Self-leveling terrace powder mortar composite

A composition and flat dry powder technology, which is applied in the field of dry powder mortar composition, can solve the problems of mortar surface whitening, desanding, strength reduction, etc., and achieve the effect of improving flexibility, stabilizing strength, and eliminating whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

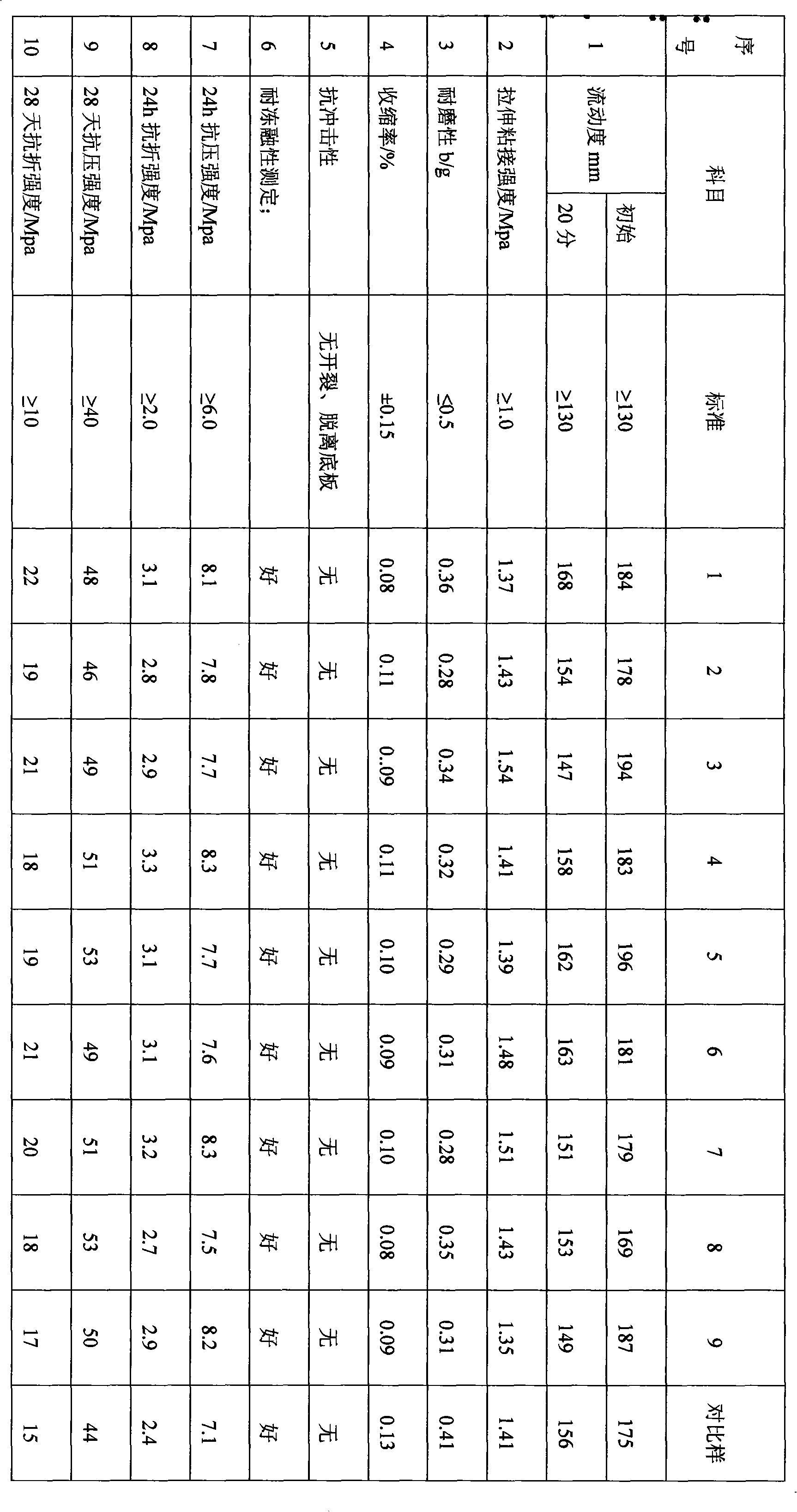

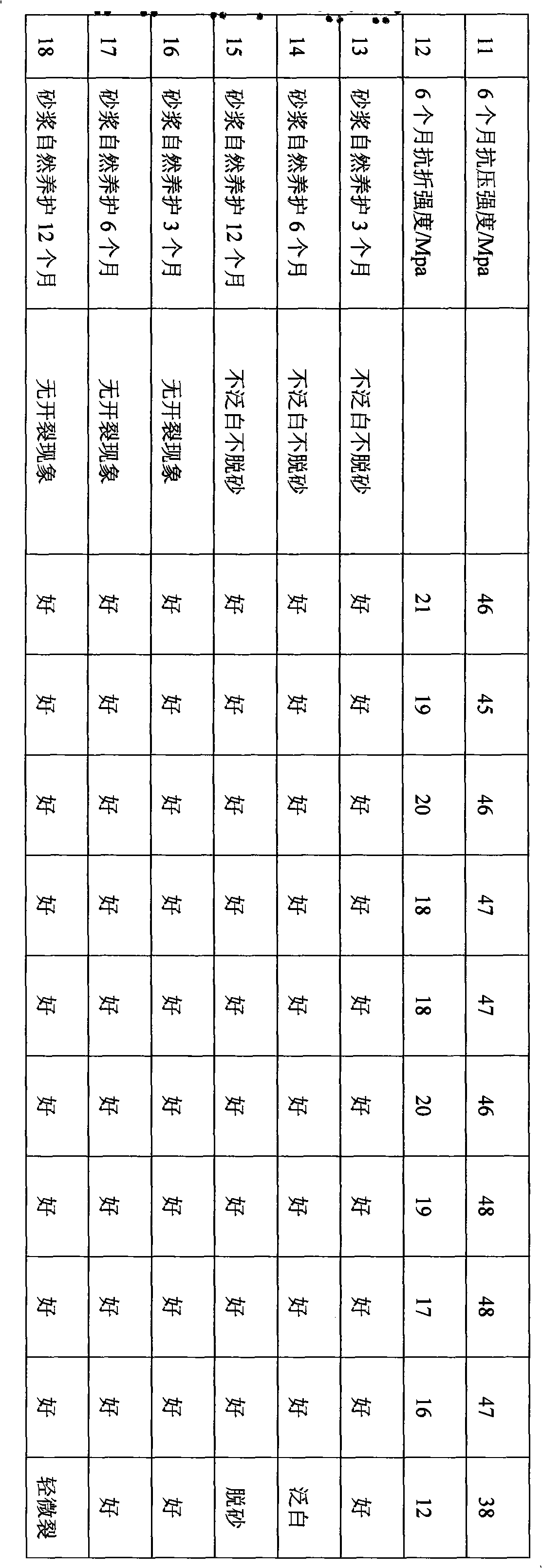

Examples

Embodiment 1

[0052] Preparation of zeolite grafted redispersible latex powder:

[0053] a) Calculated by weight, add 5 parts of zeolite powder (0.5um in particle size) to 40 parts of water, add acetic acid aqueous solution with a concentration of 10% by weight (the same below) to adjust the pH to 4, heat up to 50°C, and then add 1 part of hydroxyethyl ethyl cellulose and 0.5 part of polyvinylpyrrolidone with a weight-average molecular weight of 3000, and 2 parts of methacryloxypropyl triethoxysilane are made into bottom liquid;

[0054] b) Mix 10 parts of methyl methacrylate, 20 parts of (methyl) styrene, 20 parts of vinyl tertiary carbonate, and 1 part of butyl mercaptoacetate to make a mixed monomer, and then add 0.2 parts of allyl polyoxygen Vinyl ether ammonium sulfate, 0.2 parts of potassium persulfate and 10 parts of water are made into a mixed solution;

[0055] c) Take 5 parts of the mixed solution, 0.1 part of allyl polyoxyethylene ether ammonium sulfate, and 0.1 part of potassiu...

Embodiment 2

[0059] Preparation of zeolite grafted redispersible latex powder emulsion:

[0060] a) Calculated by weight, add 10 parts of zeolite powder (with a particle size of 1um) to 40 parts of water, add 10% aqueous acetic acid solution to adjust the pH to 5, heat up to 50°C, and then add 1 part of hydroxyethyl Ethyl cellulose and 0.5 parts of polyvinylpyrrolidone with a weight average molecular weight of 5000, and 2 parts of methacryloxypropyltriethoxysilane;

