Steel bar concrete beam reinforcing structure with partially restrained steel truss

A technology for reinforced concrete beams and reinforced structures, which is applied in building construction, building maintenance, construction, etc., can solve the problems of insignificant improvement in shear resistance, complex construction technology, and small bearing potential, and achieves improved bending and shearing capacity. The effect of safety, ensuring the quality of reinforcement, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

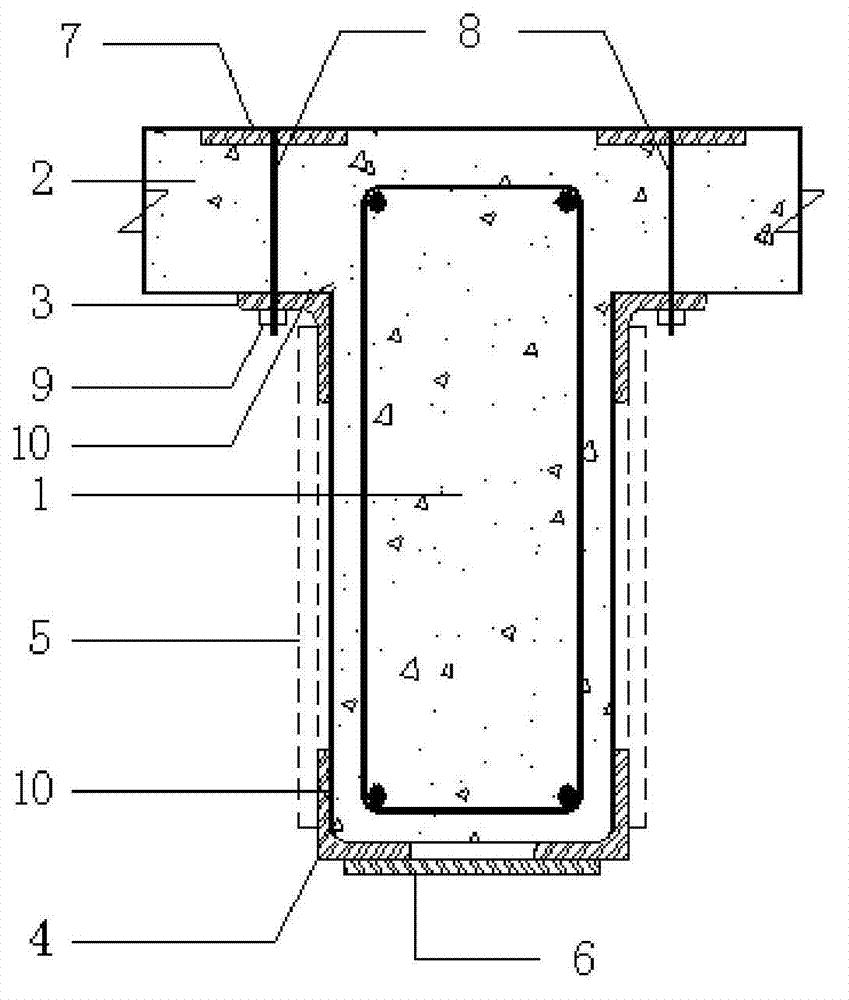

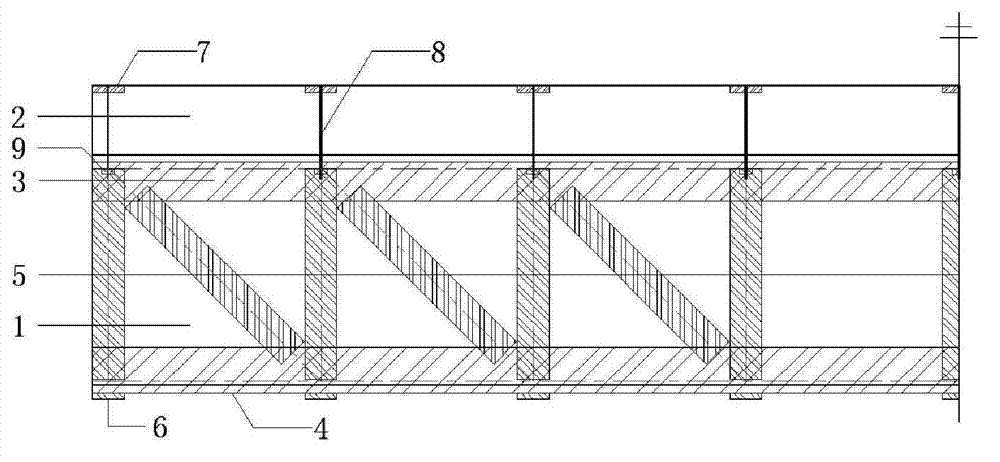

[0016] Such as figure 1 and 2 Shown: a steel truss partially restrained reinforced concrete beam reinforcement structure, including upper angle steel 3, lower angle steel 4, web panel 5, bottom plate steel plate 6, anchor steel plate 7, shear anchor bolt 8 and bolt 9, the upper The angle steel 3, the lower angle steel 4, the web panel 5 and the base steel plate 6 groups are combined to form an open steel truss tightly enclosing the beam 1 to be reinforced. The lower angle steel 4 is respectively installed on the two lower corners of the beam 1 to be strengthened. 4 are connected by a bottom plate steel plate 6, the upper angle steel 3 is installed between the beam 1 to be reinforced and the floor 2, the upper angle steel 3 and the lower angle steel 4 are connected by a web panel 5, and the anchor steel plate 7 is set on In the concrete protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com