Hot work die steel and its preparation method

A technology of hot work die steel and production methods, which is applied in the direction of manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of complex production methods, high alloy content, high cost, etc., and achieve simplified manufacturing methods and alloying element components Reasonable and save the cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

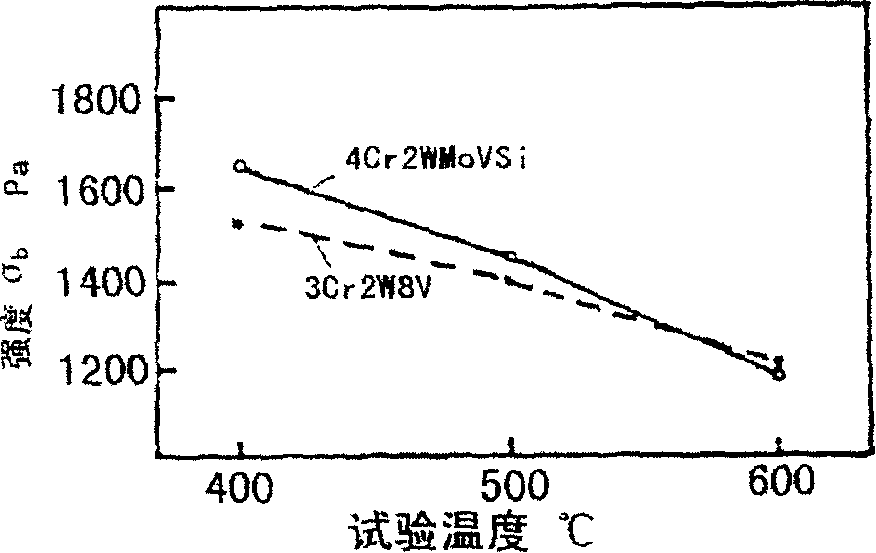

Image

Examples

Embodiment 1

[0016] According to the composition of each alloy element specified in Table 1, the steel for hot shear blades produced by using common steelmaking equipment and the smelting method of ordinary medium carbon steel, after forging, the forging temperature is 1150 ° C, and the final forging is ≥ 850 ° C; Heat treatment: Quenching at 1050°C, tempering at 590°C, stress relief tempering at 200°C after finishing. The manufacturing method and the hardness of the hot shear blades are listed in Table 2. The shear blades used for 250 tons of flying shears cut HRB335 and HRB400 ribbed steel bars with a diameter of 16-22mm at about 1000 ° C. The actual temperature of the shear blades during work 460-620°C, the test conditions are listed in Table 3.

Embodiment 2

[0018] By the composition of each alloy element specified in Table 1, repeat the method of Example 1 to make thermal shear blades, its manufacturing method and thermal shear blade hardness are listed in Table 2, and the test conditions are listed in Table 3.

Embodiment 3

[0020] By the composition of each alloy element specified in table 1, repeat the method of embodiment 1, the hot shear blade made, its manufacturing method and the hot shear blade hardness are listed in table 2, and test situation is listed in table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com