Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125 results about "Natural diamonds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

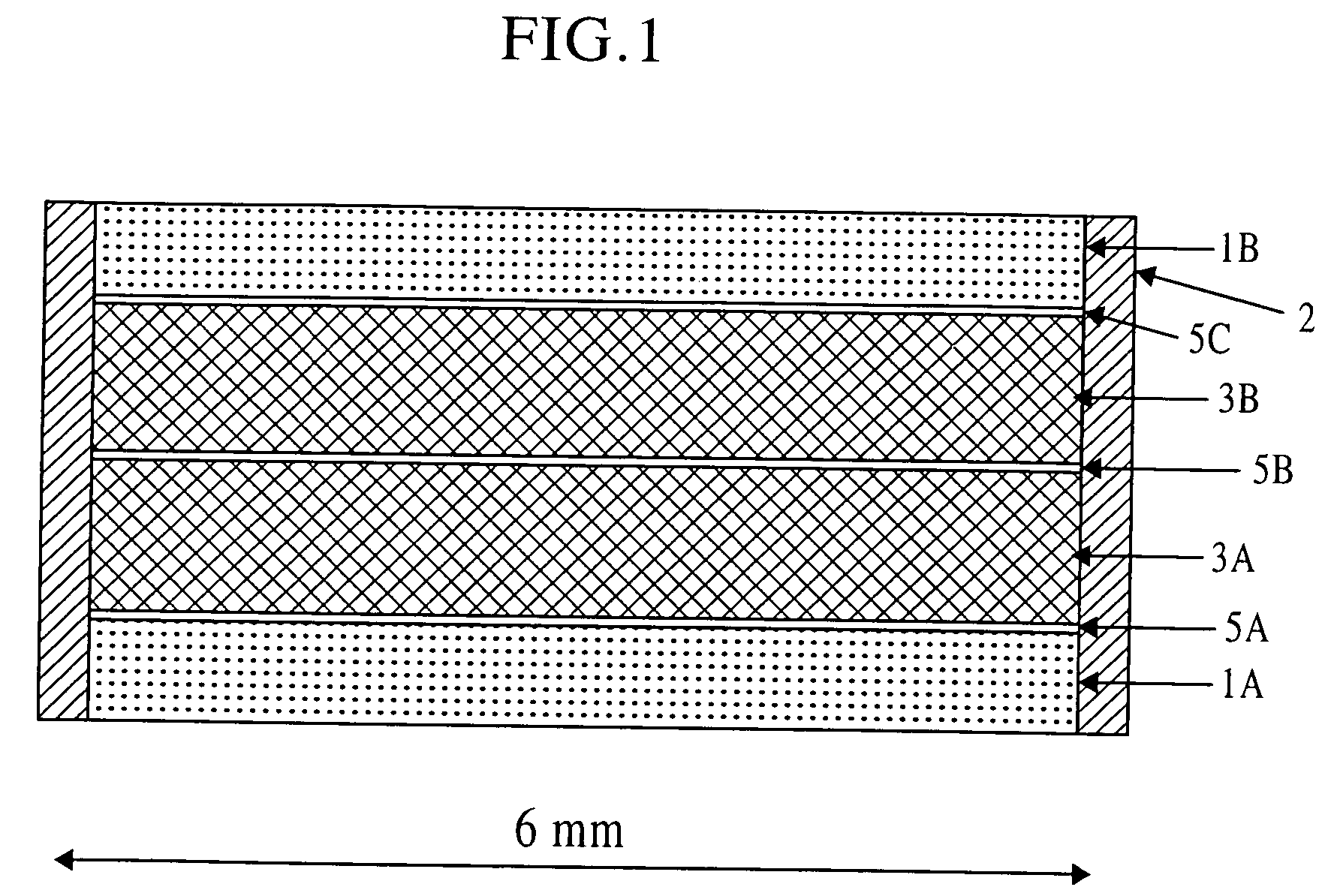

Thermally stable diamond polycrystalline diamond constructions

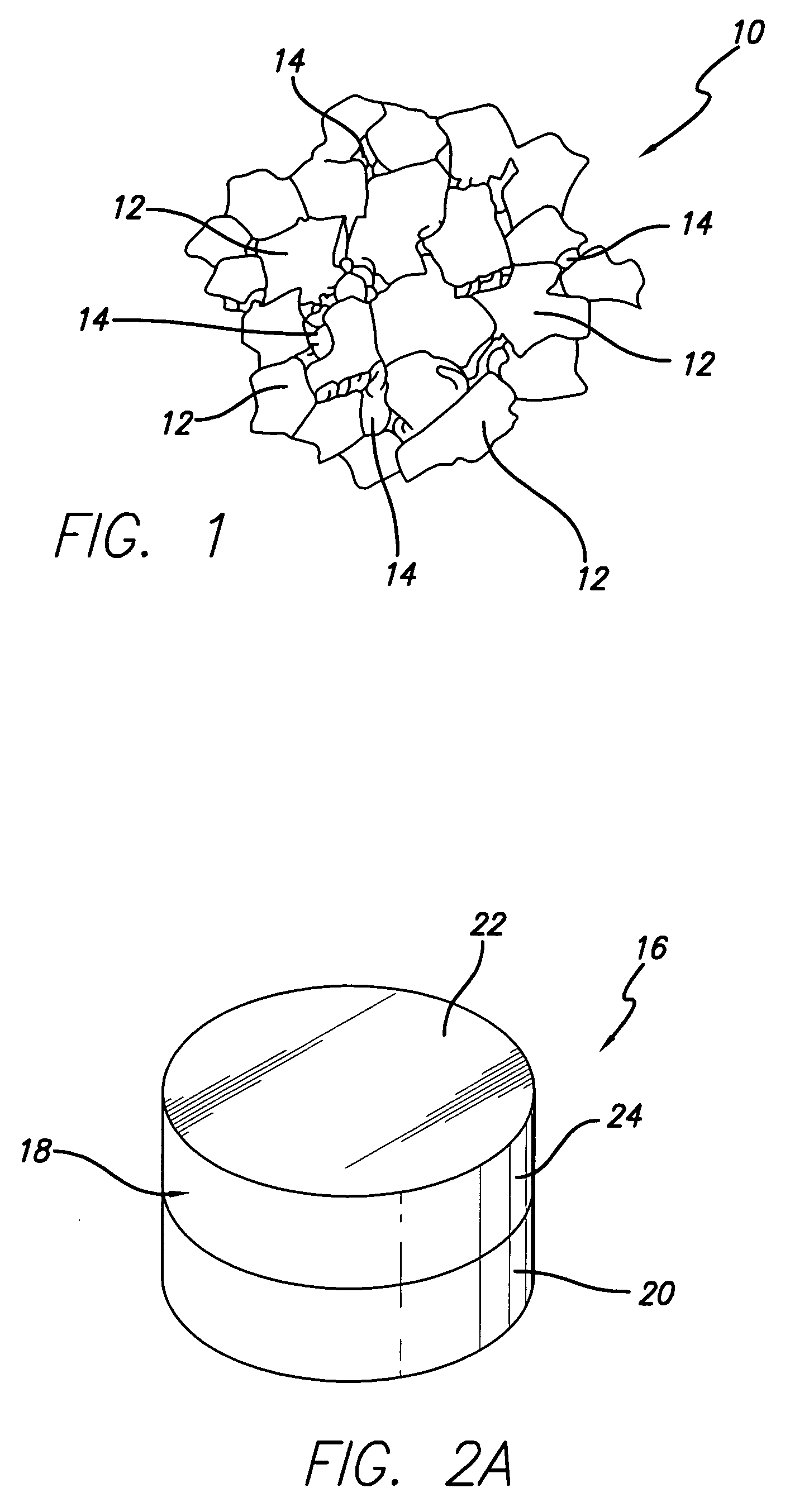

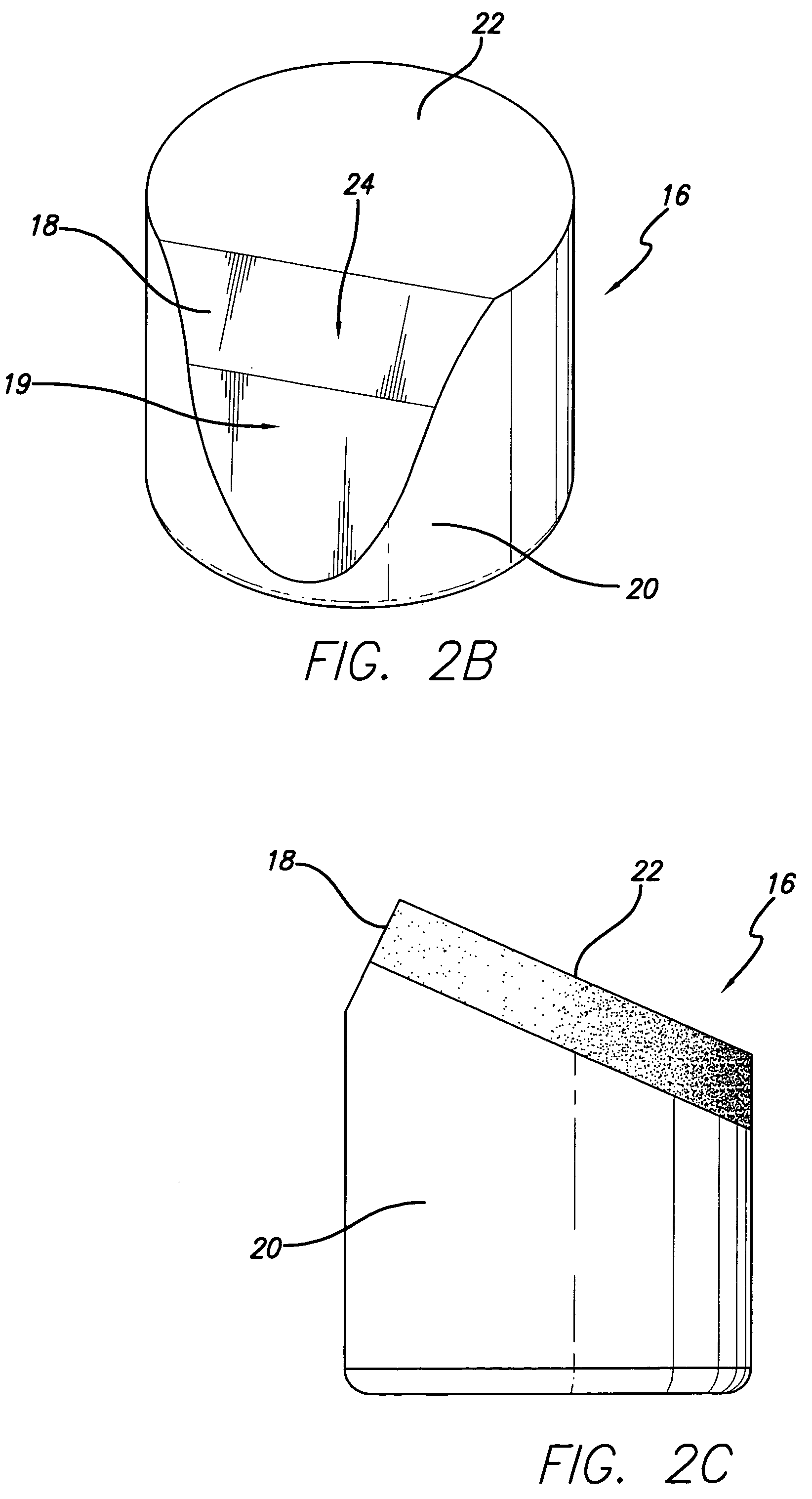

ActiveUS20060060392A1Improve thermal stabilityGood adhesionDrill bitsConstructionsDiamond crystalPolycrystalline diamond

