Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "Non-absorbent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

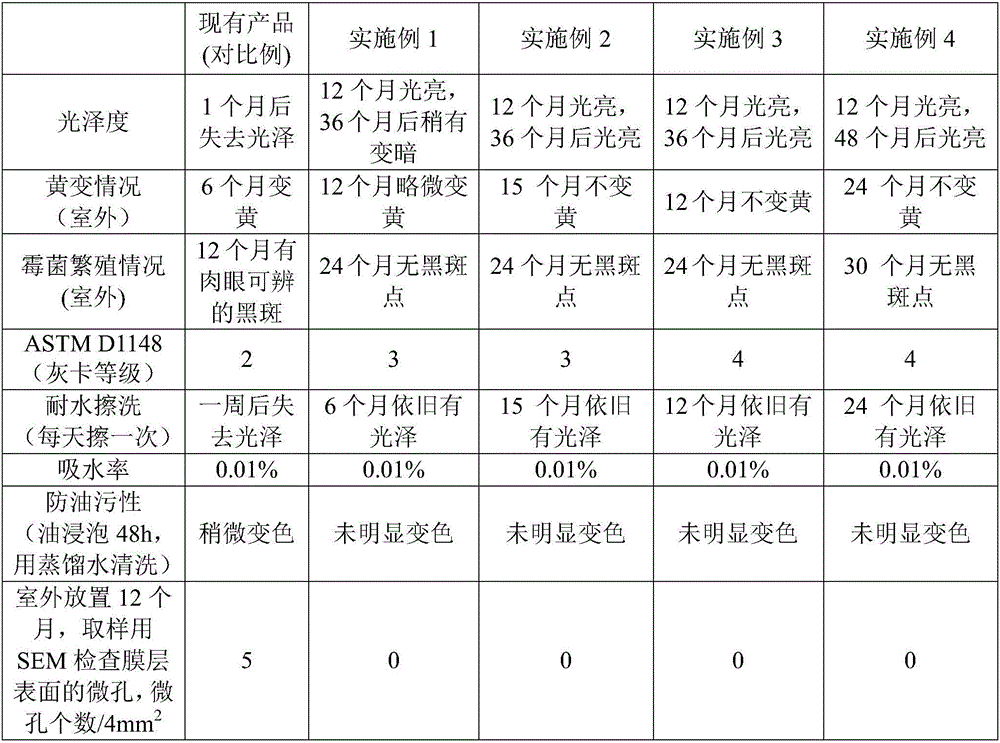

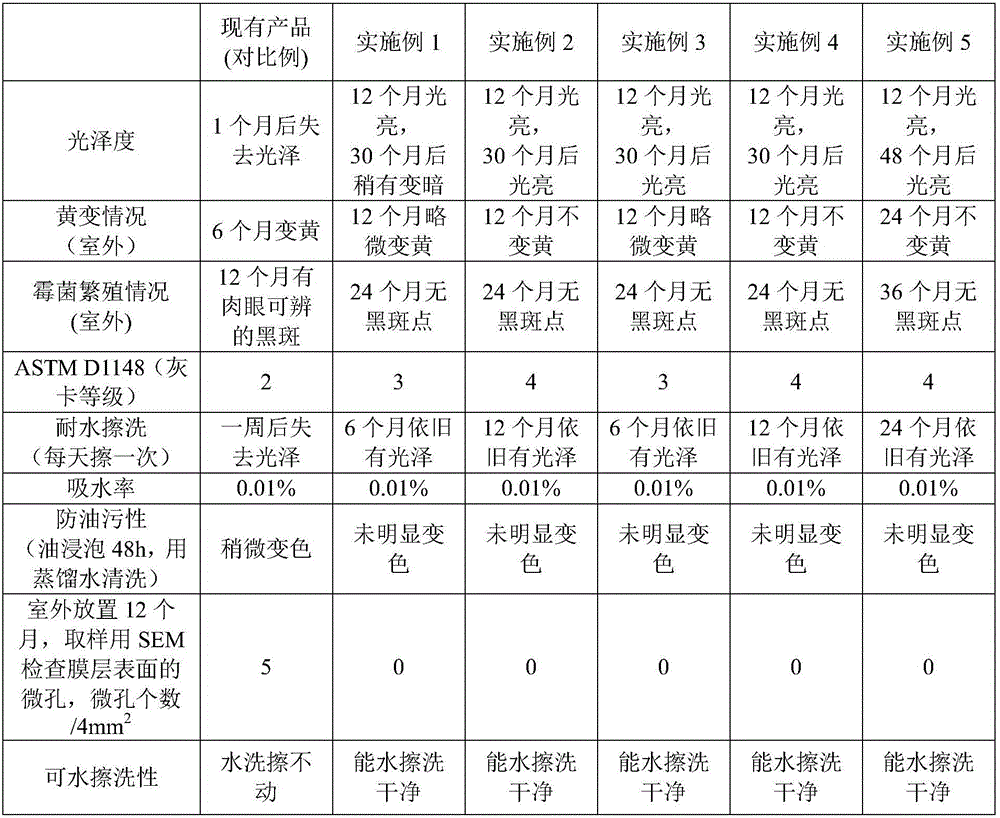

Two-component decoration sealant and preparation method thereof

InactiveCN106634755ANon-absorbentEasy to cleanNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryDefoaming Agents

The invention discloses a two-component decoration sealant. The two-component decoration sealant comprises a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 60-100 parts of epoxy resin, 3-20 parts of active diluents, 4-15 parts of thixotropic agents, 0.01-1 part of defoaming agents, 0-10 parts of coupling agents, 0.05-3 parts of ultraviolet absorbers, 0.01-1 part of purplish blue phase toners and 0.05-1 part of antioxidants; the component B is prepared from the following components in parts by weight: 60-100 parts of modified curing agents, 0.1-20 parts of accelerants, 1-15 parts of thixotropic agents, 1-15 parts of extender pigments and 0-10 parts of coupling agents. The two-component decoration sealant does not absorb water, and has oil dirt resistance, washability, scrubbing resistance, high strength, high brightness, blackening resistance and mildew resistance; meanwhile, the brightness lasting time is greatly prolonged; the two-component decoration sealant has yellowing resistance and water scrubbing resistance and is an environment-friendly decoration sealant.

