Assembled large-scale construction board with light frame and manufacturing process thereof

A technology for building boards and manufacturing processes, which is applied to building structures, buildings, building components, etc., can solve the problems of multiple construction procedures and low work efficiency, and achieve the effects of reducing post-processing procedures, convenient transportation and construction, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

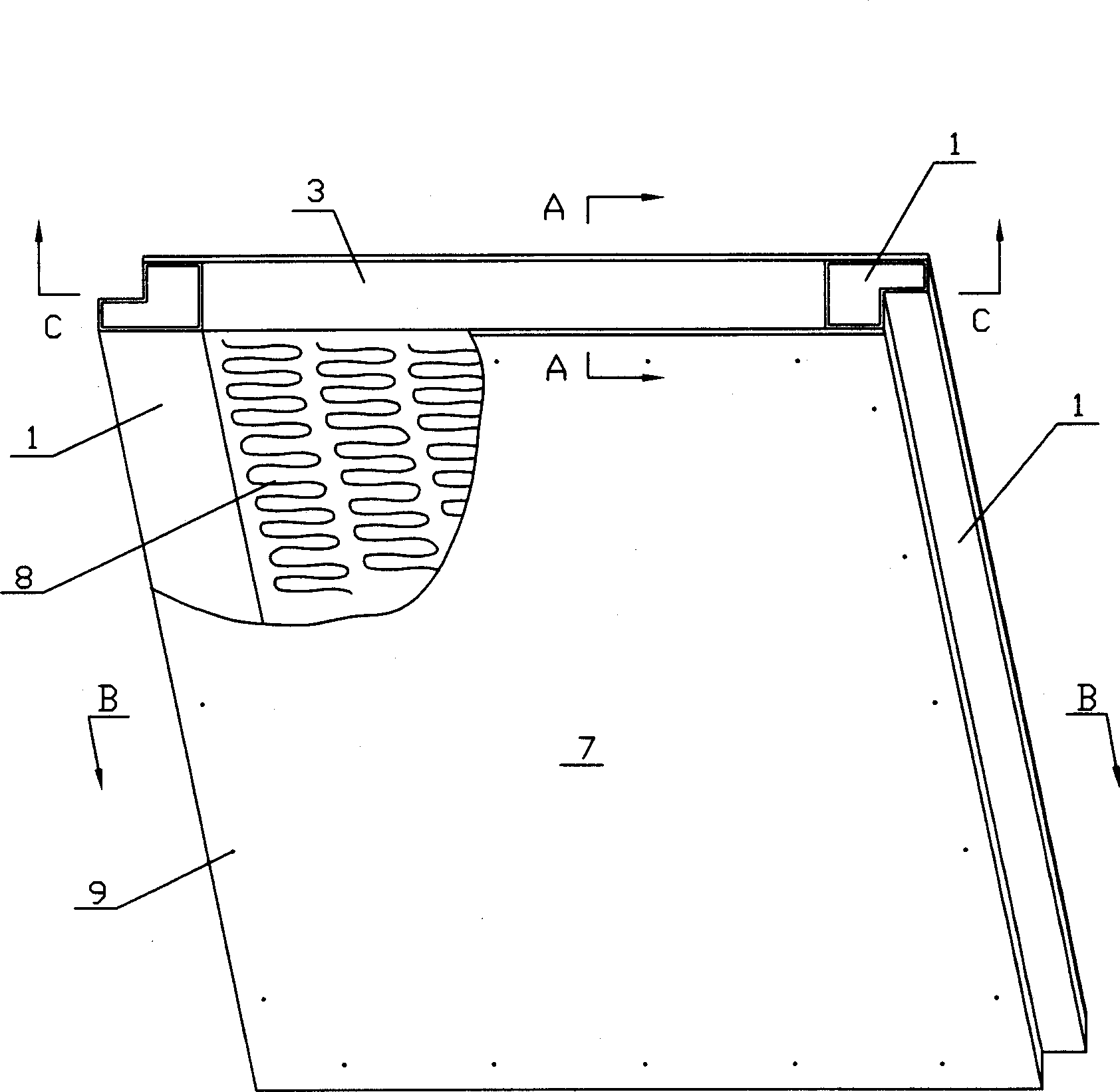

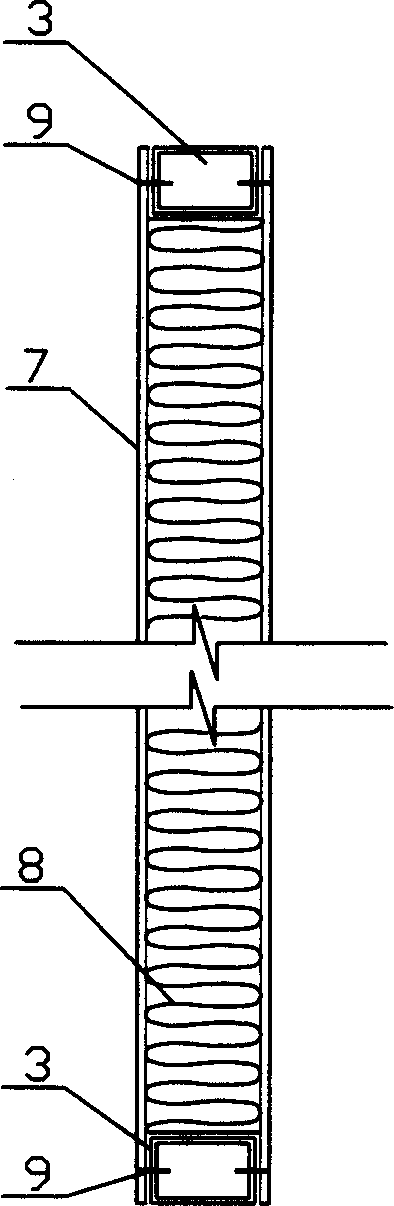

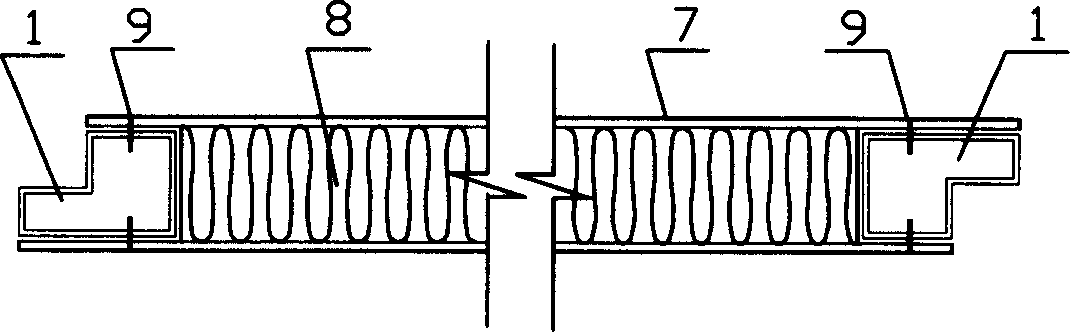

[0095] refer to Figure 1 to Figure 4 , a kind of prefabricated light frame large-scale building board material that the present invention provides, comprises light frame and two flat boards 7 spaced apart by light frame support, and this light frame has cross-section respectively by left and right two ends Shaped lightweight profile 1 and the upper and lower ends are respectively connected by mouth-shaped lightweight profile 3. The light frame composed of these 4 profiles is arranged at the edge between the two flat plates 7 to form an edge sealing structure. The two flat plates 7 The cavity surrounded by the light frame is filled with light thermal insulation material 8, and the flat plate 7 and the light frame are connected and reinforced with self-tapping screws 9.

[0096] refer to Figure 5 And Fig. 6, as an improvement, a support frame 13 is also provided in the cavity surrounded by the light frame.

[0097] refer to Figure 7 to Figure 12 , as the profile of the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com