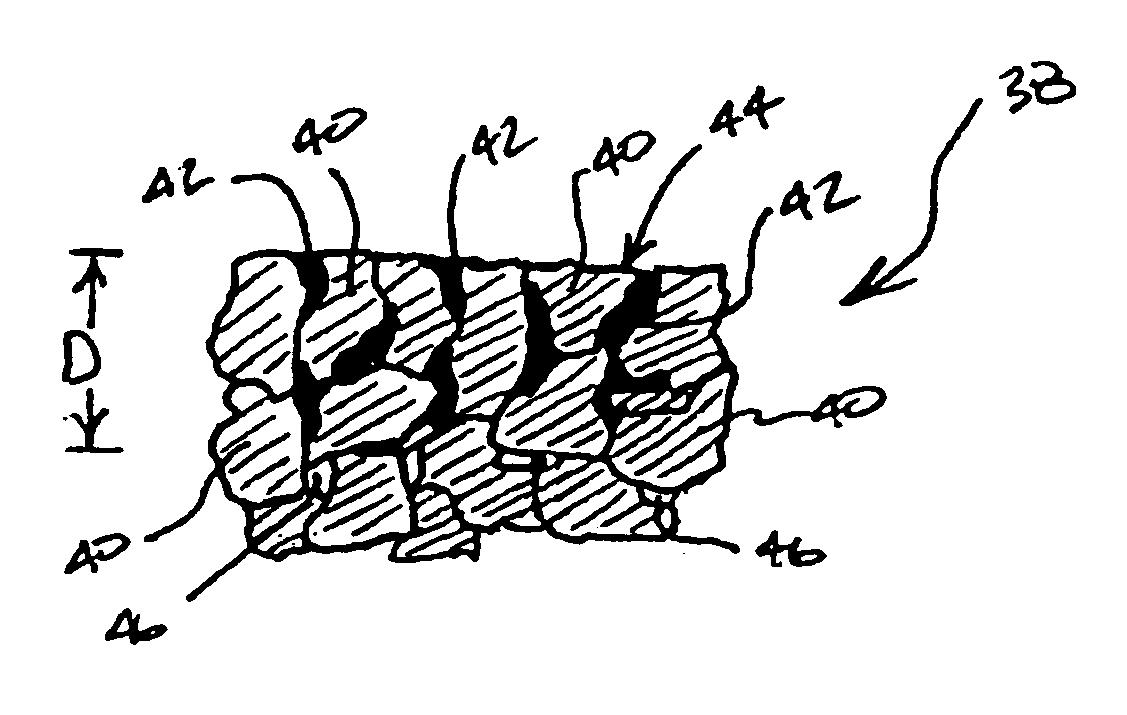

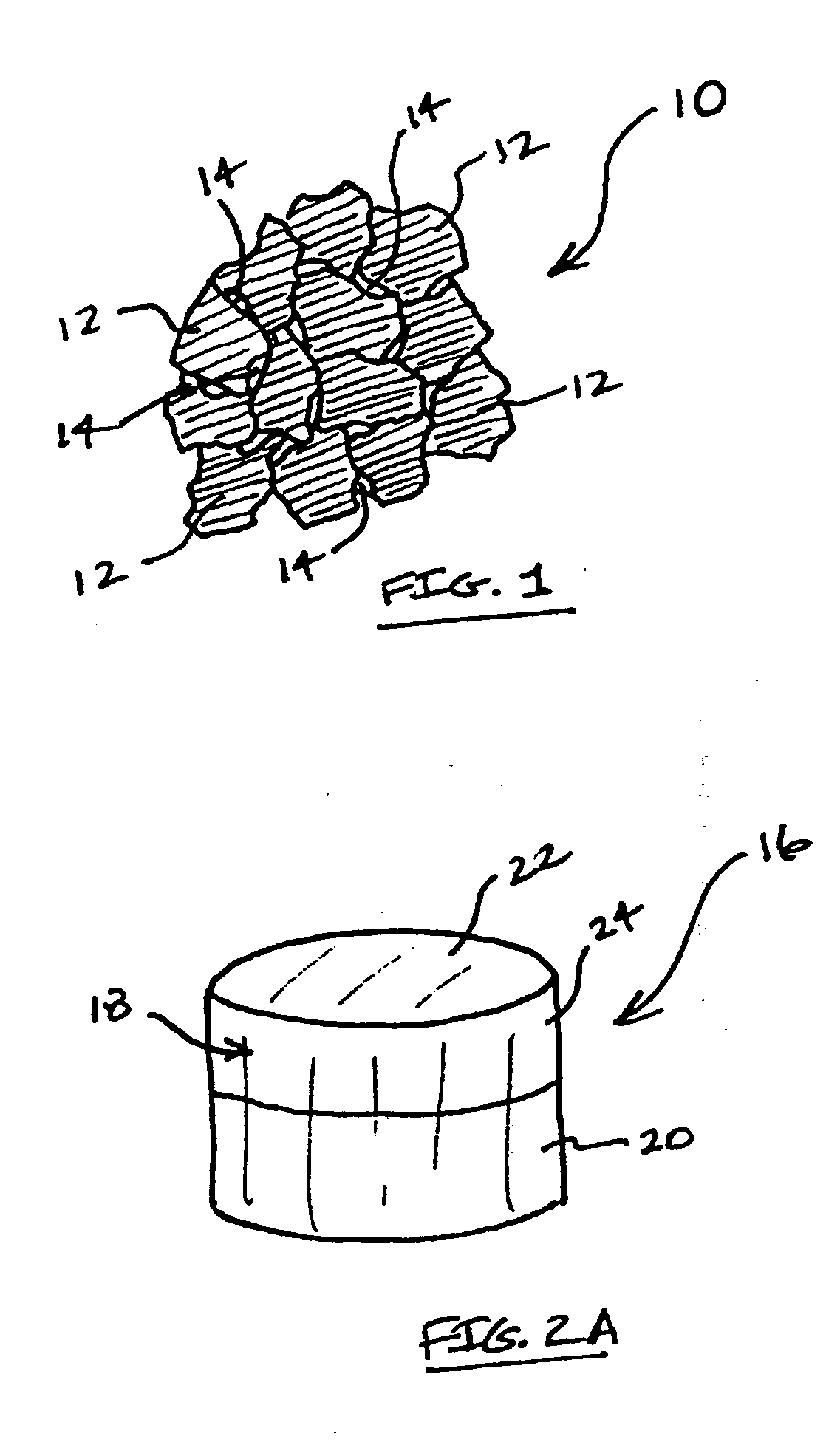

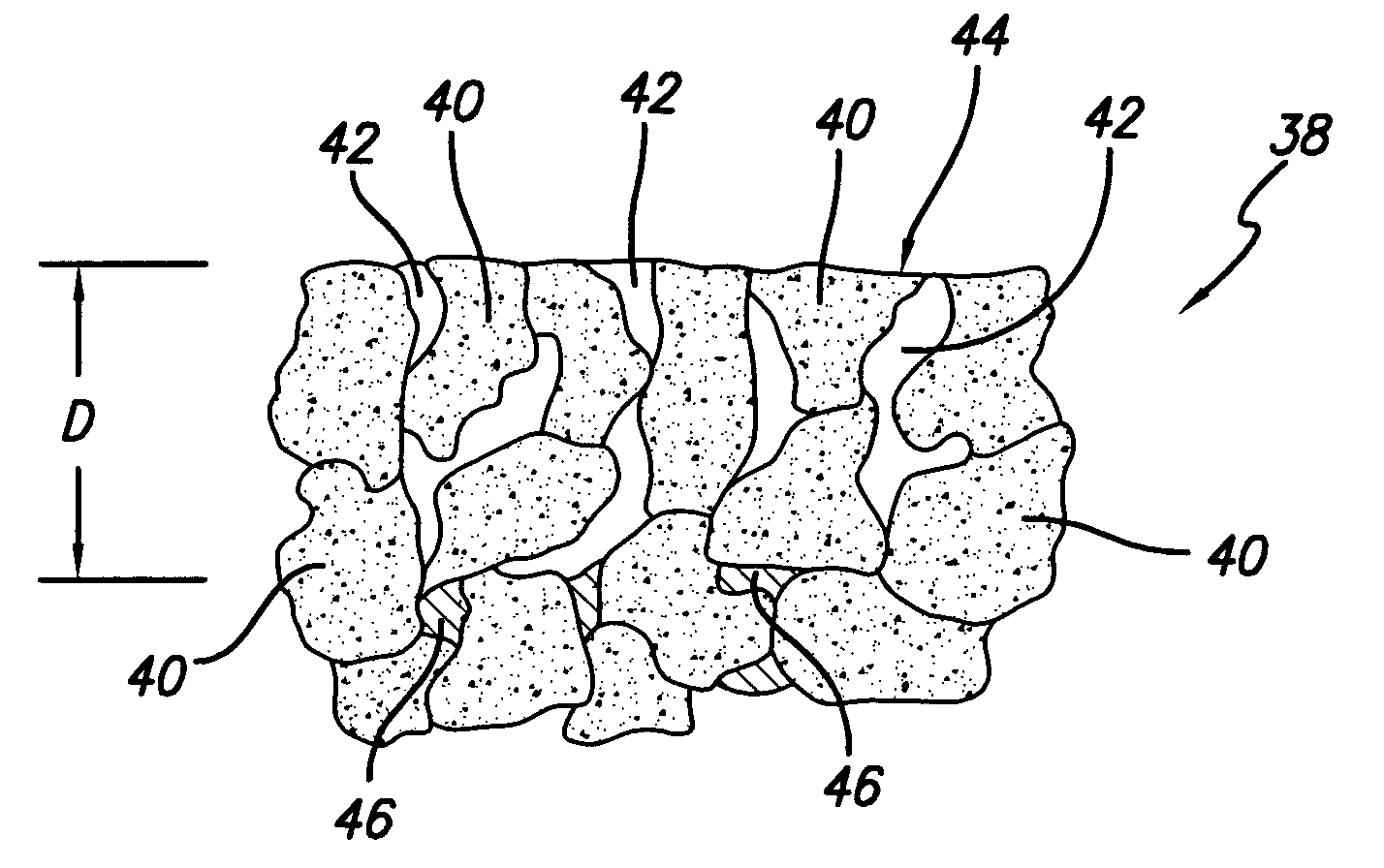

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals and interstitial regions disposed among the crystals. A metallic substrate is attached to the body. The body includes a first region substantially free of a catalyst material that extends a partial depth from a surface into the body, and a second region that includes the catalyst material. The body can include natural diamond grains and / or a blend of natural and synthetic diamond grains, and is treated to form the first region. Before treatment, a portion of the body to be treated is finished to an approximate final dimension so that the depth of the first region of the finished product is substantially the same as when treated. During treatment, catalyst materials as well as non-catalyst metallic materials are removed from the diamond body to provide a further enhanced degree of thermal stability.

Owner:SMITH INT INC

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

High pressure and high temperature production of diamonds

InactiveUS7241434B2Good colorDecrease cracking and breakageEdge grinding machinesUltra-high pressure processesNitrogenGraphite

The present invention is directed to a method for treating discolored natural diamond, especially Type IIa diamond and Type IaA / B diamond with nitrogen as predominantly B centers, for improving its color. The method includes preblocking and preshaping a discolored natural diamond to prevent its breakage in a high pressure / high temperature (HP / HT) press, placing said discolored natural diamond in a pressure transmitting medium which is consolidated into a pill. Next, the pill is placed into a HP / HT press at elevated pressure and elevated temperature within the graphite-stable or diamond-stable range of the carbon phase diagram for a time sufficient to improve the color of said diamond. Finally, the diamond is recovered from said press. Colorless and fancy colored diamonds can be made by this method.

Owner:BELLATAIRE INT

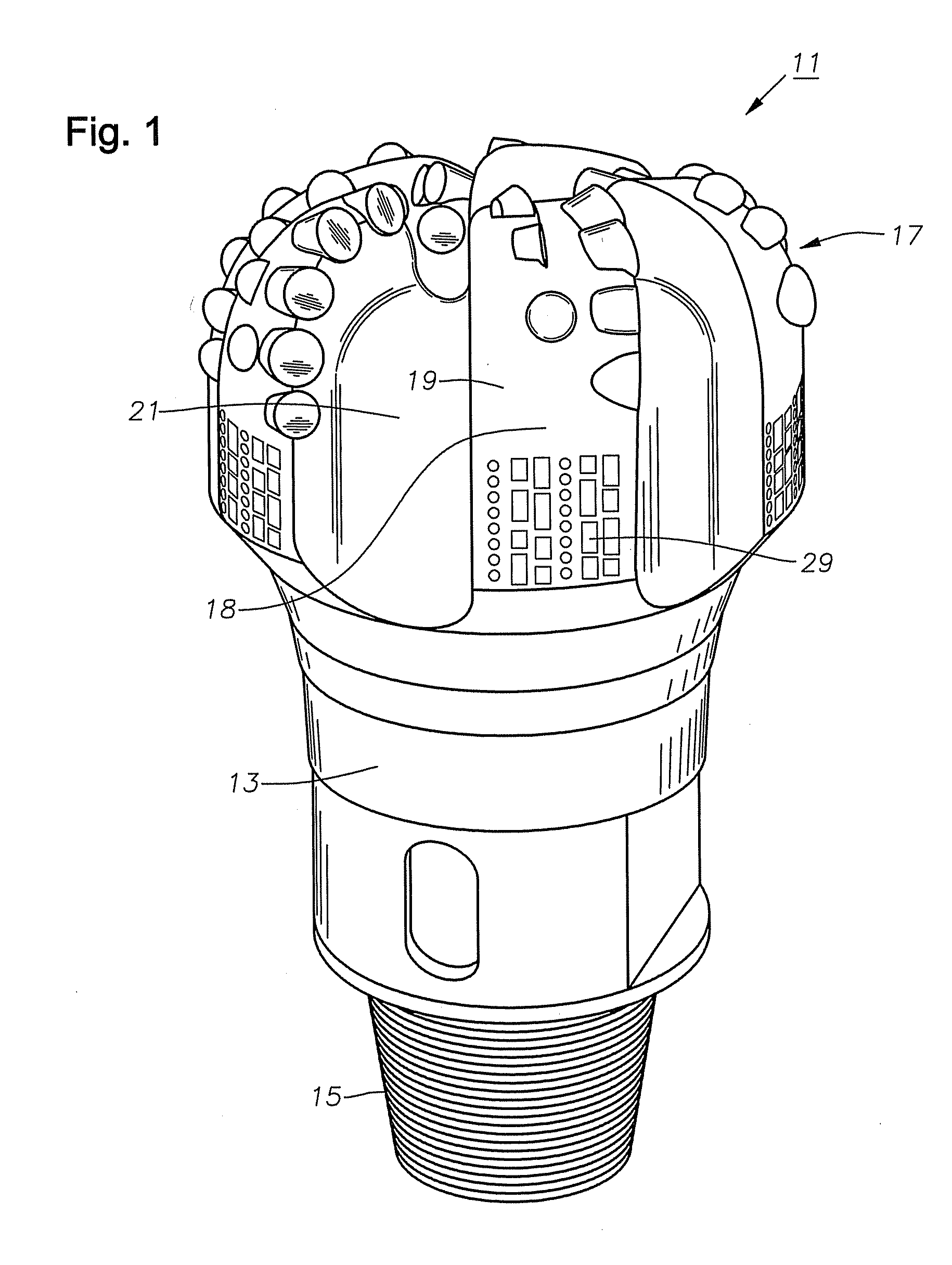

Method of Repairing Diamond Rock Bit

Hardfacing is applied on the gage surface of bit blades, the leading and trailing edges of bit blades, and on carbide inserts. The gage surface contains natural diamonds, synthetic diamonds, thermal stable polycrystalline (TSP) diamonds and carbide inserts, and the hardfacing is applied over at least a portion of them. As the primary cutters on the bit blades are worn down during drilling, the gage surface of the bit is also worn down. A hardfacing is applied to the worn gage surfaces of the bit, thereby allowing the bit to drill deeper and longer without requiring replacement.

