Method for manufacturing seamed flux-cored welding wire

A welding wire and seam welding technology, applied in the field of seam flux-cored welding wire, can solve the problems that have not been put into practical application, and achieve the effect of improving feedability and increasing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

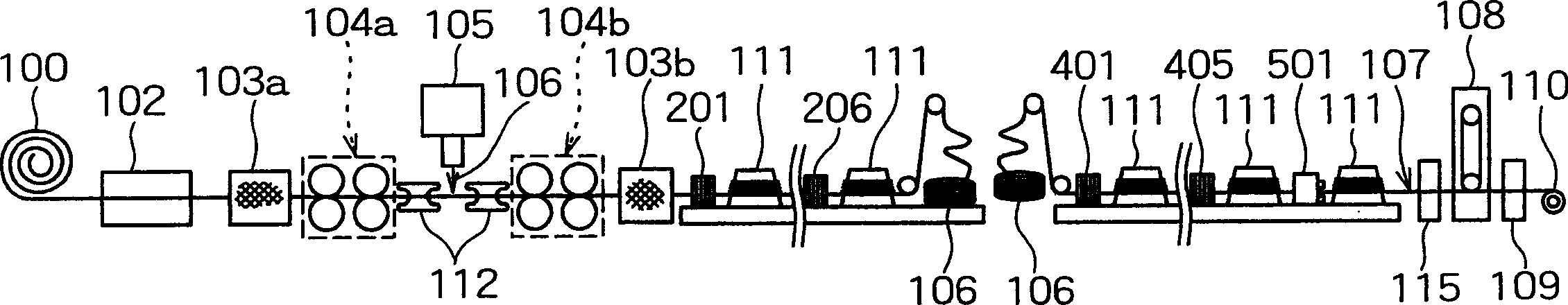

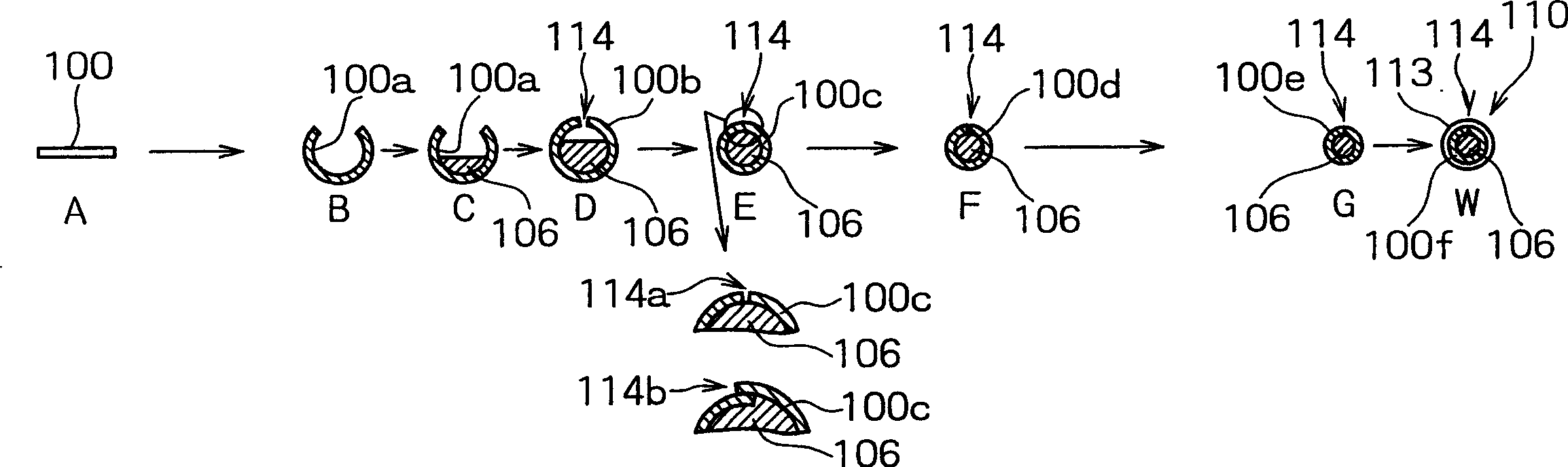

[0133] Hereinafter, embodiments of the present invention will be specifically explained. in Figure 1A In the FCW manufacturing process shown, the 1.2mm product diameter FCW is made of various strip steels (rings) made of low carbon steel with the composition shown in Table 1, each flux with the composition shown in Table 2 is used, and the use shown in Table 3. Ingredients of each lubricant. In this step, as shown in Tables 4 and 5, the ratio t / w between the thickness t and the width w of the strip is changed in various ways (the width is 12 to 14 mm, and the thickness is in the range of 0.85 to 1.4 mm). The drawing conditions of the secondary welding wire are changed as shown in Tables 4 and 5. Incidentally, Table 4 shows the examples of the present invention, and Table 5 shows the comparative examples.

[0134] Here, as in the environment used for FCW products, due to the defects of the air conditioning system, nature and environment, the condition of preventing the moisture ab...

Embodiment 8

[0152] For Invention Example 8, where the residual wire drawing lubricant deposition amount after wire drawing is relatively small 0.5 g per 10 kg of welding wire, compared with other invention examples with relatively large lubricant deposition amount, the secondary wire drawing The maximum speed is small. For this reason, the moisture content of the entire welding wire is slightly increased compared with other inventive embodiments with high-order welding wire drawing maximum speed. However, in the weldability evaluation of the inventive example, no porosity defect occurred in the welded joint. This tendency to increase the moisture content indicates the following fact. That is, depending on the environment used for FCW production, specifically, when it is difficult to control the small amount of moisture content in the atmosphere during the wire drawing process, the moisture content in the atmosphere during the wire drawing process is very high. There is a great possibility tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com