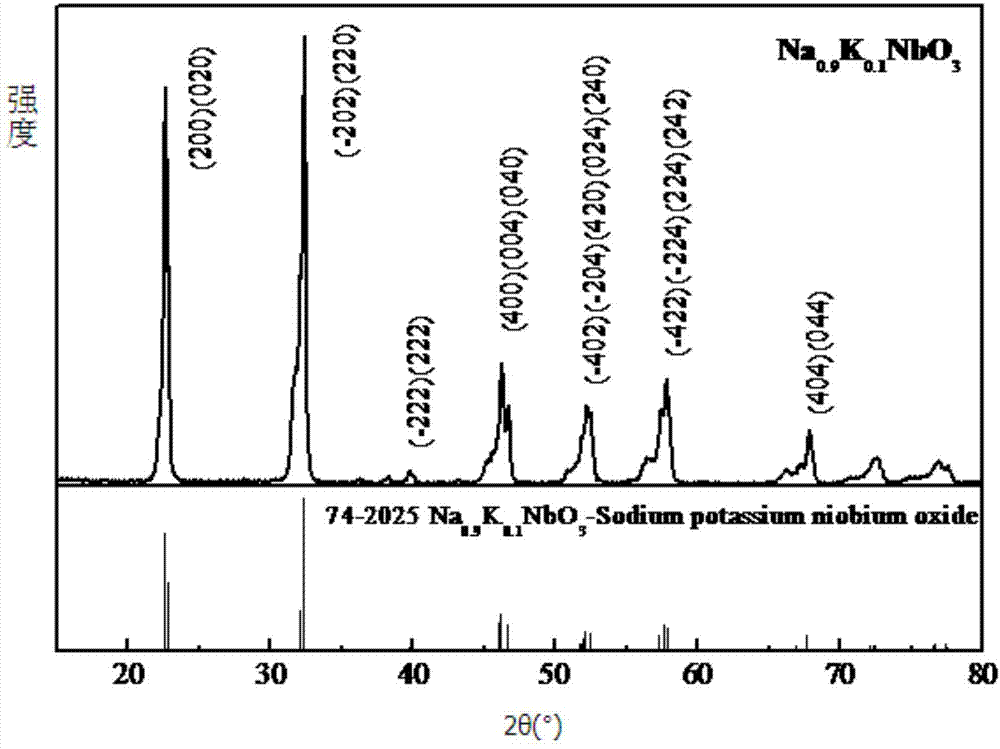

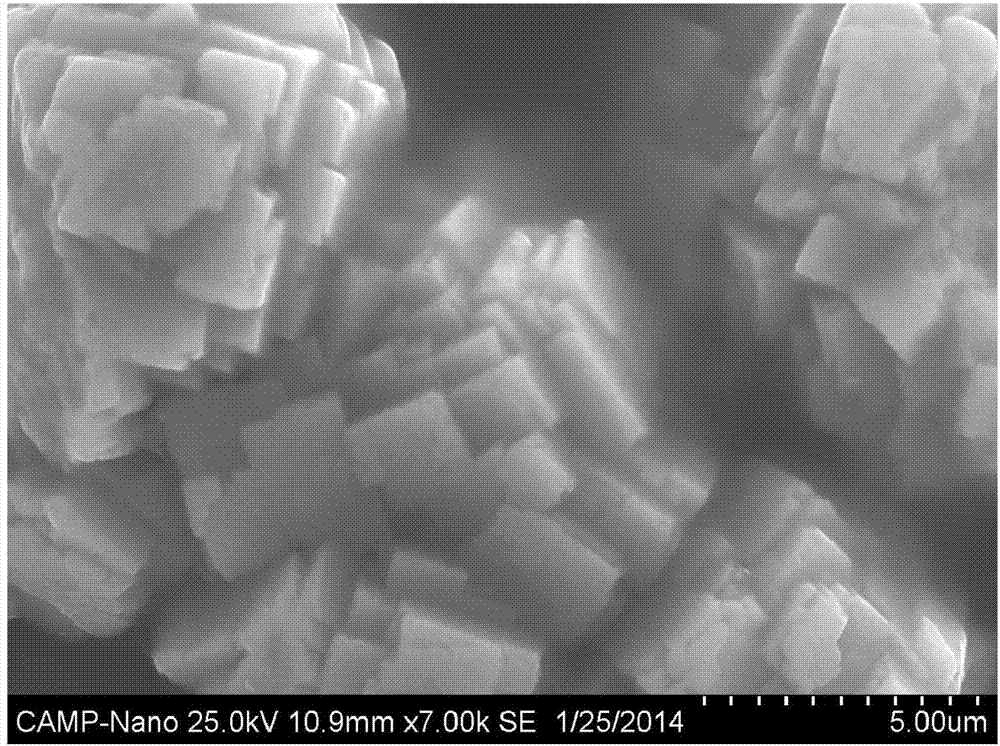

One-step method for synthesizing leadless piezoelectric K0.1Na0.9NbO3 powder by hydrothermal process

A technology of lead-free piezoelectric and hydrothermal method, which is applied in the field of preparation of lead-free piezoelectric ceramic K0.1Na0.9NbO3 powder, can solve the problems of waste of raw materials, complicated operation, long cycle, etc., to reduce the use of raw materials, The preparation process is simple and the preparation cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Take potassium hydroxide solution A with a concentration of 5 mol / L and sodium hydroxide solution B with a concentration of 5 mol / L; add solution A to uniform solution B at a KOH / NaOH molar ratio of 3:1, Stir uniformly to obtain a mixed solution, add isopropanol in the proportion of 5ml isopropanol per 20ml of the mixed solution to form a mixed lye C, and the total of KOH and NaOH in the mixed lye is x mol;

[0021] Step 2: Massage the ratio x: Niobium pentoxide = 20:1 ratio. Add 0.005mol of niobium pentoxide to the mixed alkali solution, use a magnetic stirrer, stir for 30 minutes to form a uniform precursor solution; pour the precursor solution into the water In the hot reaction kettle, the filling degree is controlled to 80%, and after sealing, it is placed in a thermostat for hydrothermal synthesis at 220°C for 6 hours, and cooled to room temperature to obtain material D;

[0022] Step 3: After the material D is rinsed with deionized water to neutrality, it is dr...

Embodiment 2

[0024] Step 1: Take potassium hydroxide solution A with a concentration of 5 mol / L and sodium hydroxide solution B with a concentration of 5 mol / L; add uniform solution A to uniform solution B at a KOH / NaOH molar ratio of 6:1 In the mixed solution, stir evenly to obtain a mixed solution. Add 5ml isopropanol to each 20ml of the mixed solution to form a mixed lye C. The KOH and NaOH in the mixed lye are x mol;