Owner:BAKER HUGHES INC

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20080010905A1Improve thermal stabilityGood adhesionPigmenting treatmentConstructionsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

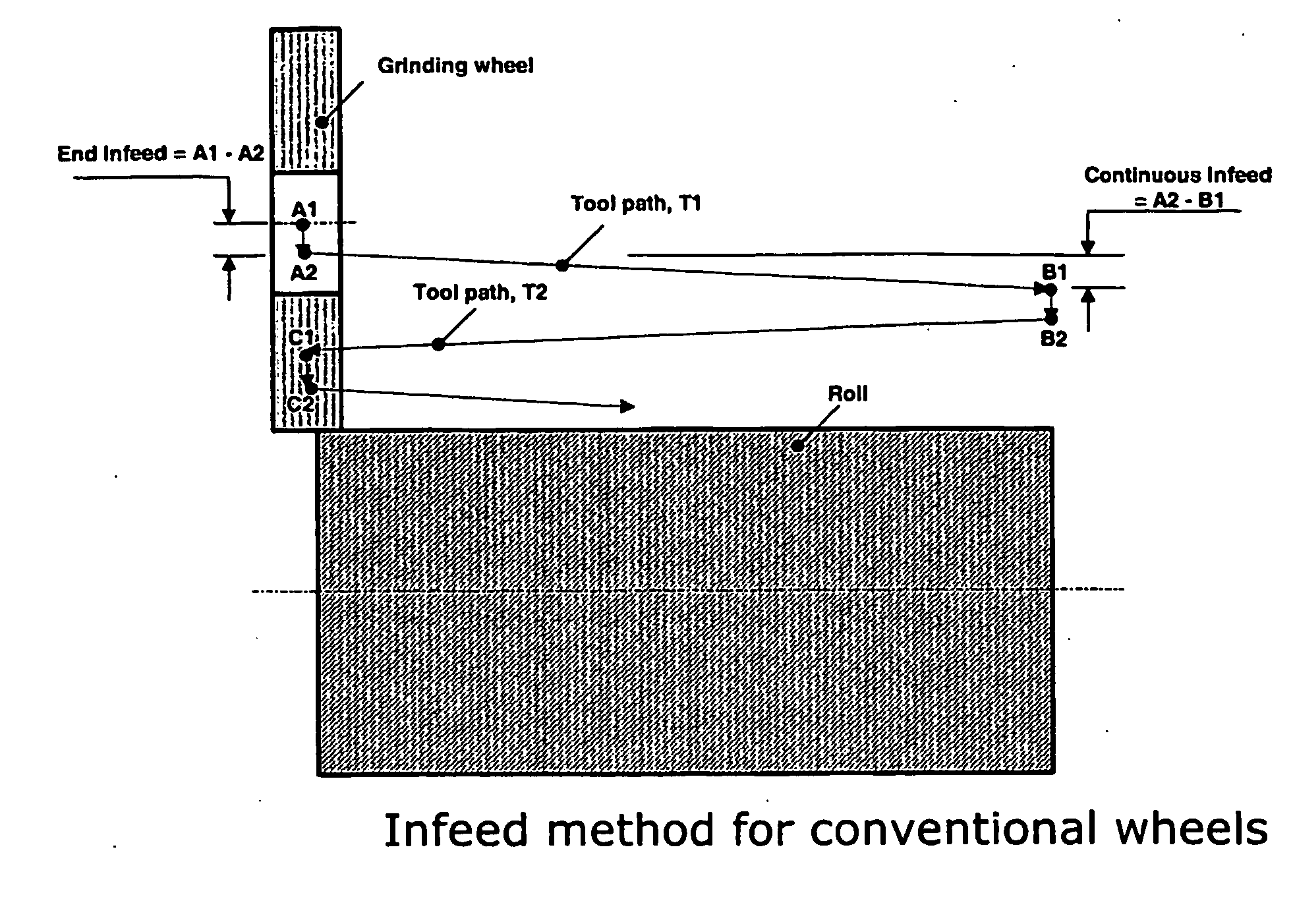

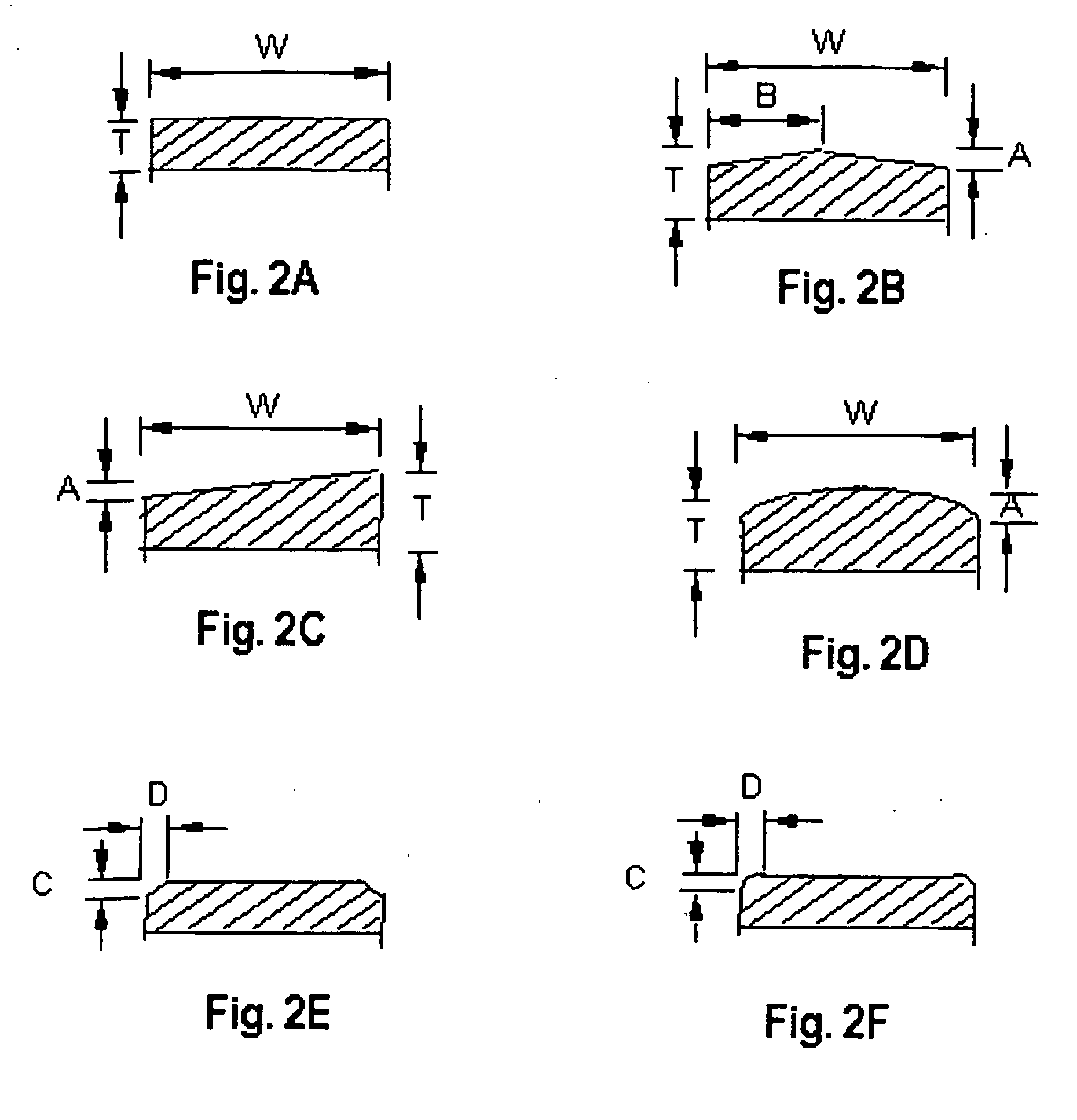

Grinding wheel for roll grinding application and method of roll grinding thereof

ActiveUS20070099548A1Constant speed ratioLong grinding lifeRevolution surface grinding machinesRolling equipment maintainenceBoron nitrideWheel wear

Iron and steel rolls are ground to production quality requirements with a grinding wheel that requires minimal wheel wear compensation, profile error compensation or taper error compensation during the grinding process. The grinding wheel consists essentially of a superabrasive material selected from the group of natural diamond, synthetic diamond, cubic boron nitride, and mixtures thereof, in a bond system, for a grinding wheel with extended wheel life, and which removes minimum amount of stock off the roll to achieve desired roll geometry.

Owner:DIAMOND INNOVATIONS INC

A Rigid Composite Structure with a Superhard Interior Surface

InactiveUS20070256345A1Easy to keepHigh strengthCylinder headsCylindersSuperhard materialPolycrystalline diamond

A rigid composite structure has a first bore formed in a metallic material and a second bore formed by a super hard interior segment or segments disposed within the first bore. Each segment may be lined adjacent to one another and held under compression within the first bore. The segments may be made of super hard materials such as natural diamond, synthetic diamond, polycrystalline diamond, single crystalline diamond, cubic boron nitrate or other superhard composite materials which exhibit low thermal expansion rates and are generally chemically inert. The resultant rigid composite structure may possess higher tolerances to high pressures and high temperatures within the second bore.

Owner:NOVATEK IP +1

Method for preparing high-performance polycrystalline diamond by utilizing hinge-type cubic press

ActiveCN103331129ATightly boundExcellent thermal stabilityUltra-high pressure processesHeat stabilityPolycrystalline diamond

The invention discloses a method for preparing high-performance polycrystalline diamond by utilizing a hinge-type cubic press. The method is characterized in that diamond or diamond-containing carbon powder are taken as raw materials, and any metal or ceramic binder is not added. After purification, the powder surfaces are purified for 0.5 h-5 h at a vacuum degree of 4*10<-3>-4*10<-5> Pa, at the temperature of 800-1500 DEG C. The diamond powder with purified surfaces is pre-formed, placed on the hinge-type cubic press, sintered for 1-30 min at the temperature of 1400-2500 DEG C, under the pressure of 8-20 GPa to prepare high-performance polycrystalline diamond block materials. The high-performance polycrystalline diamond is single in phase, chemical bonds are formed among crystal grains, and integrated closely on a large scale to form high-strength diamond- diamond interfaces. The high-performance polycrystalline diamond is almost the same as natural diamond monocrystalline in hardness, and is better than binder-containing artificial polycrystalline diamond in heat stability and hardness.

Owner:SICHUAN UNIV

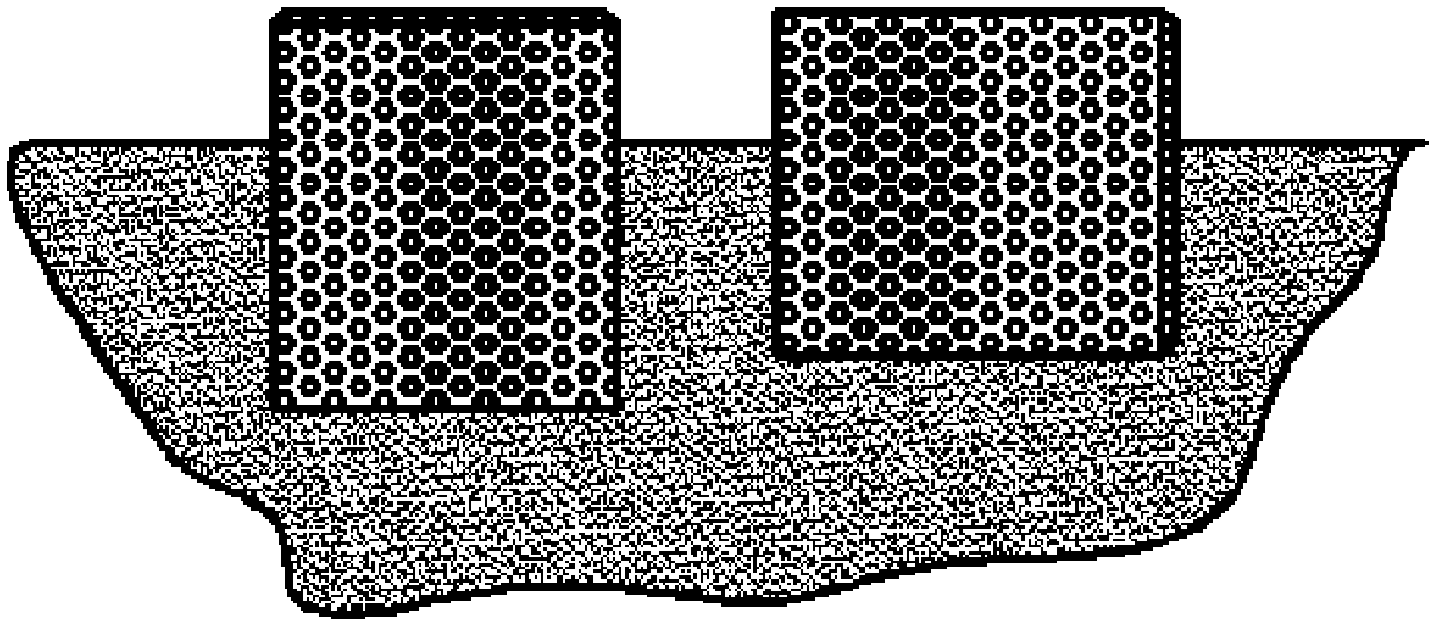

Hot pressed and diamond impregnated drill tooth applicable to strong abrasive hard formation

