System method for intelligent control over continuous-casting process

An intelligent control and continuous casting technology, which is applied in the field of intelligent control system of continuous casting process, can solve the problems of poor control ability, large fluctuation of billet quality, and less excavation of production rules, so as to improve accuracy and reliability, reduce Comprehensive cost, the effect of reducing energy consumption and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

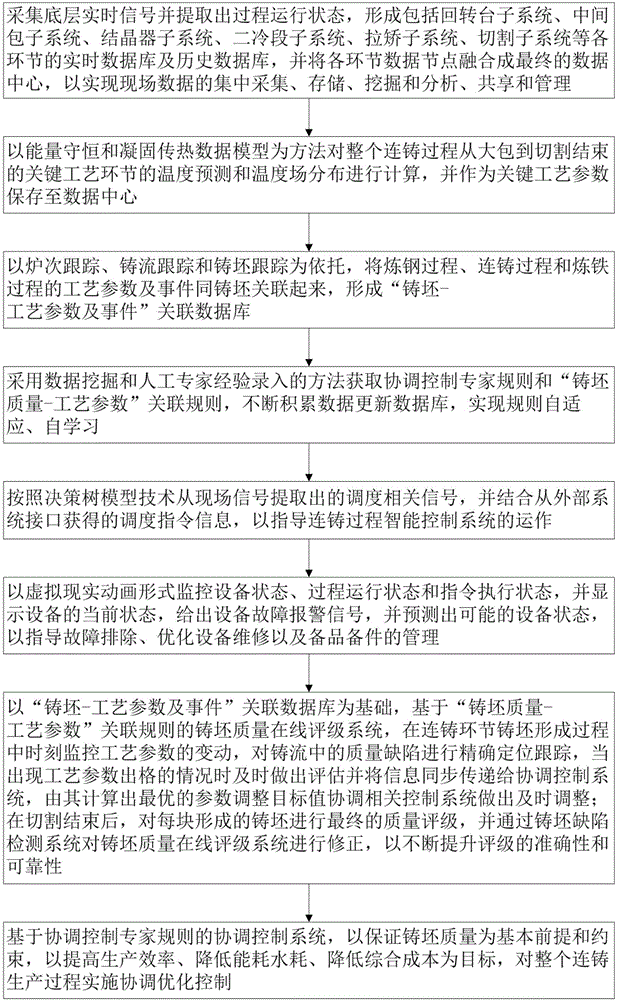

[0029] see figure 1 , the present invention provides a system method for intelligent control of continuous casting process, comprising the following steps:

[0030] S1. Collect the underlying real-time signals and extract the process operation status to form a real-time database and historical database including the rotary table subsystem, the tundish subsystem, the crystallizer subsystem, the secondary cooling section subsystem, the pulling and straightening subsystem, the cutting subsystem, etc. , and integrate the data nodes of each link into the final data center to realize the centralized collection, storage, mining and analysis, sharing and management of on-site data;

[0031] S2. Using the energy conservation and solidification heat transfer data model as a method to calculate the temperature prediction and temperature field distribution of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com