Construction method for microseisms monitoring and stress relieving of strong rockburst tunnel

A technology for microseismic monitoring and stress relief, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as poor stress relief effects, and achieve stress relief in place, pertinence, simplicity and practicality, and reliable release effect detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

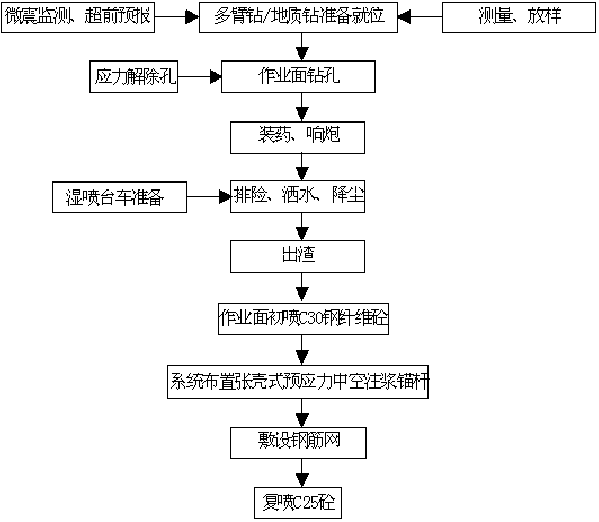

[0043] This embodiment discloses a construction method for microseismic monitoring and stress relief in strong rockburst tunnels, mainly to overcome the shortcomings of blind drilling and blasting and poor stress release effects in the previous stress release process, and to have accurate prediction of stress concentration locations, The stress is relieved in place, the detection result of the relief effect is reliable, the prevention and control of rockburst is highly targeted, simple and practical, strong operability and good effect, etc. The whole construction steps are as follows: figure 1 shown.

[0044] First, install a microseismic monitoring system, and conduct microseismic monitoring and rockburst prediction. The main functions of the microseismic monitoring system are as follows:

[0045] (1) Real-time and continuous collection of various triggers or continuous micro-damage signal data generated on site, timely locate the spatio-temporal distribution of micro-damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com