Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Improve pull strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

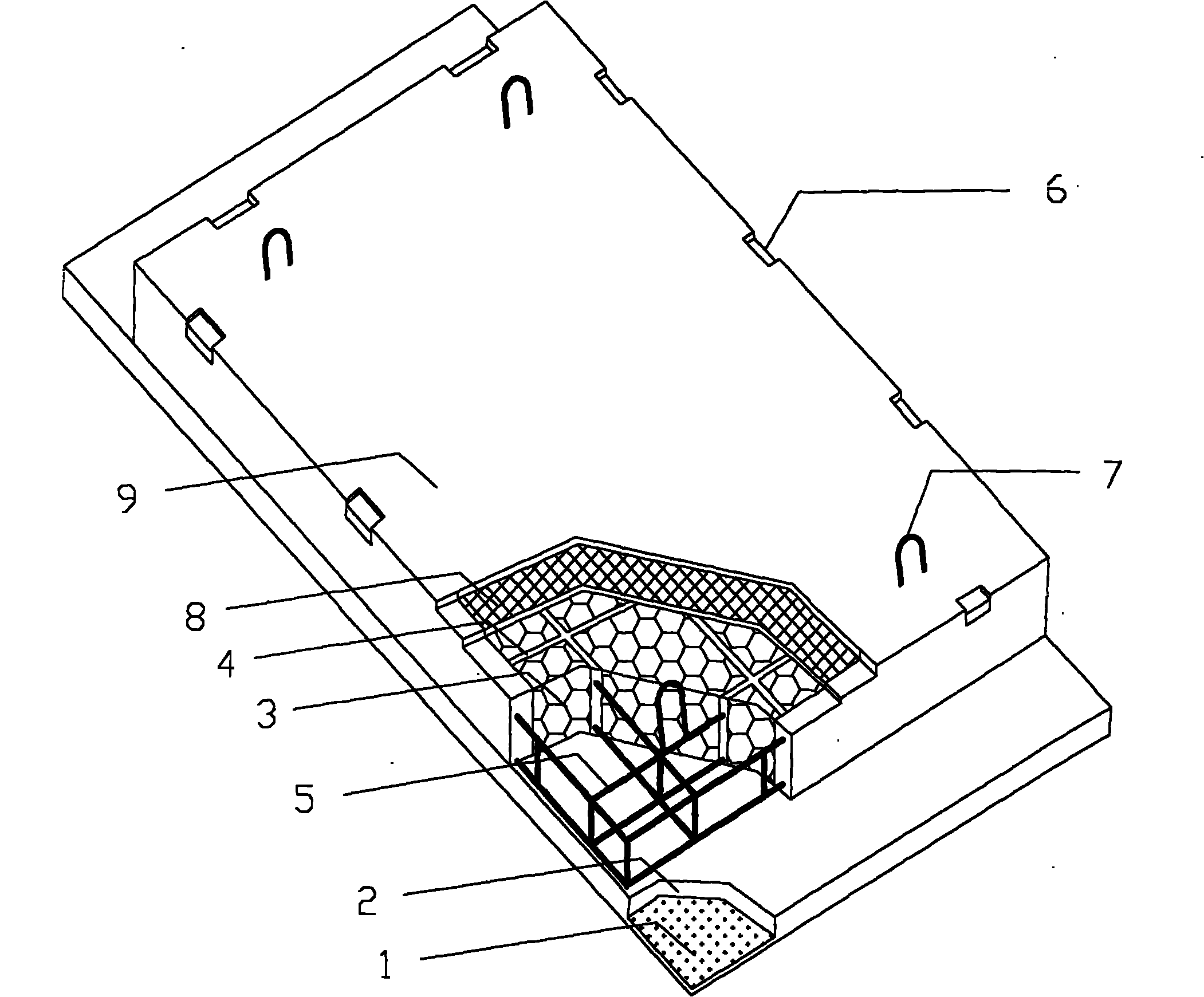

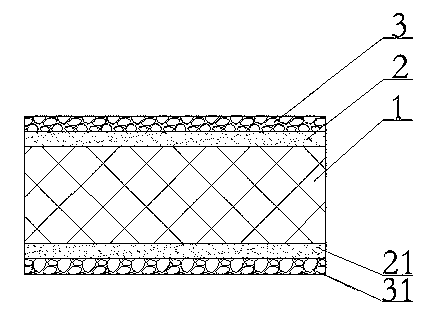

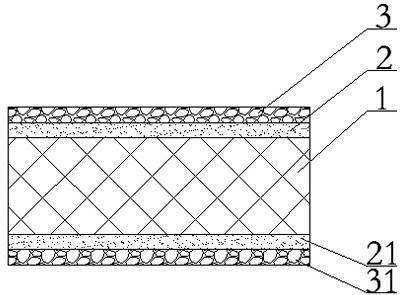

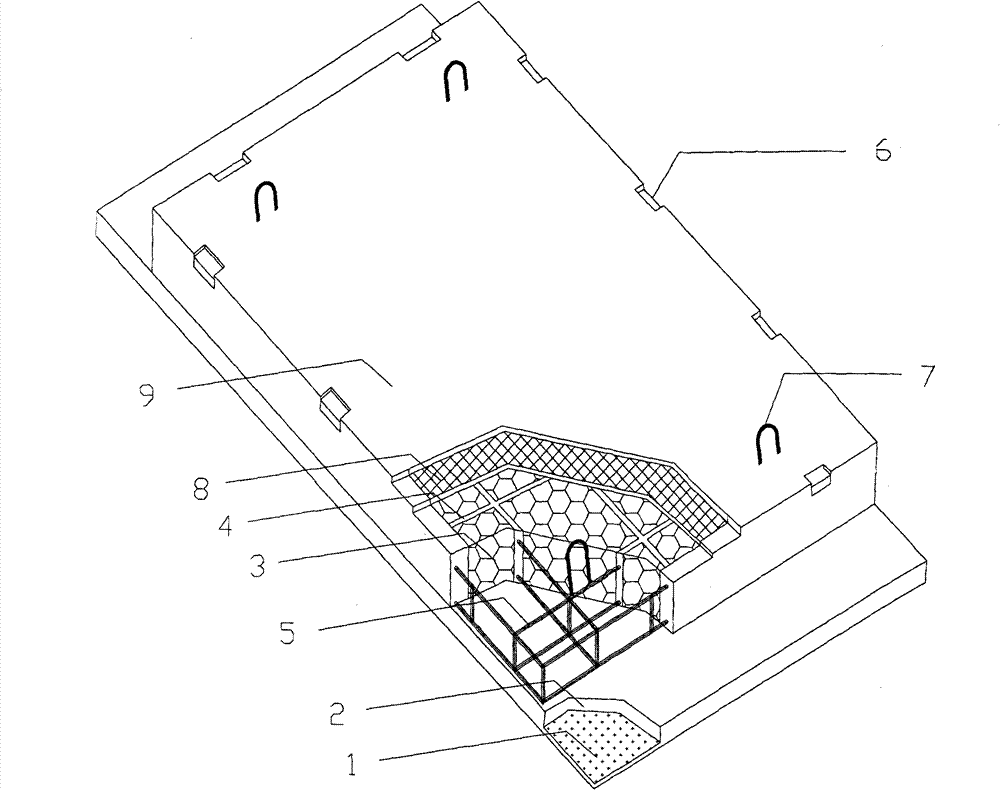

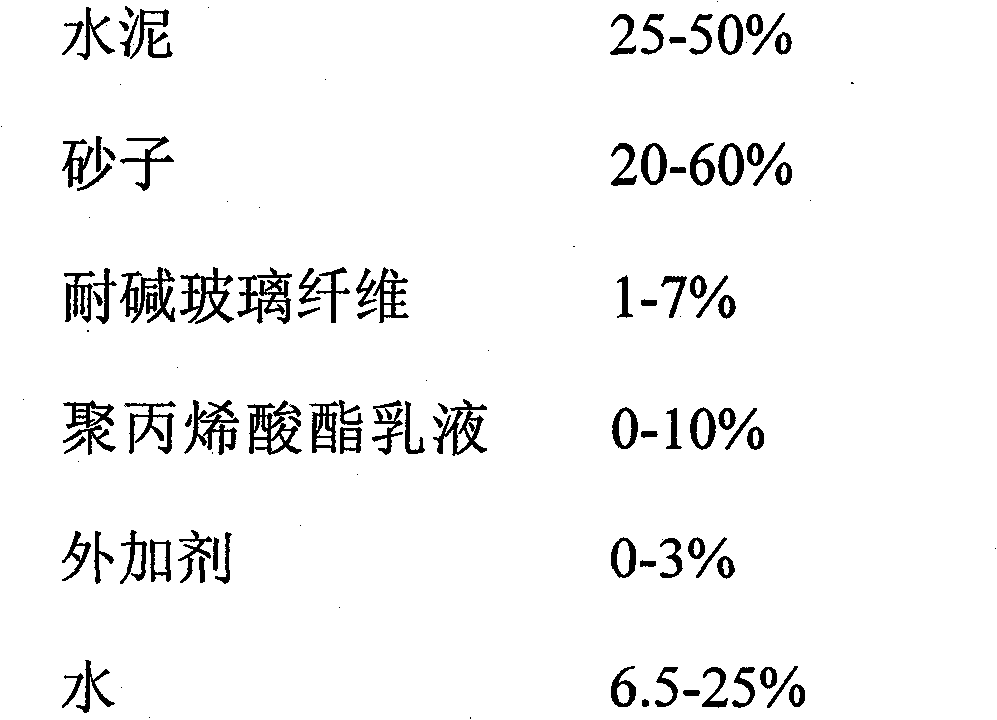

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501AReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

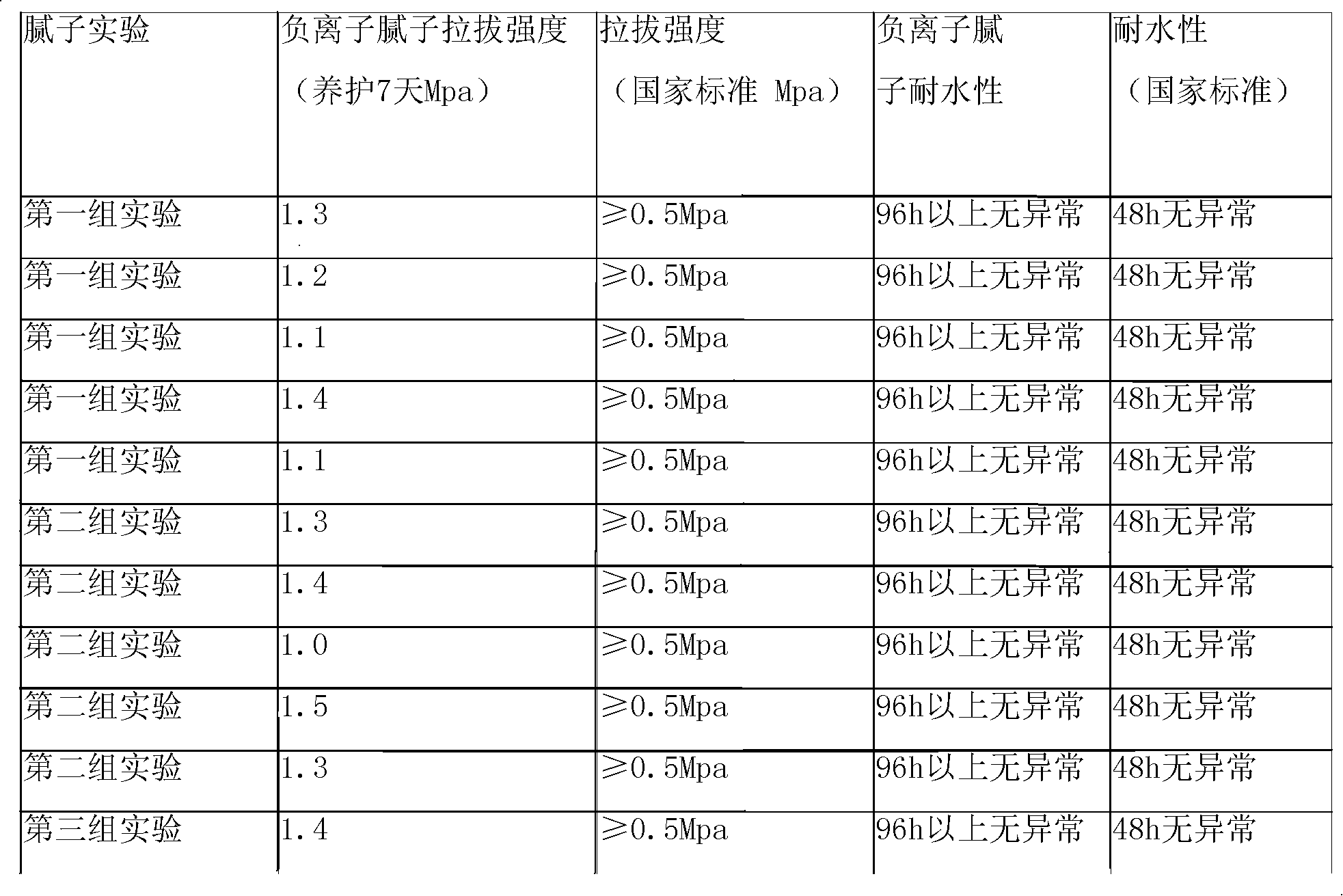

Architectural interior anion waterproof putty powder and preparation method thereof

InactiveCN101225261AHigh removal rateImprove water resistanceFilling pastesLight energyWater resistant

The invention relates to a building interior anionic water resistant putty powder. The weight ratios of the components are 100 to 300 portions active calcium powder, 200 to 700 portions calcium carbonate powder, 50 to 200 portions anion powder, 1 to 10 portions cementing material and 1 to 5 portions cellulose; wherein, the anion powder is the mixed powder of ultrafine tourmaline powder and physical adsorption materials, the fineness of the ultrafine tourmaline powder is more than 2.6 Mum and the purity of the ultrafine tourmaline powder is more than 95 percent, the physical adsorption material is diatomite or modified active carbon and the weight of the physical adsorption material is 20 to 35 percent the total weight of the anion powder. The building interior anionic water resistant putty powder has the advantages that: the preparation method does not need the excitation of light energy sources and has not the danger of over standard radioactivity, so the removal ratios of formaldehyde and toluene is increased greatly, the putty powder plays the role of eliminating pollution and purifying air, meanwhile, the water resistant performance of the putty powder are enhanced.

Owner:莱恩斯建材(北京)有限公司

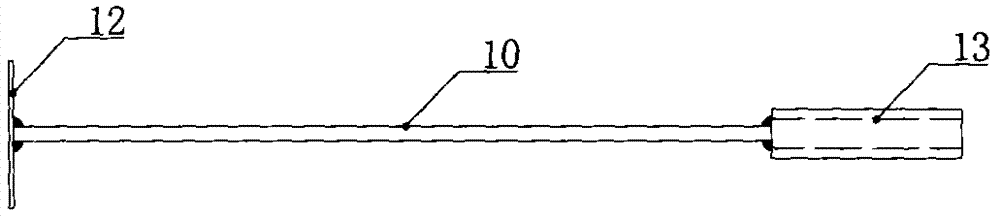

Method for installing and connecting decoration and heat preservation combined plates on wall made of low-strength materials

InactiveCN103790322AImprove pull strengthHigh construction guarantee rateCovering/liningsEngineeringCement mortar

The invention belongs to a method for installing and connecting decoration and heat preservation combined plates on a wall made of low-strength materials. The method is characterized by including the steps of fixing a panel to the wall through expansion anchors, drilling a special anchor rod hole penetrating through a base wall, inserting a special anchor rod into the special anchor rod hole from the indoor side, enabling a polygonal cap of the special anchor rod to be sunken in a counter bore and closely attached to the bottom of the counter bore, and then enabling the counter bore to be flattened through cement mortar. The special anchor rod is composed of a pull rod and a screw, the polygonal cap is fixedly arranged at one end of the pull rod, and a long nut is fixedly arranged at the other end of the pull rod; when the pull rod is long enough and can be completely inserted into the special anchor rod hole from the indoor side, the tip at the long nut end of the pull rod can extend to be close to an opening of a prefabricated rivet hole of the plate. According to the method, safety and durability of the decoration and heat preservation combined plate installed and connected to the wall made of the low-strength materials are well achieved.

