Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

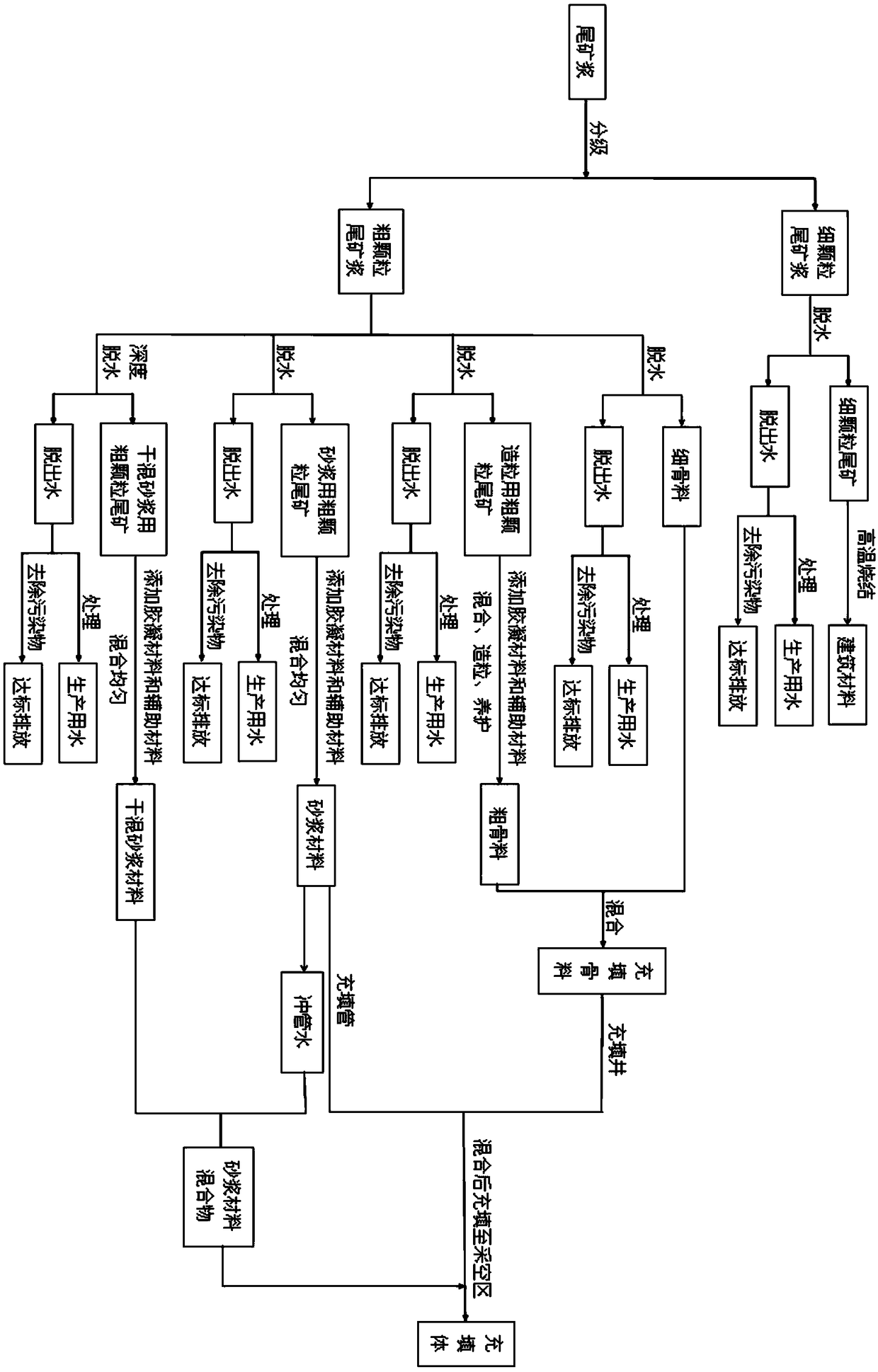

307results about How to "Improve filling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

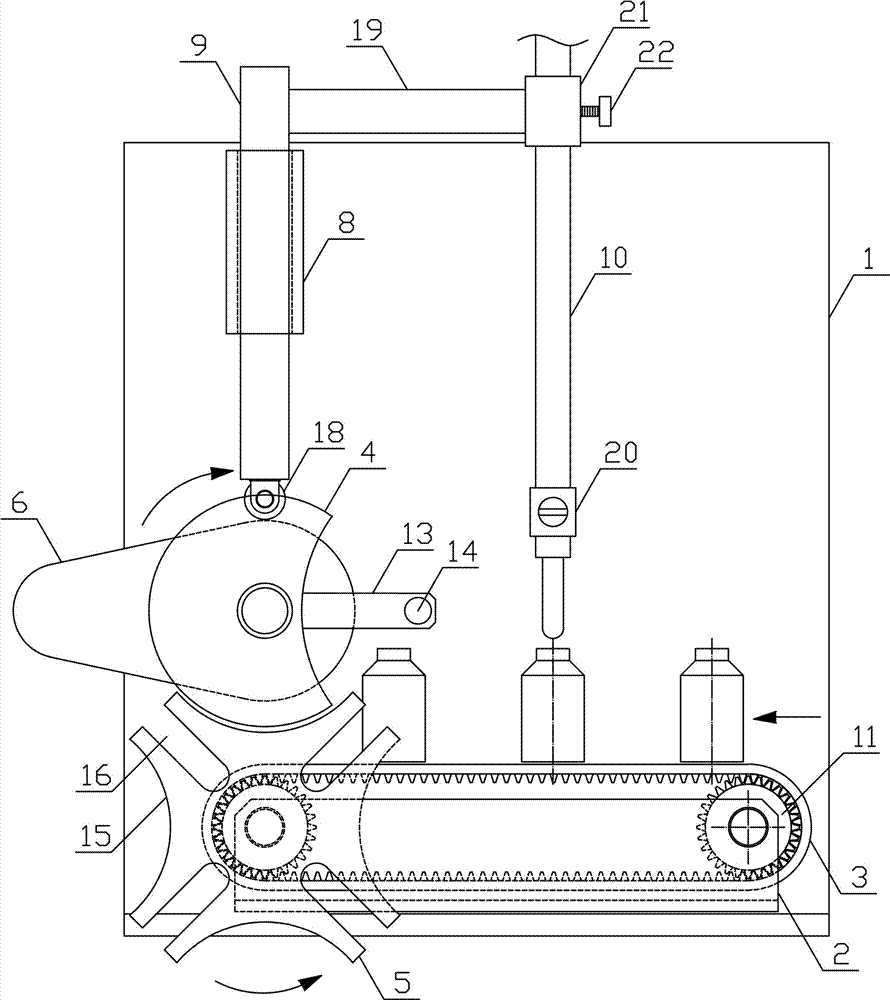

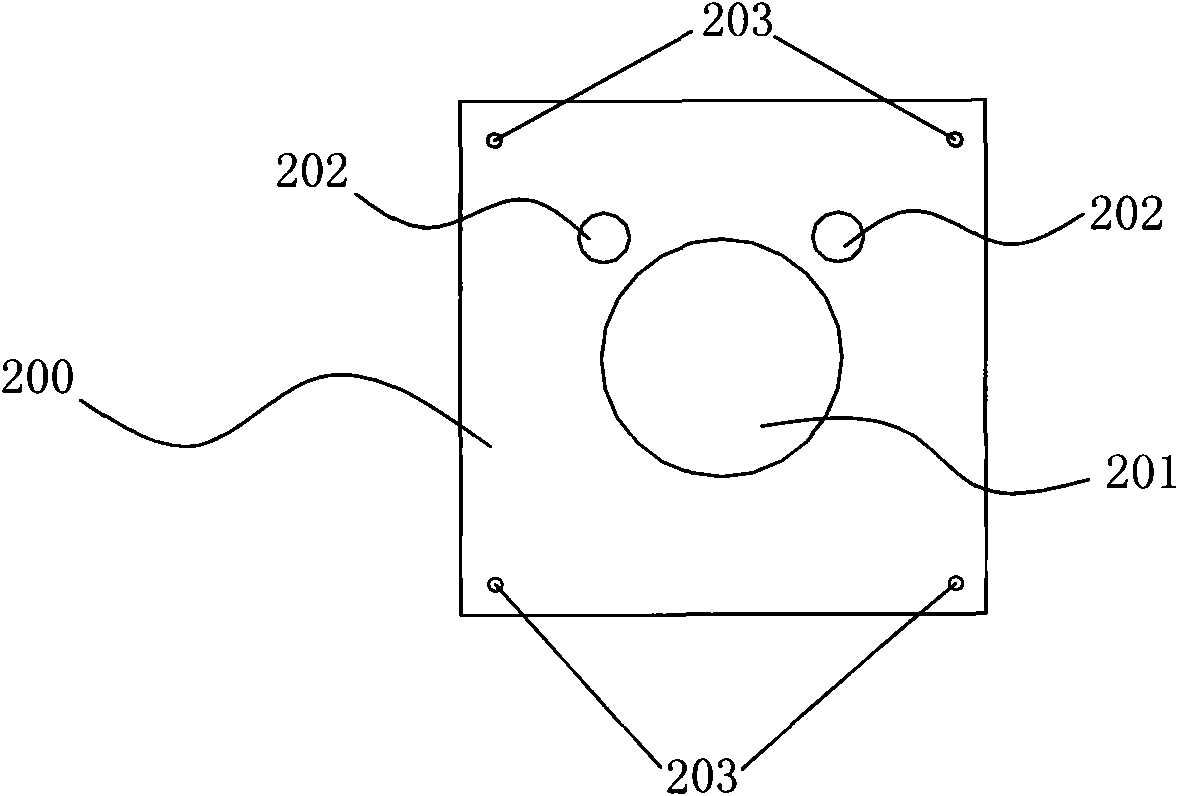

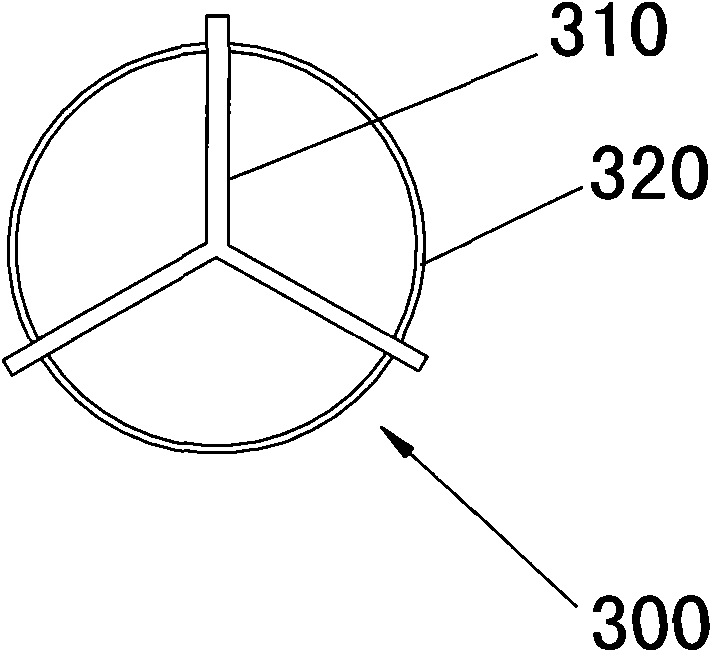

Continuous filling mechanism

InactiveCN107055439ASmooth transmissionThe conveyor belt can be moved intermittently according to the needs, and the transmission is smoothLiquid bottlingFilling materialsEngineering

The invention discloses a continuous filling mechanism, which belongs to the field of material filling machinery and equipment. The invention includes a fixed bracket, a transmission bracket, a round can conveyor belt, a rotating circular plate, a slotted rotary plate, a rotating cam, a rotating motor, a lifting sleeve, a lifting guide rod and a filling material tube, and the round can conveyor belt is horizontally arranged on the transmission bracket. On the side, the rotating circular plate is vertically arranged at one end of the rotating shaft, and the card slot rotating plate is vertically arranged on one side of the translation pulley. Between two adjacent rotating arc surfaces, there are drive slots along the radial direction of the card slot rotating plate. The rotating card slot matching the wheel, the rotating motor and the rotating shaft are connected by a transmission belt transmission, the lifting sleeve is slid along the vertical direction and a lifting guide rod is installed, and the filling material tube is vertically set at one end of the filling support plate . The invention has a reasonable structural design, can quickly, efficiently and smoothly fill the round cans one by one continuously, improves the efficiency and quality of filling, and meets the needs of production and use.

Owner:屠明州

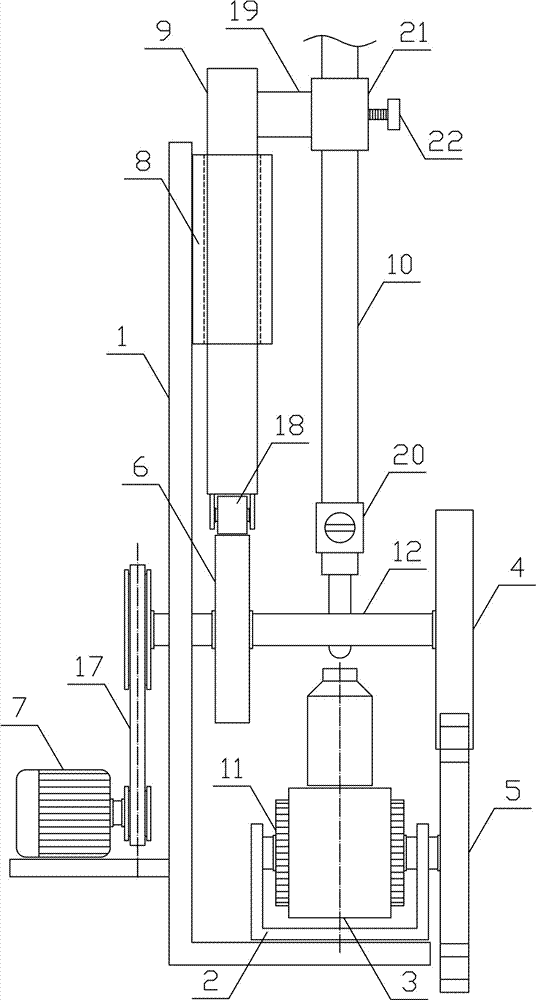

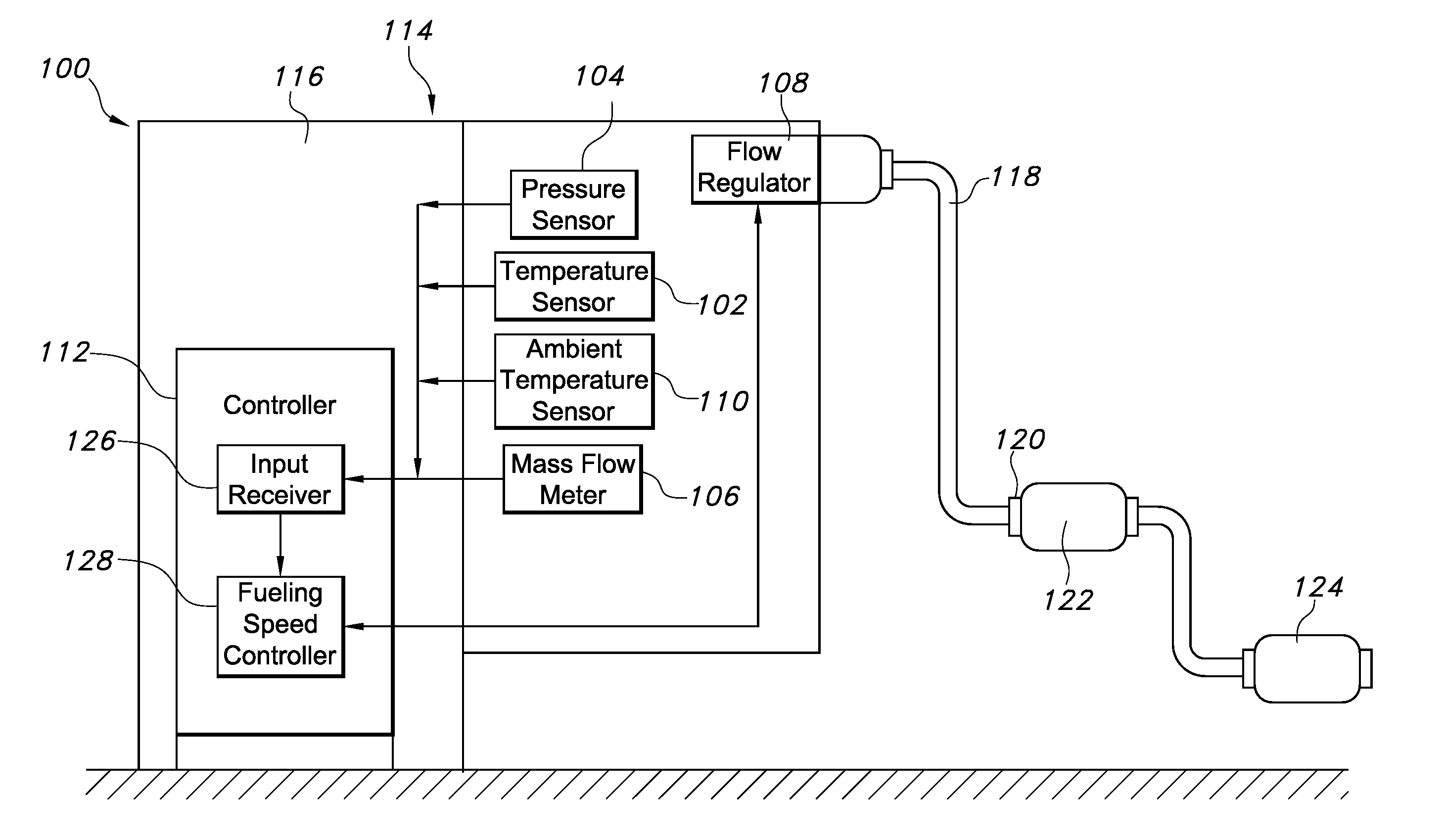

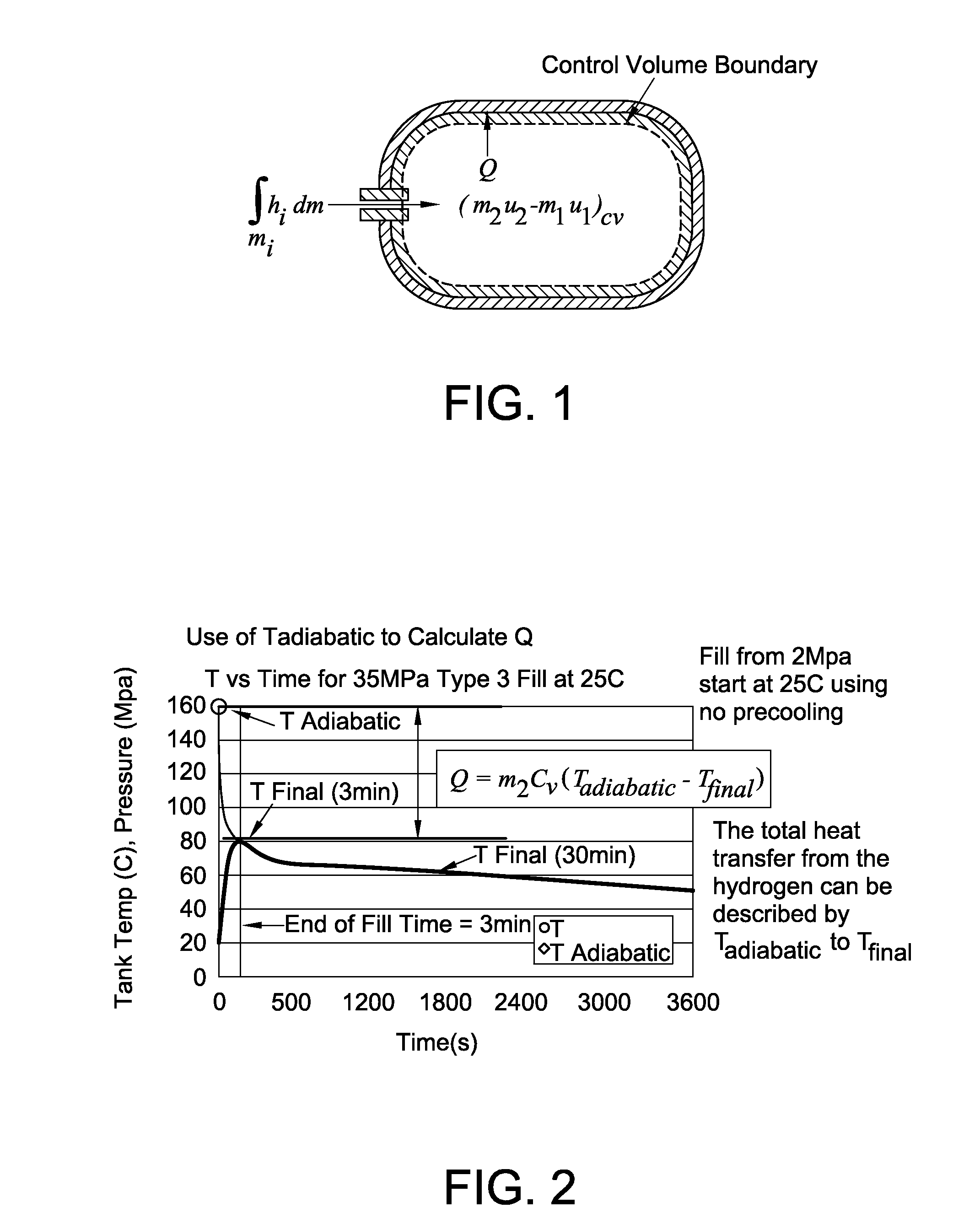

Method and system for tank refilling using active fueling speed control

ActiveUS20140290790A1Improve performanceImprove fuel performanceLiquid fillingGas handling applicationsAnalytical equationsFuel tank

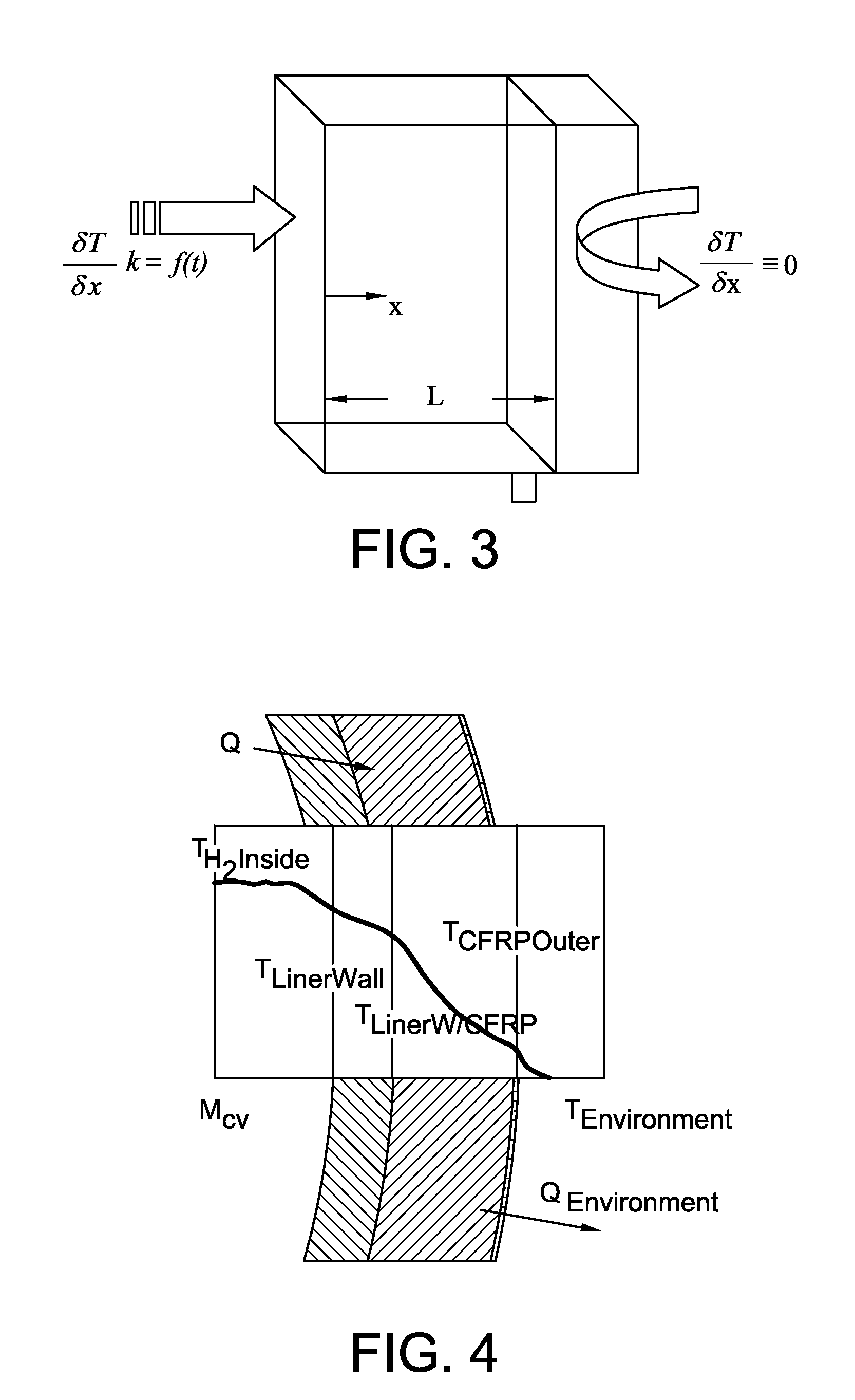

Disclosed is an improved analytical method that can be utilized by hydrogen filling stations for directly and accurately calculating the end-of-fill temperature in a hydrogen tank that, in turn, allows for improvements in the fill quantity while tending to reduce refueling time. The calculations involve calculation of a composite heat capacity value, MC, from a set of thermodynamic parameters drawn from both the tank system receiving the gas and the station supplying the gas. These thermodynamic parameters are utilized in a series of simple analytical equations to define a multi-step process by which target fill times, final temperatures and final pressures can be determined. The parameters can be communicated to the station directly from the vehicle or retrieved from a database accessible by the station. Because the method is based on direct measurements of actual thermodynamic conditions and quantified thermodynamic behavior, significantly improved tank filling results can be achieved.

