Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

420 results about "Micro electrical mechanical systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-Electrical-Mechanical Systems. A class of devices combining electrical and mechanical components that have at least one of the dimensions in the micrometer range (between 1 micron and 1 millimeter). They include sensors, actuators, microducts, and micropumps.

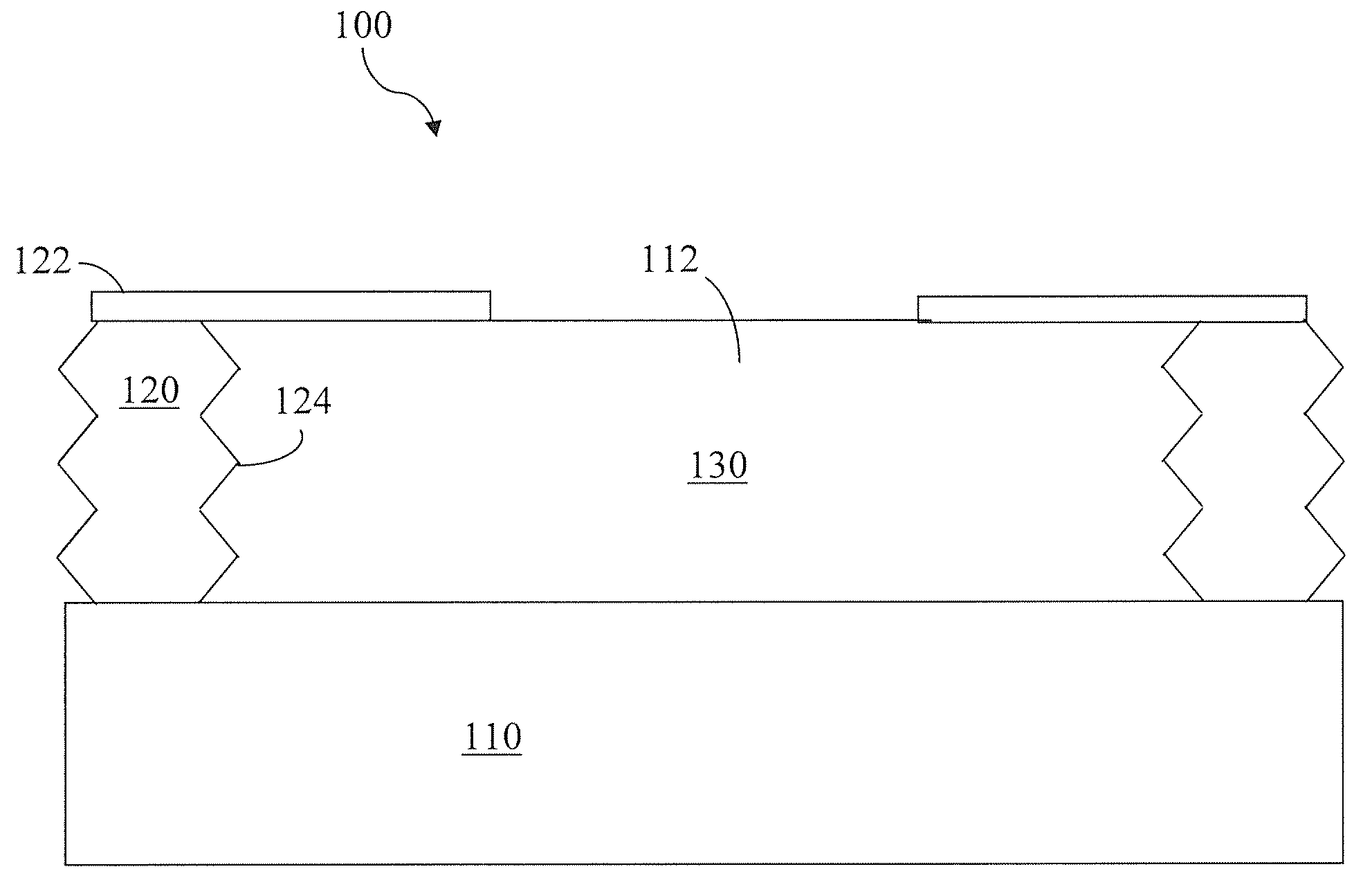

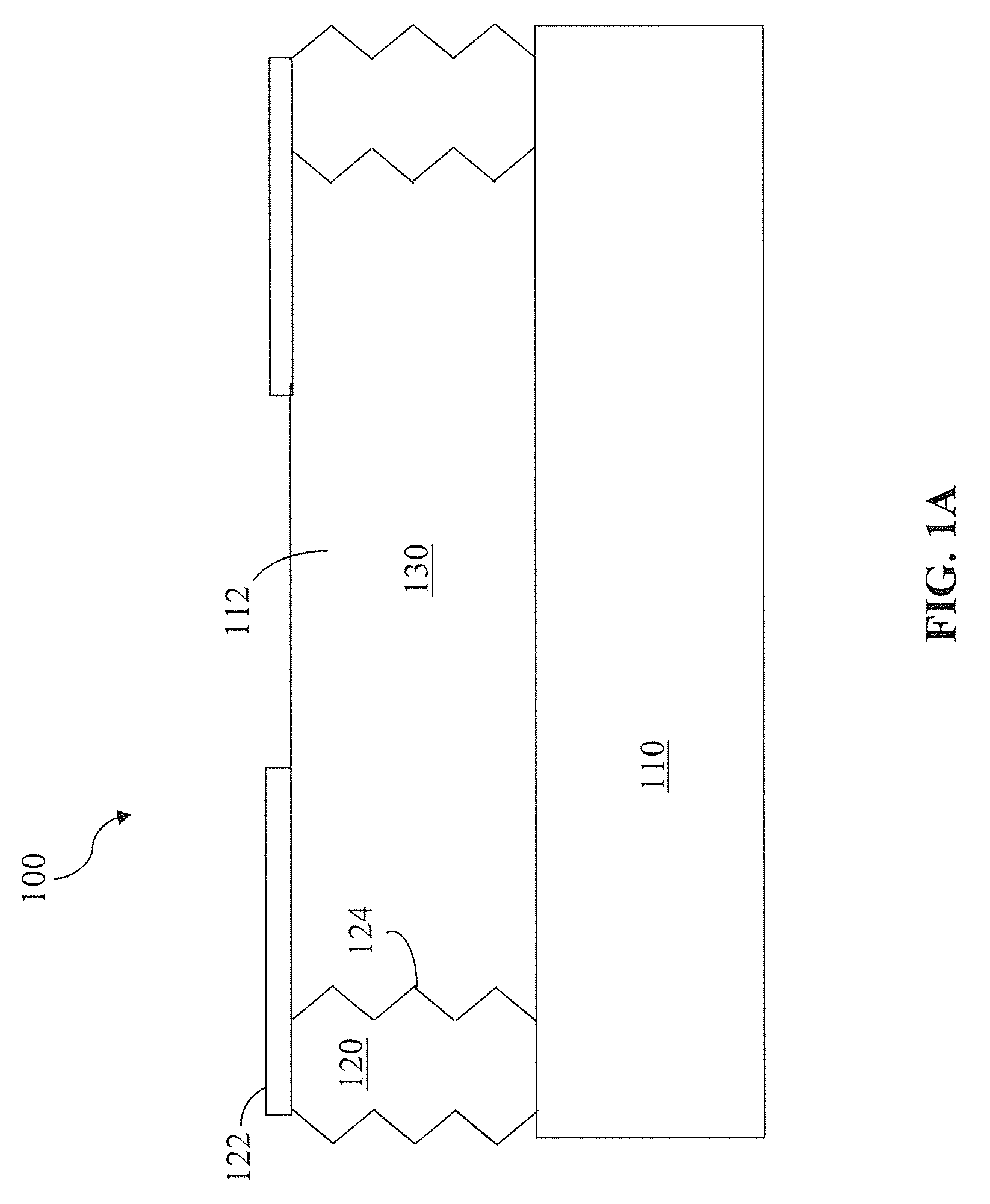

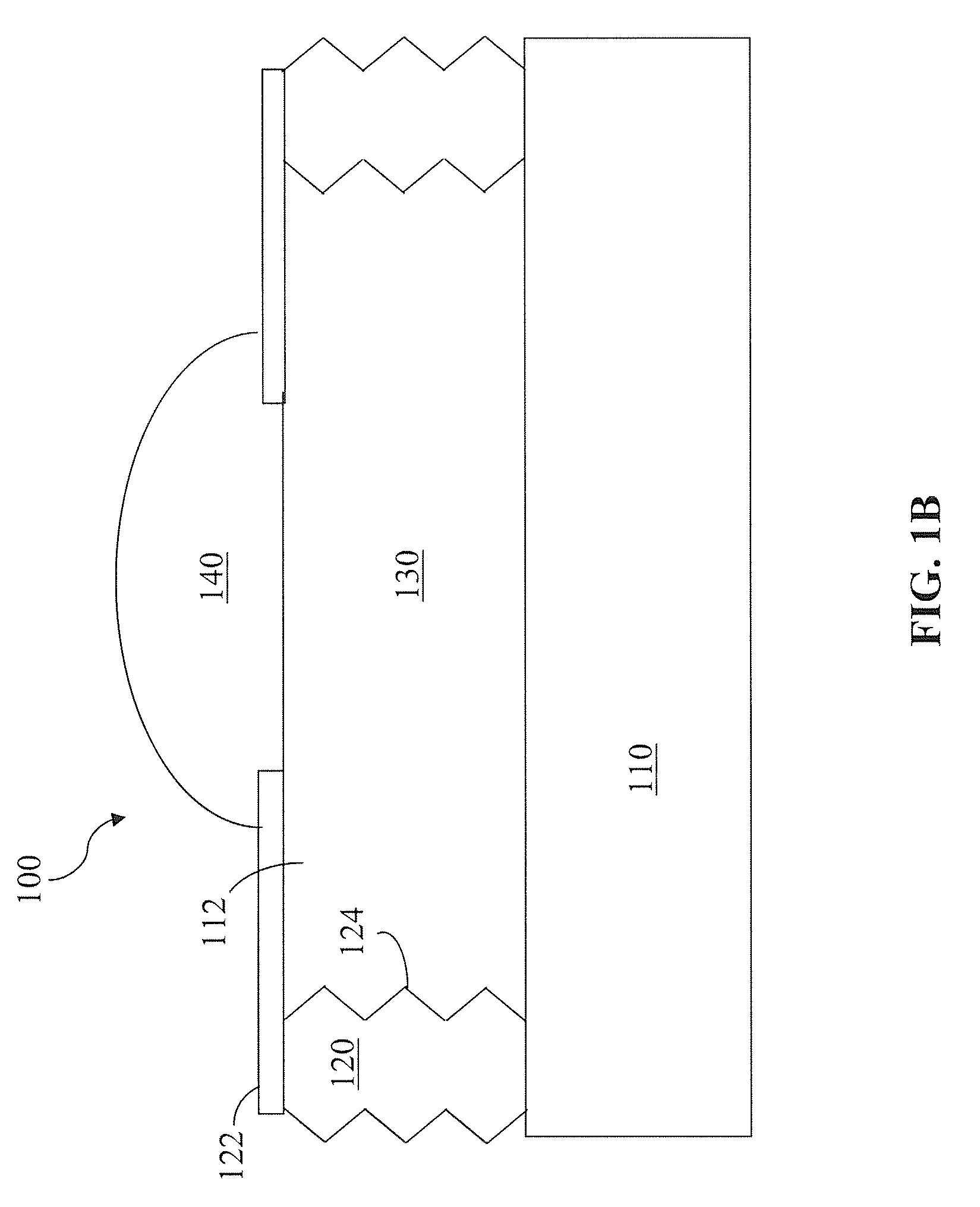

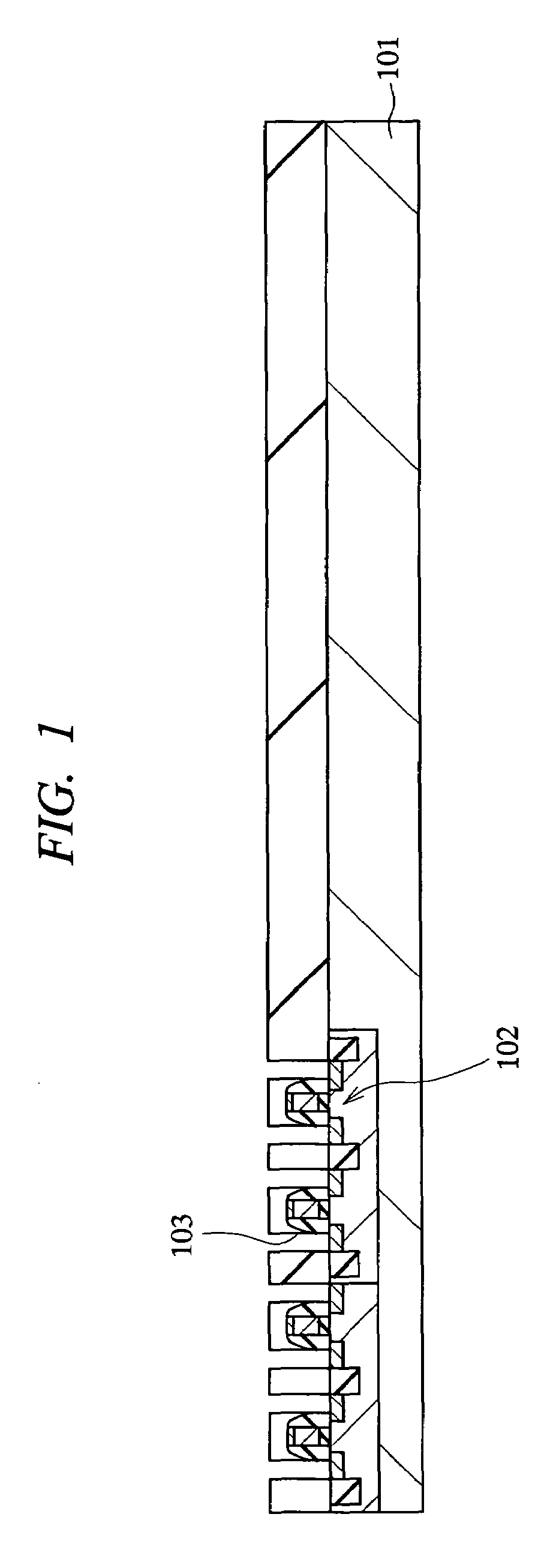

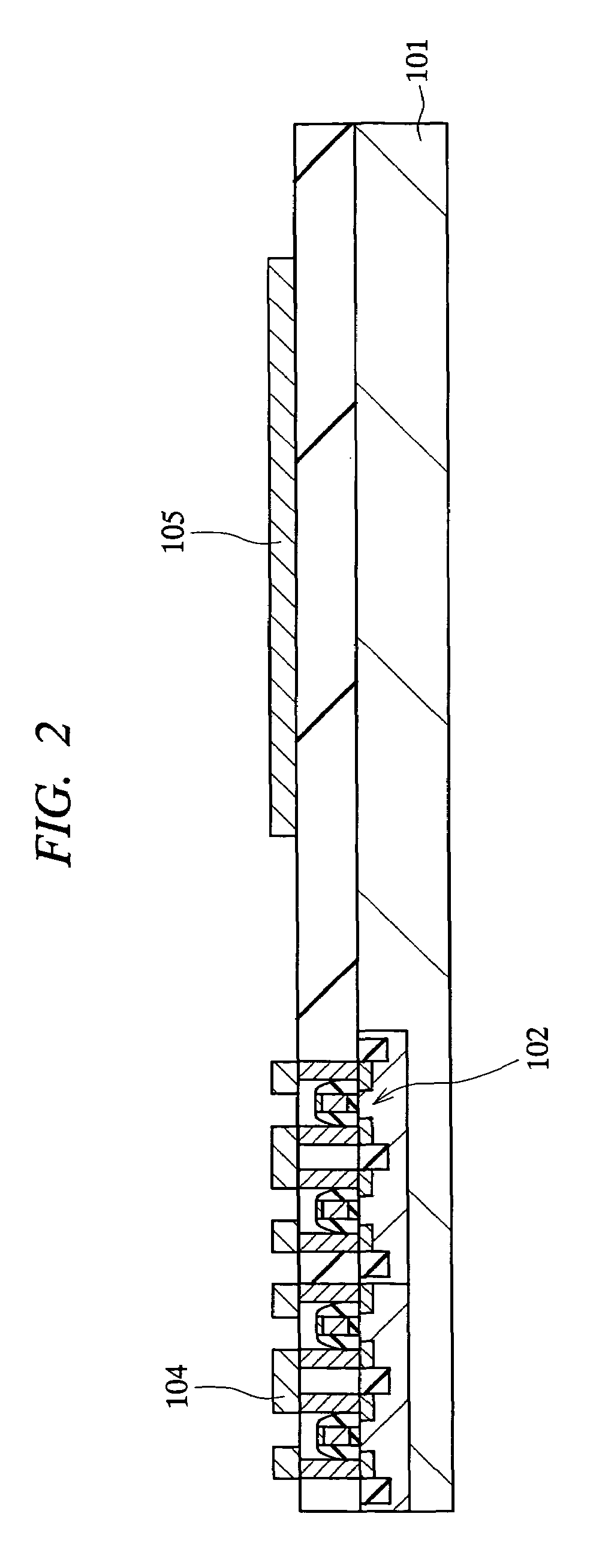

Wafer level lens replication on micro-electrical-mechanical systems

Movable lens structures in which a lens is formed on a micro-electrical-mechanical system and methods of making the same. A method of forming the lens includes forming a micro-electrical-mechanical system on a substrate, arranging a first mold inside the micro-electrical-mechanical system, and forming a lens on the micro-electrical-mechanical system using the first mold.