Owner:上海欧墅节能科技股份有限公司

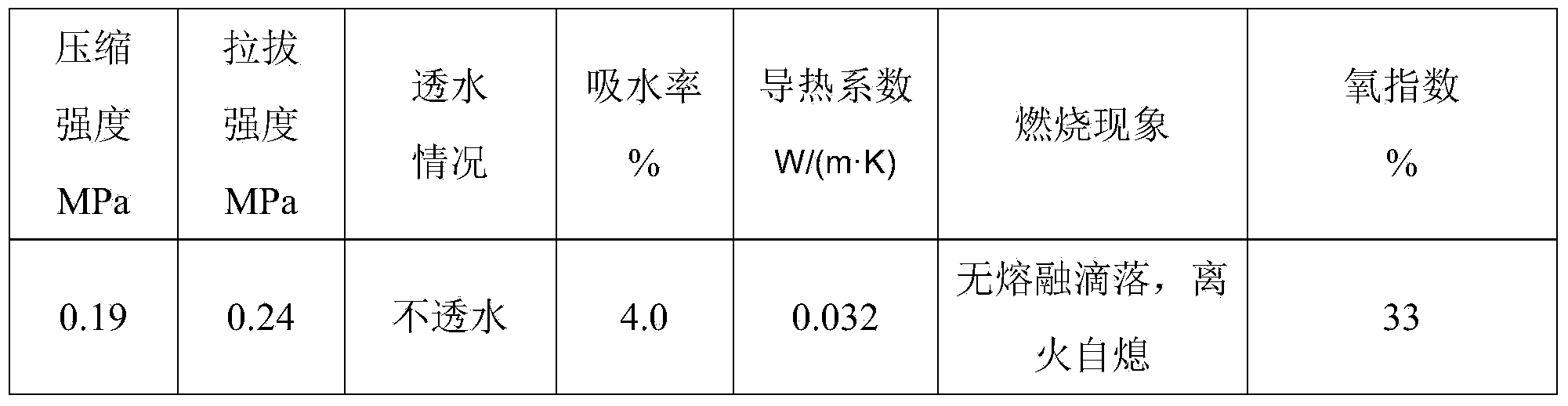

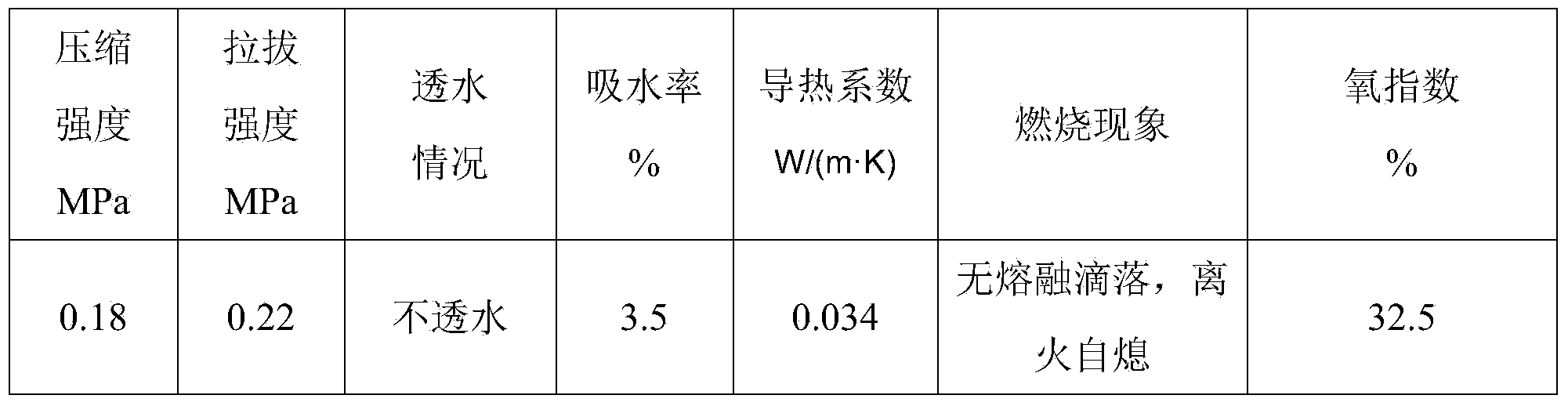

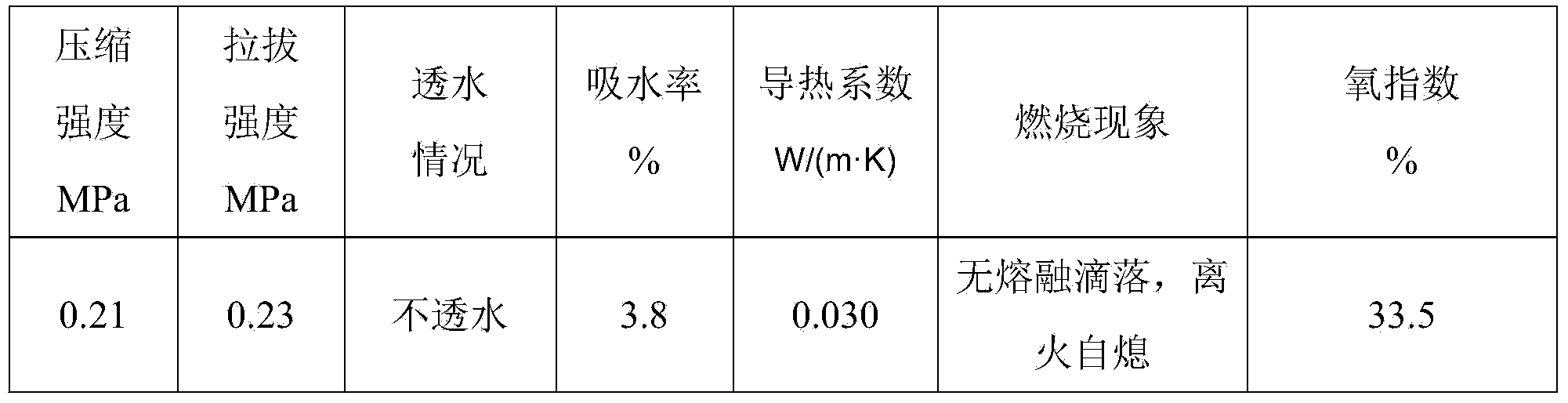

Production method of polystyrene insulation board

The invention provides a production method of a polystyrene insulation board. The production method comprises the following steps: (1) pre-foaming expandable polystyrene particles so as to obtain polystyrene beads; (2) uniformly stirring a foaming agent, a curing agent and a surface active agent so as to prepare a liquid additive; (3) adding thermosetting resin and the liquid additive to the polystyrene beads, and uniformly stirring; (4) adding a flame retardant to the obtained mixture, and uniformly mixing; and (4) transferring the obtained material to a mold, and molding under a steam pressure. The production method provided by the invention is simple in process and is capable of improving the compression strength, pull strength and fireproof performance of the product.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Elastic putty and preparation method thereof

The invention relates to elastic putty and a preparation method thereof. The elastic putty is made from the following raw materials in parts by weight: 20-25 parts of cement, 10-15 parts of fly ash or steel slag, 2-6 parts of white lime, 30-40 parts of calcium carbonate, 20-30 parts of quartz sand, 0.1-1 part of cellulose ether, 0.1-0.5 part of lignocellulose, 0.01-0.04 part of starch ether, 0.1-0.4 part of powdery water repellent and 4-15 parts of dispersible gelatine powder. The preparation method comprises the steps of adding all raw materials in a dispersion machine in proportion, and stirring the raw materials for 45 min to obtain the elastic putty. The elastic putty has good bonding strength with various materials, and has higher compressive strength, bending strength, tensile strength, permeability resistance and waterproof performance; the putty has flexibility after curing, strong protection properties, easy construction and good durability, is easy to foundry mill at early period while having high intensity at later period, is innoxious, flavourless and non-inflammable, and belongs to recycled product of industrial waste residues.

Owner:上海基成达申防水材料有限公司

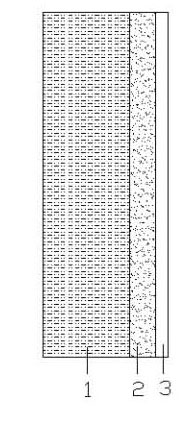

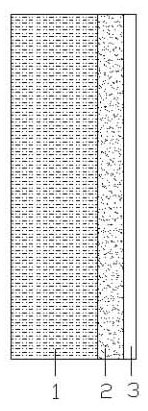

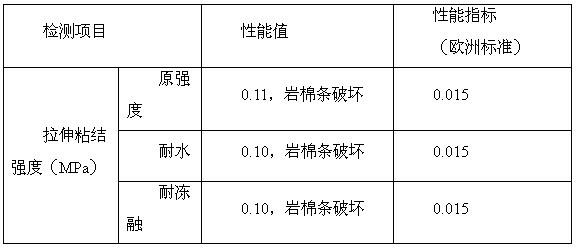

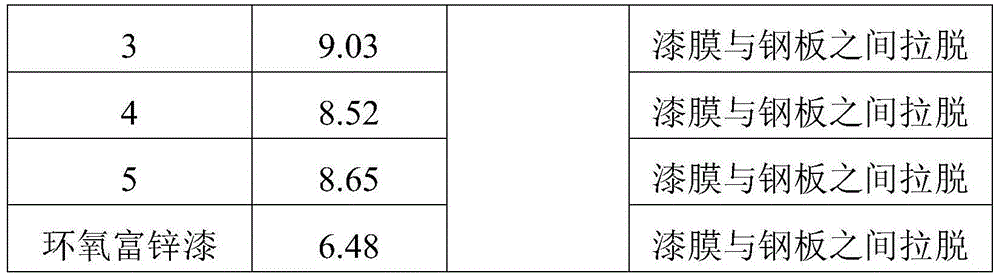

Fireproof decoration and heat insulation integrated board and preparation method thereof

InactiveCN102003051AImprove pull strengthHigh temperature and fireproofCovering/liningsHeat proofingCalcium silicateFiber

The invention belongs to the technical field of building materials and relates to a fireproof decoration and heat insulation integrated board and a preparation method thereof. The board comprises a heat insulation layer, an enhancement layer and a decoration layer, wherein the heat insulation layer is 30-100mm thick and is made of hydrophobic mineral wools with fiber alignment direction vertical to the wall surface; the enhancement layer is 3-15mm thick and is made of high-strength calcium silicate boards; and the decoration layer is made of any one of fluorocarbon paint, metallic paint, stone paint, facing mortar or emulsion paint. The heat insulation board is installed on the wall surface by adhesive bonding and anchoring and the whole system is convenient and fast in construction, safe and reliable and grade-A non-combustible and integrates decoration and heat insulation.

Owner:上海英硕聚合材料股份有限公司

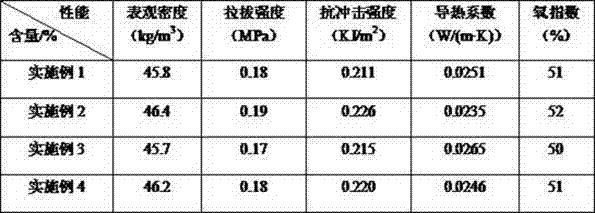

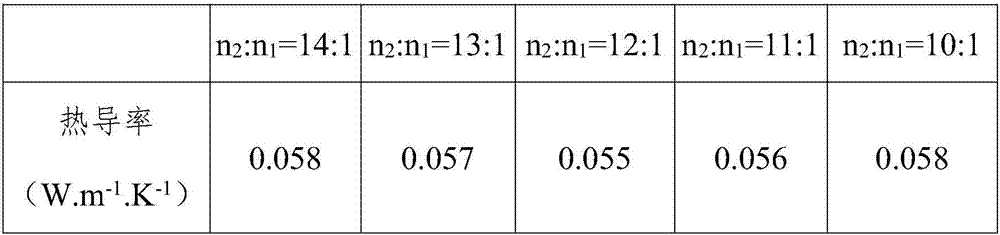

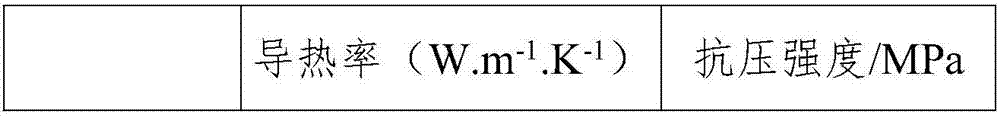

Phenolic foam plate containing nanometer aerogel and production method of phenolic foam plate

The invention relates to the technical field of phenolic foam plates and in particular relates to a phenolic foam plate containing nanometer aerogel. The phenolic foam plate containing nanometer aerogel comprises the following raw materials: phenolic resin, an emulsifying agent, a toughening agent, a foaming agent, nanometer aerogel, a fire retardant and a curing agent according to a weight ratio of 100: (1-10): (1-10): (7-12): (2-15): (2-15): (15-25). The toughening agent is prepared by mixing polyvinyl pyrrolidone with ethylene glycol according to a weight ratio being 1: (1-5). A production method of the phenolic foam plate containing nanometer aerogel comprises the following steps: evenly mixing and stirring the raw materials and pouring the raw materials into a preheated die to foam and cure. By taking the nanometer aerogel as filler and adding the special toughening agent, the strength of the plate can be improved; a compression strength is increased from about 0.14 to be greater than 0.18; a pulling strength is increased from about 0.07 to be greater than 0.12; a heat conductivity coefficient of the plate is reduced to be less than 0.022; an oxygen index is increased from about 45 to be 55.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