Owner:HONDA MOTOR CO LTD

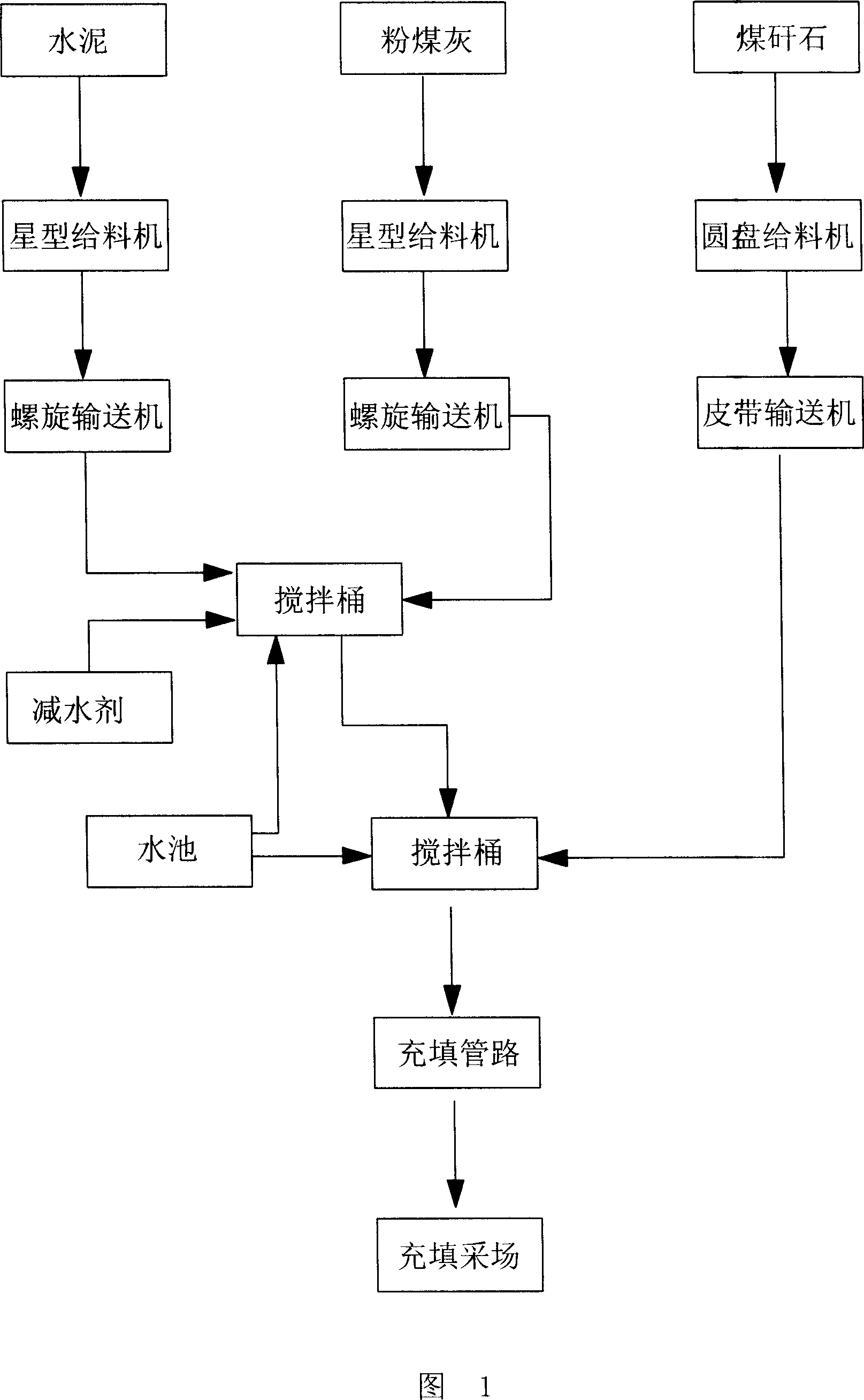

Paste-like backfill technology used in coal cutting area and the paste-like thereof

InactiveCN101008315AHigh content of dry ingredientsStrong dry material component contentMaterial fill-upWater leakageUltimate tensile strength

The invention relates to a paste self-flow stuff technique of coal mine and relative paste, which uses the coal gangue as main stuff. The invention is characterized in that the stuff technique comprises that mixing cement and powder coal into water to form pulp; adding coal gangue to form coal gangue suspension paste; using tube to self-flow transmit the paste into under-well stuff area to stuff the mining field. The invention uses coal gangue as main stuff material and uses self-flow stuff technique, with low cost and the application in the underground coal layer, to reduce the pollution of coal gangue. The inventive paste has high water contant and low water leakage, therefore, the stuff has high strength.

Owner:邸建友

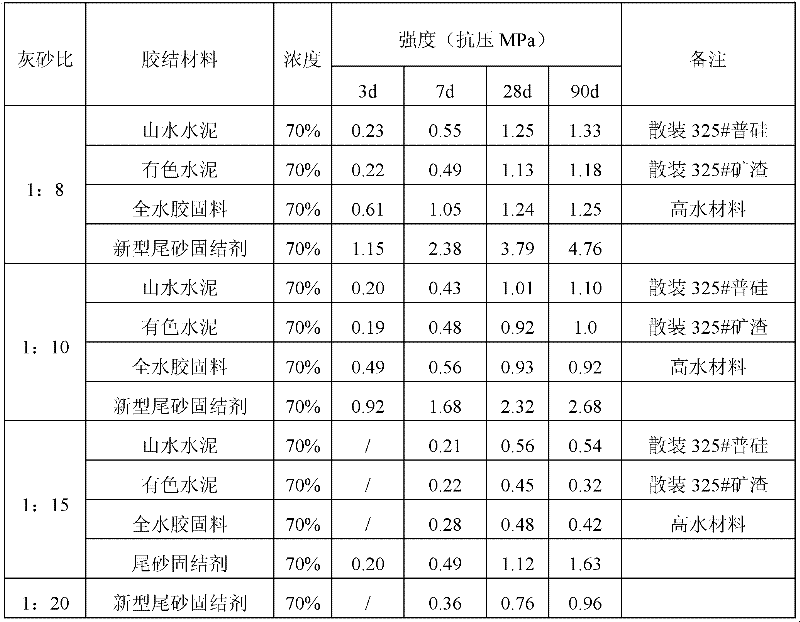

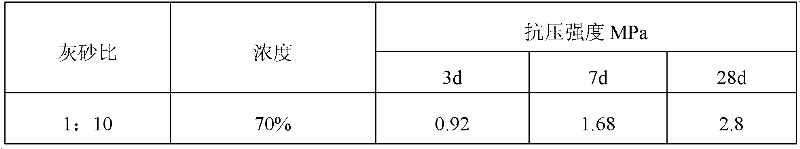

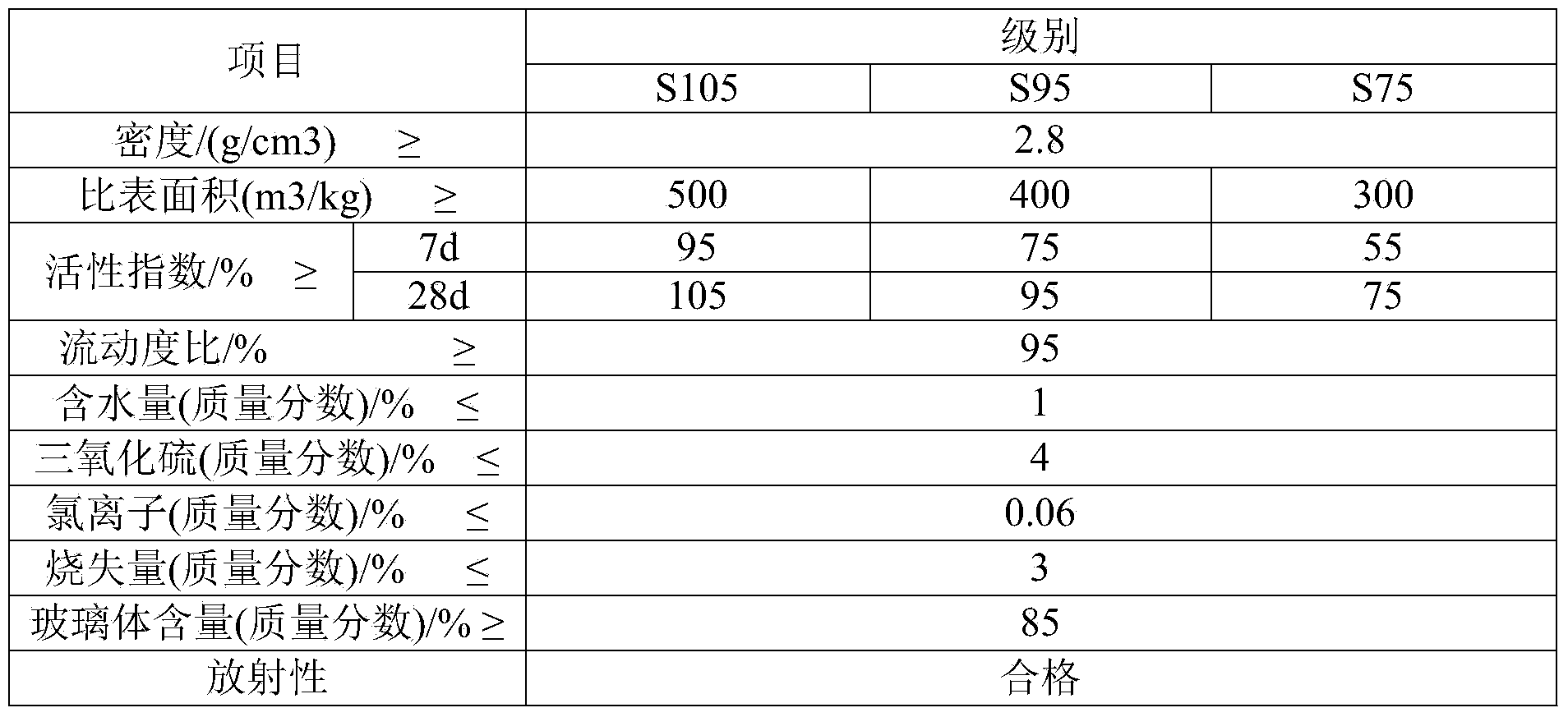

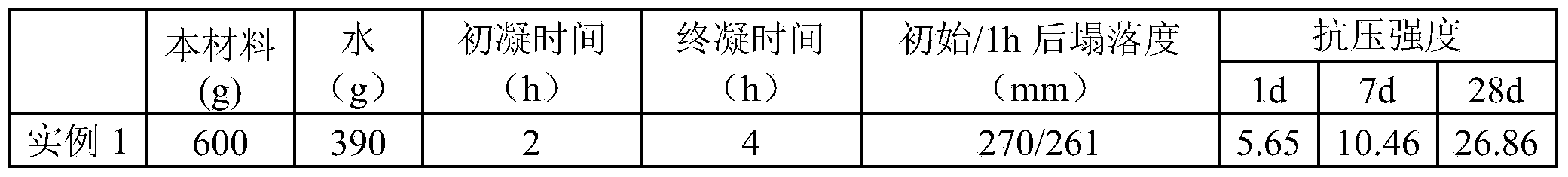

Novel tailing consolidator and preparation method thereof

The invention concretely relates to a novel tailing consolidator which uses fine powder ground from blast furnace water quenching slag as a main raw material and a preparation method of the consolidator. The consolidator is characterized in that the consolidator comprises, by mass concentration, 9 % to 17.54% of portland cement clinker, 10% to 17.54% of anhydrite, 6% to 10% of quicklime, 0.2 to 6 thousandths of Na2SO4, 0.2 to 0.5 thousandths of carboxymethyl cellulose, 5% to 10% of coal ash and 43.65% to 69.96% of the fine powder ground from the blast furnace water quenching slag. Each above component is dried by a dryer, put in a mixer to be evenly stirred, and conveyed to a bowl mill by a belt conveyer to be ground. The blast furnace slag discharged from a smeltery is used as the main raw material in the invention to reduce the cost and solve slag processing, so the consolidator has the advantages of low production cost, simple processing, and agile and convenient usage. A usage amount of the consolidator in the present invention is half or less than the usage amount of common cement under the same conditions with the same backfilling intensity.

Owner:淄博乾耀固结材料有限公司

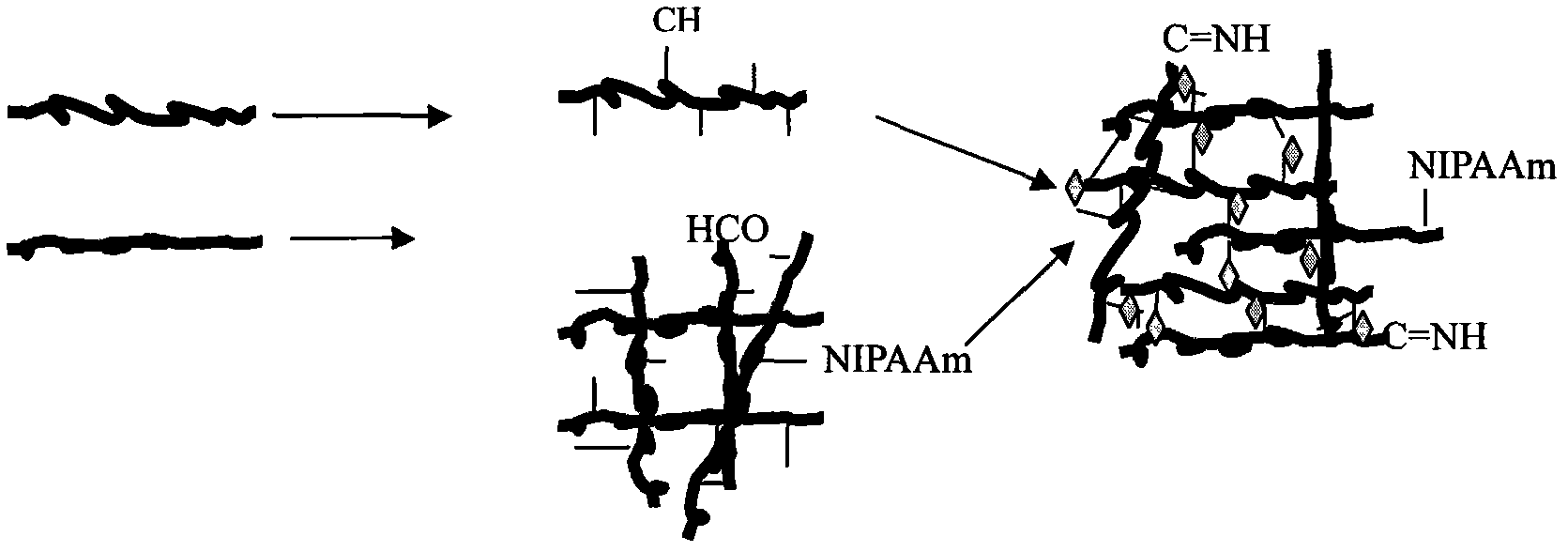

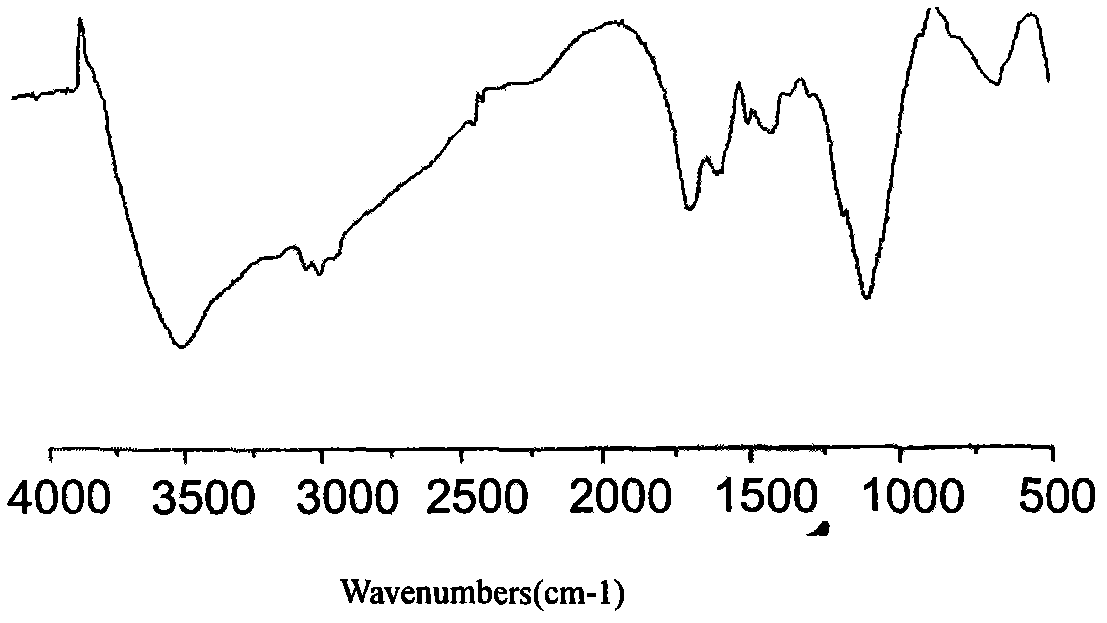

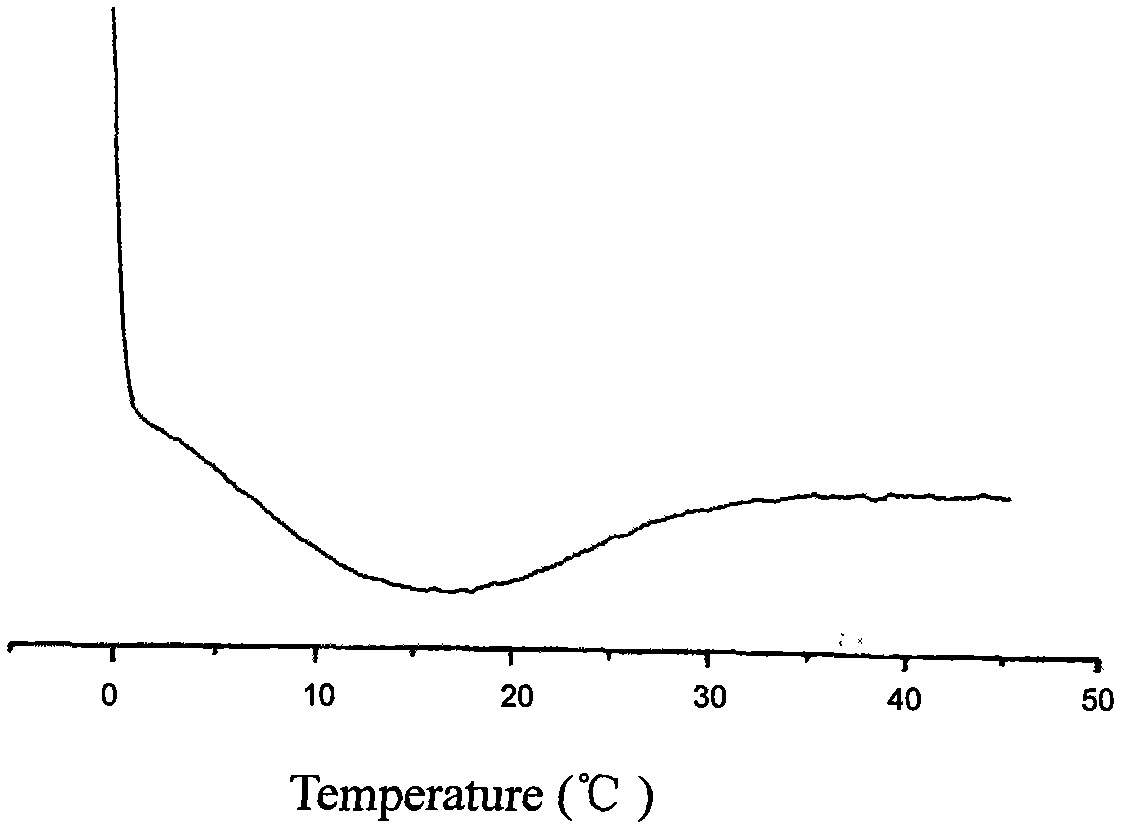

Injectable temperature sensitive gel used for filling and repairing damaged tissues

The invention relates to an injectable temperature sensitive gel used for filling and repairing damaged tissues. The gel is characterized in that: medical-grade hyaluronic acid and chitosan are used as gel raw materials; the gel swelling ratio is 2-500; and a temperature sensitive temperature is 32-37 DEG C. The gel provided by the invention has the advantages that the injection temperature sensitive gel has physical and chemical properties of a general gel, also has injectable and temperature sensitive properties and a good fluidity at a room temperature and is easy for injection; the formability in organisms is good and the degradation is slow so that the general gel can not be compared; a cross-linking agent is not used for the gel so that harms of the cross-linking agent to a human body are avoided; a gel system can prolong a persistence time of the gel in a body, and also can continuously stimulate the body to produce reactions so that the tissue in-situ regeneration and repair is promoted and the filling quality is increased; and the gel simultaneously has the advantages of reducing bacterial invansion, anticoagulation and low allergic reaction and the like.