Owner:APTINA IMAGING CORP

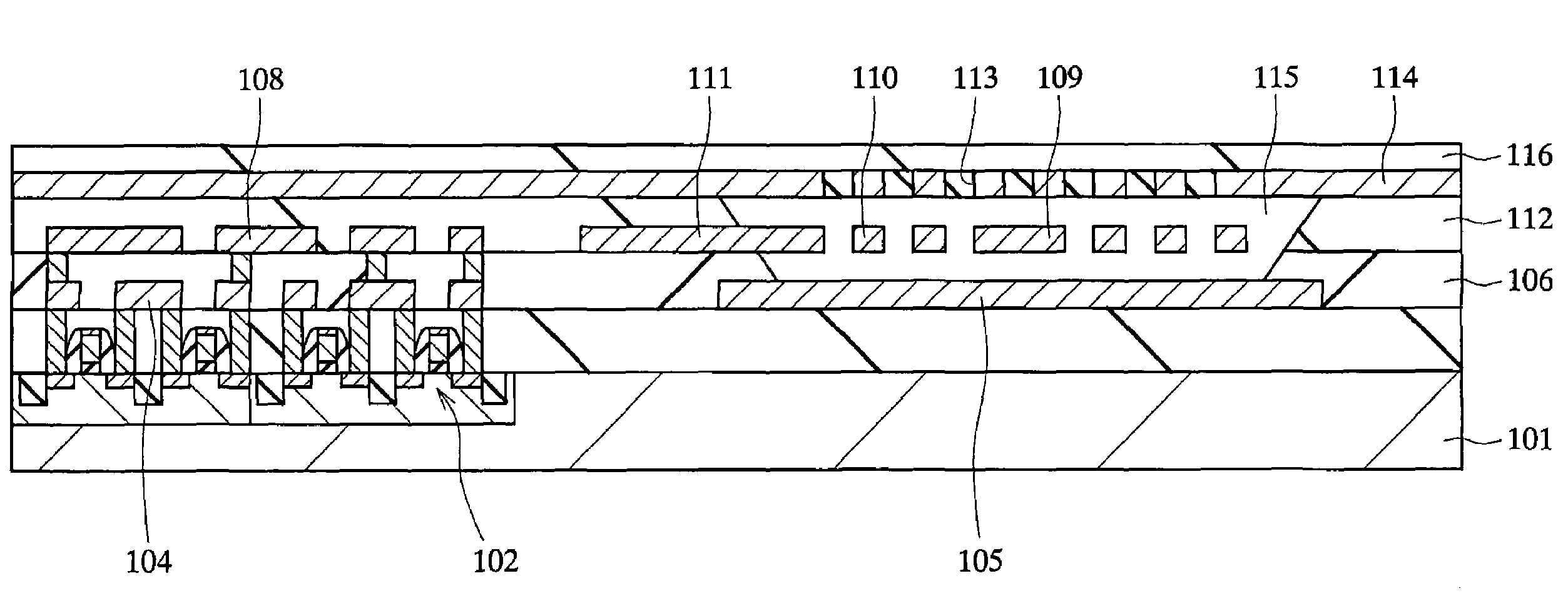

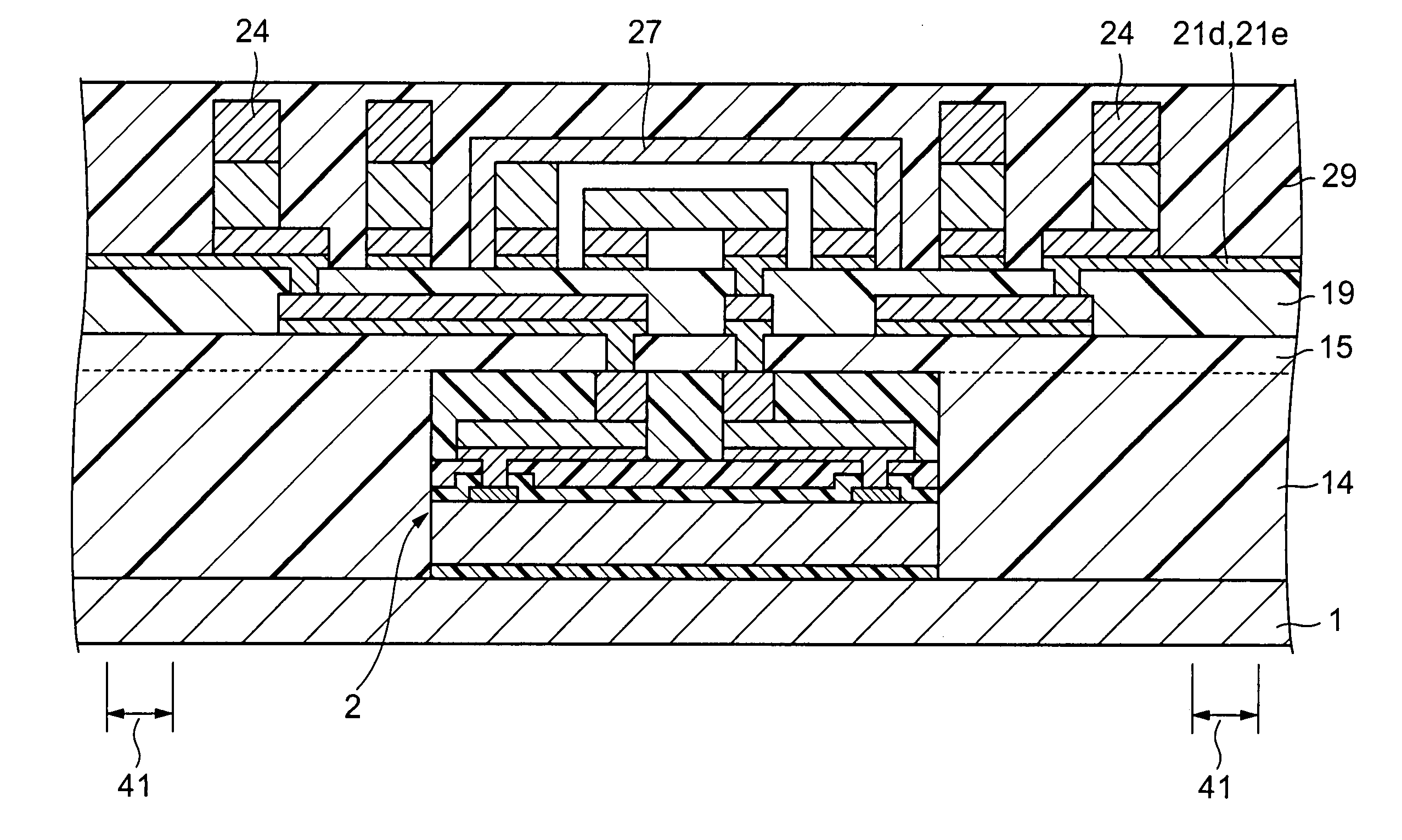

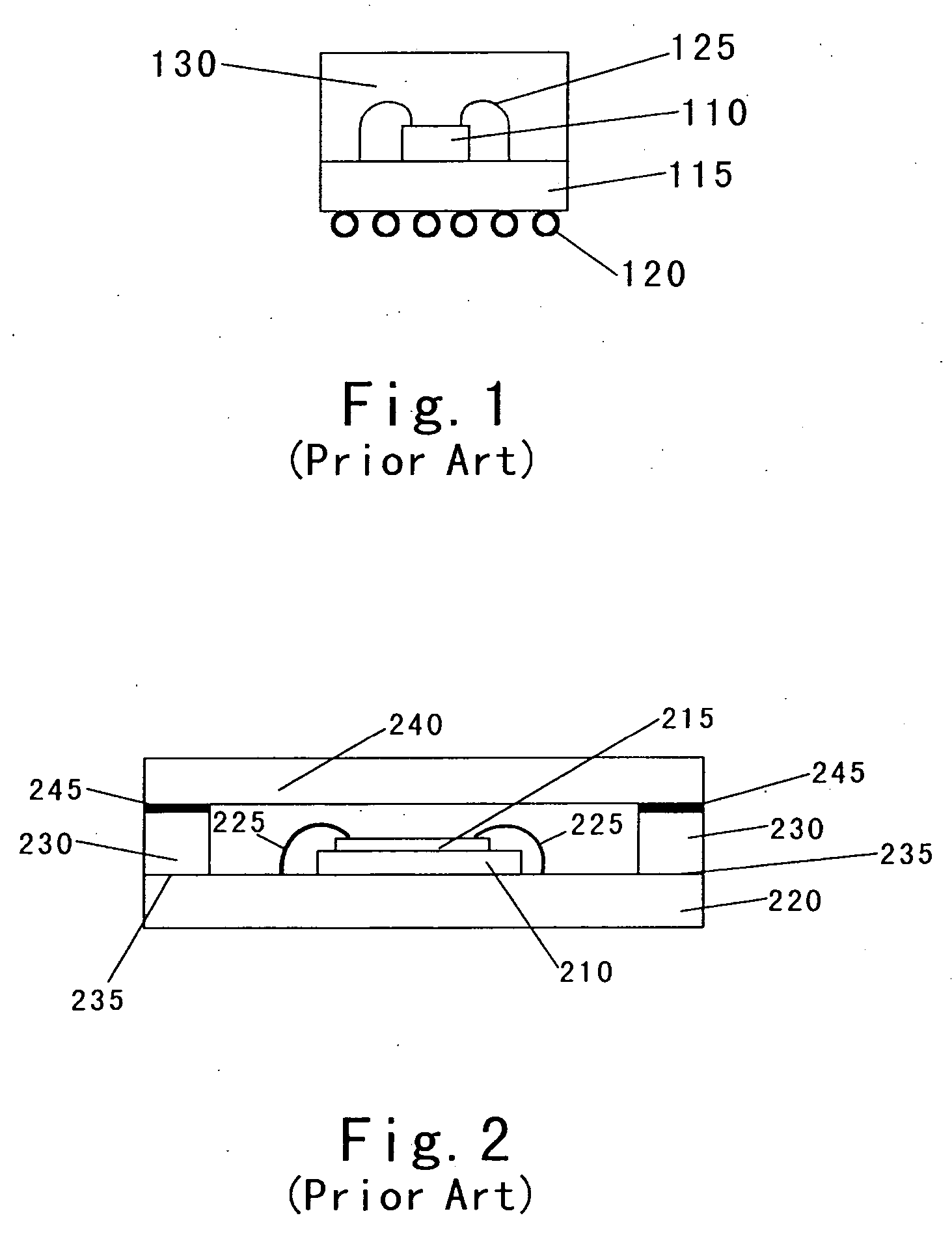

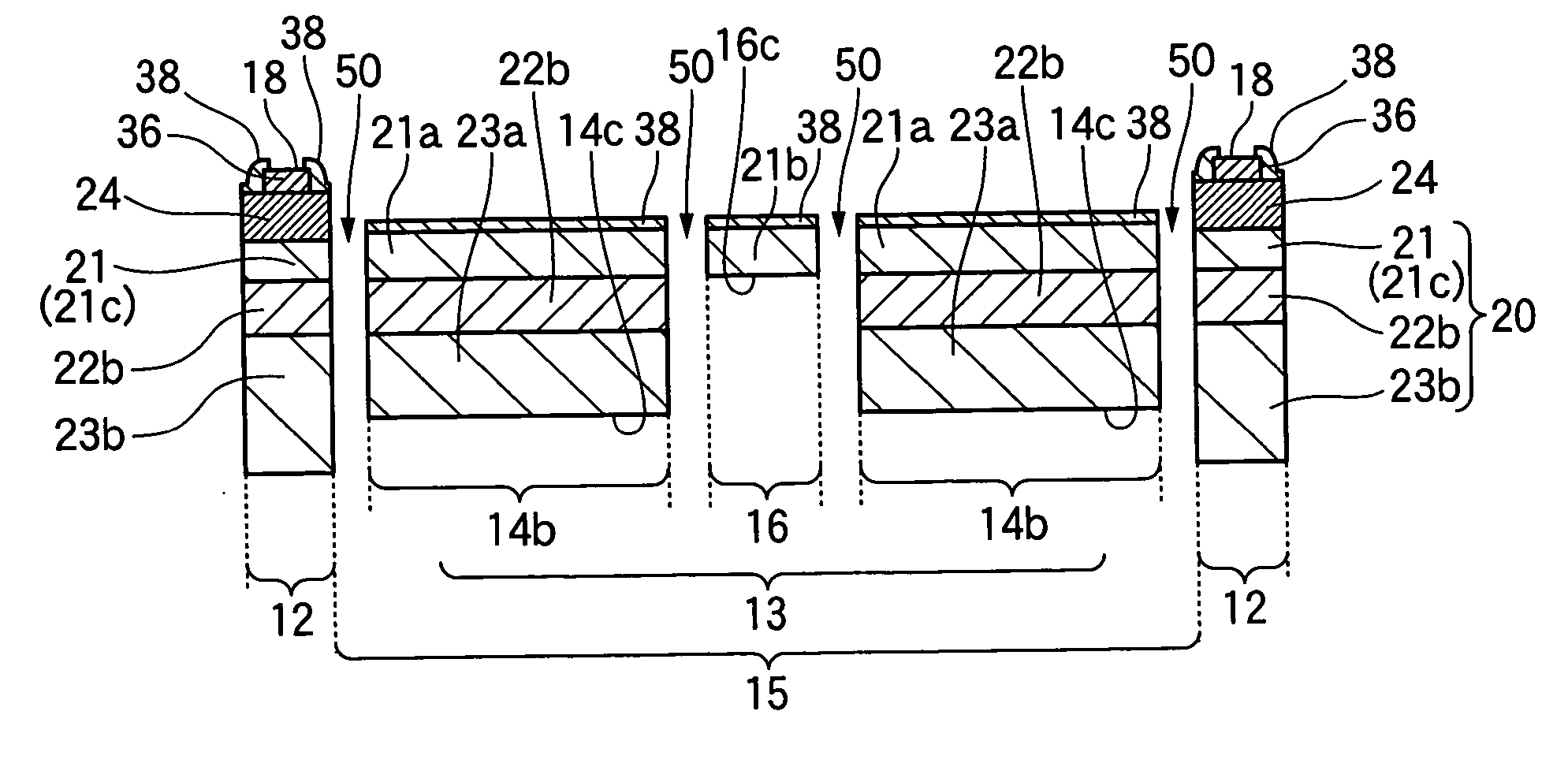

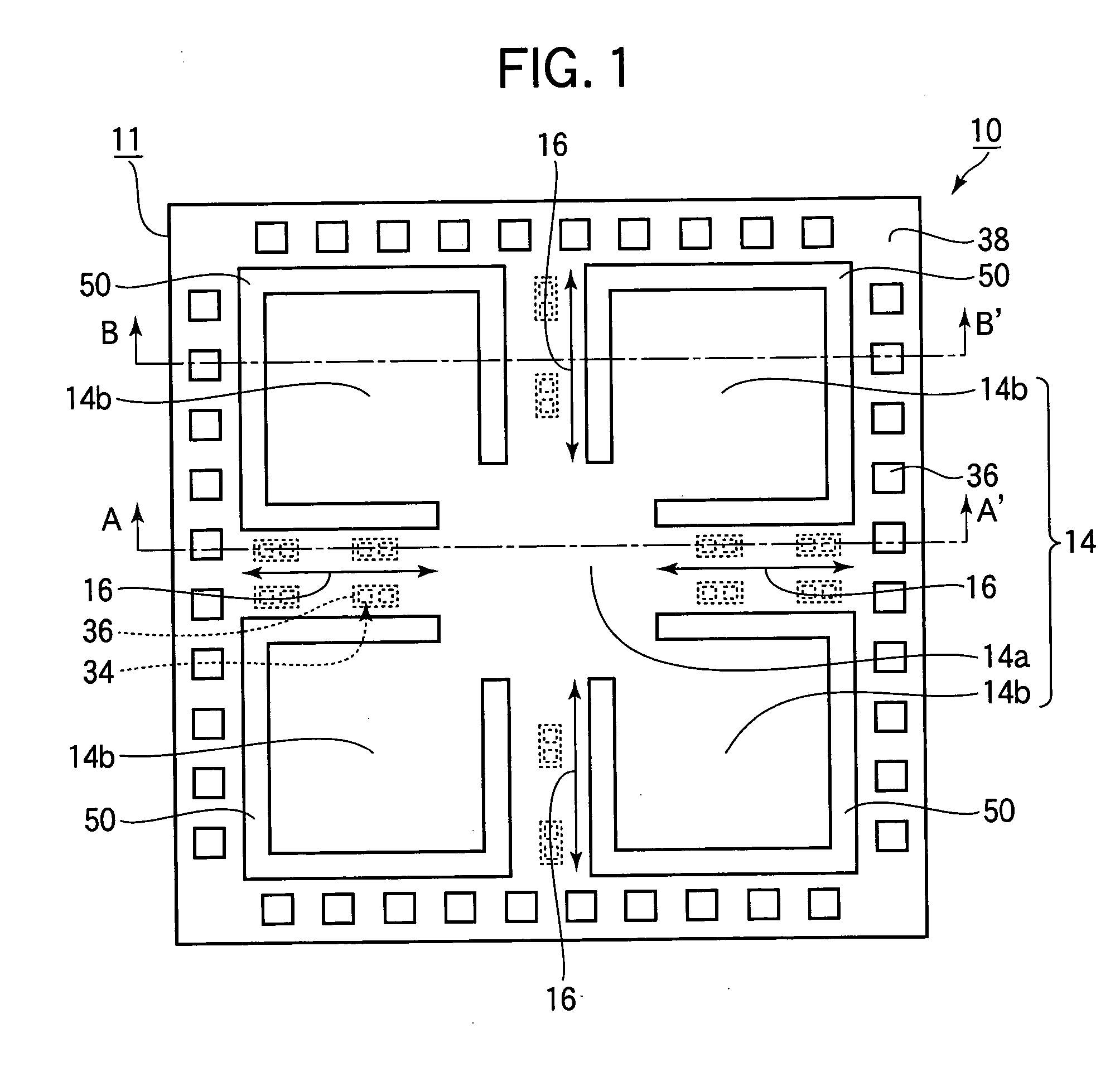

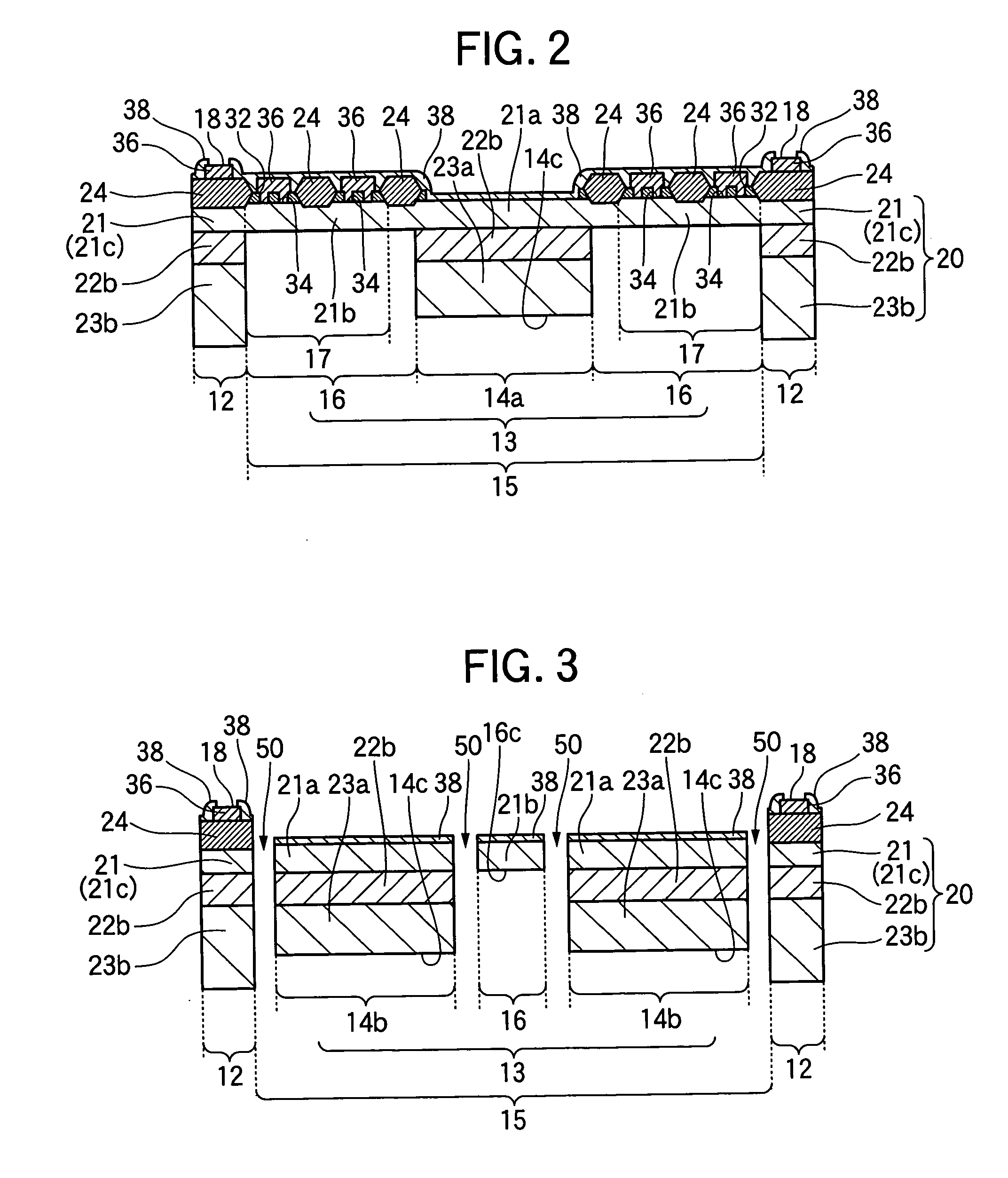

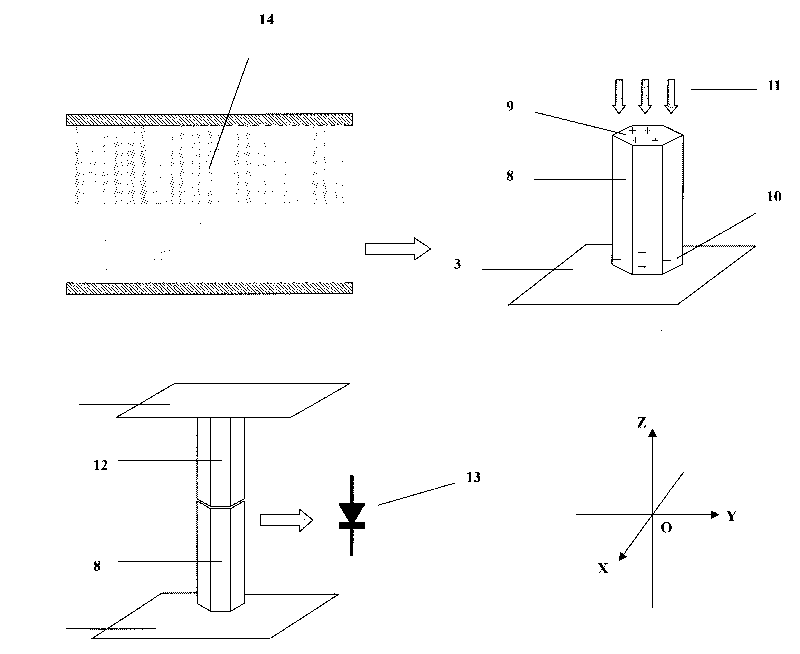

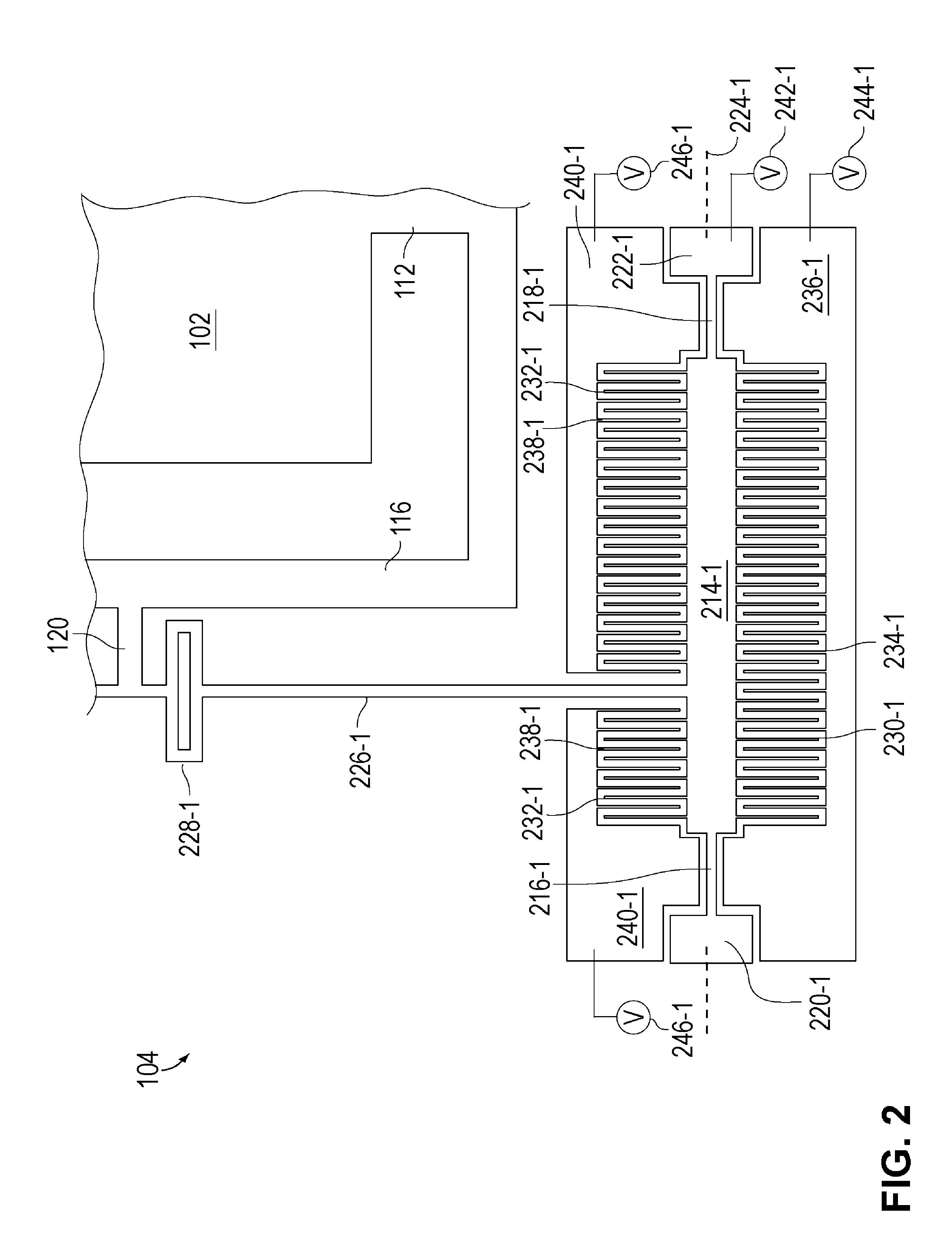

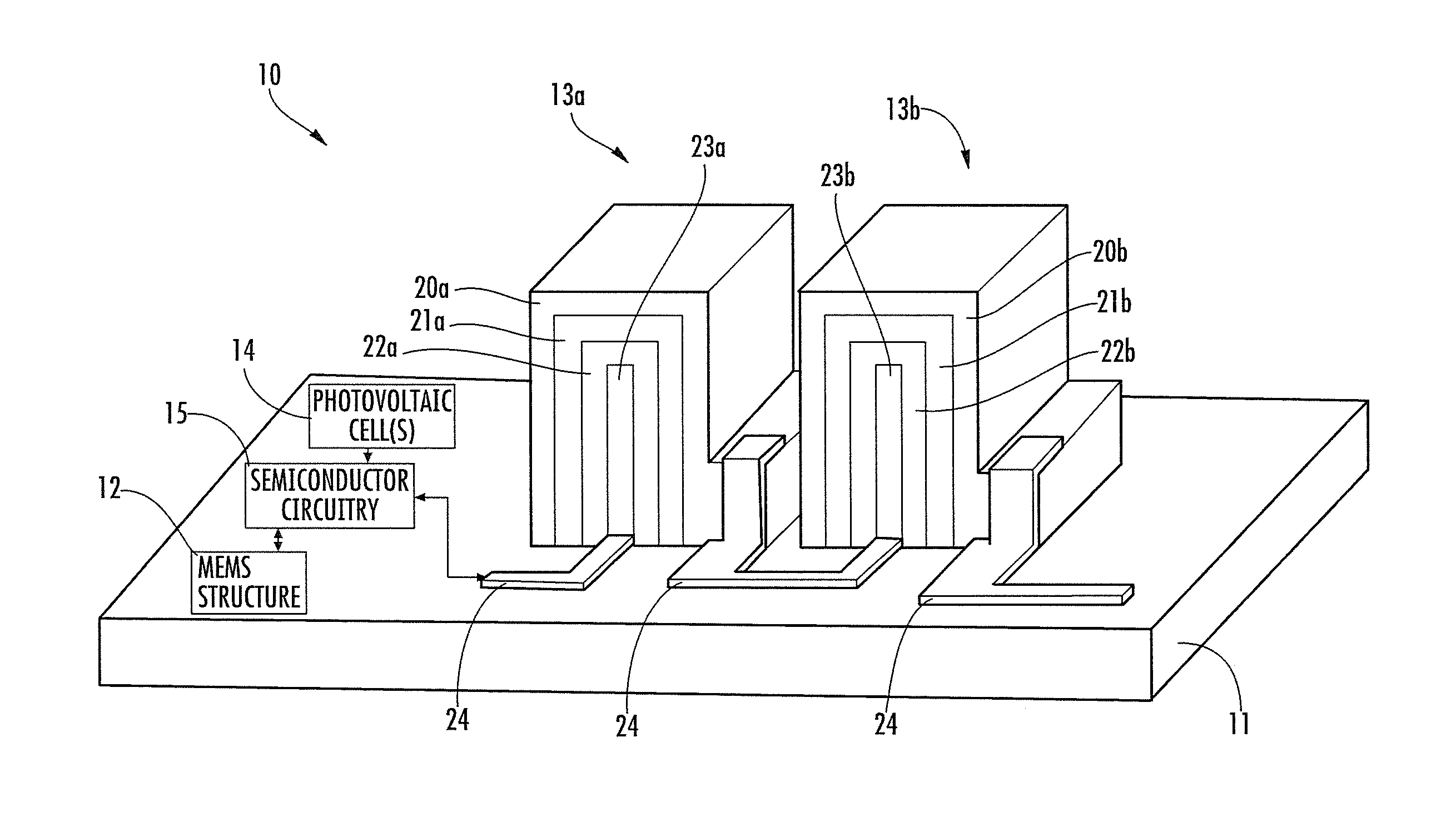

Integrated micro electro-mechanical system and manufacturing method thereof

ActiveUS7402449B2Easy to manufactureSufficient massTelevision system detailsInflated body pressure measurementDielectricEtching

In the manufacturing technology of an integrated MEMS in which a semiconductor integrated circuit (CMOS or the like) and a micro machine are monolithically integrated on a semiconductor substrate, a technology capable of manufacturing the integrated MEMS without using a special process different from the normal manufacturing technology of a semiconductor integrated circuit is provided. A MEMS structure is formed together with an integrated circuit by using the CMOS integrated circuit process. For example, when forming an acceleration sensor, a structure composed of a movable mass, an elastic beam and a fixed beam is formed by using the CMOS interconnect technology. Thereafter, an interlayer dielectric and the like are etched by using the CMOS process to form a cavity. Then, fine holes used in the etching are sealed with a dielectric.

Owner:HITACHI ASTEMO LTD

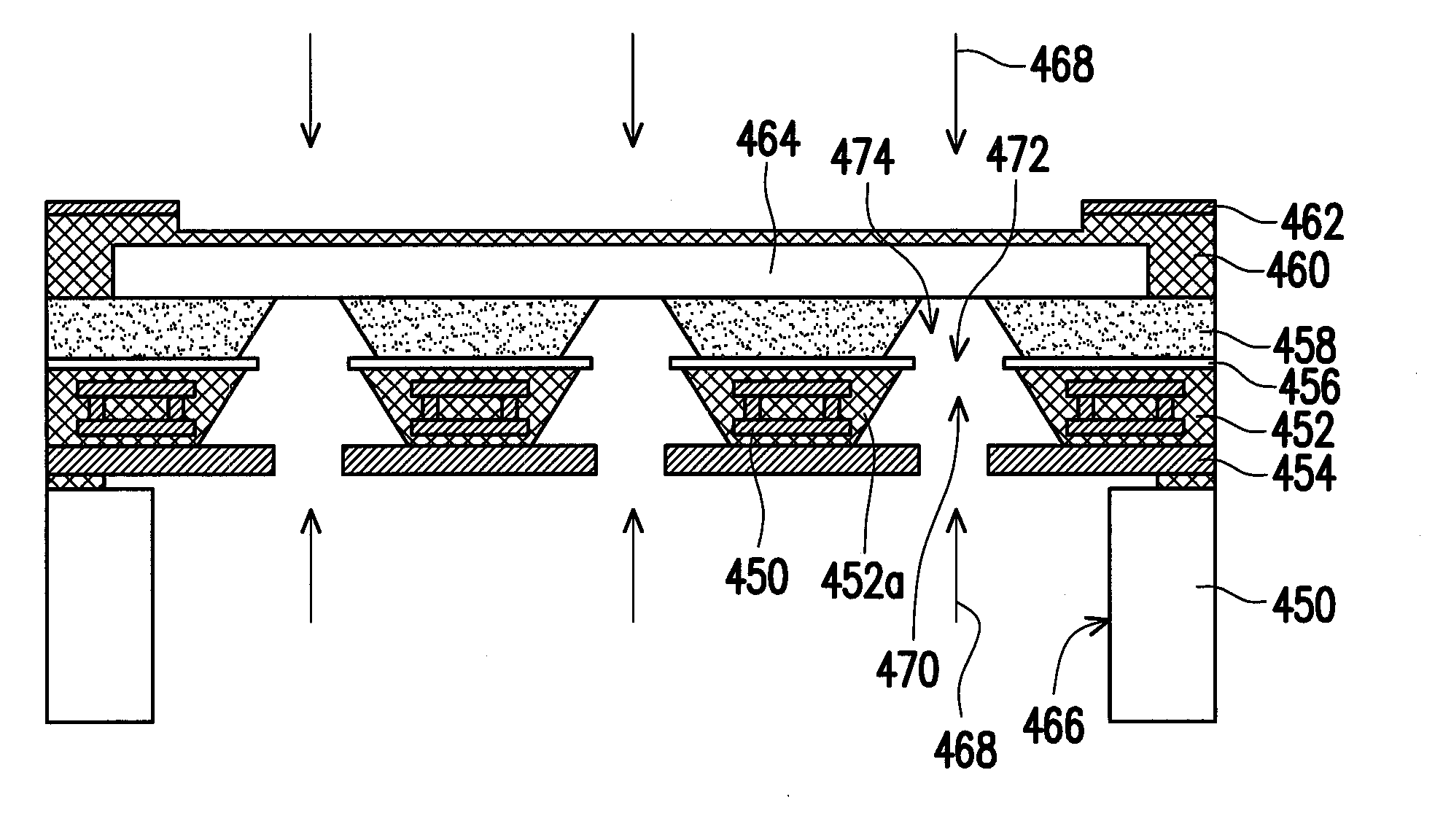

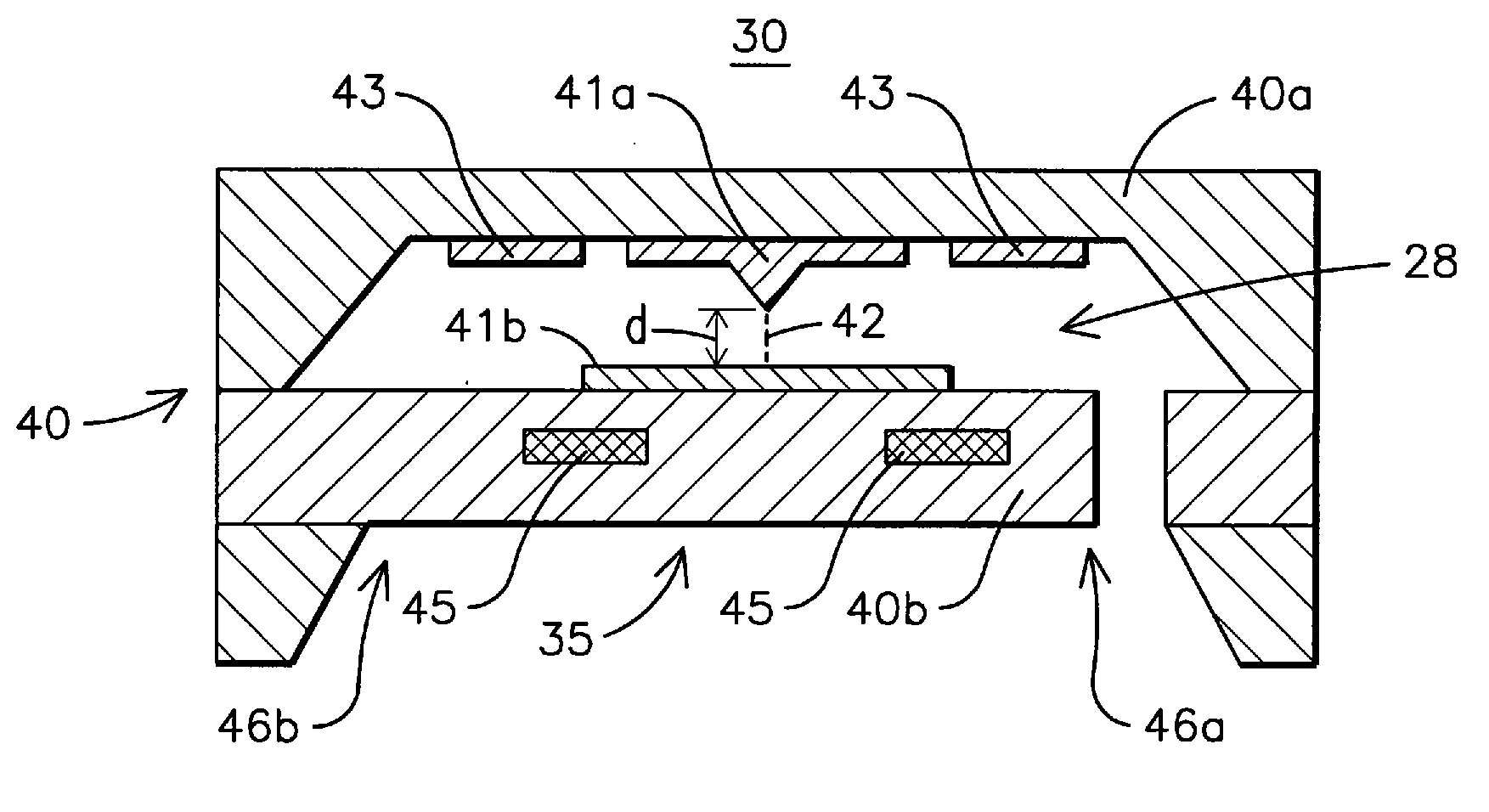

Single Die MEMS Acoustic Transducer and Manufacturing Method

ActiveUS20090169035A1Semiconductor electrostatic transducersSemiconductor/solid-state device manufacturingSemiconductor materialsTransducer

The invention relates to an acoustic micro-electrical-mechanical-system (MEMS) transducer formed on a single die based on a semiconductor material and having front and back surface parts opposed to each other. The invention further relates to a method of manufacturing such an acoustic MEMS transducer. The acoustic MEMS transducer comprises a cavity formed in the die to thereby provide a back volume with an upper portion facing an opening of the cavity and a lower portion facing a bottom of the cavity. A back plate and a diaphragm are arranged substantially parallel with an air gap there between and extending at least partly across the opening of the cavity, with the back plate and diaphragm being integrally formed with the front surface part of the die. The bottom of the cavity is bounded by the die. The diaphragm may be arranged above the back plate and at least partly extending across the back plate. It is preferred that the backside openings are formed in the die with the openings extending from the back surface part of the die to the cavity bottom. Part of or all of the backside openings may be acoustically sealed by a sealing material.

Owner:TDK CORPARATION

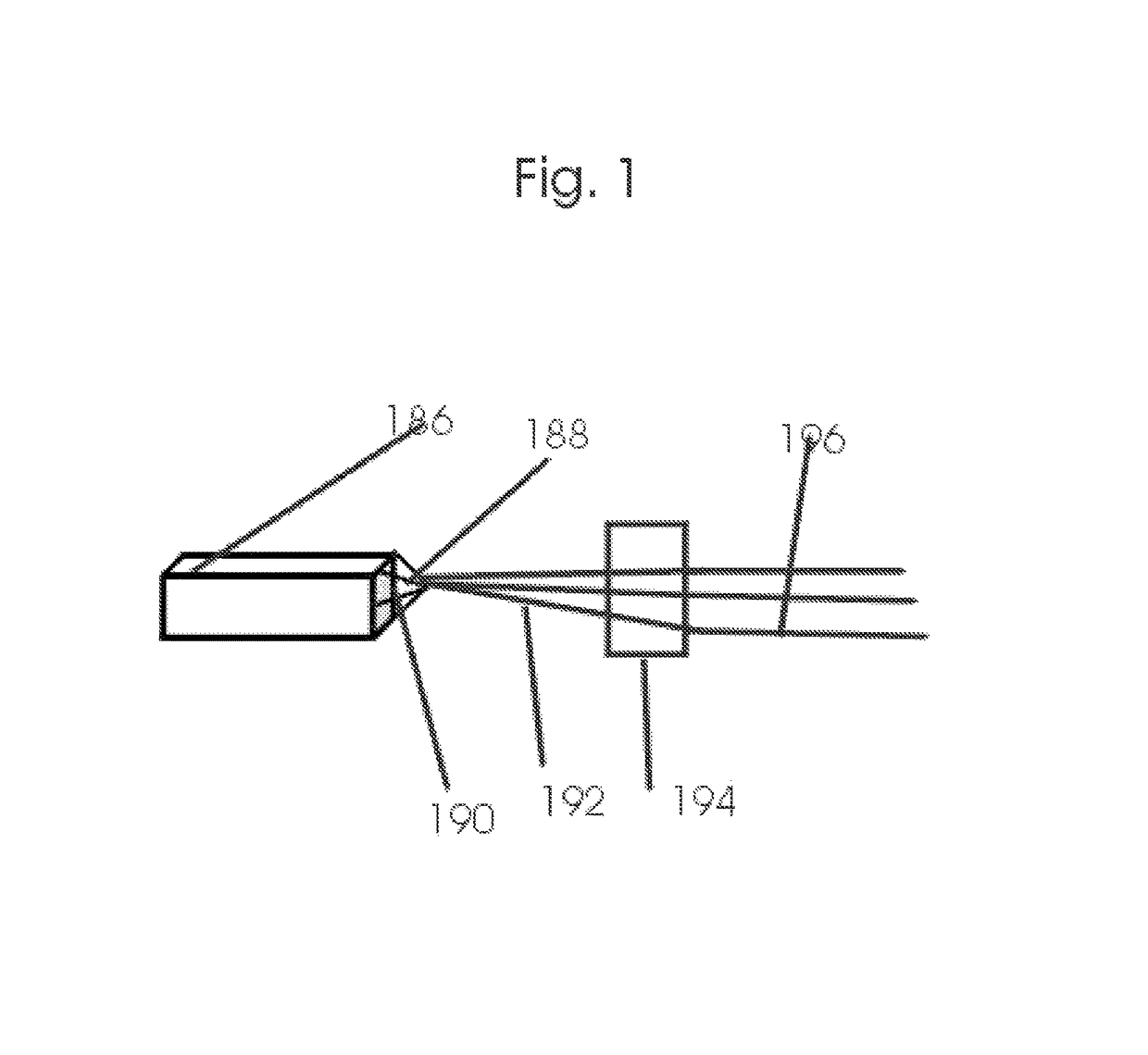

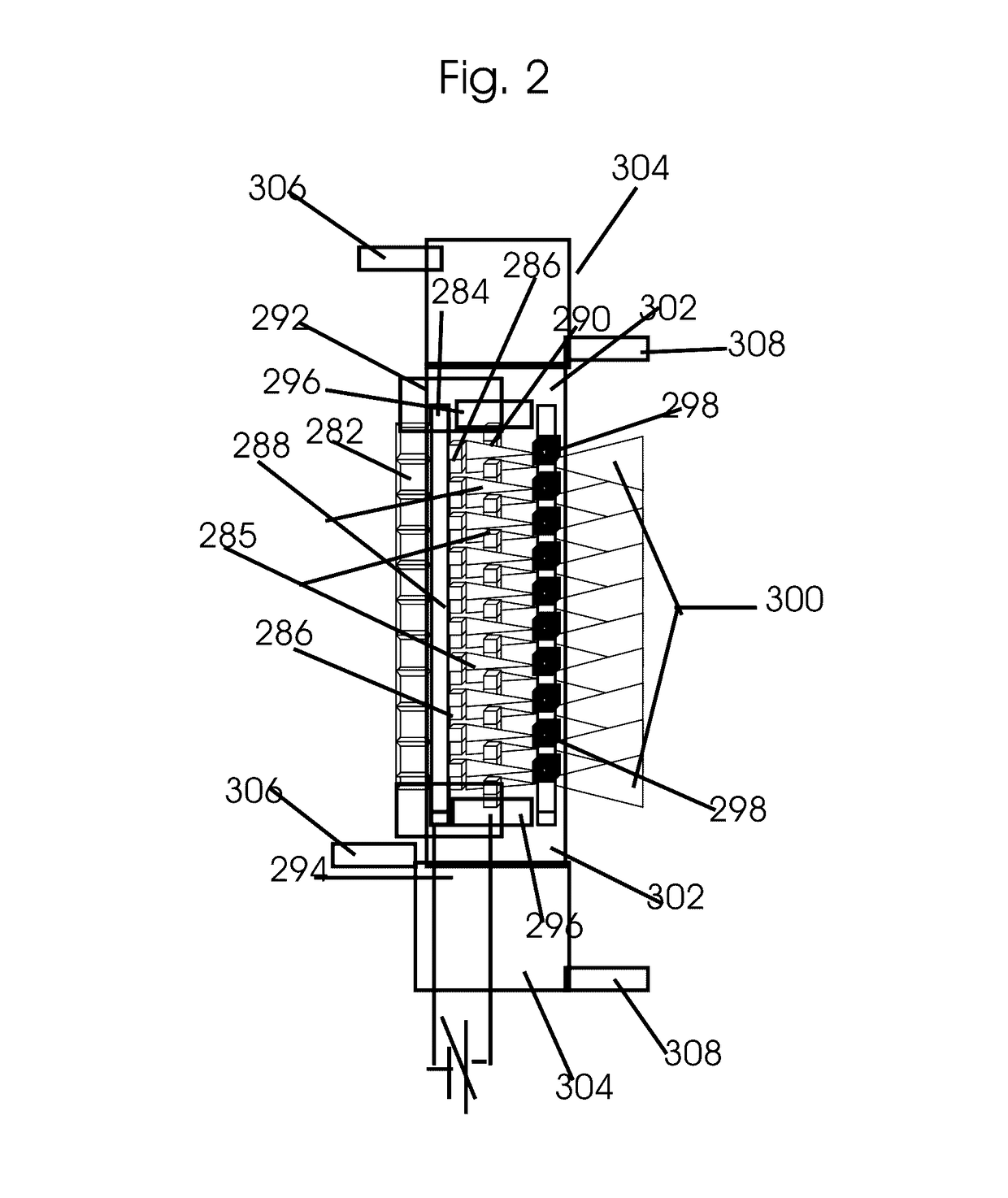

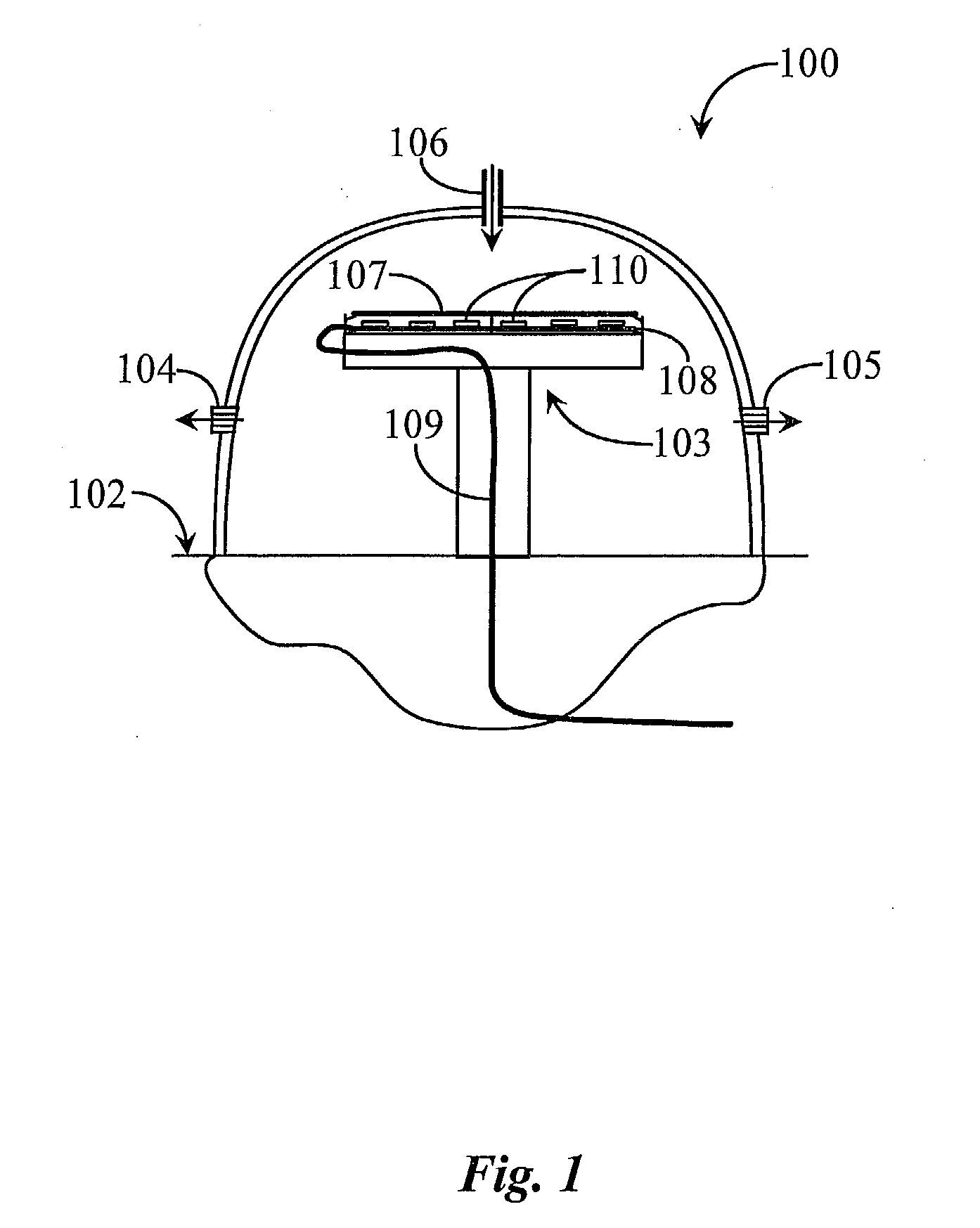

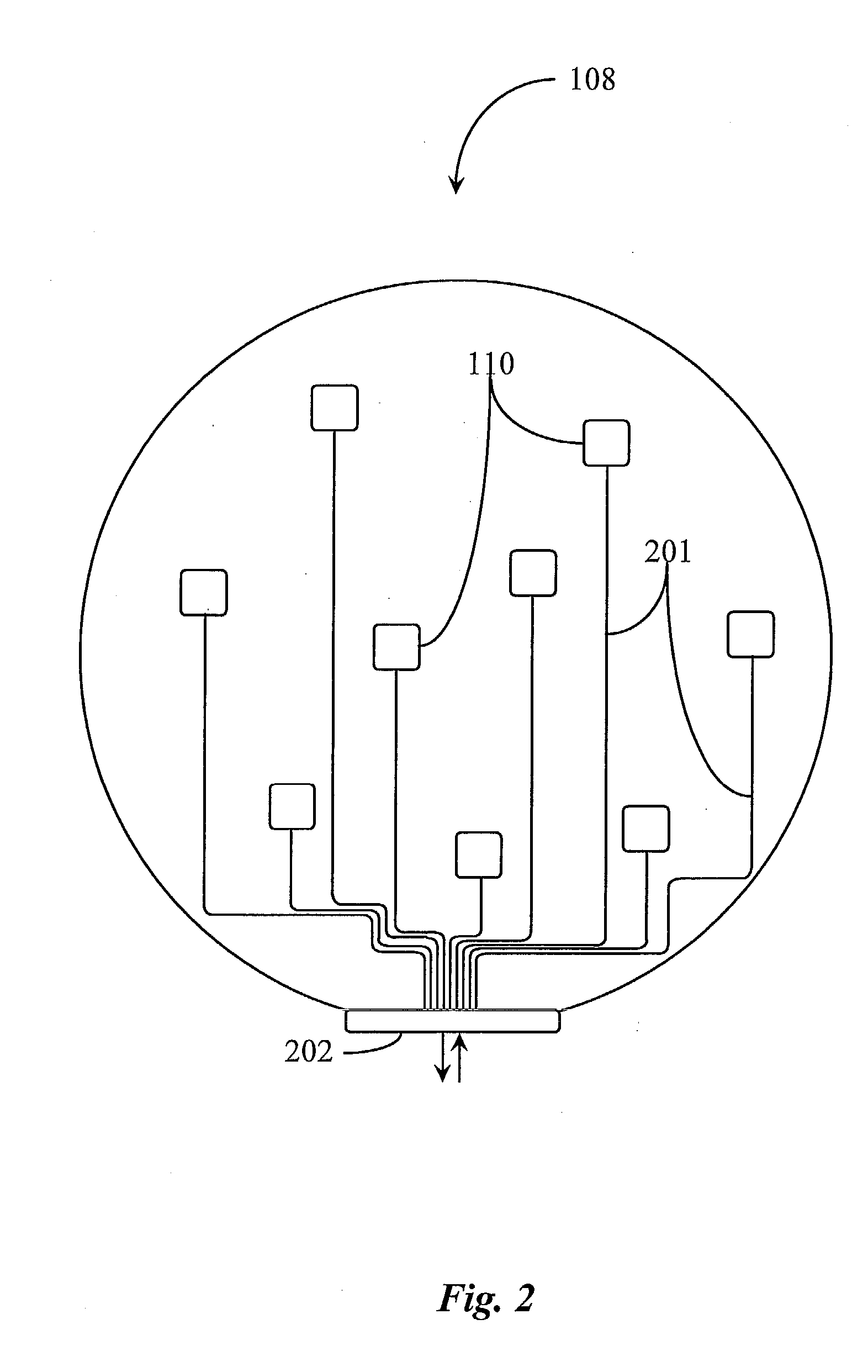

Integrated optical scanning image acquisition and display

An apparatus and method for providing image acquisition and / or image display in a limited region of interest (ROI). The apparatus comprises a micro electro-mechanical system (MEMS), preferably integrating a light source, a cantilever, a lens, an actuator, a light detector, and a position sensor. The light source provides light for illuminating the ROI, displaying an image, providing a therapy, and / or performing other functions. The cantilever comprises a resin waveguide with a fixed end attached to a substrate that supports many or all other components. A free end of the cantilever is released from the substrate during fabrication and includes the lens. The actuator scans the free end in orthogonal directions to illuminate the ROI or display an image. The position sensors detect the position of the free end for control. The light detector receives light backscattered from the ROI separate from, or at the fixed end the cantilever.

