Laboratory-oriented rapid gas infiltration process and equipment thereof

A laboratory and gas technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of difficult gas infiltration temperature, long gas infiltration time, and outdated equipment, so as to improve the gas infiltration efficiency , simple structure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

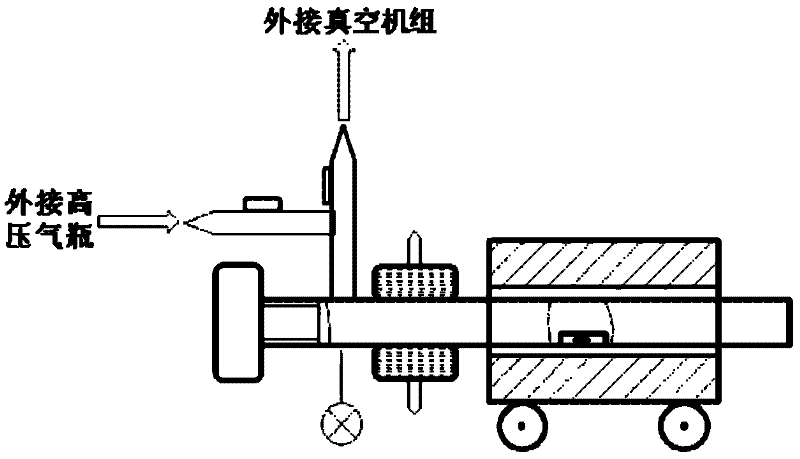

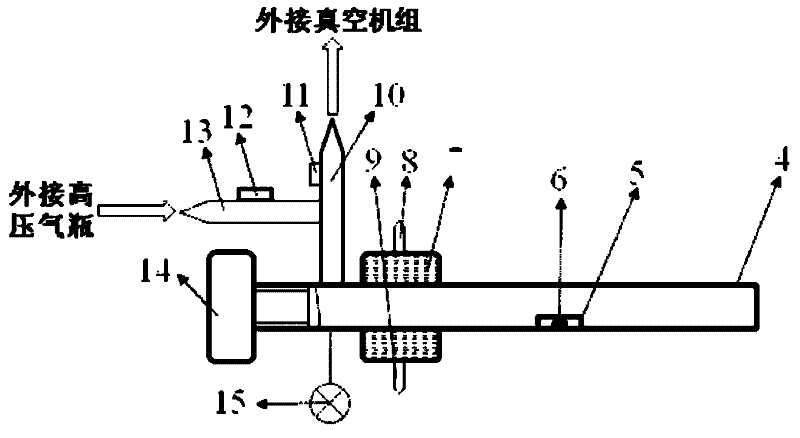

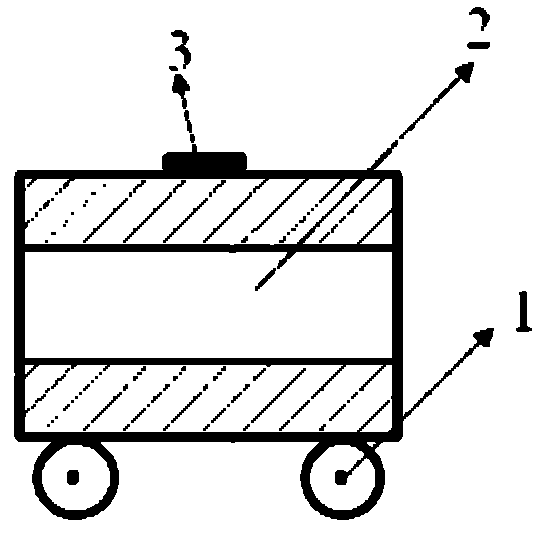

[0033] see figure 1 □ image 3 , facing the rapid gas infiltration (or solid-gas reaction) process and its equipment for the laboratory, an annular cooling water chamber 7 is provided at the 1 / 3 of the circular furnace tube 4 from the open end, and the cooling water chamber is respectively provided with The cooling water outlet 8 and the cooling water inlet 9 connected with the annular cooling water chamber 7 can effectively reduce the heat diffusion along with the metal circular furnace tube, which is beneficial to protect the furnace tube bolts with sealing rings at the other end to achieve better sealing Effect: the closed furnace tube 4 is used to infiltrate gas (or solid-gas reaction), which can increase the gas pressure in the closed container; the tubular resistance furnace 2 can move and adjust freely along the guide rail, so that the sample is located in the center of the uniform temperature zone of the furnace cavity ; Since the side of the circular furnace tube 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com