The invention provides a hot pressed and diamond impregnated drill tooth applicable to a strong abrasive hard formation, which consists of a composite matrix and a natural diamond and is composed by a hot pressing and sintering process, wherein the composite matrix consists of 25-43% of WC (wolfram carbide), 15-25% of casting WC, 15-30% of Cu, 13-20% of Co, 11-17% of Ni, 1-3% of Mn, 1-2% of P and 0.5-1% of artificial single-crystal diamond powder; the natural diamond is a titanium coated natural diamond, the particle size range is 40-100 meshes, and the concentration is 75-110%; and the drill tooth is cylindrical. The drill tooth provided by the invention can be inlaid on a bit matrix in the vertical and horizontal ways and has cutting and grinding combined functions for rock breaking in the soft and hard interlaced and abrasive formation, high rock breaking efficiency and long service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

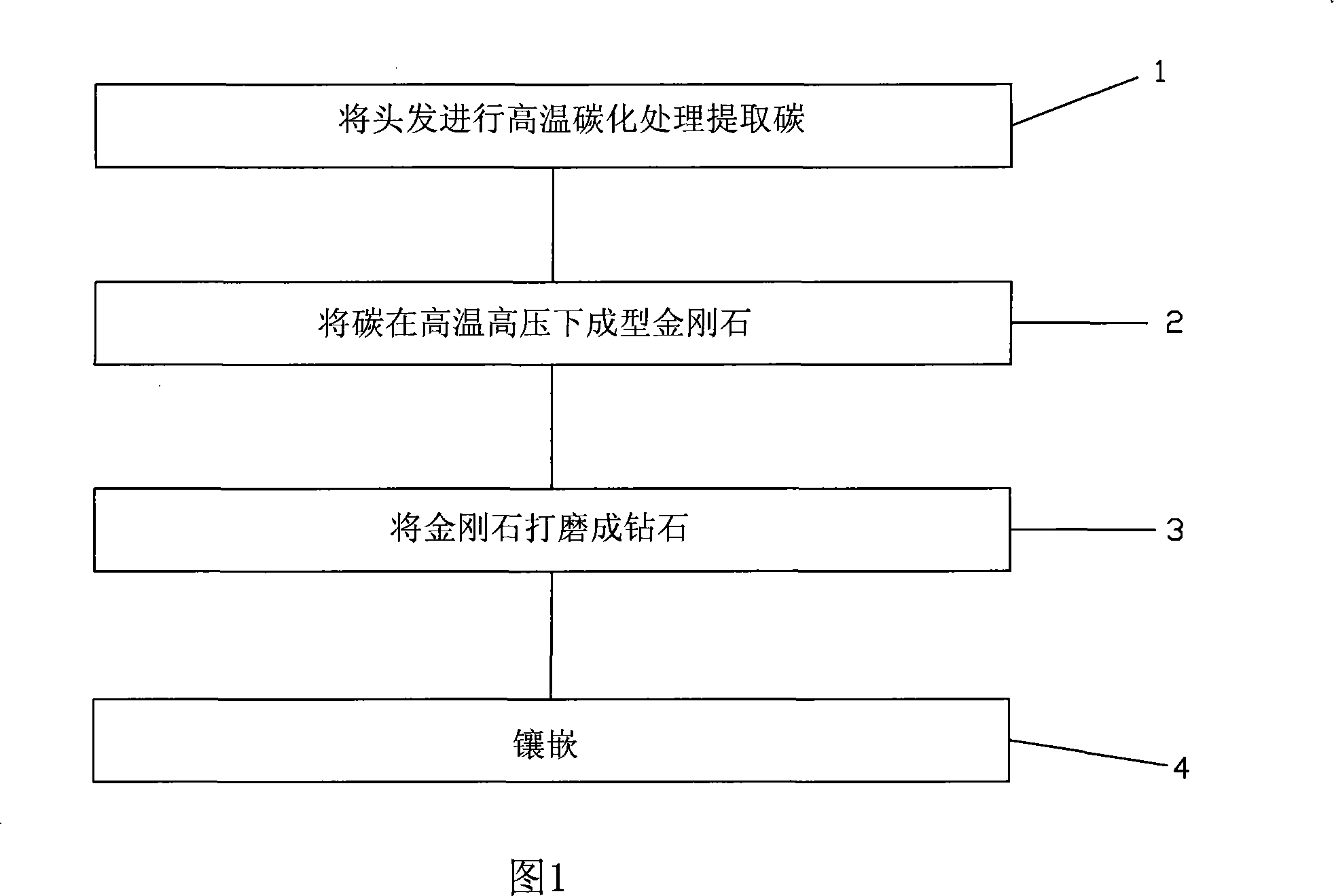

Technique for producing artificial diamond

InactiveCN101171987ALow costEasy accessUltra-high pressure processesJewelleryOptical propertyCarbonization

The invention relates to a manufacturing process of an artificial diamond, which comprises the following steps: step one: hair is processed through high temperature carbonization to extract carbon; step two: carbon is molded into adamas at high temperature and high pressure; step three: the adamas is burnished into the diamond; step four: inlaying is performed. The manufacturing process of the artificial diamond of the invention adopts the hair as the raw material, the cost of the raw material is low, and the acquisition of the raw material is convenient; the acquired artificial diamond has the same optical property, physical property and chemical property as a natural diamond; thereby the artificial diamond has unique emotion bailment meaning and good commercial value.

Owner:邓湘凌

Method for processing polycrystalline diamond for diamond processing

InactiveCN101940893AImprove impact toughnessImprove wear resistanceUltra-high pressure processesPolycrystalline diamondNatural diamonds

The invention provides a method for processing polycrystalline diamond for diamond processing. The method comprises the following steps of: mixing diamond powder and metal nickel serving as basic raw materials with a certain amount of boron, and adding the mixture into a carbon synthetic die; heating the synthetic die in a vacuum furnace in vacuum; putting a vacuum heated semi-finished product into a diamond hexa-orientation press for high temperature high pressure synthesis, and releasing pressure to obtain the polycrystalline diamond PCD for diamond processing. When the polycrystalline diamond PCD prepared by the technical scheme is used for processing the diamond, the product is soft, and has good impact toughness and higher abrasion resistance. Compared with polycrystalline diamond TSP series for petroleum and core bits, the polycrystalline diamond PCD has much lower abrasion consumption; and compared with natural diamond, the polycrystalline diamond PCD has higher grinding efficiency. Furthermore, the product has good self-sharpening performance and high grinding efficiency.

Owner:ZHENGZHOU SANHE DIAMOND

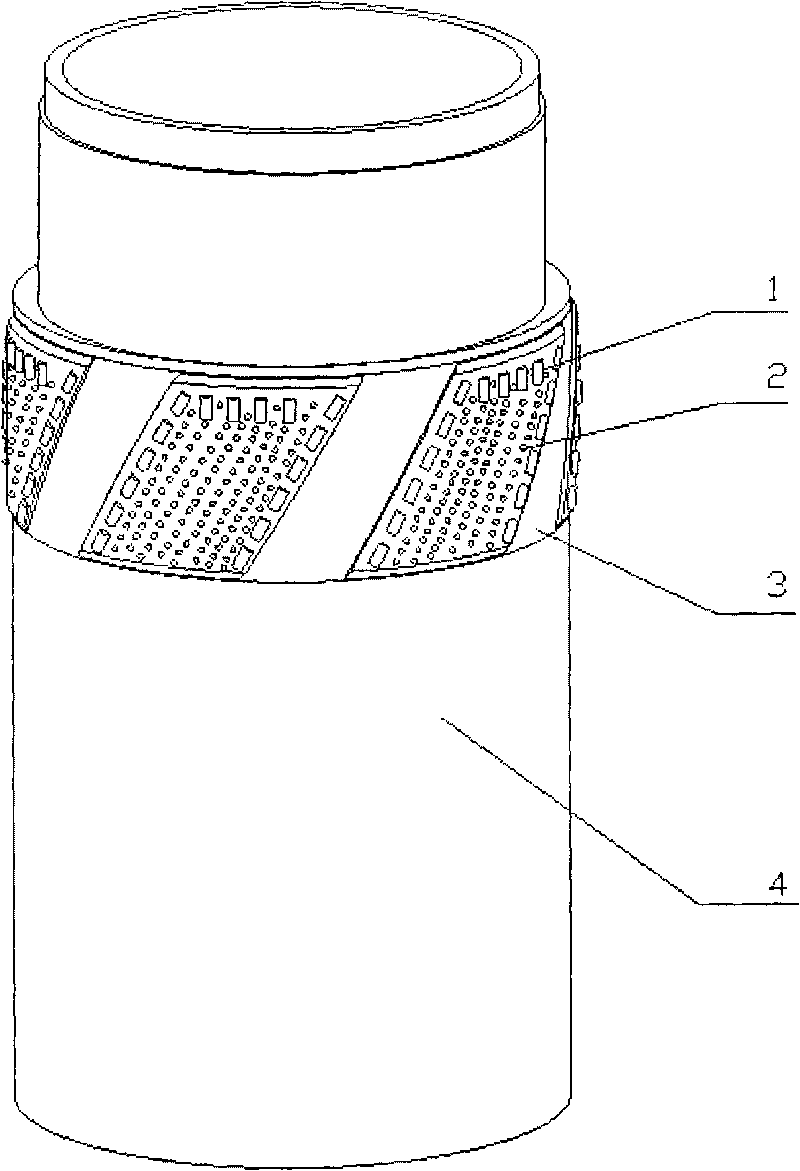

Natural diamond impregnated bit for geological exploration and preparation method thereof

The invention relates to a natural diamond impregnated bit for geological exploration and a preparation method thereof. The coarse-grain natural diamond impregnated bit for the geological exploration comprises a steel body and a carcass sintered at the top end of the steel body, wherein the carcass is made of nano pre-alloyed powder by sintering, and natural diamonds with the grain size of 0.8 to 1.7 millimeters which are arranged regularly in order are impregnated and sintered in a working lining of the carcass. The invention also relates to a method for preparing the natural diamond impregnated bit. In the method, the natural diamonds are impregnated in the nano pre-alloyed powder carcass to improve the impregnating fastness and the utilization ratio of the natural diamonds. The speed of the natural diamond impregnated bit for drilling mud rocks, shale rocks and lime rocks can reach 5 meters per hour, and the service life of the natural diamond impregnated bit can reach 1,625 meters.

Owner:长沙锐合钻石工具有限公司

Hot-press diamond-impregnated drill bit and manufacturing method thereof as well as application of hot-press diamond-impregnated drill bit to strong-abrasiveness hard formation

InactiveCN103028731AImprove rock breaking efficiencyImprove wear resistanceDrill bitsCarbideTitanium

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for homogeneous endotaxy repair and homogeneous epitaxial growth of diamond single crystal

InactiveCN101696515AAchieve a breakthroughHigh transparencyPolycrystalline material growthFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention relates to a method for homogeneous endotaxy repair and homogeneous epitaxial growth of a diamond single crystal. The method is characterized by comprising the step of carrying out endotaxy repair and epitaxial growth of vapor deposition at a temperature between 700 DEG C and 2,000 DEG C by adopting CVD chemical vapor deposition diamond equipment and taking the diamond single crystal as a seed crystal. The method can simultaneously realize homogeneous endotaxy repair and homogeneous epitaxial growth of the diamond single crystal, can be used for repairing the inside cavity, cracks and other defects of the traditional diamond, removing the internal impurities and color of the diamond and increasing the transparency and the cleanliness and can carry out homogeneous epitaxial growth in various orientations of the outer surface of the diamond single crystal to obtain a larger pure diamond single crystal. The method has mild realization condition and low running cost, and can be used for repair and growth of seed crystals of artificial and natural diamond single crystal.

Owner:宋建华

Surface set natural diamond bit and production process

The invention discloses a surface set natural diamond bit, the carcass surface is inserted with natural diamond. Its production processes are: the first step, bit carcass cold-pressed forming, and binding natural diamond on the pre-modeling blocks; the second step, putting the pre-modeling blocks into the graphite mold; the third step, laying steel body on the graphite mold; the fourth step, non-pressure sintering; the fifth step, machining and finishing the products. The surface set natural diamond bit produced through the invention cam avoid the defect of diamond can not be used fully of the ordinary man-made diamond bit working layer, the cold-pressed forming also avoids the phenomenon of metal powder leak in the heat pressing forming sintering process, the consumption of metal (or alloy) is saved. The drilling efficiency of the surface set natural diamond bit is increased 30%, the drilling life is increased 100%. The invention is a manufacture process of surface set natural diamond bit has long use life of nit, low sintering temperature and short sintering time.

