High-viscosity PBX (Polymer Bonded Explosive) injection-compression molding method and device

An injection molding, high-viscosity technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of high-viscosity PBX charging difficulties, etc., and achieve the effects of low working noise, guaranteed controllability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

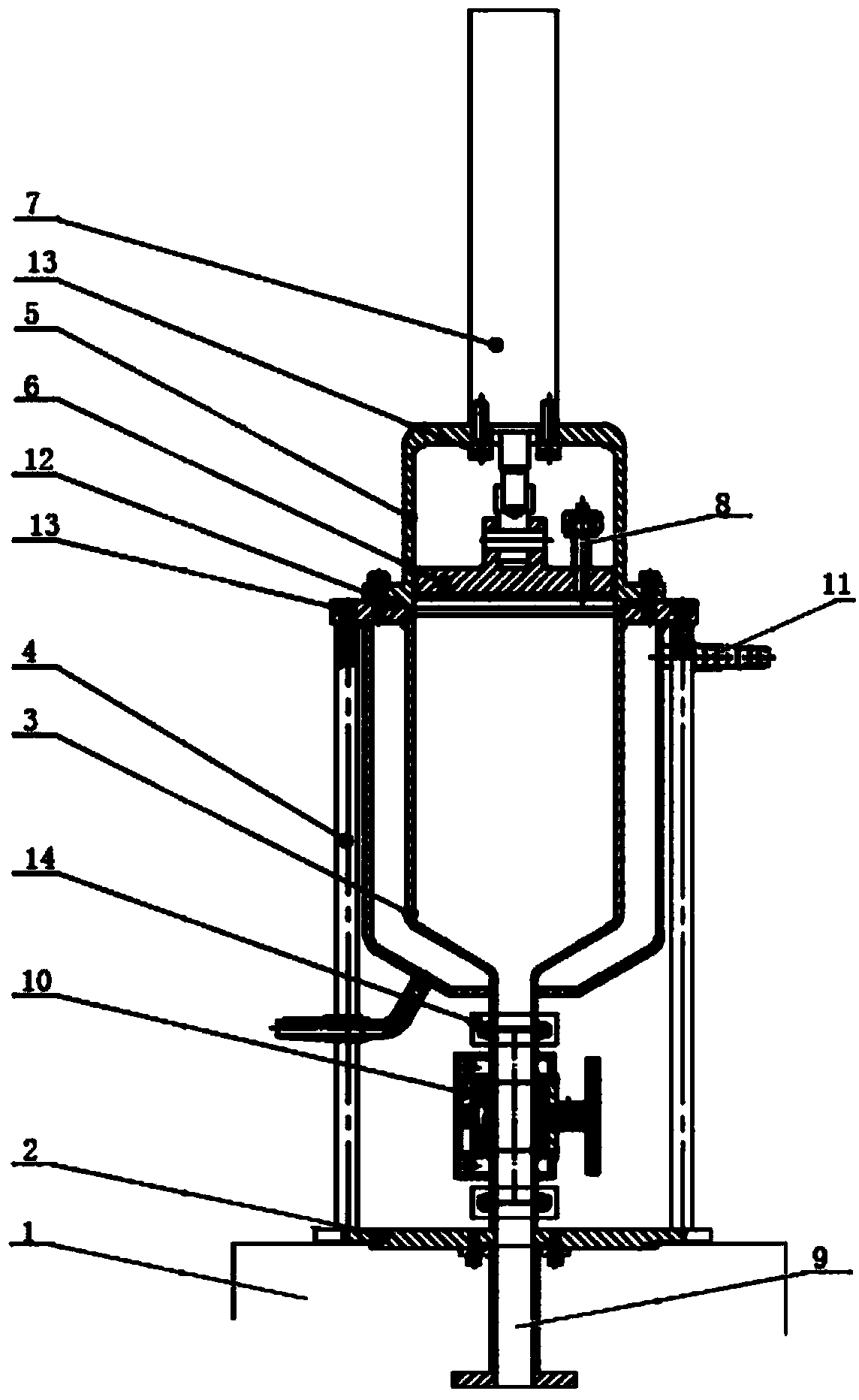

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] Such as figure 1 As shown, the main structure of the high-viscosity PBX explosive injection molding device (hereinafter referred to as the injection device) is made of OCr 18 Ni 9 The cartridge 3 and the installation cartridge 5 of the material, the upper end of the cartridge 3 is cylindrical, the lower end is funnel-shaped, the injection pipe 9 at the lower end of the cartridge 3 is provided with a plug valve 10, and the upper and lower ends of the plug valve 10 are covered by two A quick clamp 14 is fixed on the injection pipe 9, and the stopcock 10 can open and close the passage of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com