Water-based antirust agent

A water-based rust inhibitor and additive technology, applied in anti-corrosion coatings, coatings, latex paints, etc., can solve the problems of high toxicity for operators and pollute the environment, achieve low cost, reduce cumbersome processes, and improve the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: First, 38.7Kg of water is added to the reactor, and after starting the agitator, 1Kg of urotropine, 0.1Kg of OP-10, 5Kg of alcohol ester-12, 1Kg of triethanolamine, 4Kg of ethylene glycol and 0.2Kg of lactic acid are added successively Zinc or zinc humate, stir well and then add 50Kg of R-1026 acrylate emulsion produced by Handan Restar Synthetic Chemical Co., Ltd., and then stir evenly.

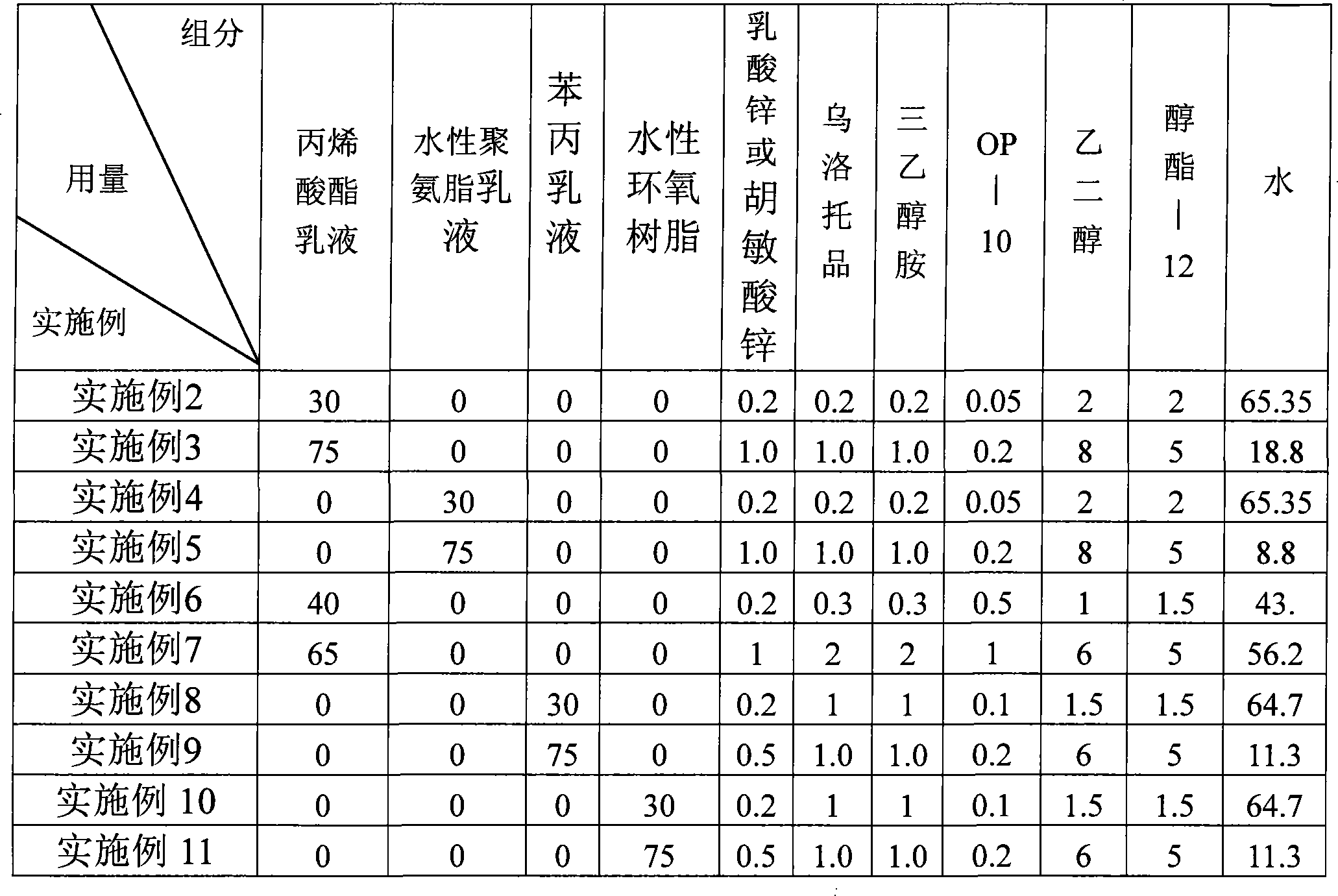

[0020] The difference between other embodiments and embodiment 1 is shown in the table below:

[0021] Unit: (Kg)

[0022]

[0023] The water-based polyurethane emulsion in the above-described embodiment is produced by Guangdong Heshan Heben Polyester Chemical Co., Ltd., and its model is H28; the styrene-acrylic emulsion is produced by Baoding Dongda Chemical Co., Ltd., and its model is BC-2008; water-based epoxy resin Produced by Guangzhou Yunsheng Environmental Protection Technology Co., Ltd., its model is YS-611 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com