Surface-set reamer used in geological exploration and manufacturing method thereof

A technology of geological exploration and reamer, which is applied in earthwork drilling, drilling equipment, drill bits, etc., can solve the problems of short service life of reamer, low tap density of metal powder, poor wear resistance of matrix, etc., and achieve improvement Abrasion resistance, improved tap density, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

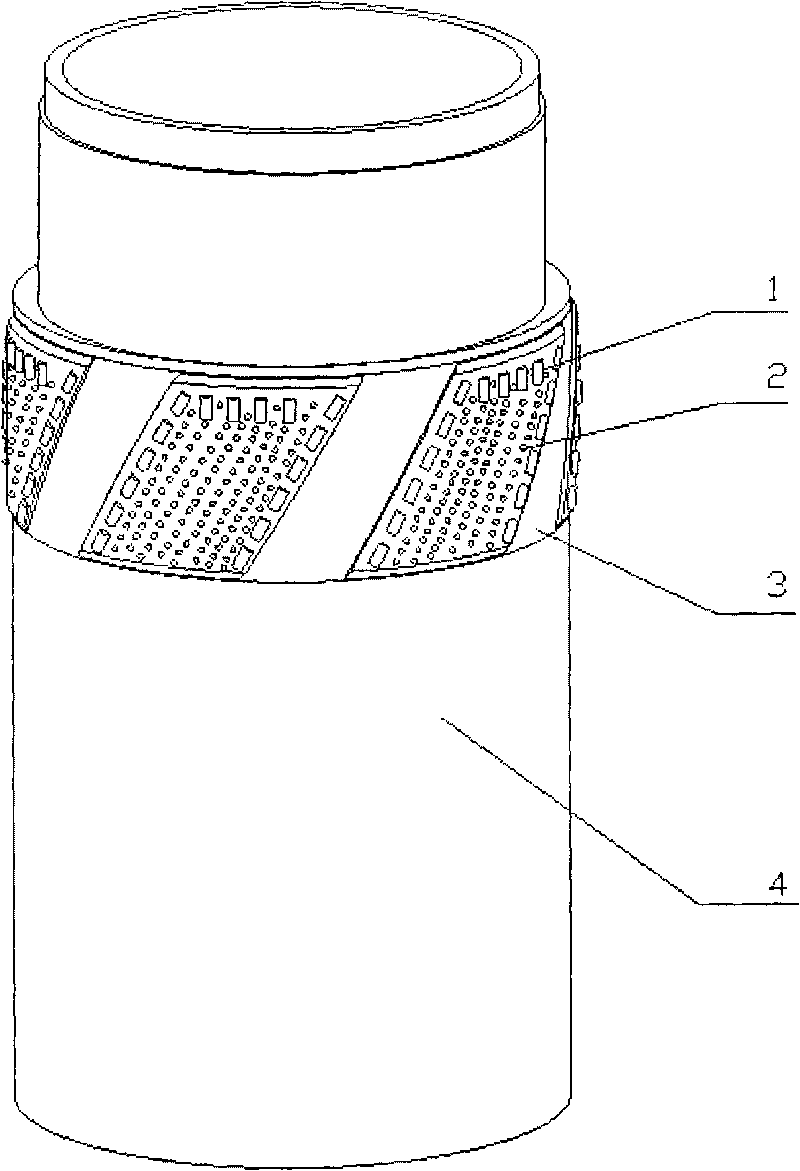

[0017] refer to figure 1 The embodiment of the surface-mounted hole reamer includes a steel body 4, the upper part of the steel body 4 is sintered and fixed with a carcass 3, and the surface of the carcass 3 is inlaid with natural diamond particles 2 and cylindrical artificial diamond polycrystals 1 in a regular and orderly manner; the carcass It is sintered by uniformly mixing 250-mesh ordinary metal powder, nano-prealloyed powder, and 180-mesh micro-artificial diamond polycrystalline particles (weight ratio: ordinary metal powder: nano-prealloyed powder: micro-polycrystalline particles = 3:3:1) ;

[0018] Cylindrical synthetic diamond polycrystal 1 has a specification of Φ2×4;

[0019] The particle size of natural diamond particle 2 is 40 grains / carat;

[0020] The weight percent composition of the nano pre-alloy is: W2C65%, Ni25%, Cu6%, Zn4%.

[0021] Manufacture: Adhere cylindrical synthetic diamond polycrystal 1 and natural diamond particles 2 to the mold regularly and...

Embodiment 2

[0024] The size of the cylindrical artificial diamond polycrystal 1 of the hole reamer in this embodiment is Φ1.5×4.

[0025] The particle size of the natural diamond particles 2 is 80 particles / carat.

[0026] The weight percent composition of the nano pre-alloy is: W2C68%, Ni22%, Cu5%, Zn5%.

[0027] The particle size of described natural diamond particle is 80 grains / carat;

[0028] The rest is the same as the embodiment.

[0029] Manufacturing method is the same as embodiment 1.

[0030] The reamer of this embodiment drills into the broken formation, and its service life reaches 3220 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com