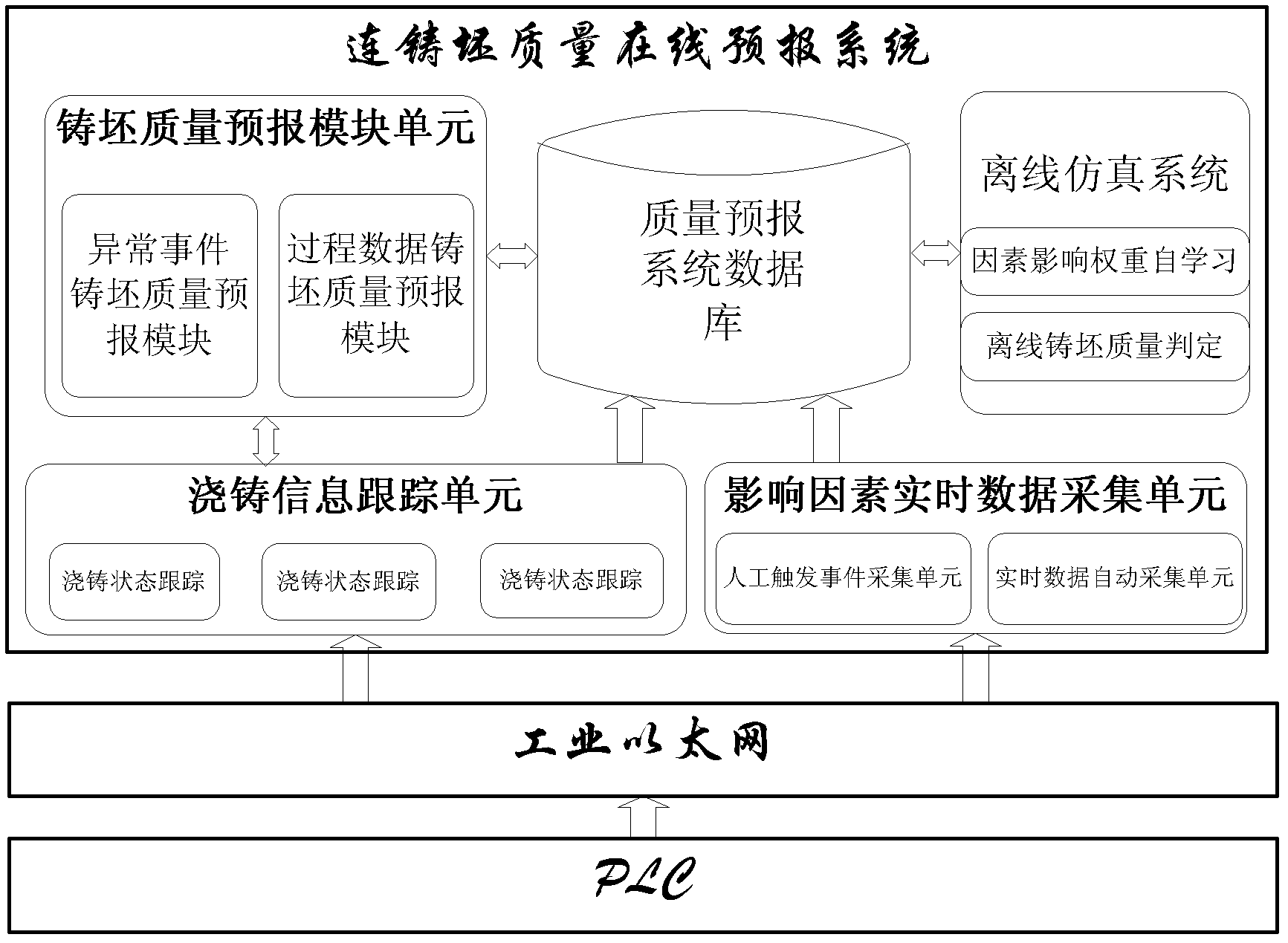

Method for controlling on-line prediction of continuous casting blank quality

A continuous casting billet and quality technology, which is applied in the control field of continuous casting billet quality online prediction, can solve the problems of not being used online and the model not being hot tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] (1) Continuous casting times: 1140474

[0034] This pouring time includes 7 heats of low carbon steel SPHC molten steel in heats 111A04483, 111A04484, 111A04485, 111A04486, 111A04487, 111A04488, 111A04489, and adopts 35 rules for judging the quality of automobile plates.