Owner:冯淑芹

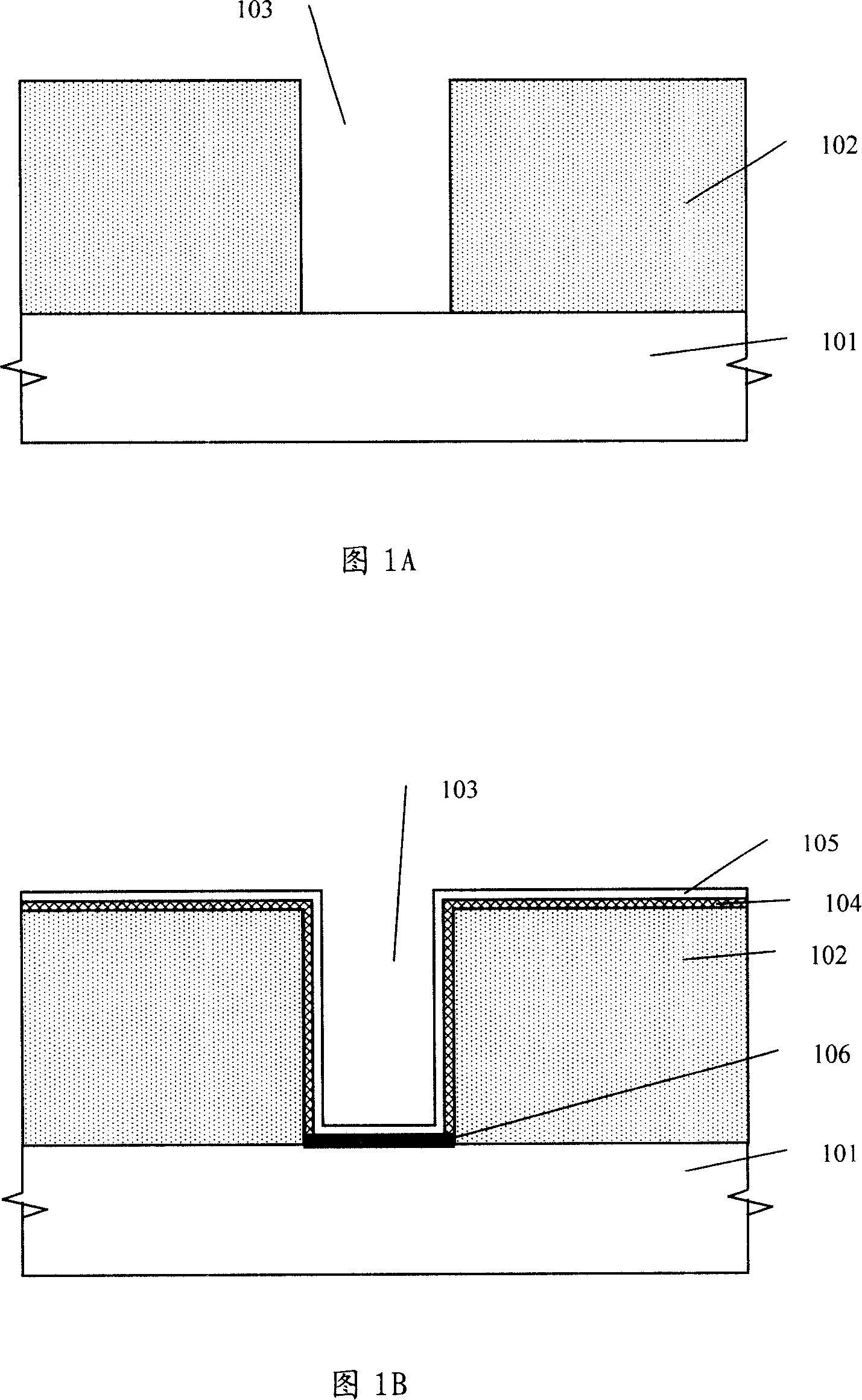

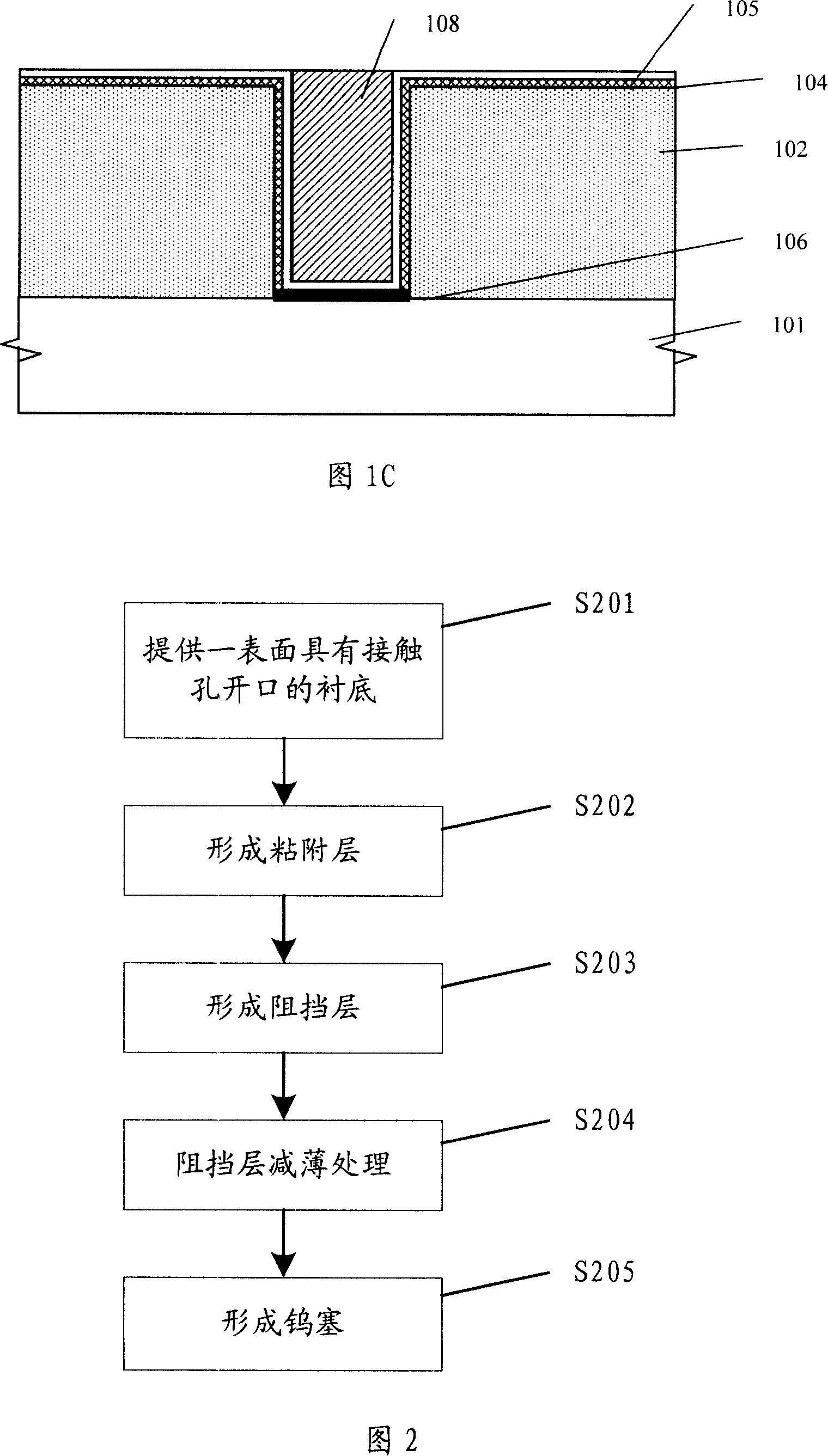

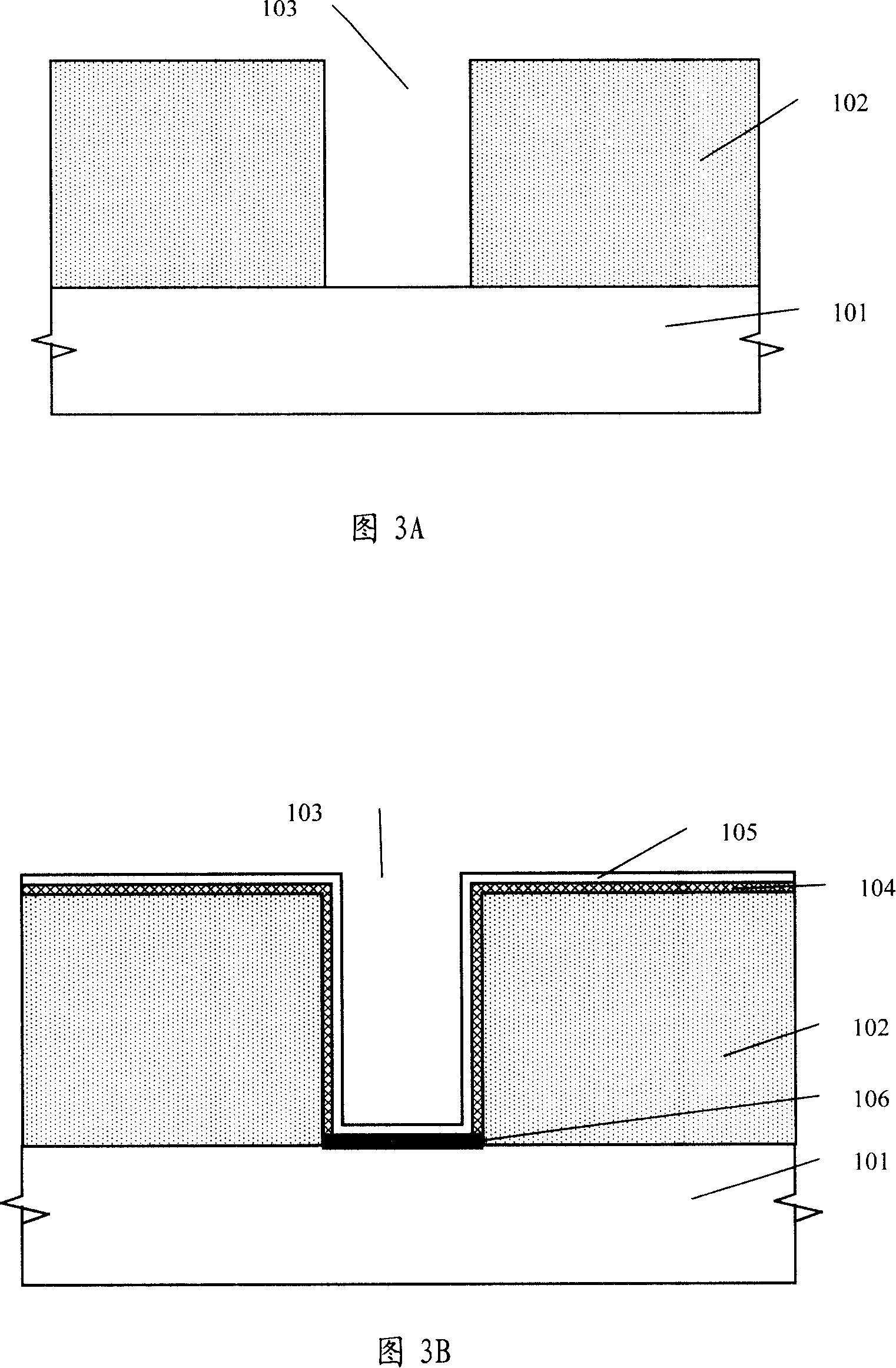

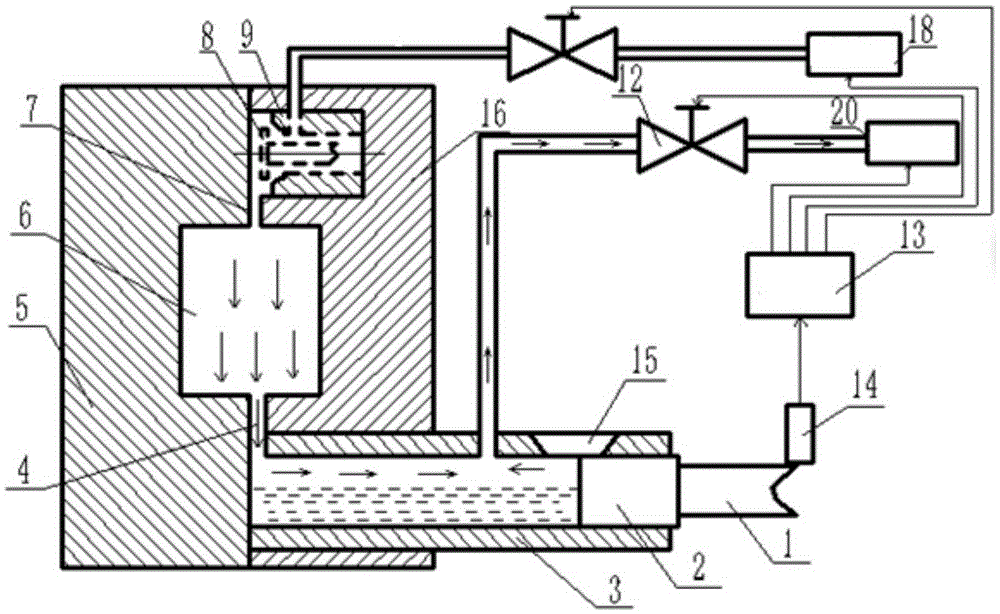

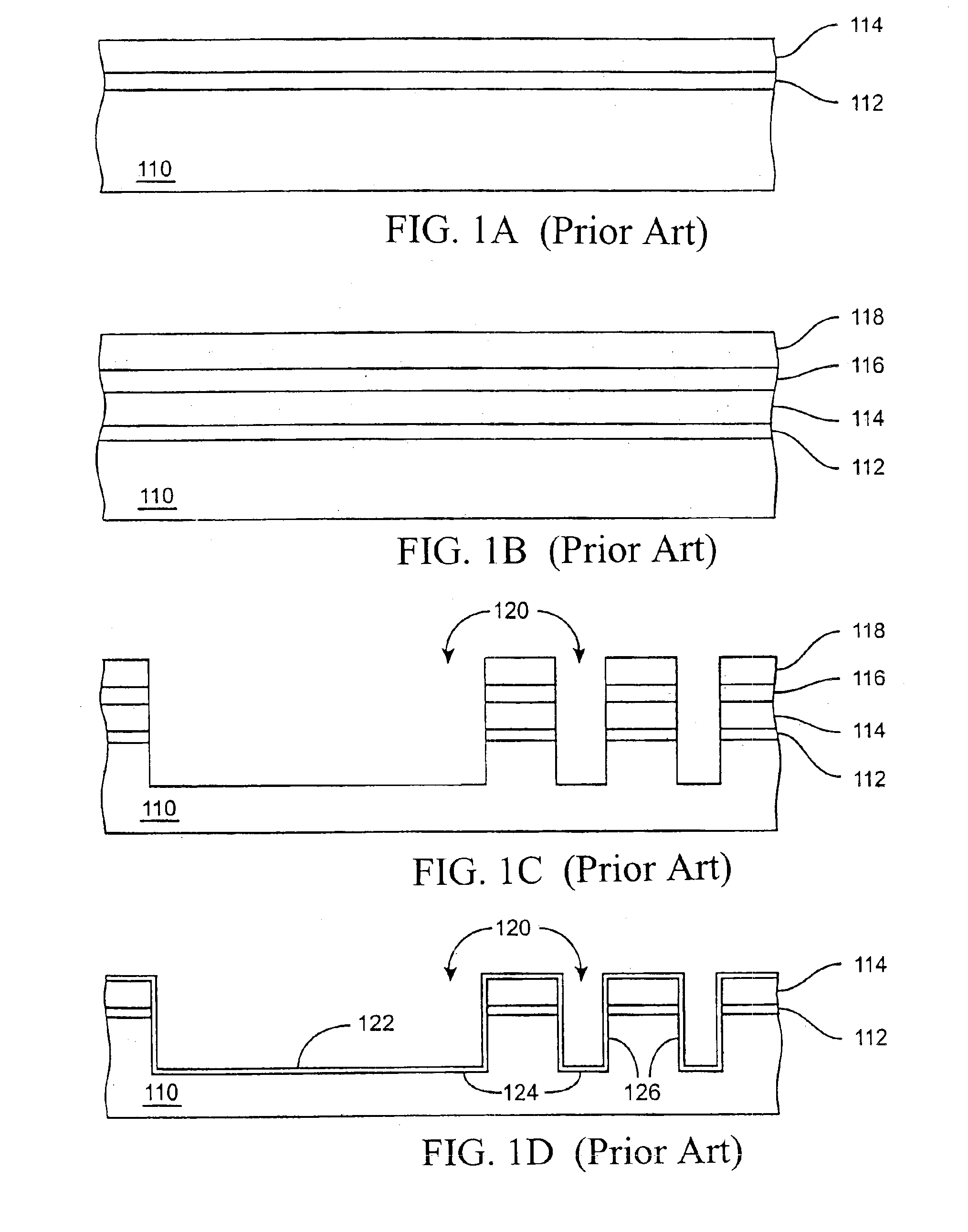

Filling method of contact hole

ActiveCN101140898AReduce contact resistance valueExcellent electrical propertiesSemiconductor/solid-state device manufacturingMaterials scienceContact hole

A padding method for contact hole is provided, which comprises: providing an underlay with at least one open mouth on its surface; forming the adhesion layer on the said underlay; forming the barrier layer on the said adhesion layer; reduction processing to the said barrier layer at bottom of the open mouth of the contact hole; forming W-Plug inside the said open mouth of the contact hole. The padding method in the invention reduces the thickness of the barrier layer at bottom of the contact hole and improves the electrical properties of the contact hole.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

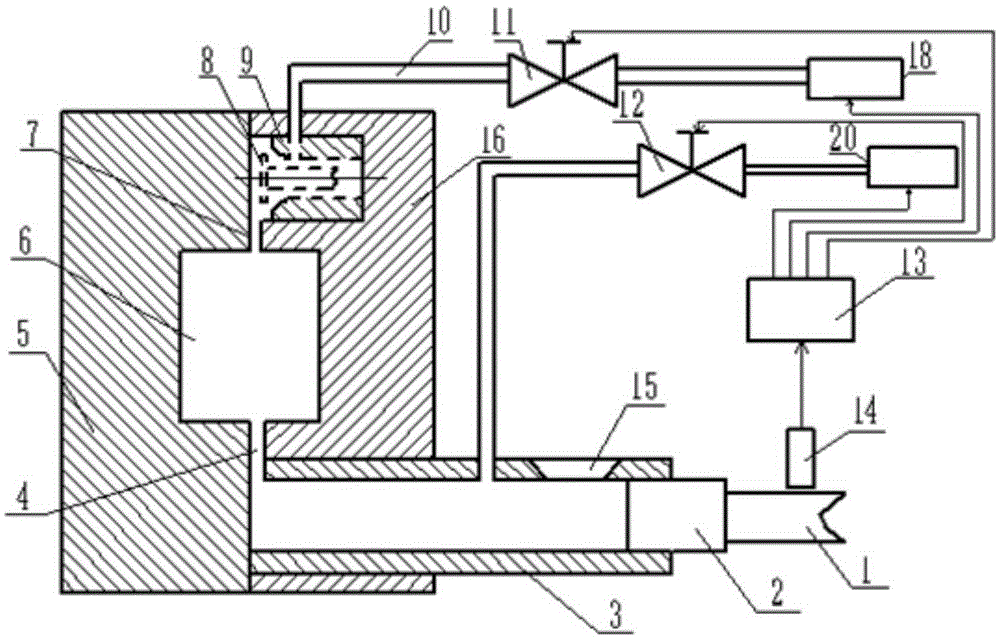

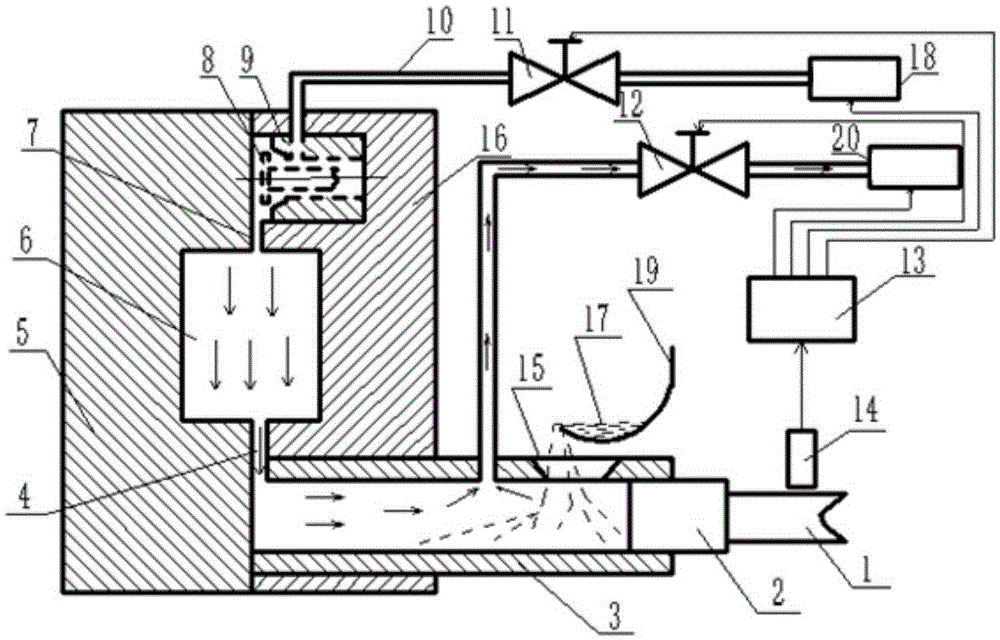

Die-casting mechanism of horizontal freezing chamber vacuum die-casting machine and method for using die-casting mechanism for die-casting operation

ActiveCN105414515AReduces chances of getting into cavitiesEliminate the effects ofDie castingEngineering

The invention discloses a die-casting mechanism of a horizontal freezing chamber vacuum die-casting machine. The die-casting mechanism comprises a pressure chamber, a die-casting die, a vacuum valve, a punch, an injection rod, a first stop valve, a first vacuum system, a second stop valve, a second vacuum system, a control device and a displacement sensor. The die-casting die comprises a fixed die body and a movable die body, the movable die body and the fixed die body are matched, and therefore a cavity, an inner gate and an exhausting way are formed. The vacuum valve is arranged in a valve cavity in the fixed die body. The punch is fixedly connected with the injection rod. The pressure chamber is provided with a casting gate and a pipe connecting joint, the pipe connecting joint is connected with a second vacuum pipe, the other end of the second vacuum pipe is connected with the second stop valve, and the second stop valve is connected with the second vacuum system. The control device is used for controlling operation of the first vacuum system and the second vacuum system and controlling opening and closing of the first stop valve and the second stop valve. The die-casting mechanism has the beneficial effects of being good in vacuumizing effect, easy and convenient to arrange and maintain, low in fault rate and long in service life.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

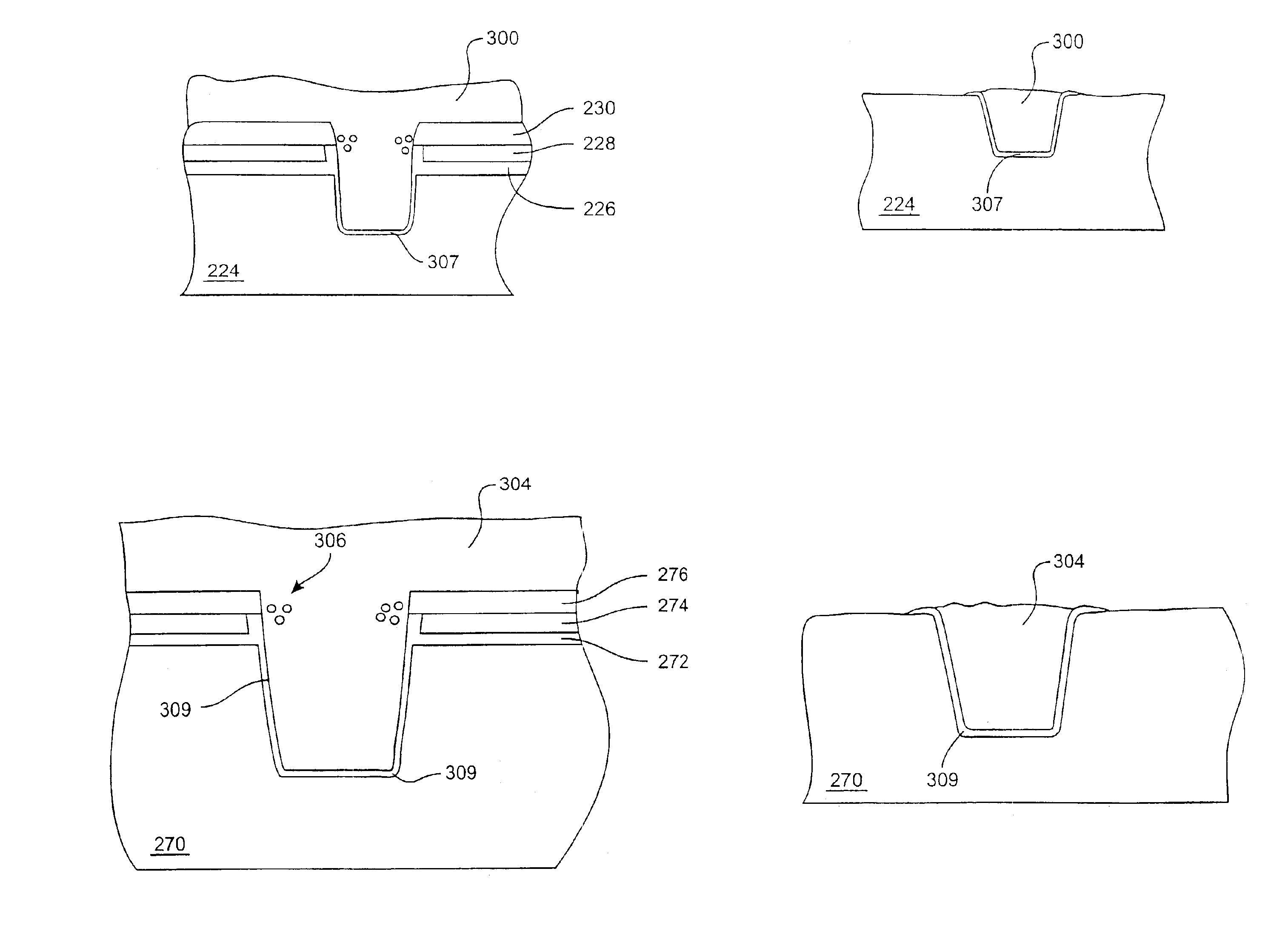

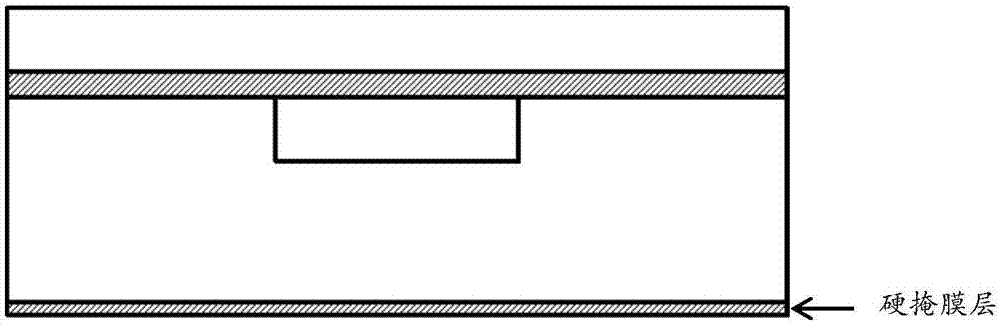

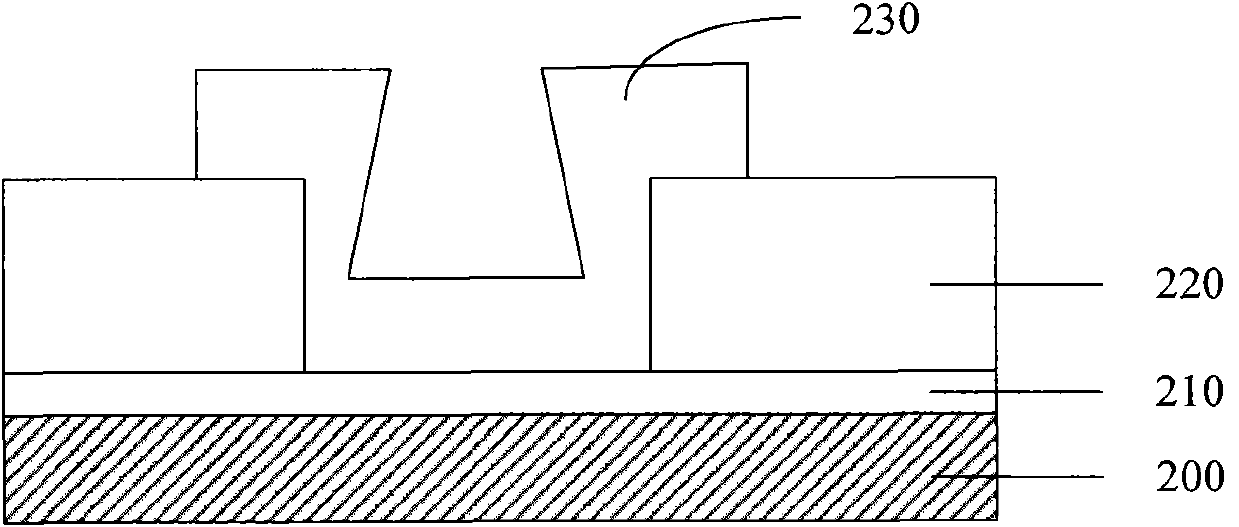

Integration scheme using self-planarized dielectric layer for shallow trench isolation (STI)

InactiveUS6875558B1Improving trench fill qualityQuality improvementPhotomechanical apparatusSemiconductor/solid-state device manufacturingAnti-reflective coatingDielectric layer

A method for forming a trench isolation structure on a substrate. The method includes applying a pad oxide layer (226) on the substrate (224), applying a polysilicon layer (228) over the pad oxide layer, and applying a CVD anti-reflective coating (ARC) (230) over the polysilicon layer. A photoresist is formed on the CVD ARC and a trenched is etched at a desired location. One embodiment provides a method for depositing a trench oxide filling layer (300) on the trenched substrate utilizing the surface sensitivity of dielectric materials such as O3 / TEOS to achieve a substantially self-planarized dielectric layer. Prior problems with porous trench fill, particular near trench corners, are obviated by use of the polysilicon layer. After deposition, an oxidizing anneal can be performed to grow a thermal oxide (307) at the trench surfaces and densify the dielectric material. A chemical mechanical polish can be used to remove the excess oxide material, including the porous regions.

