Hot-press diamond-impregnated drill bit and manufacturing method thereof as well as application of hot-press diamond-impregnated drill bit to strong-abrasiveness hard formation

A technology for impregnating diamonds and diamond drills is applied to hot-pressing impregnated diamond drill teeth and its manufacturing method and its application in strong abrasive hard formations, and can solve the problems of high cost of drill bits, decreased diamond quality, and expensive natural diamonds. , to achieve the effect of being suitable for large-scale production, improving rock breaking efficiency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

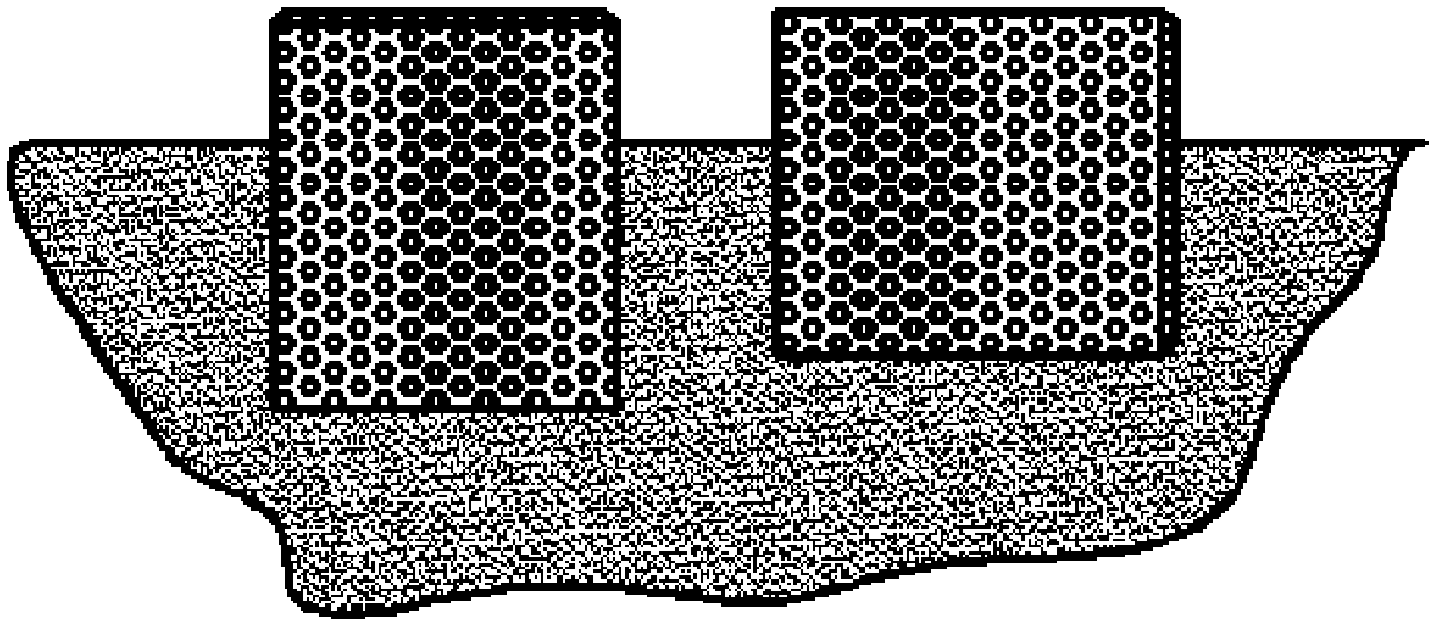

Image

Examples

Embodiment 1

[0037] The drill teeth are manufactured by hot pressing, the drill teeth specification is φ13×15mm, matrix material (mass percentage, 200 mesh to 400 mesh): p 2%, Mn 1%, Co 17.5%, Cu 15.4%, Ni 15.4%, Cast tungsten carbide 20.5%, WC 27.6%, artificial single crystal diamond powder 0.7%; diamond concentration 100% (volume concentration), diamond particle size 70 mesh to 80 mesh; sintering process parameters: sintering pressure 22MPa, sintering temperature 1060°C, heat preservation 4min.

[0038]The above-mentioned drill teeth are inlaid vertically and horizontally to process a 101.6 (referring to a drill diameter of 101.6mm, that is, a drill size of 4in) hot-pressed impregnated diamond drill bit, and drill into siliceous cemented quartz with a drillability of 9.2. sandstone. Drilling parameters: WOB 1.5t, speed 106rpm, pump volume 11L / s. The drilling speed of the diamond bit is 1.38m / h, and the average wear rate is only 0.014g / m.

Embodiment 2

[0040] The drill teeth are synthesized by hot pressing, the drill tooth specification is φ19×15mm, the matrix material (mass percentage, 200 mesh to 400 mesh): p 1.5%, Mn 3%, Co 14.5%, Ni12.7%, Cu 20% , cast tungsten carbide 22.6%, WC 25%, artificial single crystal diamond powder 0.7%; diamond concentration 80% (volume concentration), diamond particle size 60 mesh to 70 mesh; sintering process parameters: sintering pressure 22MPa, sintering temperature 1060°C, Keep warm for 4 minutes.

[0041] The above-mentioned drill teeth are inlaid with vertical and horizontal alternately, and 101.6 hot-pressed diamond-impregnated drill bits are processed to drill into siliceous cemented quartz sandstone with a drillability of 7.3. Drilling parameters: WOB 1.5t, speed 106rpm, pump volume 11L / s, the drilling speed of the diamond bit is 2.13m / h, and the average wear rate is only 0.019g / m.

Embodiment 3

[0043] The drill teeth are synthesized by hot pressing, the drill tooth specification is φ19×10mm, the matrix material (mass percentage, 200 mesh to 400 mesh): p 1.9%, Mn 1%, Ni12%, Co 13.9%, Cu 17%, casting Tungsten carbide 21%, WC 32.5%, artificial single crystal diamond powder 0.7%; diamond concentration 110% (volume concentration), diamond particle size 70-80 mesh; sintering process parameters: sintering pressure 22MPa, sintering temperature 1060°C, heat preservation 4min.

[0044] The above-mentioned drill teeth are inlaid in a vertical and horizontal manner, and a 101.6 hot-pressed diamond-impregnated drill bit is processed to drill into siliceous cemented quartz sandstone with a drillability of 9.7. Drilling parameters: WOB 1.5t, speed 106rpm, pump volume 11L / s, the drilling speed of the diamond bit is 1.35m / h, and the average wear rate is only 0.012g / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Column height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com