Owner:HUNAN KOSEN NEW MATERIAL

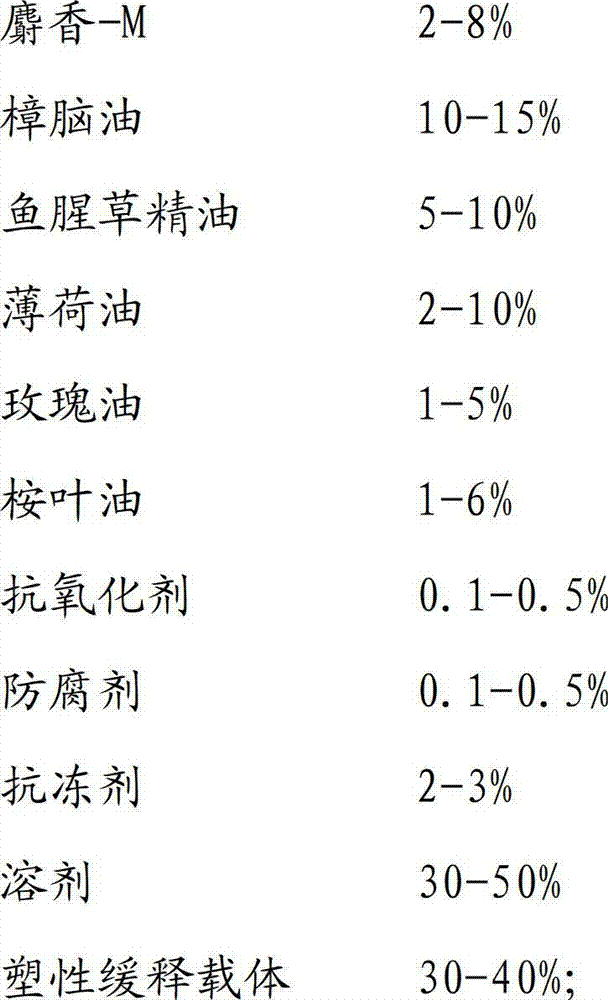

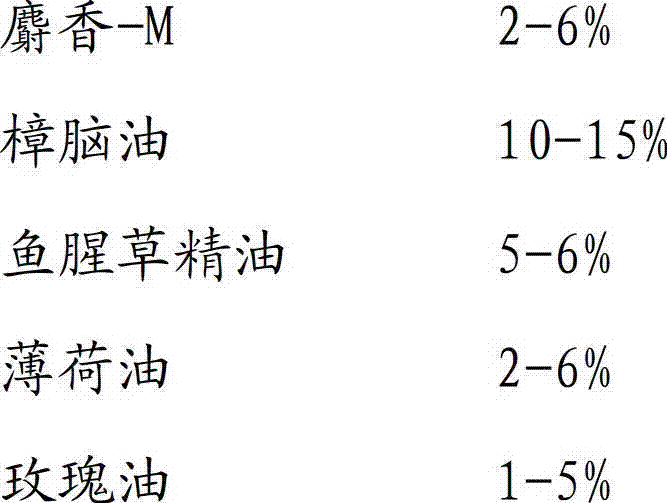

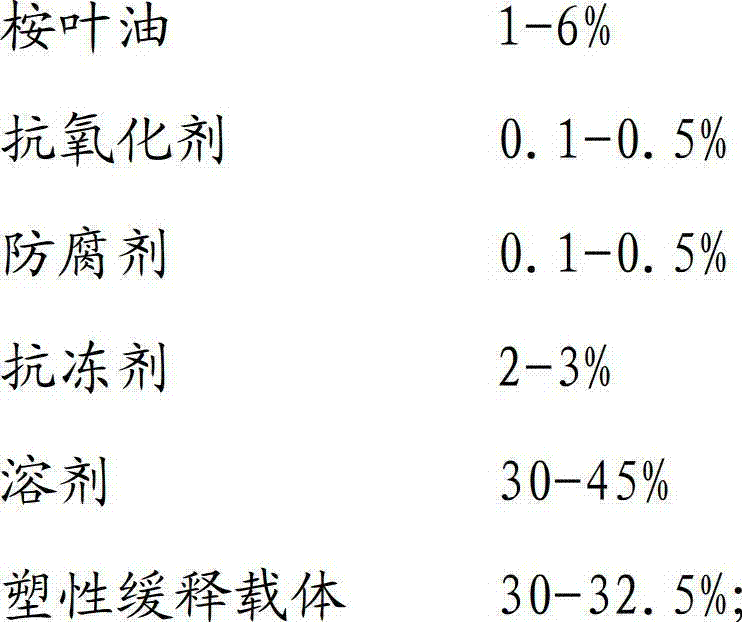

Bird repellent and preparation method thereof

ActiveCN103070202ANo harmWill not affect normal functioningBiocidePest repellentsAdditive ingredientAntioxidant

The invention discloses a bird repellent. The bird repellent comprises the following raw materials in percentage by weight: 2-8% of musk-M, 10-15% of camphorated oil, 5-10% of ordate houttuynia essential oil, 2-10% of mint oil, 1-5% of rose oil, 1-6% of eucalyptus oil, 0.1-0.5% of antioxidant, 0.1-0.5% of preservative agent preservative agent, 2-3% of antifreeze agent, 30-40% of solvent and 30-40% of plastic slow-release carrier; and the total of the raw materials is 100%. According to the invention, bird repellent ingredients and additives, which are harmless to birds, are adopted; volatile substance is slowly released through the slow-release carrier technique; all the ingredients are nontoxic and harmless, cannot cause harm to birds, and do not cause environmental pollution; the use is convenient; the content of odorous bird repellent component is high, the effect is durable, and a sustainable action of 180-240 days can be achieved in one attempt; the bird repellent has the characteristics of being non-absorbent and being non-conducting; and the bird repellent can work normally under severe weather conditions, such as coldness, high temperature, rain and strong wind.