[0061] b) Mix 10 parts of ethyl methacrylate, 20 parts of methyl styrene, 20 parts of vinyl tertiary carbonate and 1 part of molecular weight modifier mercaptoethanol to make a mixed monomer, take 50 parts of the mixed monomer and add 0.2 parts Allyl polyoxyethylene ether, 0.2 parts of sodium persulfate and 10 parts of water are made into a mixed solution;

[0062] c) Take 5 parts of the mixed solution, 0.1 part of allyl polyoxyethylene ether and 0.1 part of sodium persulfate, add them to the bottom liquid prepared in step a)...

Embodiment 3

[0067] 300 parts of ordinary portland cement (42.5), 100 parts of aluminate cement, 400 parts of quartz sand (70-140 mesh) 140 parts of heavy calcium carbonate (200-350 mesh), 10 parts of anhydrite, the 40 parts of zeolite grafted redispersible latex powder, 10 parts of zeolite powder, 6 parts of water reducer (polycarboxylate high-efficiency water reducer, Suzhou Xingbang Chemical Building Materials Co., Ltd., the product of brand SUNBOPC-1030, the same below), disinfectant 2 parts of foaming agent (Hangzhou Haichuan Chemical Co., Ltd., brand D-801, the same below), 1 part of tartaric acid, 0.5 part of lithium carbonate, 1 part of carboxymethyl cellulose ether (20,000 molecular weight), 1 part of aluminum powder 1 part, 1 part of thixotropic lubricant, 230 parts of water.

[0068] Example 3

[0069] Ordinary Portland cement (42.5) 250 parts, aluminate cement 50 parts, quartz sand (70-140 mesh) 300 parts, heavy calcium carbonate (200-350 mesh) 300 parts, anhydrite 20 parts, z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com