Owner:UNIV OF WASHINGTON +1

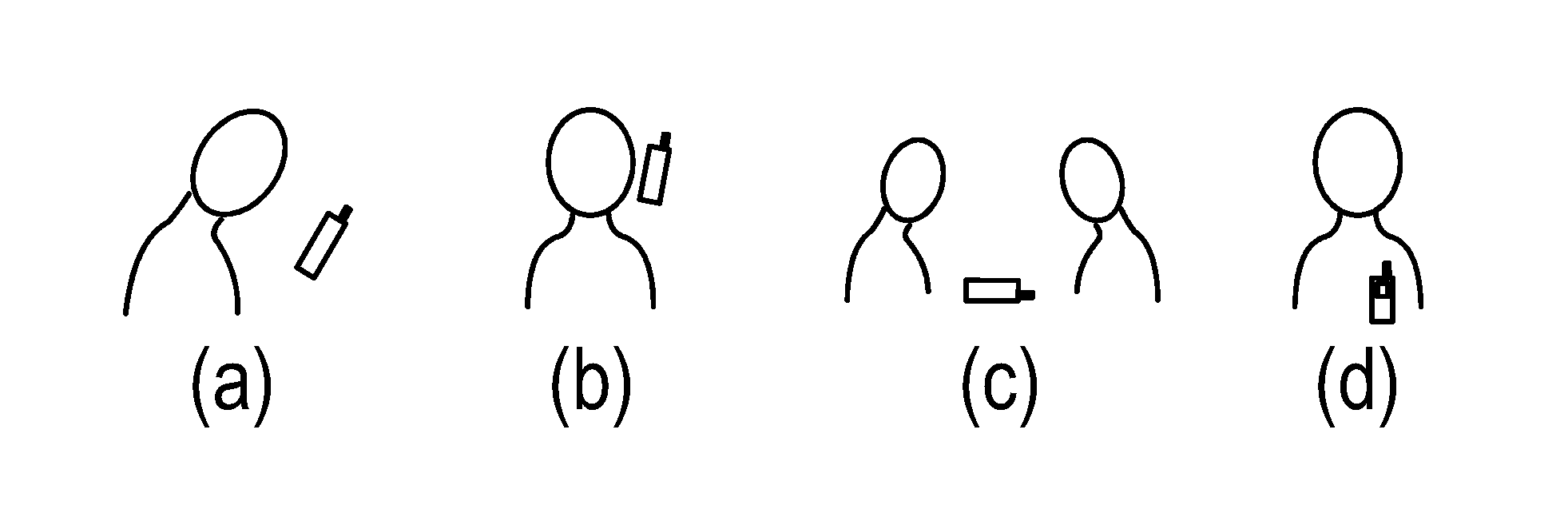

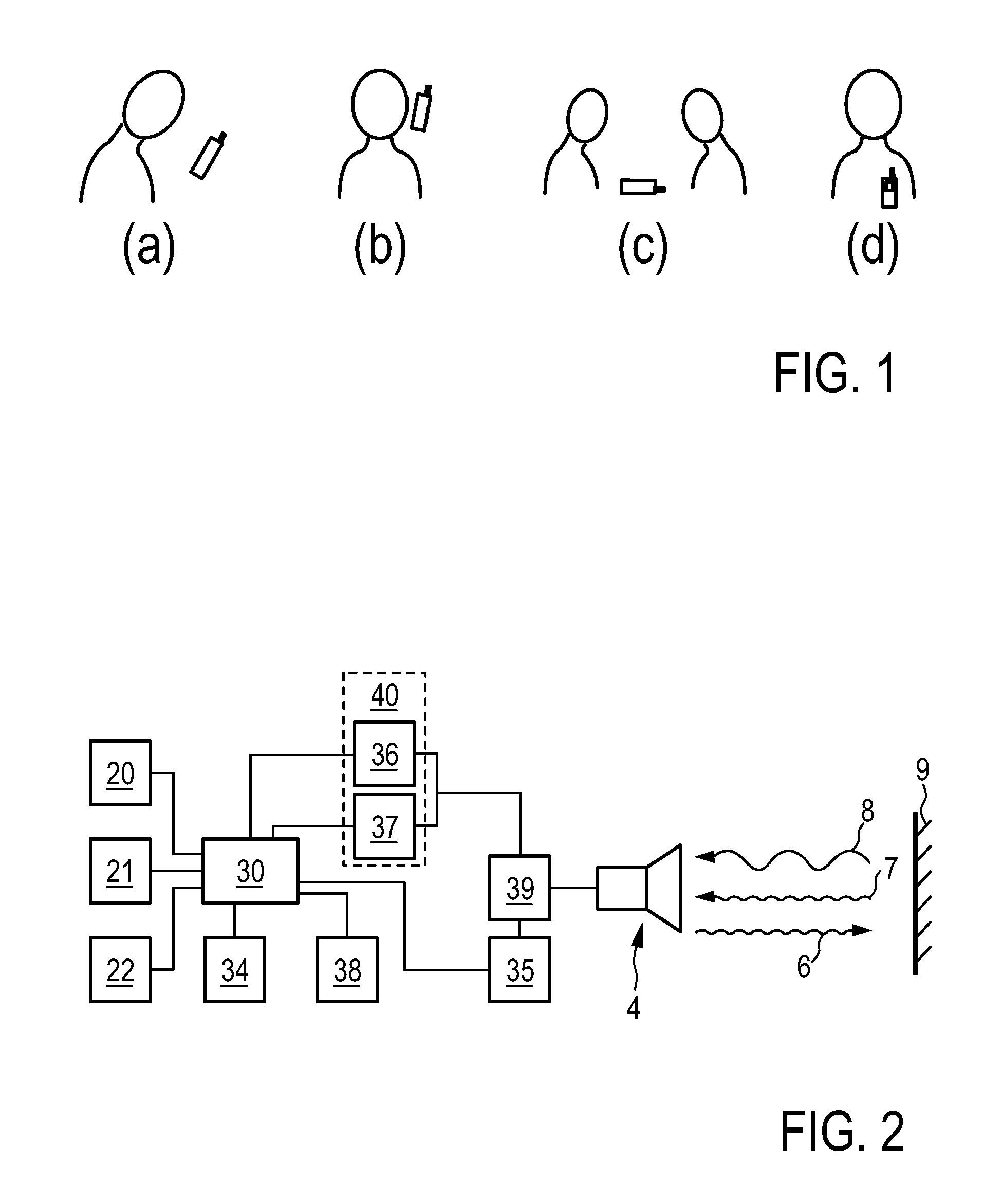

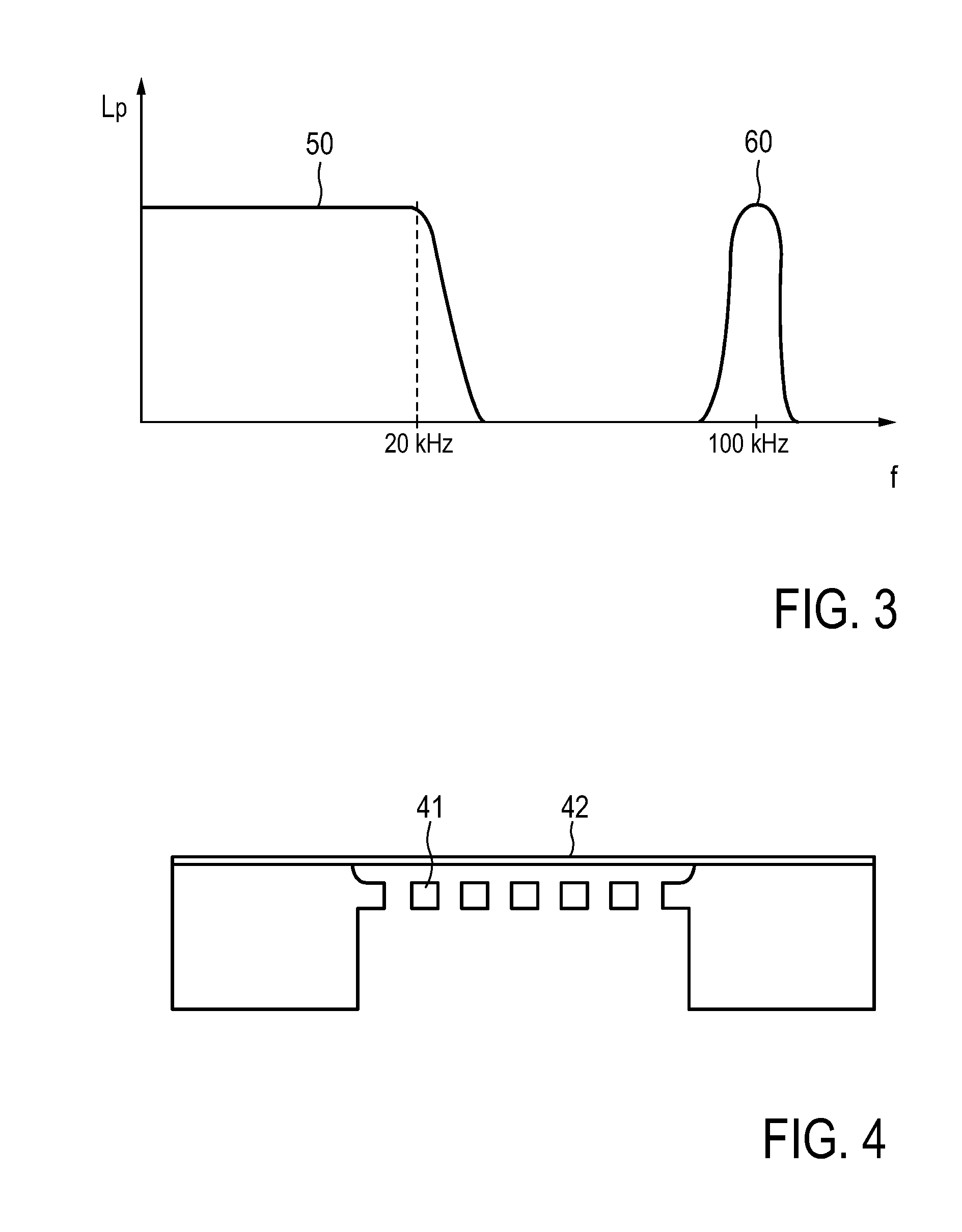

Proximity sensor, in particular microphone for reception of sound signals in the human audible sound range, with ultrasonic proximity estimation

ActiveUS20110003614A1Lower resonance frequencyReduce hardware complexityPiezoelectric/electrostrictive microphonesInterconnection arrangementsProximity sensorSonification

Proximity sensor, particularly for usage in an electronic mobile device, comprising at least one acoustic transducer adapted for receiving acoustic signals at least in parts of the frequency range of human audible sound and emitting and / or receiving ultrasonic signals for proximity estimation. The acoustic transducer preferably is a Micro-Electro-Mechanical-Systems (MEMS) microphone. Further, a method in an electronic device comprising an acoustic transducer is provided comprising the steps of generating at least one electric signal in the frequency range of ultrasonic sound, emitting at least one ultrasonic signal by means of the acoustic transducer; receiving at least one ultrasonic signal by means of the acoustic transducer; deducing from the at least one emitted ultrasonic signal and the at least one received ultrasonic signal at least the delay between emission of the emitted ultrasonic signal and reception of the corresponding ultrasonic signal.

Owner:NXP BV

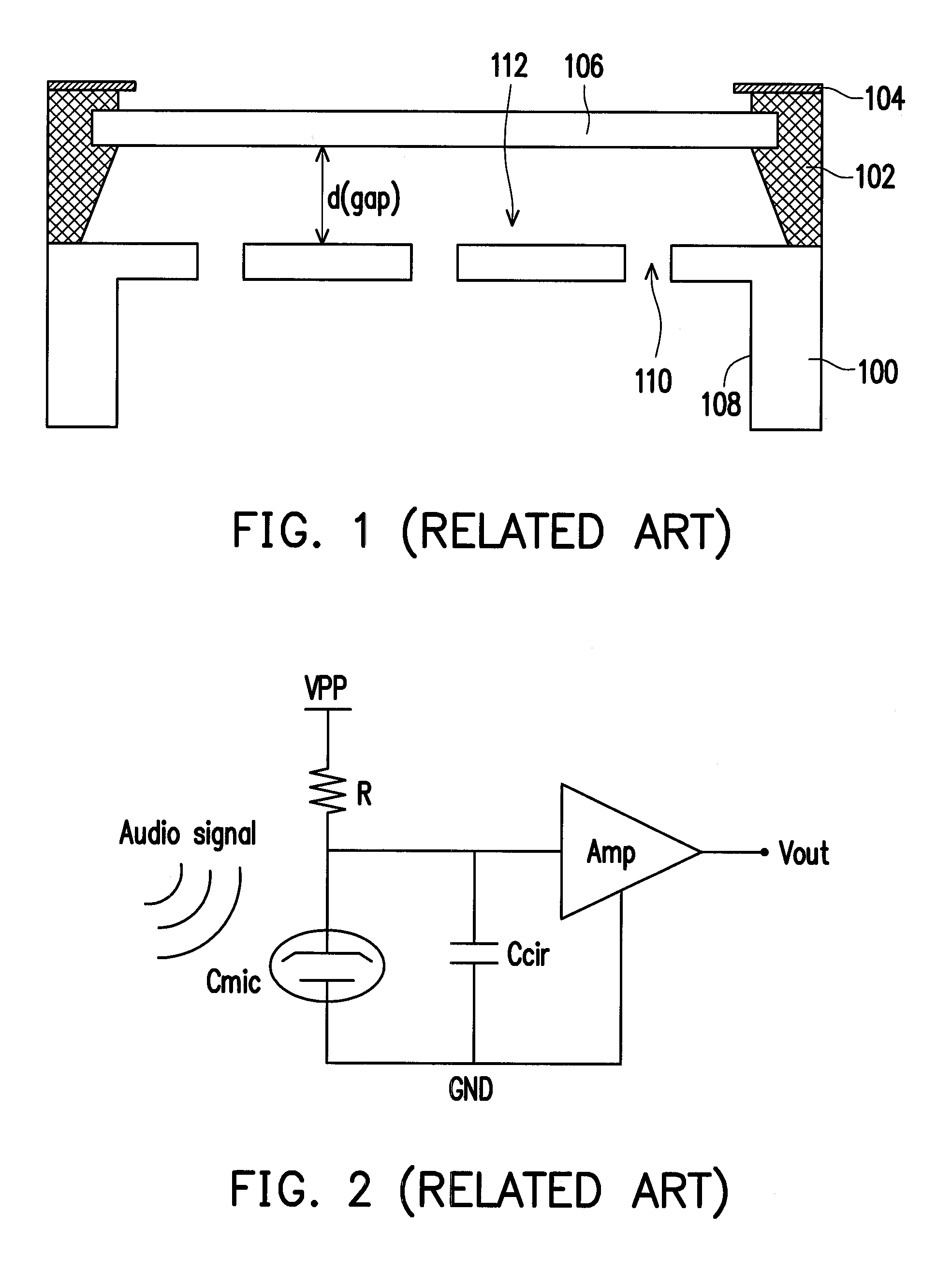

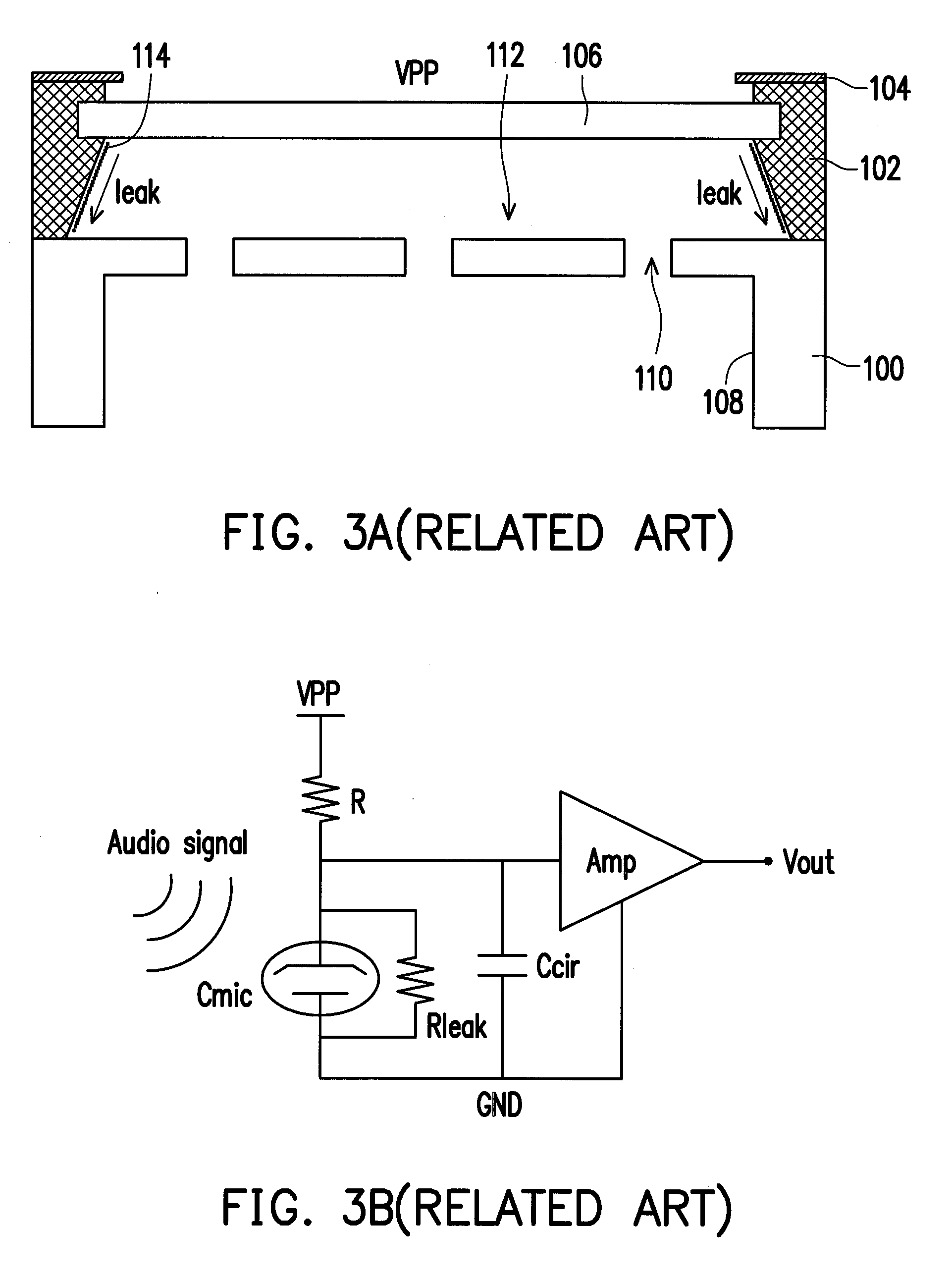

Micro-electro-mechanical systems (MEMS) device and method for fabricating the same

ActiveUS20130056841A1Increase capacitanceReduce thicknessSemiconductor electrostatic transducersCapacitor with electrode distance variationMicro electrical mechanical systemsEngineering

A MEMS device includes a substrate. The substrate has a plurality of through holes in the substrate within a diaphragm region and optionally an indent space from the second surface at the diaphragm region. A first dielectric structural layer is then disposed over the substrate from the first surface, wherein the first dielectric structural layer has a plurality of openings corresponding to the through holes, wherein each of the through holes remains exposed by the first dielectric structural layer. A second dielectric structural layer with a chamber is disposed over the first dielectric structural layer, wherein the chamber exposes the openings of the first dielectric structural layer and the through holes of the substrate to connect to the indent space. A MEMS diaphragm is embedded in the second dielectric structural layer above the chamber, wherein an air gap is formed between the substrate and the MEMS diaphragm.

Owner:SOLID STATE SYST

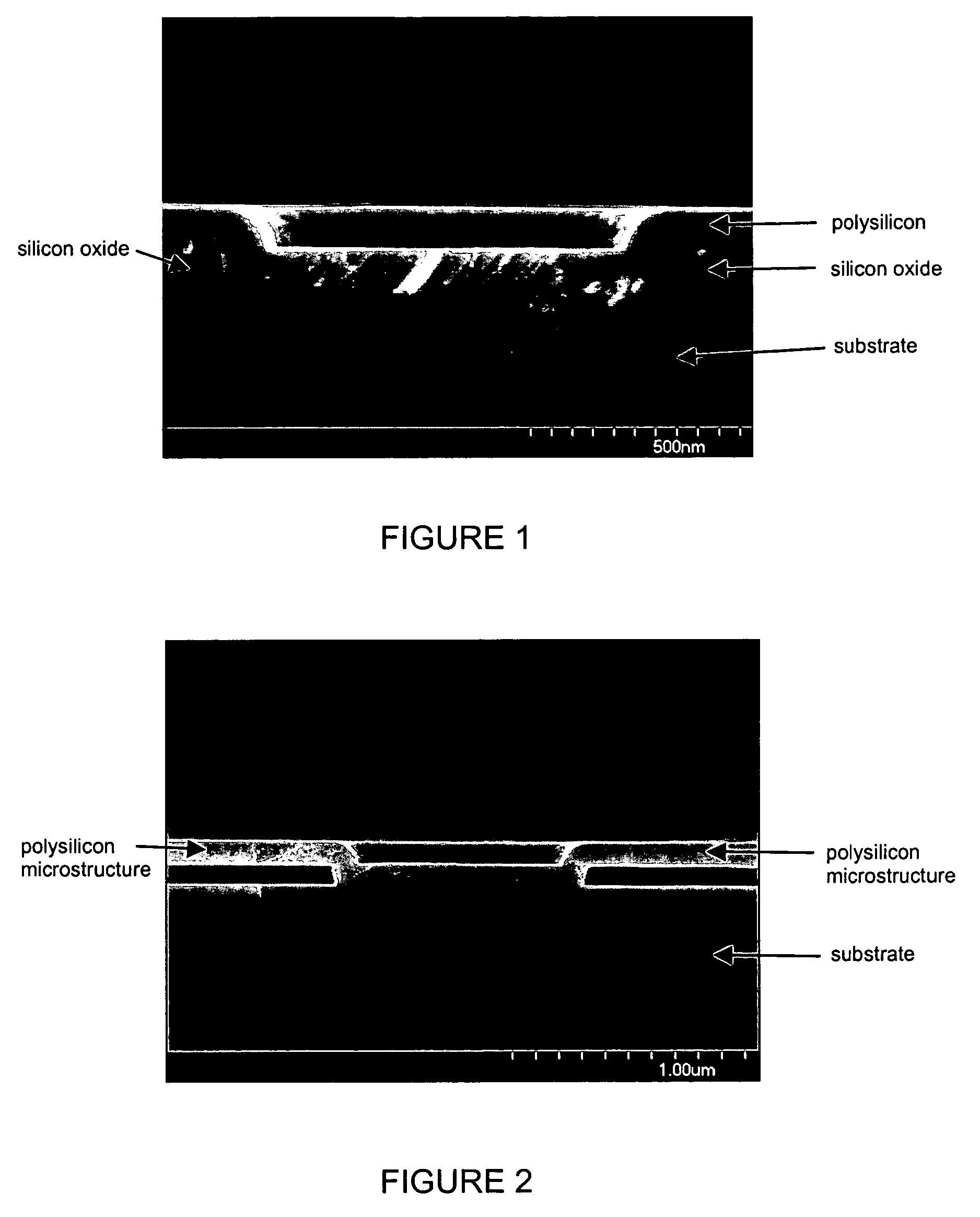

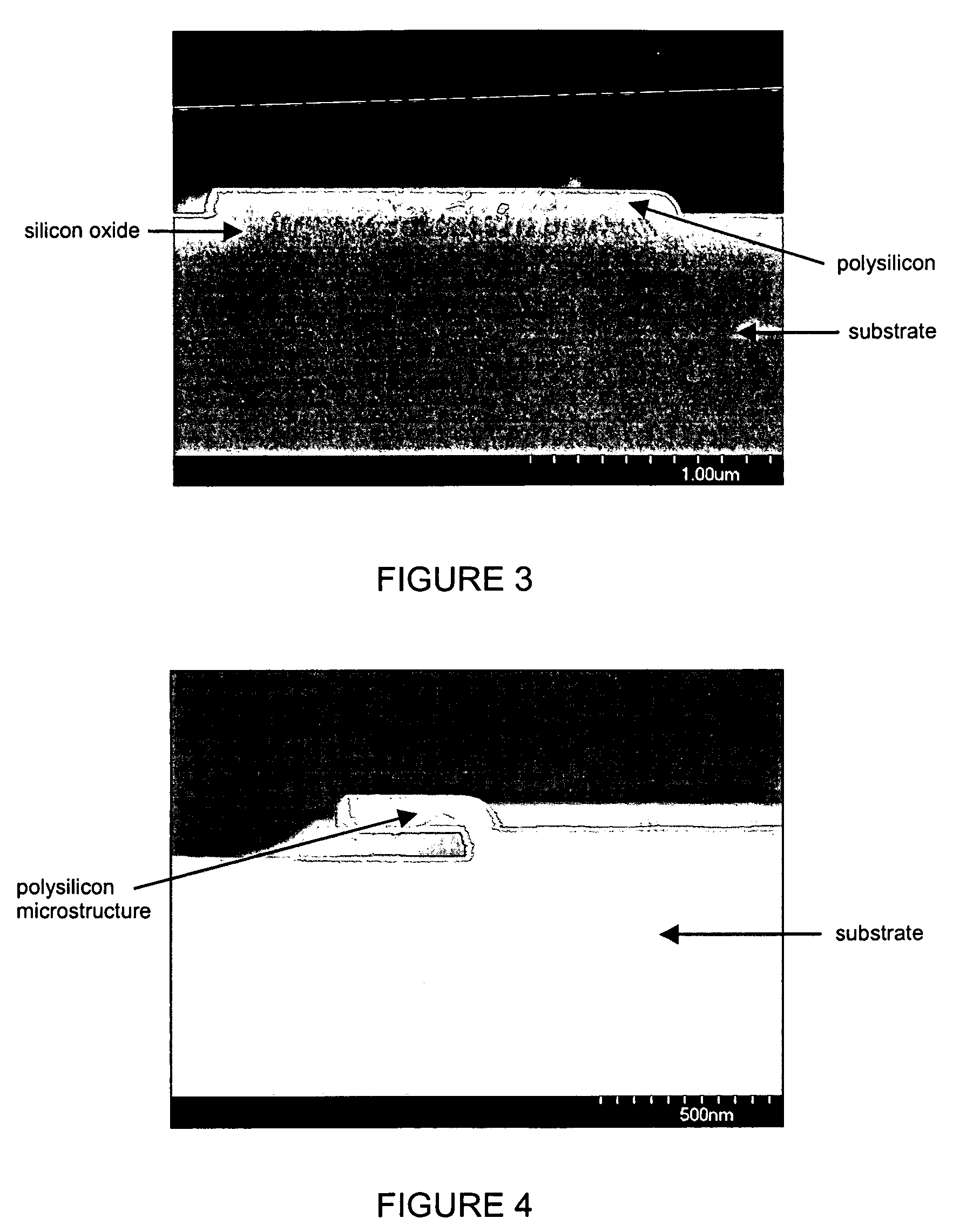

Removal of MEMS sacrificial layers using supercritical fluid/chemical formulations

InactiveUS20050118832A1Semiconductor/solid-state device manufacturingPiezoelectric/electrostrictive devicesCompound (substance)Stiction

A method and composition for removing silicon-containing sacrificial layers from Micro Electro Mechanical System (MEMS) substrates having such sacrificial layers is described. The etching compositions include a supercritical fluid, an etchant species, a co-solvent, and optionally a surfactant. Such etching compositions overcome the intrinsic deficiency of SCFs as cleaning reagents, viz., the non-polar character of SCFs and their associated inability to solubilize polar species that must be removed from the semiconductor substrate. The resultant etched MEMS substrates experience lower incidents of stiction relative to MEMS substrates etched using conventional wet etching techniques.

Owner:ADVANCED TECH MATERIALS INC

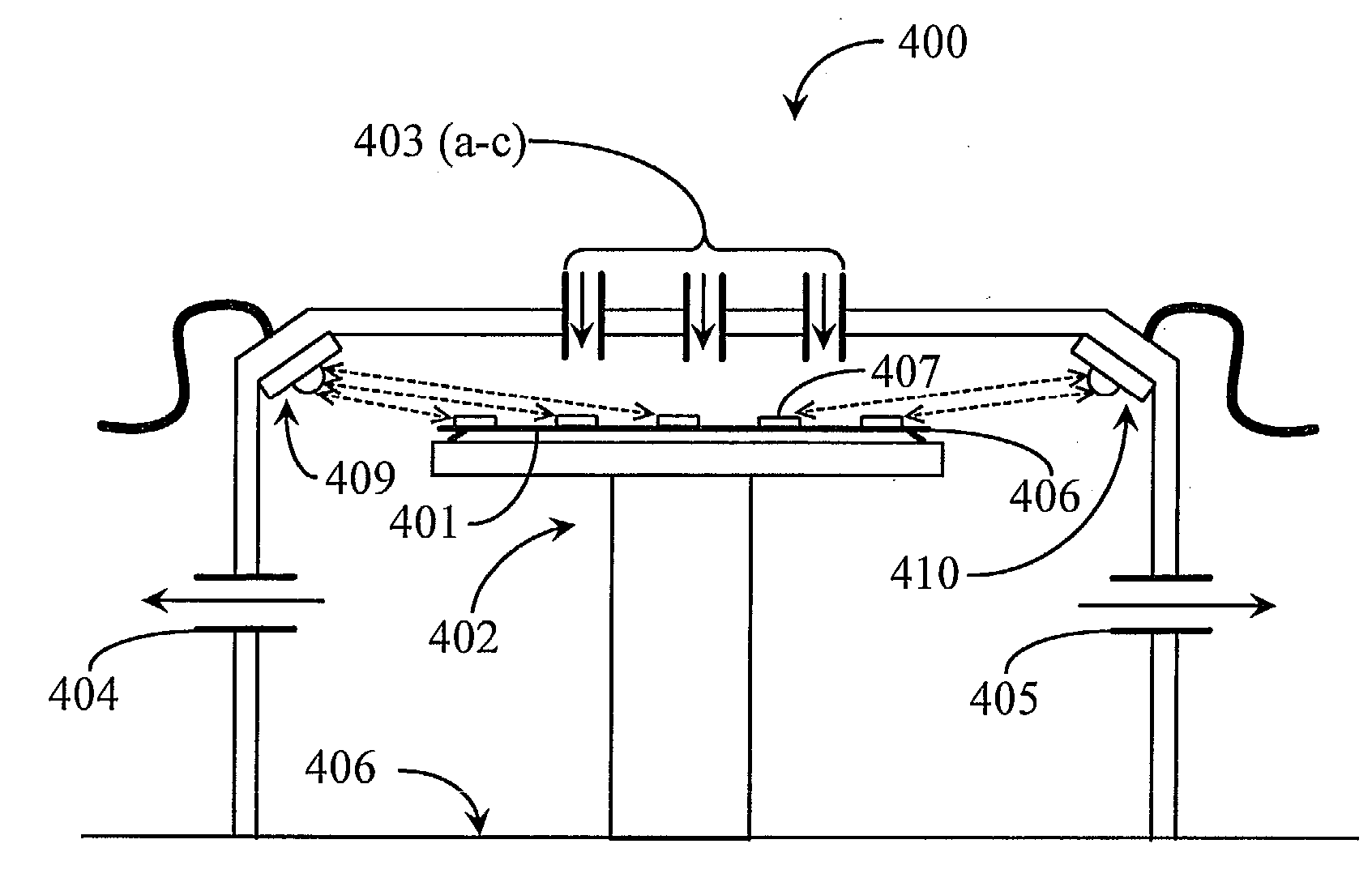

Method of image guided intraoperative simultaneous several ports microbeam radiation therapy with microfocus X-ray tubes

This invention pertains to a method of low-cost intraoperative all field simultaneous parallel microbeam single fraction few seconds duration 100 to 1,000 Gy and higher dose radiosurgery with micro-electro-mechanical systems (MEMS)-carbon nanotube based microaccelerators. It ablates cancer cells including the mesenchymal epithelial transformation associated cancer stem cells. Microbeam brachy-therapeutic radiosurgery is performed. Microaccelerators are configured for simultaneous parallel microbeam emission from varying angels to an isocentric tumor. Their additive dose rate at the isocentric tumor is in the range of 10,000 to 20,000 Gy / s. It eliminates most tumor recurrence and metastasis which enhances cancer cure rates. It also exposes cancer antigens which induces cancer immunity. Stereotactic breast core biopsy is combined with, positron emission tomography and computerized tomography and phase-contrast imaging. Parallel microbeam brachytherapy preserves normal breast appearance. Migration of normal stem cells from unirradiated valley regions heals the radiation damage to the normal tissue.

