Method for preparing high-performance polycrystalline diamond by utilizing hinge-type cubic press

A technology of polycrystalline diamond and six-sided pressing machine, which is applied in the process of applying ultra-high pressure, etc., can solve the problem of large particle size, affecting hardness, wear resistance, thermal stability, and difficulty in achieving ultra-fine cutting tool edges Problems such as flatness and sharpness, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

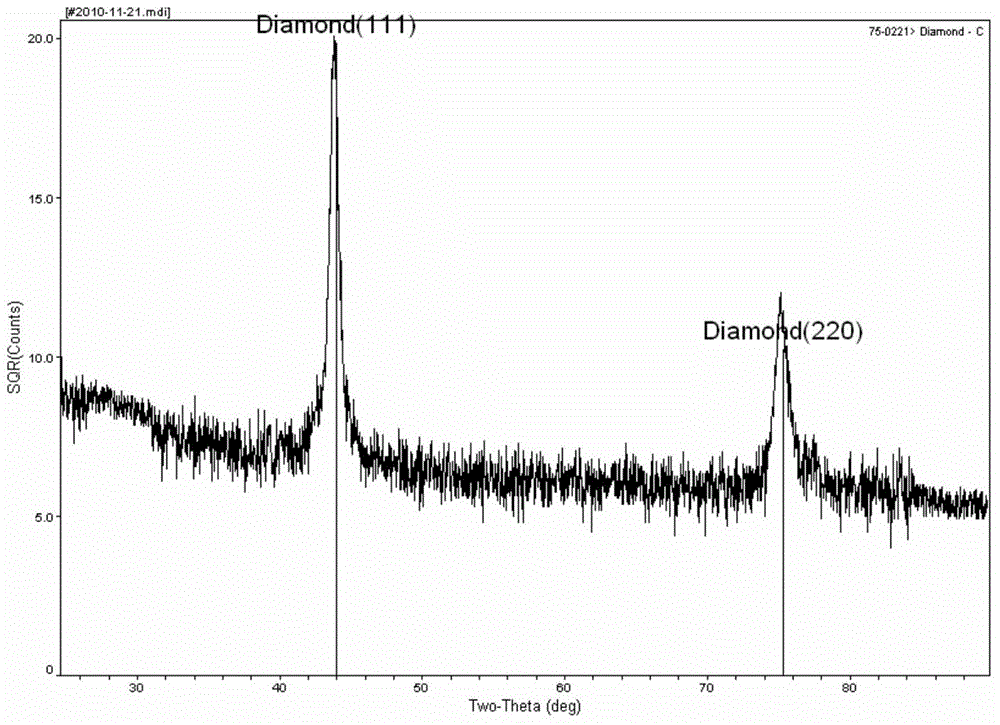

Image

Examples

Embodiment 1

[0044] Commercially available diamond powder with an average particle size of 10-20nm prepared by the detonation method is treated with hydrofluoric acid with a concentration of 20%-40%. The ratio of hydrofluoric acid to diamond powder is 2:1 by weight, add it to the purification kettle, stir and heat it to 70°C in a water bath, and treat it for 72 hours. After the powder settles, pour off the liquid and wash it with deionized water to medium properties, then put the above diamond powder in hydrochloric acid with a concentration of 20%-38%, the ratio of hydrochloric acid to diamond powder is 2:1 by weight, add it to the purification kettle, stir and heat it to 70°C in a water bath, and process After 72 hours, after the powder settles, pour off the liquid and wash it with deionized water to neutrality. After repeating the above acid solution and impurity removal for 3-5 times, dry the diamond powder; then dry the diamond powder in a vacuum of 4x10 -3 Pa, the temperature is 800°...

Embodiment 2

[0046]Commercially available diamond powder with an average particle size of 100-200nm prepared by the detonation method is treated with hydrofluoric acid at a concentration of 20%-40%. Add hydrofluoric acid to diamond powder in a weight ratio of 2:1, add it to the purification kettle, stir and heat it to 70°C in a water bath, and treat it for 72 hours. After the powder settles, pour off the liquid and wash it with deionized water until Neutral, then put the above diamond powder in nitric acid with a concentration of 20%-30%, the ratio of nitric acid to diamond powder is 2:1 by weight, add it to the purification kettle, stir and heat in a water bath to 70°C , treated for 72 hours, after the powder settles, pour off the liquid, and wash with deionized water to neutrality, repeat the above acid dissolution and impurity removal for 3-5 times, then dry the diamond powder; then put the diamond powder in a vacuum 4x10 -4 Pa, the temperature is 1000°C, and the treatment is for 3 hou...

Embodiment 3

[0048] The diamond powder with an average particle size of 0-2 μm prepared by crushing large-grain diamonds is treated with hydrofluoric acid with a concentration of 20%-40%. Add hydrofluoric acid to diamond powder in a weight ratio of 2:1, add it to the purification kettle, stir and heat it to 70°C in a water bath, and treat it for 72 hours. After the powder settles, pour off the liquid and wash it with deionized water until Neutral, then put the above diamond powder in nitric acid with a concentration of 20%-30%, the ratio of nitric acid to diamond powder is 2:1 by weight, add it to the purification kettle, stir and heat in a water bath to 70°C , treated for 72 hours, after the powder settles, pour off the liquid, and wash with deionized water to neutrality, repeat the above acid dissolution and impurity removal for 3-5 times, then dry the diamond powder; then put the diamond powder in a vacuum 4x10 -5 Pa, the temperature is 1200°C, and the treatment is for 2 hours to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com