Pulse current assisted hollow shunt billet micro-forming die and method

A pulsed current, micro-forming technology, applied in the direction of metal extrusion dies, etc., can solve the problems of slow heating speed, low die life, and difficulty in filling small die cavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

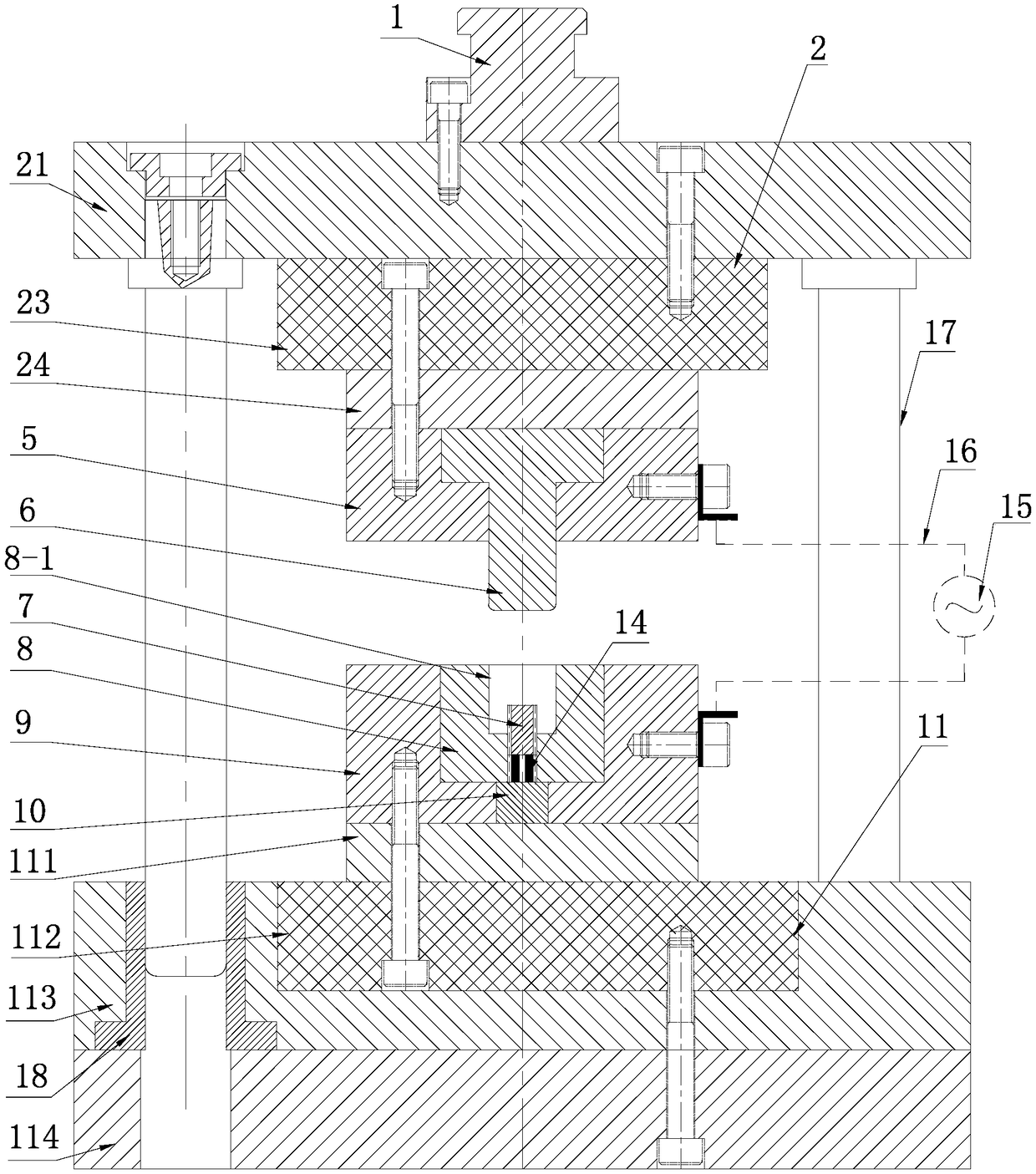

[0024] Specific implementation mode one: combine figure 1 and Figure 4 Explain, a pulse current assisted blank hollow shunt micro-forming mold, which includes a mold handle 1, an upper plate 2, a punch fixing plate 5, a punch 6, a die 8, and a die fixing block 9 arranged in sequence from top to bottom , demoulding pad 10 and lower plate 11; the punch 6 is fixed in the upper, lower and smaller step through holes on the punch fixing plate 5, the die handle 1 and the punch fixing plate 5 are respectively connected with the upper plate 2, and the concave The mold fixing block 9 is connected with the lower plate 11, the upper end of the die fixing block 9 is grooved and embedded with the die 8, and the lower end is opened with a passage through the cavity of the die 8, and the demoulding pad 10 is arranged in the passage, with The blank 14 of the split hole is arranged in the cavity of the die 8, and the lower end is in contact with the demoulding pad 10, the cavity is matched wi...

specific Embodiment approach 2