Owner:APPLIED MATERIALS INC

Needle tube type filling machine and filling method thereof

The invention discloses a needle tube type filling machine and a filling method thereof. The needle tube type filling machine comprises a liquid feeding device, a perfusion needle tube connected with the liquid feeding device and capable of extending into a bottle, and an exhaust passage capable of being hermetically communicated with a gap between the outer wall surface of the perfusion needle tube and the inner wall surface of an opening of the bottle, wherein a speed control device capable controlling the exhaust velocity of the needle tube type filling machine is arranged in the exhaust passage. The needle tube type filling machine is used for performing perfusion by extending the needle tube into the bottle so that the air in the bottle can be exhausted along the periphery of the needle tube, then the speed control device is used for controlling the air exhaust velocity to realize the effective control of the perfusion speed to ensure that the speed control during the perfusion is possible, and thus, a special perfusion mode of slow filling-quick filling-slow filling and the like is formed according to needs, and subsequently, foaming phenomena in the process of the perfusioncan be effectively reduced and the filling quality is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

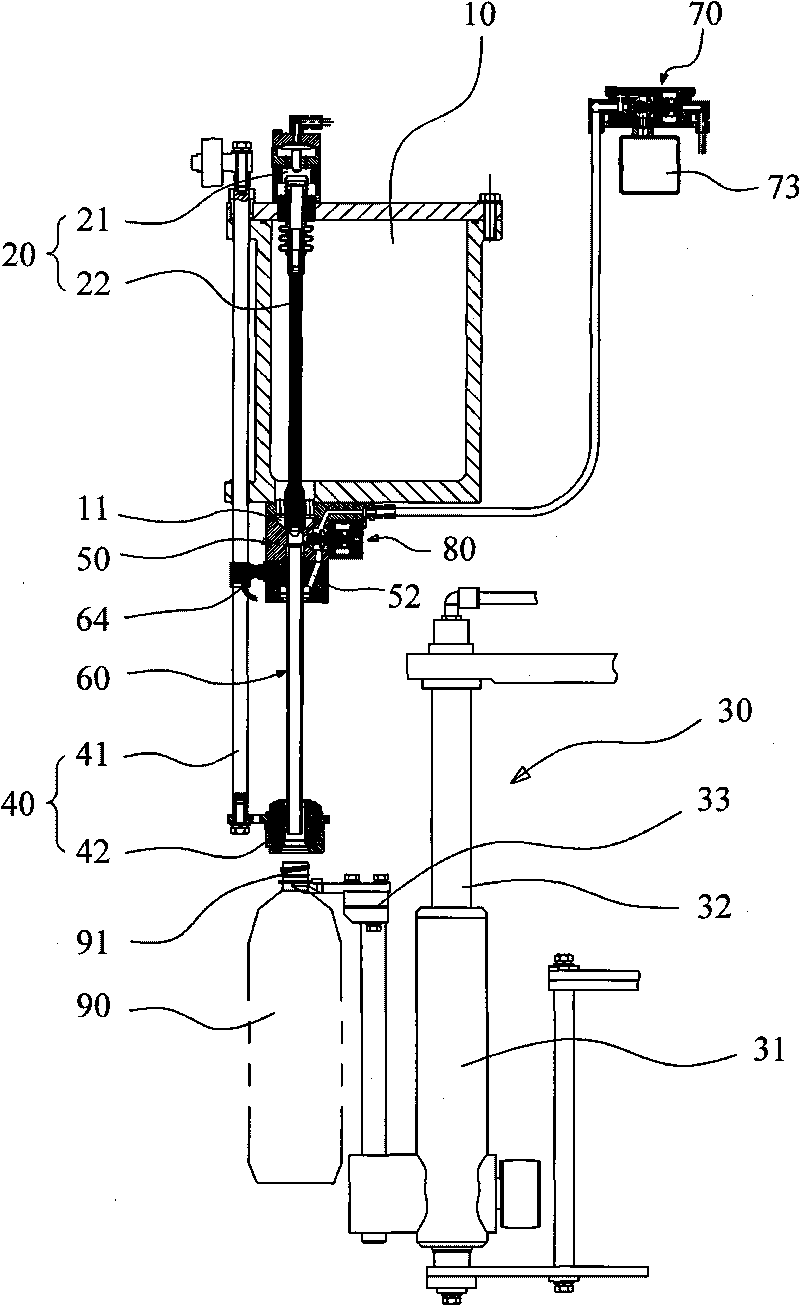

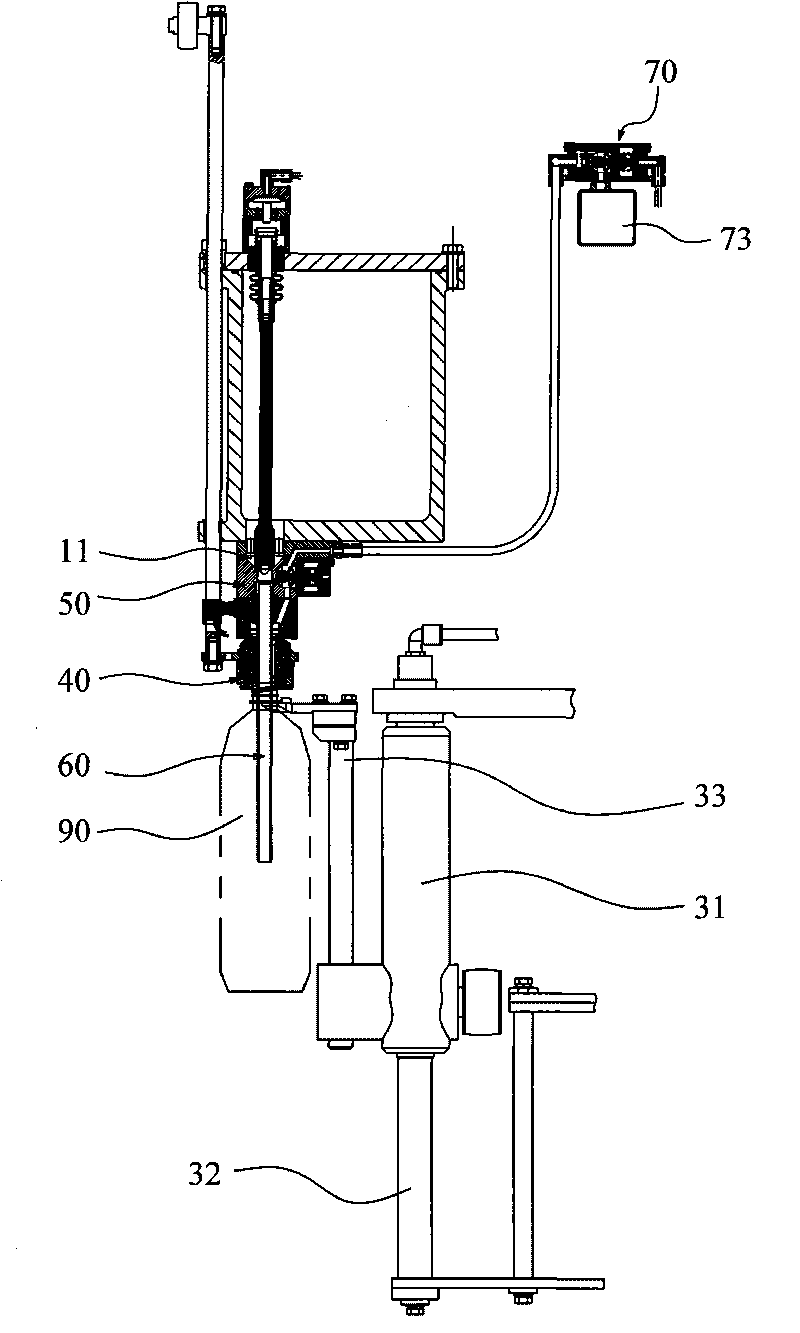

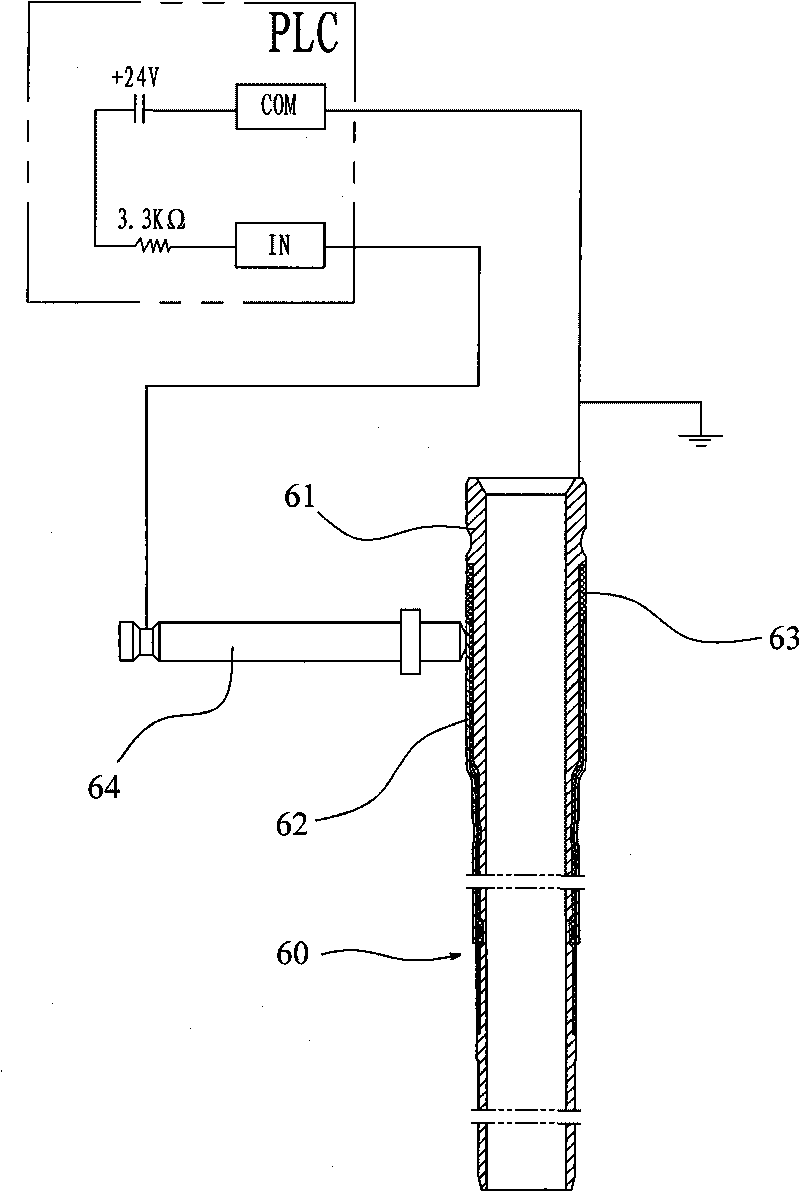

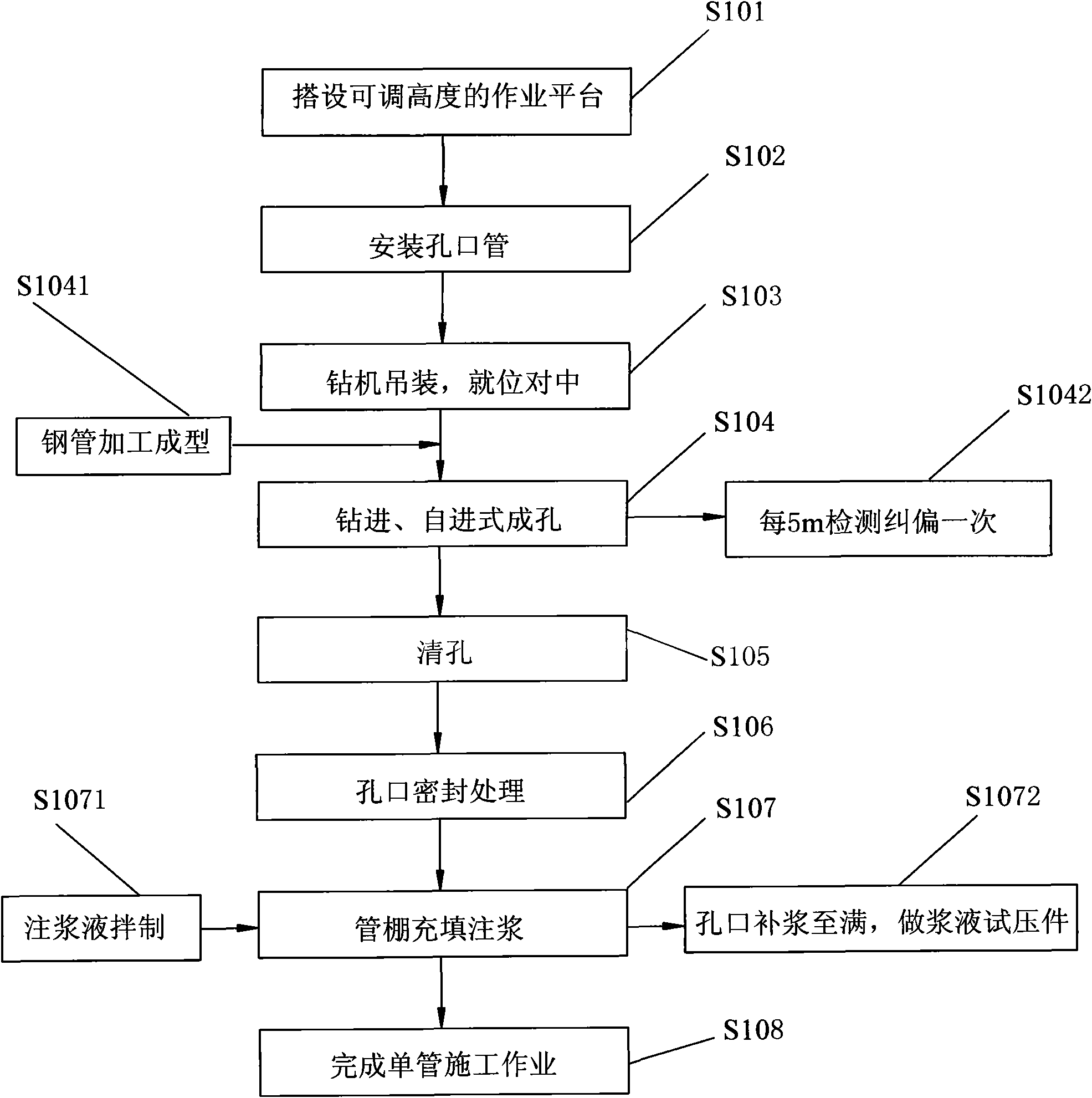

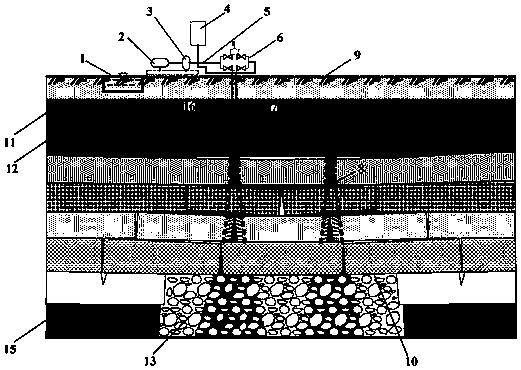

Method for reinforcing concealed tunnel

ActiveCN101624910ABlock lossImprove filling qualityDrill bitsUnderground chambersSteel tubeDrill bit

The invention discloses a method for reinforcing a concealed tunnel, which builds a pipe shed for the arch of the tunnel and reinforces the pipe shed by means of grout injection before tunneling. The method comprises the following steps of: setting up a work platform; installing a hollow opening pipe; hoisting and positioning a drilling machine; machining and forming a steel tube of the pipe shed; drilling and forming a hole in a self-advancing way; cleaning the hole, sealing a hole opening; stirring and preparing grout injecting liquid; filling the grout injecting liquid into the pipe shed; and subsequently operating. In the technical scheme of the method, a positioning plate is arranged at a hole opening section, a check valve is arranged in the steel tube of the pipe shed, and a self-advancing drill head is directly connected with the steel tube of the pipe shed in a welding way, so as to effectively heighten the construction precision of the pipe shed, well guarantee an injection effect, reduce the probability of hole caving due to the injecting and the filling are not immediately, simplify construction work procedures, height construction efficiency; and a grout injecting technology with several times is adopted, so as to guarantee the pressure of grout injection at 1.5MPa-2.0MPa, obviously heighten the injection quality of the pipe shed, and improve the advanced support effect of the pipe shed to the concealed tunnel.

Owner:GUANGZHOU JISHI CONSTR GRP

Filling material used for mining remained gateway along goafs

The invention discloses a filling material used for a mining remained gateway along goafs. The filling material comprises 35-55% of coal ash, 5-25% of quicklime powder, 5-20% of ground slag powder, 2-20% of silicate cement, 20-40% of red mud, 0.35-5.5% of an early strength component, 0.015-0.035% of a water reducing agent, and 0.0045-0.009% of an expansive compound. Using processes of the filling material at a pit bottom are simple. The filling material is added with water, stirred and conveyed by a single pipe. After addition of the water and stirring, workability of the slurry is good, the slump of the slurry after the slurry is allowed to stand in the pipe for 2 h is barely changed. During emergency situations, pipe blocking due to long standing time of the slurry in the pipe is not generated. By addition of the expansive component, a certain volume expansion is generated with curing of the material, the increasing speed of the strength is high, a roof can be effectively supported in time, and the filling quality is high.

Owner:SHANDONG ANSHI GREEN MINING TECH DEV

Tailings disposing and filling method

The invention discloses a tailings disposing and filling method and belongs to the field of tailings utilization and disposal. The method includes: grading tailing pulp to obtain fine-particle tailings pulp and coarse-particle tailings; dewatering the fine-particle tailings pulp and the coarse-particle tailings pulp respectively according to application to obtain fine-particle tailings and fine aggregate and coarse-particle tailings for granulation, mortar and dry-mixed mortar; sintering the fine-particle tailings at high temperature, and adding a binding material into the coarse-particle tailings for granulation, mortar and dry-mixed mortar to obtain coarse aggregate, a mortar material and a dry-mixed mortar material; mixing the coarse aggregate and the fine aggregate, conveying the samedown into a well through a filling well, conveying the mortar material down into the well through a filling pipe, mixing, and then filling; conveying the dry-mixed mortar material down into the well to be mixed with pipe flushing water to prepare a dry-mixed mortar material mixture, mixing the mixture with the aggregate, and filling. By the method, treating and hardening time of the filling material can be shortened, strength of a filled body can be enhanced, downhole operation conditions can be improved, and pollution of underground environment can be reduced.

Owner:LIAONING TECHNICAL UNIVERSITY +1

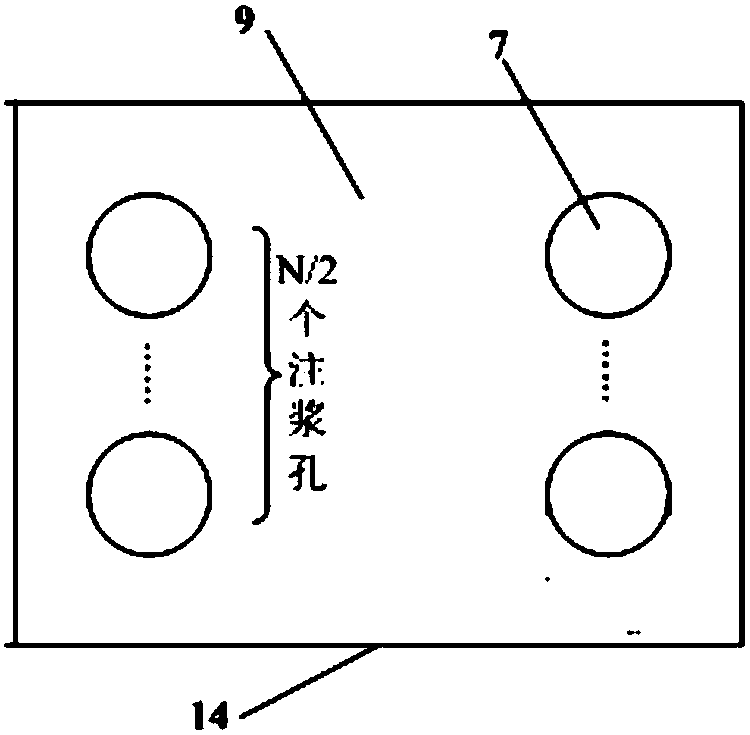

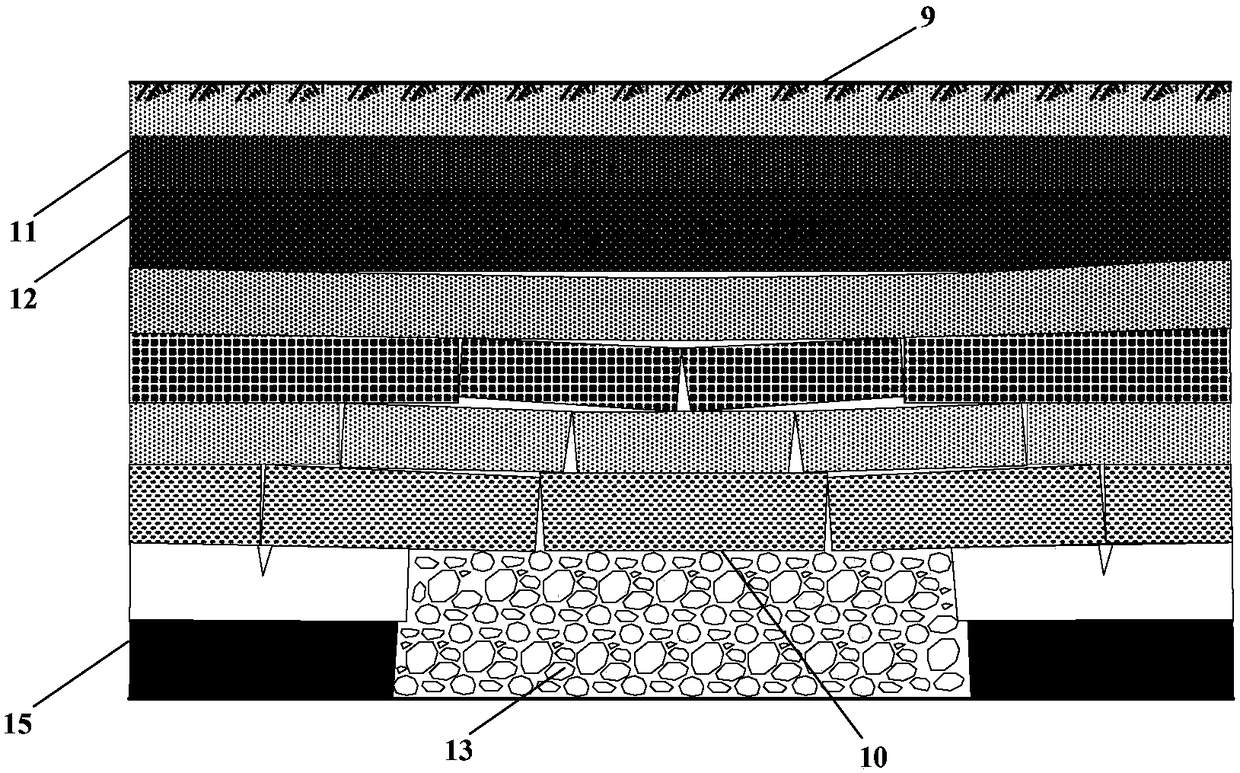

Pier type arch linkage type goaf treatment method

ActiveCN108194132AMaintain stabilityImprove filling qualityMaterial fill-upStructural engineeringUltimate tensile strength

The invention discloses a pier type arch linkage type goaf treatment method. A bracing strength of a pier column is obtained mainly through data analysis of a key layer, then a grouting hole is formedin a bottom plate of a goaf from the ground surface, the grouting hole is filled intermittently by using a pipe lifting method to form the pier till the pier is connected with the top of the key layer, and after grouting filling is completed, residual grouting holes are filled and sealed. A pier type arch linkage structure is formed by utilizing mutual cooperation of the pier formed after grouting filling aggregate is solidified and a caving top plate covering the goaf, and the stability of the top plate of the goaf is maintained.