Owner:GUANGDONG POWER GRID CO LTD CHAOZHOU POWER SUPPLY BUREAU

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

Gaft polymer, wood-plastic material containing same and its preparing method

InactiveCN1470540AMoisture content requirements relaxedCorrosion resistancePolyolefinPlastic materials

The present invention provides a graft polymer, a wood-plastic material containing said graft polymer and their preparation method. Its preparation method includes the following steps: firstly, in the presence of organic silane grafting polyolefine to obtain a graft polymer, then using said graft polymer as total or partial base material, and in the presence of catalyst mixing it with wood powderfilling material, then making them undergo the processes of extruding, plasticizing and forming to obtain the invented wood-plastic material with double characteristics of wood and plastics. Said wood-plastic material can be made into package, tray, building material and pipe material, etc. instead of pure wood.

Owner:PETROCHINA CO LTD

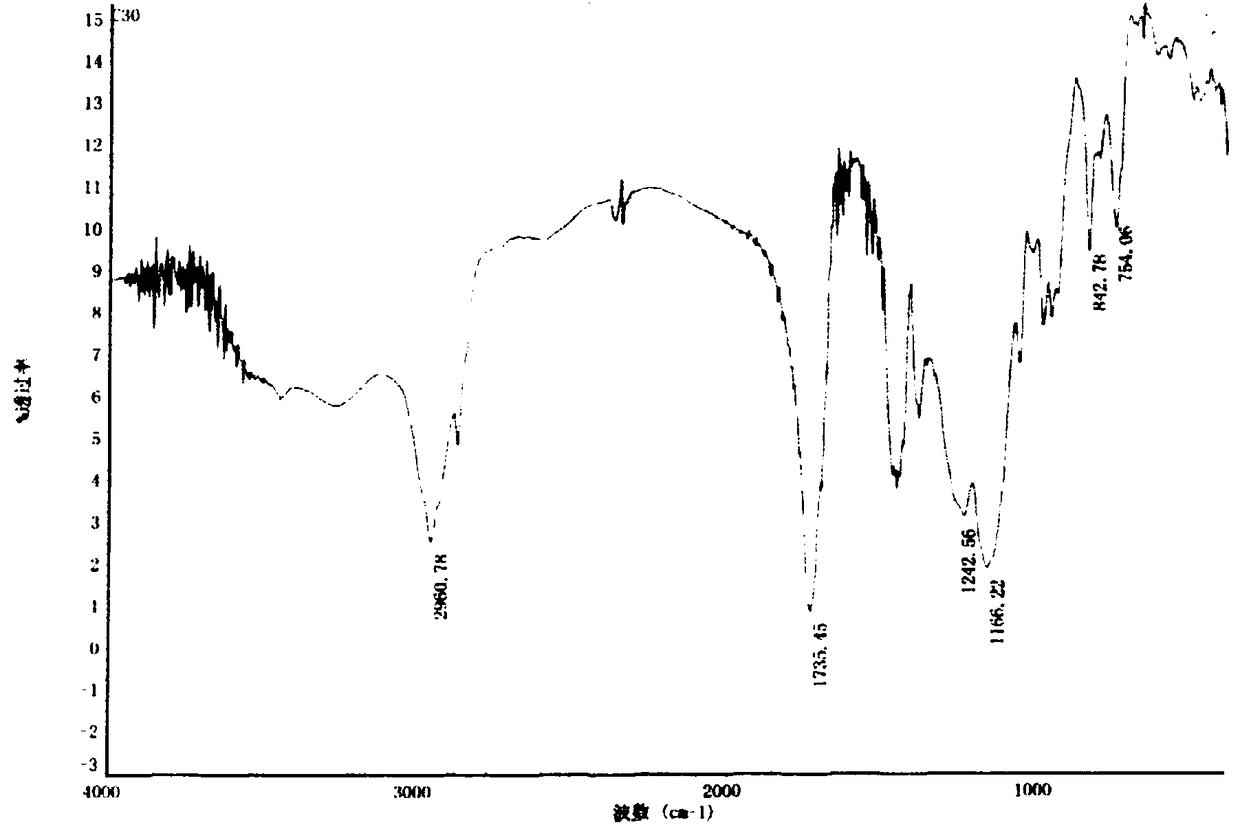

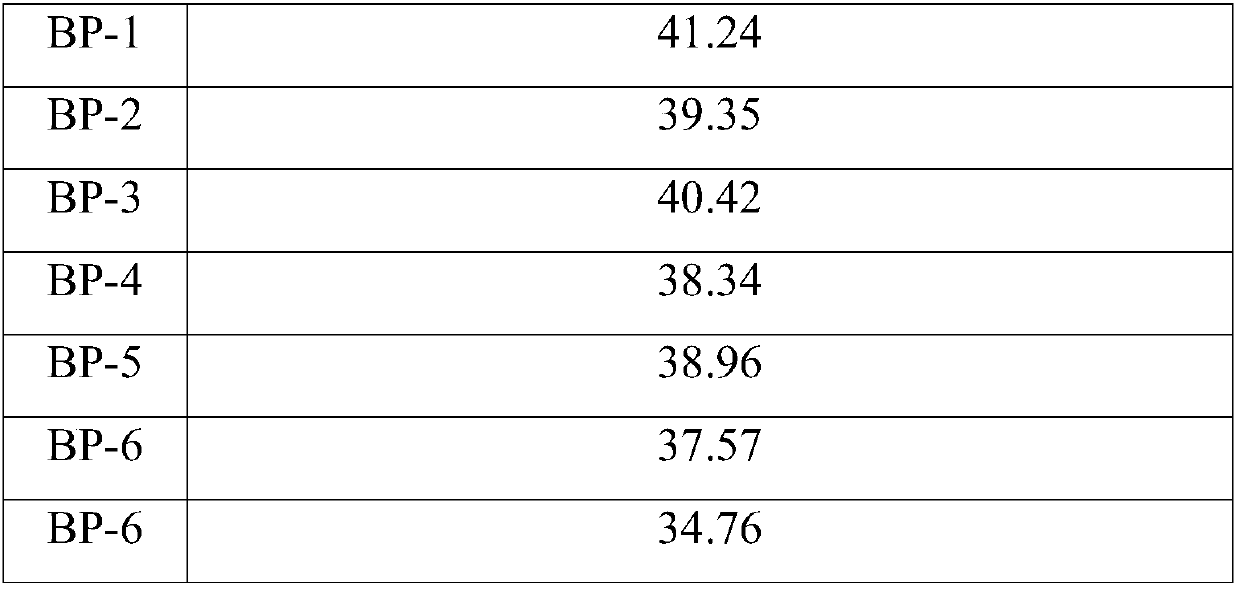

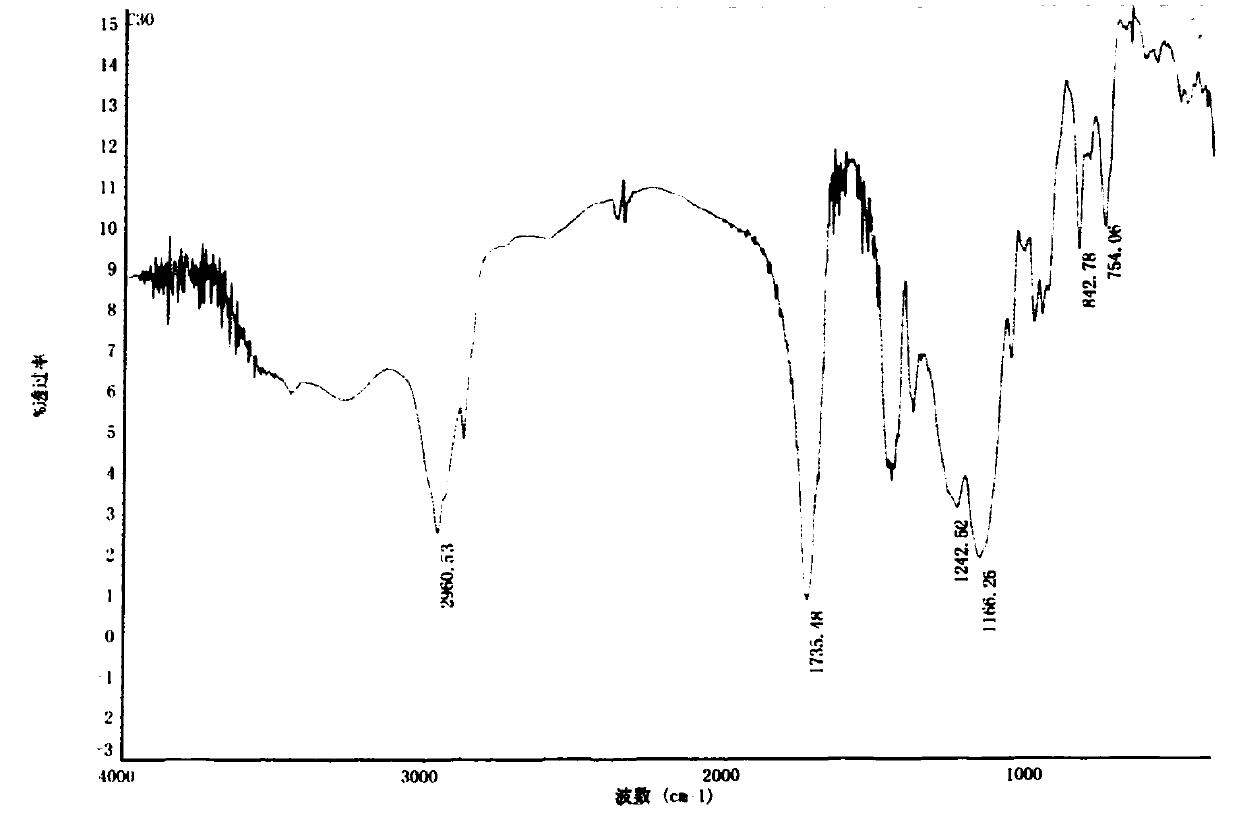

Nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester and preparation method thereof

ActiveCN108559018AGood environmental effectDoes not involve emissionsInksPolymer scienceDistribution characteristic

