Large-tonnage helical broaching machine

A spiral broaching machine with large tonnage is applied in the field of machine tools, which can solve the problems of short broaching stroke, no automatic loading and unloading device, and high labor intensity, and achieve the effect of improving the precision of machining gears.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the drawings and embodiments.

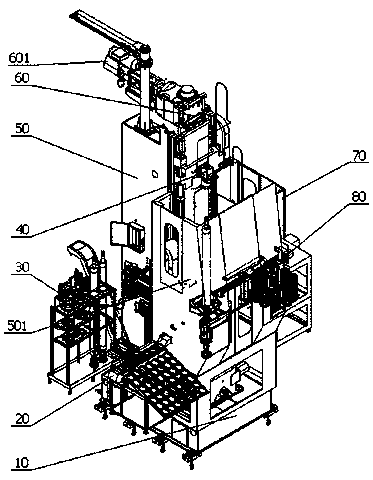

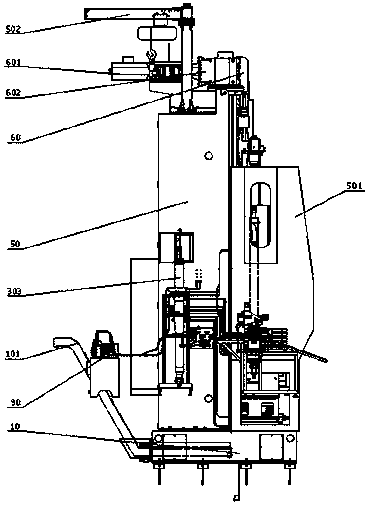

[0043] Reference Figure 1~5 , A large-tonnage screw broaching machine of the present invention includes a bed 50, a base 10, a main clamping tool body, a broaching tool, a main slide plate 502, a tool magazine 30, an automatic feeding mechanism 20, an automatic feeding mechanism 80, and a push The material device 207, the workpiece pressing device 504, the knife transfer mechanism 40, the servo drive device, the main broaching drive mechanism 60, the high-precision numerical control system, the electric control cabinet 70 controlled by the fully enclosed loop, and the hydraulic system 90; the bed 50 is installed on the base 10, the base 10 is equipped with a C-axis tool rotation servo motor and transmission device, a main clamp body and a protective cover 501; one side of the bed 50 is installed with an automatic feeding mechanism 80, and the other side An automatic fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com