Owner:SHANDONG UNIV OF SCI & TECH

Filling Level Sensor for Short Measuring Distances

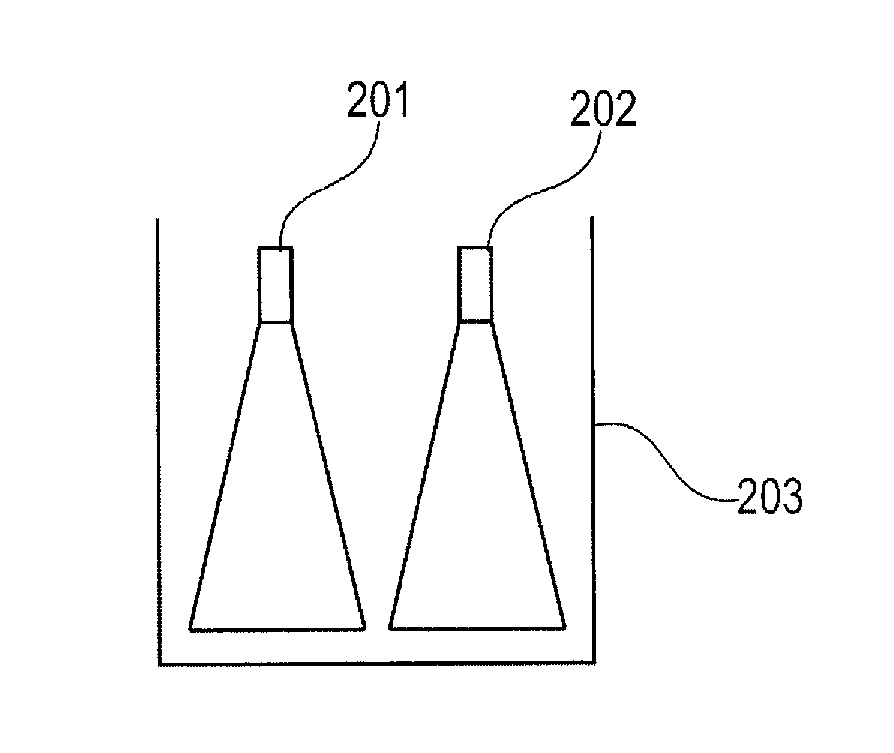

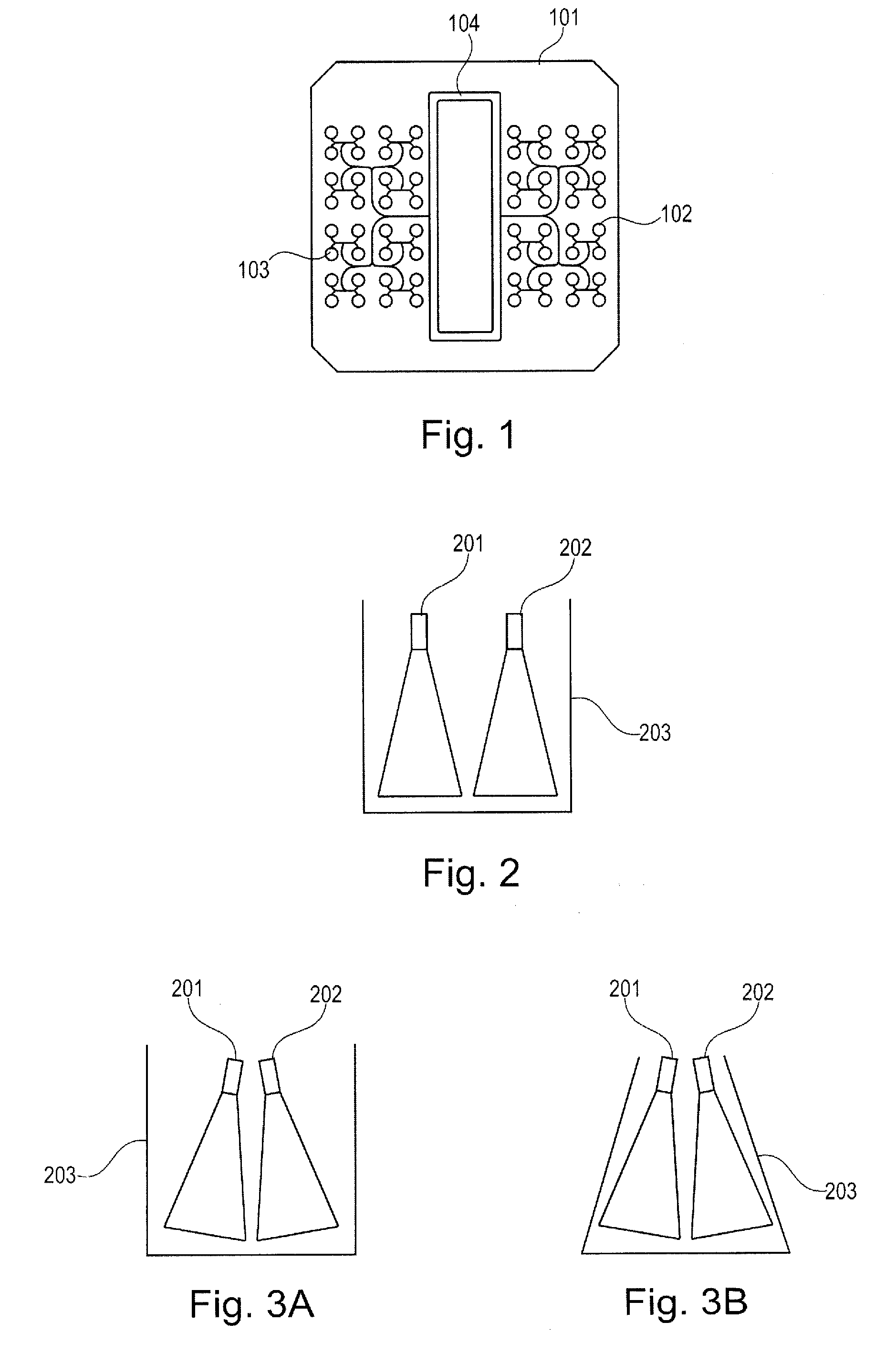

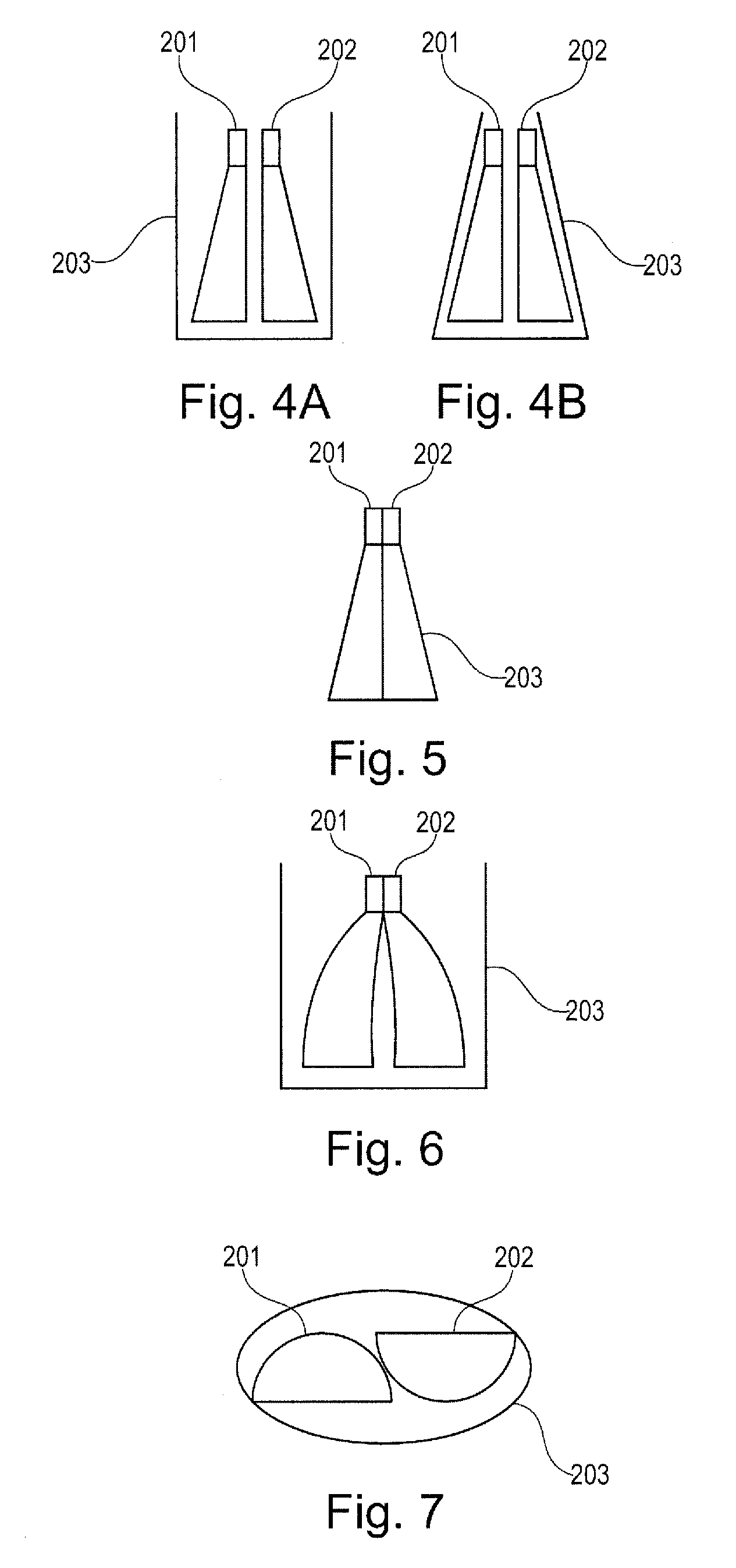

InactiveUS20090128396A1Improve stabilityEasy to manufactureWaveguide hornsRadiating element housingsShortest distanceLevel sensor

A filling level sensor for a short distance measurement includes a first antenna transmitting a transmission signal to a material surface; a second antenna receiving a reception signal reflected by the material surface; and a common outer enclosure enclosing the first antenna and the second antenna.

Owner:VEGA GRIESHABER GMBH & CO

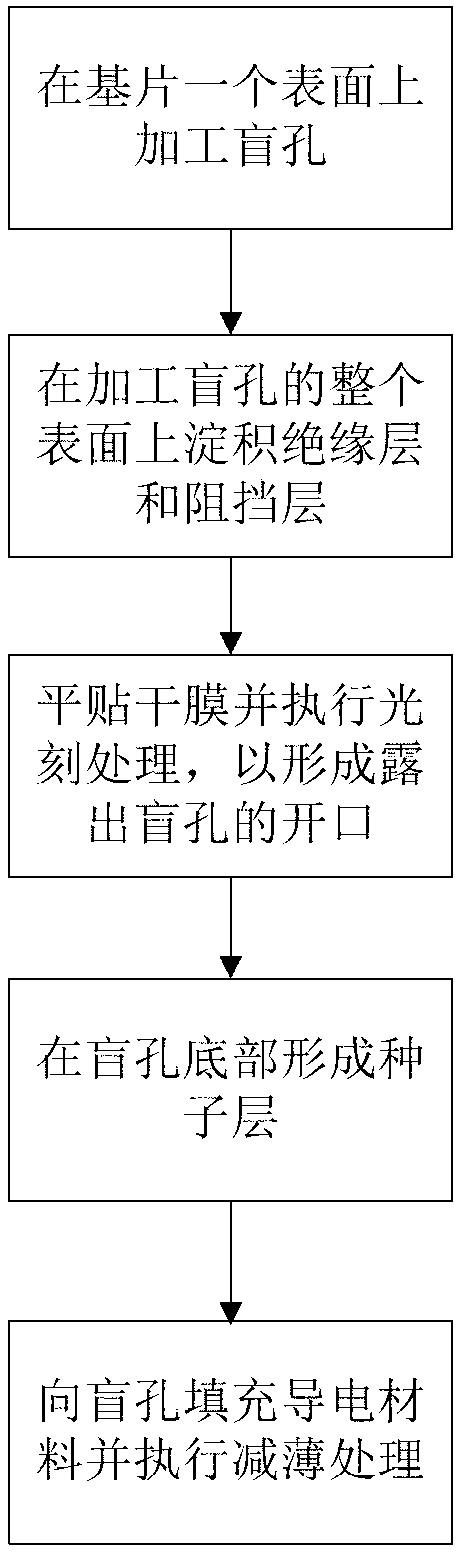

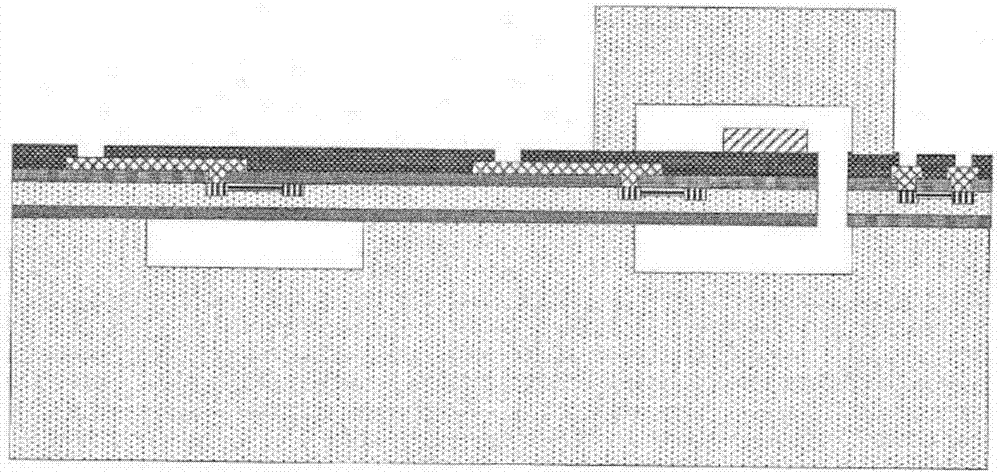

Manufacturing method of through hole interconnection structure and product of through hole interconnection structure

InactiveCN103258789AQuality improvementFilling high speedSemiconductor/solid-state device manufacturingInterconnectionEngineering

The invention discloses a manufacturing method of a through hole interconnection structure. The manufacturing method of the through hole interconnection structure comprises the following steps: (a) a blind hole is machined in one surface of a substrate; (b) an insulating layer and a barrier layer are deposited on the whole surface in sequence, where the blind hole is machined, of the substrate; (c) a light-sensitive dry film is paved on and attached to the surface, containing the barrier layer, of the substrate, and exposure imaging treatment is carried out on the surface, so that an opening exposed out of the blind hole is formed; (d) the dry film is used as a covering film, a seed layer is formed on the barrier layer on the bottom of the blind hole, and the seed layer is prevented from covering the barrier layer deposited on the lateral wall of the blind hole; (e) growth from bottom to top is achieved with the seed layer on the bottom of a through hole as guiding media, and the thickness of another surface of the substrate is reduced until the blind hole is machined to be the through hole. The invention further discloses a product of the through hole interconnection structure. According to the manufacturing method of the through hole interconnection structure and the product of the through hole interconnection structure, through hole electroplating which is convenient to control, low in cost, and high in efficiency can be achieved, and the product of the through hole interconnection structure and with better filling effect can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Piezoresistive compound sensor suitable for surface mounting technology and manufacturing method thereof

ActiveCN107265388AEasy to packSimple processDecorative surface effectsSolid-state devicesSurface mountingEngineering

The invention relates to a piezoresistive compound sensor suitable for a surface mounting technology and a manufacturing method thereof. The piezoresistive compound sensor comprises a planar integrated or vertical integrated structure; a used wafer structure comprises a substrate layer, a top layer, an insulating layer in the wafer and cavities arranged at interface positions in the substrate layer and the insulating layer, wherein the top layer and the substrate layer are doped in a reversal phase manner; an electric isolation groove is arranged on the substrate layer; metal pins are formed on the substrate layer surrounded by the electric isolation groove; a piezoresistive strip of the compound sensor, an electrical lead wire area and an electric connection channel are formed on the top layer, and the electric connection channel is arranged in the overlapped area of the electrical lead wire area and substrate silicon ; releasing grooves are arranged on the insulating layer on the surface of the top layer, top layer silicon and the insulating layer in the wafer to form a movable structure of the compound sensor, and a protective cover plate is linked to form a sealed cavity The piezoresistive compound sensor provided by the invention is convenient for subsequently achieving three-dimensional packaging with a corresponding control circuit (IC), and is low in cost.

Owner:GUANGDONG HEWEI INTEGRATED CIRCUIT TECH

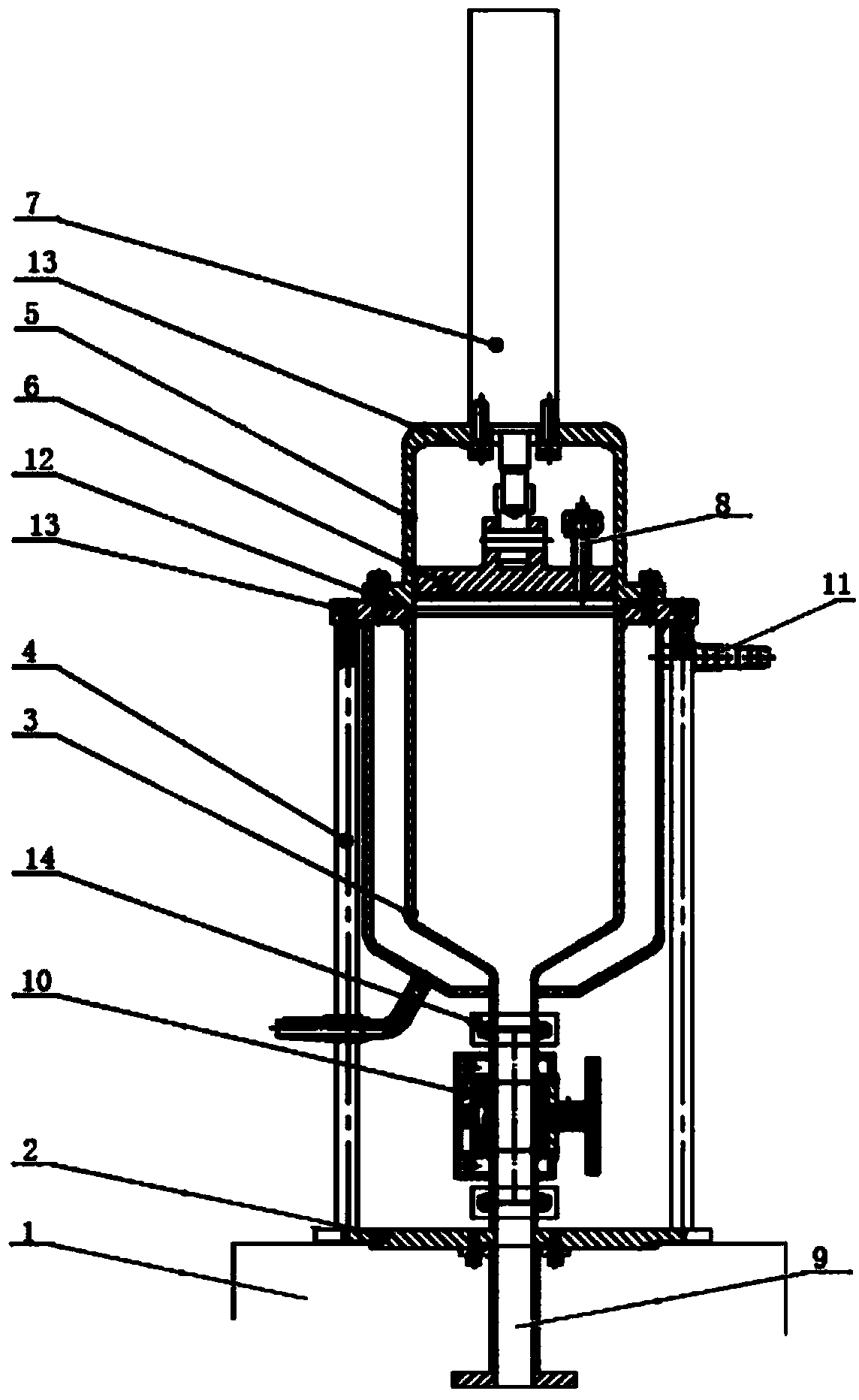

High-viscosity PBX (Polymer Bonded Explosive) injection-compression molding method and device

ActiveCN103936533AImprove filling qualitySolve the problem of poor rheology in high viscosity PBX processExplosive working-up apparatusCompression moldingEngineering

The invention discloses a high-viscosity PBX (Polymer Bonded Explosive) injection-compression molding method and device. The device is provided with an explosive charging barrel and an installing barrel, wherein an extrusion piston is arranged in the installing barrel and is connected to an air cylinder, the air cylinder can be used for controlling the extrusion piston to move up and down and stop, so that explosive slurry in the explosive charging barrel is pressed and injected into a mold to realize the explosive charging; the air cylinder is provided with two speed control valves so as to control the speed of the extrusion piston, and the device is aslo provided with a silencer, circulating water, a sealing ring and the like, so that the injection-compression molding device is further improved. The injection-compression molding device is used in the injection-compression molding method, so that the high-viscosity PBX charging is safely and efficiently realized. The injection-compression molding method and device can be used for solving the problem of poor rheological property of the high-viscosity PBX technology, can effectively ensure the controllability of internal quality of products when the explosive is charged in a complex structure in a large quantity, so as to obtain the explosive pouring parts with high filling quality; moreover, the charging process is rapid, safe, low in working noise, and simple and convenient to operate.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

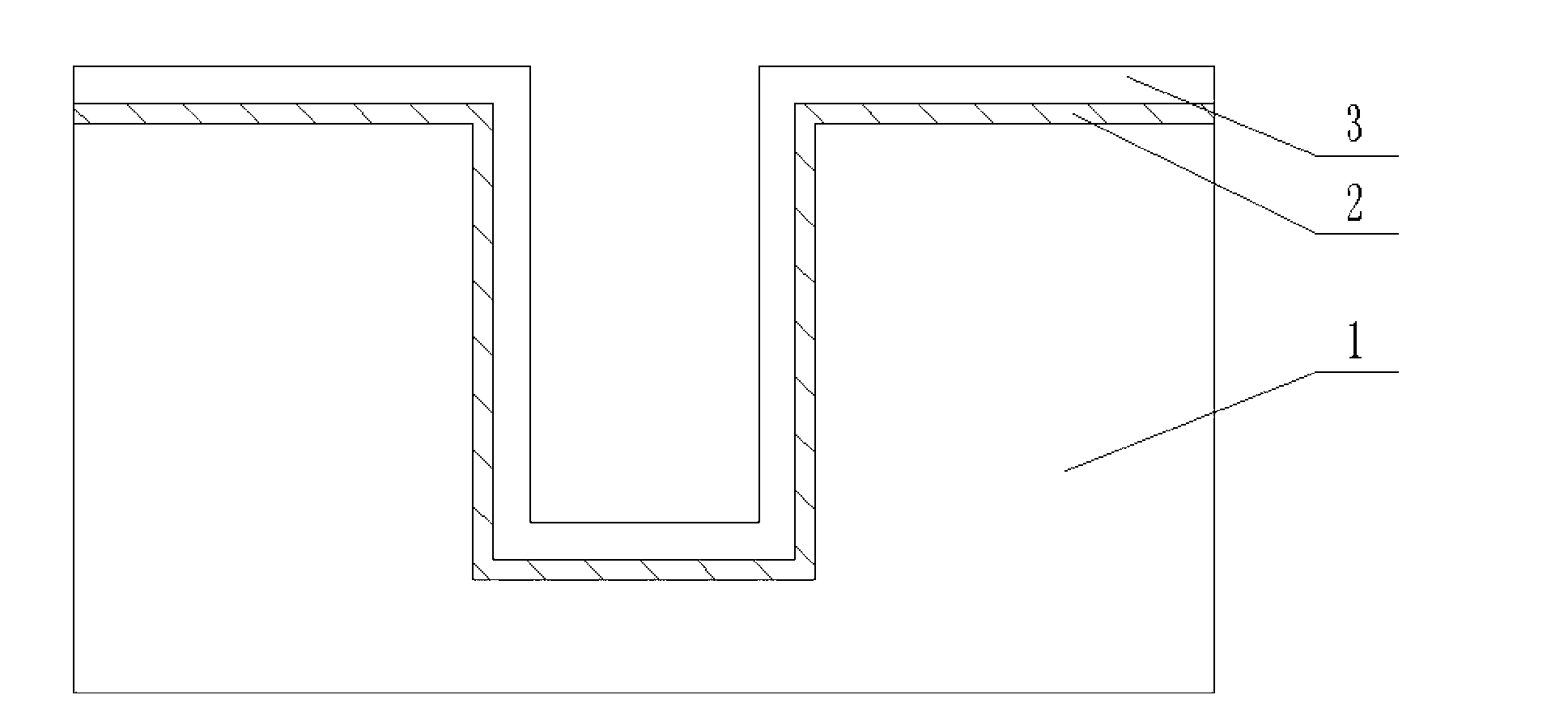

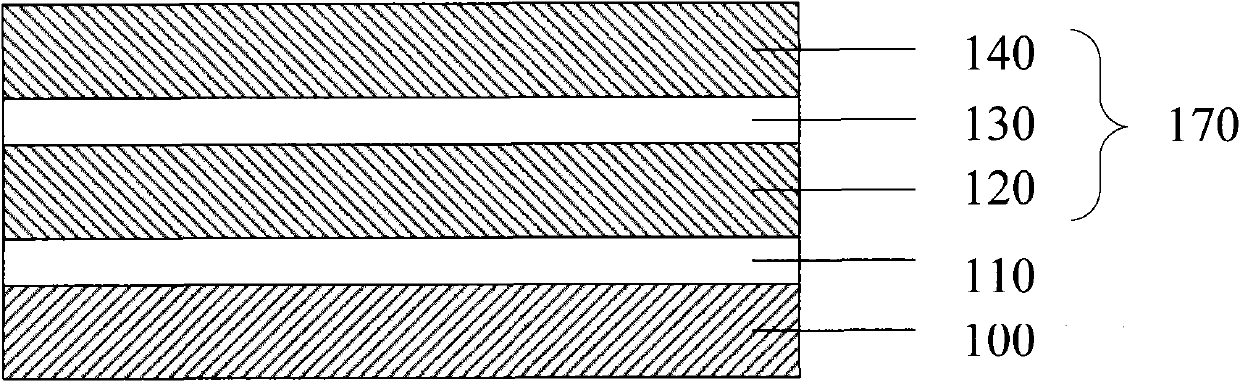

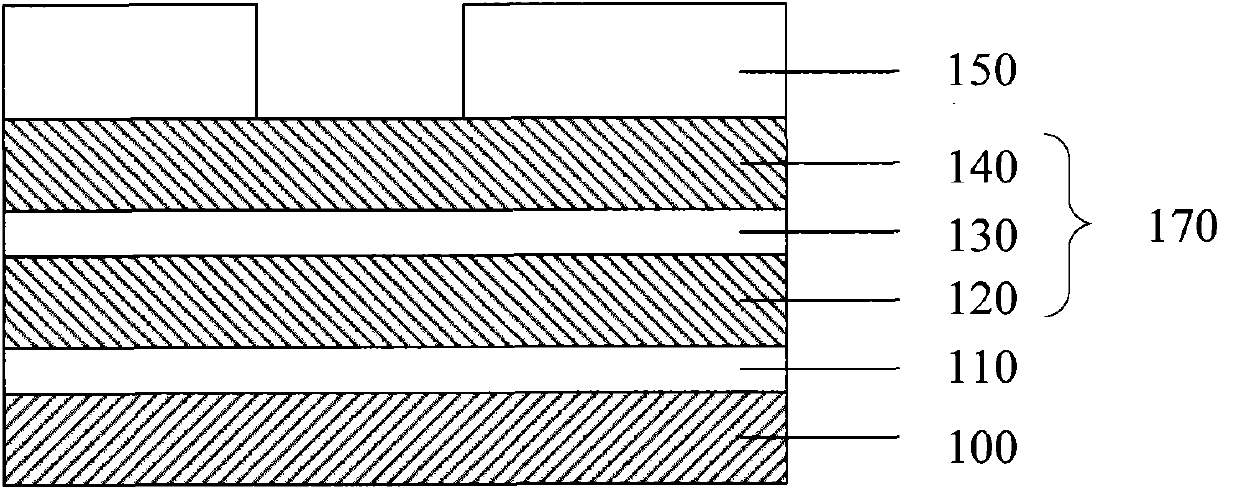

Opening and forming method thereof

InactiveCN102024696ADefects that prevent increase in sheet resistanceImprove filling qualitySemiconductor/solid-state device detailsSolid-state devicesEtchingMetal

The invention discloses an opening and a forming method thereof. The forming method of the opening comprises the following steps of: dynamically adjusting fluoroform flow and bias power during main etching for forming the opening; and adjusting the amount of polymer produced during the etching, wherein the fluoroform flow is gradually increased and the bias power is gradually decreased. In the invention, the amount of the polymer produced during the etching can be adjusted by independently adjusting technological parameters of an etching menu and dynamically adjusting the fluoroform flow and the bias power during the main etching for forming the opening, so the appearance of the opening is influenced, the defect of increased square resistance of a filled metal layer caused by over-thick filling or bottom enlargement of the formed opening in the prior art are overcome, and the opening formed by the process contributes to improving the filling quality of the metal layer. In the process, related technological parameters in the etching menu are partially adjusted without addition of the complex process or obvious influence on the productivity and the production cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