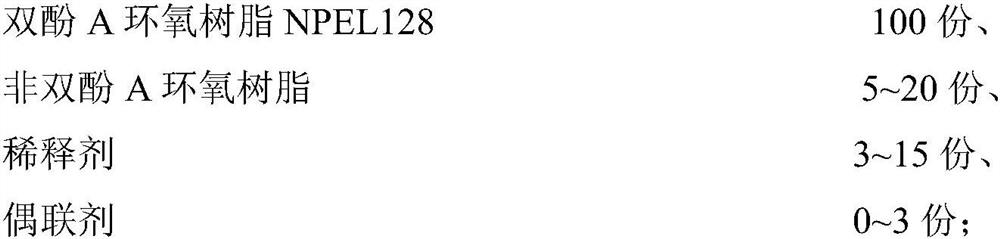

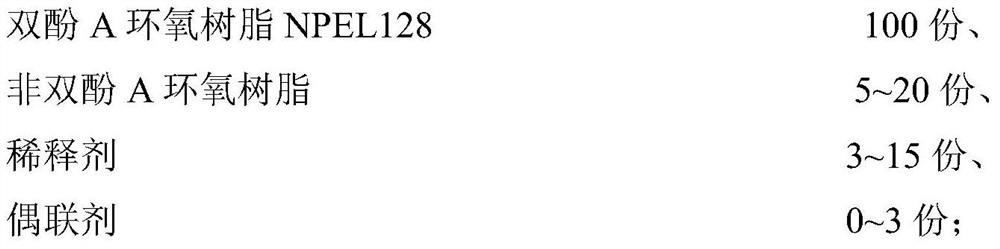

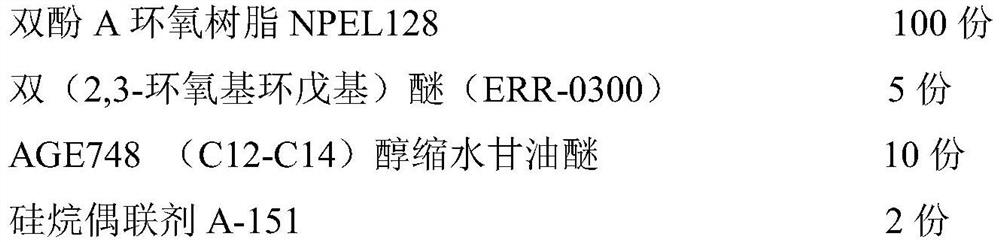

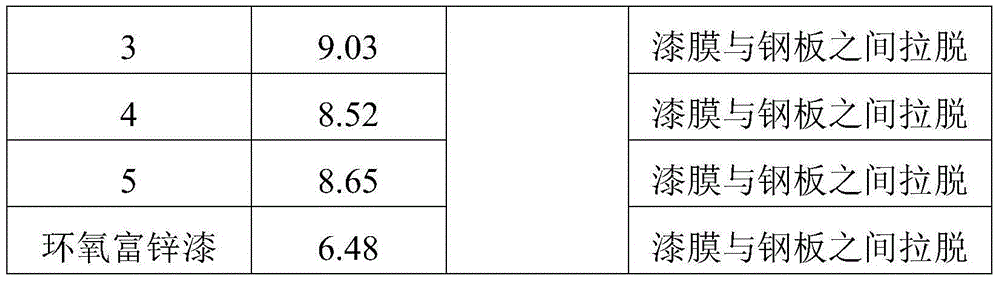

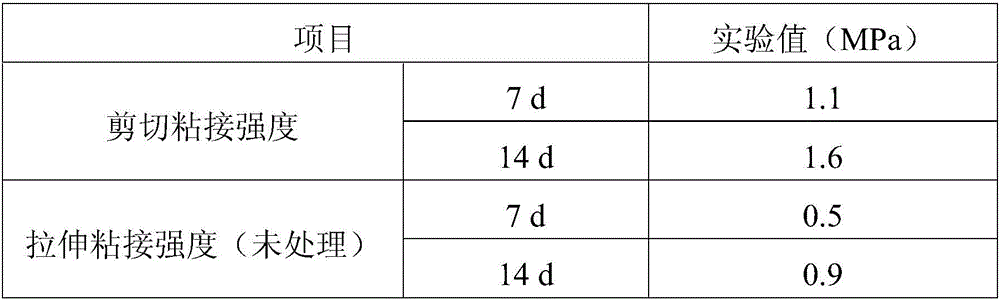

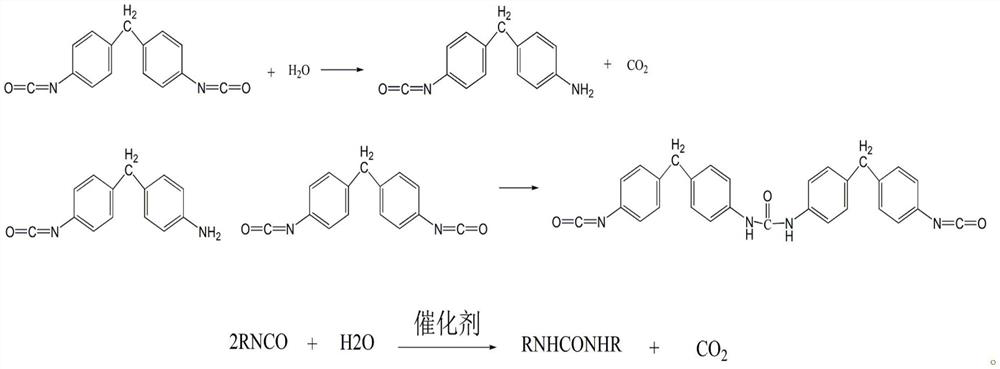

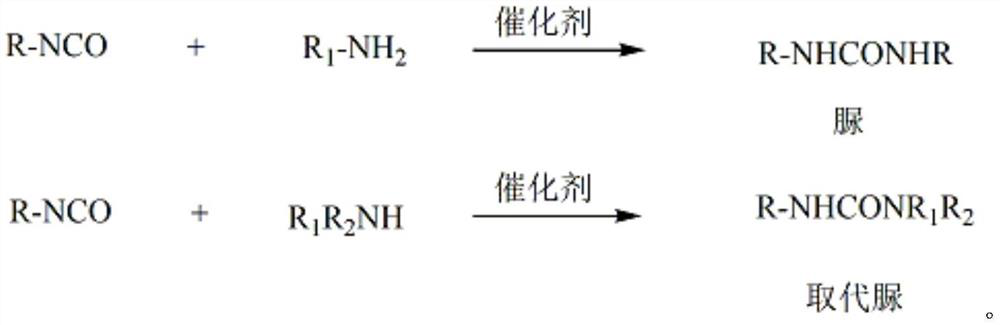

Second-order hot-mixed epoxy tack coat oil and application thereof

PendingCN111826110AImprove pull strengthHigh bonding strengthEpoxy resin adhesivesPolymer scienceFirming agent

The invention discloses second-order hot-mixed epoxy tack coat oil and application thereof. The oil comprises a resin component A and a curing component B, and the resin component A comprises bisphenol A epoxy resin NPEL128, non-bisphenol A epoxy resin, a diluent and a coupling agent. The curing agent component B comprises a high-temperature curing agent and a normal-temperature curing agent, wherein the ratio of the epoxy resin component A to the curing agent component B is (2: 3)-(3: 2). The second-order hot-mixed epoxy adhesive layer oil is high in bonding strength, excellent in flexibilityand good in waterproof performance, and can be widely applied to large-span steel bridge deck pavement as the second-order hot-mixed epoxy tack coat oil.