Owner:SAHADEVAN VELAYUDHAN

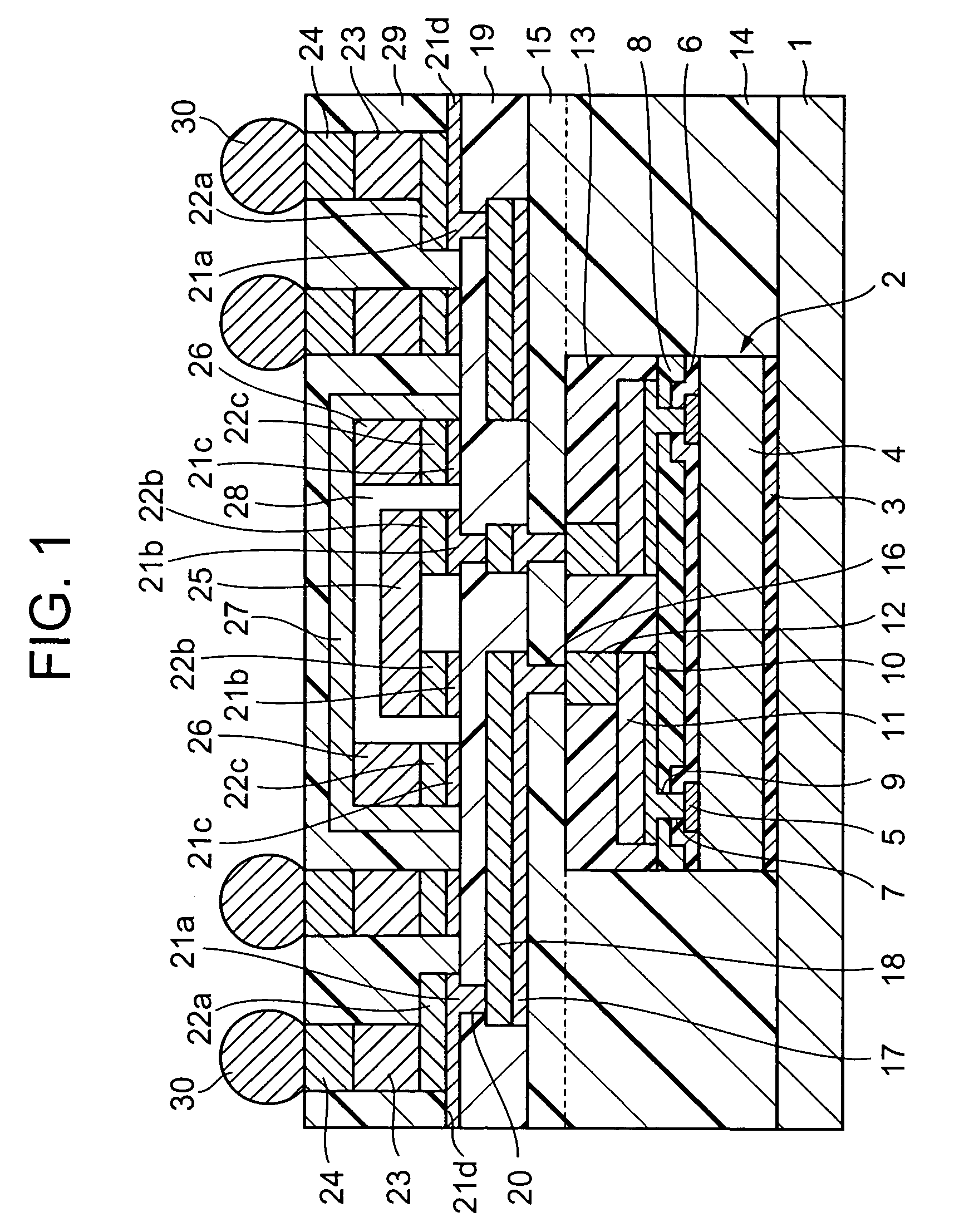

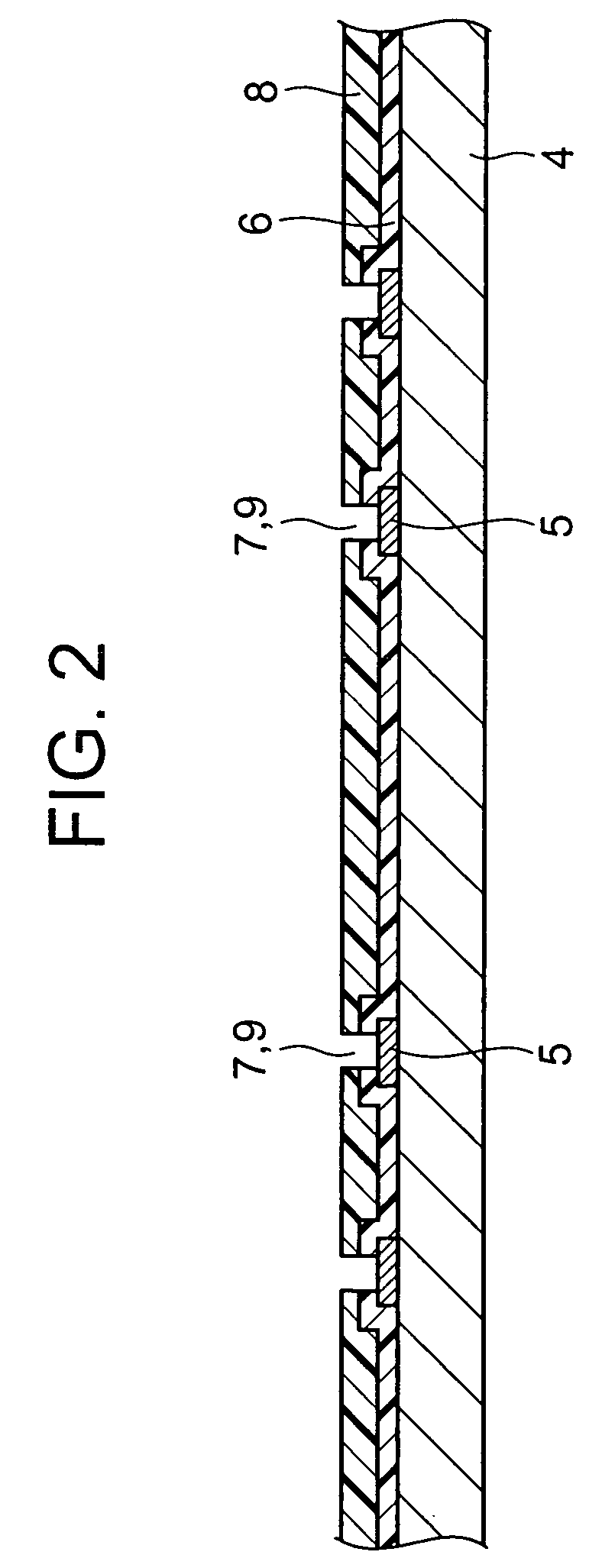

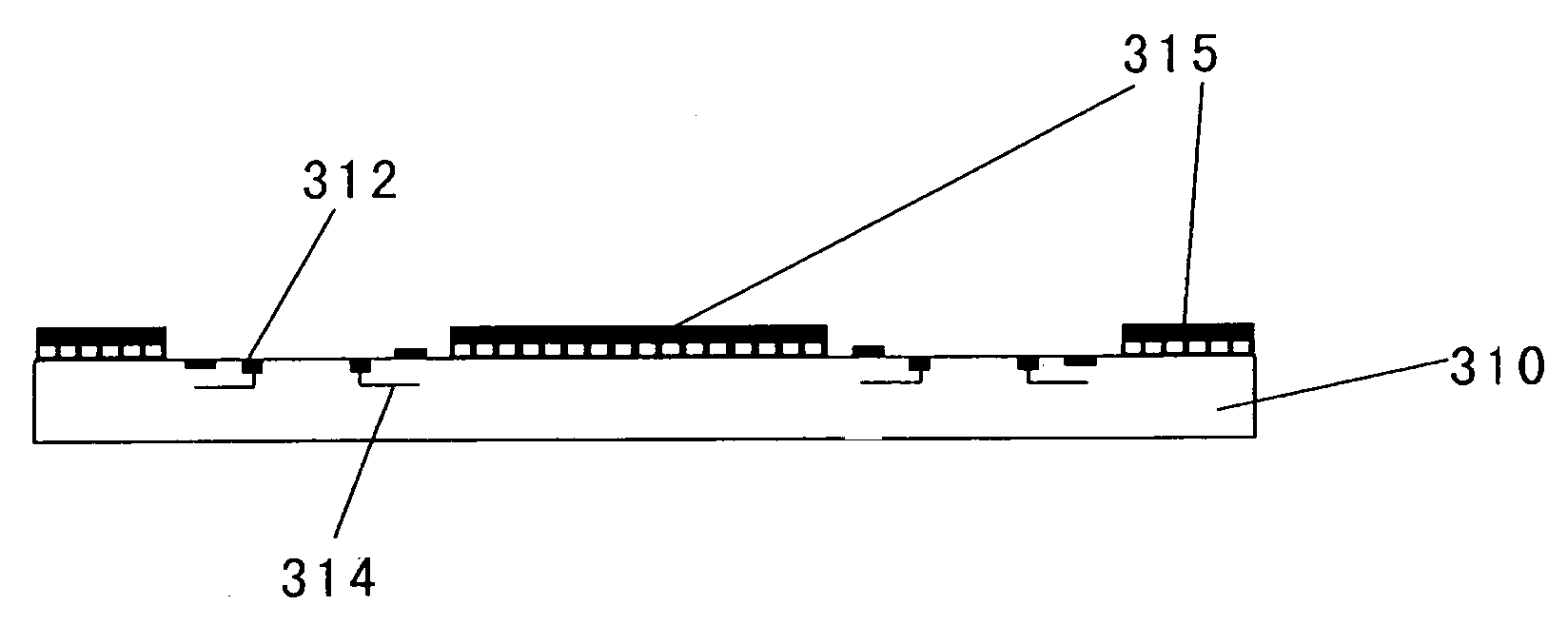

Semiconductor package having built-in micro electric mechanical system and manufacturing method thereof

InactiveUS7030494B2Semiconductor/solid-state device detailsSolid-state devicesExternal connectionEngineering

A semiconductor package includes a semiconductor structure having a plurality of electrodes for external connection which are provided on a semiconductor substrate, an insulation layer provided on the semiconductor structure, an upper wiring having connection pad portions and provided on the insulation layer such that at least parts of the upper wiring are connected to the electrodes for external connection of the semiconductor structure, a micro electric mechanical system electrically connected to parts of the connection pad portions of the upper wiring, pole electrodes provided so as to be electrically connected to other connection pad portions of the upper wiring, and an upper insulation film covering the vicinities of the pole electrodes and at least the vicinity of the micro electric mechanical system.

Owner:AOI ELECTRONICS CO LTD

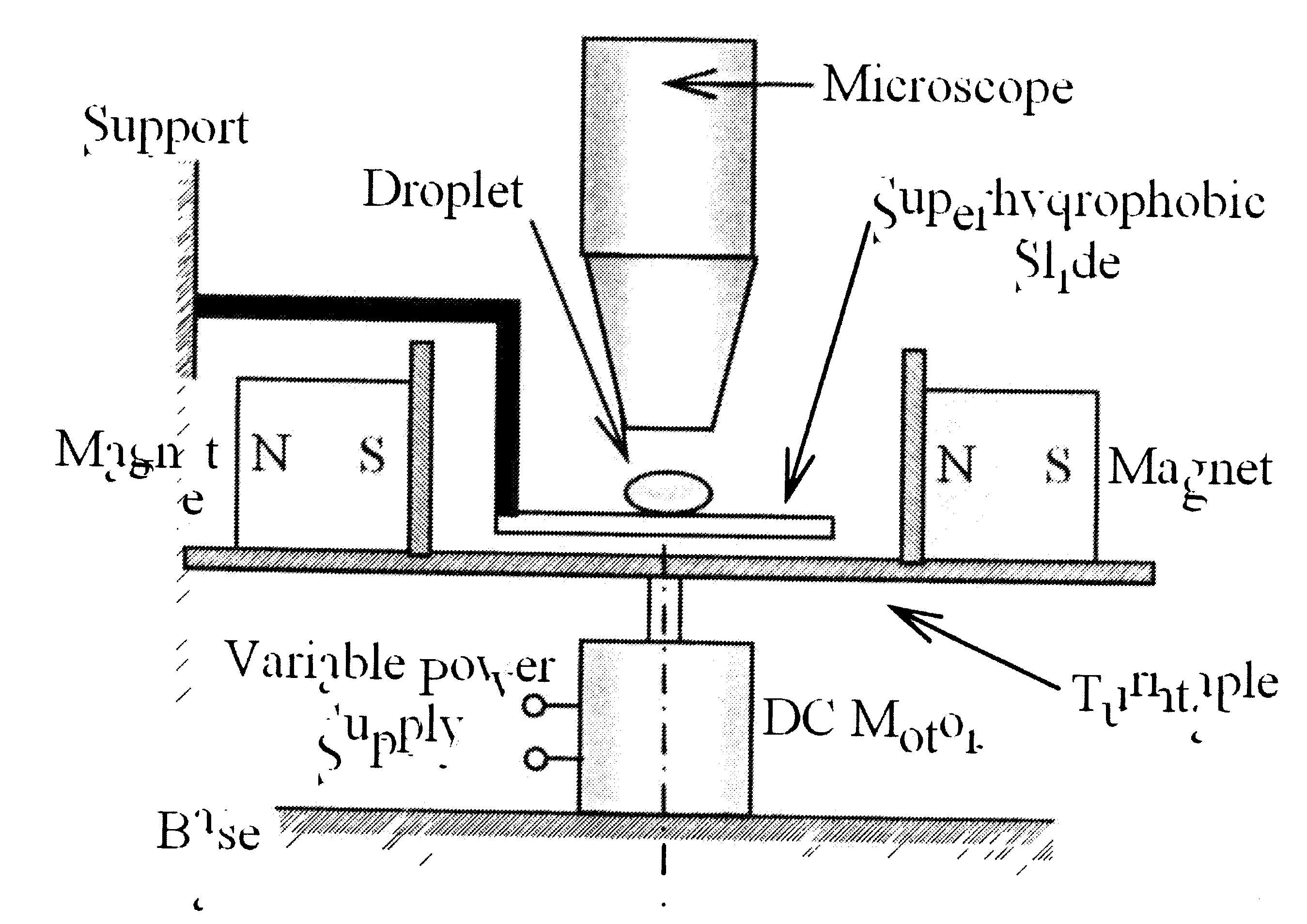

Method and apparatus for magnetic mixing in micron size droplets

InactiveUS20070207272A1Increase fluid-particle interactionEfficient productionMixersPretreated surfacesDiffusionMicrosphere

Active mixing by magnetic stirring is demonstrated inside a picoliter-size liquid droplet. Magnetic microspheres are added to the droplet, which form aligned chains under the influence of a homogeneous magnetic field. When the magnetic field is rotated, the chains also rotate synchronously. Viscous interaction between the particle-chains and the liquid induces advective motion inside the droplet thereby enhancing mixing which is otherwise diffusion-limited. The concept can be effectively used to create a lab-in-a-droplet for MEMS (Micro-Electrical-Mechanical Systems) and Bio-MEMS applications.

Owner:VIRGINIA TECH INTPROP INC

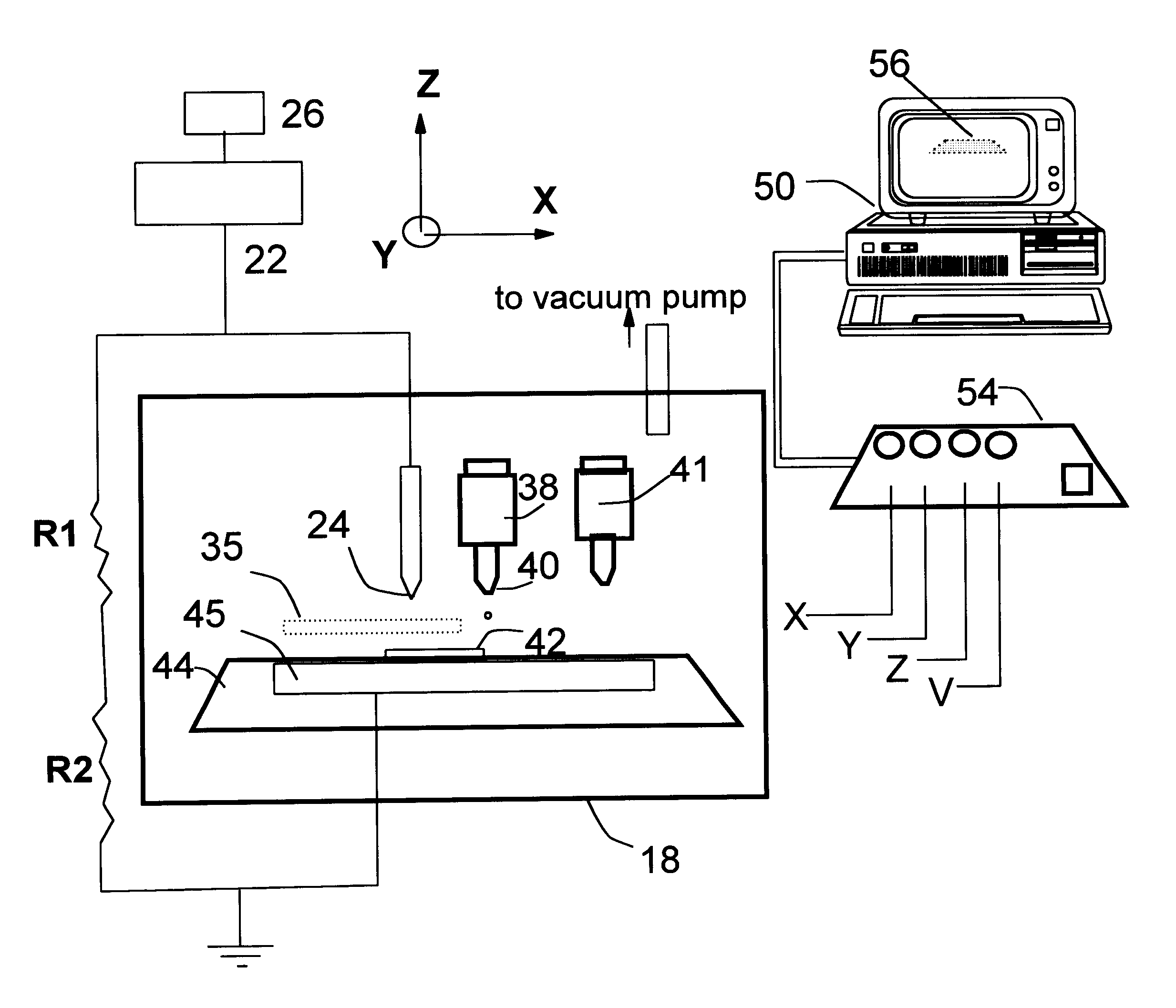

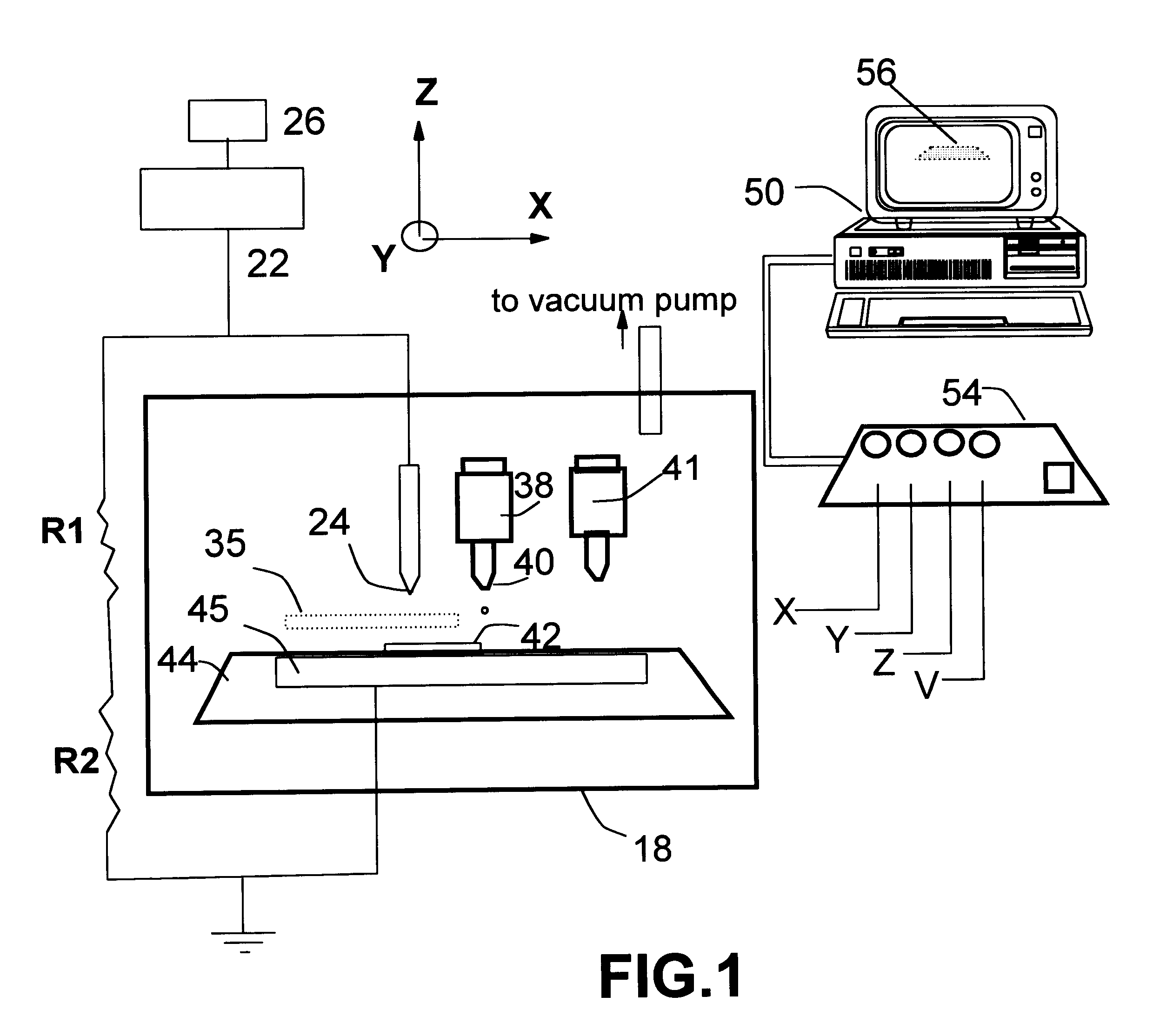

Direct write method for polarized materials

InactiveUS6706234B2Piezoelectric/electrostrictive device manufacture/assemblyAdditive manufacturing apparatusTarget surfaceThin layer

A direct-write method for depositing a polarized material of a predetermined computer-aided pattern onto a target surface, the method including the following steps: (1) forming a solution of a material capable of being polarized using a polarization solvent which can be removed by evaporation to provide a polarized material; (2) operating dispensing devices to dispense and deposit the solution onto the target surface substantially point by point and at least partially removing the solvent from the deposited solution to form a thin layer of substantially solidified material of the predetermined pattern; and (3) during the solvent-removing step, operating a high DC voltage for poling the deposited solution to achieve polarization in the material. The invention also provides a freeform fabrication method for building a multi-layer device, such as a micro-electro-mechanical system (MEMS), that exhibits piezoelectric or pyroelectric properties.

Owner:NANOTEK INSTR GRP LLC

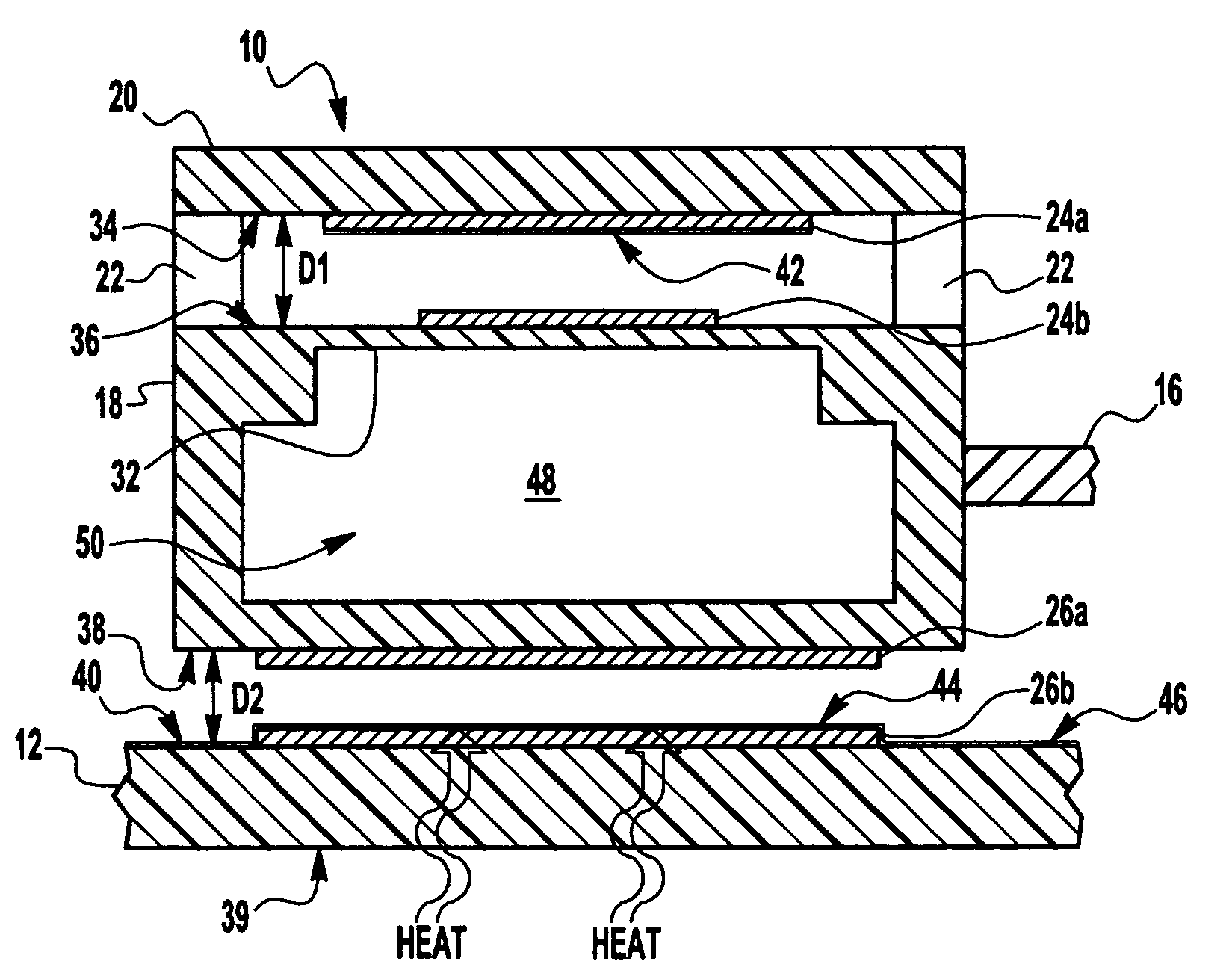

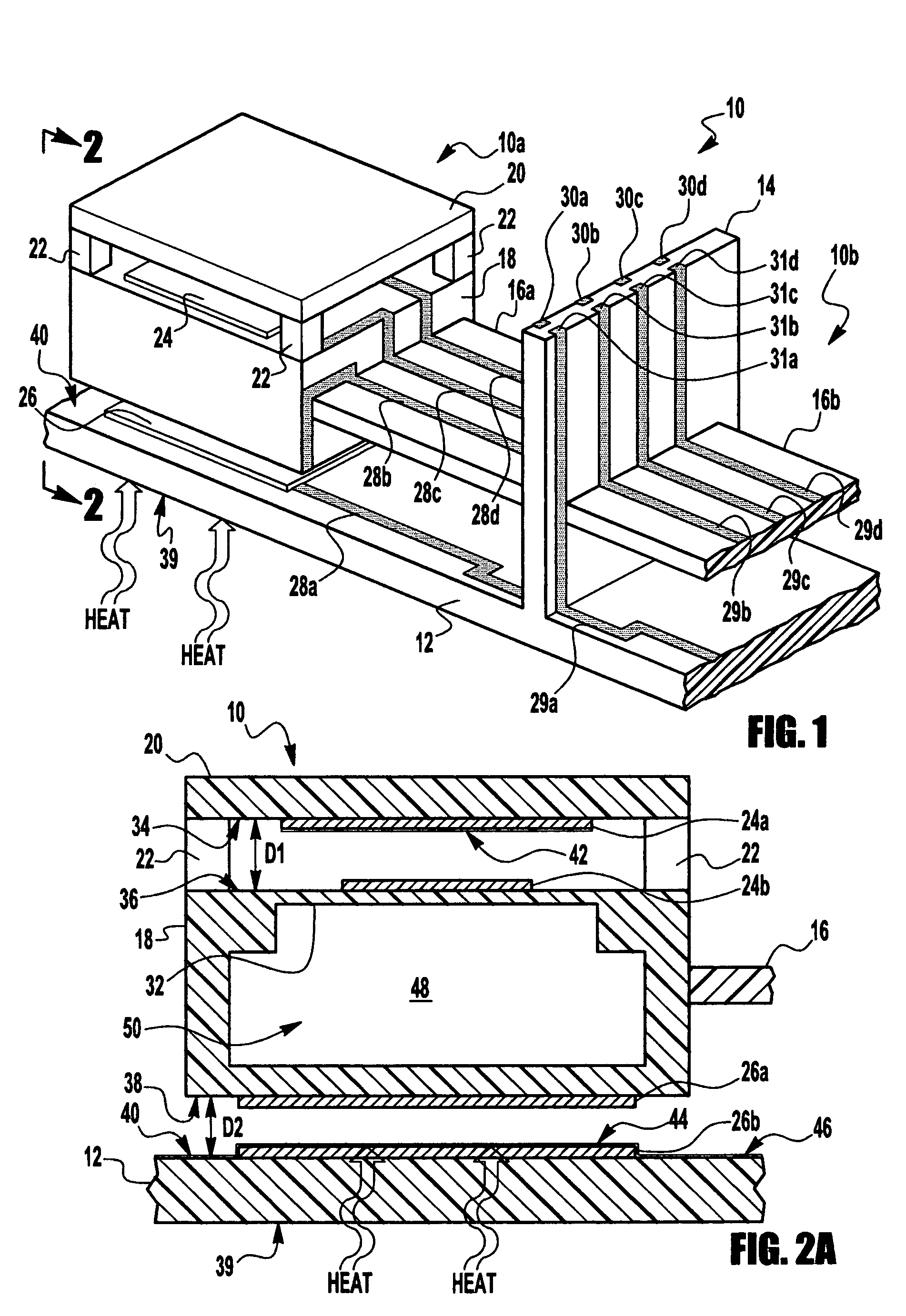

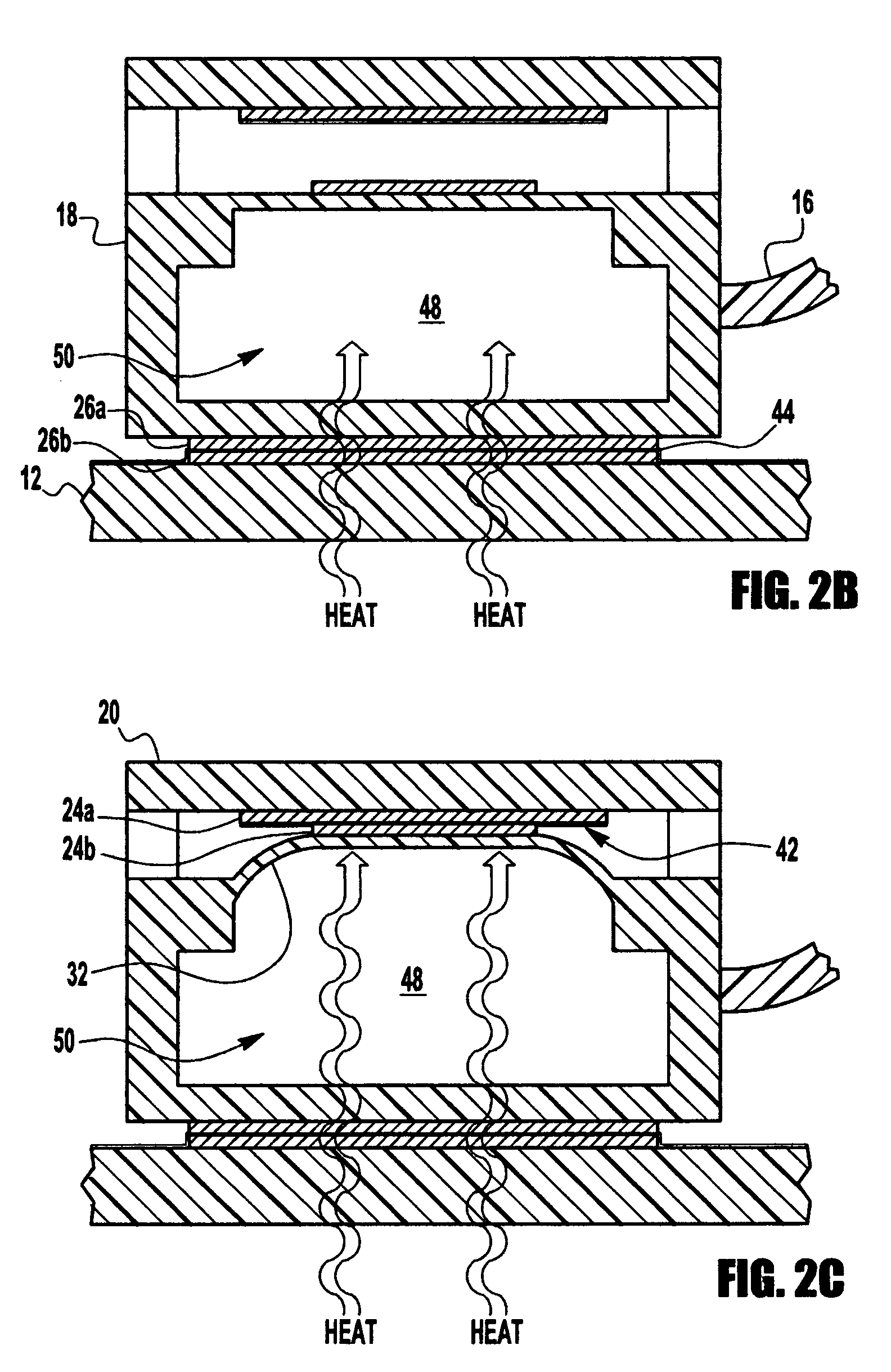

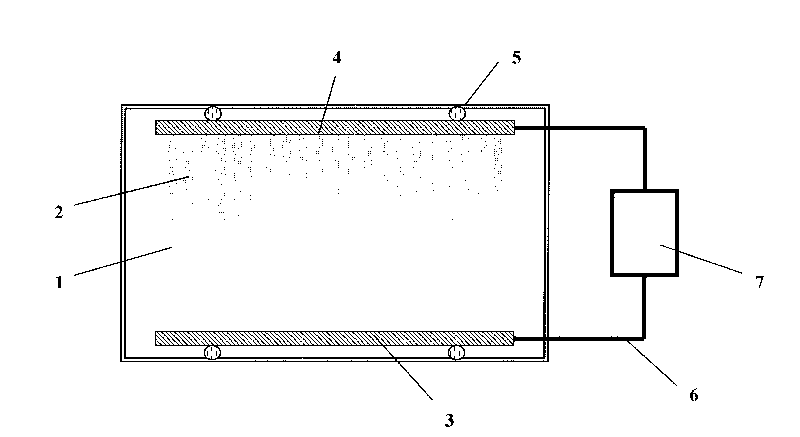

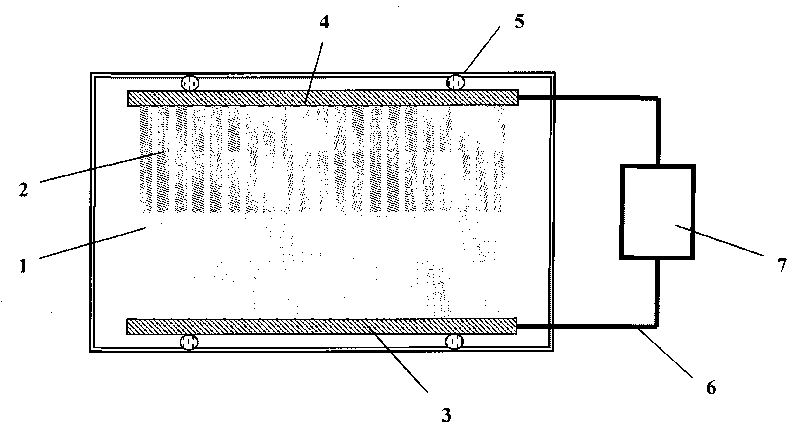

MEMS closed chamber heat engine and electric generator

A heat engine, preferably combined with an electric generator, and advantageously implemented using micro-electromechanical system (MEMS) technologies as an array of one or more individual heat engine / generators. The heat engine is based on a closed chamber containing a motive medium, preferably a gas; means for alternately enabling and disabling transfer of thermal energy from a heat source to the motive medium; and at least one movable side of the chamber that moves in response to thermally-induced expansion and contraction of the motive medium, thereby converting thermal energy to oscillating movement. The electrical generator is combined with the heat engine to utilize movement of the movable side to convert mechanical work to electrical energy, preferably using electrostatic interaction in a generator capacitor. Preferably at least one heat transfer side of the chamber is placed alternately into and out of contact with the heat source by a motion capacitor, thereby alternately enabling and disabling conductive transfer of heat to the motive medium.