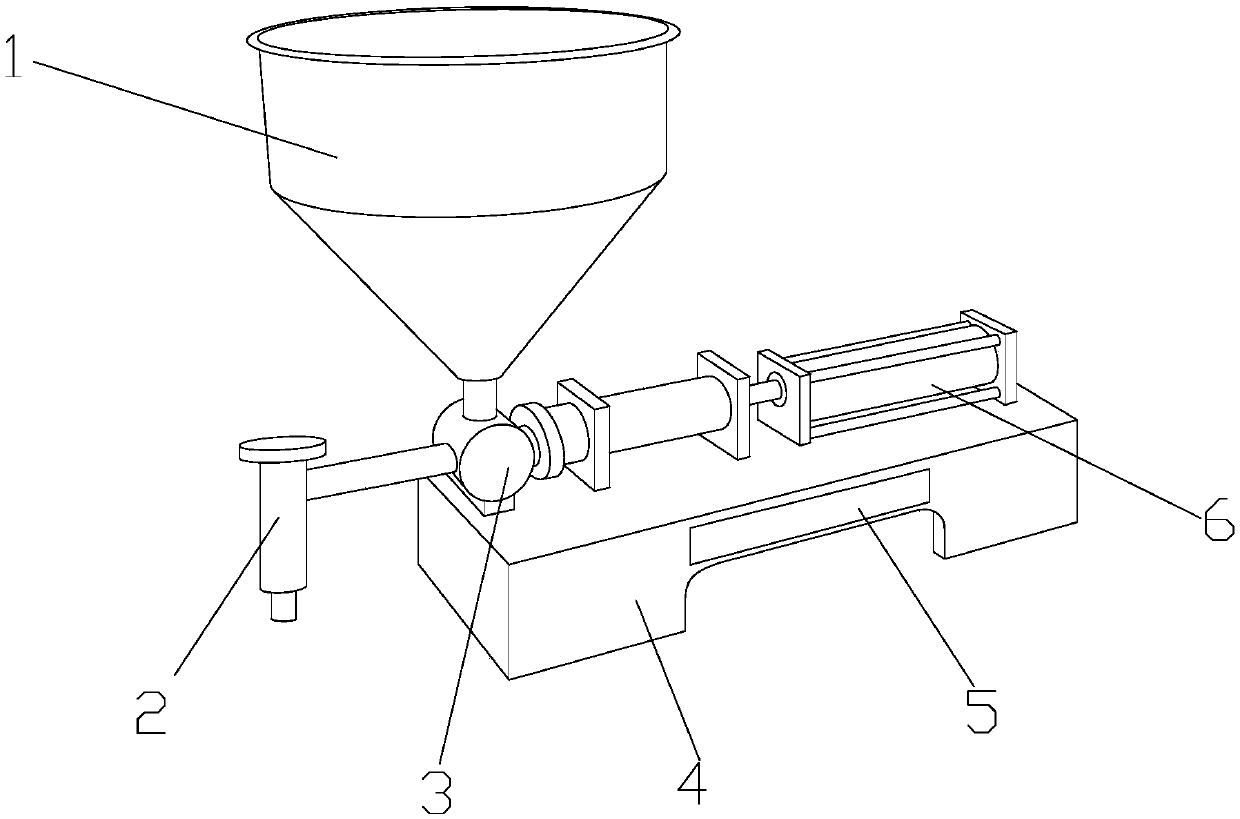

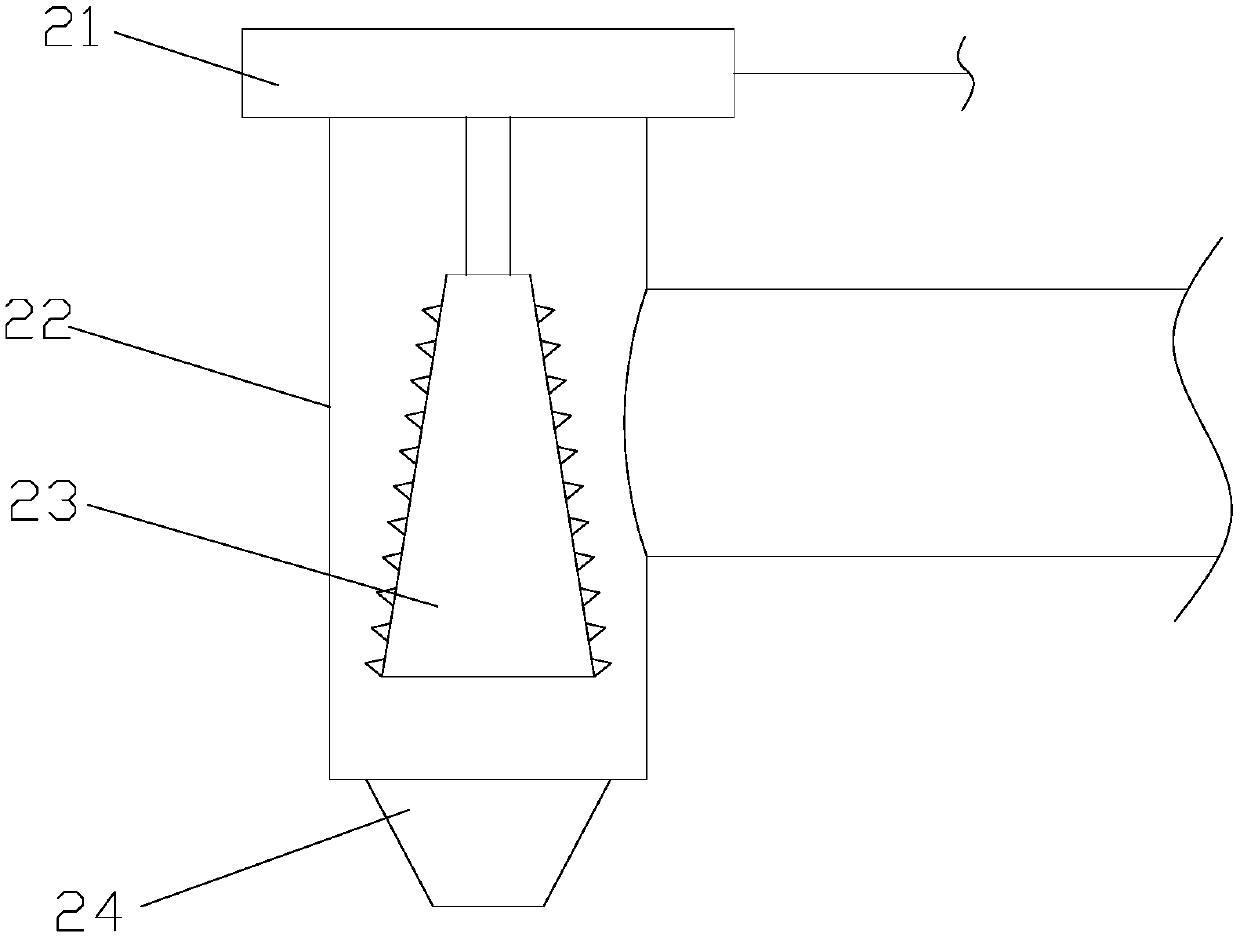

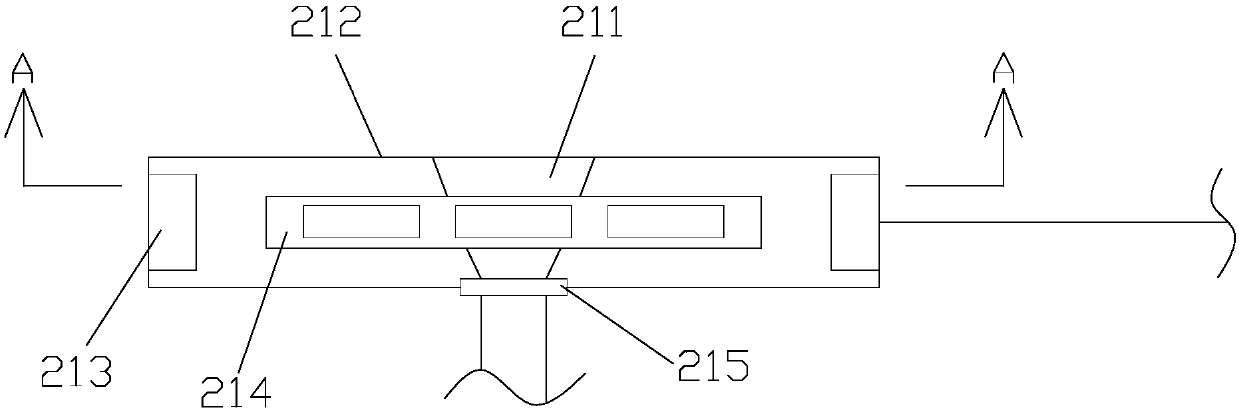

Glue filling machine capable of eliminating bubbles based on resonance principle

The invention discloses a glue filling machine capable of eliminating bubbles based on a resonance principle. The glue filling machine capable of eliminating the bubbles based on the resonance principle structurally comprises a glue stirring storage tank, a filling structure, a communicating device, a device supporting seat, a control panel, and a driving air cylinder. According to the glue filling machine, through combination of a driving structure, a vibrating bubble-eliminating apparatus, and a filling nozzle , in the glue filling process, the vibrating bubble-eliminating apparatus is driven to work by the driving structure, thus after entering a filling pipeline, glue is affected by the vibrating bubble-eliminating apparatus to generate resonance, air inside the glue can be quickly expelled, the plurality of the glue is effectively improved, meanwhile after filling is completed, the bottom of the filling nozzle can be automatically sealed, the situation that the undrained glue inside the filling pipeline is affected by the vibrating bubble-eliminating apparatus and drops onto a working table or a bottle body is avoided, and the filling quality is improved.

Owner:南京浦创智谷企业管理有限公司

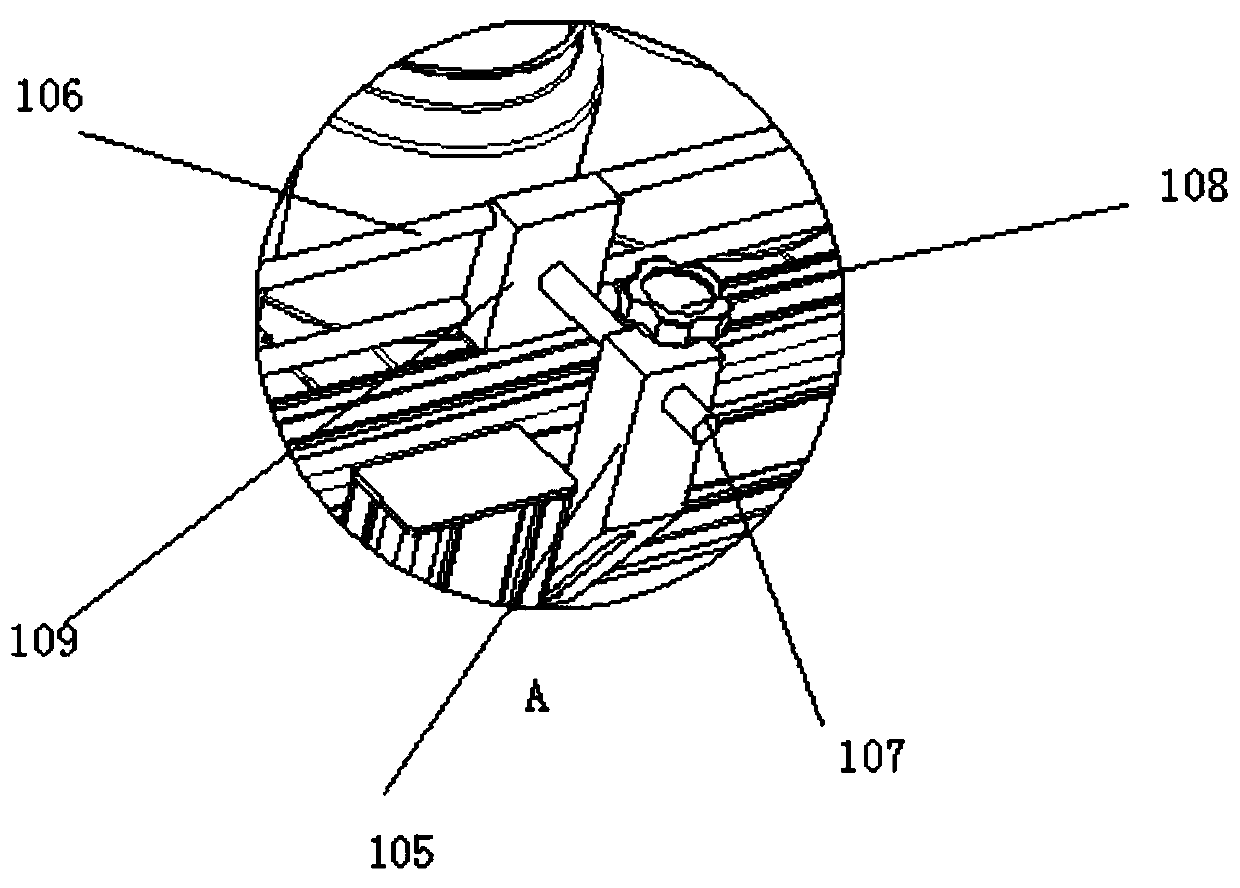

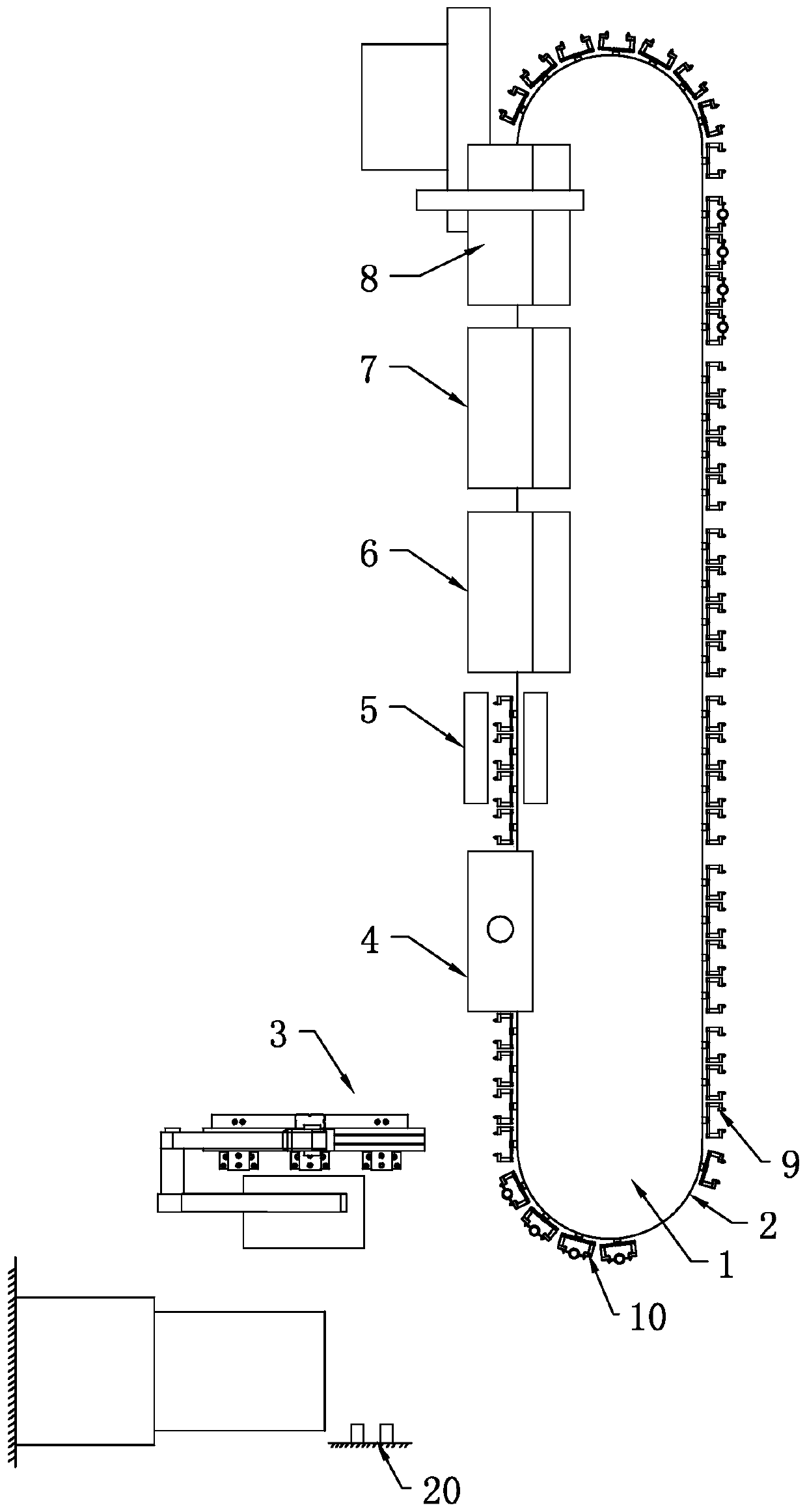

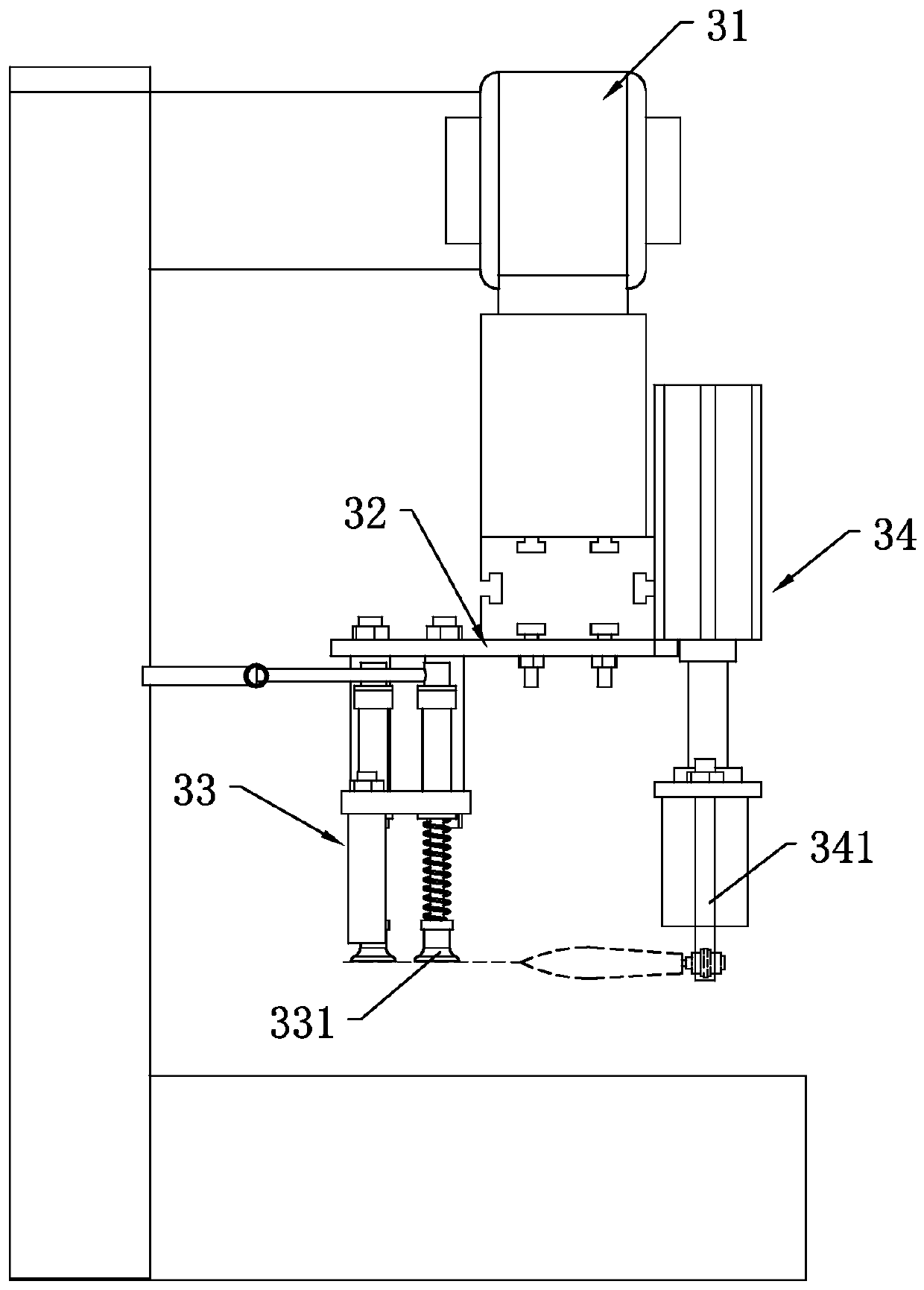

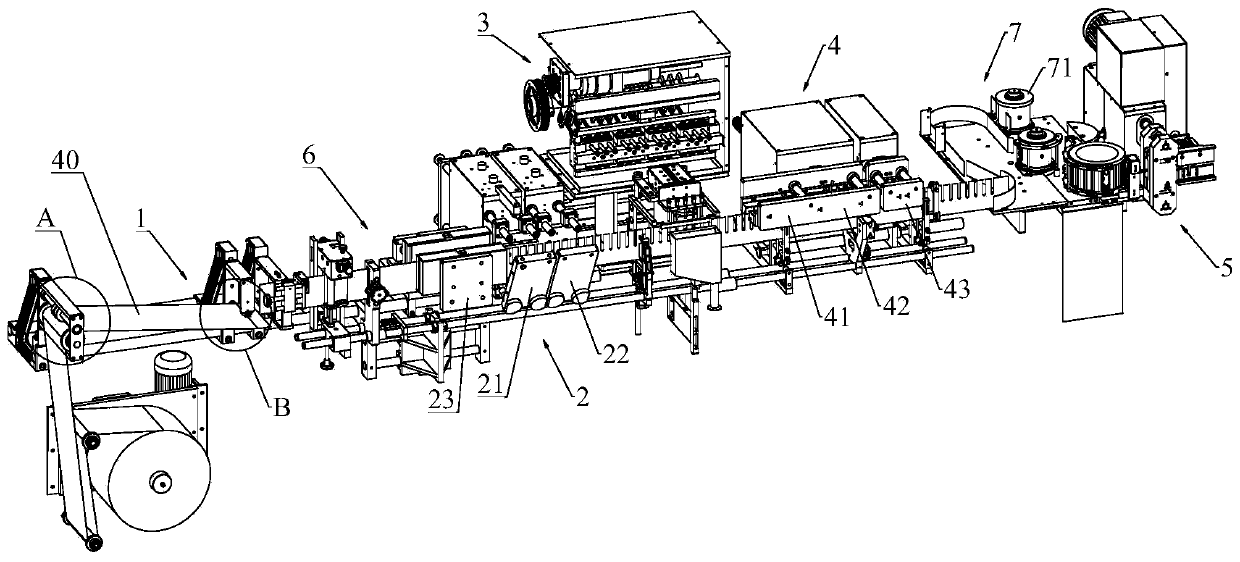

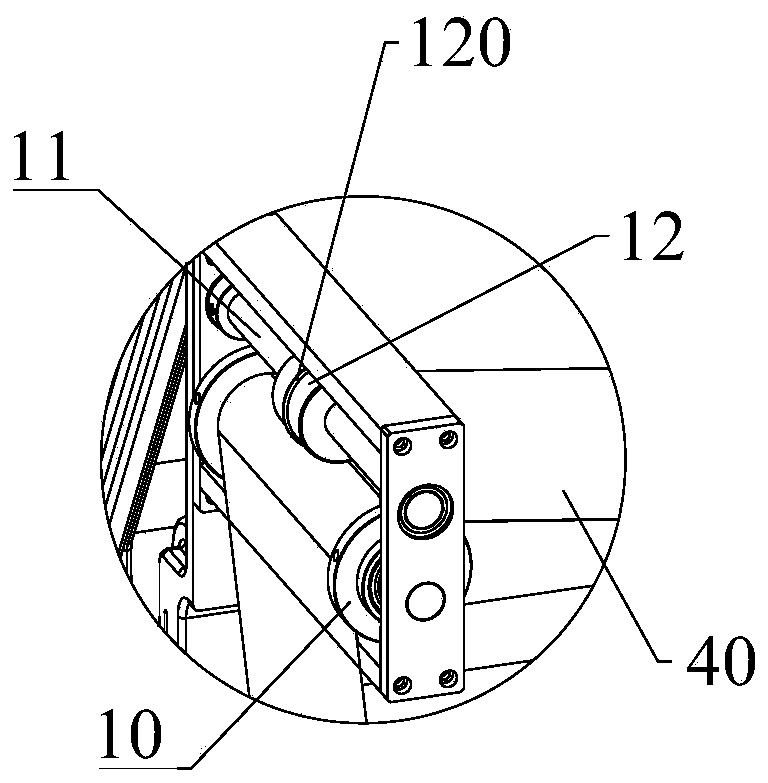

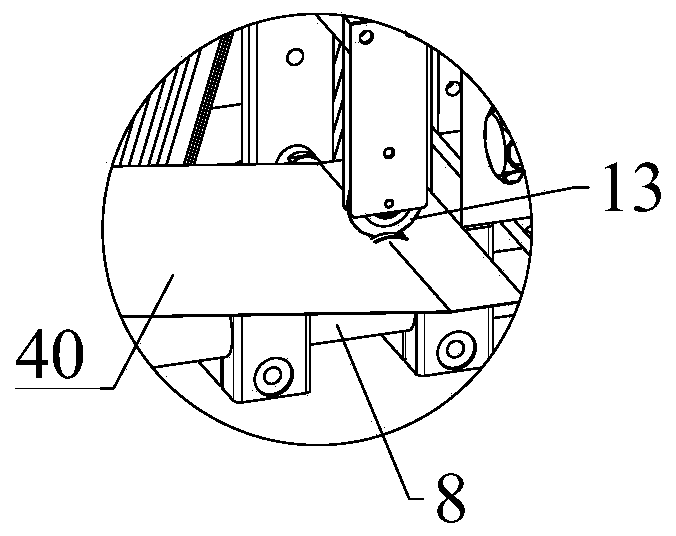

Cosmetic granular mask powder bottling equipment

InactiveCN111547282ARealize the role of protection guidancePracticalCapsRotary stirring mixersCakingFeed tank

The invention discloses cosmetic granular mask powder bottling equipment. The cosmetic granular mask powder bottling equipment comprises a conveying frame, a chain plate conveying belt is fixedly arranged on the conveying frame, a feeding table and a cap screwing frame are sequentially arranged over the conveying frame in the advancing direction of the chain plate conveying belt, and a feeding tank and a tank cap feeding barrel are arranged on the feeding table side by side in the horizontal direction. When filling bottles are conveyed to the position under the feeding tank on the chain plateconveying belt, first air cylinders on the two sides of the conveying frame drive clamping blocks to clamp and fix the filling bottles, in a filling process of mask powder, a second motor drives a stirring rod to drive latticed stirring blades to stir in the feeding tank, the stirring blades of the latticed structure can repeatedly filter and crush the mask powder in the feeding tank, caking of the mask powder in the feeding tank can be effectively avoided, and the filling quality of the mask powder is greatly improved.

