Device and method for testing bearing precision performance and method for determining bearing precision initial failure part

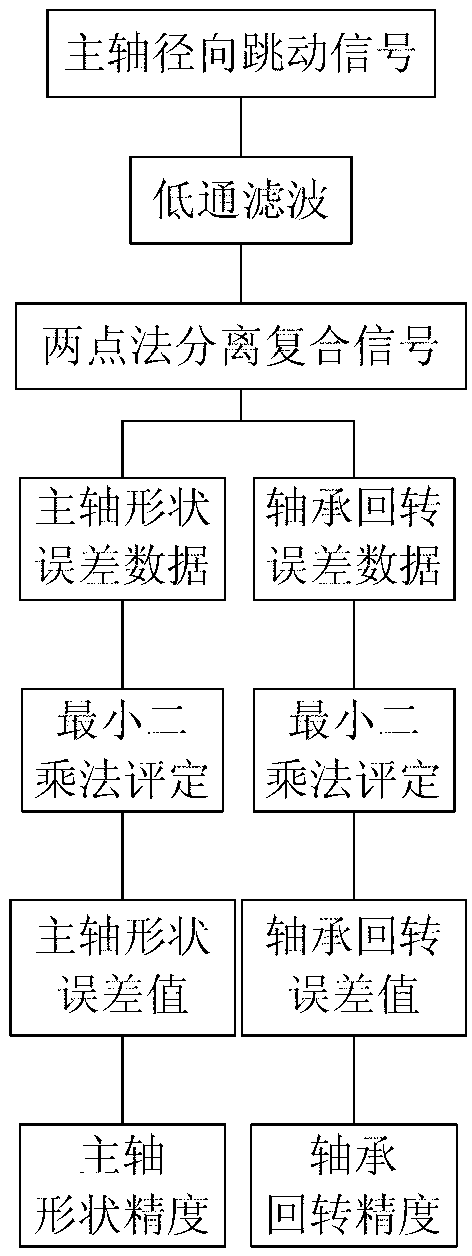

A bearing accuracy and testing device technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inability to identify and extract, large error in measurement results, and low speed of measurement, so as to improve temperature measurement accuracy, rotation accuracy and rigidity , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing, the present invention is described in further detail:

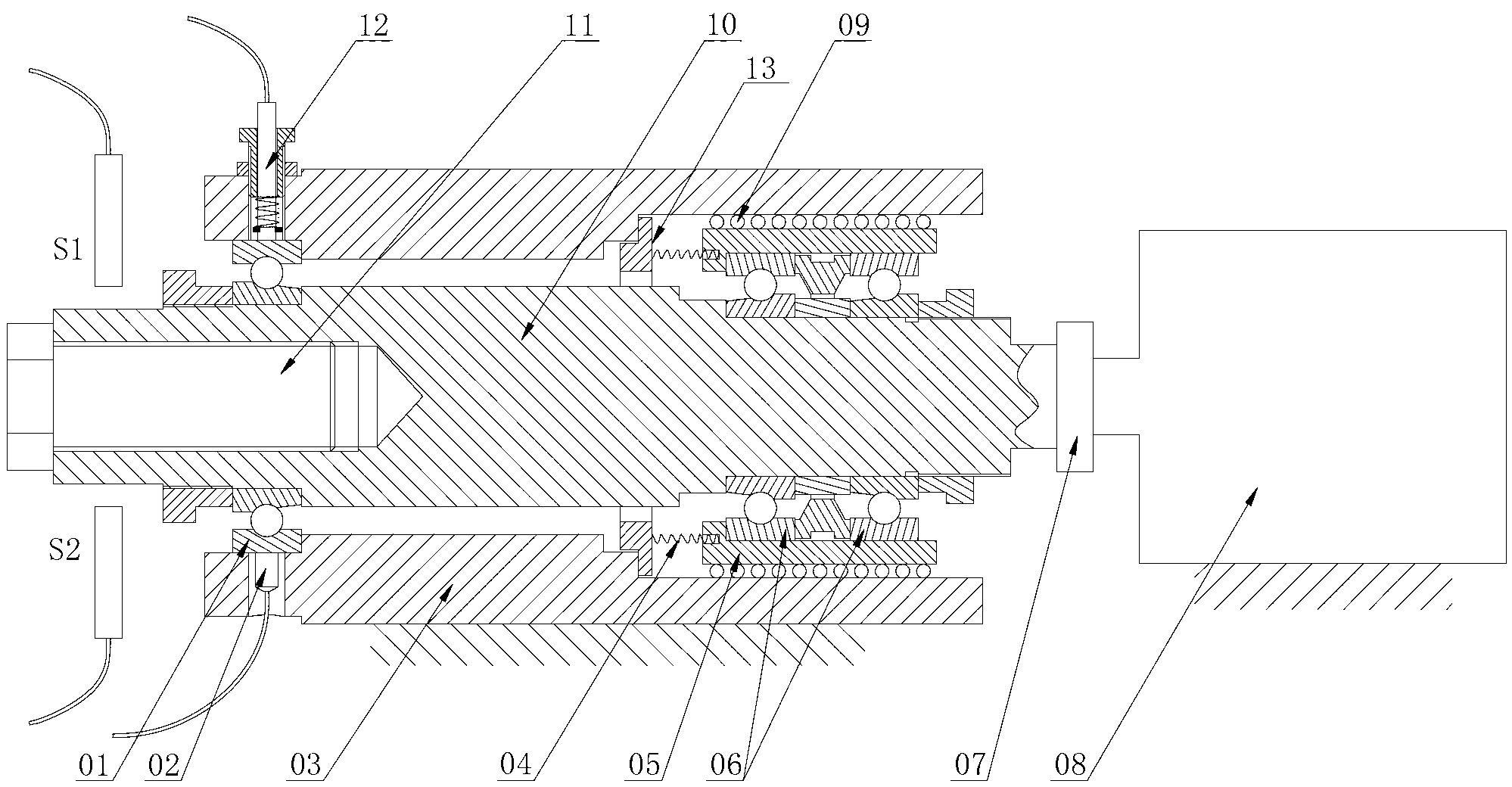

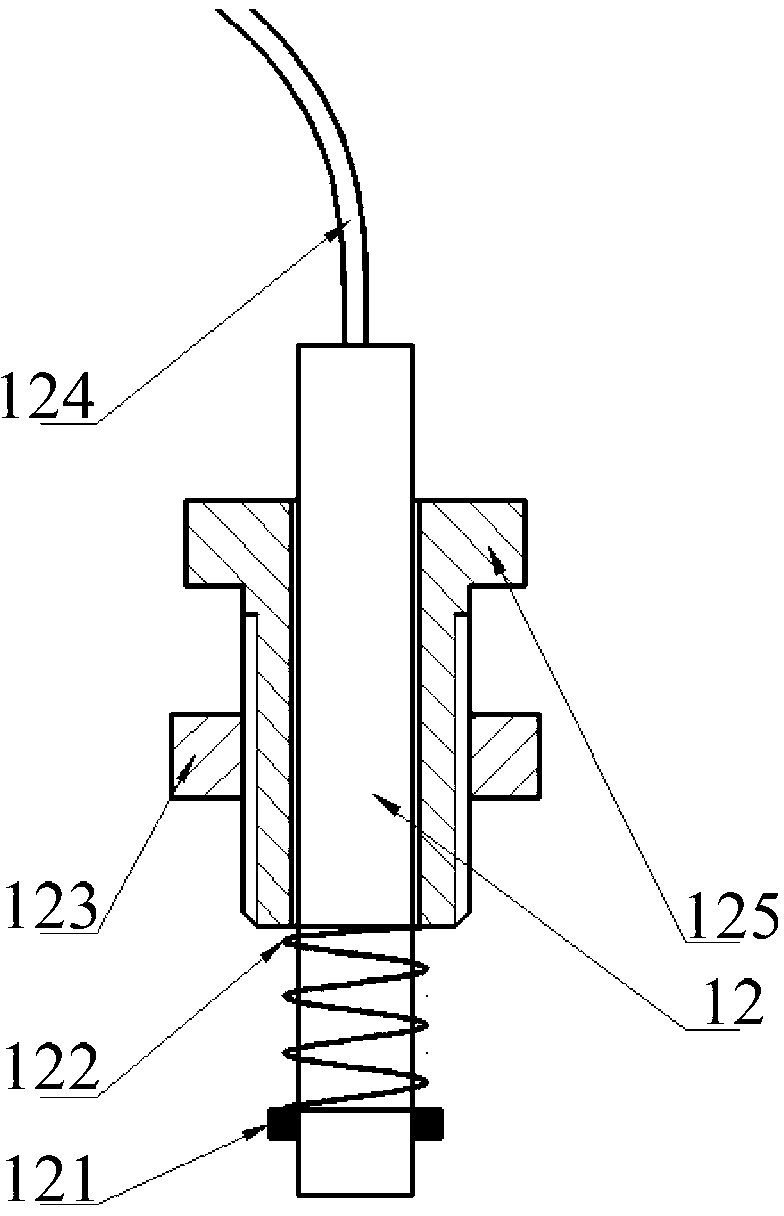

[0050] see Picture 1-1 and Figure 1-2 , the present invention includes a main shaft and a servo motor 8, the servo motor 8 is installed on the first frame, the main shaft is fixed on the second frame through the main shaft housing 3 sleeved outside it; the main shaft includes a main shaft mandrel 10, and the main shaft core The front end of the shaft 10 is processed with a threaded hole for installing the eccentric mandrel 11, and the eccentric mandrel 11 for applying radial quantitative loading to the main shaft is installed in the threaded hole at the front end of the main shaft mandrel 10; The shaft coupling 7 is fixedly connected with the output shaft of the servo motor 8, and the servo motor 8 drives the main shaft to rotate. The flexible connection minimizes the impact of the vibration of the servo motor on the main shaft and ensures the reliability of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com