Owner:NASA UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

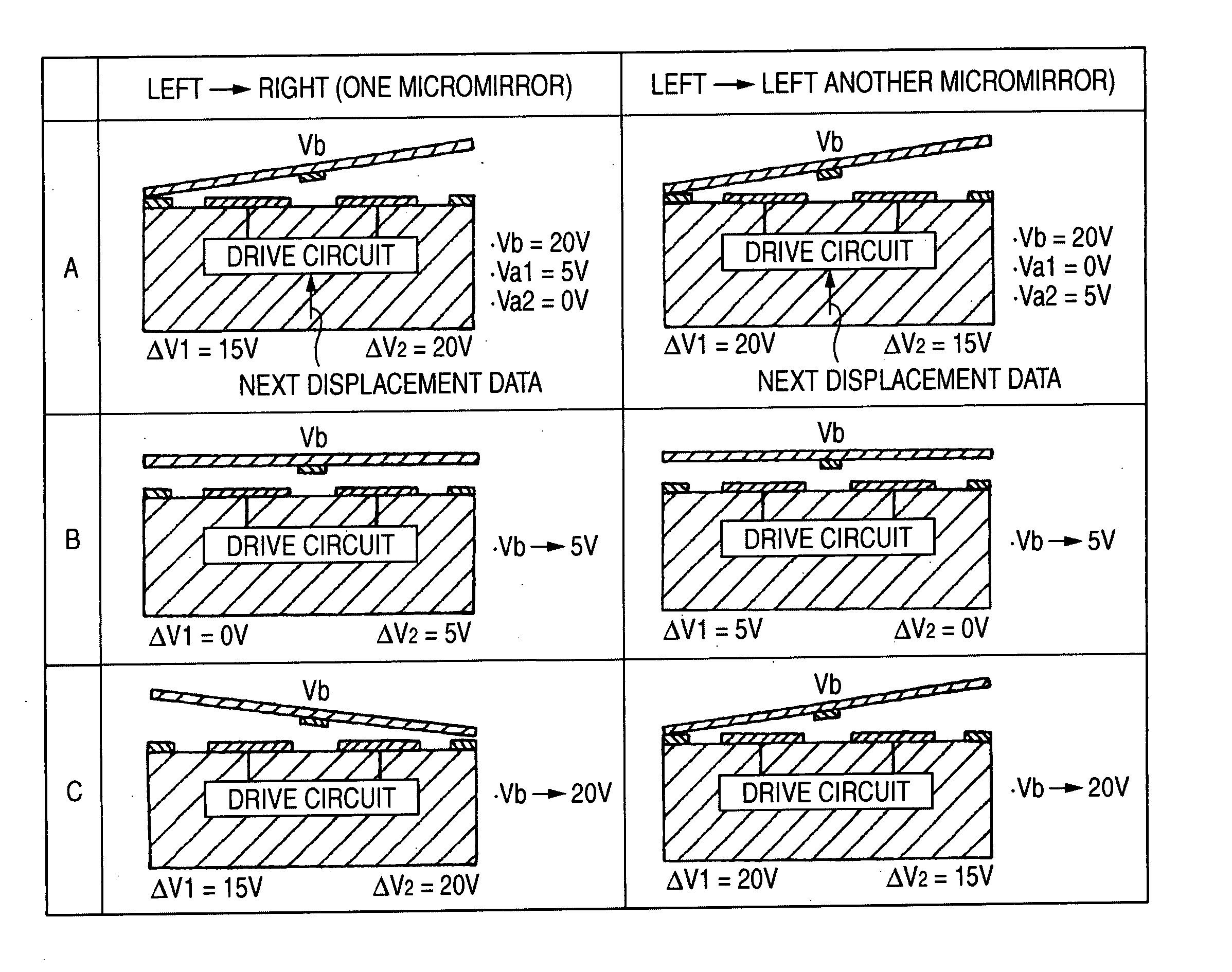

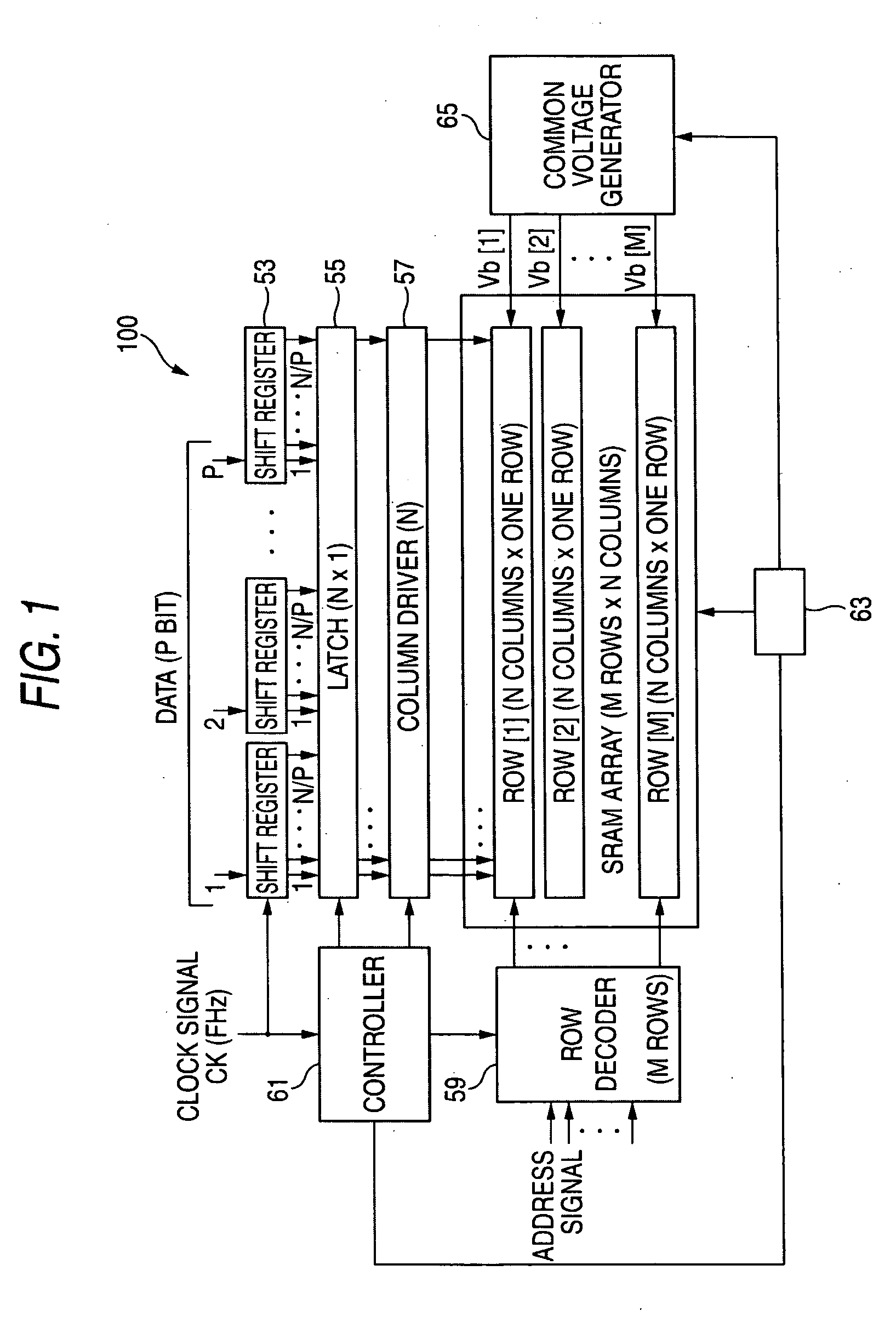

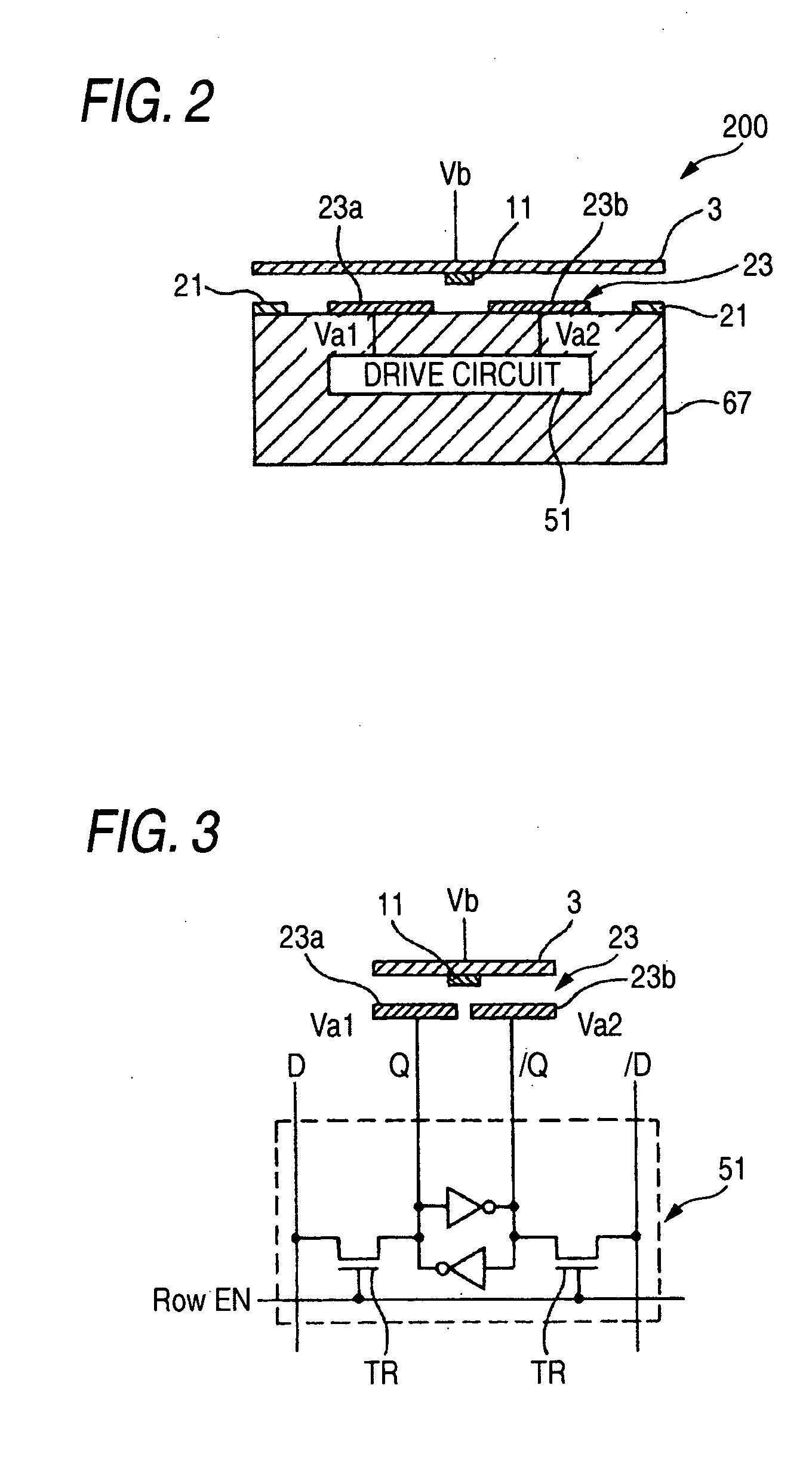

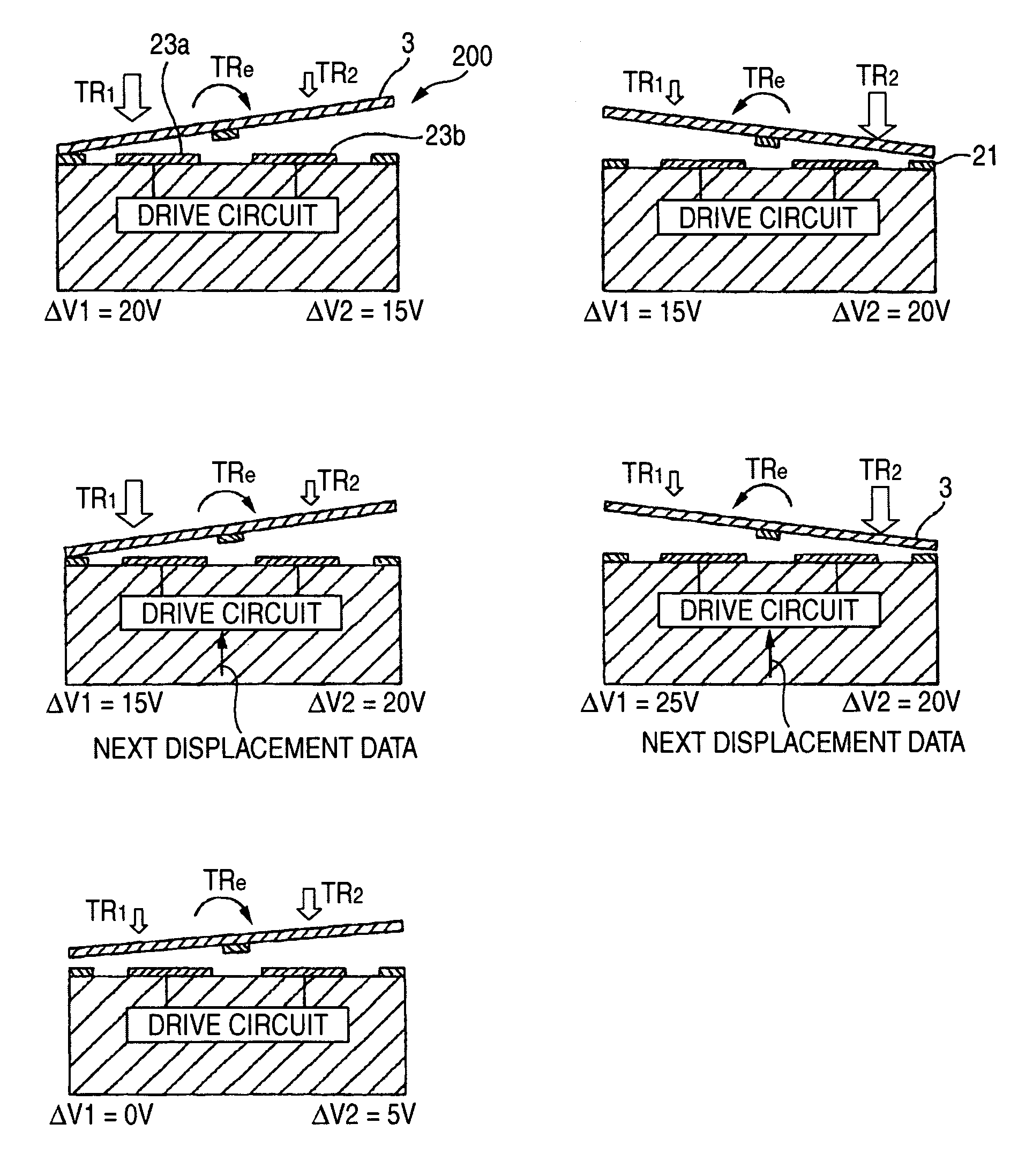

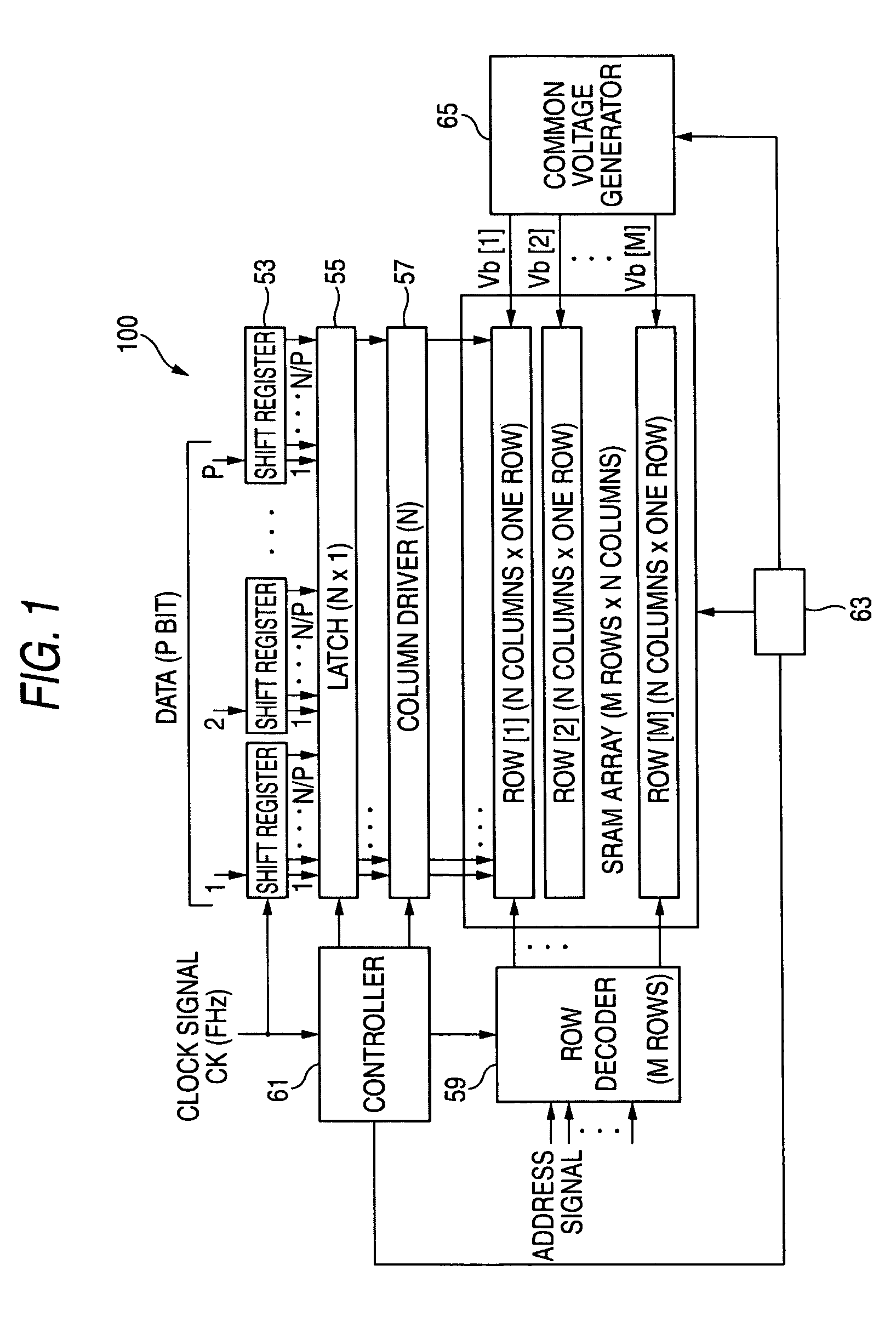

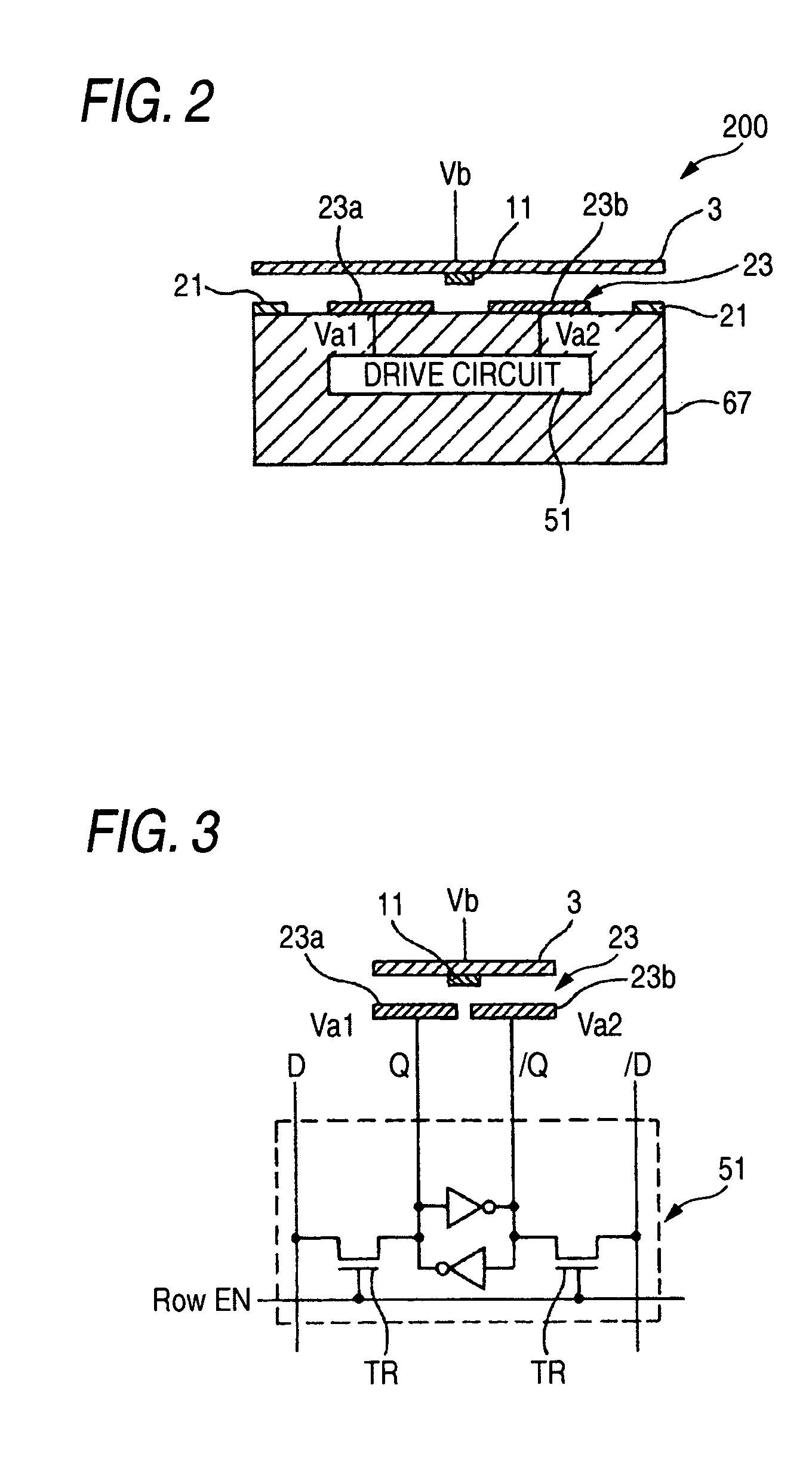

Driving method of spatial light modulator array, spatial light modulator array, and image forming apparatus

InactiveUS20050219676A1Shortening of a drive cycleStatic indicating devicesNon-linear opticsSpatial light modulatorImage formation

A driving method of a spatial light modulator array having plural spatial light modulators of micro-electro-mechanical system, the plural spatial light modulators each including: a movable part supported to be capable of being elastically displaced and provided with a movable electrode; and a fixed electrode disposed to face the movable part, wherein in a case where the voltages are applied to the electrodes and the movable part is driven and displaced in a fixed electrode direction, an absolute value of an inter-electrode voltage between the movable electrode and the fixed electrode is decreased while the movable part is transitioning in a direction of the fixed electrode.

Owner:FUJIFILM HLDG CORP +1

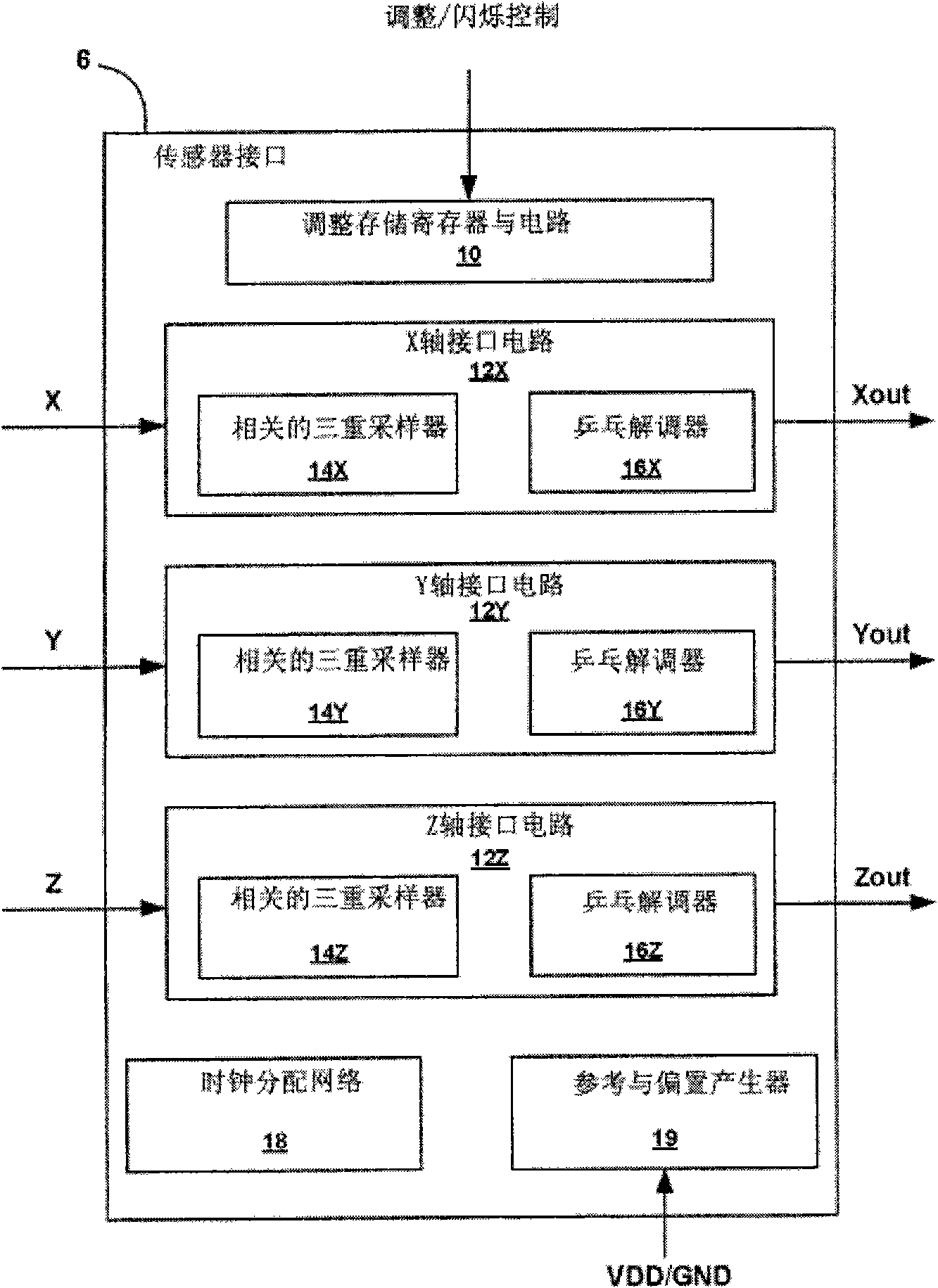

Capacitive interface circuit for low power sensor system

ActiveCN101568805ADownsampling of Noise ComponentsConverting sensor output electrically/magneticallyLow noiseCapacitance

This disclosure describes a capacitive interface circuit for a low power system. The capacitive interface circuit is configured to achieve very low noise sensing of capacitance-based transducers, such as a micro-electro-mechanical system (MEMS)-based sensor, with high resolution and low power. The capacitive interface circuit uses a differential amplifier and correlated triple sampling (CTS) to substantially eliminate, or at least reduce, kT / C noise, as well as amplifier offset and flicker (1 / f) noise, from the output of the amplifier. The capacitive interface circuit may further include an output stage that reduces glitching, i.e., clock transients, in the output signal by allowing transients in the amplifier output to settle. In this manner, the circuit can be used in a low power system to produce a stable, low-noise output.

Owner:MEDTRONIC INC

Removal of MEMS sacrificial layers using supercritical fluid/chemical formulations

InactiveUS7160815B2Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingCompound (substance)Stiction

A method and composition for removing silicon-containing sacrificial layers from Micro Electro Mechanical System (MEMS) and other semiconductor substrates having such sacrificial layers is described. The etching compositions include a supercritical fluid (SCF), an etchant species, a co-solvent, and optionally a surfactant. Such etching compositions overcome the intrinsic deficiency of SCFs as cleaning reagents, viz., the non-polar character of SCFs and their associated inability to solubilize polar species that must be removed from the semiconductor substrate. The resultant etched substrates experience lower incidents of stiction relative to substrates etched using conventional wet etching techniques.

Owner:ADVANCED TECH MATERIALS INC

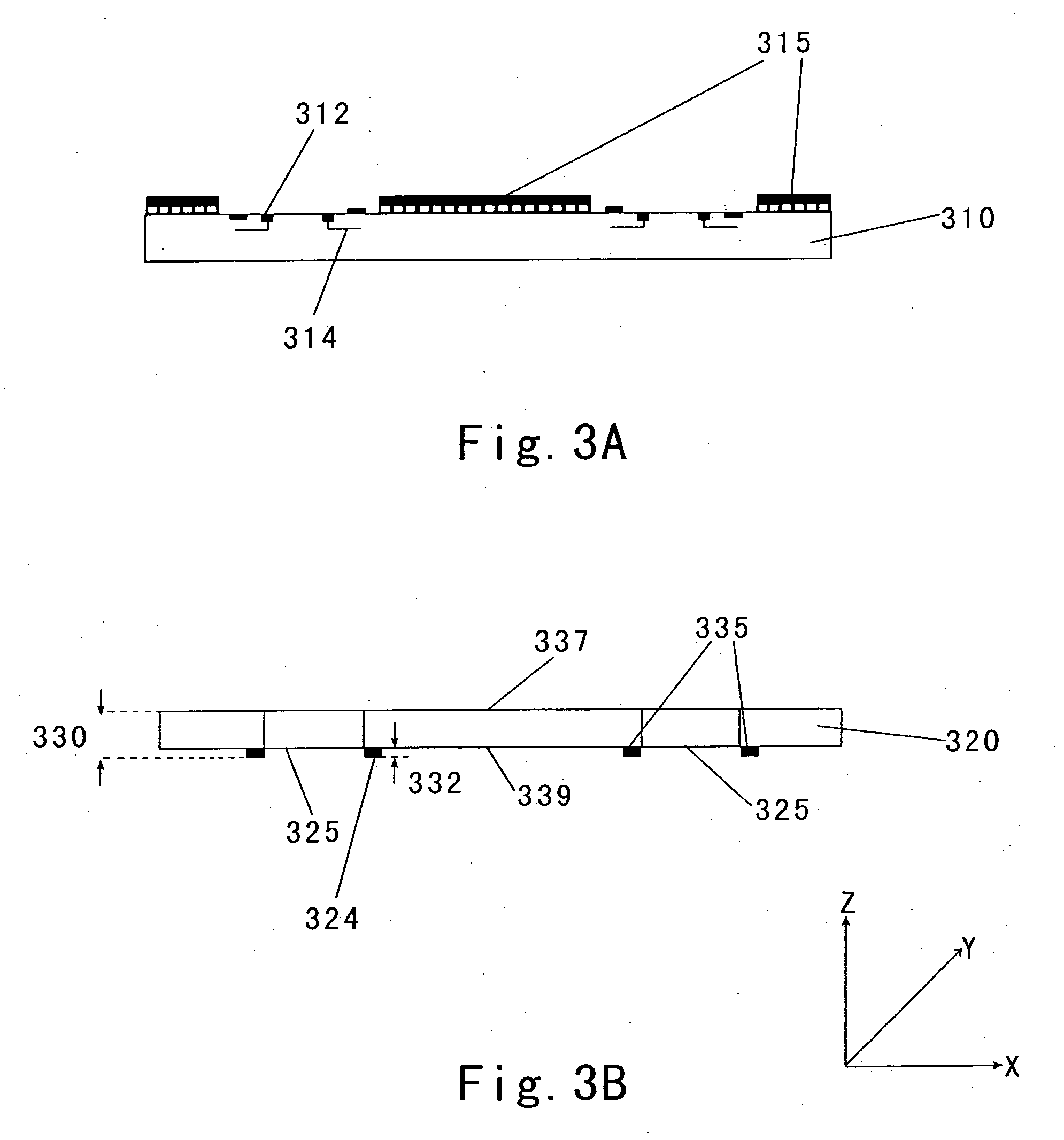

Method and apparatus for micro-electro mechanical system package

ActiveUS20060024919A1Easy to useHigh device yieldSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageLateral extension

A method of manufacturing a multi-substrate semiconductor package. The method includes providing a first substrate with a plurality of first dies present thereon and forming a plurality of electrical contacts on an upper surface of a lateral extension portion of at least one of the plurality of first dies on the first substrate. The method also includes providing a second substrate, the second substrate comprising a plurality of second dies, at least one of the plurality of second dies comprising an interconnect region. Further, the method includes forming a sandwich structure by bonding the second substrate to an upper surface of the first substrate to form an intermediate level within the sandwich structure and separating the dies. The method also includes coupling an electrically conductive structure through the interconnect region of the one second dies to the lateral extension portion of the one first die.