Owner:合肥语江生物科技有限公司

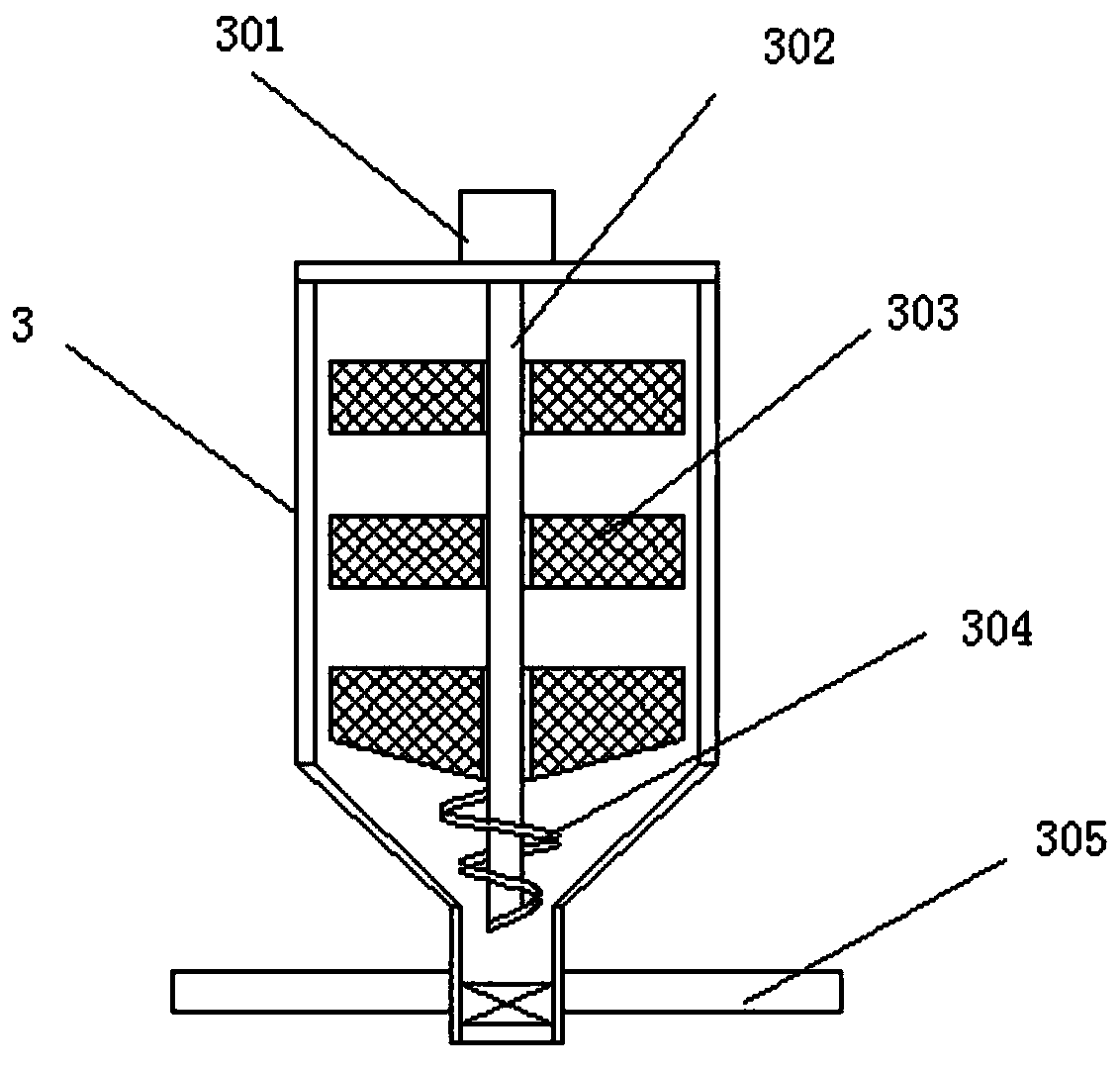

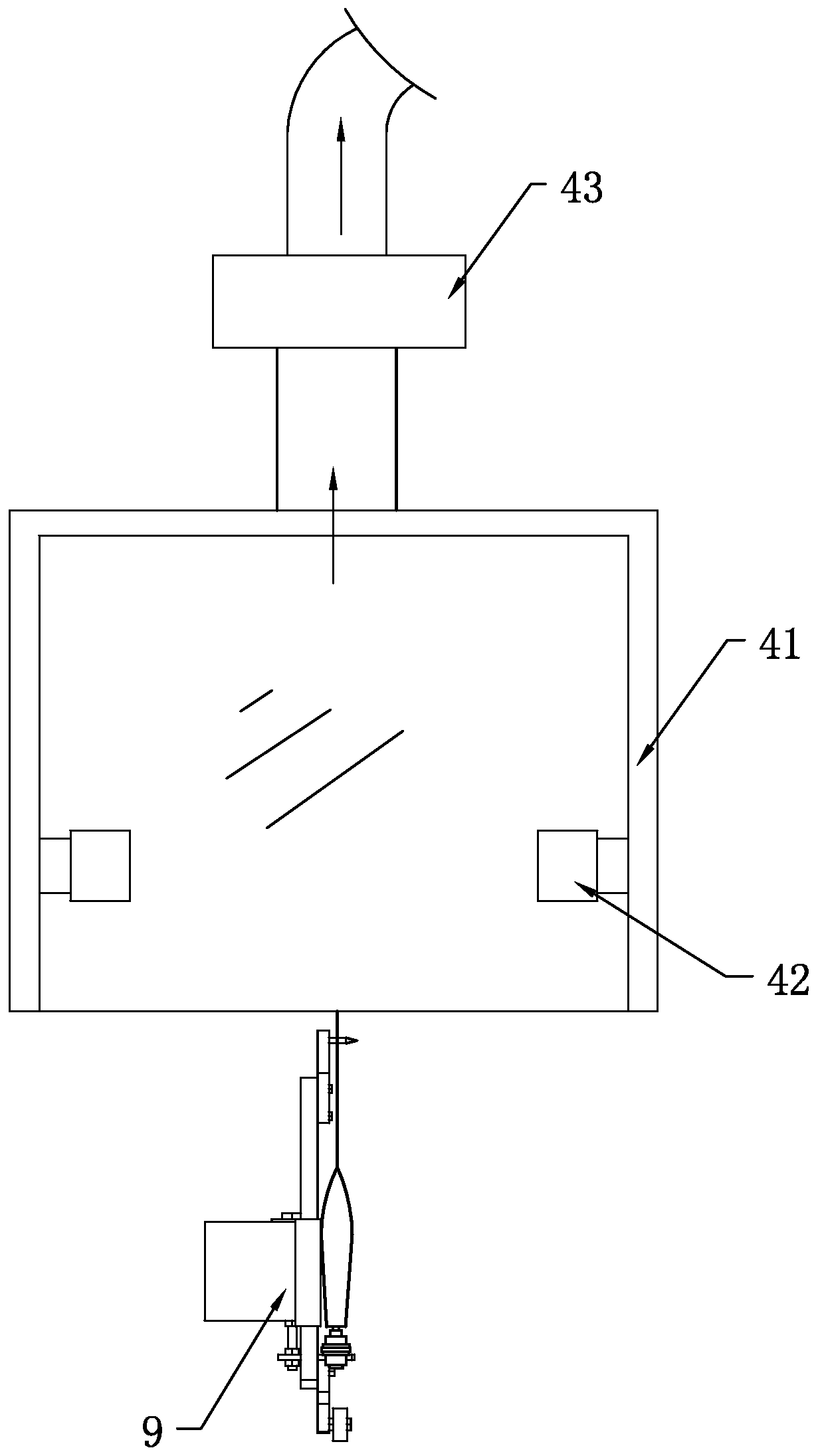

Powder cavity subpackaging system of powder-liquid double-chamber bag

PendingCN111017349AIncrease productivityReduce oxidationPackaging by pressurising/gasifyingWrapper twisting/gatheringTransfer lineEngineering

Owner:北京锐业制药有限公司

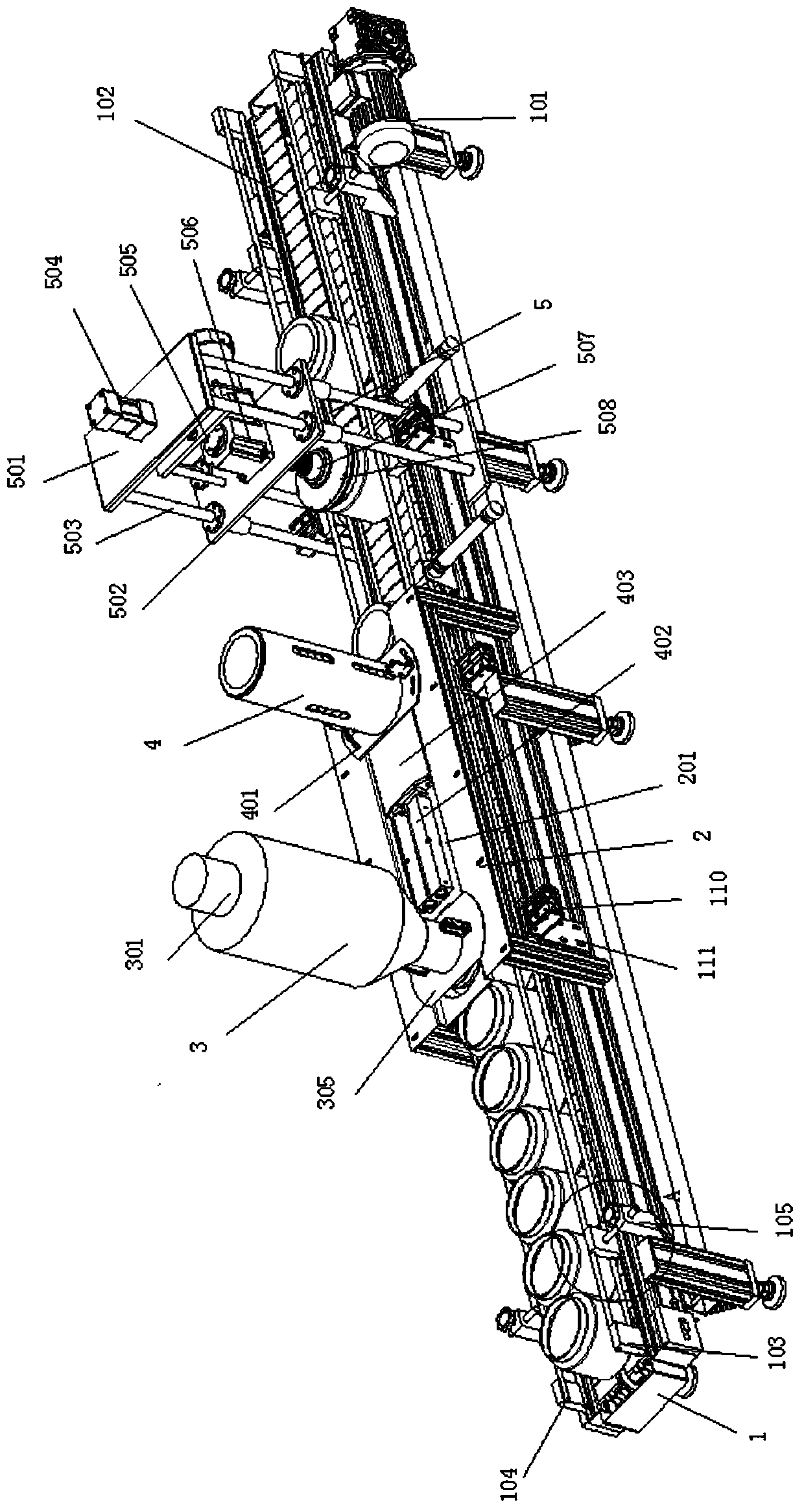

Injection molding filling machine and working method thereof

PendingCN111572842AHigh degree of automationImprove filling efficiency and filling qualityWrapper twisting/gatheringSuccessive articlesMoulding deviceFilm material

The invention relates to an injection molding filling machine and a working method thereof. The injection molding filling machine comprises a pretreatment device, a cavity molding device, a filling device, a top sealing molding device and a blanking molding device; the pretreatment device is suitable for pressing and folding the middle part of a released film material, so that the film material isfolded in half; the cavity forming device is suitable for carrying out heat sealing on the folded film material according to the body outline of a packaging material and blowing air into a heat sealing area to form a packaging material cavity with an opening; the filling device is suitable for filling agent liquid into the packaging material cavity; the top sealing molding device is suitable forperforming heat sealing on an opening part of the packaging material filled with the agent liquid so as to form a complete bag packaging material; and the blanking molding device is suitable for cutting film strips into bag packaging material units according to the preset number of bag packaging materials. According to the injection molding filling machine, injection bagged forming and filling areachieved through the pretreatment device, the cavity molding device, the filling device, the top seal molding device and the blanking molding device, the cost is low, and the efficiency is high.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

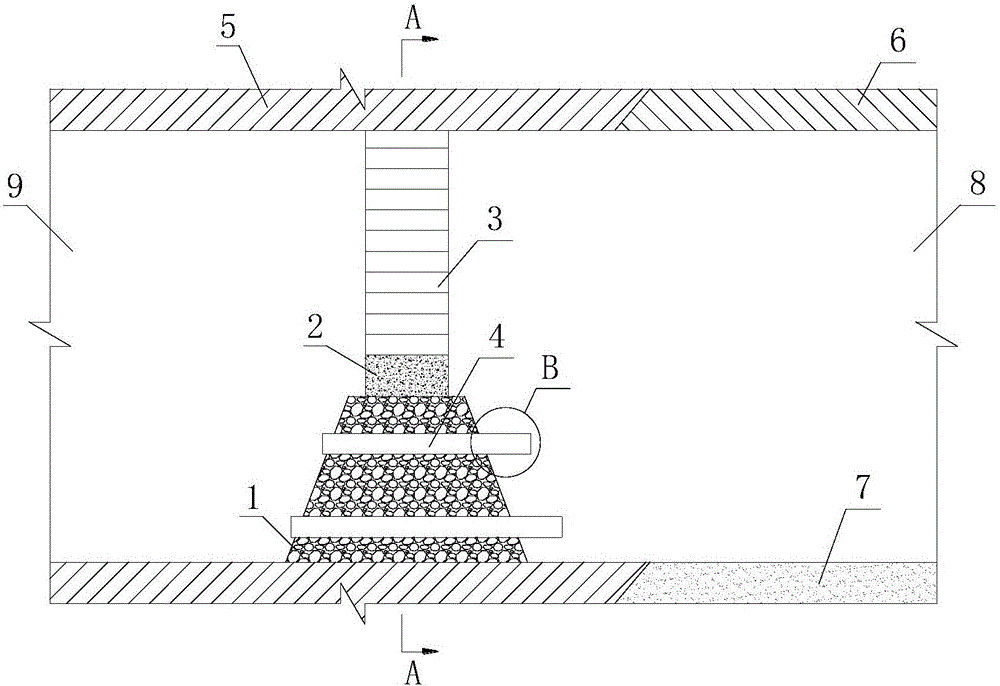

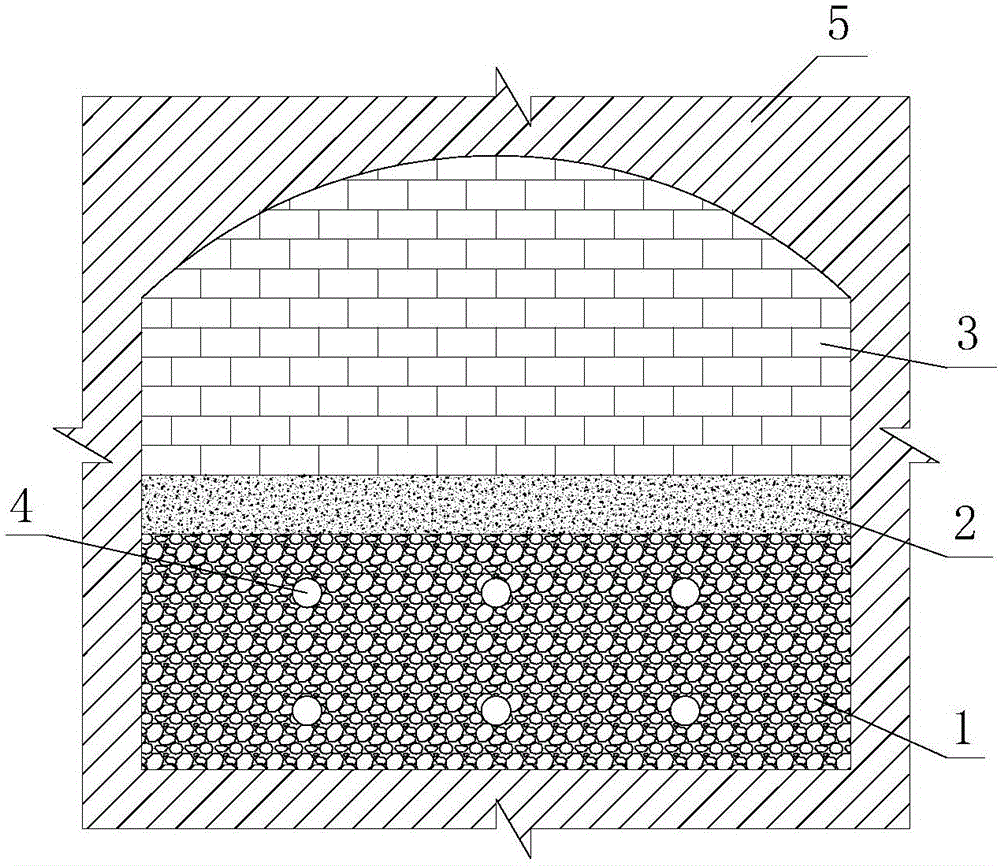

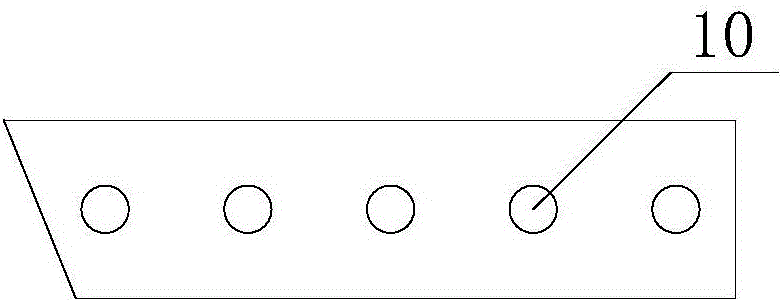

Mine underground high-water-permeability filling retaining wall and construction method thereof

The invention discloses a mine underground high-water-permeability filling retaining wall and a construction method thereof. The filling retaining wall comprises an in-surrounding-rock barren layer, a pervious concrete layer and a pervious brick layer which are arranged in sequence; the barren layer is located at the bottom of the pervious concrete layer, a plurality of pervious pipes are embedded in the barren layer, the pervious brick layer is located at the top of the pervious concrete layer, the upper portion of the pervious brick layer is connected with surrounding rock, and the interior of the surrounding rock is divided by the barren layer, the pervious concrete layer and the pervious brick layer into a roadway and a goaf. The construction method is characterized in that a carry-scraper or a self-discharging truck is adopted for carrying nearby waste stone to the filling retaining wall preset position, and the pervious pipes are preset into the waste stone; the waste stone is compacted to form the barren layer, and then a layer of pervious concrete is paved on the barren layer to form the pervious concrete layer; and after solidification of the concrete of the pervious concrete layer, pervious bricks are constructed in a seam staggering manner. The mine underground high-water-permeability filling retaining wall has the high water permeability, and the filling material gelation time can be shortened; and waste stone generated under the shaft is sufficiently used, and consumption of bricks is reduced.

Owner:GUIZHOU KAILIN GRP CO LTD +1

Bonding filling material and method for carrying out downhole filling using the same

ActiveCN102020979AEasy to transportGood filling effectMaterial fill-upDrilling compositionBond propertiesHigh effectiveness

The present invention relates to a bonding filling material and a method for carrying out downhole filling using the same, wherein the said gangue bonding filling material comprises: 68.6-82.2% by weight of gangue; 12.7-21.8% by weight of coal ash; and 1-18.7% by weight of water. Pressure intensity of the rammer compacter for filling and compacting in filling the bonding filling material is more than or equal to 20 Mpa. According to the invention, filling effect and filling quality are improved, and the movement of the overlying strata can be effectively controlled. The bonding filling material is filled directly without any additives, and the bonding property of the bonding filling material is increased due to the addition of coal ash as one filling material. The conveying system in the invention has simple requirements and enables continuity and high effectiveness of the filling. Downhole treatment of gangue and coal ash is fulfilled, and ecological and living environment around mining area are improved.

Owner:JIZHONG ENERGY +1

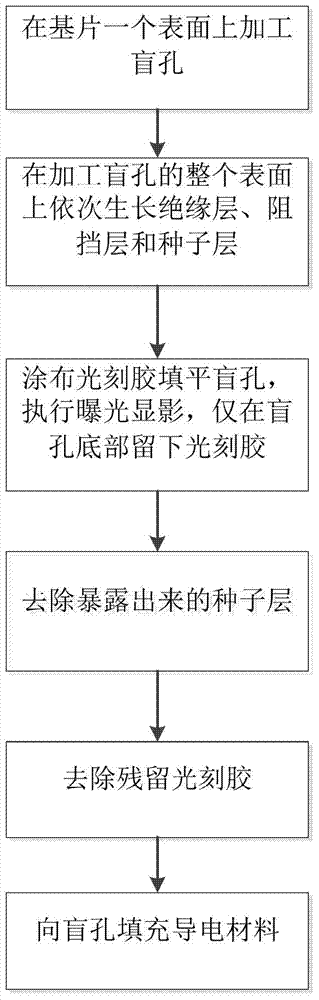

Method for achieving through hole interconnection by filling through hole from bottom to top and product thereof

InactiveCN103325700AQuality improvementFilling high speedSemiconductor/solid-state device detailsSolid-state devicesInterconnectionPhotoresist

The invention discloses a method for achieving through hole interconnection by filling a through hole from bottom to top. The method includes the steps that (a) a blind hole is machined in one surface of a substrate; (b) an insulating layer, a barrier layer and a seed layer are sequentially formed on the surface, provided with the blind hole, of the substrate; (c) the surface of the seed layer is coated with photoresist, the blind hole is filled and leveled up, and then exposure and development treatment is carried out so that the photoresist can only remain on the portion, at the bottom of the blind hole, of the surface of the seed layer; (d) the portion, not covered with the photoresist, of the seed layer is removed, wherein the portion, at the bottom of the blind hole, of the seed layer is not affected; (e) the residual photoresist is removed; (f) conducting materials are filled into the blind hole to achieve generation from bottom to top; (g) the surface, not provided with the blind hole, of the substrate is thinned so that a through hole can be formed, and then the process of through hole interconnection is finished. The invention further discloses a corresponding through hole interconnection structure product. By means of the method, the process of through hole electroplating can be carried out with convenient control, low cost and high efficiency, and the through hole interconnection structure product with better filling effects can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

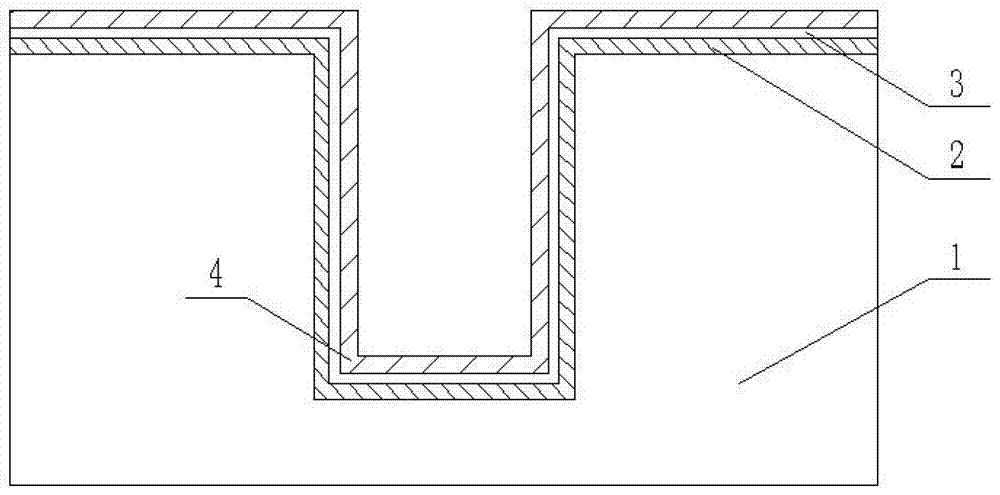

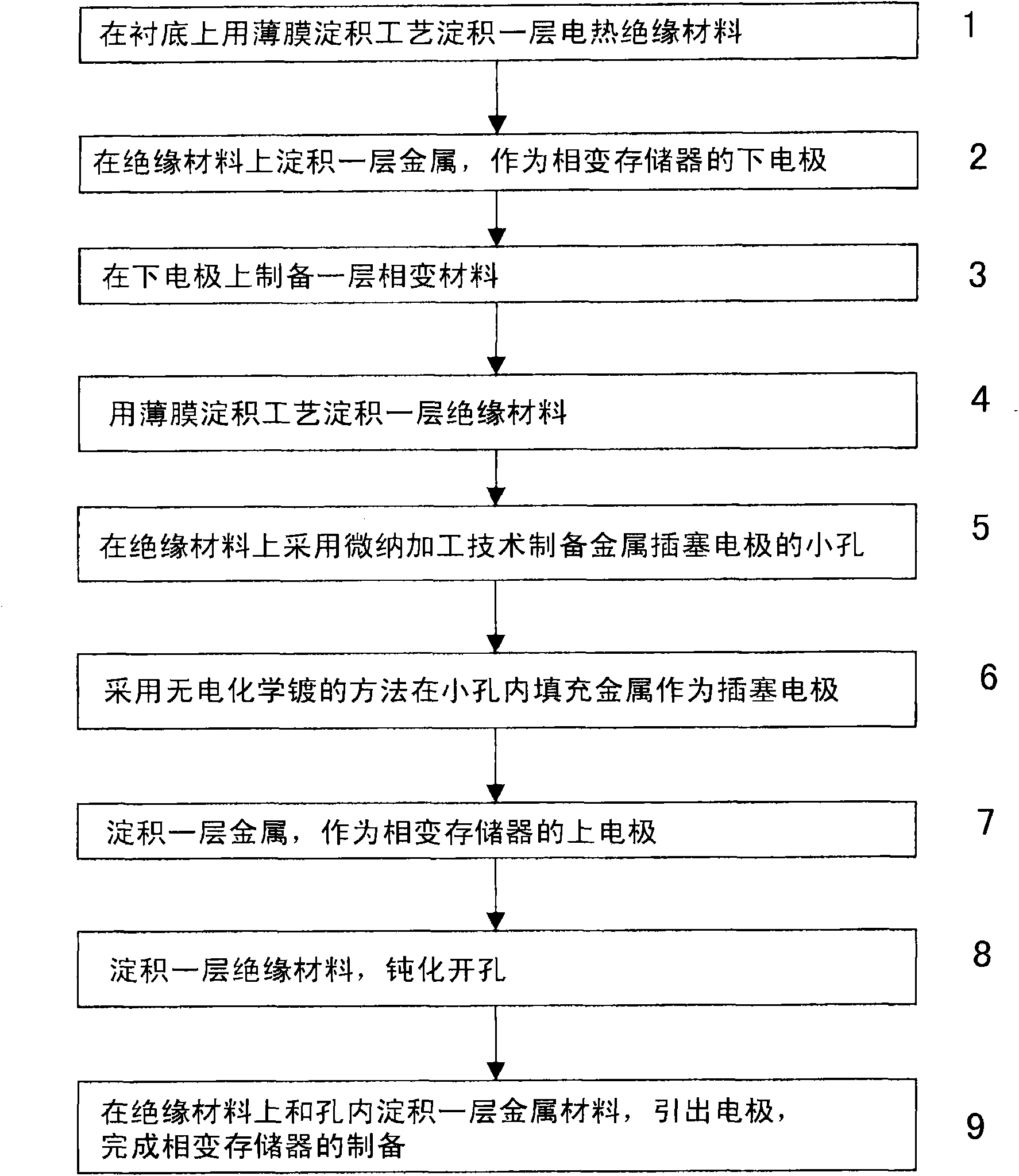

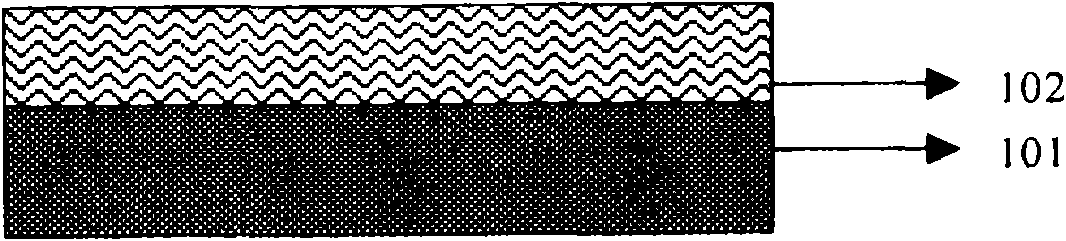

Production method of phase-change memory

InactiveCN101826596AImprove filling qualityLow costSemiconductor/solid-state device manufacturingPhase-change memoryMetallic materials