Owner:长沙锐合钻石工具有限公司

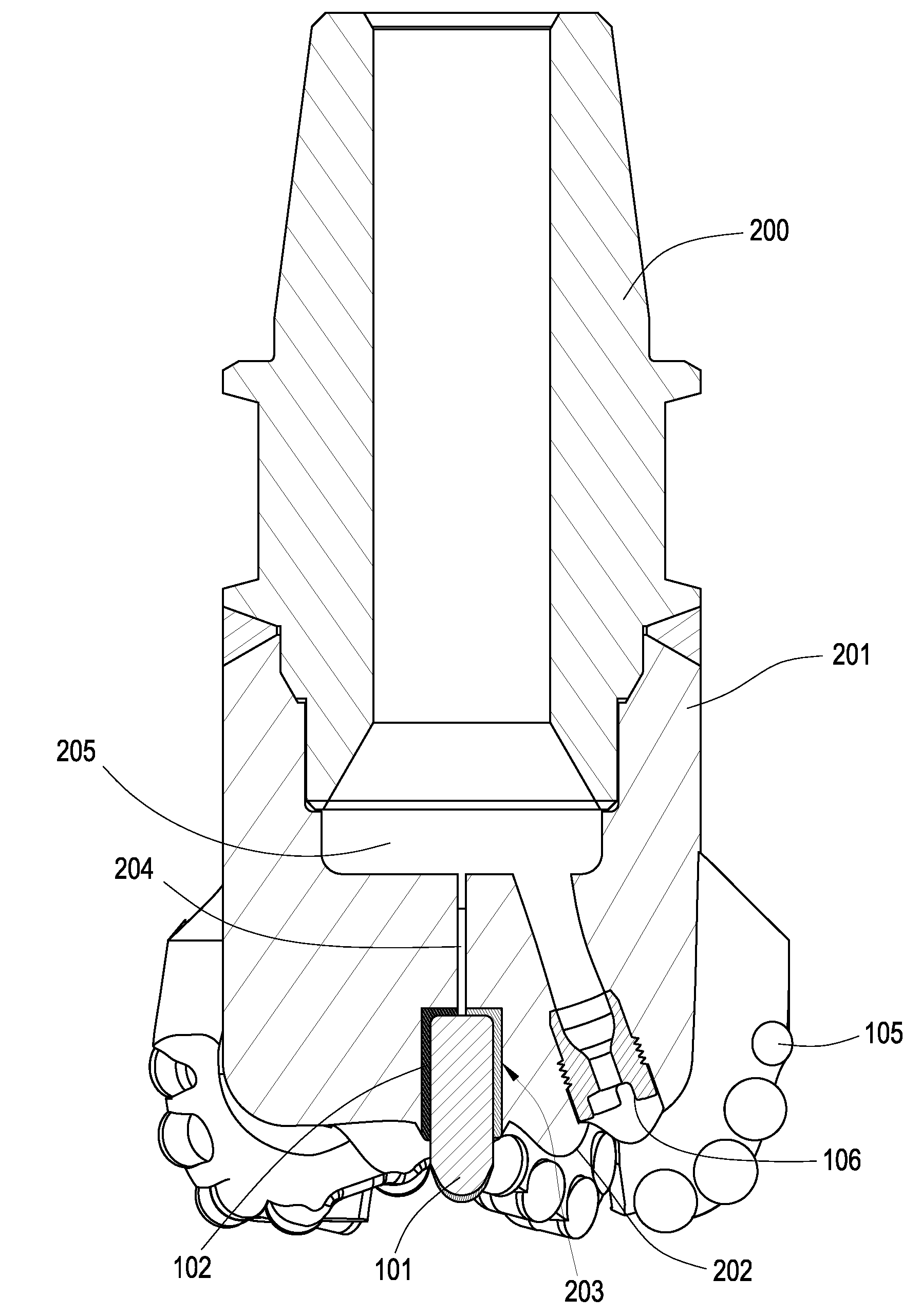

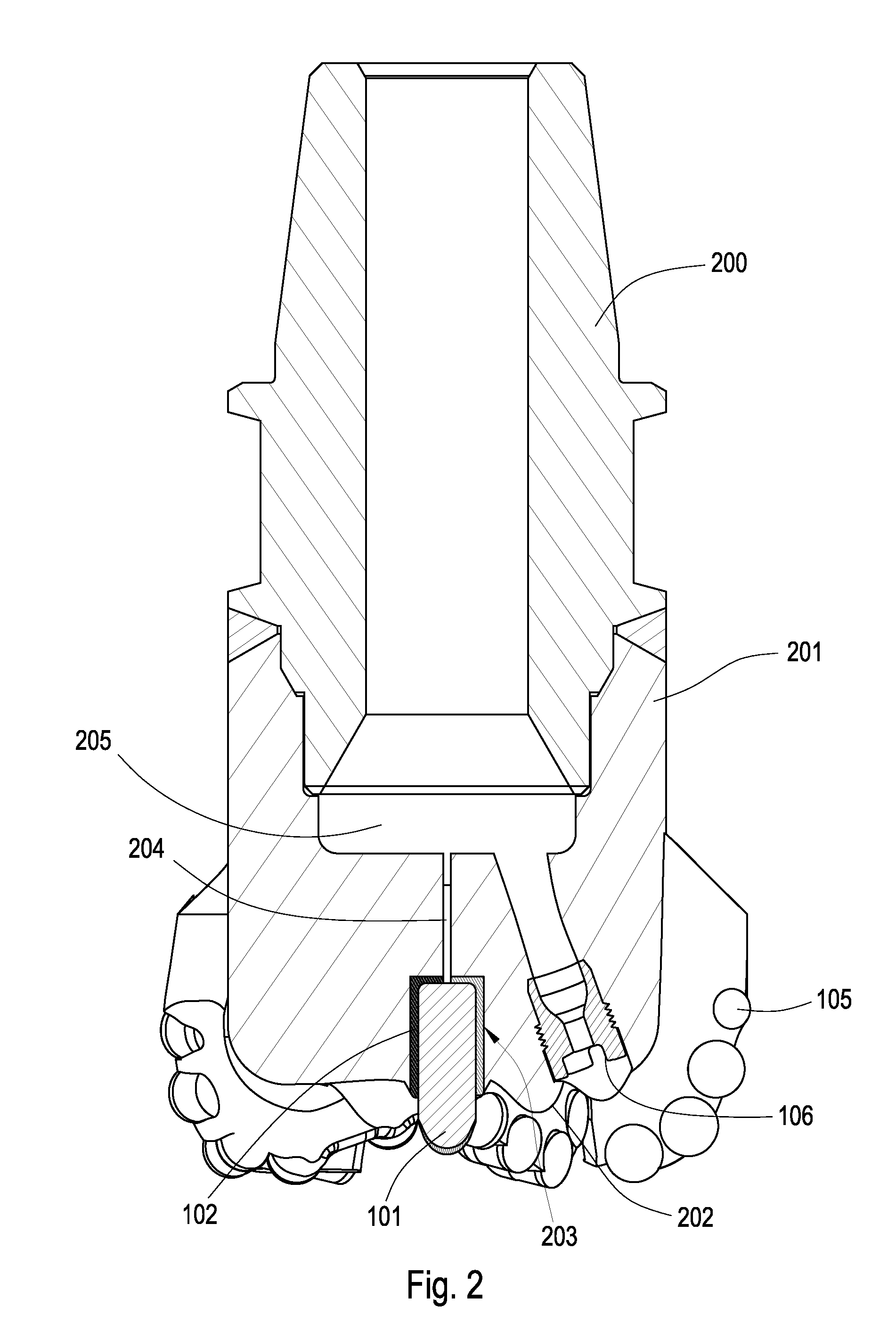

Method of Assembling a Drill Bit with a Jack Element

A method of assembling a drill bit with a bit body intermediate a shank and a working face with a plurality of blades comprised of at least one cutting element. The working face also comprising a jack element disposed within a pocket that may be substantially coaxial with the axis of rotation of the drill bit. The jack element may comprise an abrasion resistant material comprised of a material selected from the following including natural diamond, polycrystalline diamond, boron nitride, tungsten carbide or combinations thereof The jack element may be press fit within a pocket that is brazed within a receptacle of the drill bit such that it is substantially centered coaxial to the rotation of the drill bit.