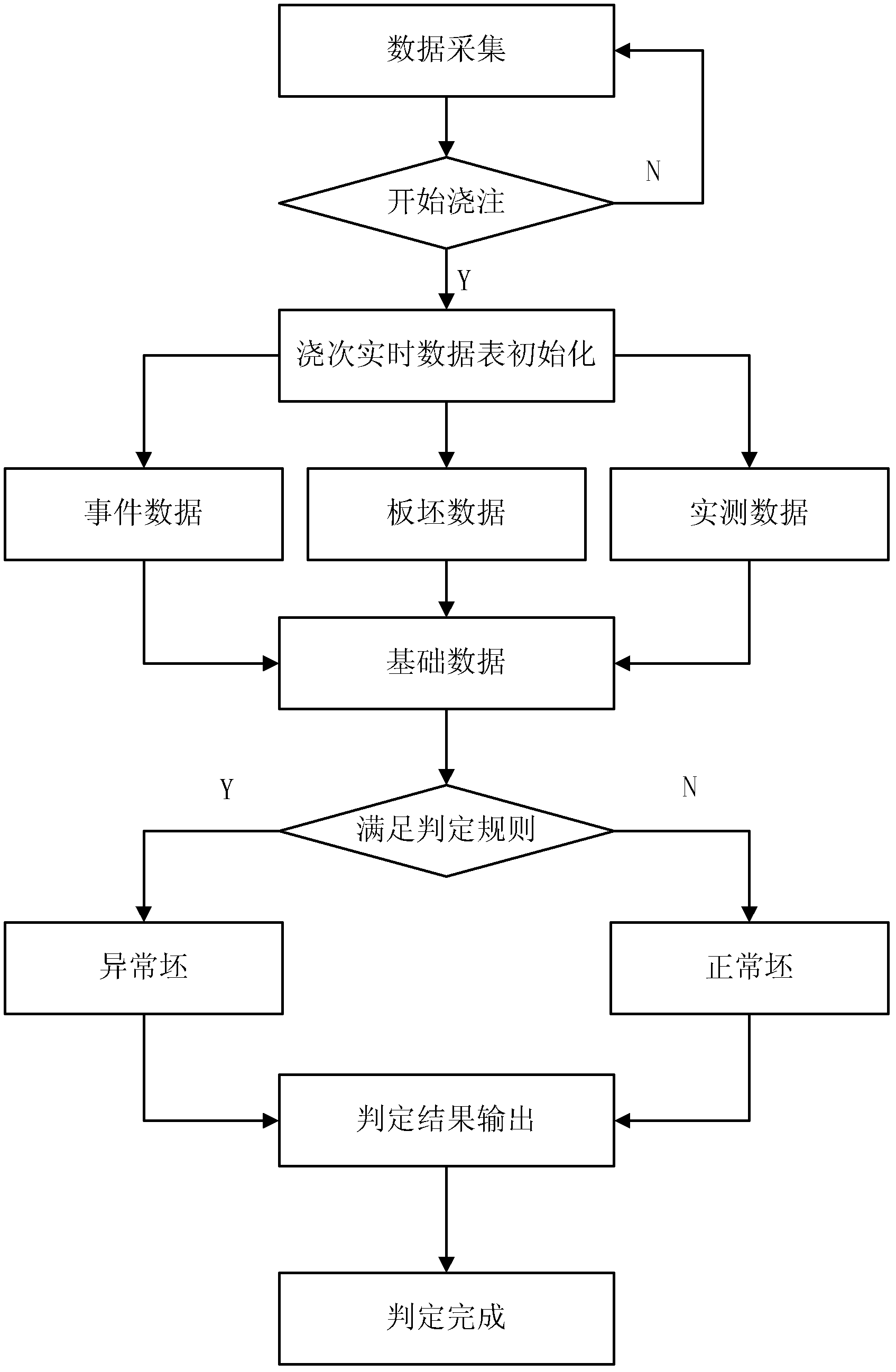

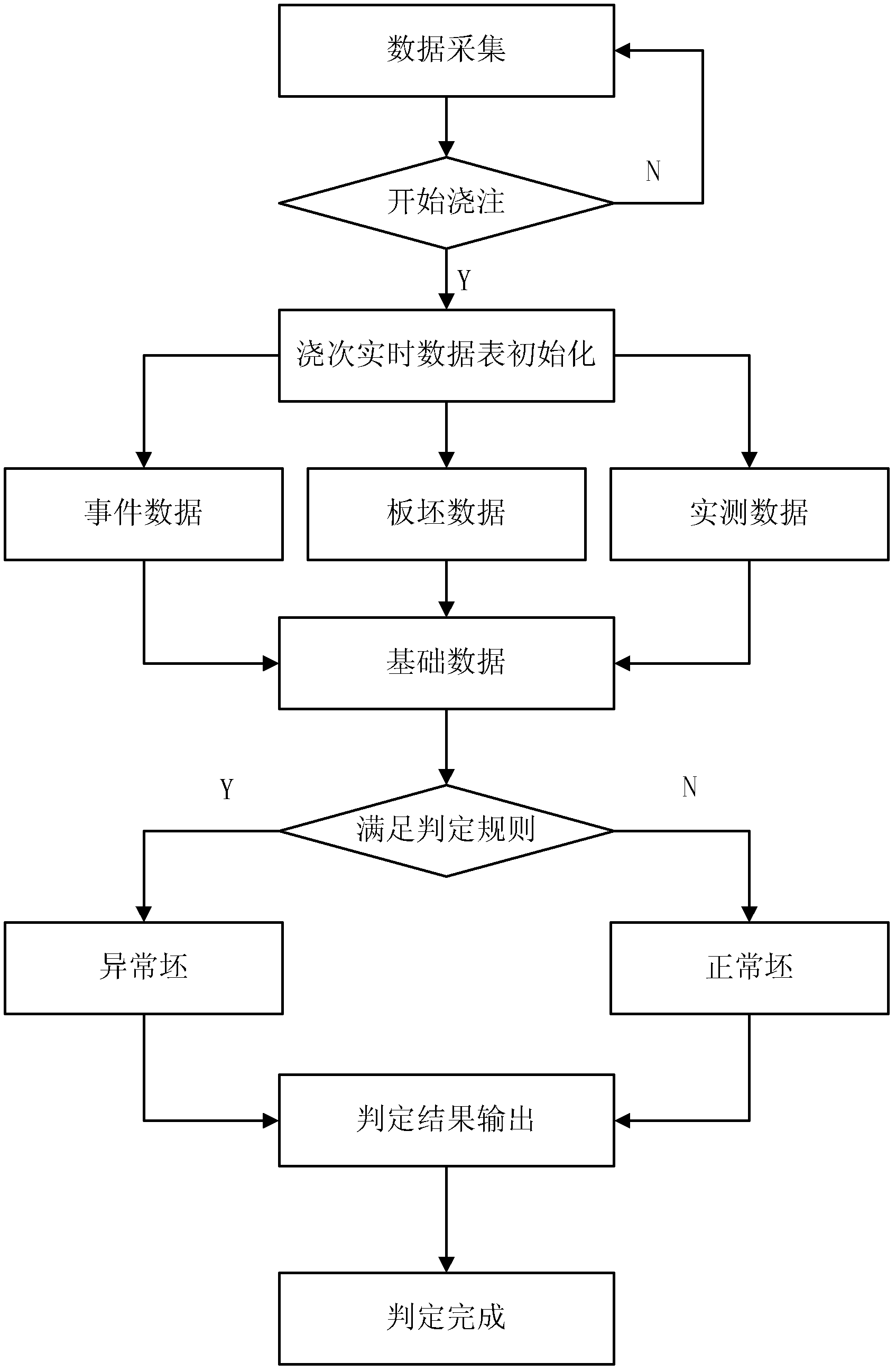

[0035] Judgment is carried out as follows:

[0036] 1: The casting state information tracking module of the quality judgment system and the real-time data collection process of influencing factors detected the arrival of 111A04483 heats and the pouring start signal of the furnace in sequence, and the system initialized the real-time data table of pouring times;

[0037] Two: The acquisition process begins to collect abnormal event information, pouring information and actual measurement data of continuous casting process parameters, and store them in the corresponding data storage unit;

[0038] Three: The pouring length is between 0.46m and 2.53m, and the system continuously detects the automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com