Owner:江苏创为交通科技发展有限公司

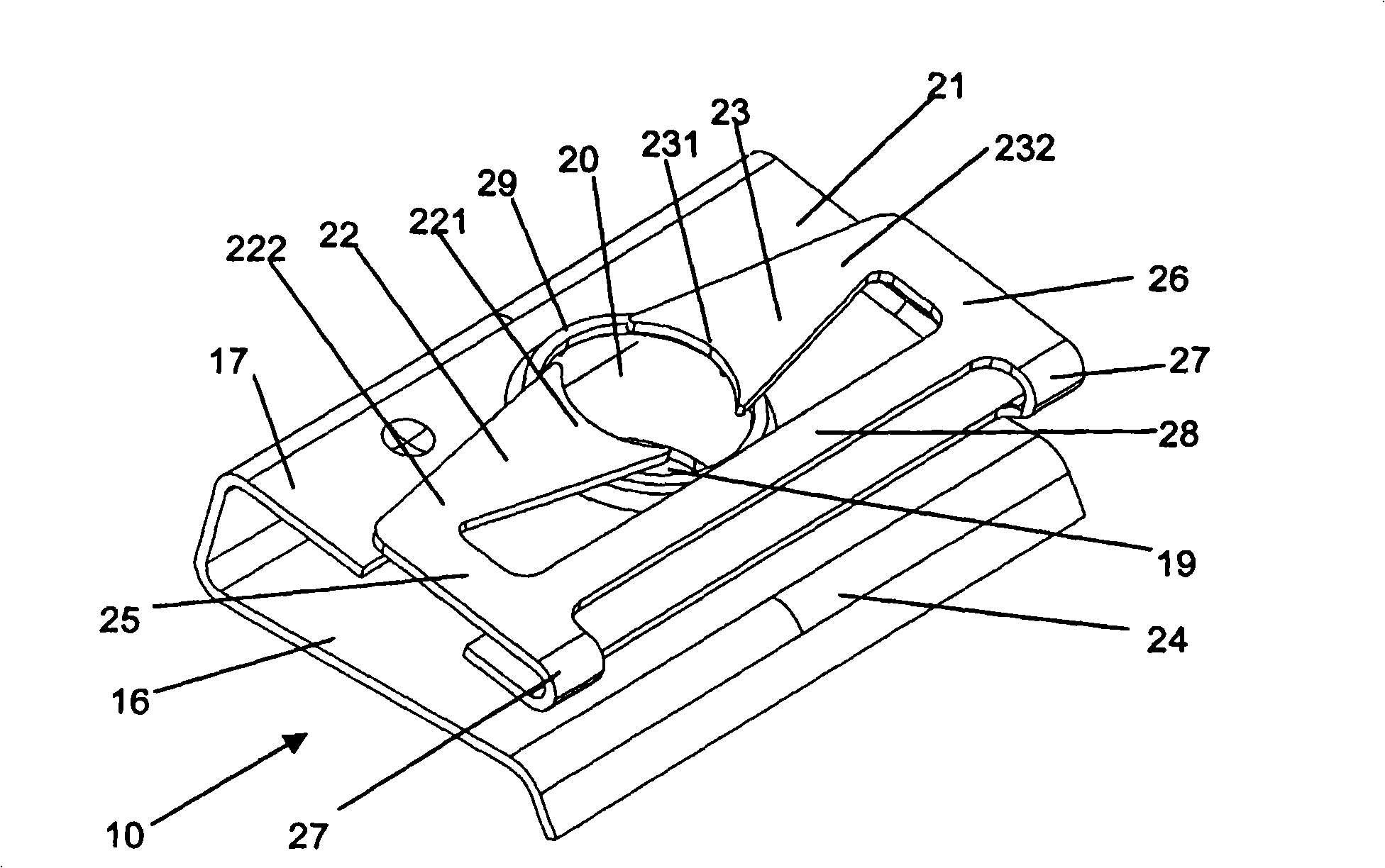

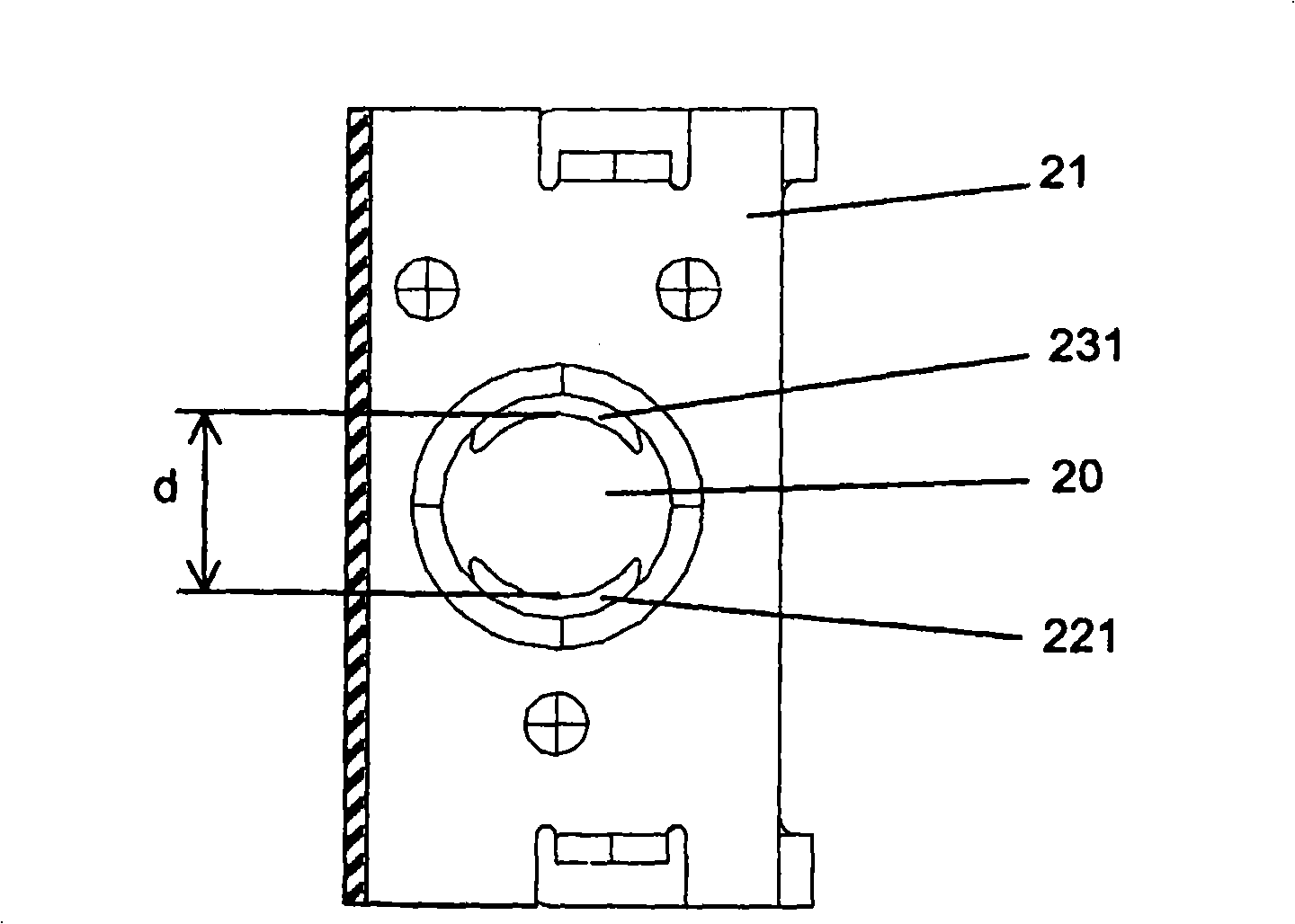

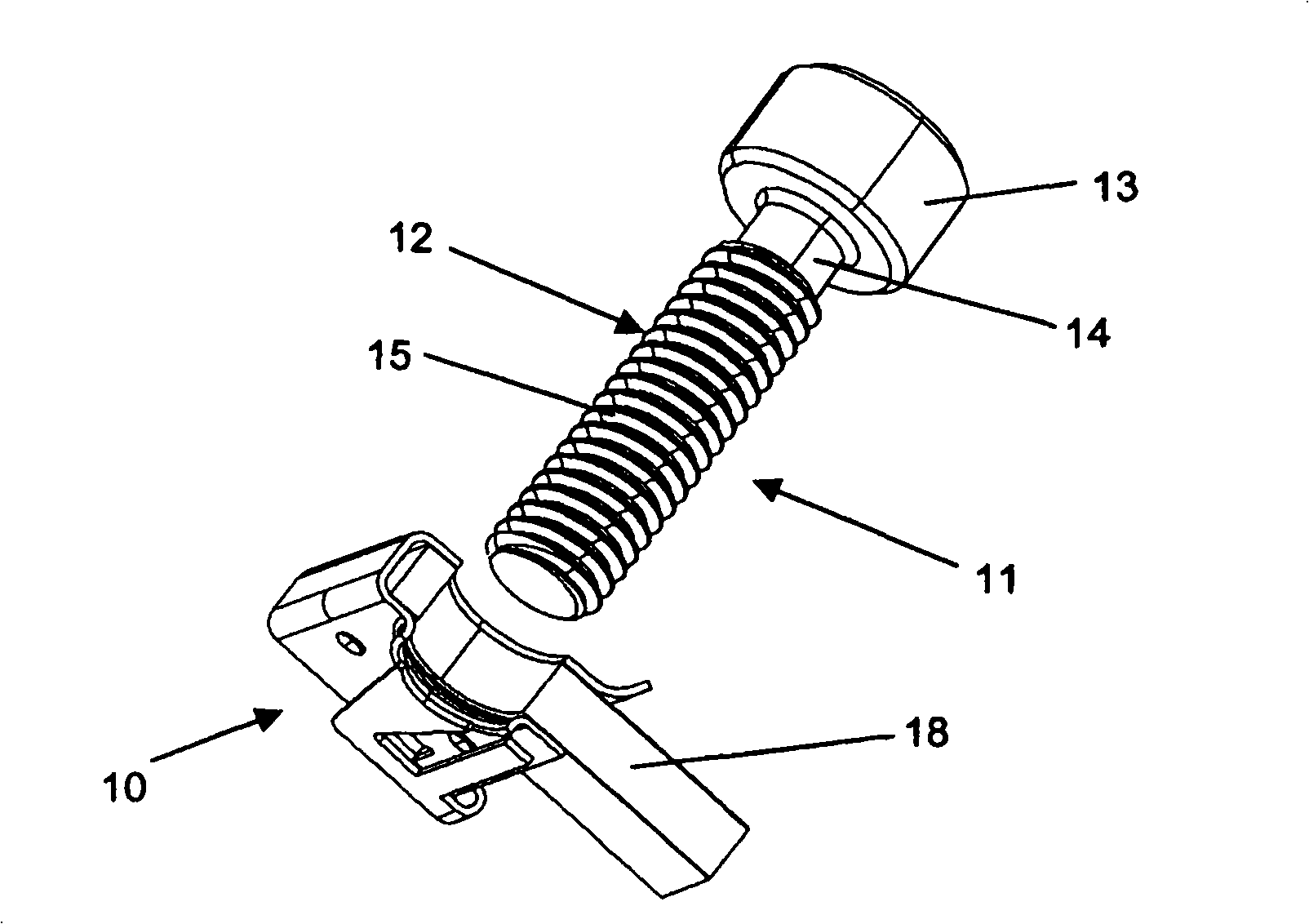

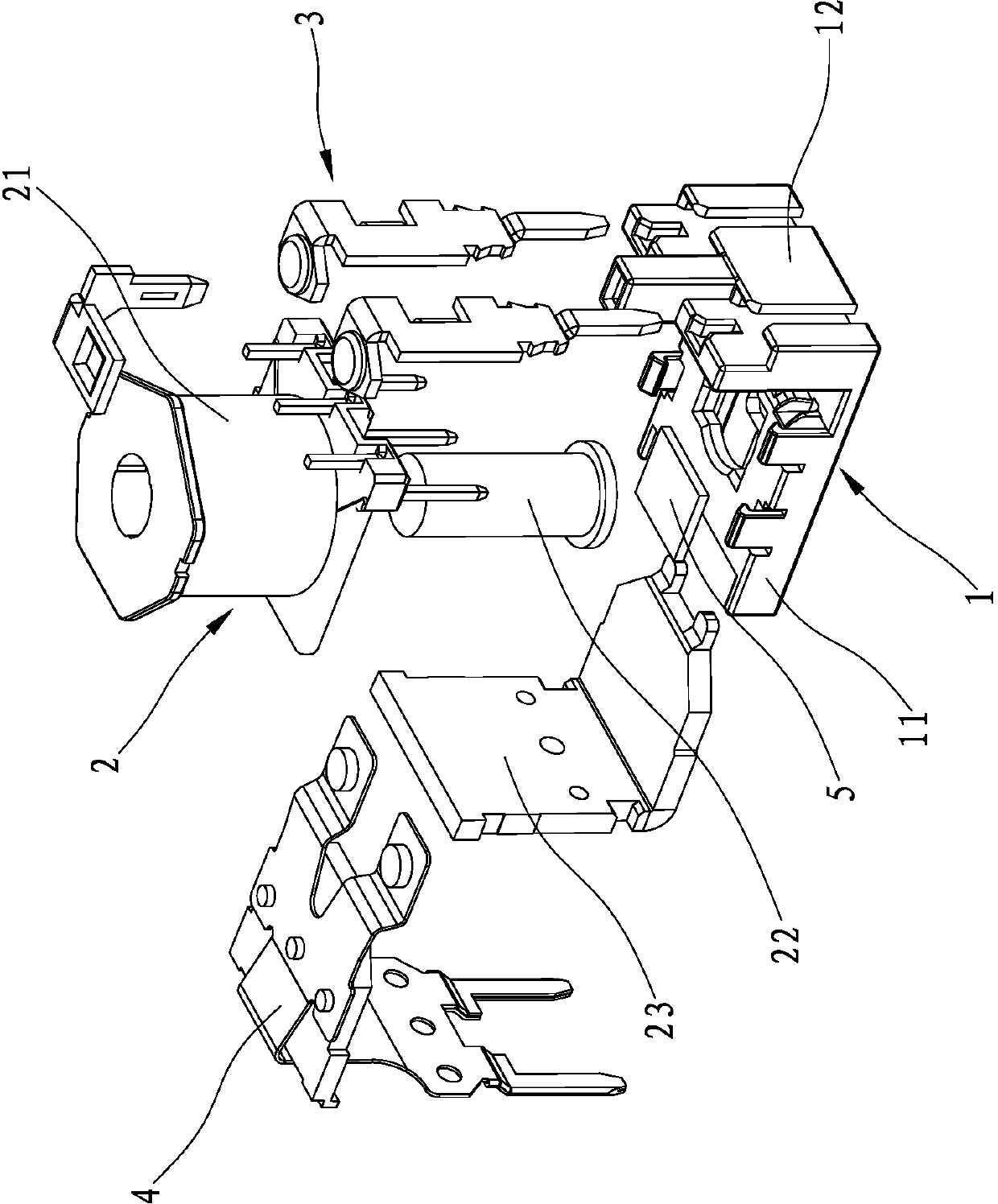

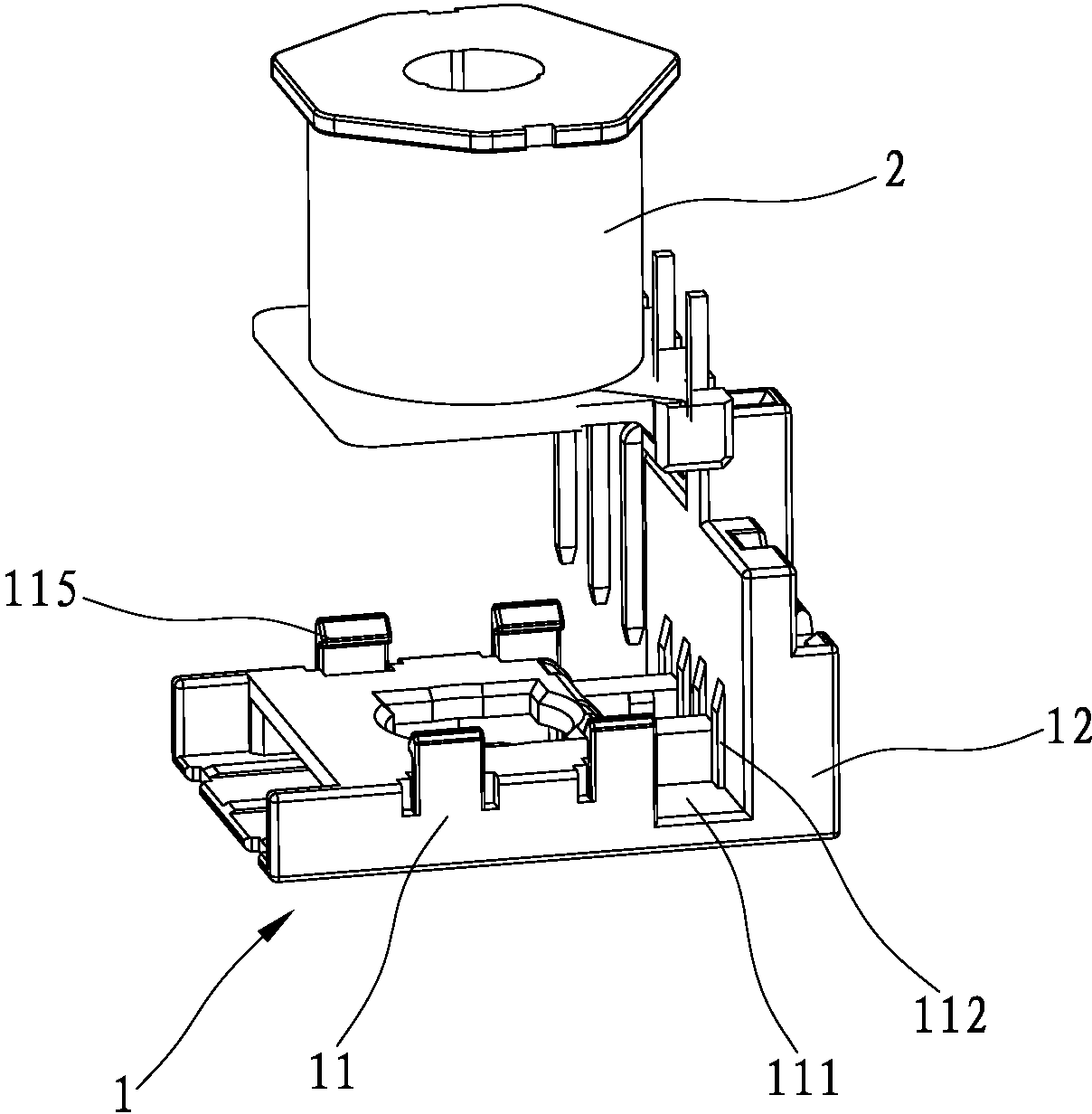

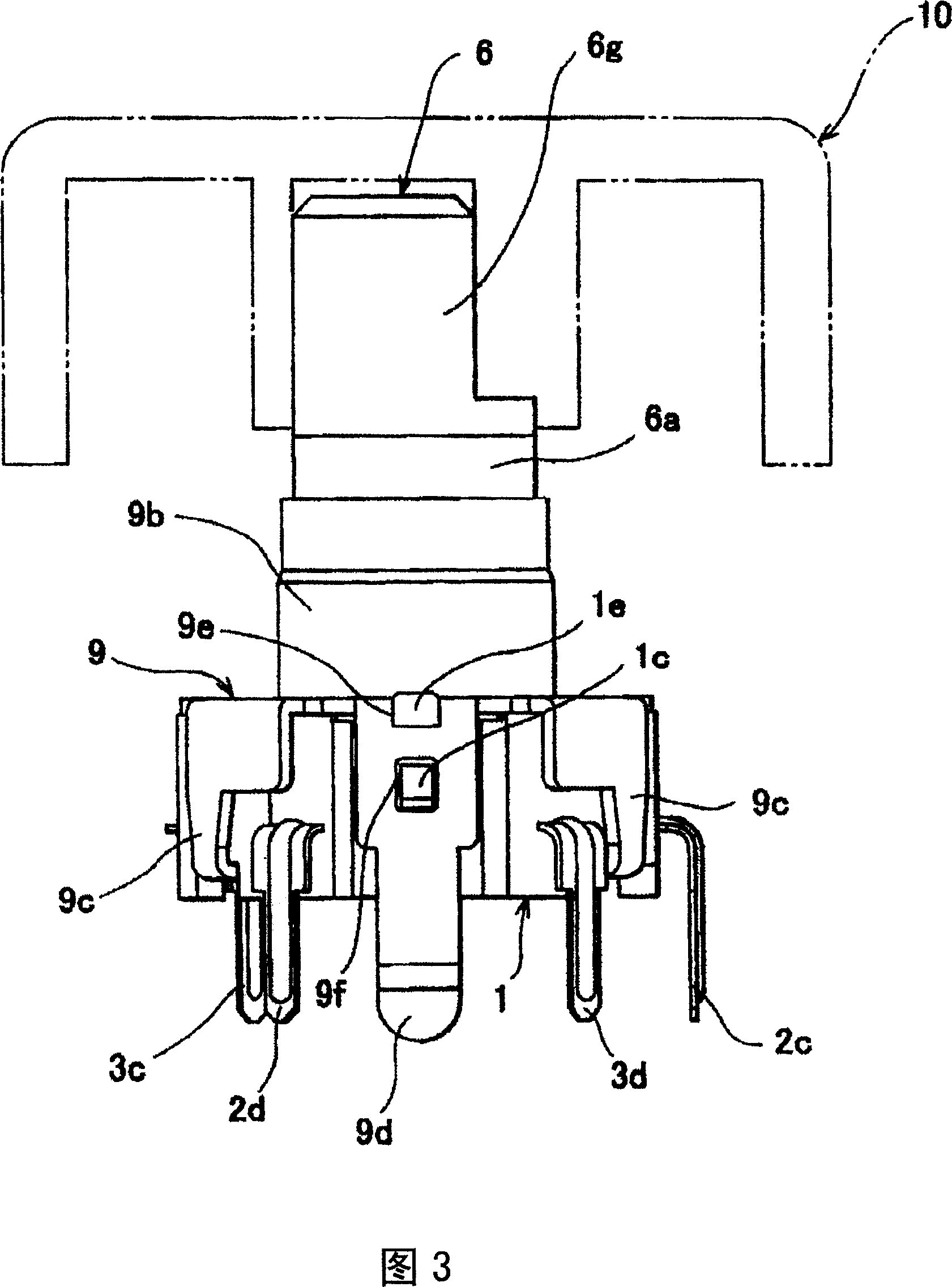

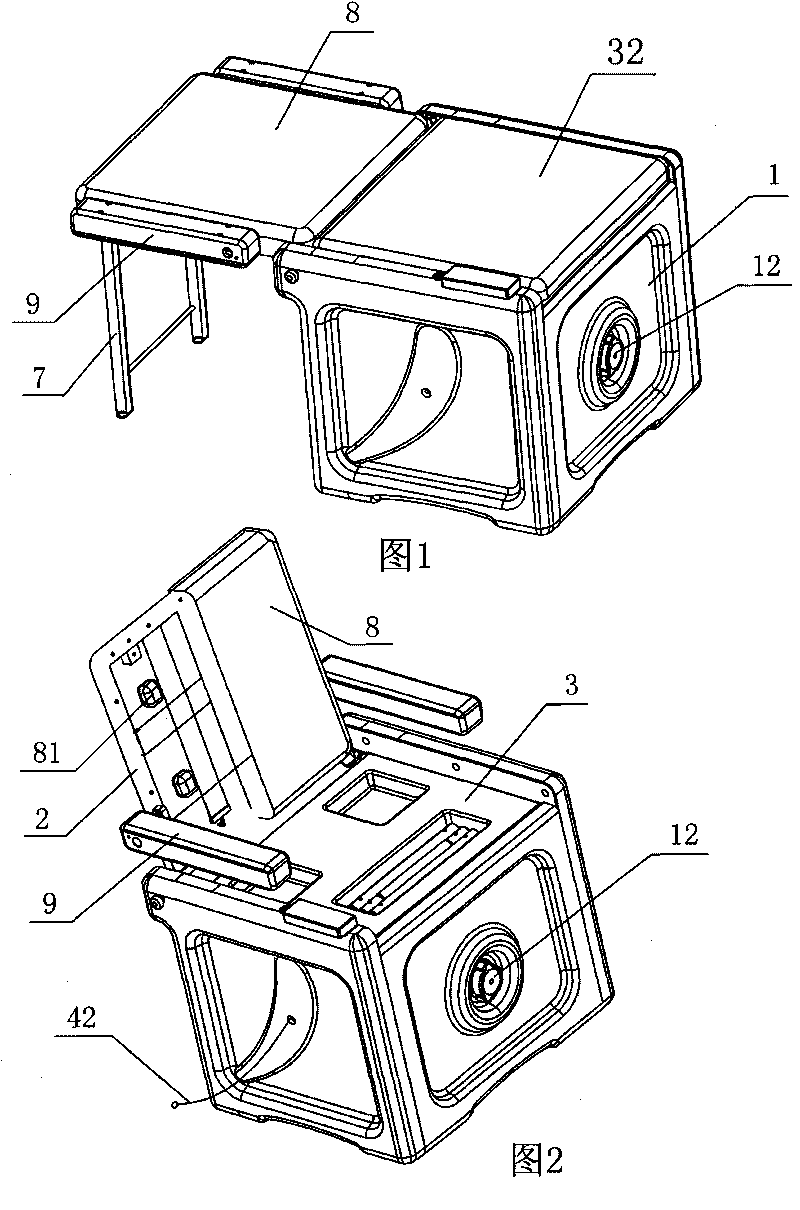

Clamping device

InactiveCN101405511AImprove pull strengthGuaranteed mechanical strengthNutsHaberdasheryEngineeringMechanical engineering

The present invention provides a clamping device which comprises: a screw member with a bearing head and a shank equipped with a threaded portion, a retainer (10) comprising a base (21) equipped with a through-hole (20) for the passage of the shank of the screw member, and retaining means supported by the base (21) to lie vertically in line with the through-hole (20), and designed to collaborate with the threaded portion in order axially to immobilize the screw member relative to the retainer (10). The retaining means consist of flexible and elastic tabs (22, 23) arranged such that they converge. Their free ends (221, 231) between them determine a gap (d) smaller than the nominal diameter of the threaded portion (15) so that they automatically engage with the threads of the threaded portion (15) when the shank (12) is inserted axially into the through-hole (20). A burr (29) is arranged at the periphery of the through-hole (20) towards the flexible tabs (22, 23) to form an end stop for the free ends (221, 231) when the shank (12) is axially withdrawn.

Owner:A RAYMOND & CO

Modified phenolic aldehyde composite insulation board and preparation method thereof

InactiveCN102704586AEnsure safetyGuaranteed economyAntifouling/underwater paintsLaminationQuartzPhenolic aldehyde

The invention relates to a modified phenolic aldehyde composite insulation board and a preparation method thereof. The modified phenolic aldehyde composite insulation board comprises a modified phenolic aldehyde insulation board, adhesion agent layers, and quartz sand layers; and the adhesion agent layers are arranged on upper and lower surfaces of the modified phenolic aldehyde insulation board respectively and are provided with the quartz sand layers. The adhesion agent layers are coated on the double surfaces of the modified phenolic aldehyde insulation board, the thickness of the adhesion agent layers is 1 to 2mm, quartz sand is compounded on the two surfaces by a compression roller through two-surface laminating, the thickness of each quartz sand layer is 2 to 3mm, and then the modified phenolic aldehyde insulation board is fed into drying equipment by an automatic rolling platform and is dried and cured. The insulation board is convenient to construct at site, short in construction period, low in cost and high in quality; and the safety and the economy of the modified phenolic aldehyde composite insulation board are guaranteed.