Owner:SCHLUMBERGER TECH CORP

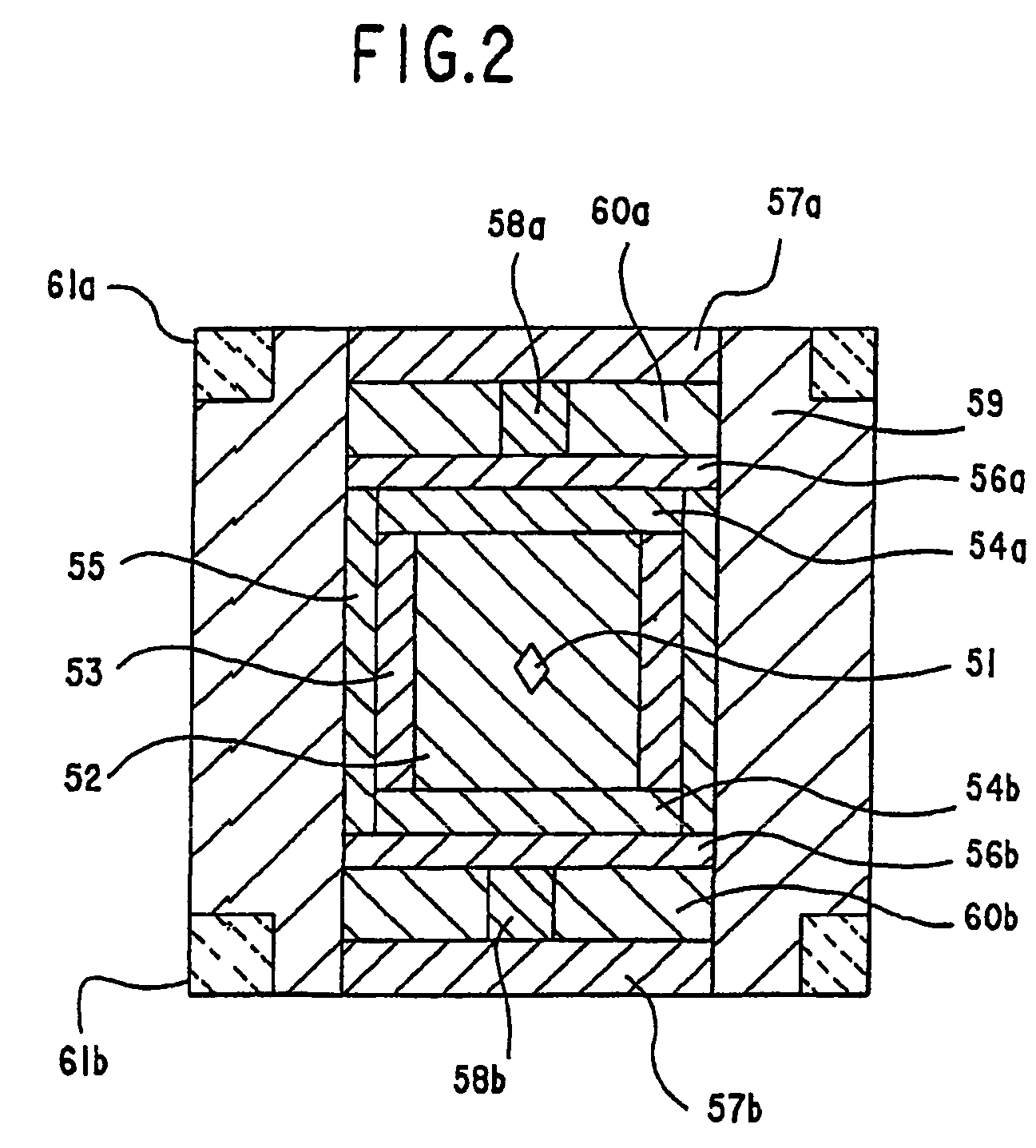

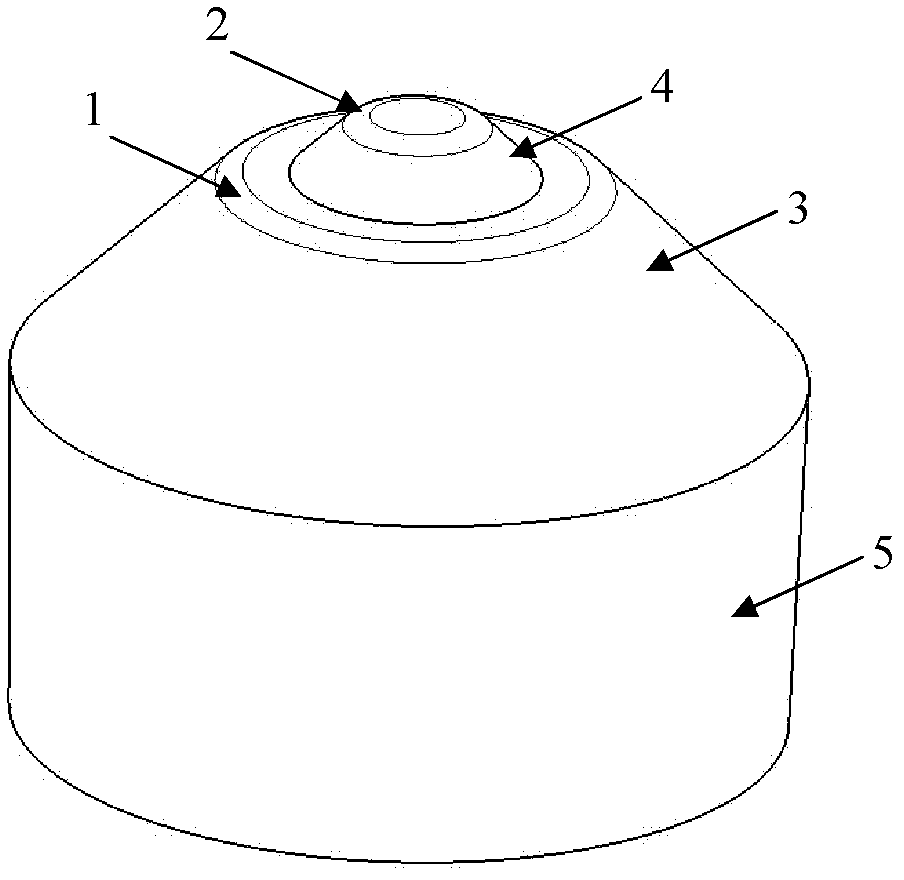

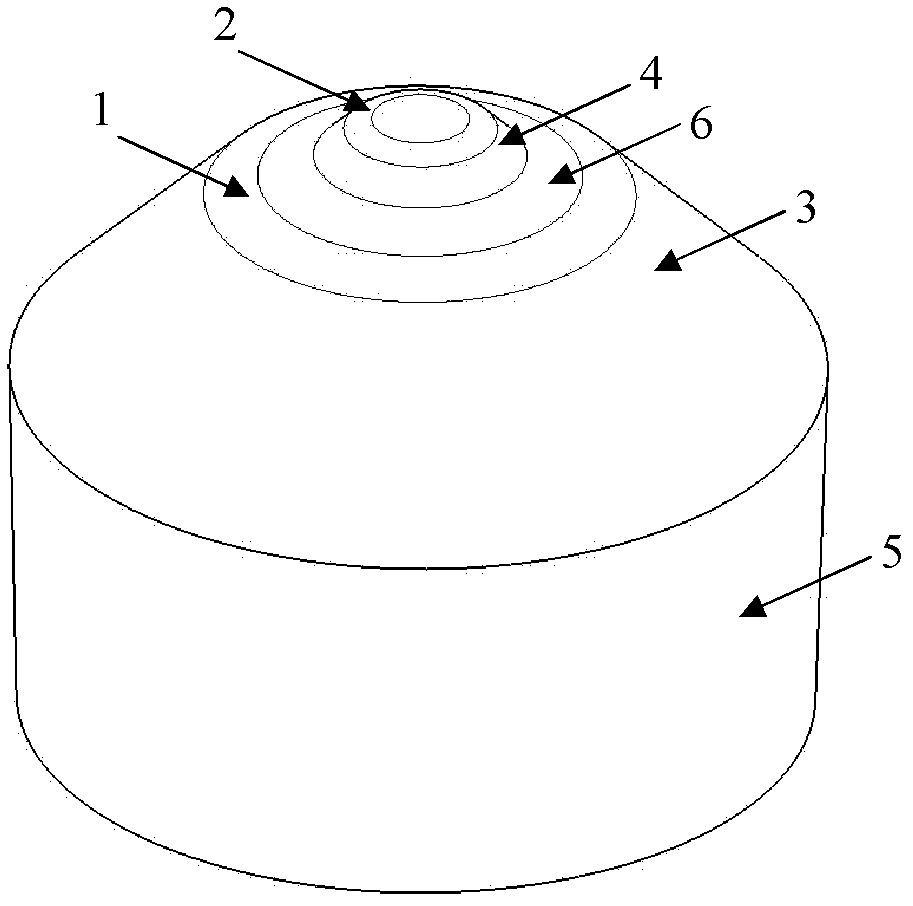

Multi-stage filleted high-pressure anvil

InactiveCN102527296AReduce investmentEasy to operateUltra-high pressure processesSuperhard materialStress concentration

The invention discloses a multi-stage filleted high-pressure anvil and relates to exploration of synthesizing preparation tools for novel superhard materials such as diamond, cubic boron nitride and products thereof, and novel materials which cannot be prepared at normal pressure, and belongs to the technical field of ultra-high pressure. The top of the multi-stage filleted high-pressure anvil has a multi-stage platform structure with fillets; the bottom of the multi-stage filleted high-pressure anvil is a column with fillets; the transition between the top and the bottom is realized by a symmetrical curved surface or a fan-shaped bevel; and the high-pressure anvil is made of steel, hard alloy, a diamond sintered body, a cubic boron nitride sintered body or natural diamond and other high-hardness materials. The defects of structural design of corners and a first-stage platform of the conventional anvil are overcome; the stress concentration effect of the anvil can be reduced; the service life of the anvil can be prolonged; the cavity pressure of hundreds of thousands to millions of atmosphere pressures can be obtained; and the multi-stage filleted high-pressure anvil can be widely applied to an anvil device, a multi-surface ejecting high-pressure device and a multi-stage boosting device, and can meet research requirements of high-pressure physics and high-pressure biology on a matter system at high temperature and high pressure.

Owner:JILIN UNIV

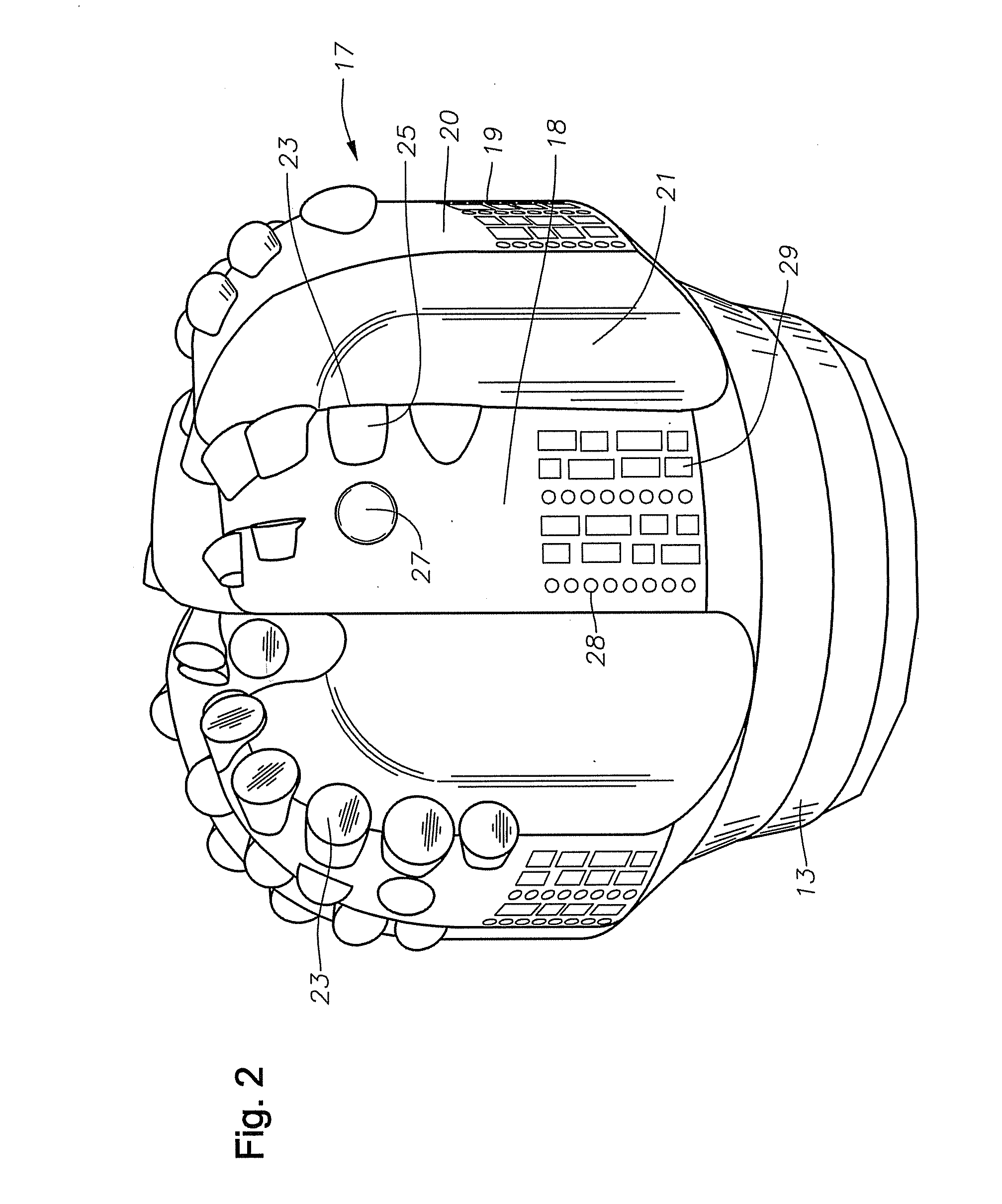

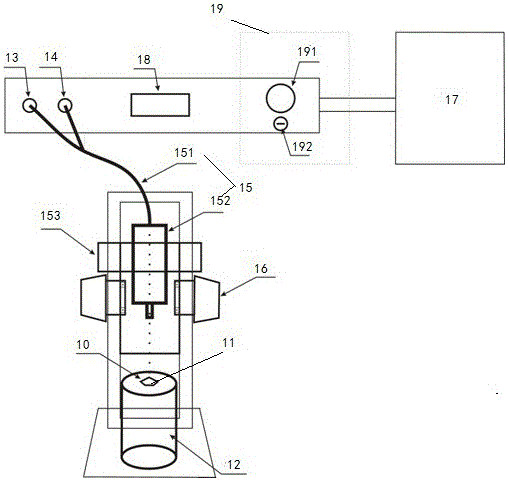

Instrument for examining gemstone

InactiveCN1459023AEasy to useQuick to useInvestigating jewelsFluorescence/phosphorescenceDisplay deviceHigh pressure

The instrument has a housing (1) mounting the following components to provide a self-contained, stand-alone instrument: a compact solid state 532nm laser 9 coupled to a window (5) in a thermally-insulated container (2) for liquid nitrogen and the gemstone (4); a compact solid state diode 655 nm laser (10) coupled to the window (5); two compact, sensitive CCD spectrometers 11 and 11 detecting luminescence features with zero-phonon lines at in the range 550-1000 nm; a processor (17) for processing the signals from the spectrometers 11 and 11 to indicate whether the gemstone (4) is a natural diamond which has not been subjected to irradiation treatment or hgih-pressure high-temperature treatment; and a display (18). The container (2) has a cover (6) and a pin (8) which is used to place and hold the gemstone (4) against the window (5).

Owner:DE BEERS UK LTD

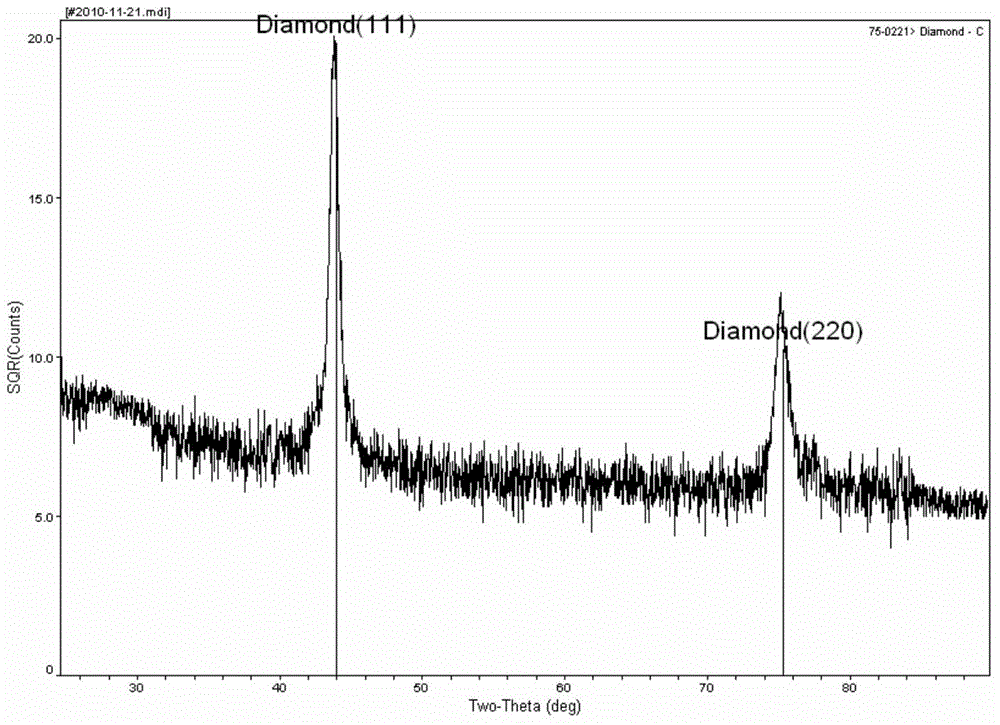

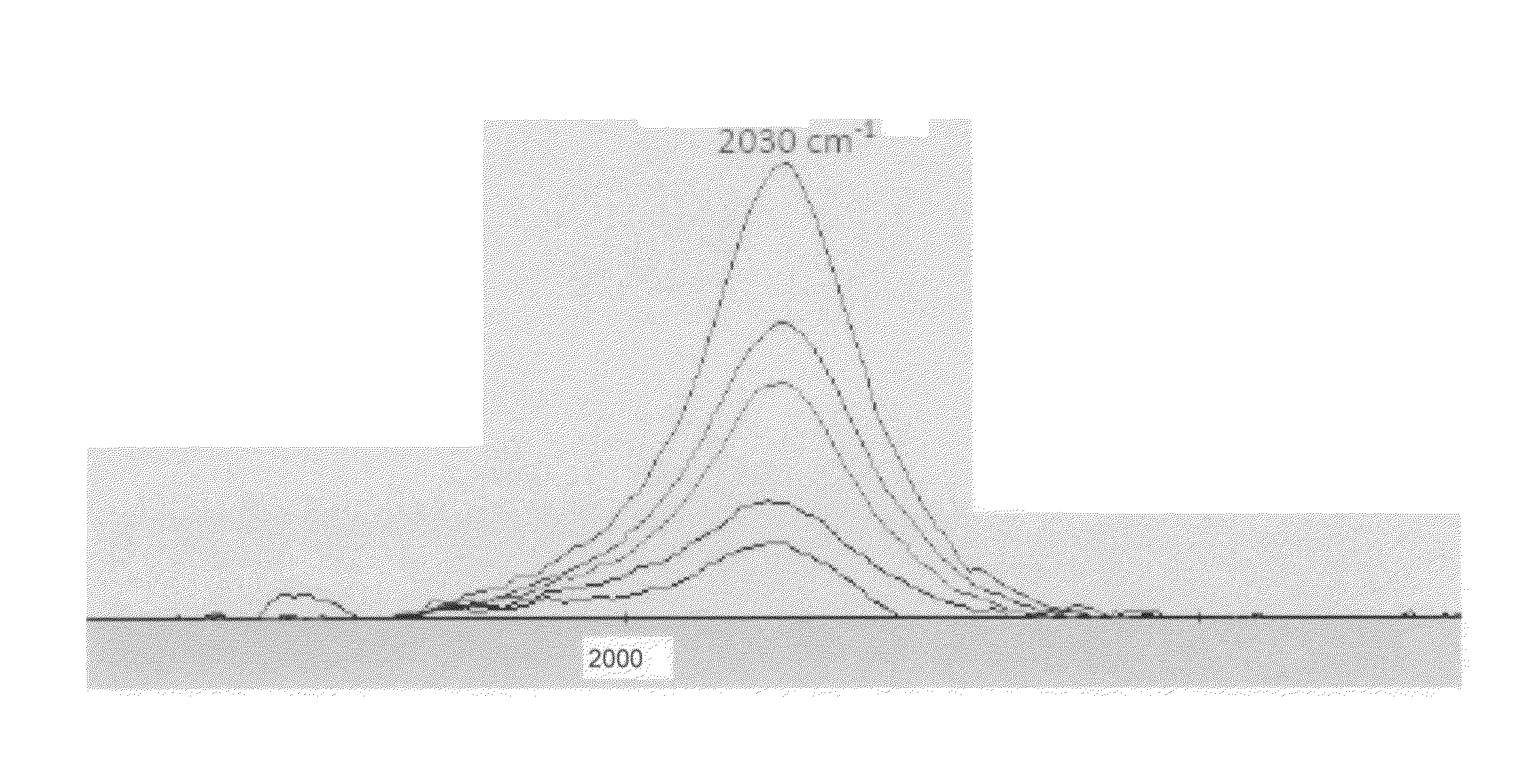

Examination method for distinguishing between natural diamond and synthetic CVD/HPHT diamonds

