Tool setting device and method for micro lathe

A tool setting device, a tiny technology, applied in auxiliary devices, turning equipment, tool holder accessories, etc., can solve the problems of determining the adjustment amount of the tool, inconsistent cutting amount, difficulty in ensuring the shape accuracy of small workpieces, etc., to improve stability, Realize the effect of real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

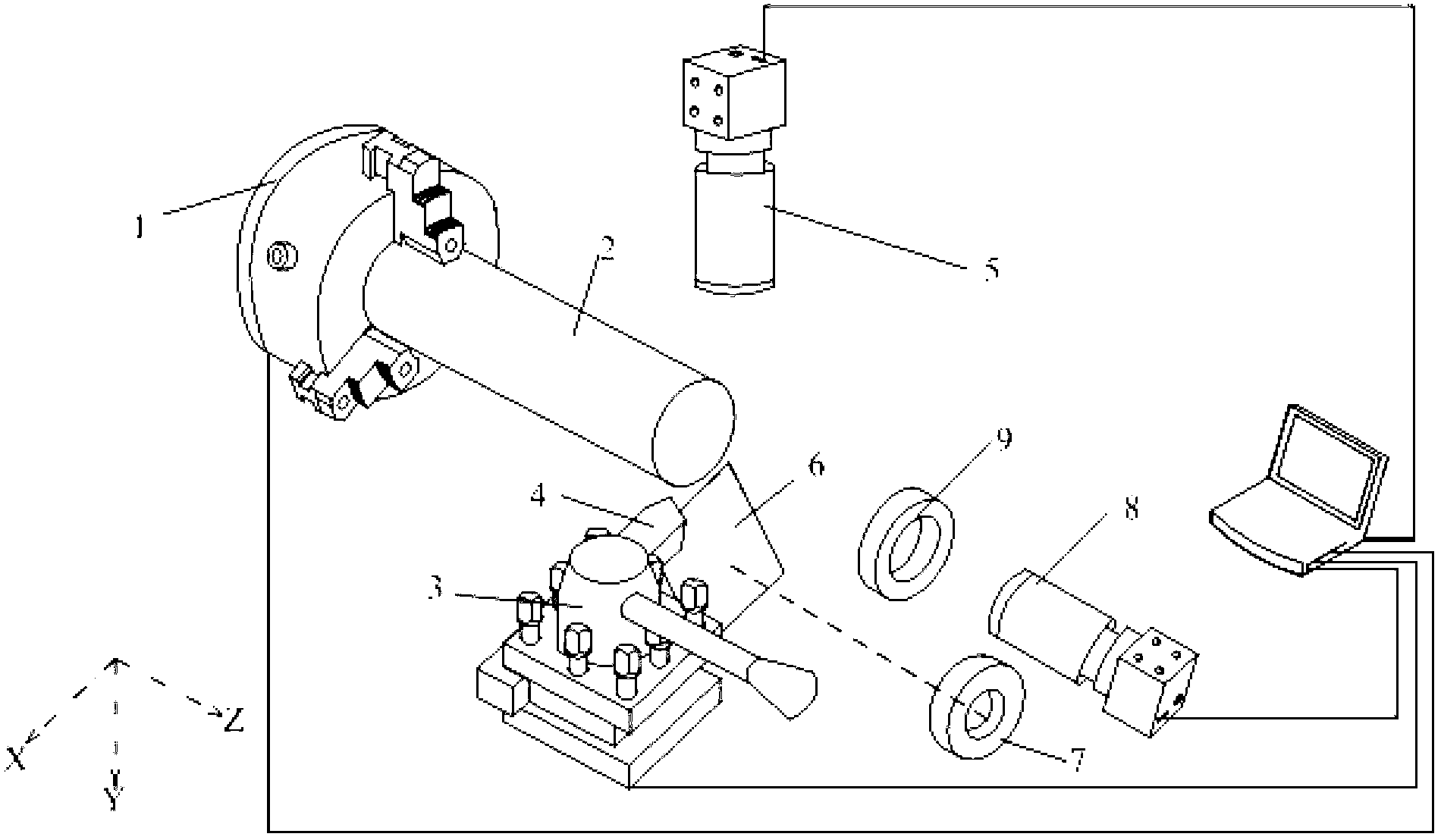

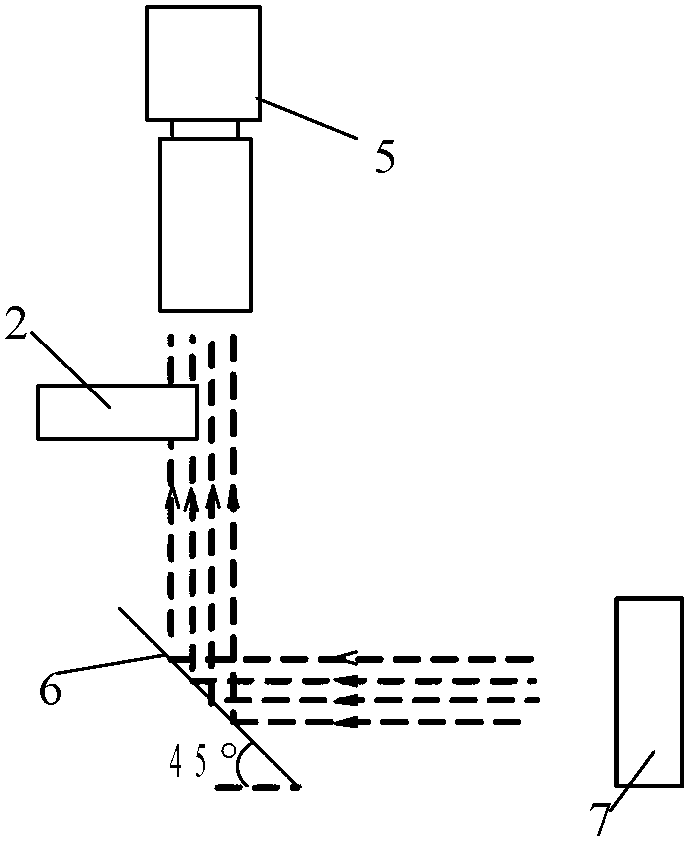

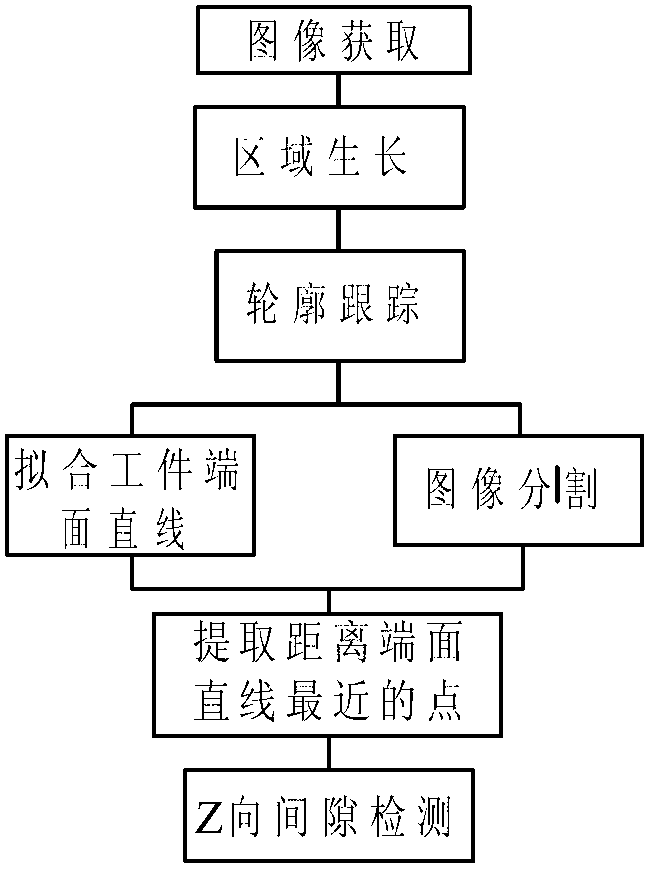

[0018] Such as figure 1 As shown, the tool setting device for a micro lathe includes: a machine chuck 1, a tool holder 3, a tool 4 and a guide rail, and the device also includes: a first CCD camera 5, a mirror 6, a first light source 7, and a second CCD Camera 8, second light source 9 and external computer; in the lathe, the direction parallel to the main axis of the workpiece 2 is the Z axis, the horizontal radial direction of the workpiece is the X axis, and the direction where the tool is away from the workpiece is the positive direction. According to the right-hand rule, the direction perpendicular to the X-axis and perpendicular to the Z-axis is the Y direction. The workpiece 2 to be processed is clamped on the machine tool chuck 1, and the tool 4 is fixed on the tool holder 3; the external computer controls the machine tool chuck 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com