Rebar mesh knitting unit

A technology of steel mesh and weaving machine, applied in wire mesh, other household appliances, household appliances, etc., can solve the problems of drawing, high cost, small weaving width, etc., and achieve the effect of promoting smooth entry and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

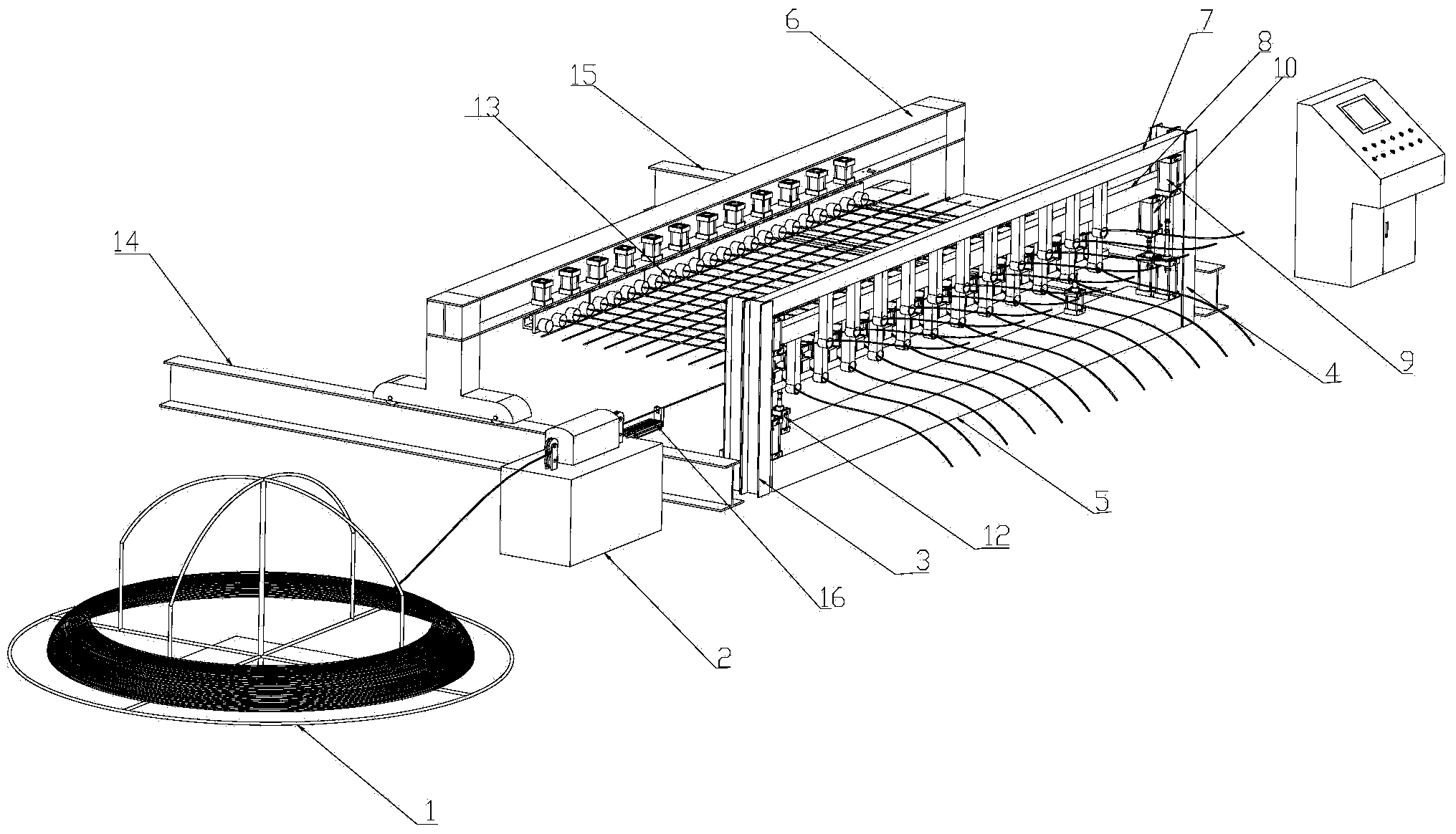

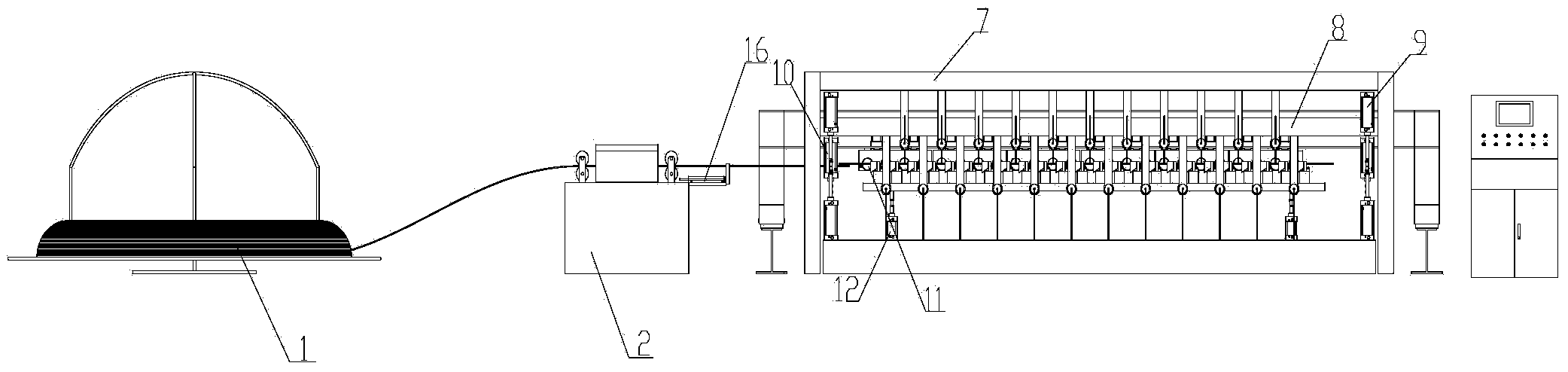

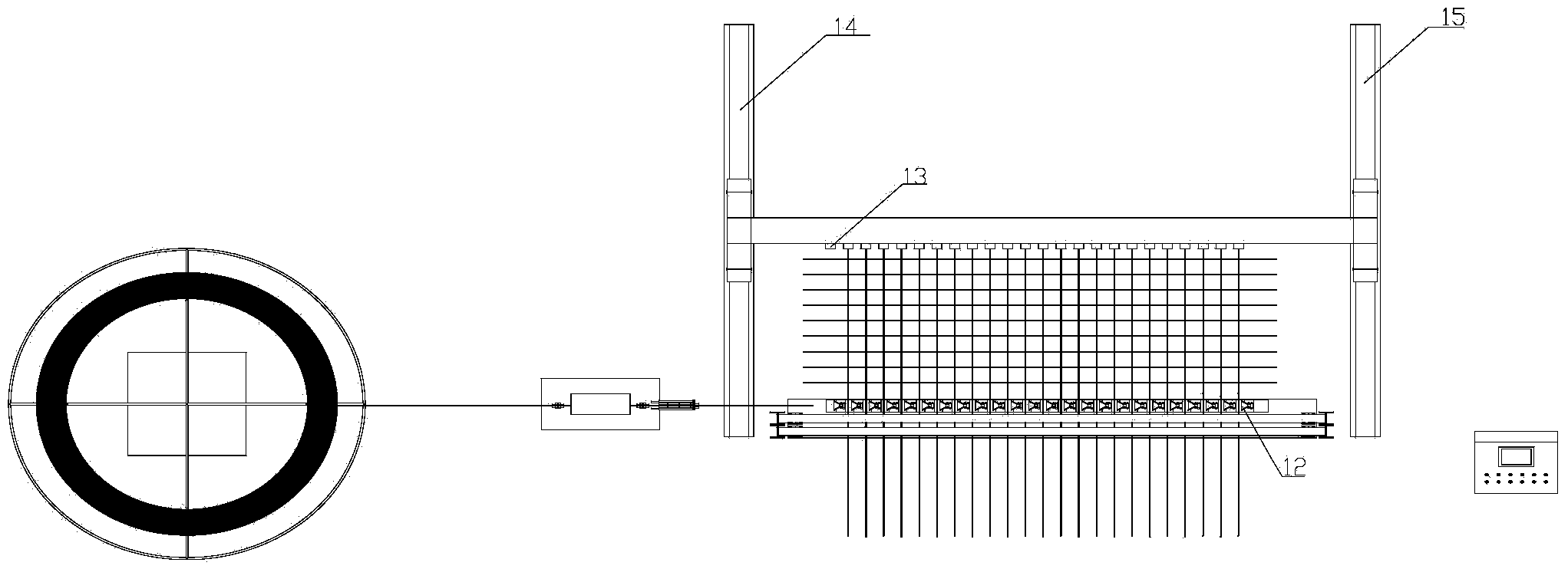

[0025] A steel mesh weaving unit provided in this embodiment includes a steel bar unit 1, a fixed-length shear 2 and a main body of a steel bar weaving machine. A vertical guide rail 3 and the second vertical guide rail 4 also include the first carriageway rail 14 perpendicular to the cuboid base 5 and the first vertical guide rail 3 and horizontally arranged respectively, perpendicular to the cuboid base 5 and the second vertical guide rail respectively. Guide rail 4 and the second driveway rail 15 that is arranged horizontally, and a mobile crosscar 6 that is parallel to the cuboid base 5 and can slide on the two driveway rails;

[0026] The first vertical guide rail 3 is completely identical to the second vertical guide rail 4 and is arranged symmetrically. Two identical vertical chutes are respectively divided on the opposite sides of the two guide rails. The first branch line swing arm 7 and the second branch line swing arm 8 and these two branch line swing arms are paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com