Manufacturing method of double-cutting diamond impregnated insert

A manufacturing method and diamond technology, which can be used in earth-moving drilling, drilling equipment, drill bits, etc., can solve the problems of low bonding strength, insufficient matrix strength, poor diamond wettability and bonding ability, etc. The effect of rock breaking efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

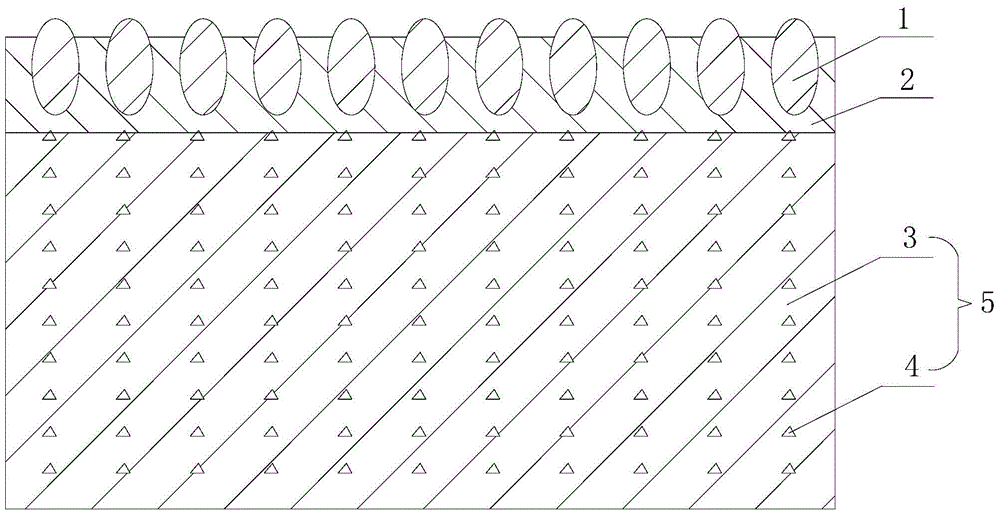

[0031] A method for manufacturing a double-cut diamond-impregnated block. The sintered layer 2 wraps natural diamond particles 1 on the surface of the impregnated block 5 through a hot-pressing impregnation sintering process; wherein the mass percentage of the sintered layer 2 components includes: tungsten carbide 40 %, cemented carbide 15%, nickel 8%, manganese 7%, copper alloy 30%; hot pressing dipping sintering process includes:

[0032] (1). Put the natural diamond particles 1, the sintered layer 2 powder and the impregnated agglomerate 5 into the corresponding positions of the graphite mold.

[0033] (2). Heating and applying pressure, the heating rate during heating is 100°C / min, and the applied pressure is 15Mpa.

[0034] (3). When the temperature rises to 980°C, keep the temperature under pressure for 300 seconds.

[0035] (4).Stop heating and perform cooling operation.

[0036] (5). Cool to 720°C under pressure, and the cooling rate is 170°C / min.

[0037] (6). Cool...

Embodiment 2

[0040] A method for manufacturing a double-cut diamond-impregnated block. The sintered layer 2 wraps natural diamond particles 1 on the surface of the impregnated block 5 through a hot-pressing impregnation sintering process; wherein the mass percentage of the sintered layer 2 components includes: tungsten carbide 55 %, cemented carbide 20%, nickel 5%, manganese 3%, copper alloy 17%; hot pressing dipping sintering process includes:

[0041] (1). Put the natural diamond particles 1, the sintered layer 2 powder and the impregnated agglomerate 5 into the corresponding positions of the graphite mold.

[0042] (2). Heating and applying pressure, the heating rate during heating is 80°C / min, and the applied pressure is 12Mpa.

[0043] (3). When the temperature rises to 900°C, keep the temperature under pressure for 250 seconds.

[0044] (4).Stop heating and perform cooling operation.

[0045] (5). Cool to 700°C under pressure, and the cooling rate is 150°C / min.

[0046] (6). Remov...

Embodiment 3

[0049] A method for manufacturing a double-cut diamond-impregnated block. The sintered layer 2 wraps natural diamond particles 1 on the surface of the impregnated block 5 through a hot-pressing impregnation sintering process; wherein the mass percentage of the sintered layer 2 components includes: tungsten carbide 30 %, cemented carbide 10%, nickel 12%, manganese 12%, copper alloy 36%; hot pressing dipping sintering process includes:

[0050] (1). Put the natural diamond particles 1, the sintered layer 2 powder and the impregnated agglomerate 5 into the corresponding positions of the graphite mold.

[0051] (2). Heating and applying pressure, the heating rate during heating is 120°C / min, and the applied pressure is 18Mpa.

[0052] (3). When the temperature rises to 1100°C, keep the temperature under pressure for 350 seconds.

[0053] (4).Stop heating and perform cooling operation.

[0054] (5). Cool to 750°C under pressure, and the cooling rate is 180°C / min.

[0055] (6). C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com