Owner:WINCELL INSULATION CO LTD

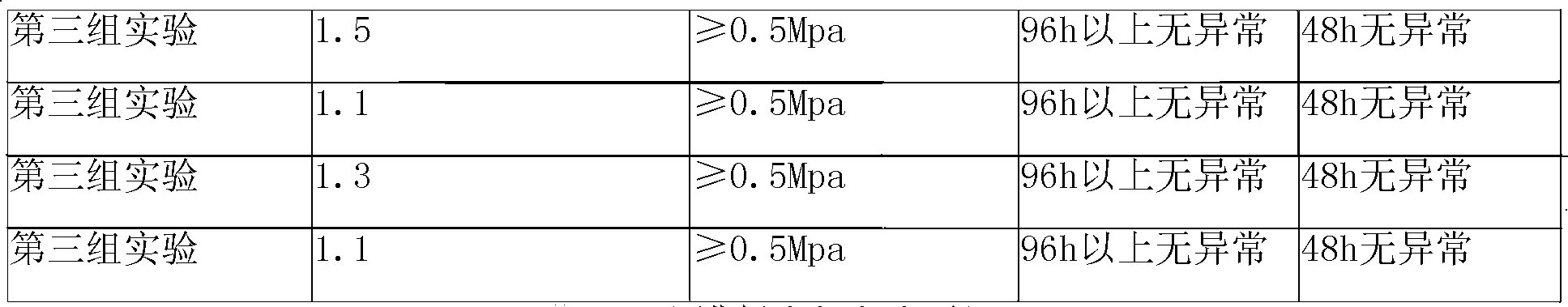

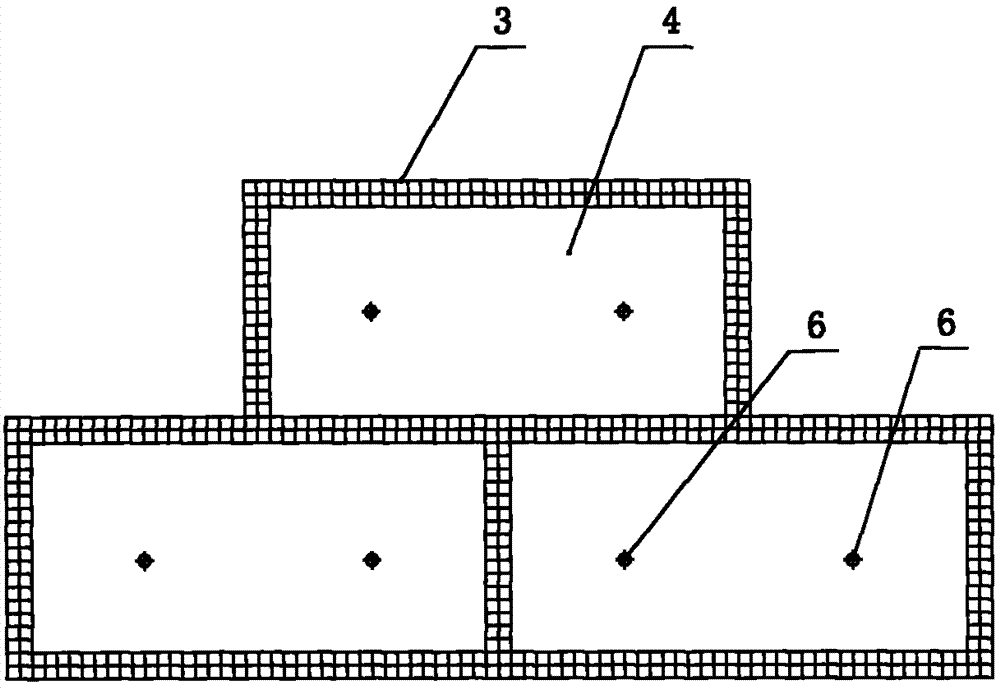

Prefabricated cast-in-place combination type superposed shear wall

The invention relates to the field of building materials. In order to be adapted to housing industrialization, the invention discloses a prefabricated cast-in-place combination type superposed shear wall which comprises an outer wall layer, a heat insulating material layer and an inner wall layer, wherein the heat insulating material layer is located between the outer wall layer and the inner wall layer, and the outer wall layer and the inner wall layer are connected through tie bars or connectors; the inner wall layer comprises a prefabricated part and a cast-in-place part, the prefabricated part of the inner wall layer is basically located at the middle portion of the outer wall layer, the area of the prefabricated part of the inner wall layer is smaller than or equal to that of the outer wall layer, and the prefabricated part of the inner wall layer reserves lateral and longitudinal reinforced steel bars; and the outer wall layer, the heat insulating material layer and the prefabricated part of the inner wall layer are made into a whole in advance; and the prefabricated part reserves the lateral and longitudinal reinforced steel bars to be anchored into the cast-in-place part of the inner wall layer. The invention has the advantages of improved building quality, energy saving, environmental protection, short working period, industrial production and increased construction safety.

Owner:沈阳万科企业有限公司

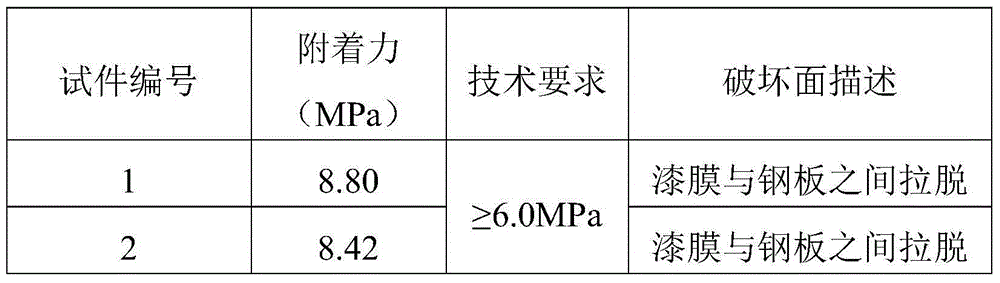

Bridge deck pavement method for orthotropic steel bridge

ActiveCN104652270AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxyFull life cycle

The invention discloses a bridge deck pavement method for an orthotropic steel bridge. The pavement method comprises the following steps: (1) performing sand-blasting and de-rusting treatment on a steel bridge panel, and coating a mica-containing epoxy anti-corrosion layer; (2) coating a solvent-free epoxy resin water-proof layer; (3) spreading a hot melt particle bonding layer which is partially sunken into the solvent-free epoxy resin water-proof layer, wherein the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; (4) paving a fine-particle asphalt mixture to form a high-elasticity modified asphalt pavement lower layer; (5) spreading a modified emulsified asphalt bonding layer; (6) paving a fine-particle or medium-particle asphalt mixture to form a high-elasticity modified asphalt pavement upper layer. By adopting the pavement method, the construction difficulty is lowered greatly, later maintenance is easy, the universality is high, a pavement lower structure is durable and long in service life, only the surface needs to be maintained in daily use, overall repeated maintenance is avoided, and the investment in a full life cycle is lowered.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

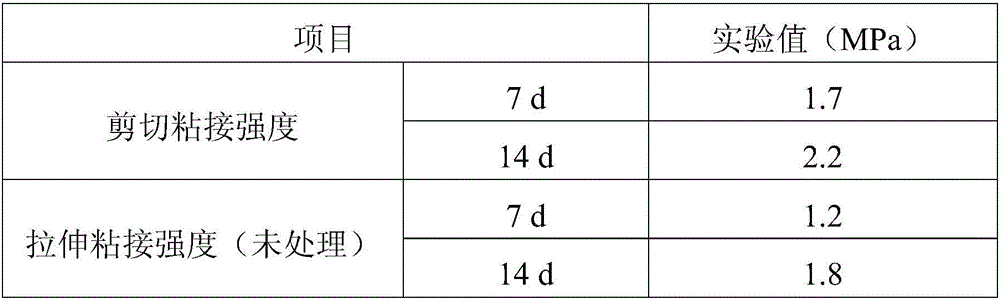

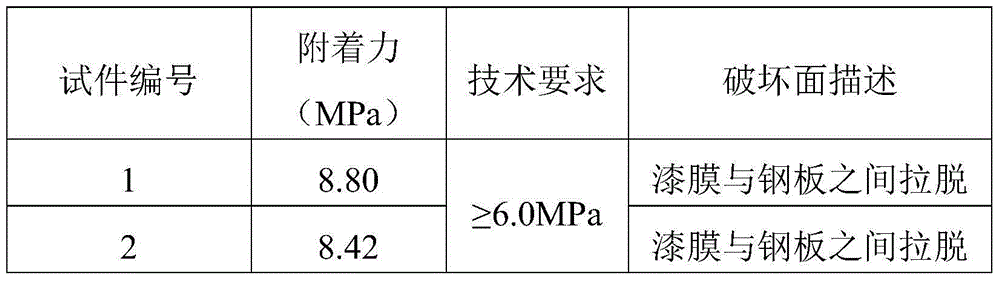

Composite polymer emulsion high-strength interface agent for vitrified brick and preparation thereof

The invention belongs to the technical field of interface agent, and discloses a composite polymer emulsion high-strength interface agent for a vitrified brick and a preparation method thereof. The interface agent comprises the following components by the mass fraction: 45-65% of a small-particle-size styrene-acrylic emulsion, 15-25% of a pure acrylic emulsion, 5-10% of a small-particle-size styrene-butadiene emulsion, 0.2-0.5% of a synergistic agent, 0.1-0.3% of a dispersant, 0.3-1.0% of a wetting agent, and the balance water. With adopting of the small-particle-size styrene-acrylic emulsion, with cooperation of the smaller-particle-size styrene-butadiene emulsion as a penetrating agent, and with collocation use of the water-based synergistic agent, the water solubility of the two kinds of emulsions are effectively improved, the compatibility of the emulsions is improved, the adhesion force and stability of an interface material are increased, the effect of penetrating into the back of a brick with low water absorption rate can be realized, the pulling strength of the material is also increased, the comprehensive effect of an acrylic emulsion is fully played, two-way permeability is achieved, and the adhesion force of a cement-based material is fully played.

Owner:广东亿固壁安粘贴技术有限公司

Core material and inorganic foaming outer layer compounded heat-insulating section

InactiveCN102359194AImprove pull strengthHigh impact strengthHeat proofingCeramicwareHigh intensityExternal cladding

The invention discloses a core material and inorganic foaming outer layer compounded heat-insulating section. At present, a heat-insulation material outside an outer wall of a building in the building industry is expected to meet the requirements of heat insulation, flame retardance, enough strength and low volume weight. However, no perfect solution for the problems is provided in the prior art. According to the core material and inorganic foaming outer layer compounded heat-insulating section disclosed by the invention, an organic material with high strength is produced into an outer compound layer of a core material in a foaming form; a plurality of tiny airtight foam holes are formed in an internal structure of the organic material by foaming the organic material; and the core material and inorganic foaming outer layer compounded heat-insulating section has the characteristics of great thickness, high strength and light weight as well as strong capability of separating an inflammable core material from outside high temperature. According to the core material and inorganic foaming outer layer compounded heat-insulating section, the heat-insulation material outside the outer wall of the building has heat insulating property, stronger flame retardance, higher strength and low volume weight and can be conveniently and firmly fixed on the outer surface of the outer wall of the building.

Owner:巢启 +1

Polyurethane putty for concrete surface treatment

InactiveCN102391706AEasy constructionEasy to embedCovering/liningsFilling pastesPolymer sciencePolymer chemistry

The invention provides bi-component polyurethane putty special for concrete surface treatment, and belongs to the field of chemical materials. A polyurethane primer special for the concrete surface treatment is characterized in that: a bi-component polyurethane system, namely an isocyanate component A and a resin component B, is used. The invention has the advantages that: the bi-component low surface tension polyurethane putty is suitable for filling and repairing planar defects (such as pin holes, air holes, pits and the like) of the concrete surface.

Owner:JIANGSU STEADY NEW ENERGY TECH DEV

Method for developing low-density high-strength phenolic foam

The invention relates to a method for developing low-density high-strength phenolic foam. The method comprises the following steps of using molybdenum disulfide to modify the phenolic resin, foaming, curing and forming, so as to obtain the low-density high-strength phenolic foam, thereby overcoming the disadvantages of brittleness, easiness in slag falling, low strength and the like of the phenolic resin. The method has the advantages that a silane coupling agent is grafted with the molybdenum disulfide, so as to improve the dispersivity of the molybdenum disulfide in the phenolic resin and the compatibility with the resin; after treating by the silane coupling agent, the molybdenum disulfide can be grafted with amino groups, and the phenolic resin contains hydroxymethyl groups, so that under the reaction action of the amino groups and hydroxymethyl groups, the effect of increasing viscosity is realized, and the mechanical, water-resistant and anti-aging properties are improved; by adding the molybdenum disulfide, the heat conduction coefficient of the phenolic foam is reduced, the mechanical property of the phenolic foam is improved, and the low-density high-strength phenolic foam with water-resistant, heat-insulation and toughening properties can be obtained for building projects.

Owner:UNIV OF JINAN

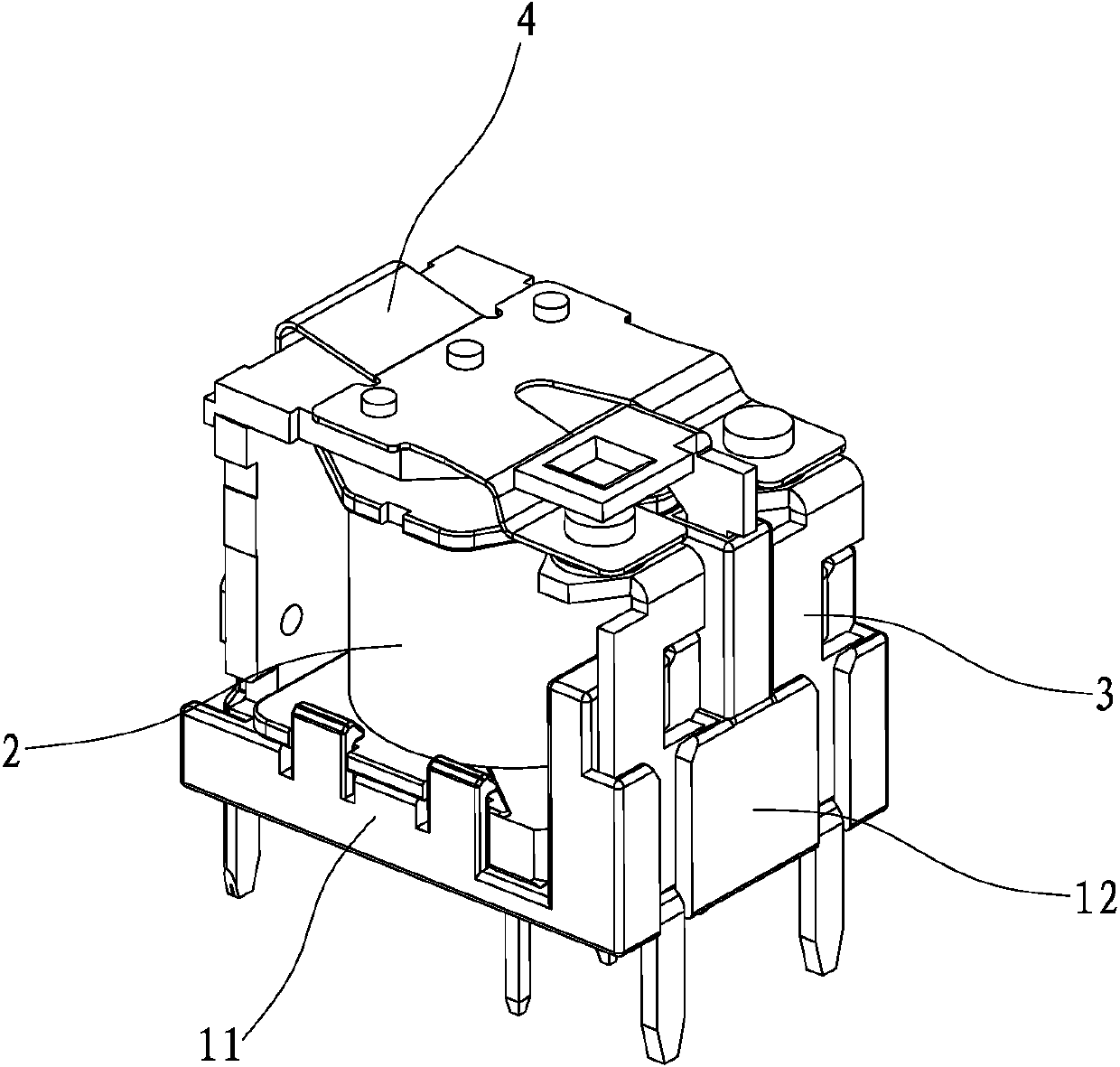

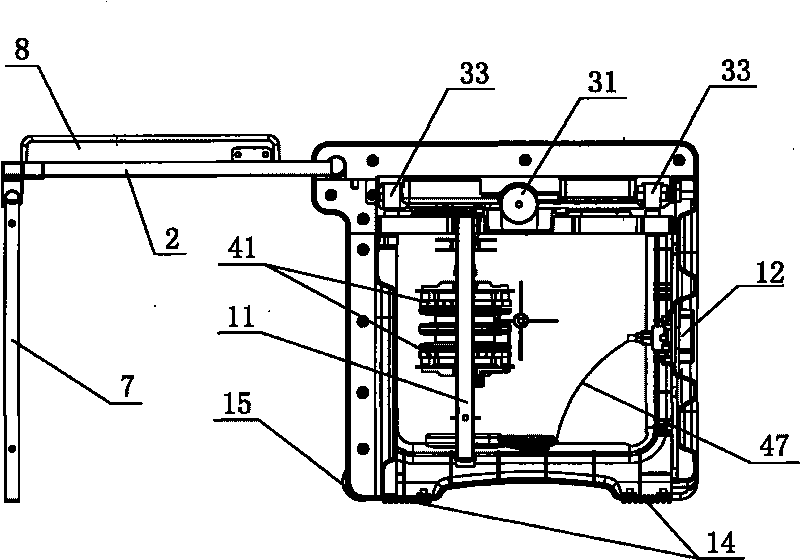

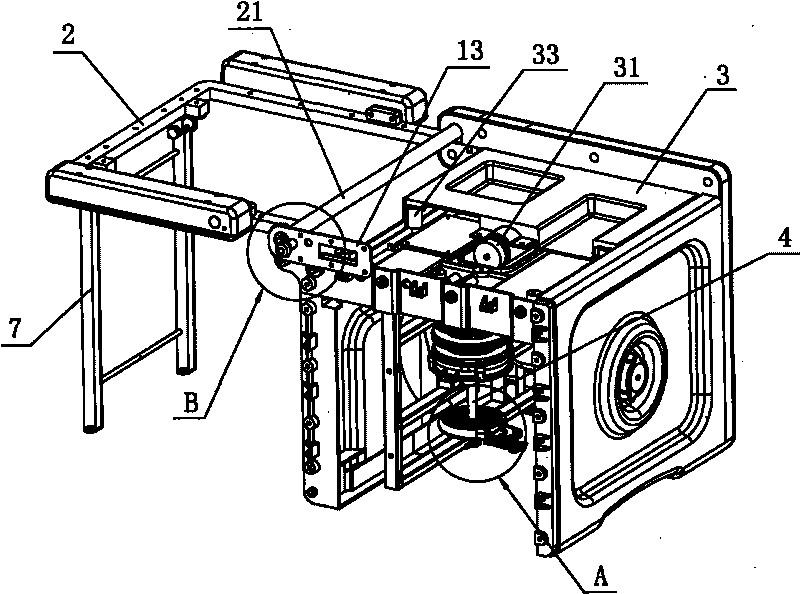

Printed board type electromagnetic relay with L-shaped base

ActiveCN104217899ASimple structureImprove pull strengthElectromagnetic relay detailsEngineeringBoard type

