A high-temperature internal pressure fatigue testing machine

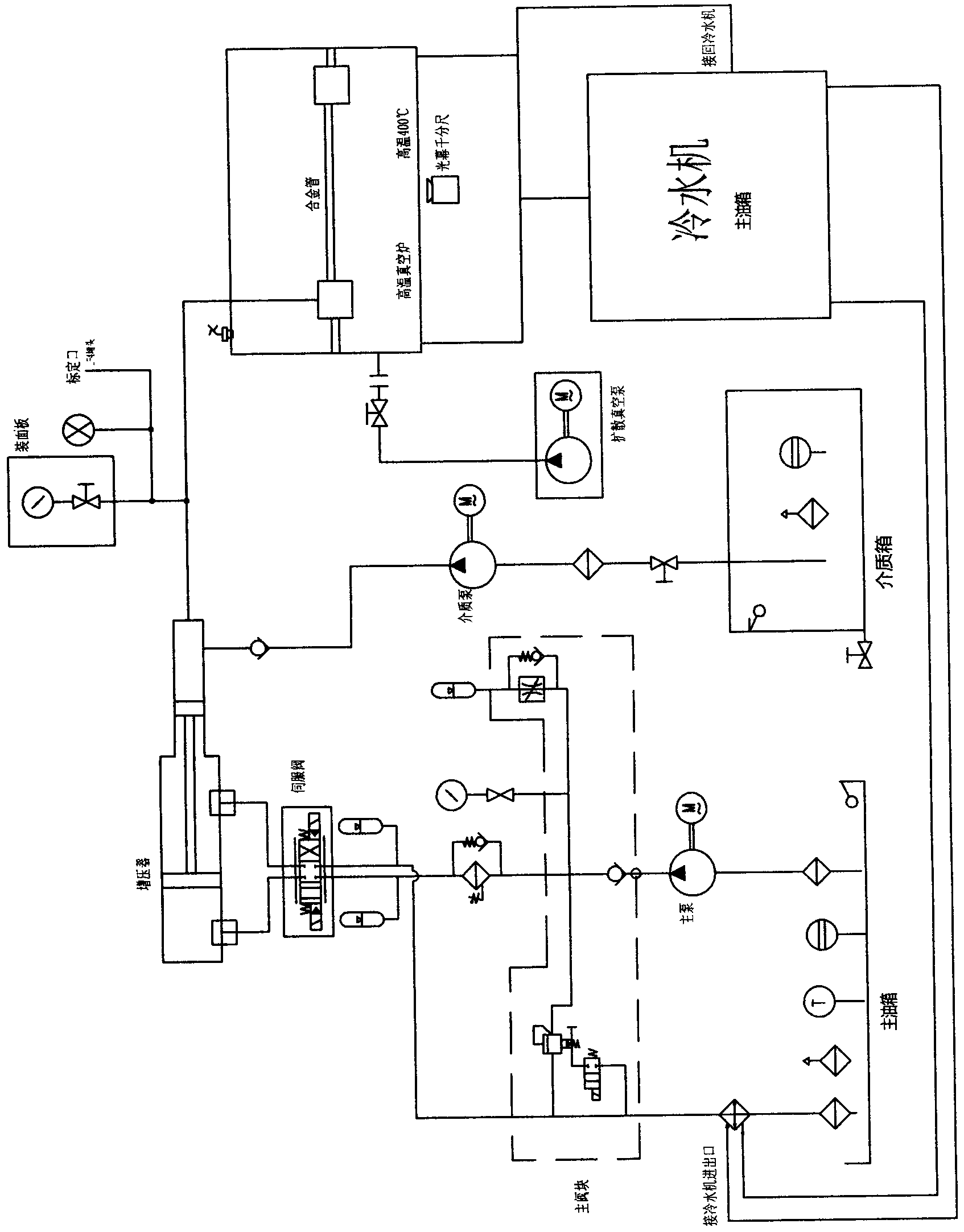

A fatigue test and internal pressure technology, applied in the field of fatigue test machines, can solve problems such as high pressure and high temperature, achieve high temperature measurement accuracy, eliminate surface oxidation, and accurately measure and control temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