The invention relates to a production method a phase-change memory, which comprises the following steps: step 1, depositing a first insulating material layer on a substrate; step 2, depositing a metal layer on the first insulating material layer to be used as a lower electrode of the phase-change memory; step 3, preparing a phase-change material layer on the metal layer; step 4, depositing a second insulating material layer on the phase-change material layer by a thin film deposition process; step 5, preparing small holes of metal plug electrodes on the second insulating material layer by micro / nano processing technology; step 6, filling metal in the small holes to be used as plug electrodes by adopting a non-electrochemical plating method; step 7, depositing a metal material layer on the second insulating material layer to be used as an upper electrode of the phase-change memory; step 8, depositing a third insulating material layer on the metal material; step 9, carrying out passivation opening on the third insulating material layer; and step 10: depositing a metal electrode layer on the third insulating material layer and in the passivation opening again to complete the production of the phase-change memory.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

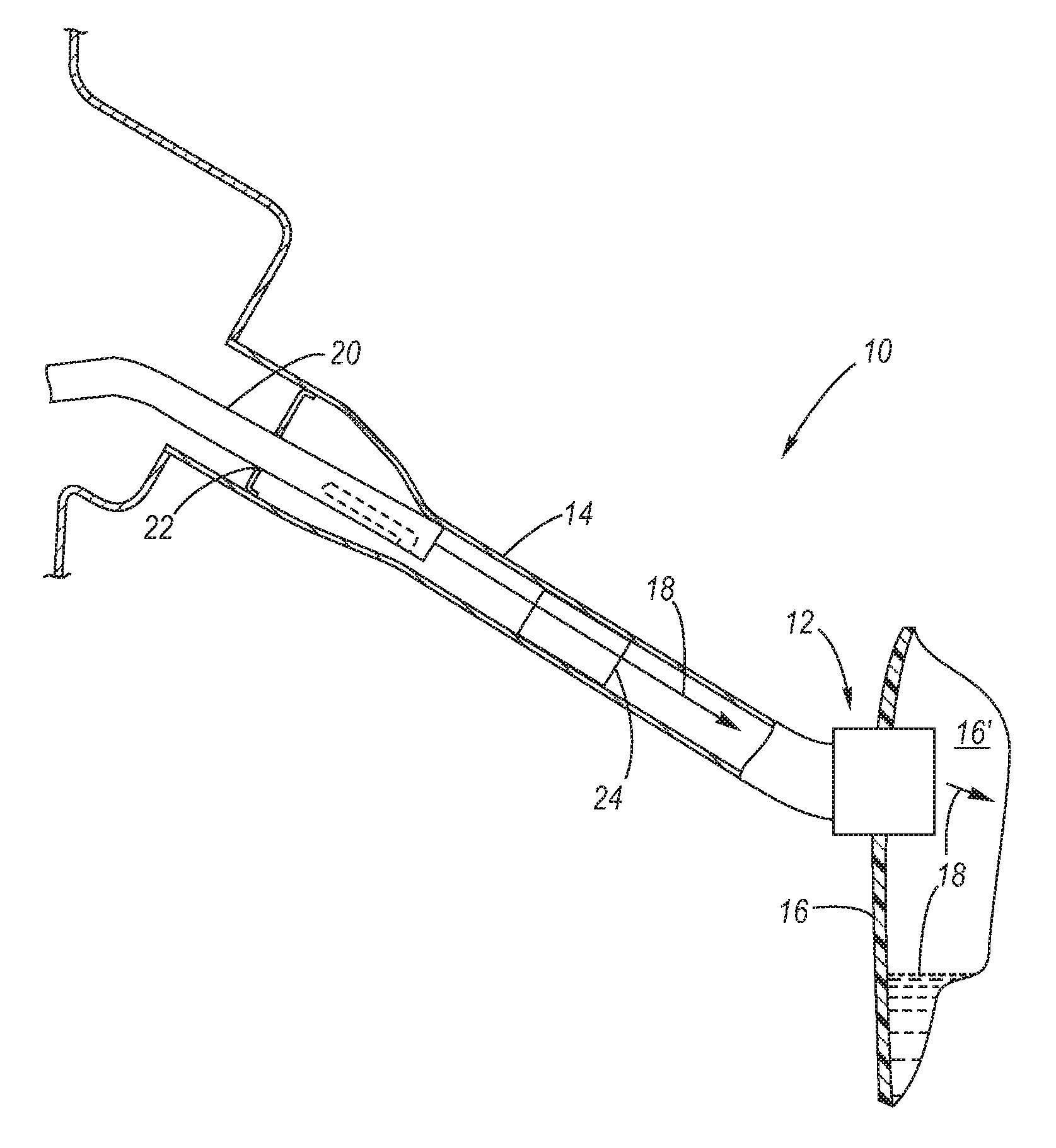

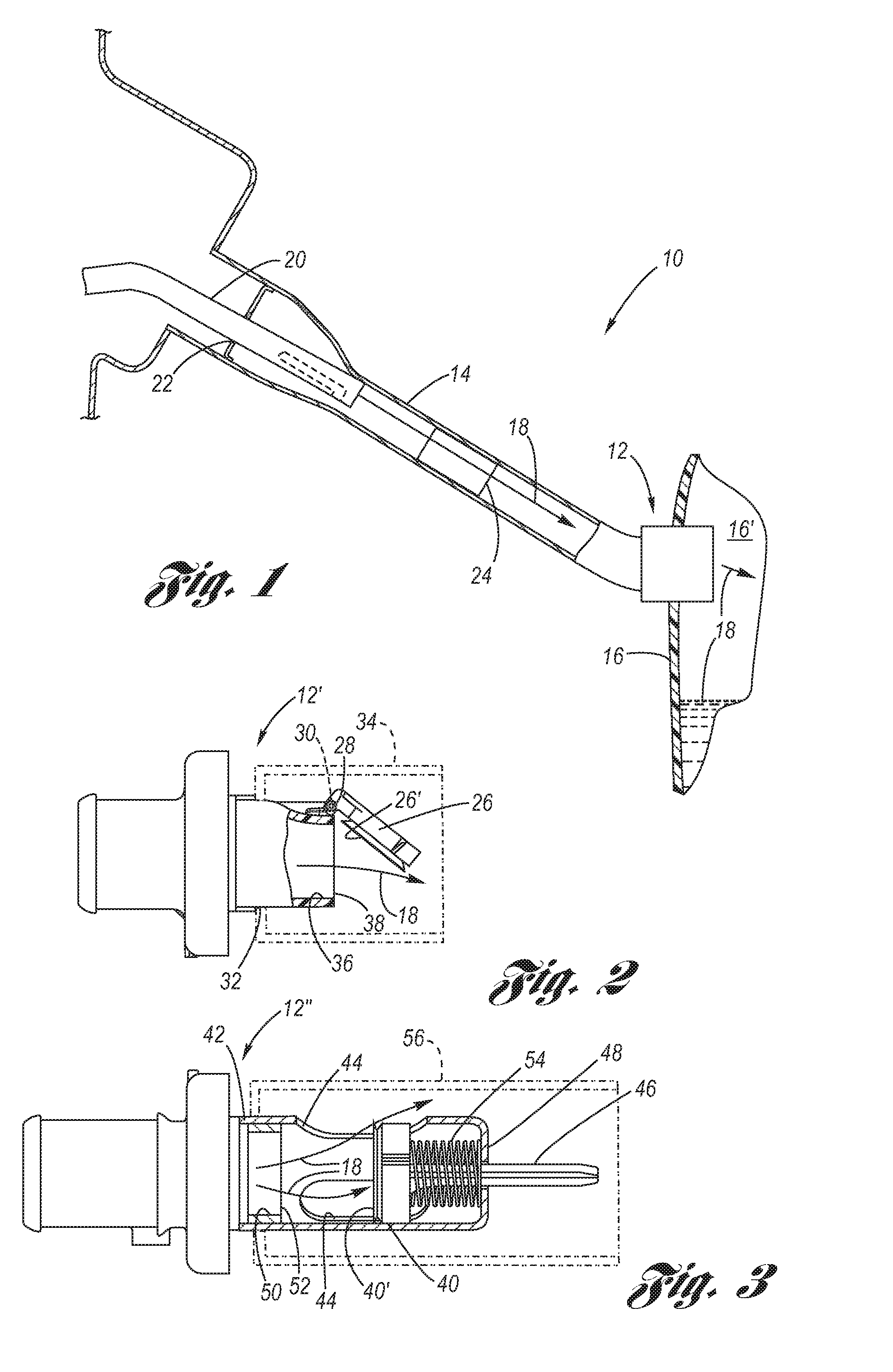

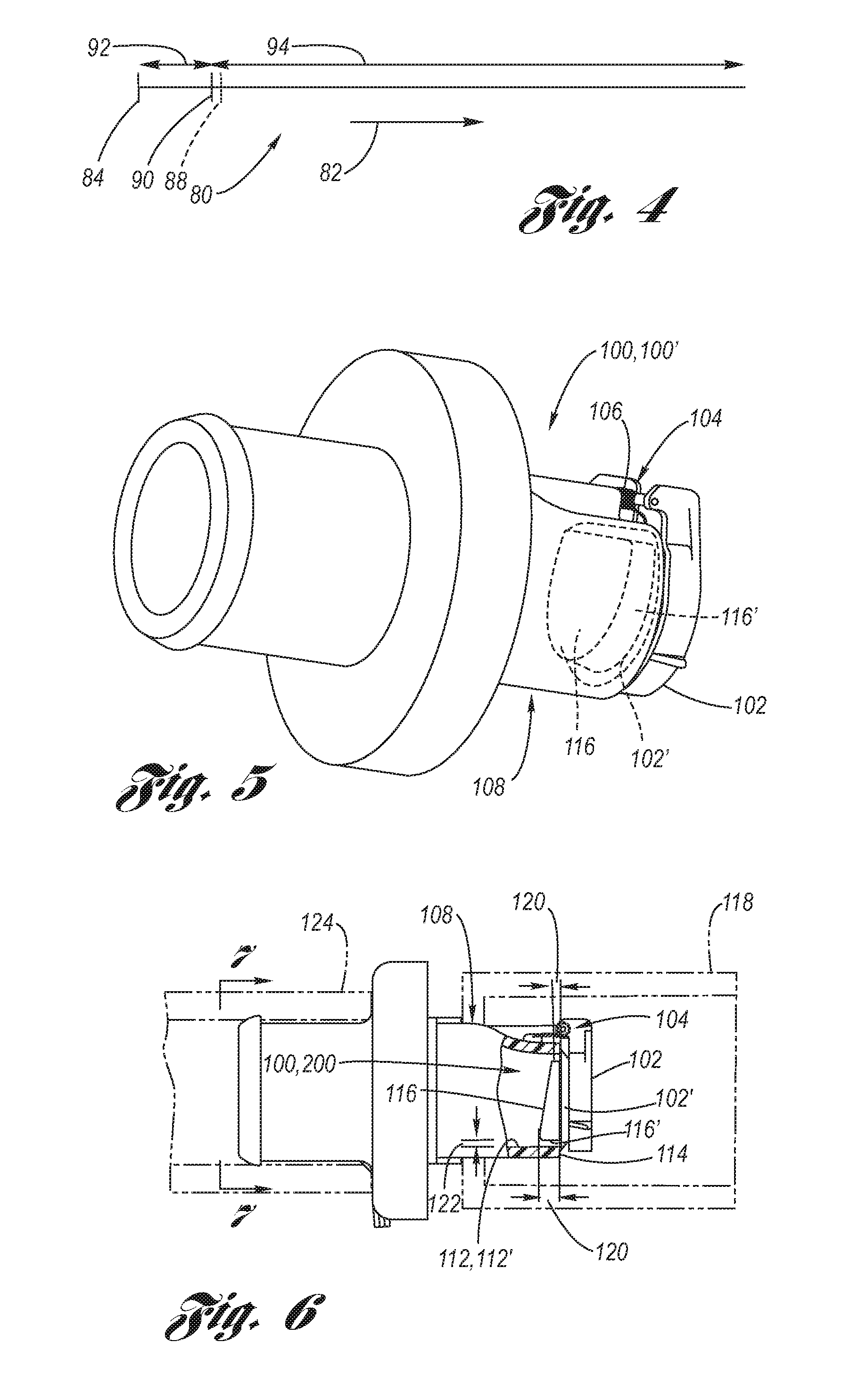

Fuel System Inlet Check Valve with Flame Arresting feature

ActiveUS20120298385A1Improve fuel fill qualityLessening of flow restrictionContainer filling methodsCheck valvesCheck valveEngineering

An inlet check valve assembly with flame arresting feature. An internal flame arresting feature utilizes a flame arrester body attached to a valve member which protrudes into the valve throat. An external flame arresting feature utilizes a hood concentrically disposed relative to the valve member. The flame arresting feature is configured relative to movement of the valve member with respect to the throat such that fluidic communication between the fuel fill pipe and the fuel tank is limited to less than the minimum flame propagation distance of the fuel and air mixture in which a combustible mixture may exist in the fuel fill pipe, whereby any flame front in the fuel fill pipe will quench thereat before reaching the fuel tank.

Owner:GM GLOBAL TECH OPERATIONS LLC

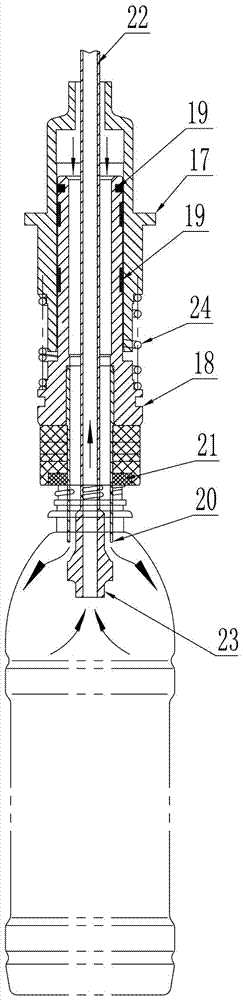

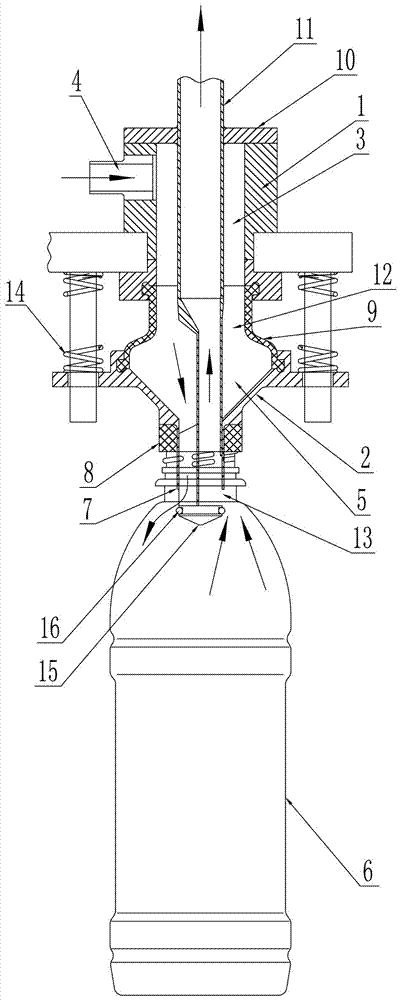

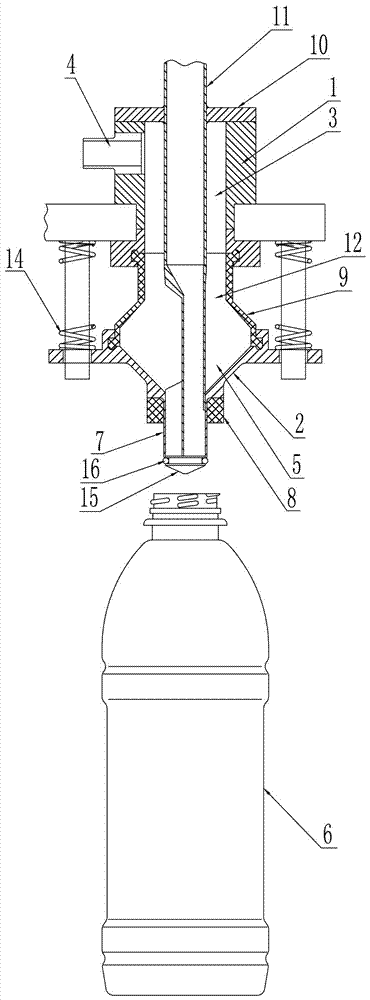

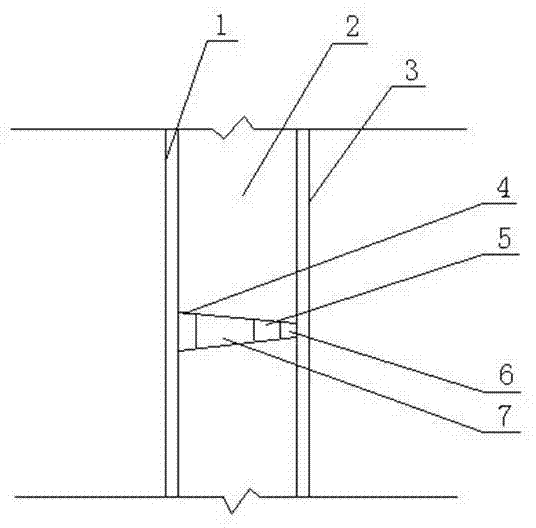

Particle filling valve

The invention discloses a particle filling valve which comprises an upper valve base and a lower valve base. Inner cavities penetrating the corresponding valve bases are formed in the upper valve base and the lower valve base correspondingly, a feeding hole is formed in the side wall of the upper valve base, a pipe-shaped filling nozzle with a bottle opening sealing ring is arranged at the bottom of the lower valve base, and the upper valve base and the lower valve base are connected through a flexible cup; a valve cap is arranged at the top of the upper valve base and is provided with an eccentric air return pipe, the upper end of the eccentric air return pipe extends out of the valve cap, the lower end of the eccentric air return pipe downwards penetrates the upper valve base, the flexible cup and the lower valve base sequentially to be tightly attached to the inner wall of the pipe-shaped filling nozzle, then downwards extend out of the pipe-shaped filling nozzle and be provided with a sealing plug, and an opening type air return opening is formed in the side wall of a pipe section, in sliding contact sealing with the pipe-shaped filling nozzle, of the eccentric air return pipe; and reset springs are arranged on the outer sides of the upper valve base and the lower valve base, and the reset spring enables the lower valve base to have the trend that the pipe-shaped filling nozzle is tightly pressed on the sealing plug all the time. The particle filling valve has the beneficial effects that sanitation dead corners are avoided, and the air return opening can be prevented from being blocked.

Owner:江苏普华盛包装科技有限公司

Method for padding of split bolt hole of concrete shear wall

InactiveCN103541439AImprove fill qualityGood anti-seepage and thermal insulation effectBuilding insulationsShear wallPolyurethane

The invention discloses a method for padding of a split bolt hole of a concrete shear wall. According to the method for padding of the split bolt hole of the concrete shear wall, a traditional uniform-section split bolt is replaced by a variable-section split bolt sleeve when a shear wall formwork is reinforced. The method for padding of the split bolt hole of the concrete shear wall comprises the following steps that the split bolt hole is formed in the concrete shear wall, a variable-section circular truncated cone rubber plug is placed and stuffed in the split bolt hole from the inner side of the concrete shear wall, a polyurethane foaming material which has the air hardening performance, resists seepage and preserves heat is injected into the split bolt hole, and an inner portion with the length of 15mm of the split bolt hole and an outer portion with the length of 15mm of the split bolt hole are reserved and padded with expanded mortar. According to the method for padding of the split bolt hole of the concrete shear wall, full-hole padding is guaranteed and padding is dense; the polyurethane foaming material which has the air hardening performance, resists seepage and preserves heat is used for padding, so that the padding quality is improved, and the seepage-proof and heat-preservation effect is good.

Owner:BAOJI NO 1 CONSTR

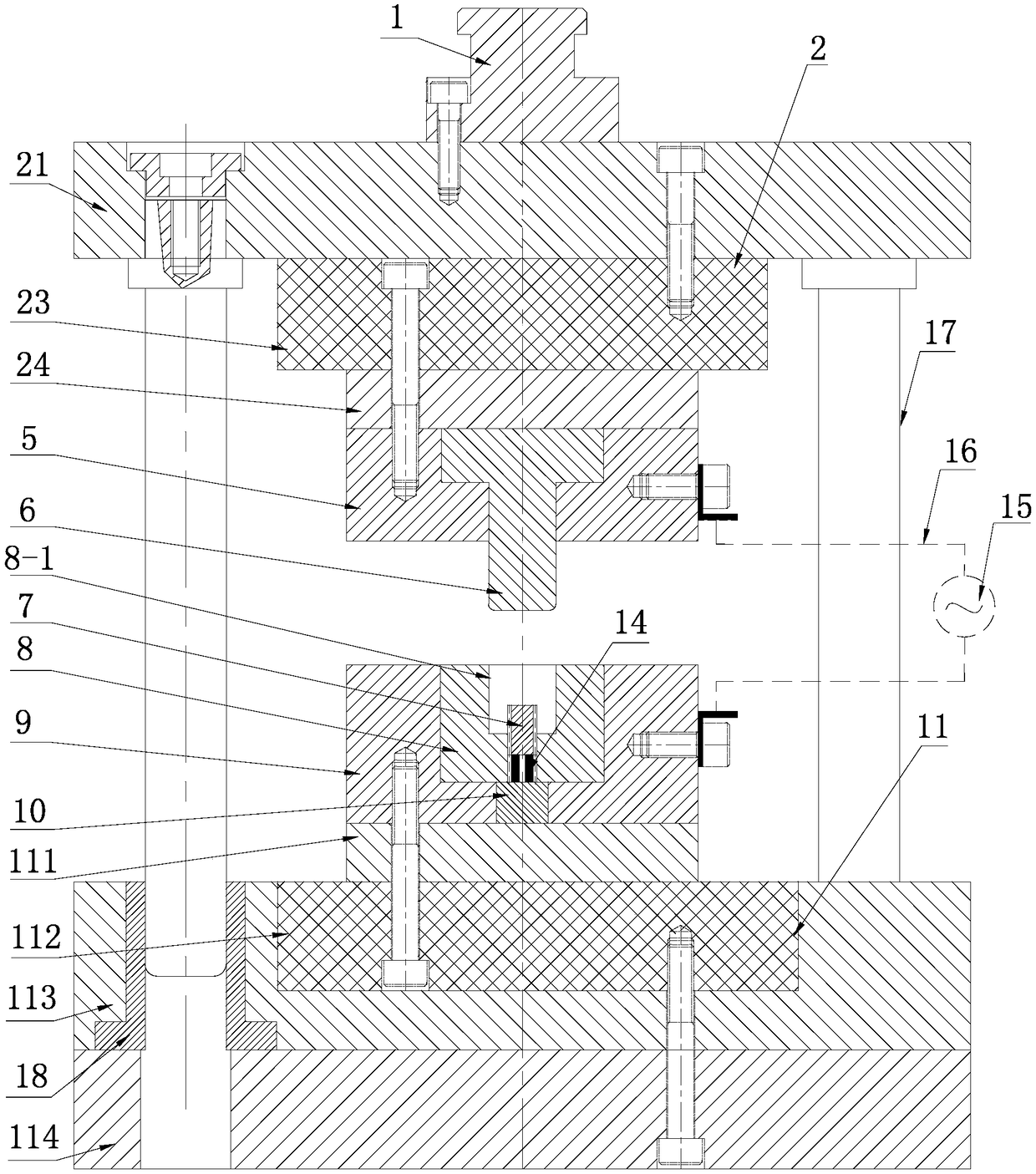

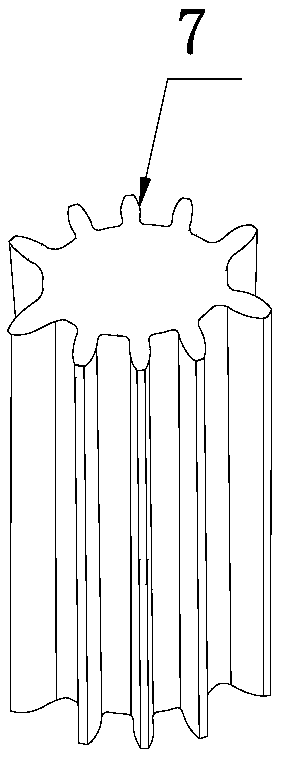

Pulse current assisted hollow shunt billet micro-forming die and method

ActiveCN108994102AImprove filling qualityHigh forming precisionExtrusion diesPulse power supplyTitanium alloy

The invention discloses a pulse current assisted hollow shunt billet micro-forming die and method and relates to a micro-forming die and method for miniature parts. In order to solve bottleneck problems that billets of miniature parts made of titanium alloy and other difficult-to-form materials have slow heating speeds, the micro die cavity is difficult to fill, the service life of the die is lowand the like, the micro-forming die comprises a die handle, an upper plate, a punch fixing plate, a punch, a female die, a female die fixing block, a demolding cushion block and a lower plate arrangedfrom top to bottom in sequence, wherein the punch is fixed in a stepped through hole which is large in top and small in bottom on the punch fixing plate. The forming method comprises the following steps: 1, die assembling, arranging the billet in the cavity of the female die, enabling pressure equipment to move downwards to drive the punch to move downwards so as to be in contact with the upper end face of the male die, continuously enabling the male die to move downwards to reach a certain pre-tightening pressure with the billet and stopping; 2, starting a pulsed power supply, heating the billets, and performing extrusion forming; 3, taking out the male die and the formed miniature parts. The invention belongs to the technical field of machine manufacturing and plastic micro-forming.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com