Tunnel steel arch frame lock foot anchoring stock net-spraying composite structure

A technology of locking foot anchor rod and combined structure, which is applied in tunnels, tunnel lining, installation of anchor rods, etc., can solve problems such as affecting the effect of support, and achieve the benefits of construction safety and structural stability, reduction of project cost, and great academic value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

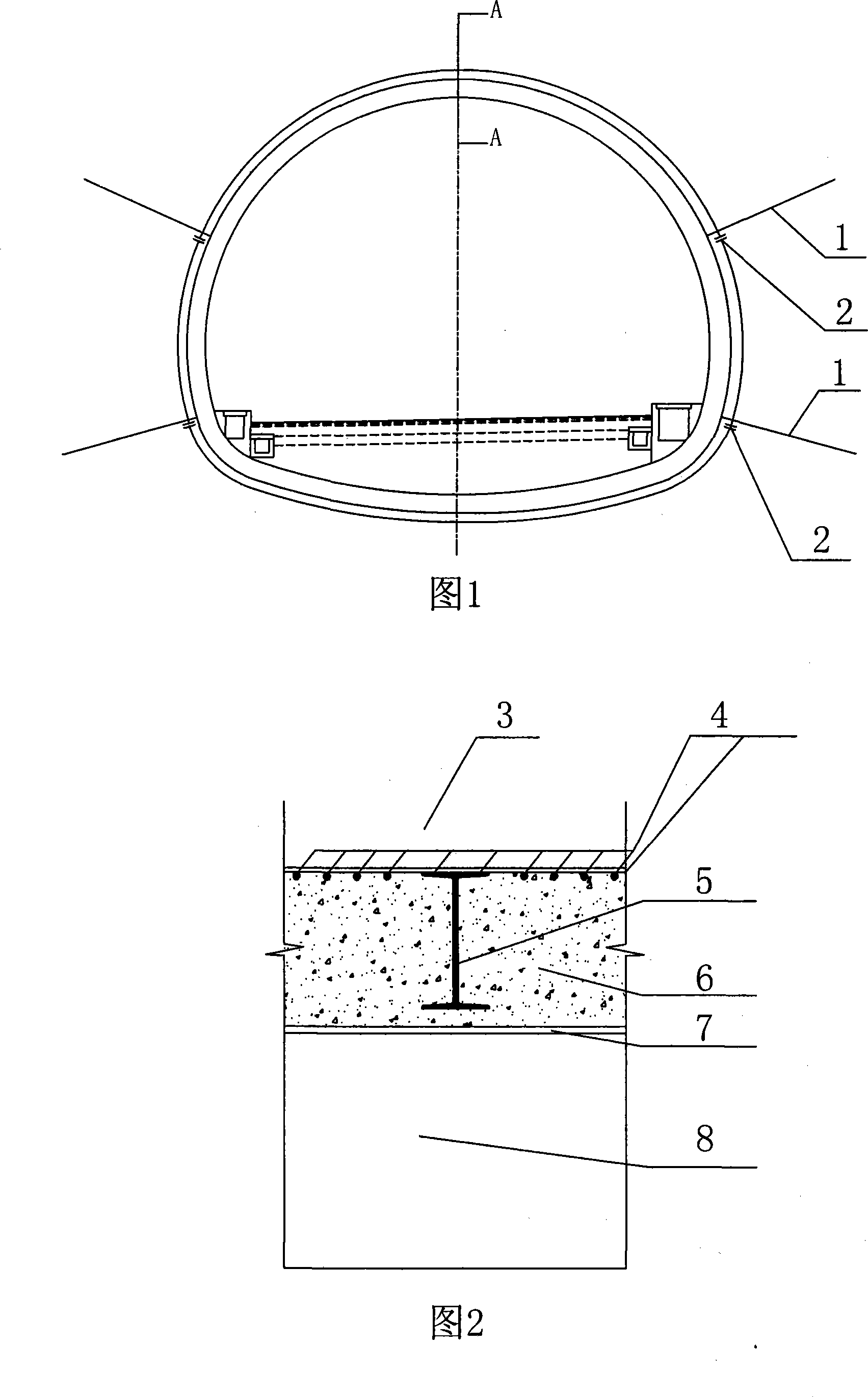

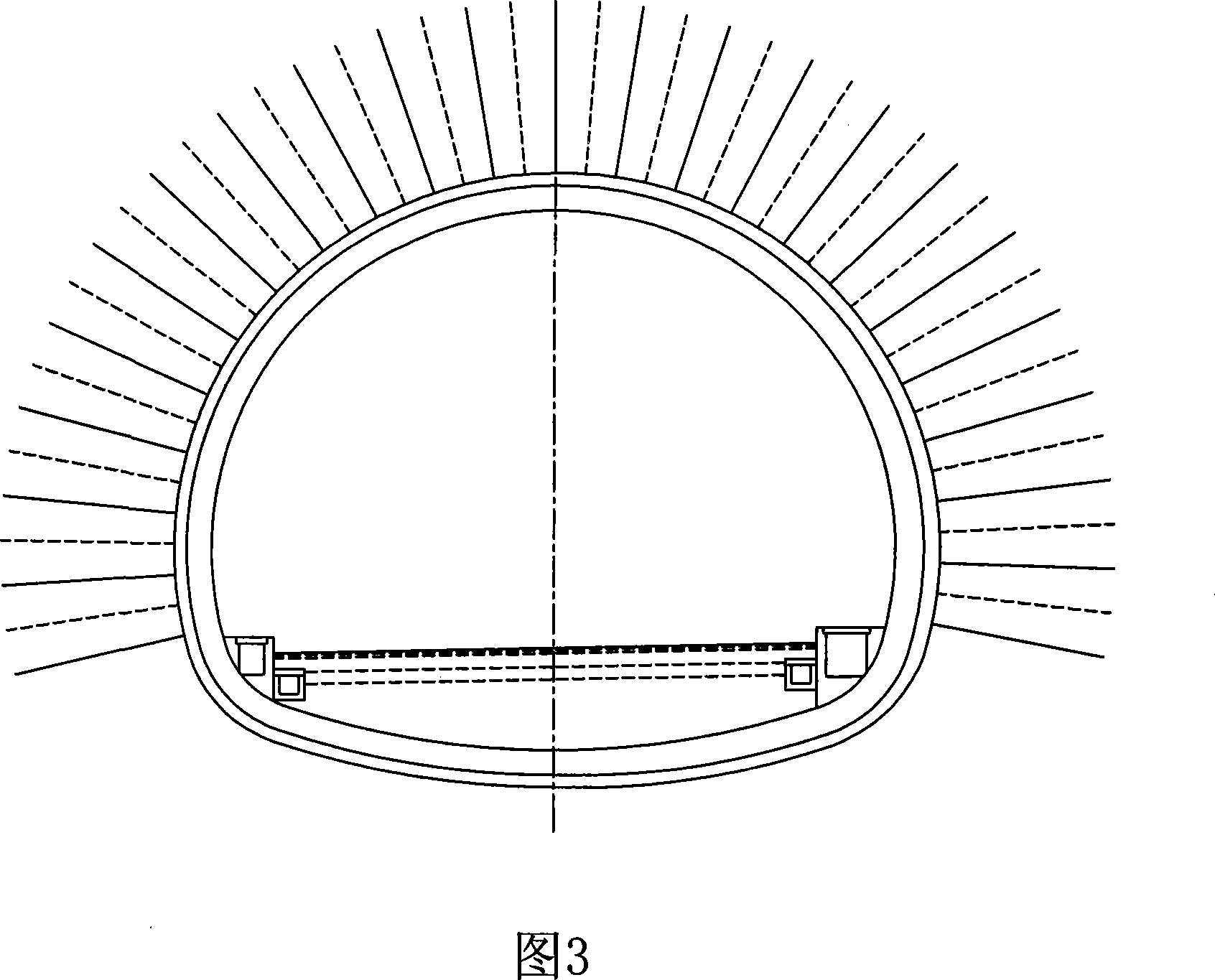

[0029] In the present invention, under the condition of weak surrounding rocks (levels IV, V, VI surrounding rocks), the initial support is changed from the form of bolt-sprayed support (system anchor + shotcrete + steel mesh + steel arch) to steel sprayed support. The form of protection (steel arch + locking foot anchor (pipe) + steel mesh + shotcrete), that is, the system anchor is canceled and replaced by the locking foot anchor (pipe) at the joint of the steel arch frame. Referring to Fig. 1 and Fig. 2, it includes a steel arch 5, on which a steel mesh 4 is arranged, at the joint 2 of the steel arch 5 is provided with a locking anchor rod (pipe) 1, and around the steel arch 5 is a shotcrete layer 6. A molded concrete layer 8 is outside the shotcrete layer 6, and a waterproof layer 7 is provided between the shotcrete layer 6 and the molded concrete layer 8. During actual use, after the tunnel is excavated, the concrete is sprayed first, then the steel arch 5 is erected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com