The invention discloses nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester which comprises a basic monomer comprising methyl methacrylate, methacrylic acid and butyl acrylate, wherein the basic monomer is polymerized into the nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester under the action of an emulsifier and an initiator in a pure water system; the D50 particle size of the nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester is 40-65nm; the multi-dispersion index PDI (Mw / Mn) of the copolyester is lessthan 1.05. The invention further provides a preparation method of the acrylic acid copolyester. The nano-grade aqueous narrow molecular weight distribution acrylic acid copolyester disclosed by the invention is prepared from water as a dispersion medium merely, is directly polymerized in the pure water system, exists stably, has a nano-grade narrow bandwidth distribution characteristic, has the characteristics of low viscosity and high solid contents, in addition is free of water absorption or after-tack and is good in waterproof property. Functionalized modification can be also achieved.

Owner:SHANGHAI XIANKE CHEM CO LTD

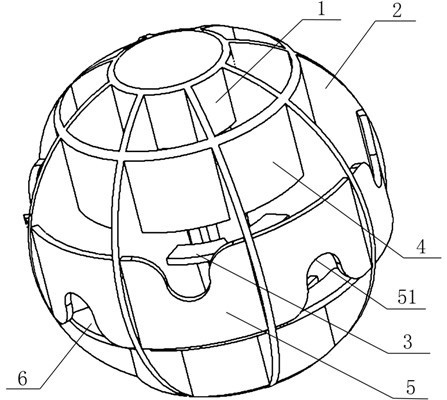

Labyrinth-shaped spherical hollow filler

InactiveCN102614606AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical shaped

The invention discloses a labyrinth-shaped spherical hollow filler which is characterized in that coaxial tubular bodies are arranged at the two ends of the filler respectively, and a plurality of fan-shaped bodies are uniformly connected to the circumference of the two tubular bodies; a ring-shaped body is arranged at the middle parts of the two tubular bodies respectively and connected with each fan-shaped body; two large tubular bodies are arranged on the outer side of each tubular body and have a larger radius than that of the tubular bodies; and a ring-shaped belt is arranged in the position close to the vertex of each fan-shaped body. The internal structure of the labyrinth-shaped spherical hollow filler is spatially divided into a plurality of cells. Compared with the prior art, the cells are communicated to ensure the movability of liquid in the internal space, so as to, on one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the labyrinth-shaped spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

Foamed glass and ceramic product and its making process

The present invention belongs to the field of glass and ceramic product technology, and is especially sound absorbing and heat insulating foamed glass and ceramic product for wall filling, building decorating, etc. and its making process. The foamed glass and ceramic product is made with glass, china clay and / or waste ceramic as main material, industrial or domestic solid waste accounting for over 50 wt% and foaming agent, and through crushing, dry mixing and ball milling, sintering while producing bubbles coated by the melt, and cooling to form the sintered product with closed bubbles. The making process is simple and low in power consumption, and the product has excellent performance, density of 0.2-1.0 g / cu cm, breaking strength of 3-6 MPa, and the advantages of both glass and ceramic.

