Diamond die production process

A technology of diamond wire drawing die and production process, applied in wire drawing die and other directions, can solve the problems of increasing production cost, increasing the amount of diamond, high price of natural diamond, etc., and achieving the effect of saving the amount of materials and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

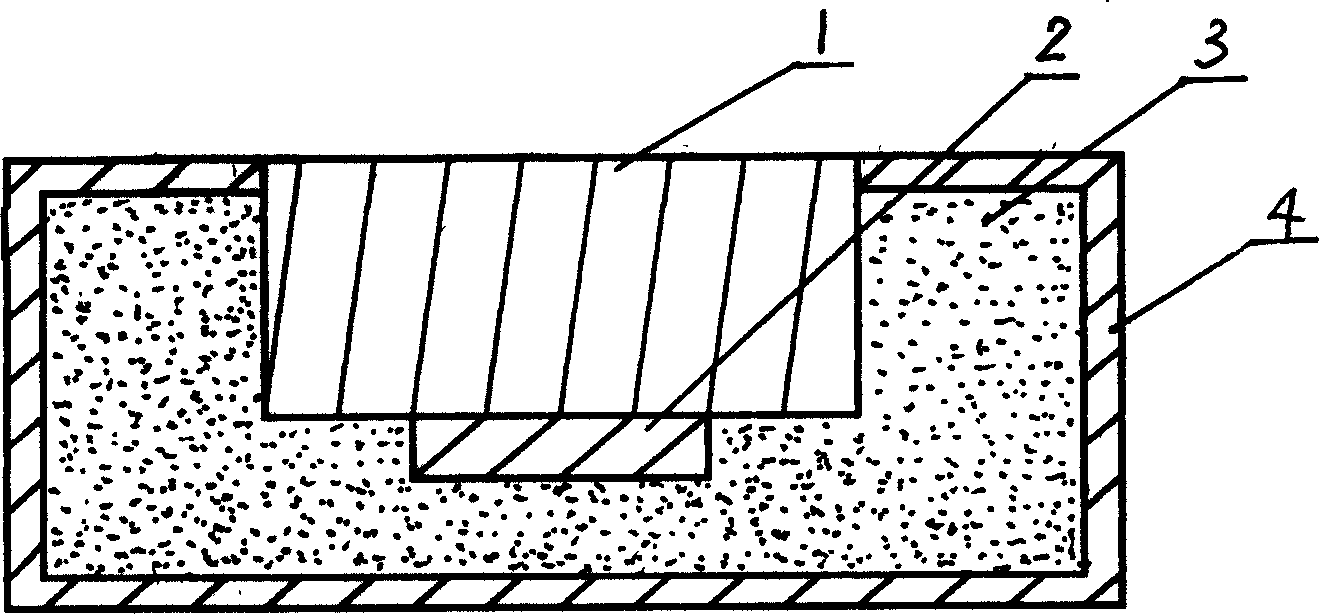

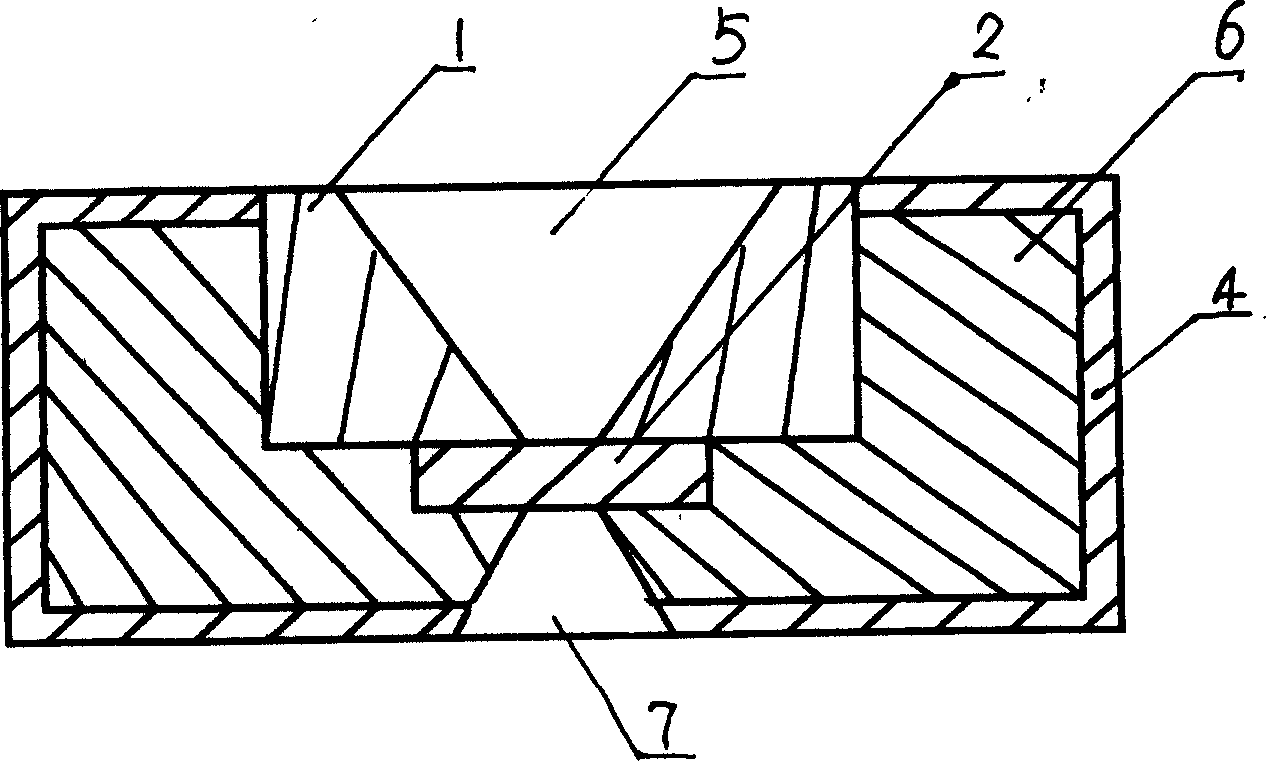

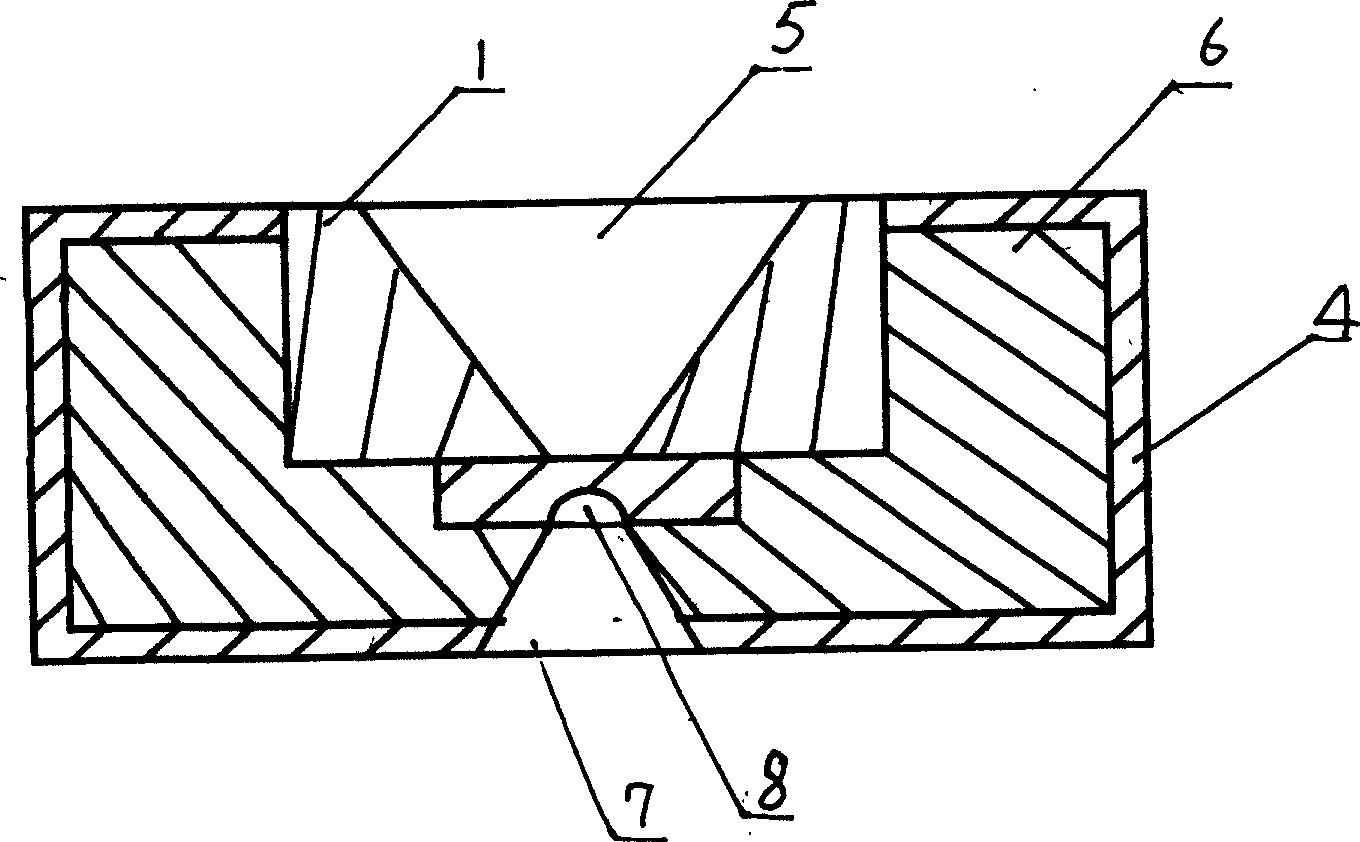

[0011] The diamond wire drawing die production process of the present invention comprises: 1) selection of diamonds: selecting natural diamonds of good quality, with a weight of about 3-4 points. 2) Grinding: Grinding the selected natural diamond into two parallel planes on a grinding machine, the thickness of which is greater than or equal to 0.65mm. 3) Inserting sleeve: Insert the ground natural diamond 2 into the stainless steel mold sleeve 4 with metal powder 3, and then cover the cover sheet 1, such as figure 1 shown. Sintering in the hot-press sintering machine, so that the natural diamond 2 is fixed in the stainless steel mold cover 4 to obtain a rough mold cover. After sintering, the position of the natural diamond 2 in the stainless steel mold cover 4 and the hardness of the sintered body 6 must meet the specified technical requirements. 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com