The invention discloses a printed board type electromagnetic relay with an L-shaped base, which comprises a magnetic path part, the L-shaped base, a movable spring armature component and a fixed spring contact component. The L-shaped base is composed of a bottom plate and a side plate which is formed integrally through radial extension of the bottom plate; the magnetic path part is mounted on the bottom plate of the L-shaped base; the fixed spring contact component is arranged on the side plate of the L-shaped base and is located at one side of the magnetic path part; the movable spring armature component is arranged on the bottom plate of the L-shaped base and is located at the other side of the magnetic path part; the magnetic path part, the movable spring armature component and the fixed spring contact component are assembled by regarding the L-shaped base as a reference for installation. As the L-shaped base serves as the unique reference for installation, the structure is simplified, the assembling error is reduced and the assembling precision is improved.

Owner:厦门宏发交通电器有限公司

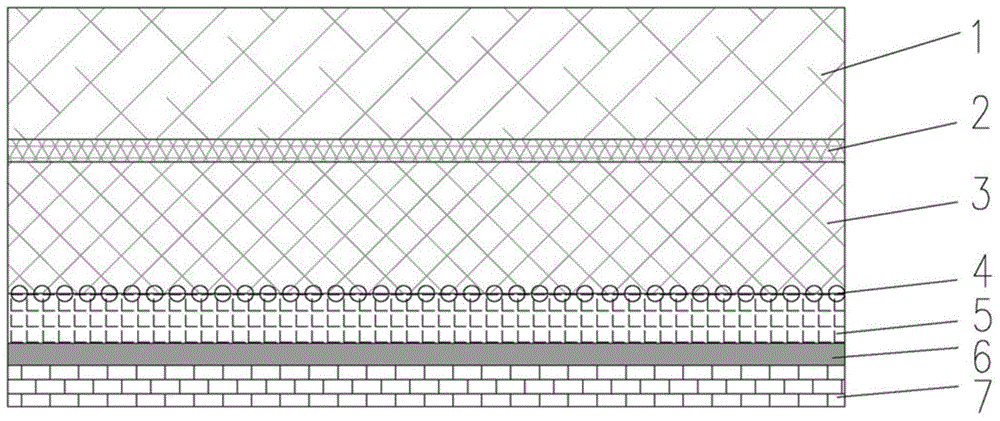

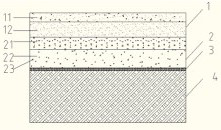

Bridge deck pavement structure for orthotropic steel bridge

ActiveCN104652269AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxySolvent free

The invention discloses a bridge deck pavement structure for an orthotropic steel bridge. The pavement structure comprises a mica-containing epoxy anti-corrosion layer, a solvent-free epoxy resin water-proof layer, a hot melt particle bonding layer, a high-elasticity modified asphalt pavement lower layer, a modified emulsified asphalt bonding layer and a high-elasticity modified asphalt pavement upper layer from bottom to top, wherein the total pavement thickness is 6-8 centimeters; the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; the high-elasticity modified asphalt is modified asphalt of which the elastic recovery is over 95 percent at 25 DEG C; the pavement lower layer is formed by paving a fine-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with a mineral mixture; the pavement upper layer is formed by paving a fine-particle or medium-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with the mineral mixture. By adopting the pavement structure, the water-proof layer and the asphalt pavement layer are combined integrally through the hot melt particle bonding layer, so that the shearing strength and durability of the pavement structure are ensured.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

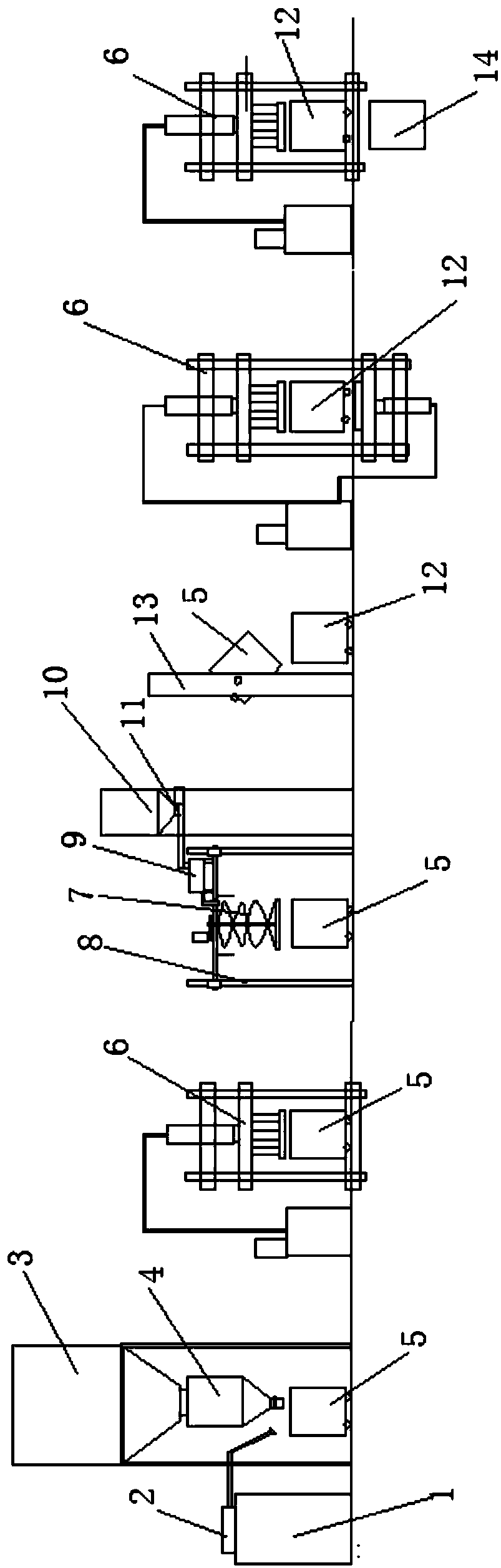

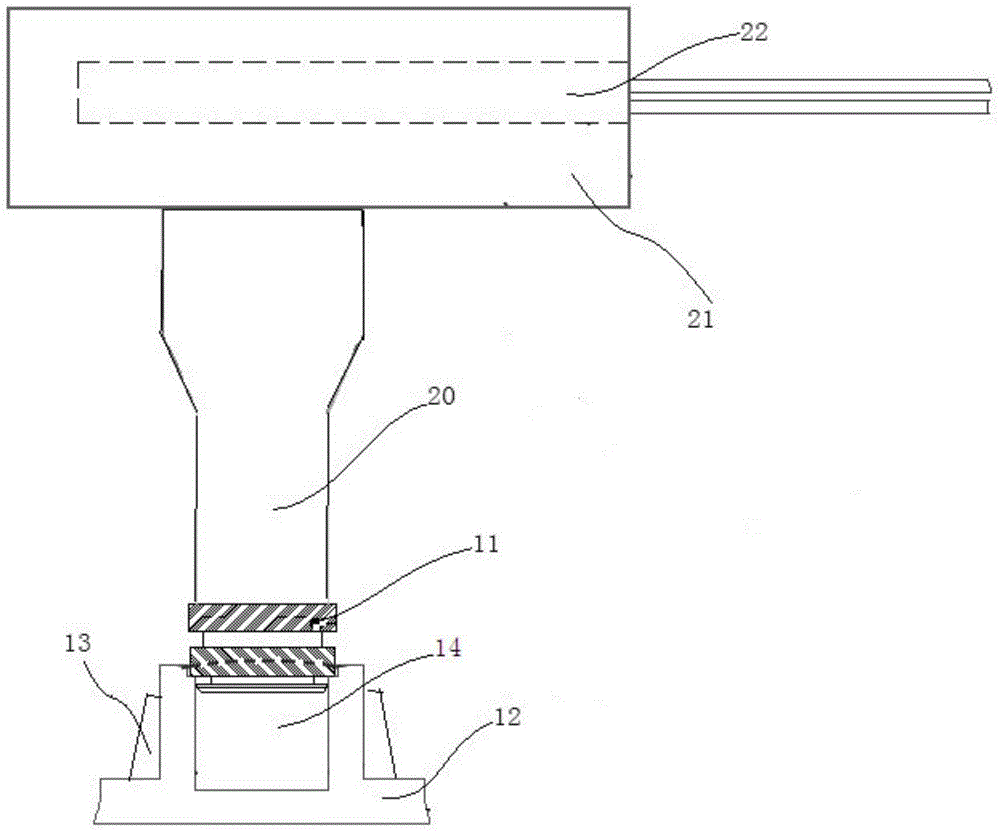

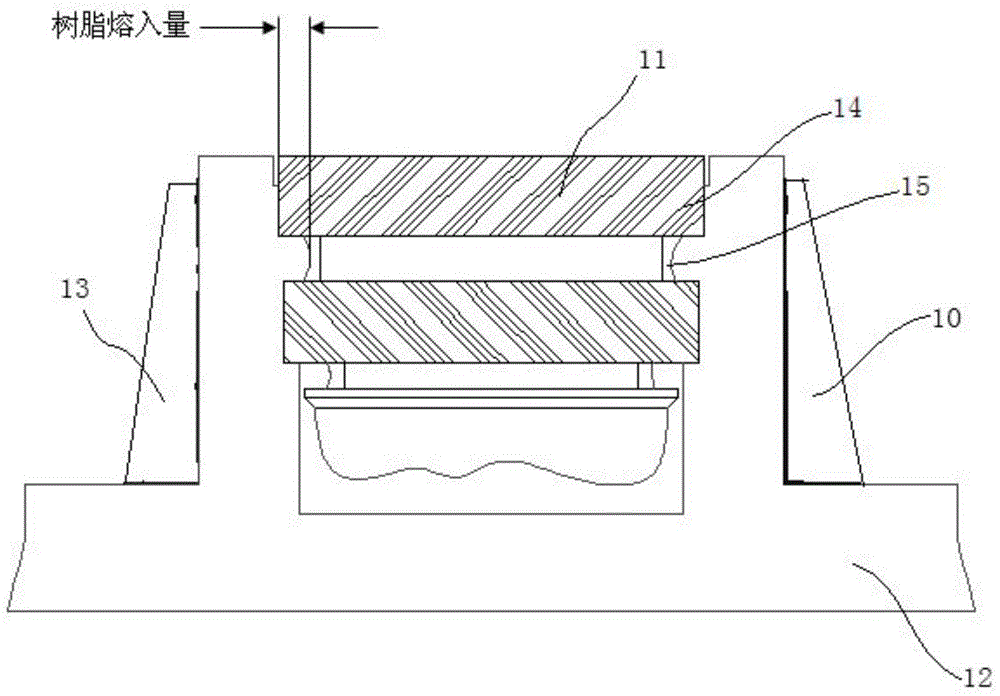

Method for preparing polyphenyl particle heat-insulation boards

ActiveCN109249518AReduce porosityImprove pull strengthDischarging arrangementFeeding arrangmentsPorositySurface layer

The invention discloses a method for preparing polyphenyl particle heat-insulation boards. The method is characterized in that raw materials for the polyphenyl particle heat-insulation boards include,by cubic meter per unit, polyphenyl particles, cement, siliceous mineral powder, gelatin powder, organic emulsion, water repellents and water; the method includes uniformly stirring the organic emulsion, the water repellents and the water to obtain mixed liquid during production, uniformly mixing the mixed liquid and the polyphenyl particles with one another in compressing barrels according to certain proportions, repeatedly compressing the mixed liquid and the polyphenyl particles in the compressing barrels by hydraulic machines, then adsorbing the mixed liquid in the surfaces of the polyphenyl particles and internal shallow surface layers of the polyphenyl particles, wrapping the surfaces of the polyphenyl particles and the internal shallow surface layers of the polyphenyl particles with the mixed liquid, scattering the compressed polyphenyl particles by stirring machines, then inputting powder materials into the stirring machines, stirring the compressed polyphenyl particles and the powder materials to obtain polyphenyl particle coated dry mixtures, jacking the polyphenyl particle coated dry mixtures in compressing tanks by the hydraulic machines in the up-down directions, carrying out pressure maintaining curing, then releasing the polyphenyl particle coated dry mixtures from molds by the hydraulic machines to obtain polyphenyl particle heat-insulation board bulks and thencutting the polyphenyl particle heat-insulation board bulks according to required sizes to obtain the required polyphenyl particle heat-insulation boards. The cement, the siliceous mineral powder andthe gelatin powder are uniformly mixed with one another to obtain the powder materials. The method has the advantages that the method is reasonable in design and easy to implement and includes simpletechnological steps, the polyphenyl particle heat-insulation boards prepared by the aid of the method are small in porosity, boards are low in heat conduction coefficient and water absorption per volume and high in pull strength, and engineering application of the polyphenyl particle heat-insulation boards can be guaranteed.