Owner:MIRADIA INC

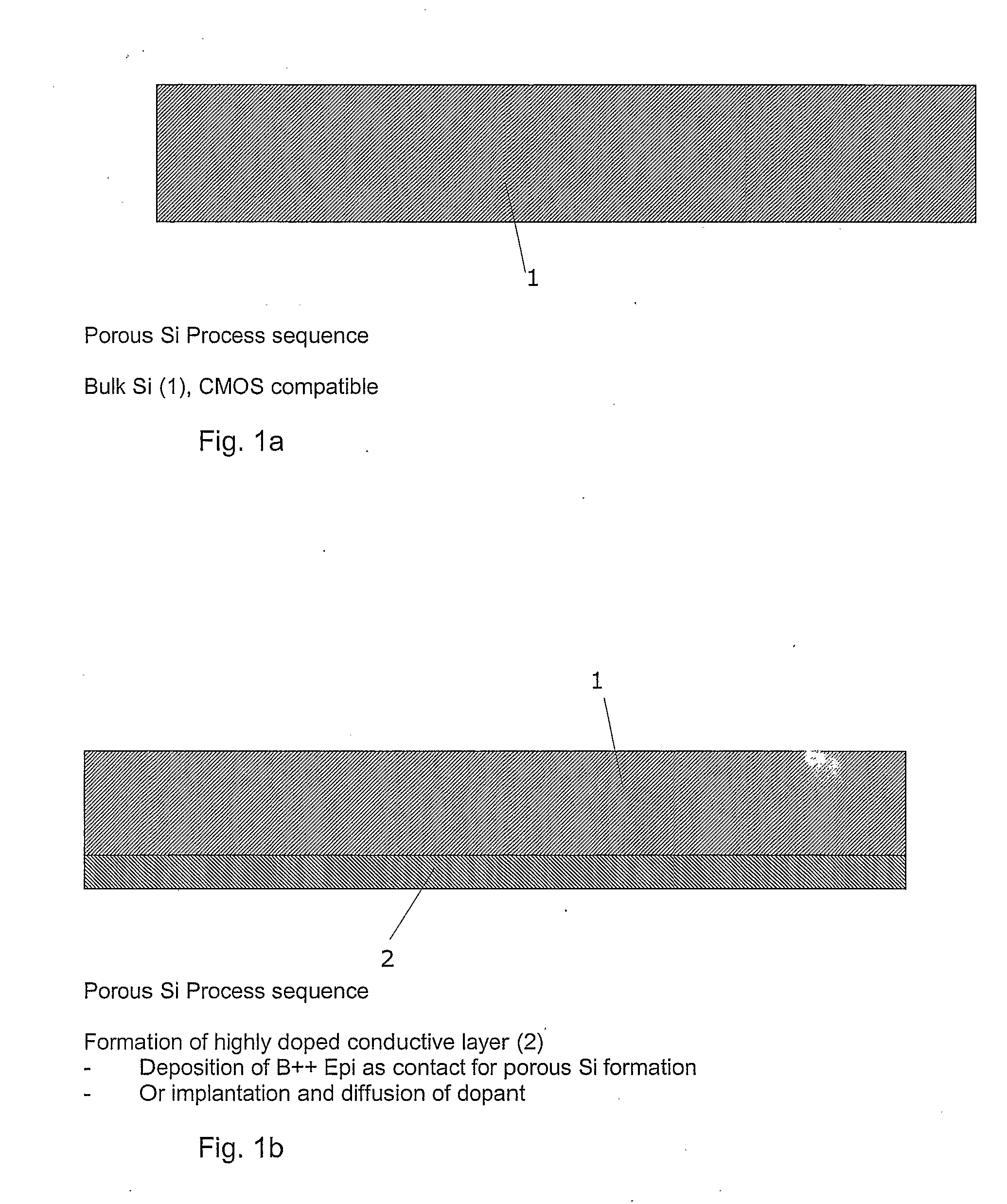

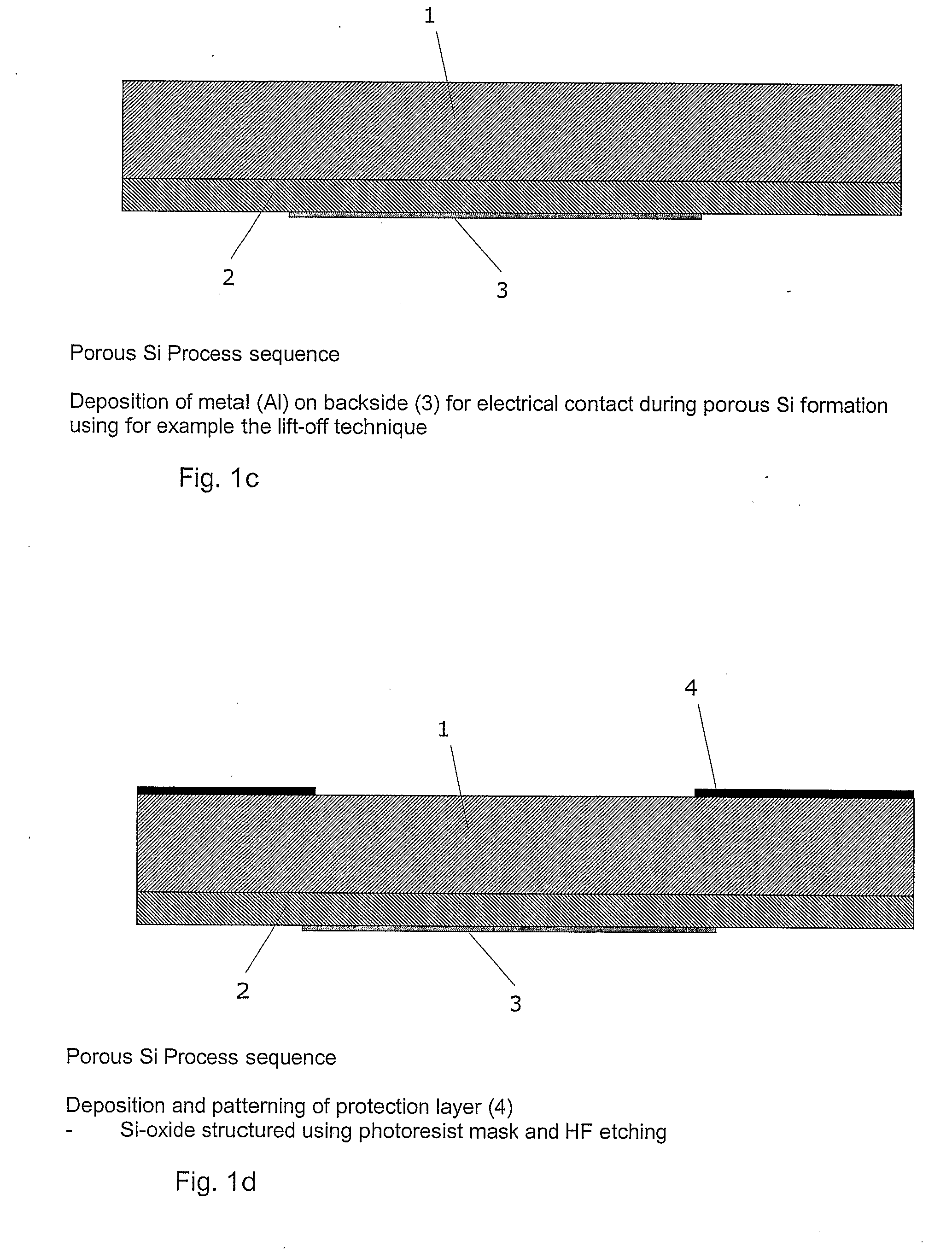

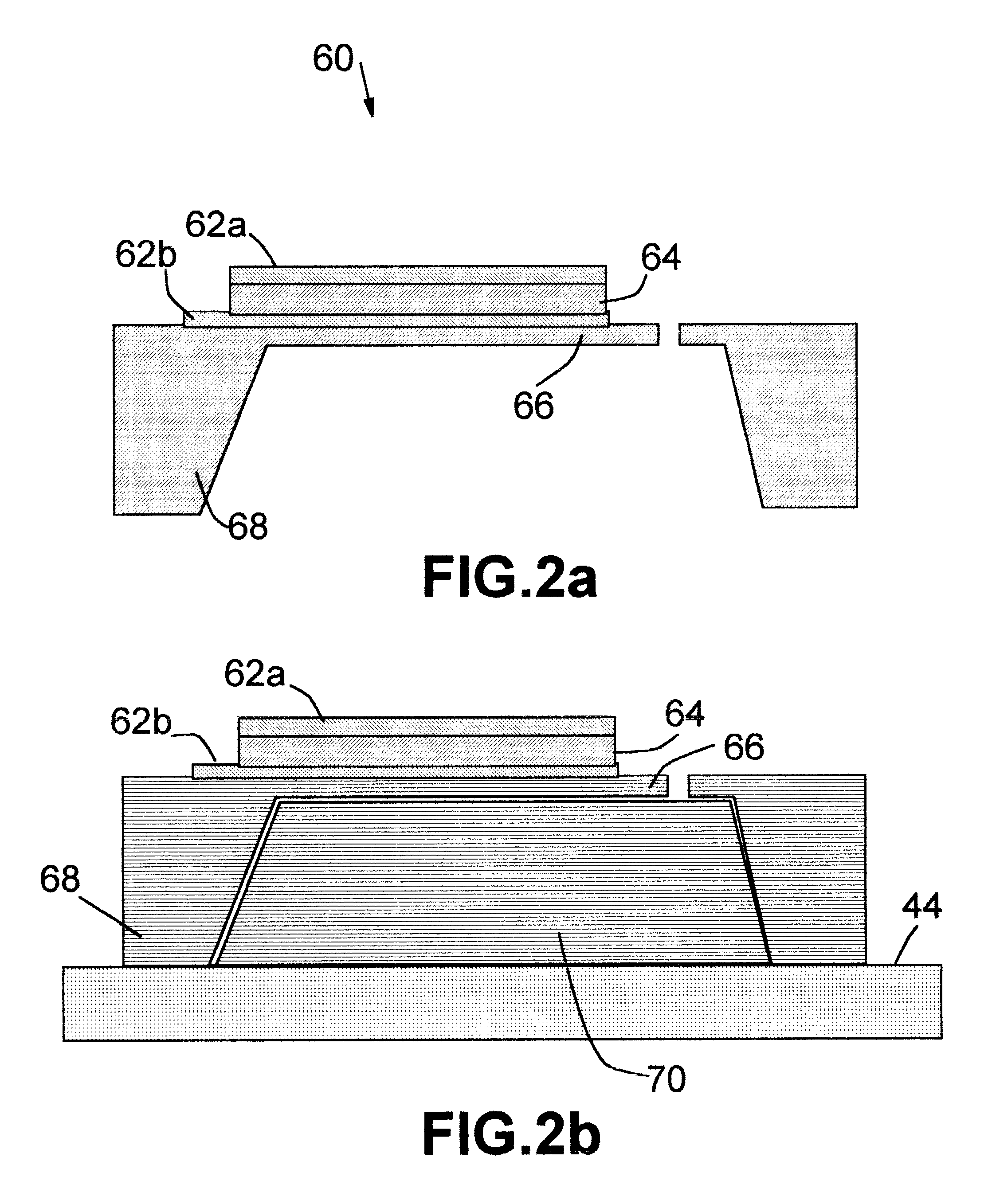

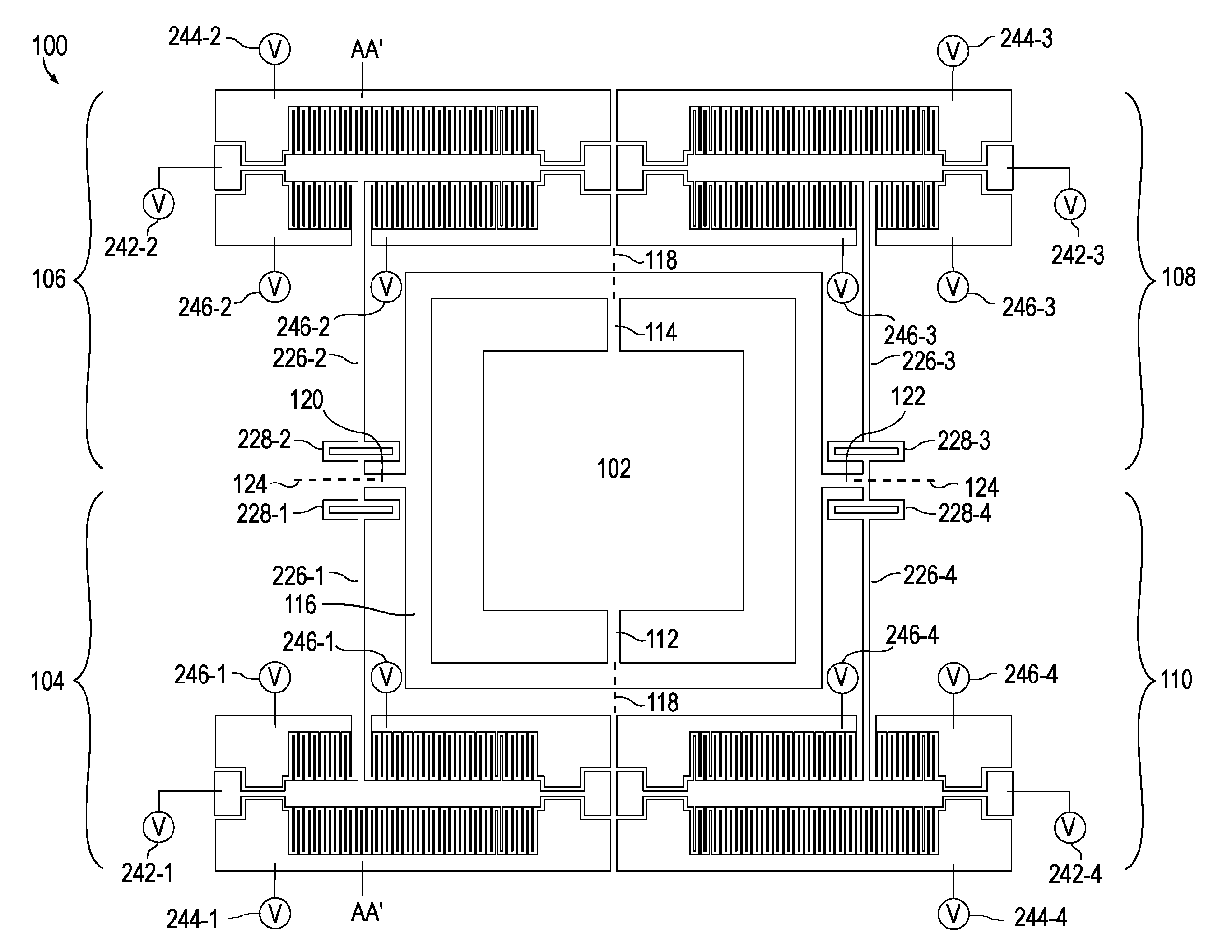

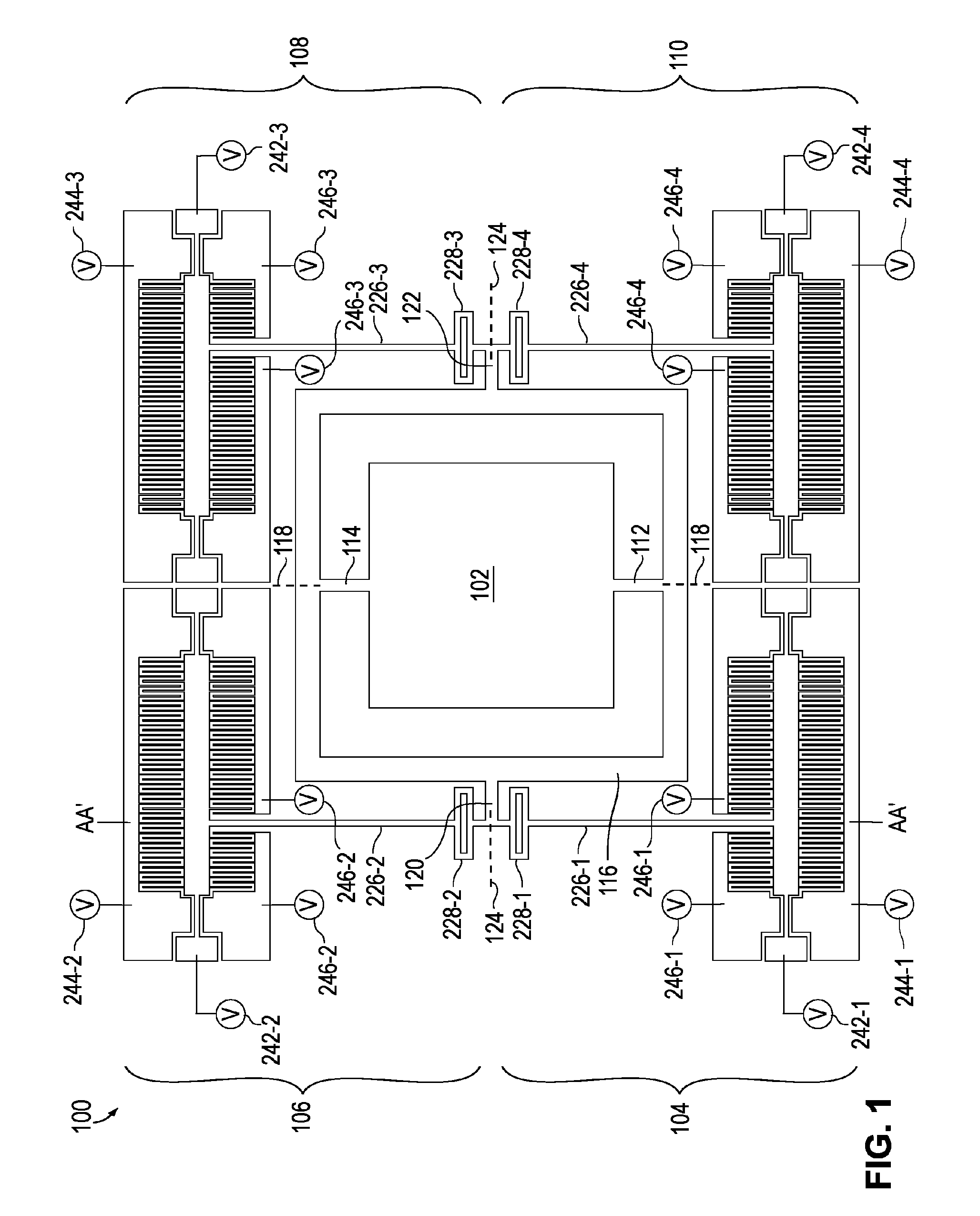

Method of manufacturing a micro-electrical-mechanical system

InactiveUS20050266599A1Simple methodAvoid damageAcceleration measurement using interia forcesDecorative surface effectsMicro electrical mechanical systemsEngineering

Micro-electrical-mechanical systems are fabricated in a substrate having a sacrificial layer sandwiched between two semiconductor layers. The semiconductor layers are selectively etched to create non-etched frames and etched microstructures immobilized within the frames by the sacrificial layer. An adhesive sheet is attached to one surface of the substrate, and the substrate is diced into chips, each including one frame and one immobilized microstructure. The sacrificial layer is then selectively etched to free a movable member in each microstructure. Finally, the chips are detached from the adhesive sheet, each chip becoming a micro-electrical-mechanical system. This fabrication method provides a simple and inexpensive way to avoid damage to the microstructure during the dicing process.

Owner:LAPIS SEMICON CO LTD

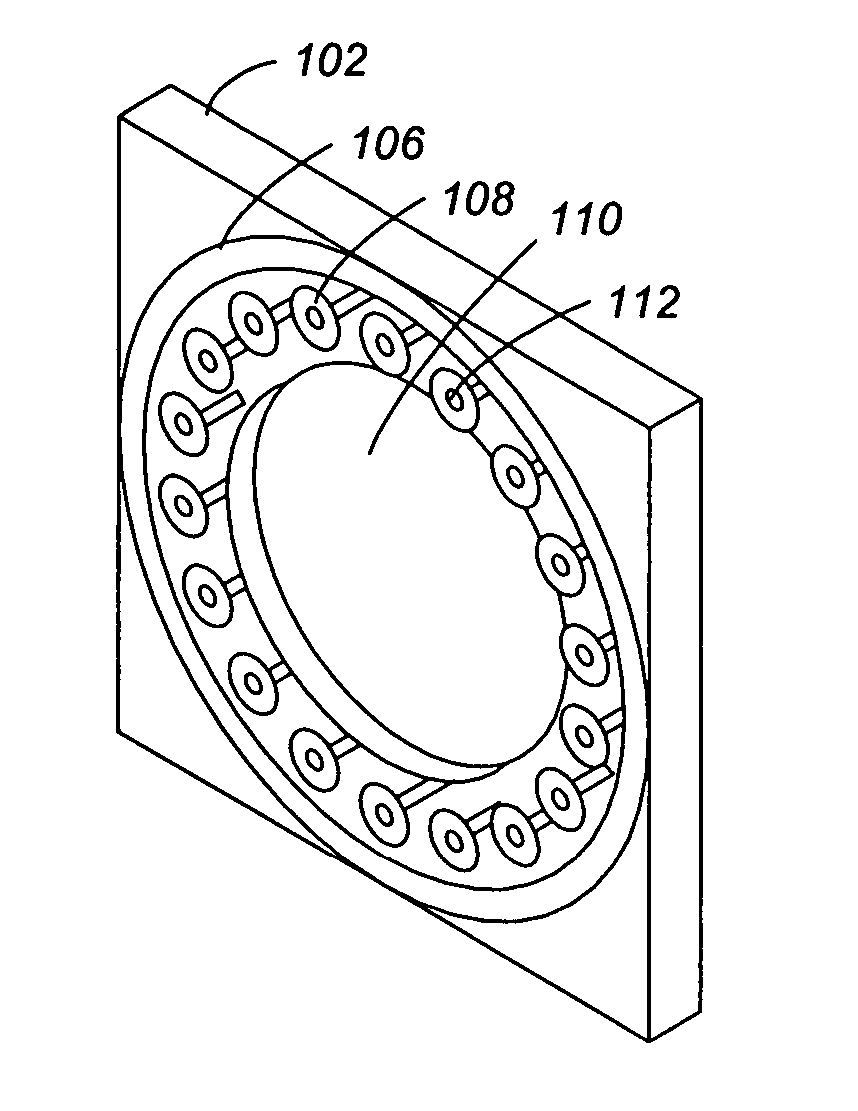

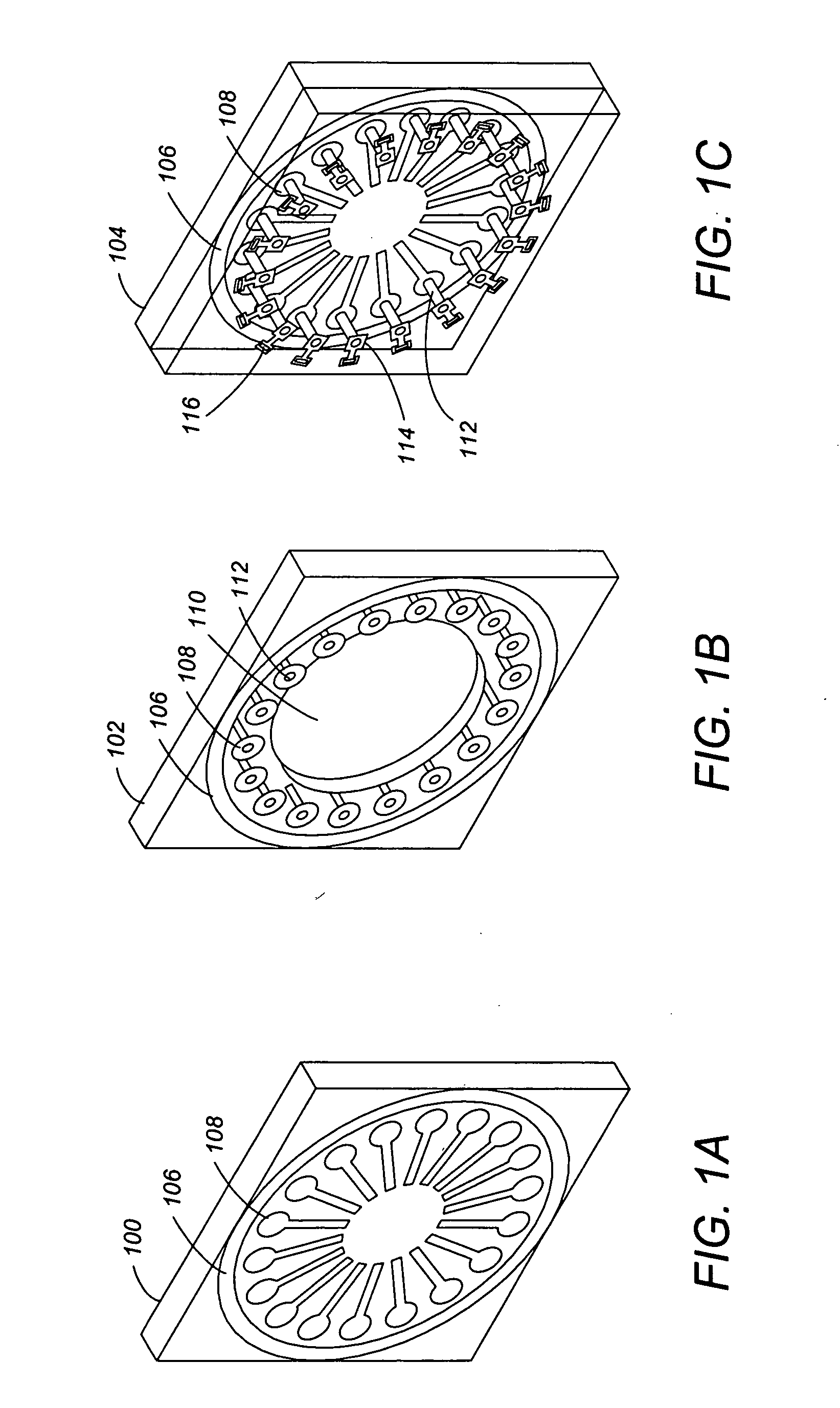

Multiple internal seal ring micro-electro-mechanical system vacuum package

ActiveUS20050017329A1Semiconductor/solid-state device detailsSolid-state devicesElectricityHermetic seal

A Multiple Internal Seal Ring (MISR) Micro-Electro-Mechanical System (MEMS) vacuum package that hermetically seals MEMS devices using MISR. The method bonds a capping plate having metal seal rings to a base plate having metal seal rings by wafer bonding the capping plate wafer to the base plate wafer. Bulk electrodes may be used to provide conductive paths between the seal rings on the base plate and the capping plate. All seals are made using only metal-to-metal seal rings deposited on the polished surfaces of the base plate and capping plate wafers. However, multiple electrical feed-through metal traces are provided by fabricating via holes through the capping plate for electrical connection from the outside of the package through the via-holes to the inside of the package. Each metal seal ring serves the dual purposes of hermetic sealing and providing the electrical feed-through metal trace.