InactiveUS20160109374A1Method is fastRaman scatteringInvestigating jewelsOptical spectrometerPhysical chemistry

This invention is within the technical field of distinguishing between natural diamond and synthetic CVD and HPHT diamonds, involves an examination technique using the Raman spectra. Procedurally, a highly sensitive Raman spectrometer (S / N>10,000) is used to scan and examine the diamond sample. The spectrometer is fitted with a tailor-made probe that has a large facula and surface area. Specially developed software is then used to perform an intensity correction and a background elimination to obtain a specific Raman spectral range (250-2800 cm−1) with the corrected intensity and a smooth baseline. Next, the Raman peak intensity of 2030 cm−1 (the post-correction and -standardization characteristic peak) is used as a basis to distinguish between natural diamond and synthetic CVD and HPHT diamonds. This method has the advantages of being non-destructive, simple, fast, and practical identification for diamonds.

Owner:PAN DONG SHYOGN

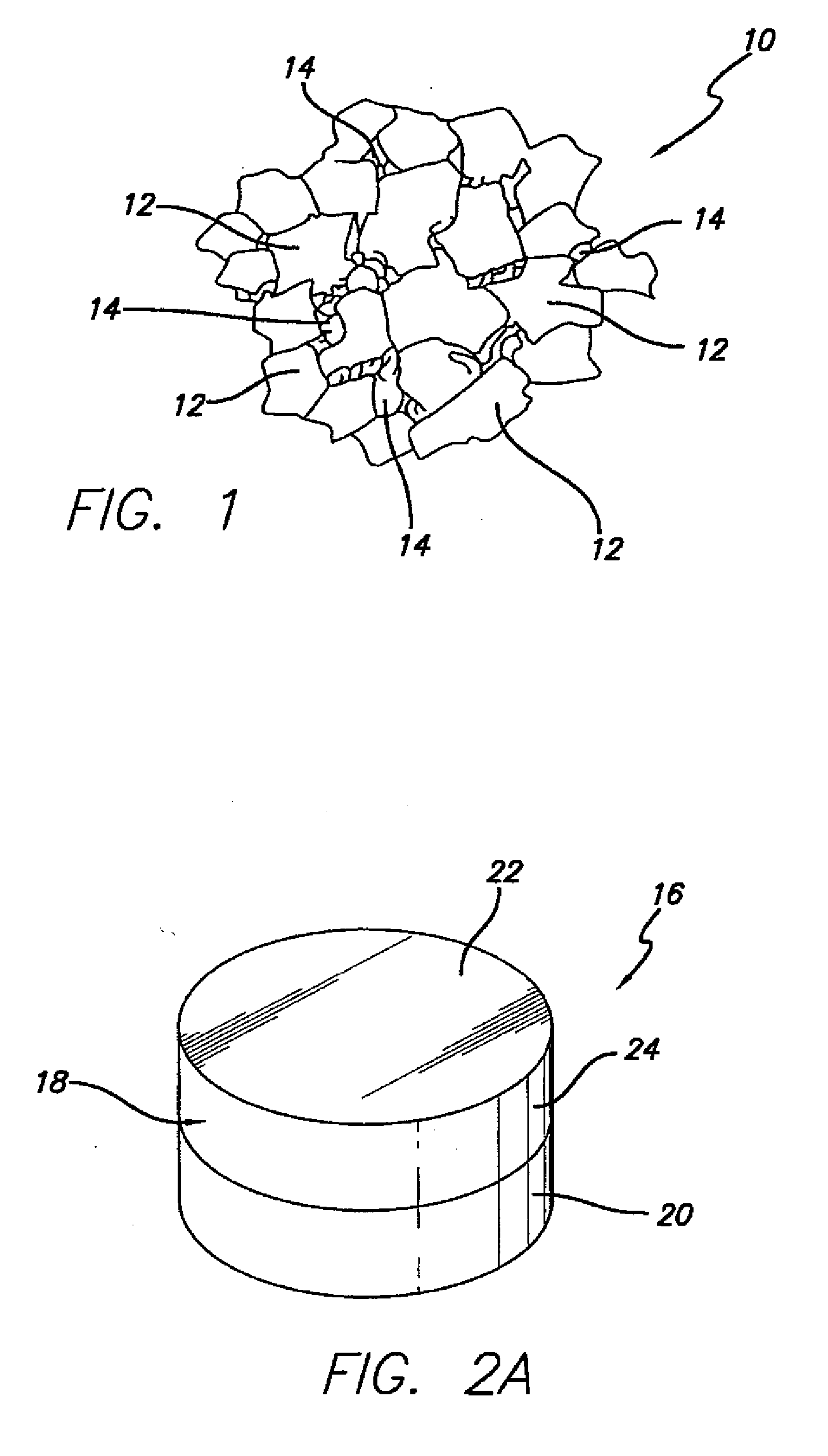

Superfine particulate diamond sintered product of high purity and high hardness and method for production thereof

InactiveUS20060115408A1High hardnessReliably producedMaterial nanotechnologyUltra-high pressure processesFreeze-dryingHardness

Disclosed is a high-purity high-hardness ultrafine-grain diamond sintered body having a grain size of 100 nm or less, which is produced by subjecting an ultrafine-grain natural diamond powder having a grading range of zero to 0.1 μm to a desilication treatment, freeze-drying the desilicated powder in solution, enclosing the freeze-dried powder in a Ta or Mo capsule without a sintering aid, and heating and pressurizing the capsule using an ultrahigh-pressure synthesizing apparatus at a temperature of 1700° C. or more and under a pressure of 8.5 GPa or more, which meet the conditions for diamond to be the thermodynamically stable. The present invention can synthesize a diamond sintered body under a lower pressure than that in a conventional method, with a diamond's original hardness and without containing any sintering aid.

Owner:JAPAN SCI & TECH CORP +1

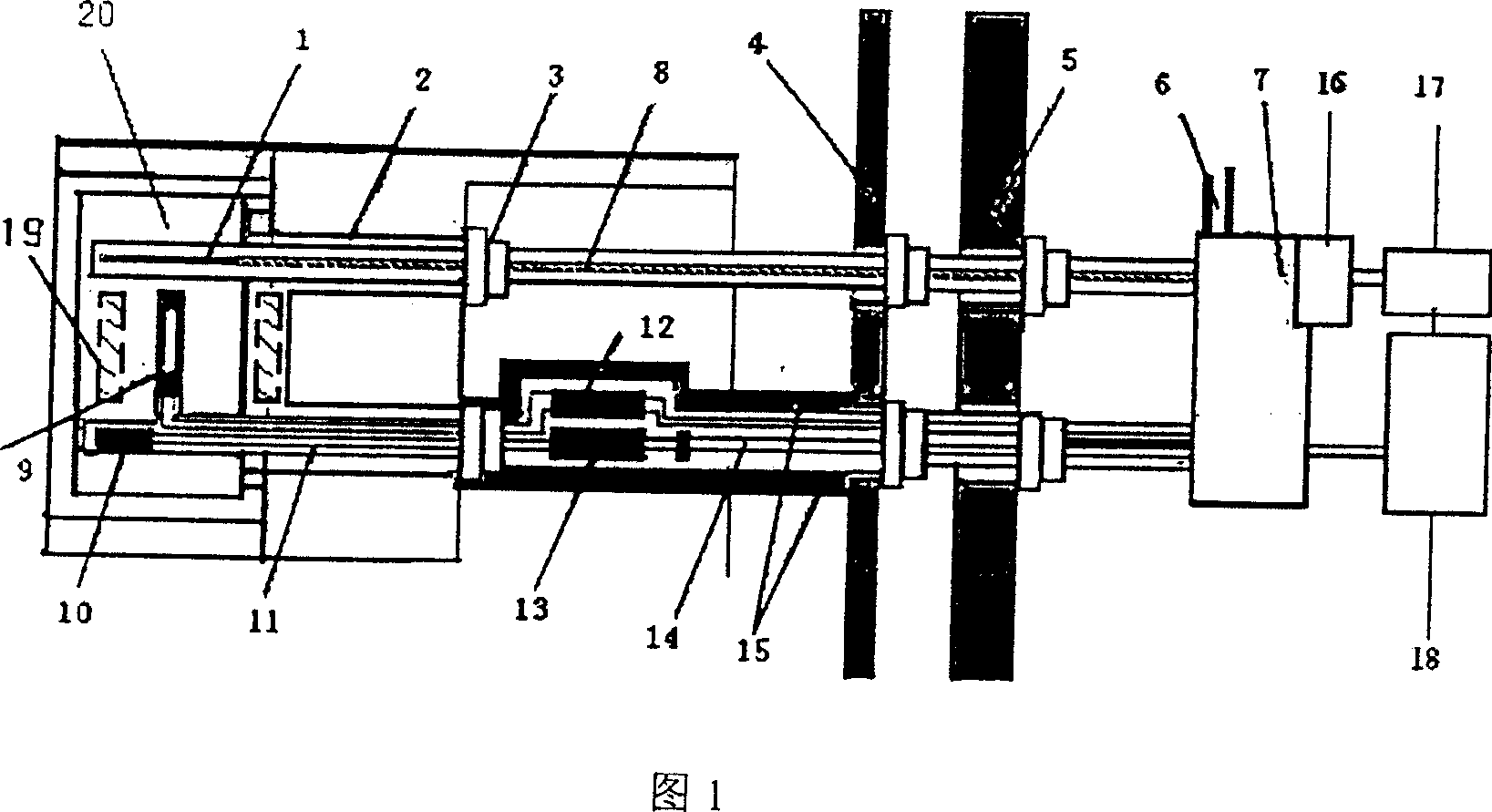

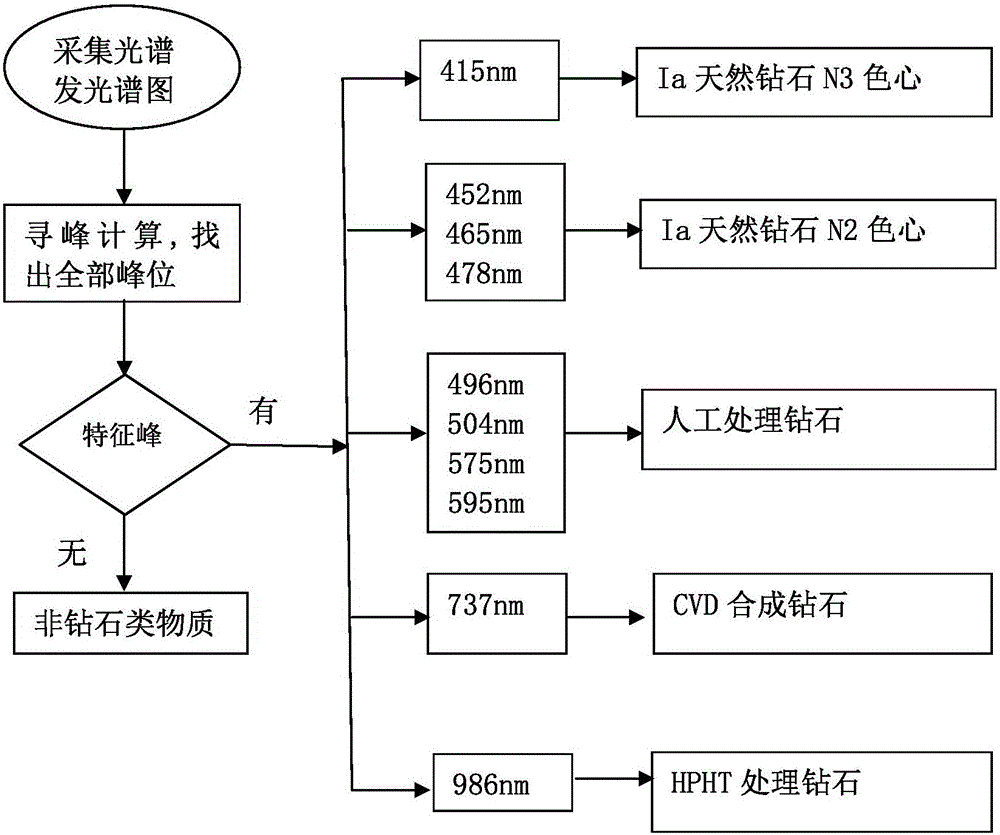

Quick detection method and detection device of diamond luminescent spectrum

PendingCN105866074AEasy to detectEasy to operateAnalysis by material excitationOptical spectrometerSpectrograph

The invention discloses a quick detection method and detection device of a diamond luminescent spectrum. The method includes the following steps that the surface of a diamond sample is irradiated by lasers with the wavelength of 405 nm; after the lasers irradiate features of lattice defects on the surface of the diamond sample, a photoluminescence phenomenon is generated, and the spectrum is formed; the spectrum is received by a spectrograph through an optical fiber mechanism and transmitted to a computer display screen; peak position feature spectrum charts of the corresponding lattice defects are displayed by the computer display screen according to different features of the diamond sample; according to the peak position features of the spectrum charts, it is confirmed that diamond is natural or synthesized; when the peak positions of the spectrum position are at the 415 nm position and the 741 nm position, it can be confirmed that the diamond is natural diamond; if the peak position of the spectrum position is at the 737 nm position and no 415 nm peak position exists, it can be confirmed that the diamond is synthesized through the chemical vapor deposition method; if the peak positions of the spectrum position are on the 883 nm position and the 884 nm position, it can be confirmed that the diamond is high-temperature high-pressure synthesized diamond. The method and device have the advantages that detection is easy, operation is convenient and distinguishing is accurate.