[0025] Step 2: Massage the ratio x: Niobium pentoxide = 10:1. Add 0.01mol of niobium pentoxide to the mixed alkali solution, use a magnetic stirrer for 60 minutes to form a uniform precursor solution; pour the precursor solution into the water In the hot reaction kettle, the filling degree is controlled to 80%, and after sealing, it is placed in a thermostat for hydrothermal synthesis at a temperature of 180°C for 10 hours, and cooled to room temperature to obtain material D;

[0026] Step 4: After the material D is rinsed with deionized water to neutrality, it is dried at 80...

Embodiment 3

[0028] Step 1: Take potassium hydroxide solution A with a concentration of 5 mol / L and sodium hydroxide solution B with a concentration of 5 mol / L; add uniform solution A to uniform solution B according to the KOH / NaOH molar ratio of 9:1 In the mixed solution, stir evenly to obtain a mixed solution, add 5ml isopropanol solution to each 20ml of the mixed solution to form a mixed lye C, and the KOH and NaOH in the mixed lye are x mol;

[0029] Step 2: Massage the ratio x: Niobium pentoxide = 20:1 ratio. Add 0.005mol of niobium pentoxide to the mixed alkali solution, use a magnetic stirrer, stir for 30-60 minutes to form a uniform precursor solution; pour the precursor solution Put it into a hydrothermal reaction kettle, control the filling degree to 80%, put it in a thermostat after sealing, perform hydrothermal synthesis at 200°C for 8 hours, and cool to room temperature.

[0030] Step 3: Take out the materials in the reactor and rinse them with deionized water until they are neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com