Owner:安徽华举建材科技股份有限公司

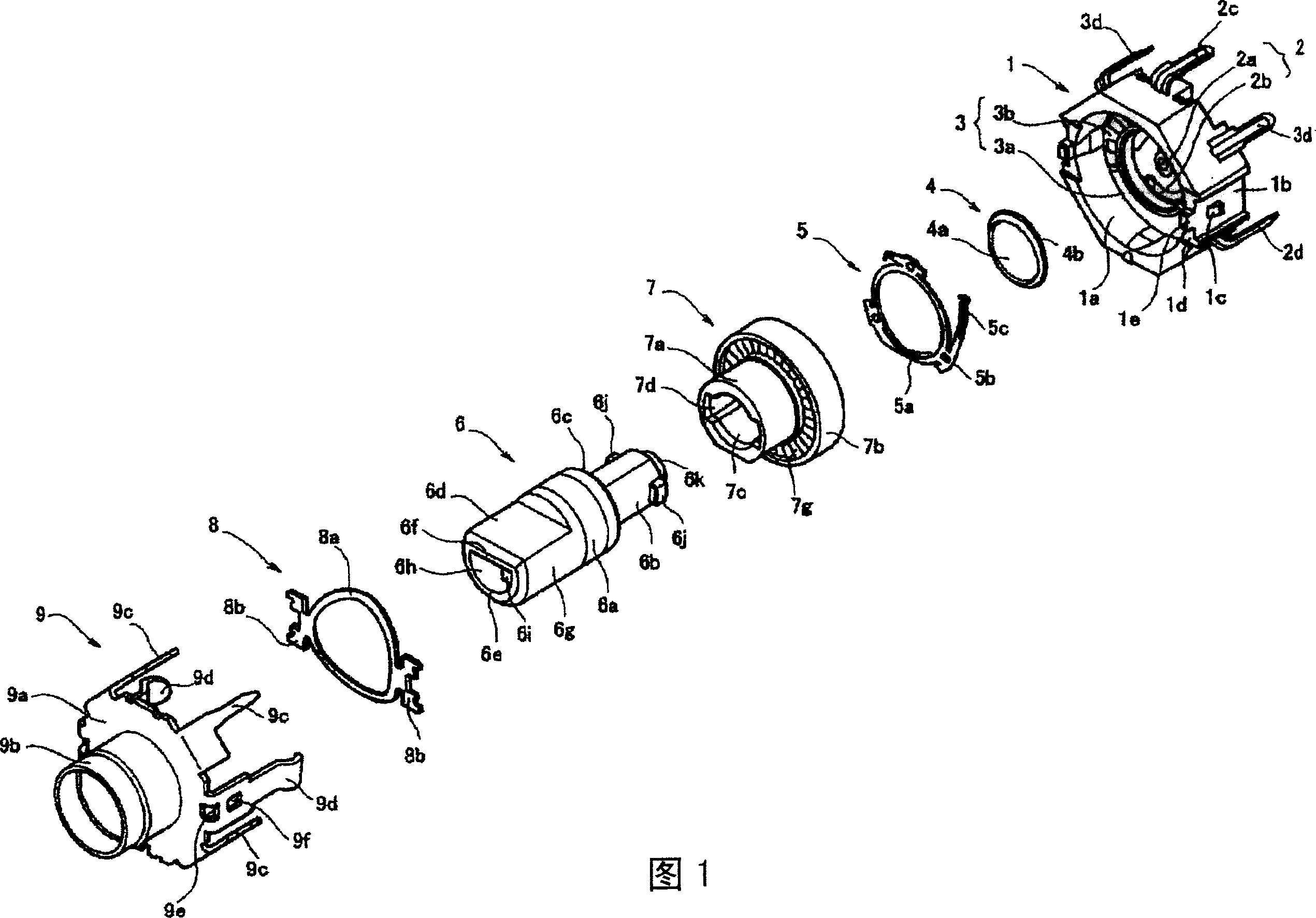

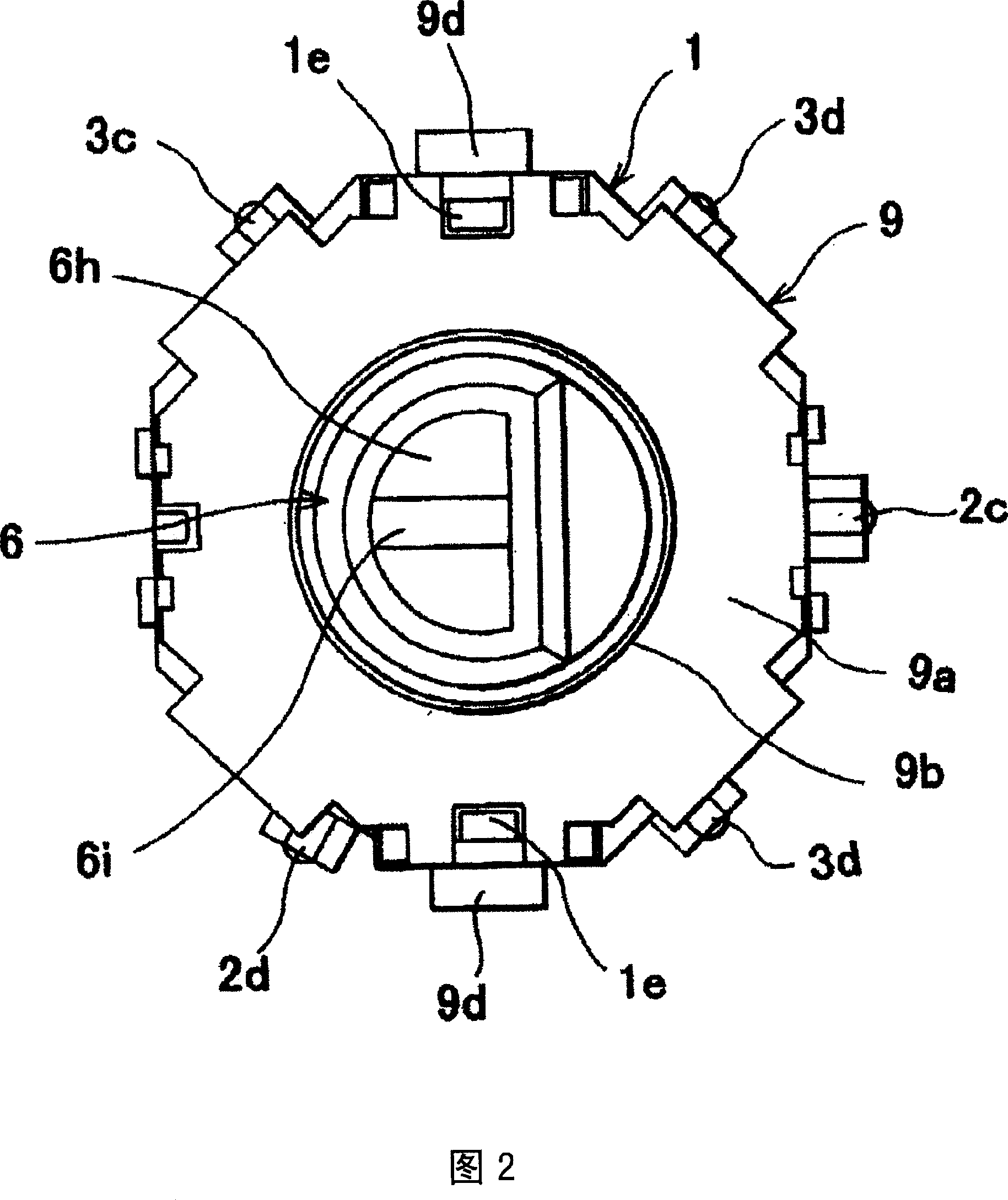

Rotary electrical component

ActiveCN101030498AImprove pull strengthPrevent pulling outElectric switchesEngineeringMechanical engineering

Owner:ALPS ALPINE CO LTD

Prefabricated cast-in-place shear wall structure

InactiveCN102877576AReduce the amount of work at heightImprove securityWallsHeat proofingEnergy analysisShear wall

The invention discloses a prefabricated cast-in-place shear wall structure, which is characterized by comprising outer page walls, heat preservation material layers and inner page walls, wherein the heat preservation material layers are arranged between the outer page walls and the inner page walls; protruded parts are arranged on the inner page walls; sunken parts are arranged on the outer page walls; exposed steel bars are retained on the protruded parts and the sunken parts; the outer page walls and the inner page walls are fixedly combined to form a whole through cement pouring; no direct contact part is formed between the outer page walls and the inner page walls; and pull bars for connecting the outer page walls and the inner page walls are arranged. The prefabricated cast-in-place shear wall structure has the following advantages: 1, the construction quality is improved; 2, energy saving and environment friendliness are achieved; 3, the working period is shortened, and industrial production is realized; and 4, the construction safety is improved.

Owner:沈阳市东陵区(浑南新区)卓科技术开发中心

Heat preservation and decoration integrated composite plate and production process therefor

The invention relates to the field of composite plates and particularly relates to a heat preservation and decoration integrated composite plate and a production process therefor. The composite plate is prepared from the following raw materials in parts by weight: 30-48 parts of calcium silicate, 2.5-4 parts of graphite, 1-5 parts of meerschaum powder, 2-6 parts of vitrified microbeads, 3-8 parts of additives, 5-9 parts of cement, 2-7 parts of zirconium dioxide powder, 1-6 parts of aluminum oxide powder and 3-7 parts of silicone rubber. According to the heat preservation and decoration integrated composite plate and the production process therefor, provided by the invention, the defect in the prior art that provided composite plates are not obvious in heat-insulating effect and poor in mechanical properties can be made up to a certain extent.