Owner:珠宝玉石首饰国检集团深圳研究所有限公司

Production technology of tin-plated wire-drawing die slip-in cover

The production process of tinned wire-drawing die inserting cover includes the procedure steps of pressing die, drawing die the turning, etc. Said invention utilizes selection of technological die cover and die core whose melting point is higher than that of internal metal powder, so that when they are heated and pressurized, said technological die cover and die core can not be deformed, and the natural diamond is covered with sintered body, so that under the condition of high temp. and high pressure the pressure acting on the natural diamond covered with sintered body is small, and said natural diamond can not be easily broken, and it is favorable for turning bell mouth in next process, and is favorable for identification of broken diamond.

Owner:周民

Downhole rock scratcher and method for identifying strength of subsurface intervals

Disclosed are a tool and method for identifying the relative strength of subsurface intervals through which a borehole has been drilled. The tool includes a tool body capable of being moved through a borehole. The tool body has pads mounted on movable arms. Preferably the arms can be loaded independently. Each pad carries scratchers, which are pushed against the borehole wall so as to create either deep narrow or shallow wide scratches. Preferably, the scratchers comprise either a single or dual element polycrystalline compact (PDC) cutter or suitable hard, wear resistant material such as tungsten carbide or natural diamond, and are pushed against the borehole wall by resiliently loaded arms. The depth of narrow scratches is measured, for example, by two tandem powered calipers and the width of wide scratches is visualized by a borehole imager.

Owner:SCHLUMBERGER TECH CORP

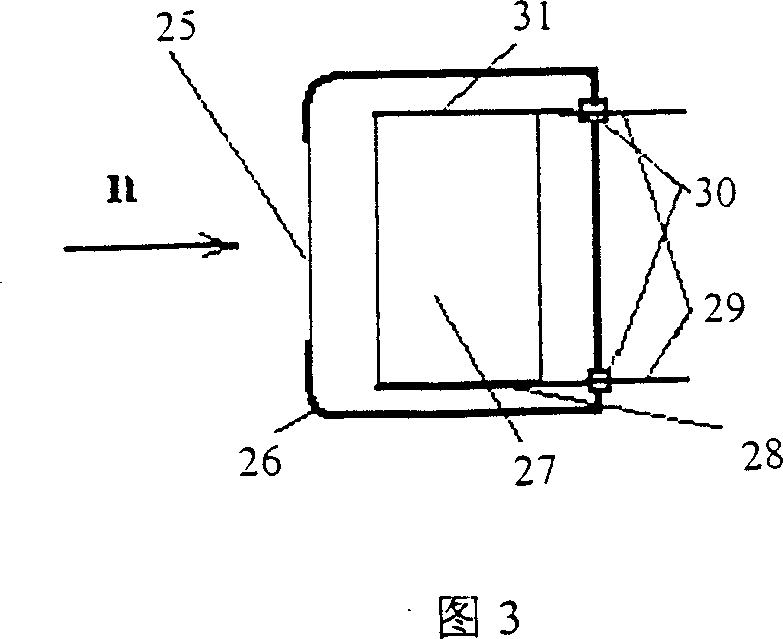

Neutron flux and energy spectrum measuring system of helium cooling solid multiplication agent tritium producing cladding

ActiveCN1948997ASimple designNuclear energy generationNeutron radiation measurementBiological activationHelium gas

The invention relates to fusion reactor tritium generating cladding neutron measuring. Helium cooling solid breeding agent tritium generating cladding neutron flux and spectrometry measuring system includes packaging foil pneumatic transmitting activation analysis subsystem which includes activation foil and pneumatic transmitting device. The activation foil is set in the measuring tube connected with operating station through cooling layer and biological shielding layer. The operating station is set helium cooling circuit and connected with helium gas dynamic force union station and HPGe measuring station connected with electronics and data gaining system. The solid breeding agent tritium generating cladding is also set micro-fission chamber combination detector and natural diamond neutron energy spectrum detector which are connected with operating station through current sensitive preamplifier and charge sensitive preamplifier, which is connected with electronics and data gaining system.

Owner:SOUTHWESTERN INST OF PHYSICS

Method and device for batch inspection of diamonds

InactiveCN105136705AEasy to remove one by oneSolve the detection speed is slowInvestigating jewelsColor/spectral properties measurementsRelative displacementSurface layer

The invention discloses a method and device for batch inspection of diamonds. The diamonds to be inspected are placed on a working table. A Y type optical fiber comprises a light inlet, a light outlet and a lighting opening, wherein the light inlet of the Y type optical fiber is connected with a light source, the light outlet of the Y type optical fiber is connected with a spectrograph, and the lighting opening of the Y type optical fiber corresponds to the diamonds being inspected in position; a driving device is arranged between the lighting opening and the working table and can drive the lighting opening and the working table to move relatively, and the diamonds to be inspected on the working table are scanned and inspected one by one through the relative movement of the lighting opening. According to the device and method, the driving device is adopted for driving the lighting opening and the working table to move relatively, manual movement is not needed, and then inspection speed and stability are improved; a light extinction layer serves as the surface layer of the working table and can reduce background reflectance during inspection and improve inspection precision; full-spectrum analysis is adopted, so that identification precision is improved and synthetic diamonds and natural diamonds are effectively distinguished.

Owner:BIAOQI ELECTRONICS TECH

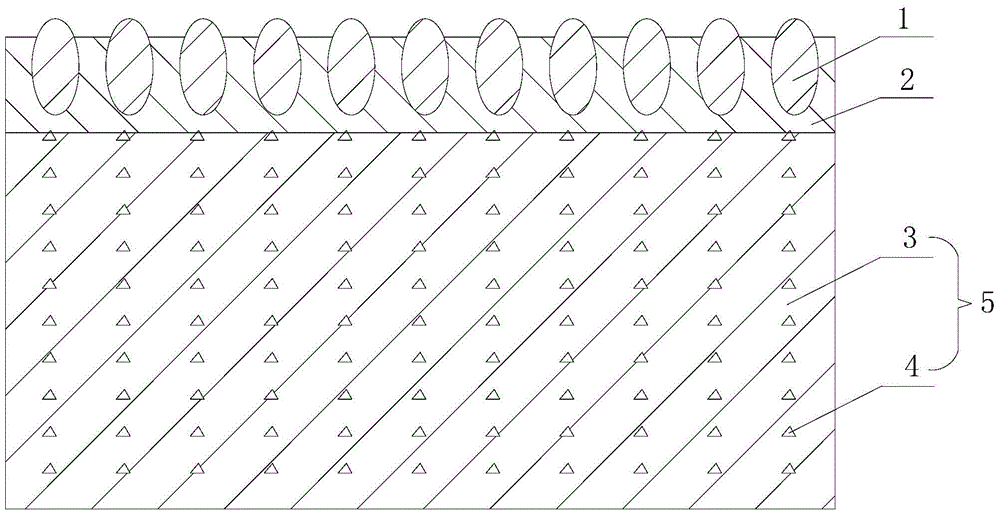

Surface-set reamer used in geological exploration and manufacturing method thereof

InactiveCN101705790AImprove wear resistanceExtended service lifeDrill bitsPolycrystalline diamondReamer

The invention relates to a surface-set reamer used in geological exploration and a manufacturing method thereof; the surface-set reamer comprises a steel body; the upper part of the steel body is sintered and fixed with a matrix, the surface of which is regularly and orderly inlaid with natural diamond particles and cylindrical artificial polycrystalline diamond; the matrix is formed by uniformly blending and sintering common metal powder with 200 meshes to 300 meshes, nanometer prealloying powder and micro-artificial polycrystalline diamond particles with 150 meshes to 200 meshes (weight ratio: common metal powder: nanometer prealloying powder: micro-polycrystalline particle is equal to 3:3:1). The invention also provides a manufacturing method of the surface-set reamer. The surface-set reamer used in geological exploration has strong abrasion performance and drills in broken strata, and the service life of the surface-set reamer reaches more than 3200 meters.

Owner:长沙锐合钻石工具有限公司

Photoluminescent diamond detection method and photoluminescent diamond detection device

InactiveCN105784648APrecise screeningHigh sensitivityRaman scatteringFluorescence/phosphorescencePhotoluminescenceLength wave

The invention discloses a photoluminescent diamond detection device. The photoluminescent diamond detection device comprises a light source, a workbench, an array detector and a data processing terminal. A to-be-detected sample is placed on the workbench. The light source is monochromatic light or hybrid light with the wavelength of smaller than or equal to 410nm. The light source emits the light to the to-be-detected sample, the to-be-detected sample acquires energy and is excited to emit light, luminous light rays are emitted into the array detector to be detected, photon information of the luminous light rays is converted into an electric signal according to wavelength sequence, the electric signal is converted into a digital signal through analog-digital conversion, the digital signal is transmitted to the data processing terminal to form a real-time photoluminescent spectrogram. The photoluminescent diamond detection device has the advantages that multiple peak positions can be measured at a time by a photoluminescence method, the problems such as whether the to-be-detected sample is a diamond, a compound diamond or a natural diamond or not are solved, detection sensitivity and detection speed are high, and detection cost is low.

Owner:BIAOQI ELECTRONICS TECH

Diamond-impregnated bit with double cutting structures

InactiveCN105952382AImprove crushing efficiencyIncrease ROPDrill bitsConstructionsGeological explorationFoundation engineering

The invention discloses a diamond-impregnated bit with double cutting structures, belonging to the technical field of drilling equipment for petroleum and natural gas, mine engineering, building foundation engineering construction, geology, hydrology and the like, and solving the problems in the prior art that a diamond-impregnated bit with a single cutting structure is short in service life in the complex stratum which is difficult to be drilled and thus adverse effects on geological exploration are caused. The diamond-impregnated bit comprises an API joint and a bit body connected with the API joint, wherein a center water channel, a plurality of blades and water channels between two adjacent blades are arranged on the bit body; double cutting structure impregnated A1 type teeth, impregnated A type teeth, impregnated B type teeth, impregnated C type teeth and double cutting structure impregnated A2 type teeth are arranged on the upper surfaces of the blades; large granular natural diamonds are impregnated on the cutting surfaces of the double cutting structure impregnated A1 type teeth and the double cutting structure impregnated A2 type teeth, and artificial small granular diamonds are uniformly and orderly arranged in the double cutting structure impregnated A1 type teeth and the double cutting structure impregnated A2 type teeth; and small granular diamonds are arranged in the impregnated A type teeth, the impregnated B type teeth and the impregnated C type teeth. The diamond-impregnated bit disclosed by the invention is used for drilling.

Owner:CCDC PETROLEUM CORING TECH

Preparation method of ultrahard anti-abrasion PCD (Poly Crystal Diamond) material containing enhanced core

The invention discloses a preparation method of an ultrahard anti-abrasion PCD (Poly Crystal Diamond) material containing an enhanced core. The enhanced-core-containing PCD (Poly Crystal Diamond) material is obtained by cutting cubic boron nitride (c-BN), cubic boron carbon nitride (c-BC2N), boron carbide (B4C) or nano twin-crystal cubic boron nitride (nt-CBN) serving as the enhanced core into small columns, burying the column bodies of the enhanced core into diamond micro powder, putting the diamond micro powder into a pyrophyllite block and performing synthesis under high-temperature and high-pressure conditions. The novel ultrahard anti-abrasion material prepared by the preparation method disclosed by the invention integrates two characteristics, which are similar to ultrahigh hardness of natural diamonds and toughness of a poly crystal material, of an ultrahard extreme material, so that the application ranges of the ultrahard extreme material and the PCD material are expanded and the increasing requirements on the performance of ultrahard anti-abrasion materials of the mechanical manufacturing and petroleum / geological exploration industries are met.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Manufacturing method of double-cutting diamond impregnated insert

The invention discloses a manufacturing method of a double-cutting diamond impregnated insert. Diamond particles are wrapped and embedded to the surface of an impregnated insert by a sintered layer through a thermocompression steeping sintering process. The sintered layer comprises the following components in percentage by weight: 30-55% of tungsten carbide, 10-20% of hard alloy, 5-12% of nickel, 3-12% of manganese and 17-36% of copper alloy. The thermocompression steeping sintering process comprises the following steps: putting the natural diamond particles, sintered layer powder and the impregnated inserts into a graphite die; heating at a heating speed of 80-120DEG C / min and applying a pressure of 12-18Mpa; when the temperature is increased to 900-1100DEG C, performing heat preservation for 250-350 seconds under pressure; cooling to 700-750DEG C at a cooling speed of 150-180DEG C / min under pressure; cooling to room temperature at a cooling speed of 150-180DEG C / min without pressure; tightly bonding the sequentially-arrayed impregnated inserts and the natural diamond particles together by virtue of the thermocompression steeping sintering process, so as to form an organic combination body with a double-layer cutting structure, so that the purpose of double-layer stepped cutting is realized.

Owner:CCDC PETROLEUM CORING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com