Owner:THE BOEING CO +1

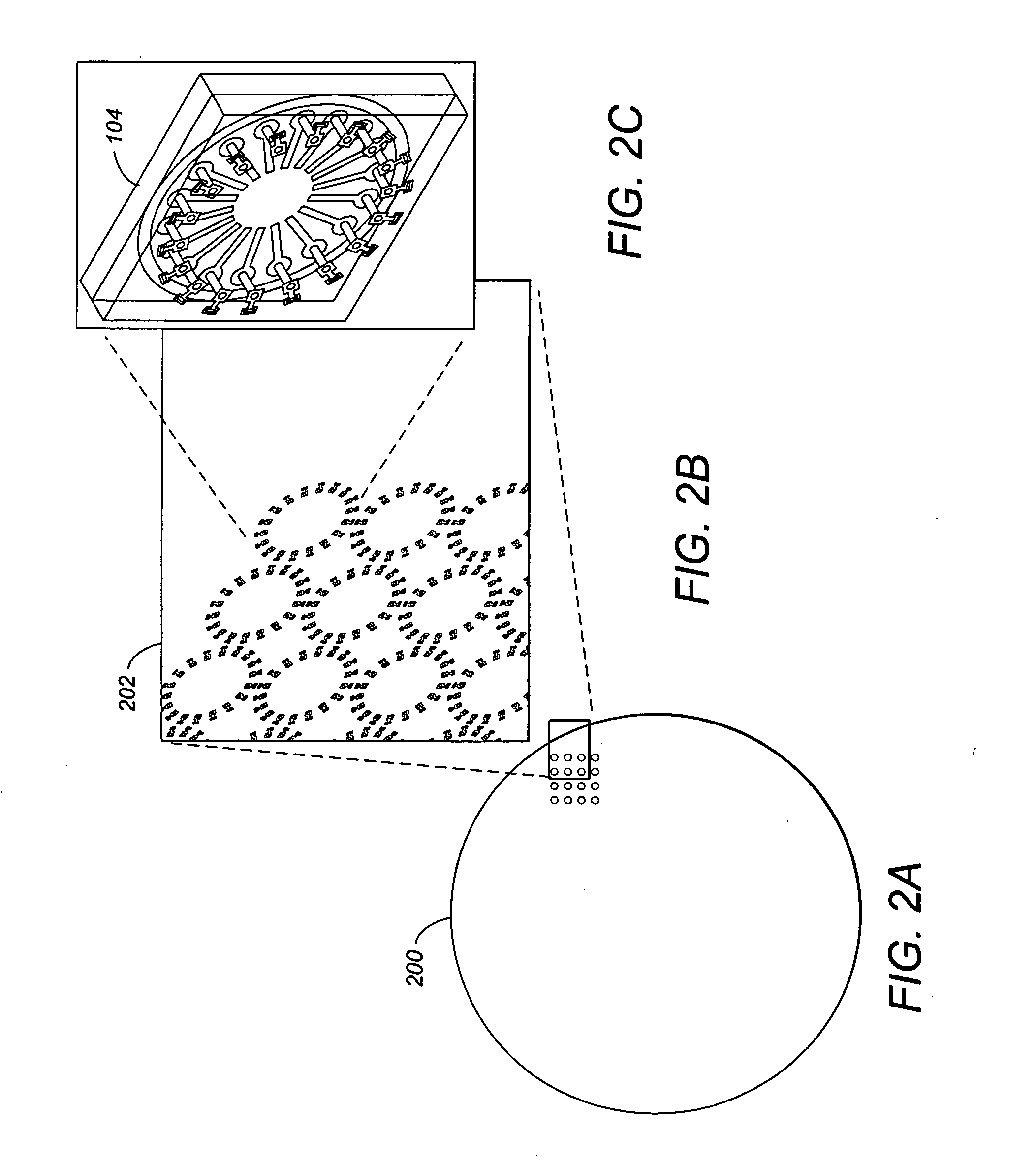

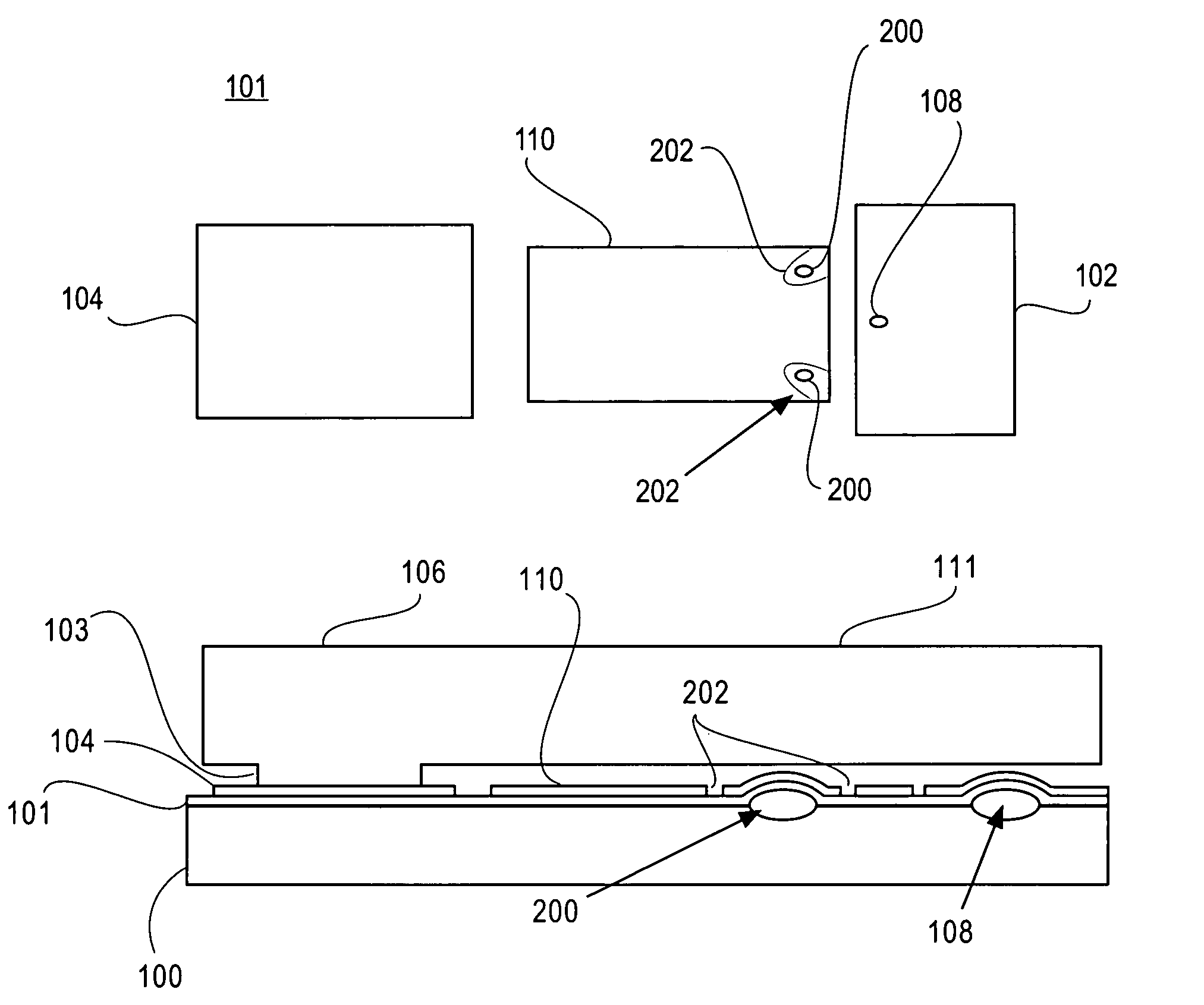

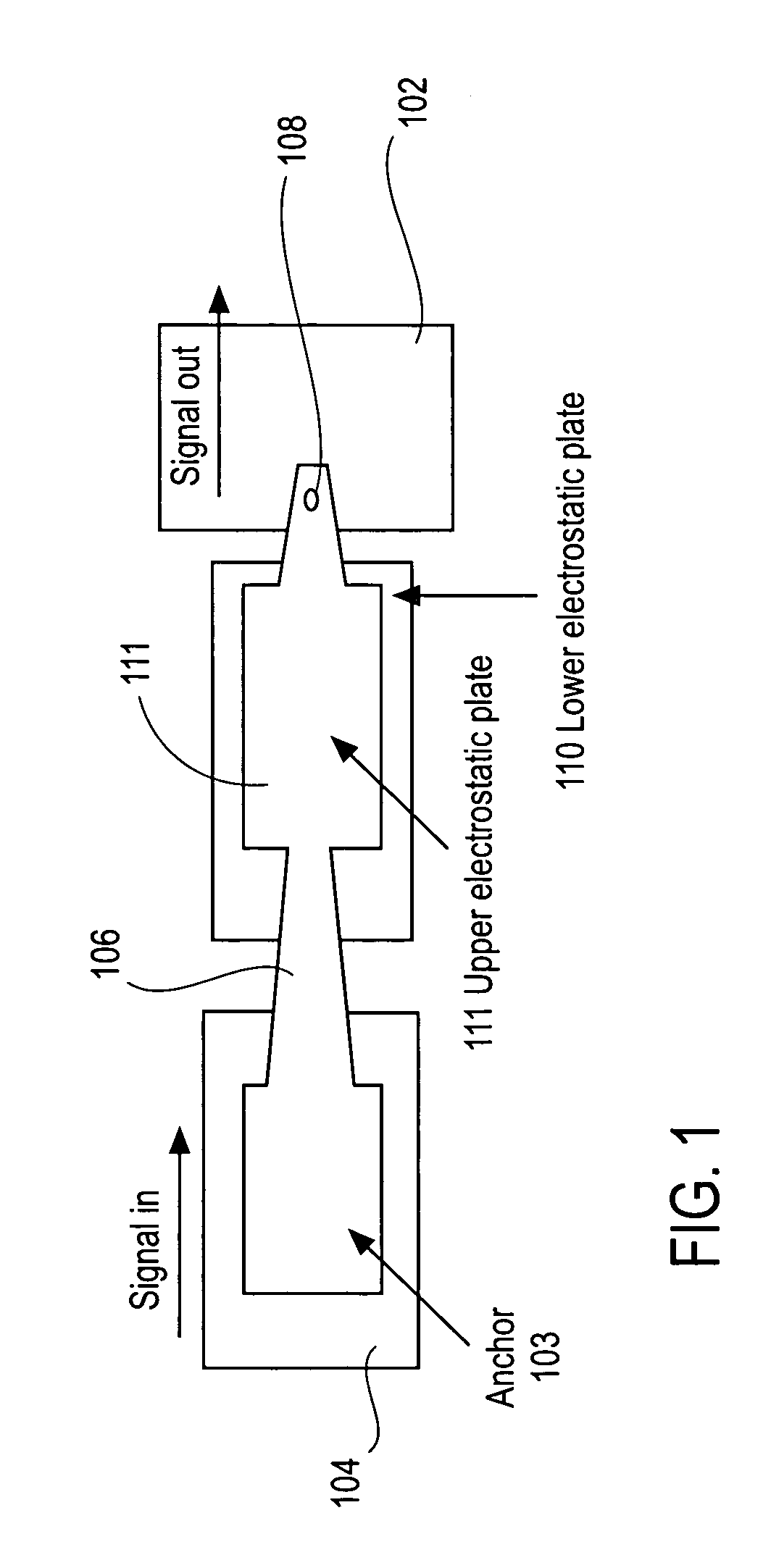

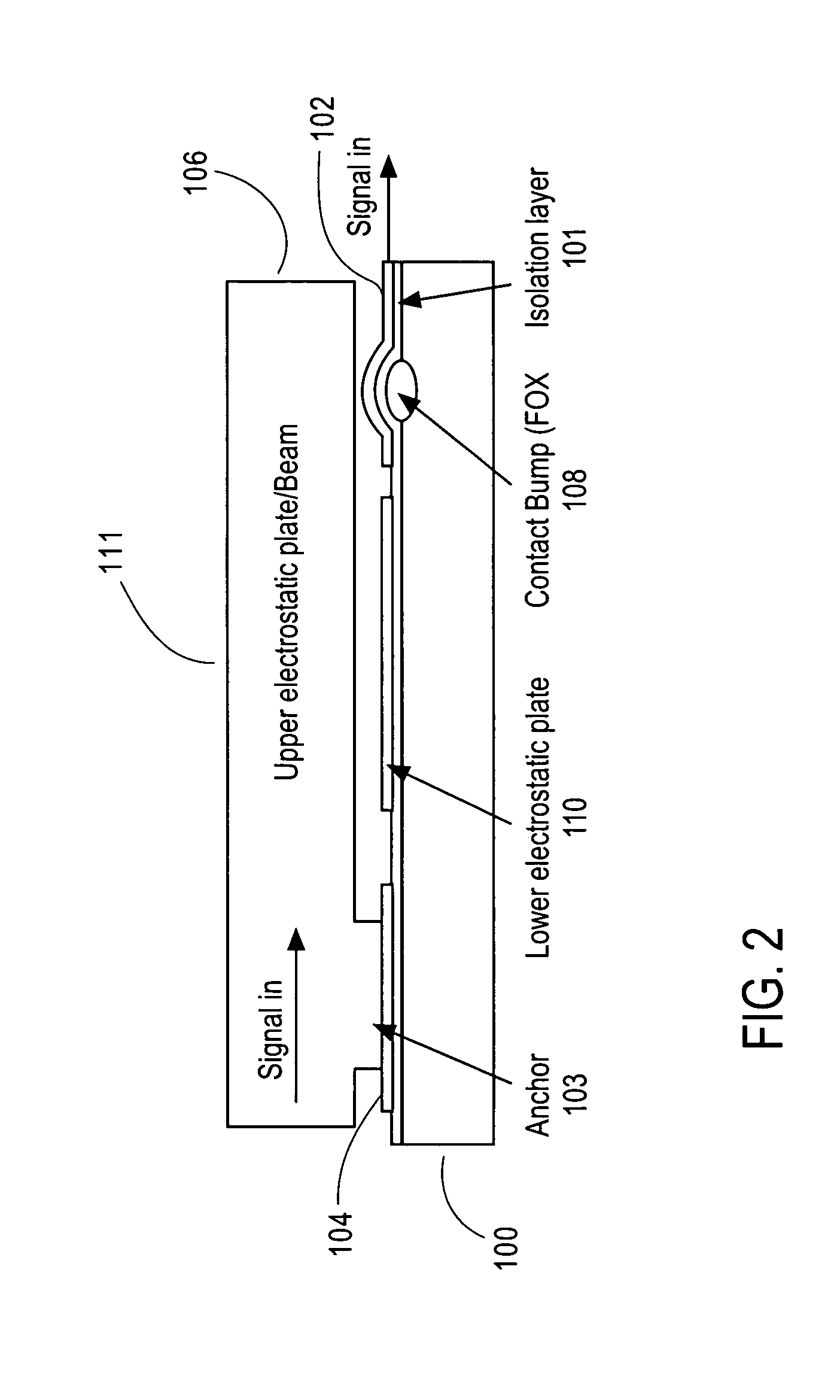

MEMS switch stopper bumps with adjustable height

InactiveUS7283024B2Electrostatic/electro-adhesion relaysElectrostrictive/piezoelectric relaysMicro electrical mechanical systemsElectric drive

In a Micro Electro-Mechanical System (MEMS) switch, a common switch failure is a short between the upper and the lower electrostatic actuation plates. Such shorts may occur due to torque deformation. Stopper bumps having a slightly lower height profile than that of the contact bumps are provided to prevent such shorts. The stopper bumps may be made using the same mask as that used to create the contact bump with the height of the respective bumps controlled by determining the diameter of the bumps.

Owner:INTEL CORP

Driving method of spatial light modulator array, spatial light modulator array, and image forming apparatus

InactiveUS7304782B2Shortening of a drive cycleStatic indicating devicesNon-linear opticsSpatial light modulatorMicro electrical mechanical systems

A driving method of a spatial light modulator array having plural spatial light modulators of micro-electro-mechanical system, the plural spatial light modulators each including: a movable part supported to be capable of being elastically displaced and provided with a movable electrode; and a fixed electrode disposed to face the movable part, wherein in a case where the voltages are applied to the electrodes and the movable part is driven and displaced in a fixed electrode direction, an absolute value of an inter-electrode voltage between the movable electrode and the fixed electrode is decreased while the movable part is transitioning in a direction of the fixed electrode.

Owner:FUJIFILM HLDG CORP +1

Nano generator

InactiveCN101710744ASimple structureThe principle is simpleElectromagnetic wave systemCircuit arrangementsNanogeneratorElectron flow

The invention discloses a novel nano generator constructed by arrays of semiconductor nanorods, nanowires or nanobelts of ZnO, Ga2O3 or SnO2 and the like with inverse piezoelectric characteristic and electric polarization characteristic. The system comprises two nano arrays A and B, the end parts of the nano arrays are mutually contacted and oppositely placed, the nano array A consists of semiconductor nanowires with inverse piezoelectric characteristic and electric polarization characteristic; and the nano array B consists of metal nanowires which have a Schottky contact characteristic when the metal nanowires are contacted with the nano array A or semiconductor nanowires coated with metal films. The nanowires in the nano arrays generate inverse piezoelectric and electric polarization phenomenon by utilizing various high-frequency alternating electromagnetic signals and electromagnetic microwave radiation signals in the space, and certain positive and negative charge accumulation is formed on the surfaces of the nanowires so as to directly convert the various high-frequency alternating electromagnetic signals and electromagnetic microwave radiation signals in the space into electrical energy to be output in a form of electron flow to drive or control the loads such as an external nanodevice or a micro-electro-mechanical system and the like.

Owner:LIAONING NORMAL UNIVERSITY

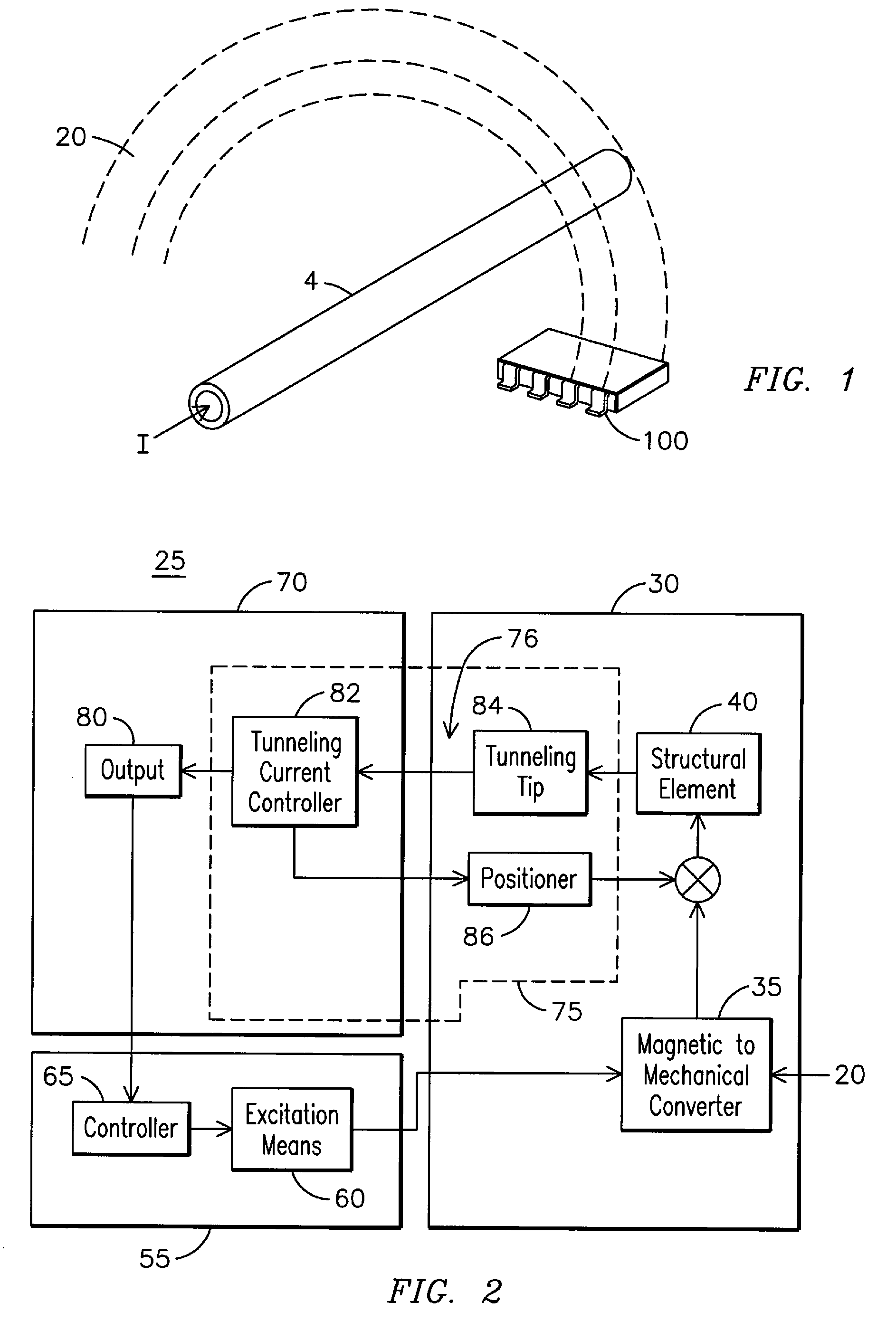

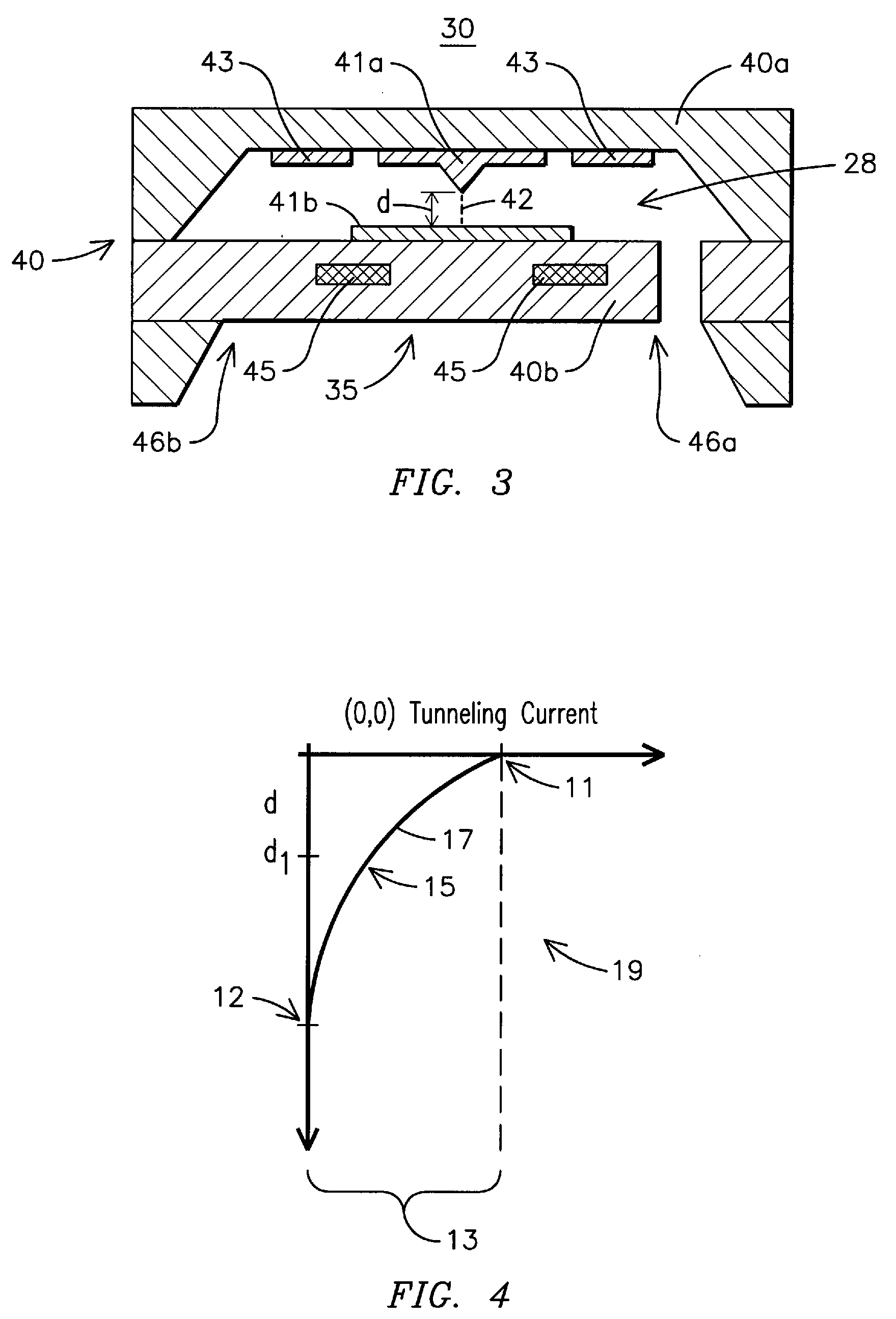

Micro-electromechanical system (MEMS) based current and magnetic field sensor using tunneling current sensing

ActiveUS20070181963A1Magnetic measurementsBase element modificationsElectrical conductorCurrent sensor

A micro-electro-mechanical system (MEMS) current sensor for sensing a magnetic field produced by an electrical current flowing in a conductor includes a first fixed element and a moving element. The moving element is spaced away from the first fixed element and is movable relative to the fixed element responsive to a magnetic field produced by an electrical current flowing in a conductor for providing a mechanical indication of a strength of the magnetic field. The sensor also includes a tunneling current generator for generating a tunneling current between the first fixed element and the moving element and a tunneling current monitor for monitoring a change in the tunneling current responsive to the mechanical indication to provide an indication of a value of the electrical current in the conductor.

Owner:ABB SPA

Anisotropic etching agent composition used for manufacturing of micro-structures of silicon and etching method

InactiveUS20070175862A1Reduce processing timeIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structureTetramethylammonium hydroxide

An anisotropic etching agent composition for manufacturing of micro-structures of silicon comprising an alkali compound and hydroxylamines; an anisotropic etching method with the use of the etching agent composition. The alkali compound is preferably tetramethylammonium hydroxide, and the hydroxylamines is preferably at least one kind selected from the group consisting of hydroxylamine, hydroxylamine sulfate, hydroxylamine chloride, hydroxylamine oxalate, dimethyl hydroxylamine hydrochloride and hydroxylamine phosphate. An anisotropic etching property whose etching rate is different in crystal face orientation especially relating with etching technology with the use of manufacturing of micro-structures of silicon used as Micro Electro Mechanical Systems (MEMS) parts, semiconductor materials, etc is provided.

Owner:MITSUBISHI GAS CHEM CO INC

Distributed Pressure Sensoring System

InactiveUS20070107523A1Fluid pressure measurement by electric/magnetic elementsMicro electrical mechanical systemsEngineering

A system is provided for sensing and monitoring pressure conditions and variations over an actual or represented surface area of a workpiece in a process chamber. The system includes a substrate and a plurality of micro-electrical-mechanical-systems (MEMS) pressure sensors fixed to the substrate.

