Novel tailing consolidator and preparation method thereof

A technology of cementing agent and tailings, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of high cost, and achieve the effect of low production cost, cost reduction and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

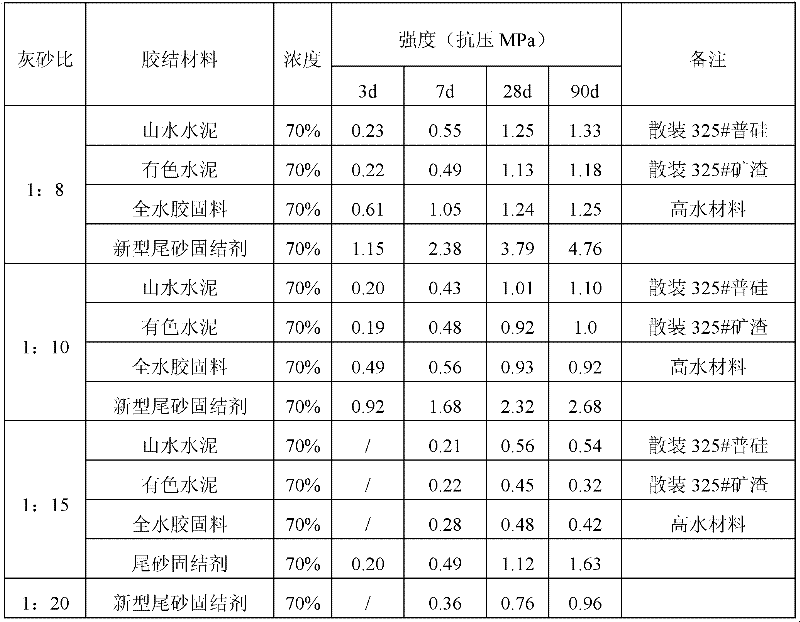

Examples

Embodiment 1

[0038] The weight concentration of each component of the present embodiment is as follows:

[0039] Component 1: Portland cement clinker 9%

[0040] Component 2: Anhydrite 10%

[0041] Component 3: Quicklime 6%

[0042] Component 4: Na2SO4 0.2‰

[0043] Component 5: Hydroxymethylcellulose 0.2‰

[0044] Component 6: Fly Ash 5%

[0045] Component 7: Blast furnace water-quenched slag ground fine powder 69.96%

[0046] The above-mentioned components are accurately weighed, stirred evenly by a mixer, transported to a ball mill by a belt conveyor for grinding, and ground to a fineness of 380m2 / kg and then put into a finished product warehouse for standby.

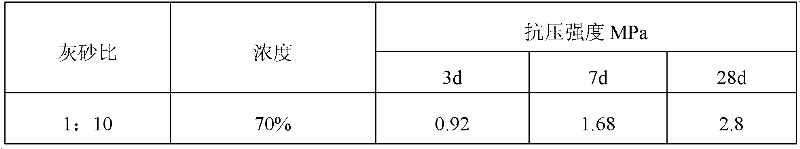

[0047]When preparing the slurry, first mix the mining tailings with water to form a slurry with uniform concentration, add the consolidation agent into the slurry through a feeder, and mix the slurry in a mixer (twin-shaft mixer) 2 minutes to form a slurry with a weight concentration of 70%, and the slurry can be transporte...

Embodiment 2

[0051] The weight concentration of each component of the present embodiment is as follows:

[0052] Component 1: Aluminoferrite cement clinker 13%

[0053] Component 2: Phosphogypsum 15%

[0054] Component 3: Quicklime 6%

[0055] Component 4: Nacl 3‰

[0056] Component 5: Hydroxymethylcellulose 0.25‰

[0057] Component 6: Bauxite powder 7.05%

[0058] Component 7: Blast furnace quenched slag ground fine powder 58.625%

[0059] The above-mentioned components are accurately weighed, transported to a ball mill by a belt conveyor for grinding, and ground to a fineness of 400m 2 / kg and put it into the finished product warehouse for later use.

[0060] To prepare the slurry, mining tailings are mixed with water to form a 60% slurry which is transported underground where the cement is passed through feeders where it is pumped or gravity piped to the backfill ore Added to the slurry in the pipeline, the cement can be mixed with the slurry through the turbulent flow in the pip...

Embodiment 3

[0064] The weight concentration of each component of the present embodiment is as follows:

[0065] Component 1: Portland cement 17.54%

[0066] Component 2: Anhydrite 17.54%

[0067] Component 3: Quicklime 5.85%

[0068] Component 4: KCl 6‰

[0069] Component 5: Hydroxyethylcellulose 0.5‰

[0070] Component 6: High Calcium Limestone Powder 9.37%

[0071] Component 7: Blast furnace quenched slag ground fine powder 43.65%

[0072] The above-mentioned components are accurately weighed, transported to a ball mill by a belt conveyor for grinding, and ground to a fineness of 420m 2 / kg and put it into the finished product warehouse for later use.

[0073] When preparing the slurry, first mix the mining tailings with water to form a slurry with uniform concentration, add the consolidation agent into the slurry through a feeder, and mix the slurry in a mixer (twin-shaft mixer) 5 minutes to form a slurry with a weight concentration of 70%, and the slurry can be transported to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com