Owner:长兴贝斯德邦建材科技有限公司

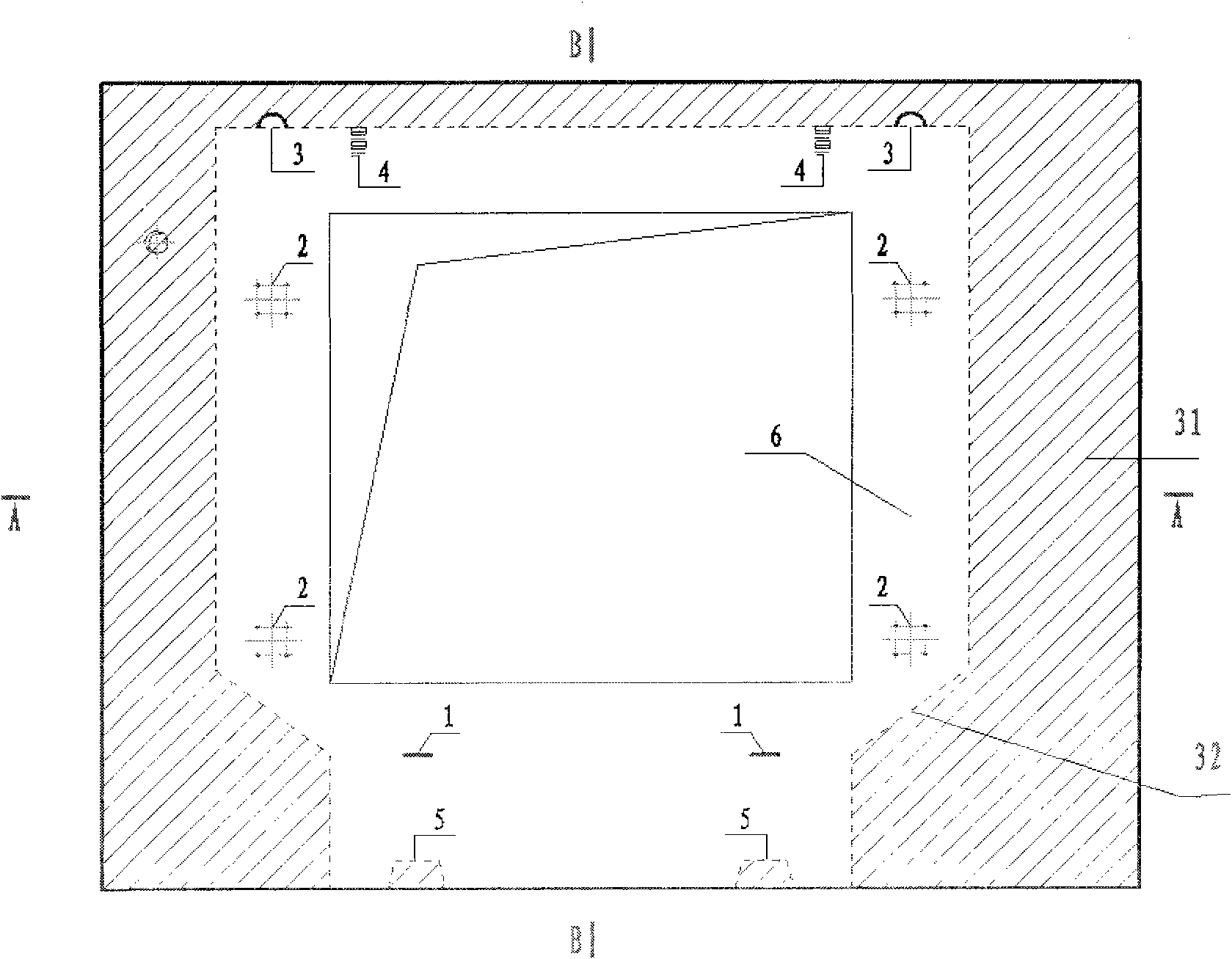

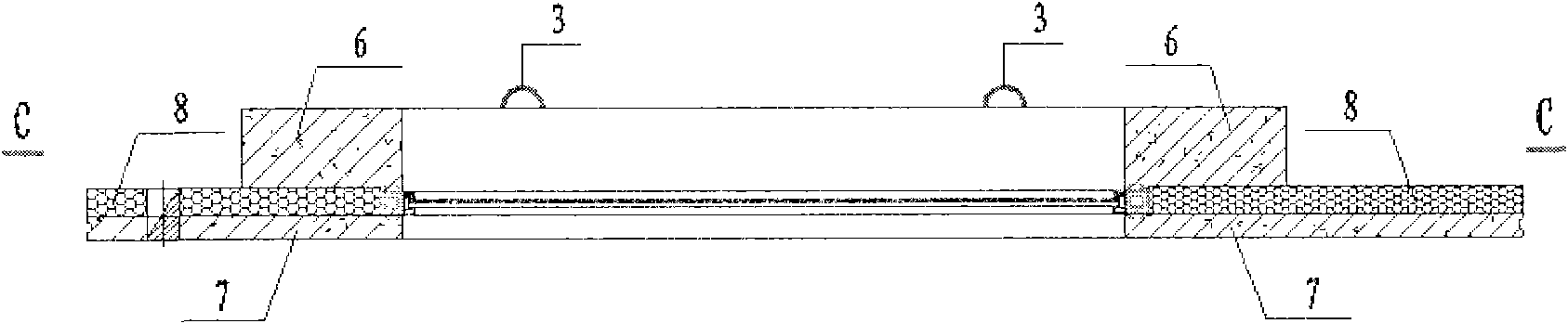

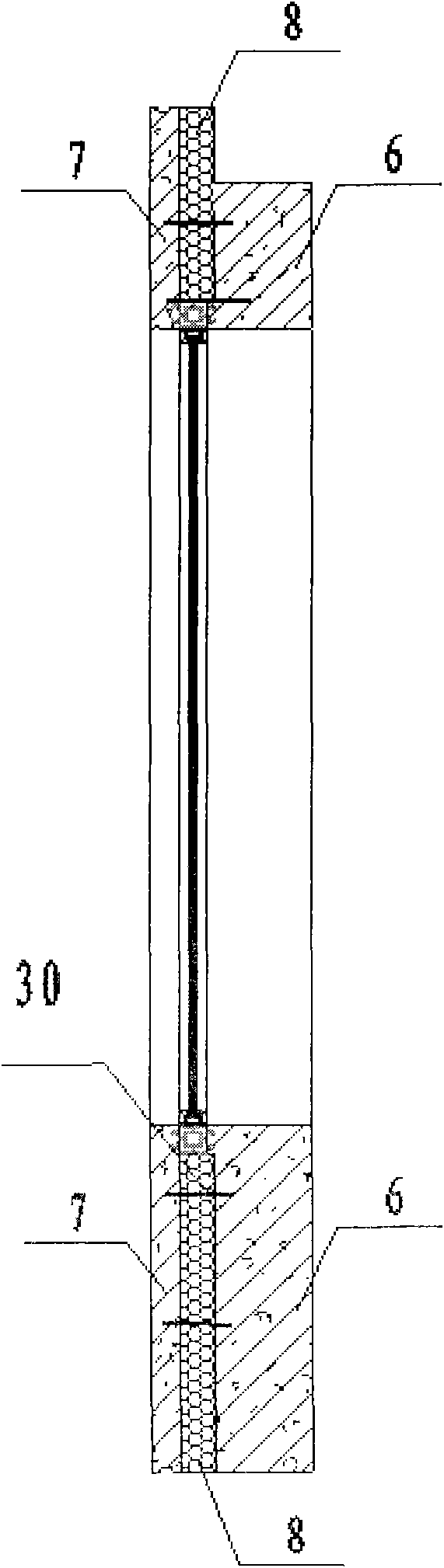

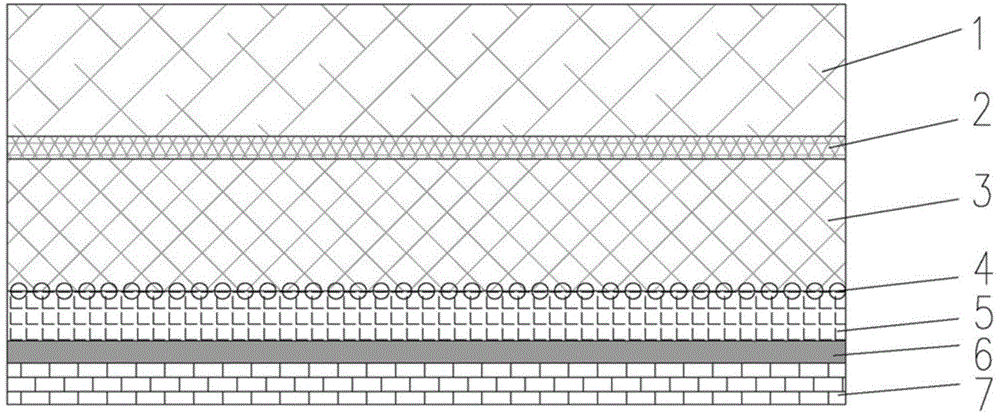

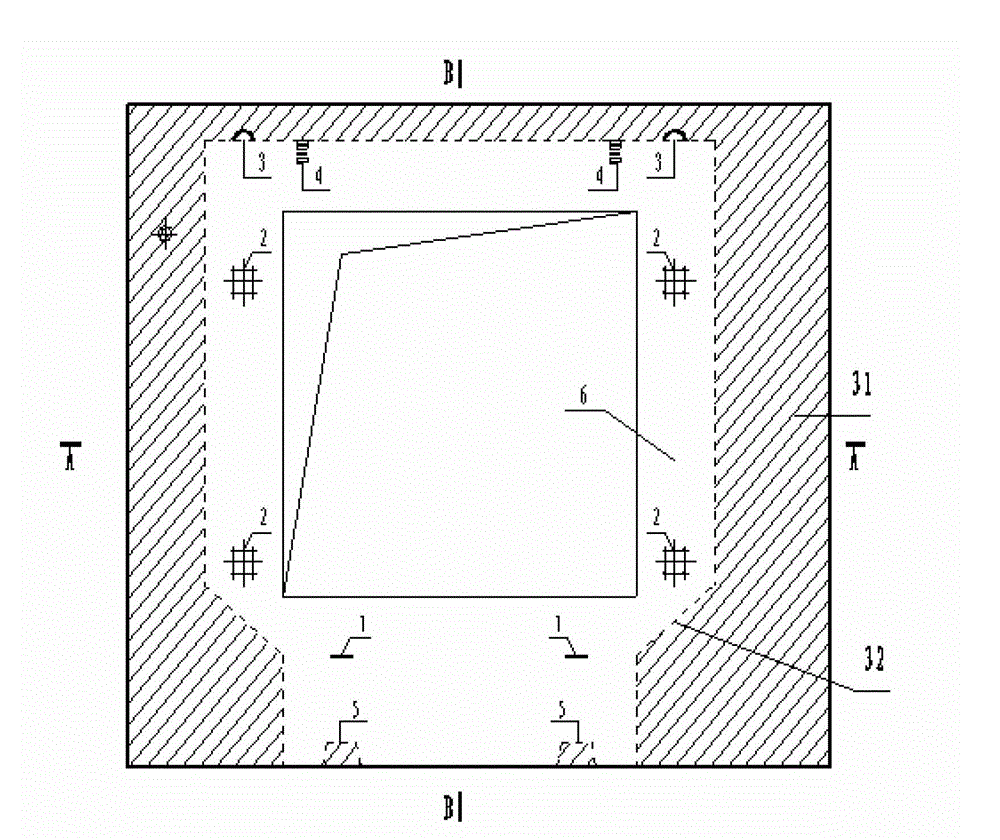

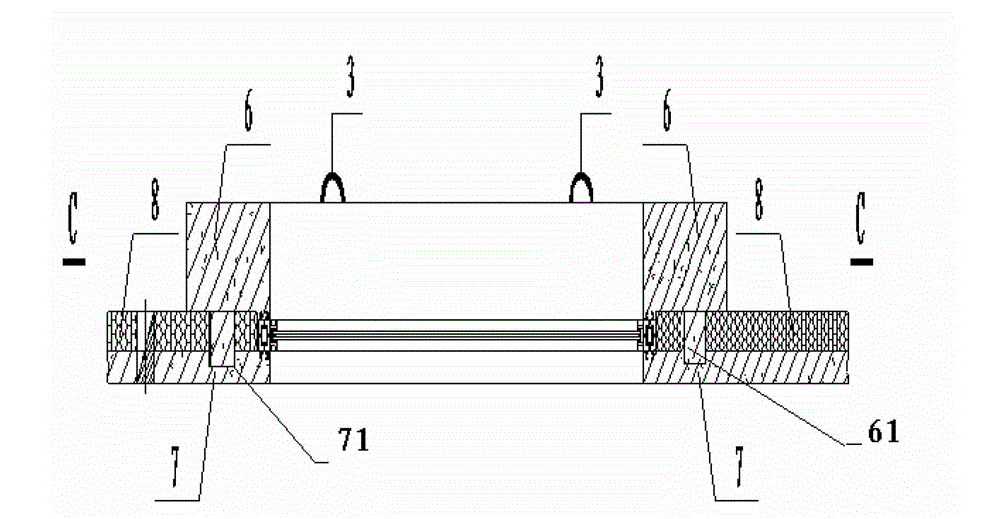

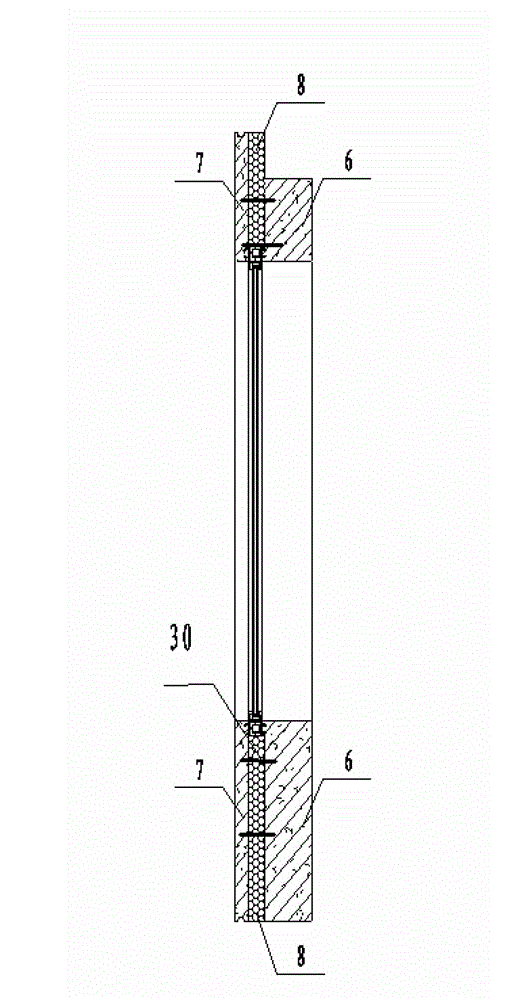

Glass fiber reinforced cement (GRC) insulation decorative wallboard and production method thereof

InactiveCN102094501BReduce pollutionReduce on-site workCovering/liningsCeramic shaping apparatusGlass fiberSteel frame

The invention relates to a glass fiber reinforced cement (GRC) insulation decorative wallboard and a production method thereof, which are applicable to structural envelope, heat insulation and decoration of an external wall for a building of a frame structure. The GRC insulation decorative wallboard comprises a decorative layer, a GRC structural layer I, a GRC structural layer II, an insulating layer, a GRC reinforcing rib, steel frames, an installation connection piece, a lifting ring and an anti-cracking material, wherein, the GRC structural layer I is compounded on the decorative layer andis equipped with the insulating layer; the GRC structural layer II is arranged on the insulating layer, and the GRC reinforcing rib is arranged in the insulating layer; the GRC structural layer I is connected with the GRC structural layer II through the GRC reinforcing rib; the steel frames are arranged in the GRC structural layer I, the GRC structural layer II and the reinforcing rib; and the anti-cracking material is laid in the GRC structural layer II.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

Method for fixing copper sleeve on notebook computer panel

InactiveCN104308501AImprove pull strengthImprove the problem of radial expansion deformationMetal working apparatusMaximum diameterEngineering

The invention provides a method for fixing a copper sleeve on a notebook computer panel. The method comprises the following steps: setting the diameter of a fixing hole which is correspondently and thermally sleeved by the copper sleeve to be 0.4cm smaller than the maximum diameter of the copper sleeve; arranging at least one pair of reinforcing ribs on the periphery of the fixing hole; thermally pressing the copper sleeve into the fixing hole to be fixed by adopting a high-temperature pressurizing manner. By adopting the method for fixing the copper sleeve on the notebook computer panel, adhesive amount entering a clearance can be increased by adjusting the inner diameter of the fixing hole, so that the binding force between the fixing hole and the copper sleeve can be increased.

Owner:SHANGHAI DIANJI UNIV

Fitness massage bench

InactiveCN101756534APromote blood circulationImprove pull strengthSofasVibration massageWhole bodyMassage

The invention discloses a fitness massage bench, which comprises a bench body. The upper end of the bench body is provided with a faceplate, and a first vibration driving device is arranged on the lower surface of the faceplate. The fitness massage bench is characterized in that a mounting bracket is arranged in the bench body, a rotating shaft is coupled on the mounting bracket, at least one swivel plate is fixedly arranged on the rotating shaft, an elastic coiling tape is wound around the swivel plate, the end of the elastic coiling tape is fixedly connected with a guy rope, and the guy rope extends out of the bench body. The invention has the advantages that when the user sits on the bench, the first vibration driving device can be started for vibrating massage of the lower part of the user. Simultaneously, when the user pulls the guy rope by arm, the upper part of the body (arms, pectoral muscle, etc.) can be trained, thereby making the whole body of the user exercise and relax, promoting the blood circulation of the body and achieving good fitness effect.

Owner:董西攀

Impact-resistant wear-resistant environment-friendly pavement and construction method

The invention discloses an impact-resistant wear-resistant environment-friendly pavement. The pavement comprises a surface layer (1), a base layer (2), a soil cloth layer (3) and a road foundation (4), and is characterized in that the surface layer (1) is provided with a wear-resistant layer (11) and a gravel-grade steel slag layer (12); the wear-resistant layer (11) is made of ultra-high performance concrete doped with glass powder and rice hull ash; the interior of the gravel-grade steel slag layer (12) is prepared from gravel-grade waste steel slag, epoxy resin, asphalt and other materials,the base layer (2) is provided with a high-modulus epoxy asphalt steel slag layer (21) and a building reclaimed material layer (22), the building reclaimed material layer (22) is provided with a stone chip filling body (23), and the soil cloth layer (3) is located below the building reclaimed material layer (22) and above the road foundation (4) and is firm in connection. The pavement disclosed by the invention can bear received vertical, transverse and vibration impact loads, and is high in firmness, good in durability, high in comfort, high in flexibility and high in high-temperature resistance.

Owner:XIANGTAN UNIV

Moisture-curing polyurethane permeable paint for calcium silicate board and application of permeable paint

InactiveCN113025175AGood sealingGood water and moisture resistancePolyurea/polyurethane coatingsPriming paintsCalcium silicatePolymer science

The invention relates to moisture-curing polyurethane permeable paint for a calcium silicate board and application of the permeable paint. The moisture-curing polyurethane permeable paint for the calcium silicate board, provided by the invention, comprises the following raw material components in percentage by weight: 98%-99% of a polyisocyanate prepolymer of diisocyanate, 0.2%-0.8% of an initiator, 0.2%-0.8% of a catalyst and 0.2%-0.8% of a defoaming agent. The moisture-curable polyurethane permeable paint provided by the invention has a good sealing effect on a light calcium silicate board, can permeate into the board as a sealing primer, and forms a film at a certain depth under the board surface through moisture curing, so that the sealed calcium silicate board has very excellent water-resistant and moisture-proof capabilities, meanwhile, the mechanical property of the board can be improved to a certain extent, and the drawing strength of the board is improved; and the construction is simple and convenient, and cost is saved.

Owner:天津中晶建筑材料有限公司

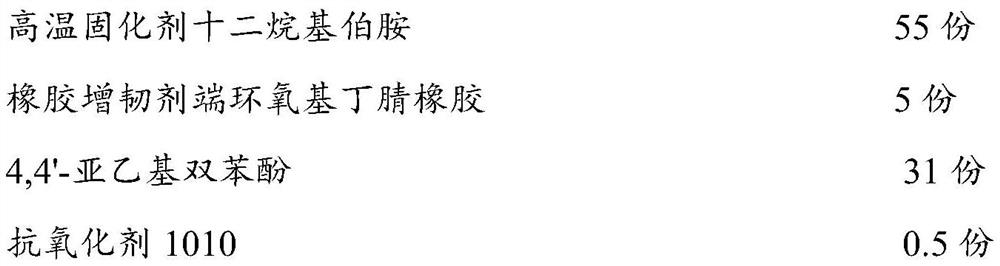

Preparation method and application of hot-mixed epoxy tack coat oil for steel bridge deck pavement

ActiveCN113549418ASlow down the curing reactionImprove compatibilityMacromolecular adhesive additivesEpoxy resin adhesivesBridge deckFirming agent

The invention discloses a preparation method and application of hot-mixed epoxy tack coat oil for steel bridge deck pavement, .Epoxy resin comprises a resin component A and a curing component B. The resin component A comprises 100 parts of bisphenol A epoxy resin, 3-15 parts of a diluent and 1-5 parts of a coupling agent; the curing agent component B comprises 0-10 parts of a rubber toughening agent, 40-80 parts of a high-temperature curing agent, 30-60 parts of a phenolic curing agent and 0.5-4 parts of an antioxidant. The ratio of the epoxy resin component A to the curing agent component B is 1: 1. The preparation method of the special hot-mixed epoxy tack coat oil for the steel bridge deck is simple, the bonding strength is high, the flexibility is excellent, the waterproof performance is good, and the special hot-mixed epoxy tack coat oil can be widely applied to large-span steel bridge deck pavement, tunnel pavement and cement bridge deck pavement as the hot-mixed epoxy tack coat oil.

Owner:SOUTHEAST UNIV

High performance antistatic self-leveling mortar

InactiveCN108726963ASmall shrinkageIncrease the speed of compoundingSolid waste managementWear resistantPolystyrene

The invention discloses high-performance antistatic self-leveling mortar. The high-performance antistatic self-leveling mortar is prepared from the following raw materials in parts by weight: 55 to 80parts of portland cement, 5 to 10 parts of sulphoaluminate cement, 10 to 15 parts of re-dispersible latex powder, 10 to 13 parts of fly ash, 0.35 to 1.5 parts of polypropylene fiber, 2 to 5 parts ofultrafine ettringite, 0.1 to 0.2 part of a water reducing agent, 0.1 to 0.2 part of an early strength agent, 0.15 to 0.3 part of a retarder, 0.15 to 0.3 part of a thickener, and 50 to 100-mesh waste polystyrene sheet broken particles. The high-performance antistatic self-leveling mortar has good fluidity, self-flow leveling, no need for vibration, simple construction, water addition, pumping pouring, and quick spreading; the mortar is wear-resistant and anti-cracking, smoothing in surface, fast and convenient in construction, has high hardening strength on the ground, excellent antistatic andwaterproof performance, can be made into colored ground of different colors, and is environmentally-friendly easy-to-operate self-leveling mortar.

Owner:安徽省万帮新型建材科技有限公司

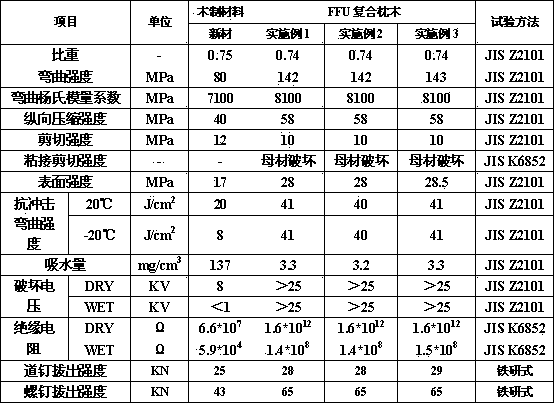

FFU (Fiber Reinforce-Foamed-Urethane) composite sleeper

The invention discloses an FFU (Fiber Reinforce-Foamed-Urethane) composite sleeper. The FFU composite sleeper is characterized by being molded by using a light corrosion-resistant structural material which is made by reinforcing synthetic resin foam through glass long fibers, wherein the glass long fibers are 20-35 nanometers in diameters, and are 2-8 centimeters in lengths; and the synthetic resin foam is made by performing chemical reaction foaming on hard ethyl carbamate resin. The FFU composite sleeper provided by the invention is a glass fiber-reinforced hard FFU microporous elastomer, has the excellent performance of high specific strength, shock absorption, noise reduction, electric insulation resistance, high durability and the like, is light in weight, is high in application property, and can be processed like wood; and the FFU composite sleeper contributes to environmental protection, and is recyclable.

Owner:SHAANXI TIANDI FOUND BUILDING NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com