Integral-type mesh welding machine

A welding mesh machine, an integrated technology, applied in welding equipment, other manufacturing equipment/tools, metal processing, etc., can solve the problems of low production efficiency, low degree of automation, inability to automatically stack and pack, etc., to improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

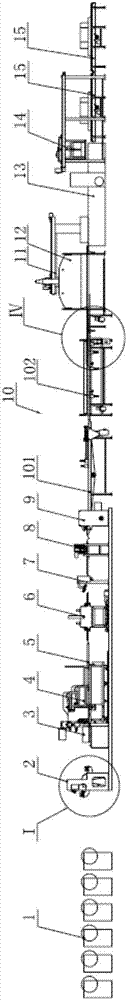

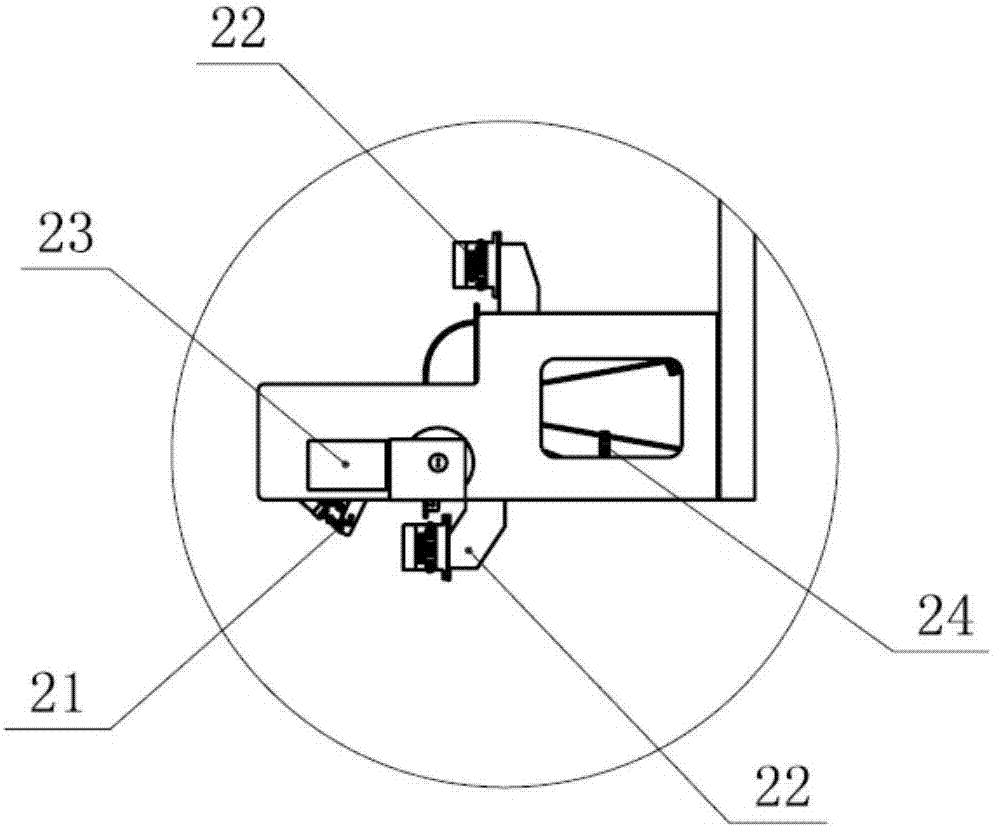

[0053] The present invention provides an integral welded mesh machine, such as figure 1 and figure 2 As shown, the integral welded mesh machine includes a longitudinal reinforcement pay-off frame 1 (not connected to the control mechanism), a longitudinal reinforcement conveying mechanism 2, Welding mechanism 3, horizontal bar blanking mechanism 4, stretching mechanism 5, shearing mechanism 9, transmission mechanism 10, baler 13, palletizing mechanism 14 and pallet traveling mechanism 15, between the stretching mechanism 5 and the shearing mechanism 9 Also be provided with the punching mechanism 6 that is all connected to the control mechanism and can open selectively and / or anti-thread mechanism 7 and / or the net cleaning mechanism 8, be provided with the bending feeding mechanism that is all conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com