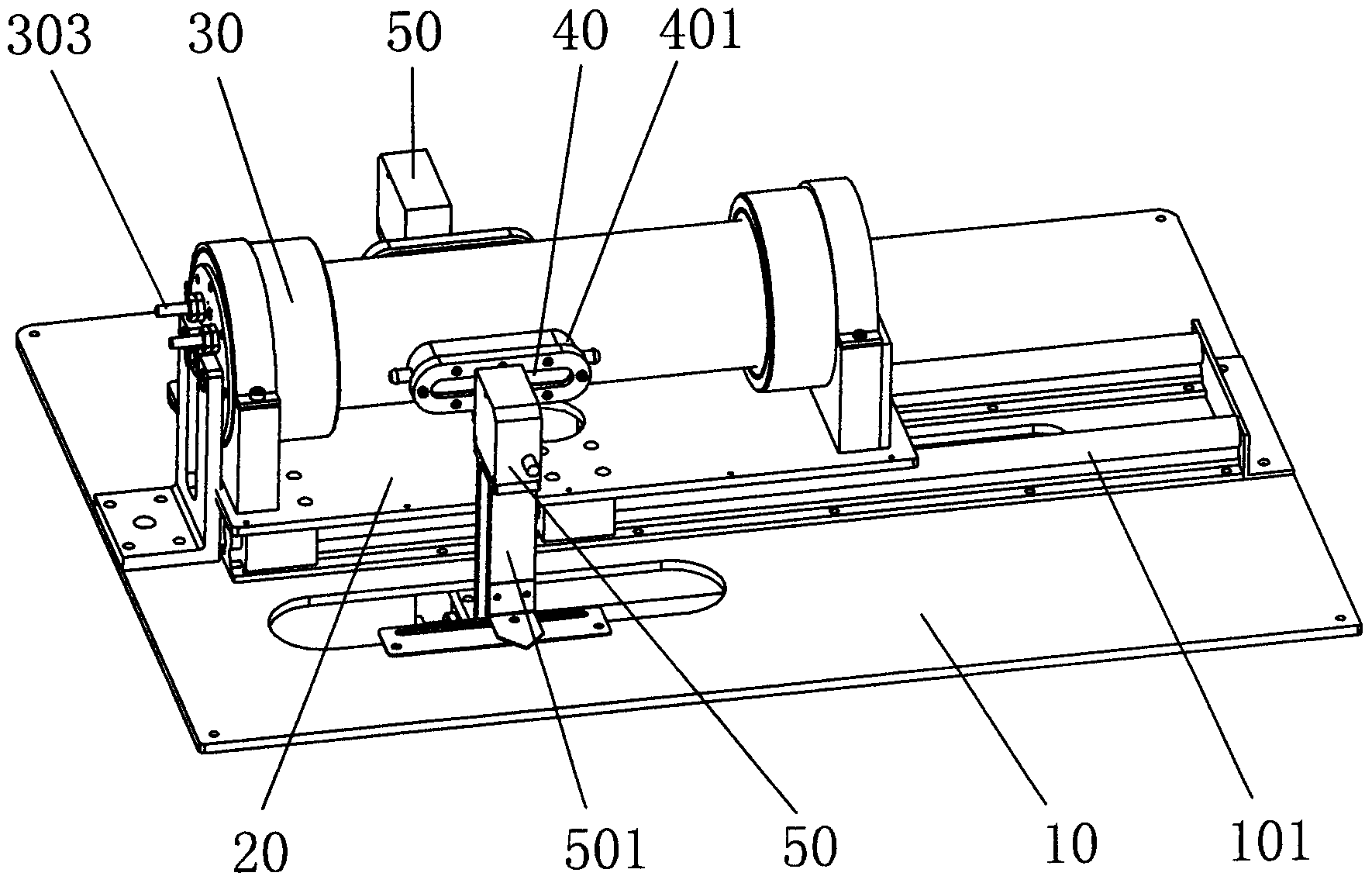

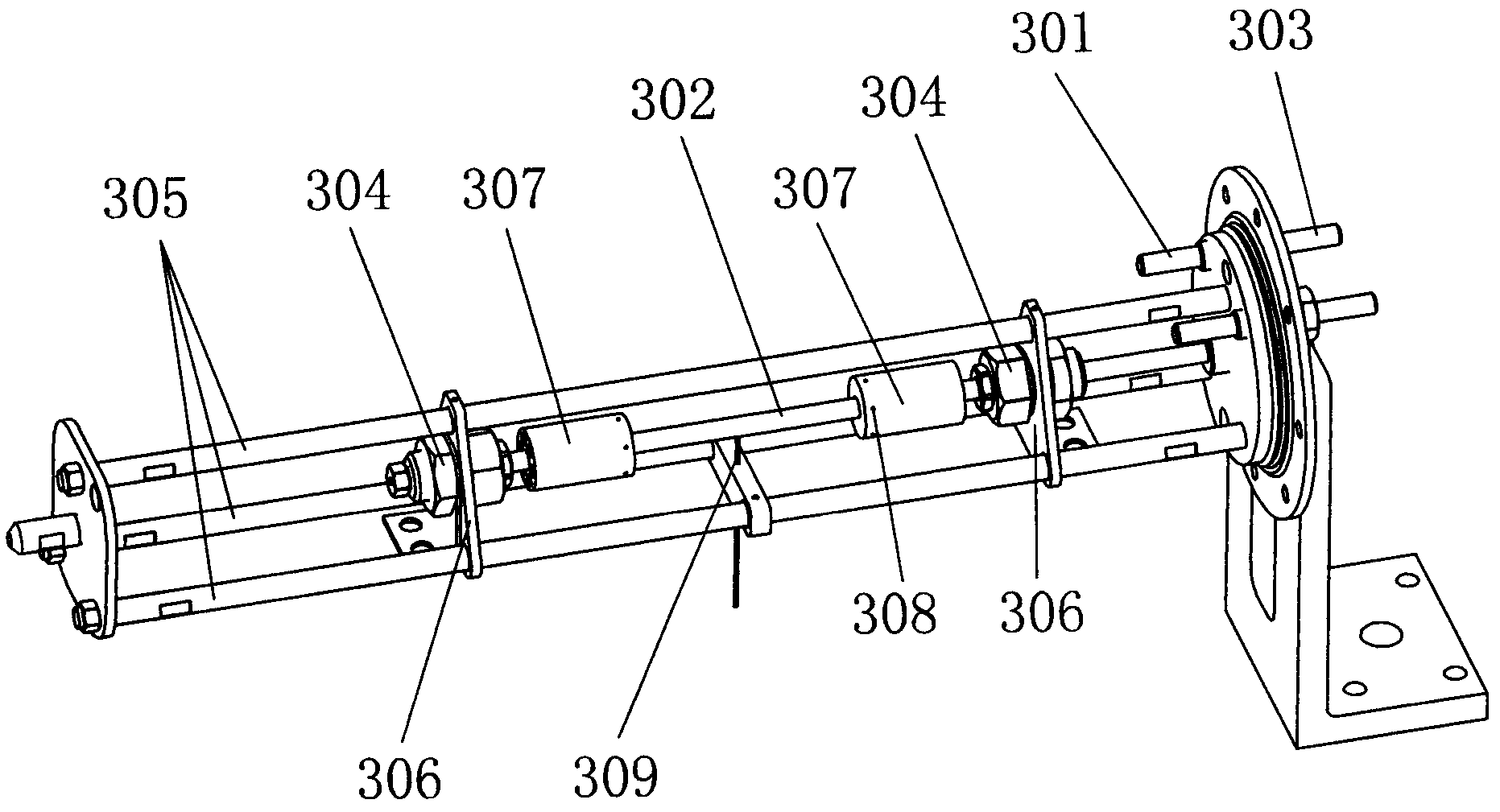

[0019] refer to figure 1 As shown, the present invention discloses a high-temperature internal pressure fatigue testing machine for performing high-vacuum, high-pressure, high-temperature, high-precision, high-frequency pulse experiments on metal alloy tubes in the nuclear industry. The high temperature internal pressure fatigue testing machine has a furnace body sliding platform 10, a slide rail 101 is arranged on the furnace body sliding platform 10, and a fixing frame 20 is slidably arranged on the sliding rail 101, and a vacuum furnace is fixedly installed on the fixing frame 20. 30, the side of the vacuum furnace 30 is provided with an observation window 40 and a light curtain micrometer 50, in the present embodiment, the side of the vacuum furnace 30 is provided with two relative observation windows 40, and the above-mentioned light curtain microm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com