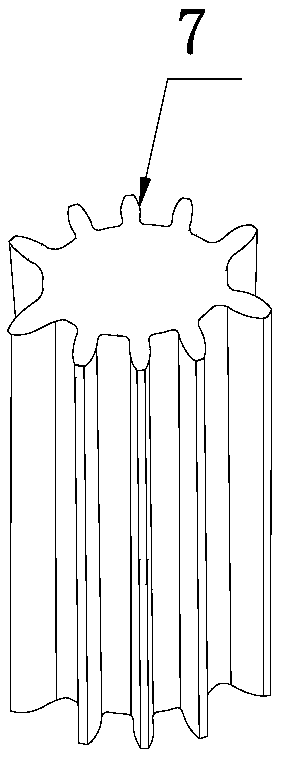

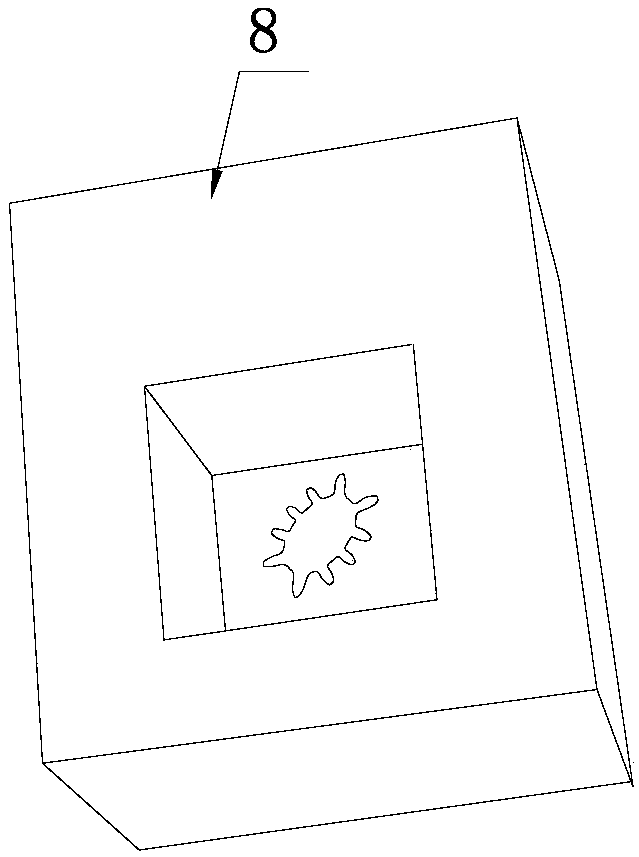

[0026] Specific implementation mode two: combination figure 2 and image 3 Explanation, the shape of the male mold 7 in this embodiment is the same as the contour shape of the micro-component, and the cavity of the die 8 is the same as the contour shape of the micro-component.

specific Embodiment approach 3

[0027] Specific embodiment three: the punch 7 has a micro-part outer contour structure, the cavity inner contour of the die 8 is a micro-part structure, and the die 8 is processed with a punch guide groove 8- which communicates with the inner cavity. 1. The matching gap between the punch 6 and the punch guide groove 8-1 is less than 5 μm, and the matching gap between the cavity of the die 8 and the punch 7 is less than 10 μm. Other compositions and connections are the same as in the first embodiment.

[0028] In the above two embodiments, the punch 7 is independent from the overall structure of the mold, which reduces the processing difficulty of the punch 7 and facilitates assembly and replacement. The matching gap between the concave die 8 and the male die 7 of this embodiment is less than 10 μm, so that the forming accuracy of the formed micro parts (such as micro gears) is completely guaranteed by the concave-convex fit, which greatly reduces the dependence on the mold ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com