Owner:GALEWSKI CARL JOHAN

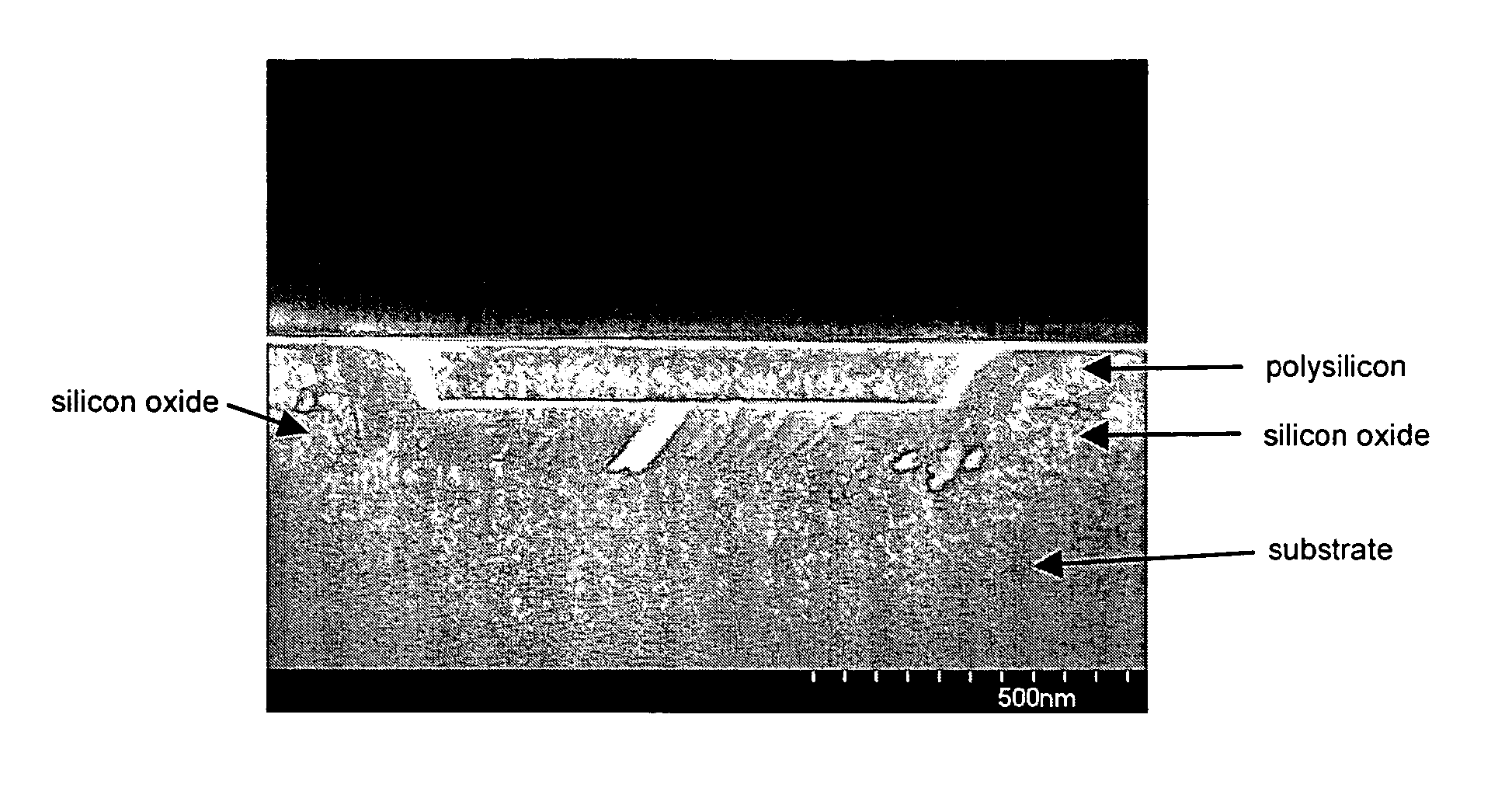

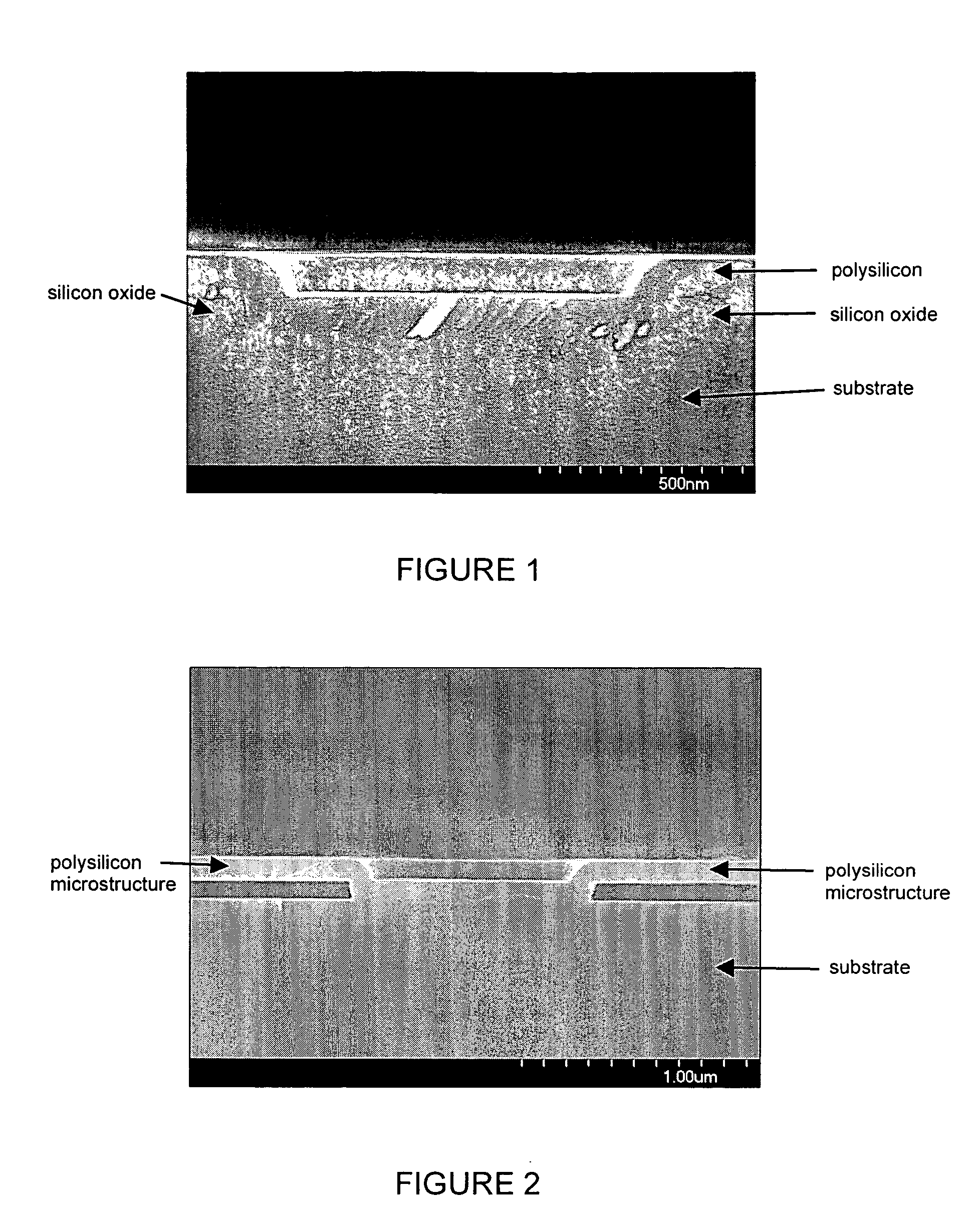

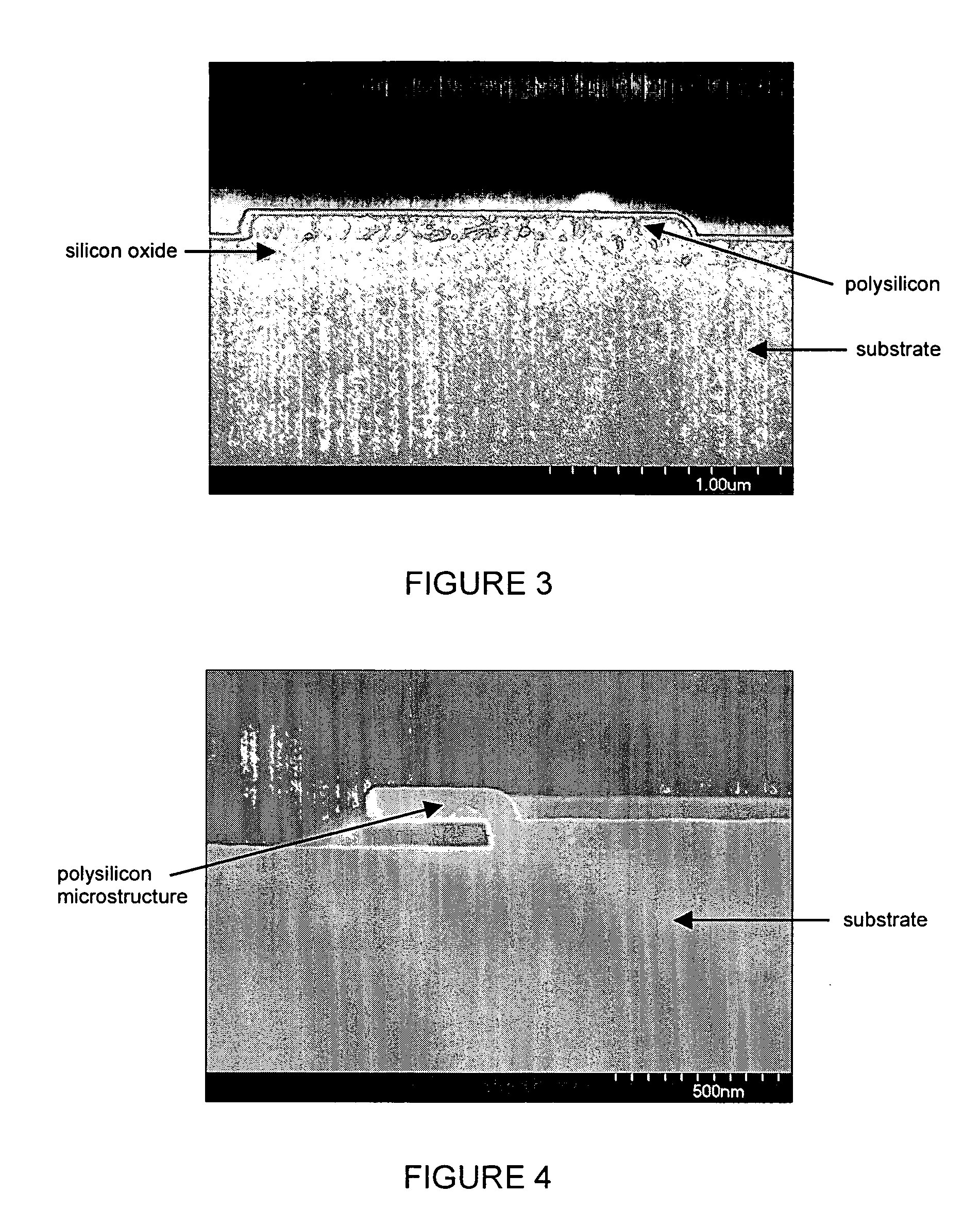

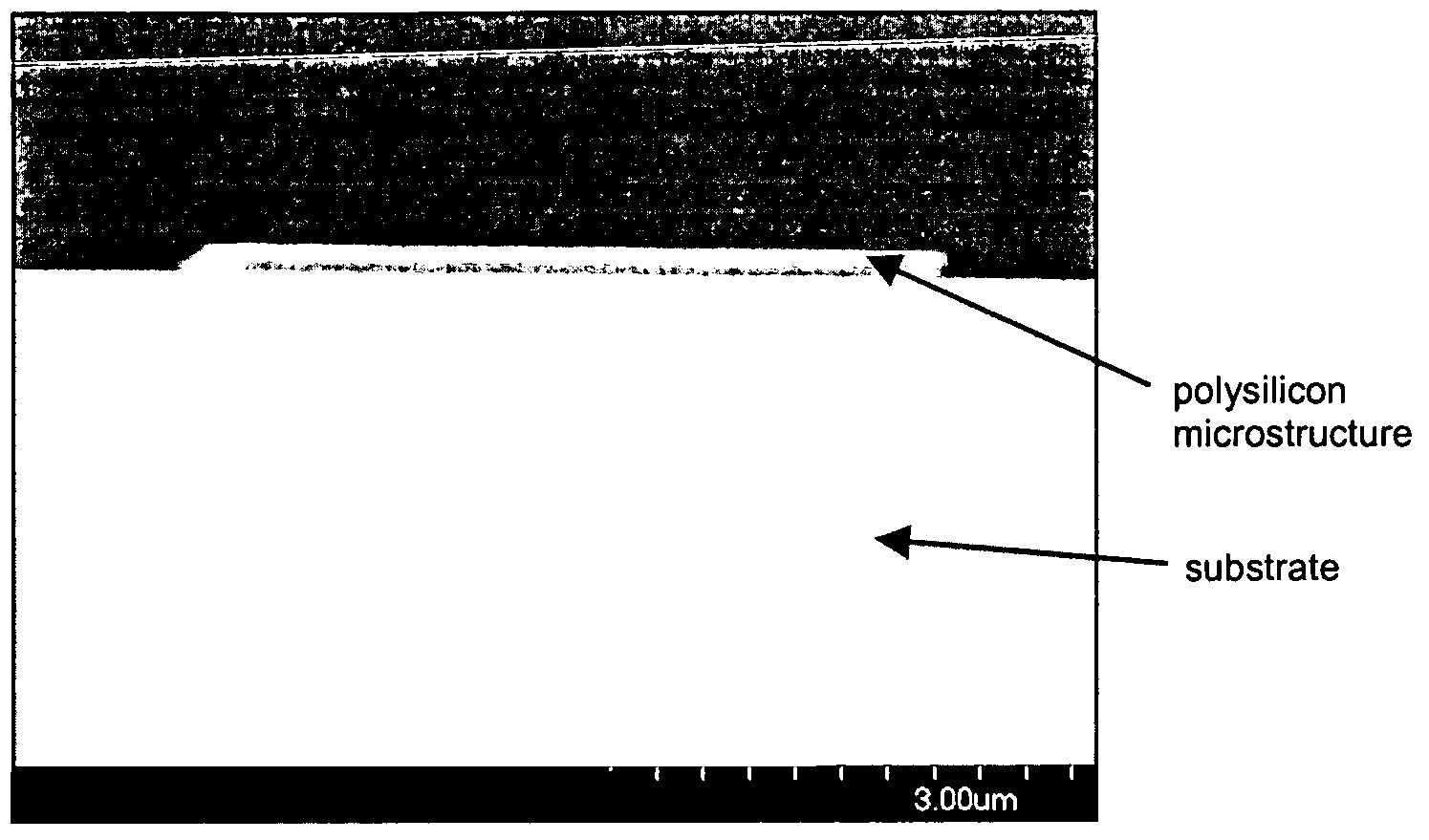

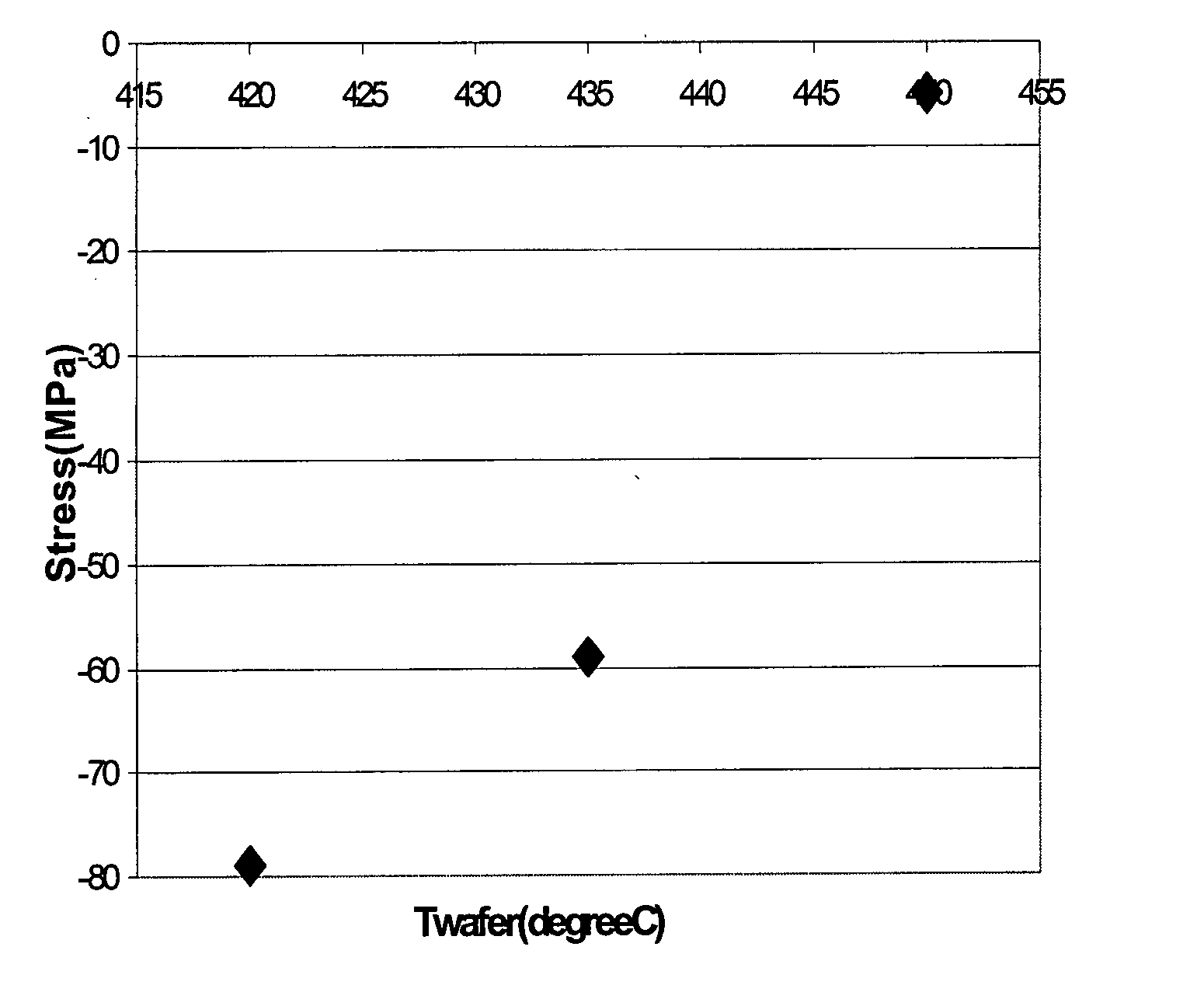

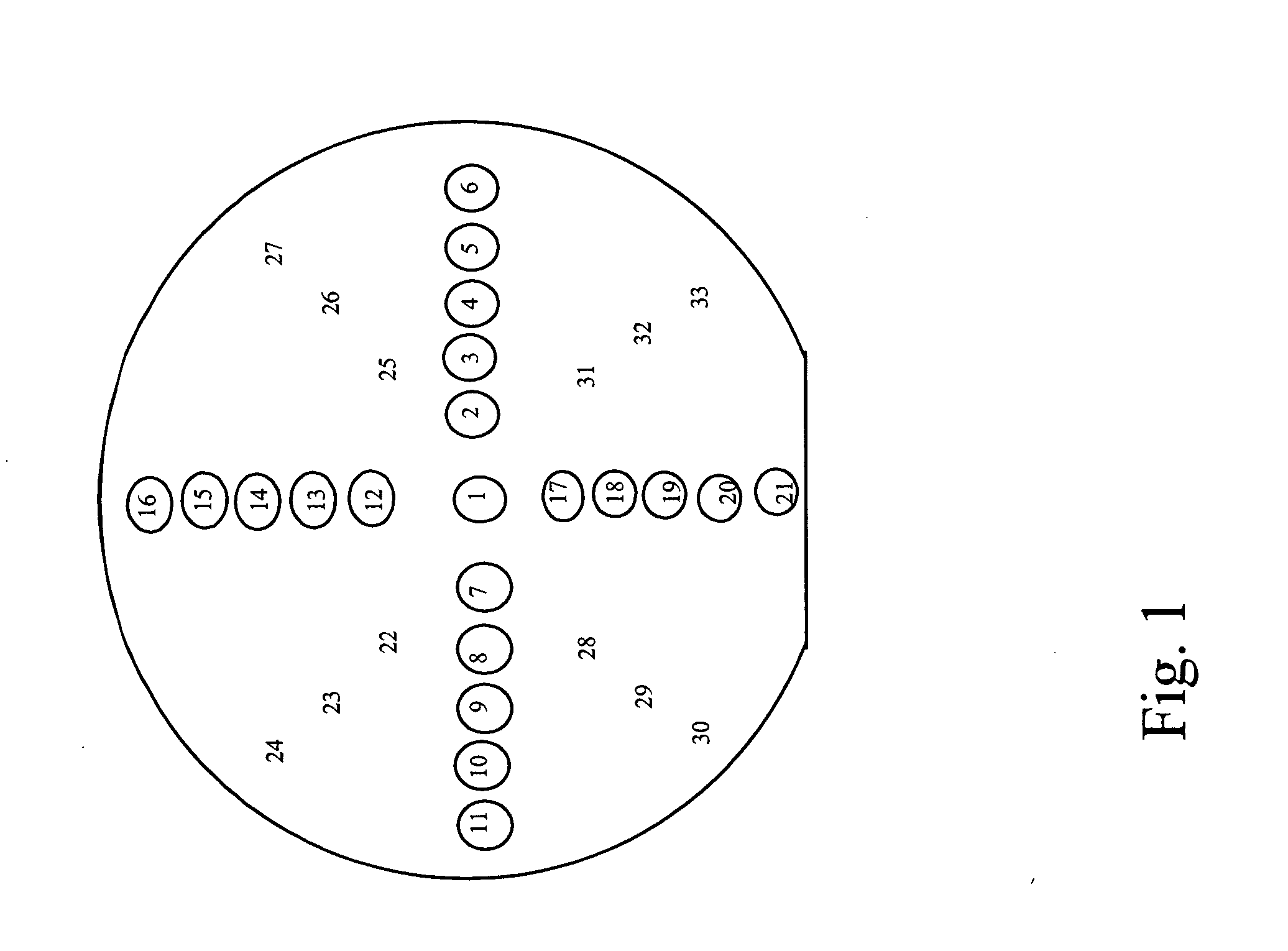

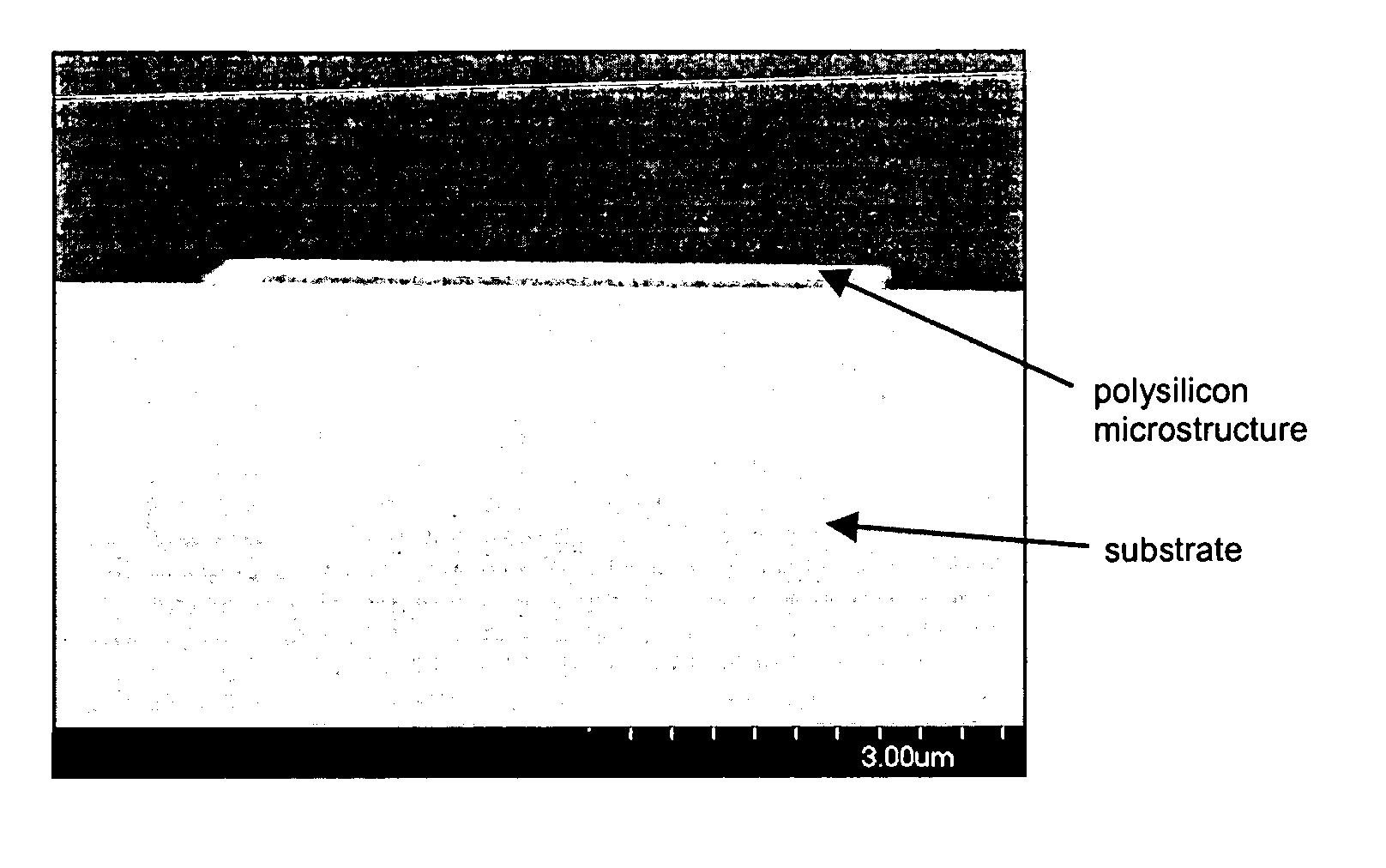

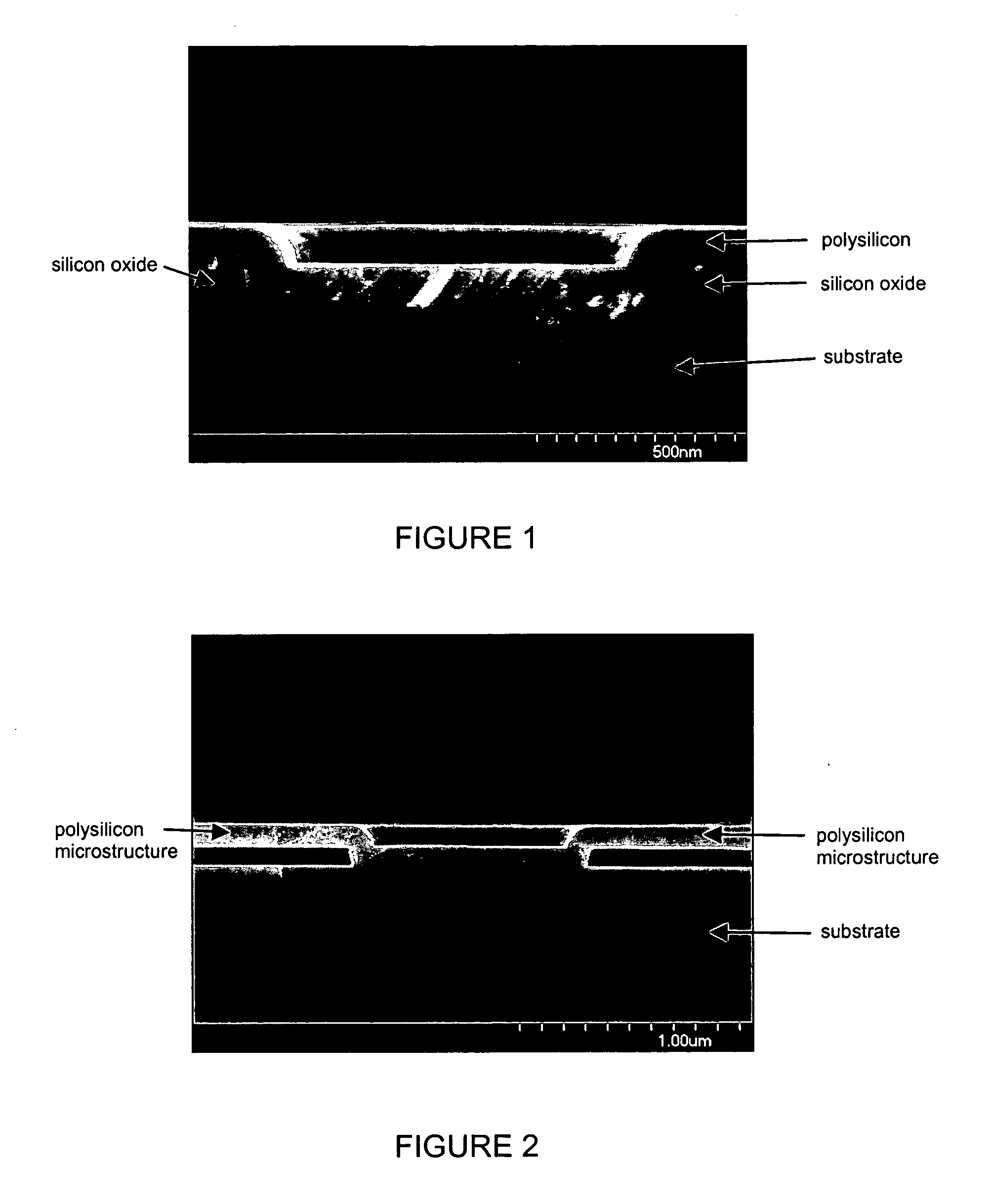

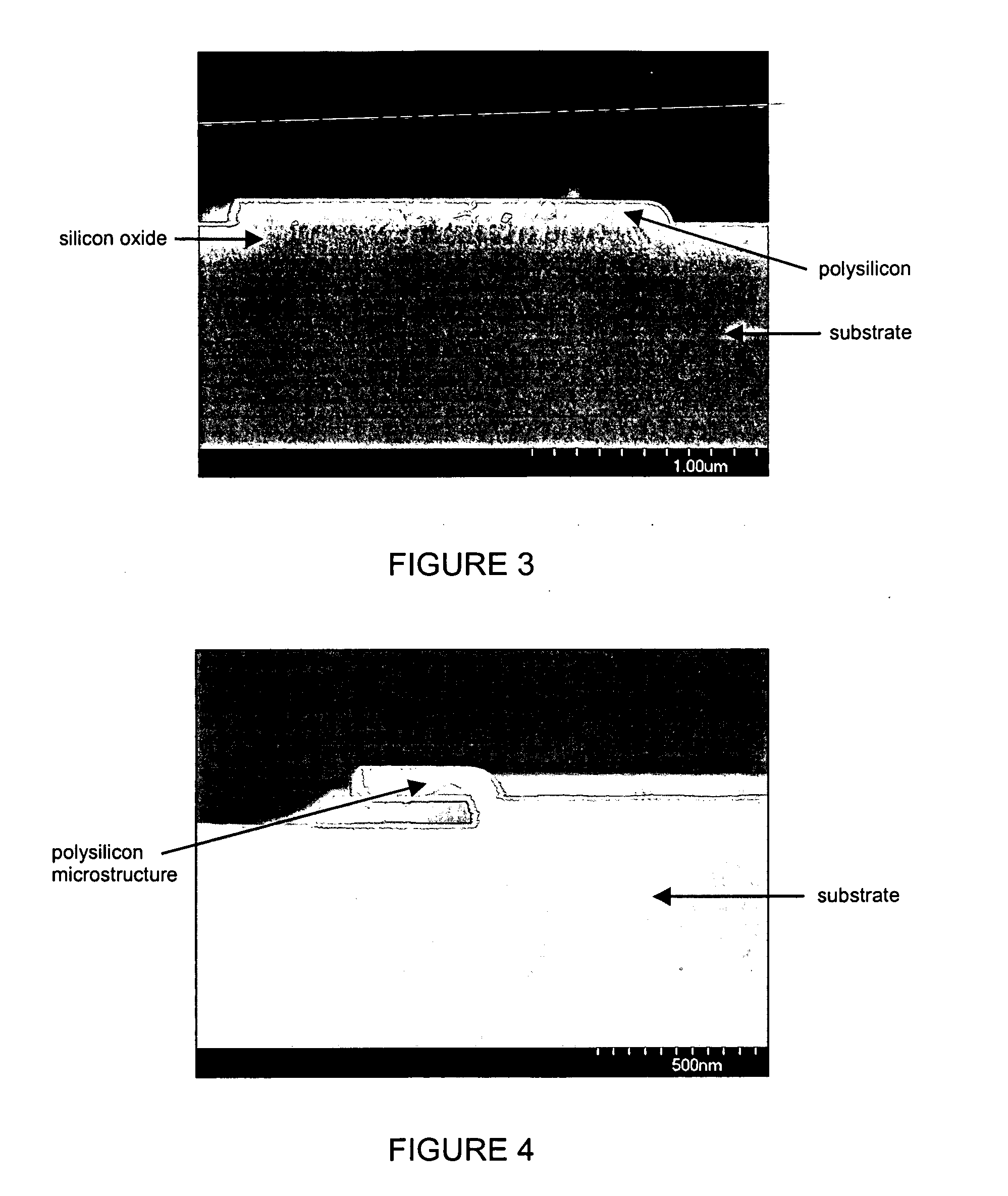

Method for producing polycrystalline silicon germanium and suitable for micromachining

InactiveUS20050037598A1Improve stress conditionHigh resistivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorSemiconductor device

The invention relates to methods for preparing as-deposited, low-stress and low resistivity polycrystalline silicon-germanium layers and semiconductor devices utilizing the silicon-germanium layers. These layers can be used in Micro Electro-Mechanical Systems (MEMS) devices or micro-machined structures.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Removal of MEMS sacrificial layers using supercritical fluid/chemical formulations

InactiveUS20050118813A1Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingCompound (substance)Stiction

A method and composition for removing silicon-containing sacrificial layers from Micro Electro Mechanical System (MEMS) and other semiconductor substrates having such sacrificial layers is described. The etching compositions include a supercritical fluid (SCF), an etchant species, a co-solvent, and optionally a surfactant. Such etching compositions overcome the intrinsic deficiency of SCFs as cleaning reagents, viz., the non-polar character of SCFs and their associated inability to solubilize polar species that must be removed from the semiconductor substrate. The resultant etched substrates experience lower incidents of stiction relative to substrates etched using conventional wet etching techniques.

Owner:ADVANCED TECH MATERIALS INC

MEMS mirror driven by one motion with oscillations of different frequency for bidirectional rotation

A micro-electro-mechanical system (MEMS) mirror system has an actuator that imparts a motion with a first periodic movement of high frequency superimposed a second periodic movement of low frequency to a frame and a mirror coupled to the frame so that the mirror rotates about two axes. The mirror is coupled by springs to the frame so the mirror is rotatable about a first axis. The frame has pivots each coupled by springs to actuators so the frame is rotatable about a second axis. The mirror has a first resonant frequency and the frame including the mirror has a second resonant frequency. The low frequency of the second periodic movement is equal to one of the first and the second resonant frequencies, and the high frequency of the first periodic movement is equal to the other one of the first and the second resonant frequencies.

Owner:ADVANCED NUMICRO SYST

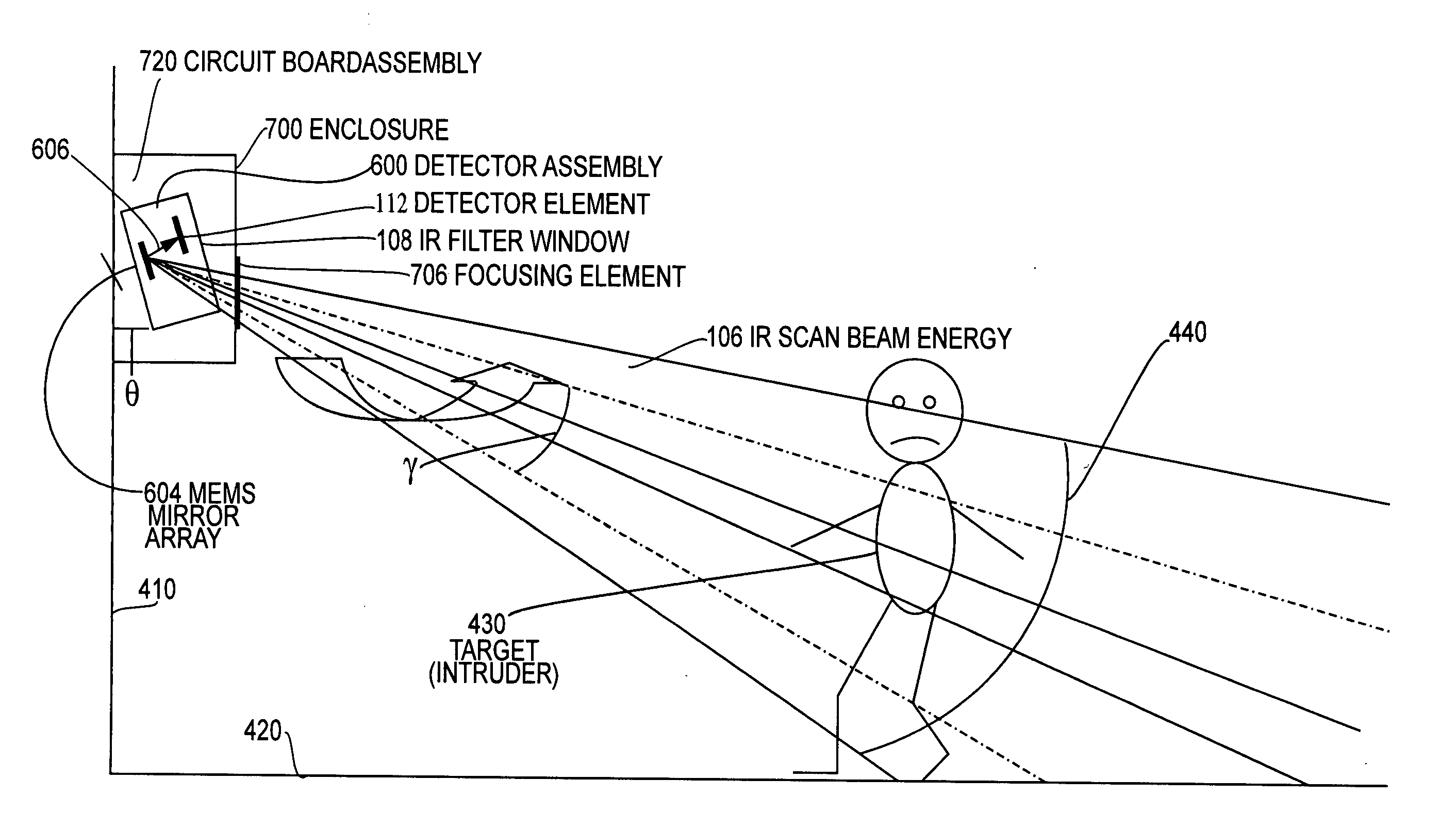

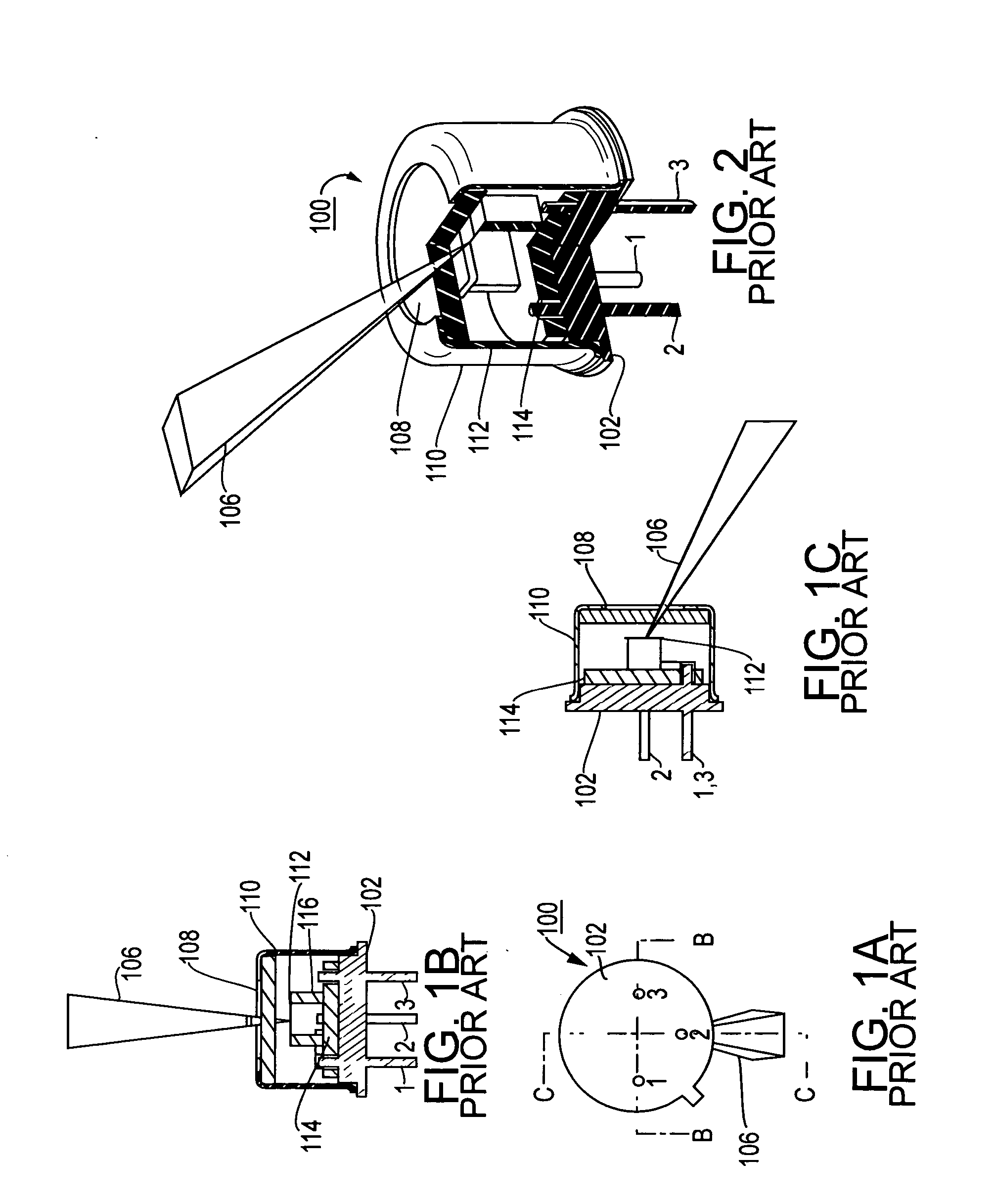

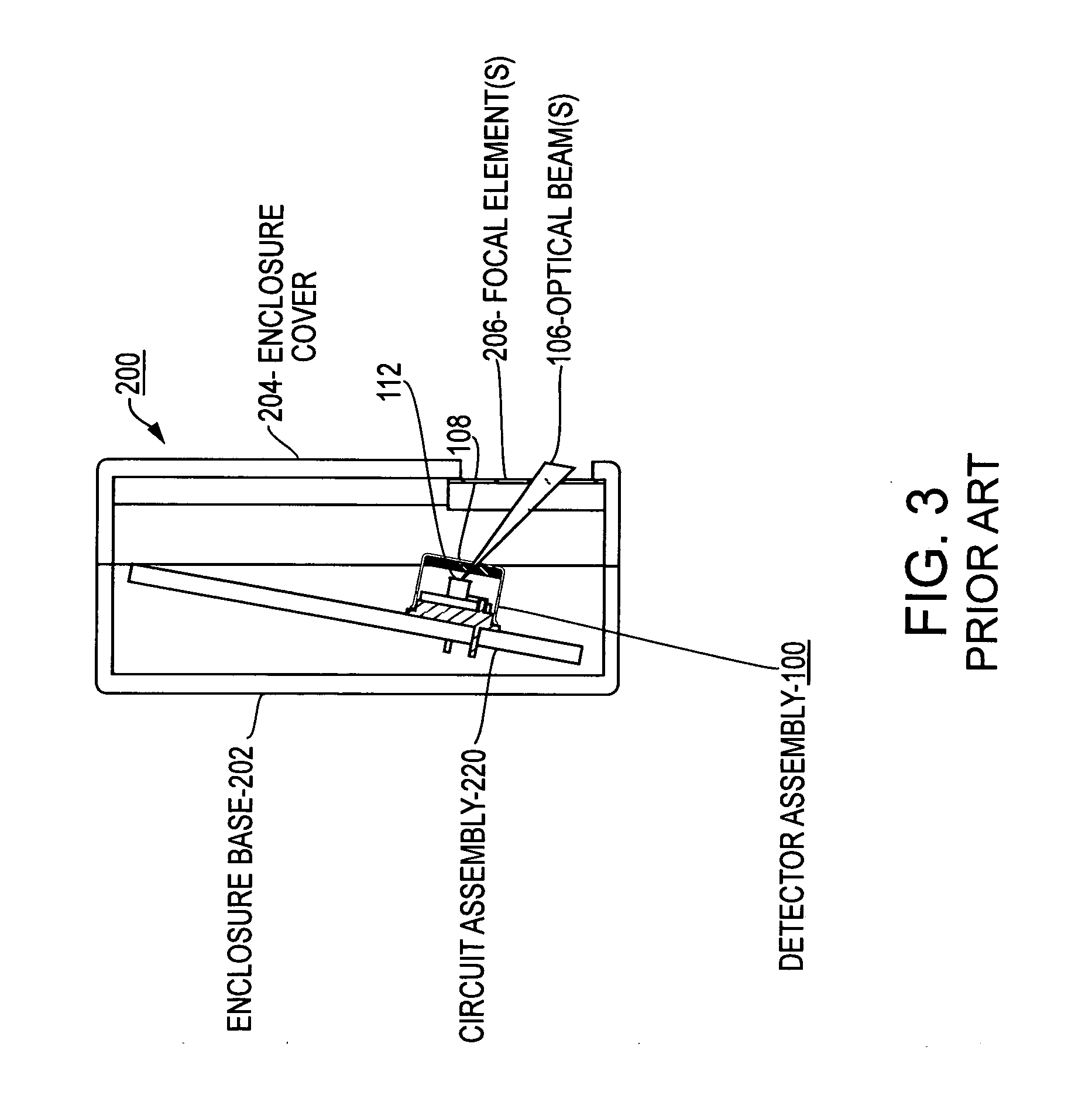

MEMS based space safety infrared sensor apparatus and method for detecting a gas or vapor

ActiveUS20060038680A1Efficient scanningRadiation pyrometryMaterial analysis by optical meansControl signalField of view

A space safety apparatus monitoring a volume of space encompassing a field of view (FOV) for detecting an intrusion including a gas or vapor, and includes a micro-electro-mechanical system (MEMS) having mirror elements in a mirror array for reflecting infra-red (IR) energy beam collected from the FOV and an IR energy detector for detecting the IR energy reflected by the MEMS array and converting the IR energy to an output signal. A processor adjusts an angle of an element of the MEMS mirror array by varying a control signal, or by switching from one to another focusing element. The method includes detection in a volume of space by positioning a MEMS mirror array to reflect IR signal with respect to active elements of an IR detector; and collecting IR energy from an ith portion of the FOV.

Owner:HONEYWELL INT INC

Structure of vertical three-dimensional combined packaging of micro electric mechanical system and manufacture method thereof

InactiveCN101525116AAvoid designAvoid manufacturing difficultiesPrecision positioning equipmentSoldering apparatusTriaxial accelerometerLead bonding

The invention relates to a structure of the vertical three-dimensional combined packaging of a micro electric mechanical system and a manufacture method thereof and is characterized by providing a novel structure of the triaxial accelerometer combined packaging and a manufacture method thereof, wherein the structure of the module combined packaging is formed by combining brackets, located by laser calibration and a triple prism and fixed by ultraviolet light cured adhesive and realizes the mutual electrical connection by lead bonding. The whole technical process is compatible with the traditional IC packaging technology and is simple. The structure provides another select for the three-dimensional acceleration measurement while reducing the cost of the packaging and simplifying the technology.

Owner:上海新微科技集团有限公司

Battery cell for MEMS device and related methods

ActiveUS20110095720A1Long life-timeSave valuable spacePrimary cell to battery groupingBatteries circuit arrangementsMicro electrical mechanical systemsEngineering

A micro electrical-mechanical systems (MEMS) device INCLUDES a MEMS substrate and at least one MEMS structure on the MEMS substrate. In addition, there is at least one battery cell on the MEMS substrate coupled to the at least one MEMS structure. The at least one battery cell includes a support fin extending vertically upward from the MEMS substrate and a first electrode layer on the support fin. In addition, there is an electrolyte layer on the cathode layer, and a second electrode layer on the electrolyte layer. The support fin may have a height greater than a width. The first electrode layer may have a processing temperature associated therewith that exceeds a stability temperature associated with the second electrode layer.

Owner:HARRIS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com