Owner:马克文 +1

Multi-component sealant and preparation method thereof

ActiveCN106753137ANon-absorbentEasy to cleanNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAntioxidant

A multi-component sealant comprises a component A, a component B, a component C and a component D, wherein the component A comprises the following raw materials in parts by weight: 60-100 parts of epoxy resin; 1-10 parts of an active diluent; 0.01-1 part of a defoaming agent; 0-10 parts of a coupling agent; 0.05-3 parts of an ultraviolet absorbent; 0.01-1 part of a purple blue phase toner; and 0.05-1 part of an antioxidant; the component B comprises the following raw materials in parts by weight:70-100 parts of a modified curing agent; 0.1-10 parts of an accelerant; and 0-10 parts of a coupling agent; the component C comprises the following raw materials in parts by weight: 130-220 parts of quartz sand; the component D comprises the following raw materials in parts by weight: 10-40 parts of extender pigment. The environmentally-friendly sealant does not absorb water, is resistant to oil and water, easy to clean, resistant to scrubbing and yellowing, high in strength and brightness and free of blackening and mildewing, and meanwhile the brightness lasting time is greatly prolonged.

Owner:HUNAN KOSEN NEW MATERIAL

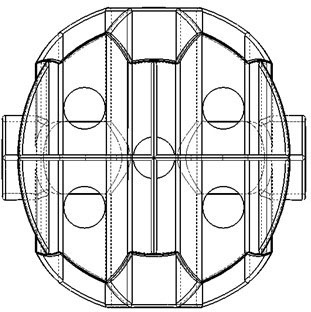

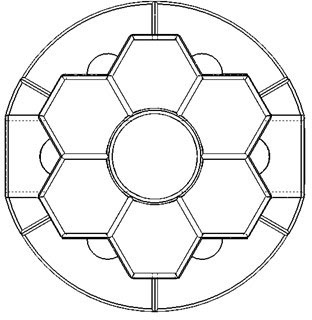

Honeycombed spherical hollow filler

InactiveCN102614604AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical form

The invention discloses a honeycombed spherical hollow filler which is characterized in that a central pipe is arranged at the center of the filler in a penetrating manner, six honeycombed hexagonal parts are arranged on the circumference of the central pipe in a way that each two of the six honeycombed hexagonal parts are connected, a longitudinal fan-shaped wing is connected to the outer side face of each honeycombed hexagonal part, a round fin is arranged on the middle cross section of the central pipe and connected with the outer side face of each honeycombed hexagonal part, and one or two honeycombed hexagonal through-pipes are arranged on the middle cross section of the central pipe and communicated with the central pipe and the outside of the central pipe. The internal structure of the honeycombed spherical hollow filler is spatially divided into a plurality of cells. The cells are communicated to ensure the movability of liquid in the internal space, so as to, one the one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the honeycombed spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

Desulfurated gypsum board

The invention discloses a desulfurated gypsum board. The desulfurated gypsum board is prepared from the following components in parts by weight: 100-150 parts of desulfurated gypsum powder, 20-45 parts of epoxy resin and 1.5-3 parts of glazes. The manufacturing method of the desulfurated gypsum board comprises the following steps: (1), weighing the raw materials in proportion; (2), placing the weighed desulfurated gypsum powder and the epoxy resin to a stirrer for being uniformly stirred, and transferring the uniformly stirred materials to a green body mould to be extruded and formed; (3), heating and maintaining an extruded and formed desulfurated gypsum semi-finished product, and grinding and polishing the desulfurated gypsum semi-finished product; (4), pressing the desulfurated gypsum semi-finished product into a green body by a board press; (5), conveying the pressed desulfurated gypsum board green body to a drying kiln for drying; (6), atomizing and spraying glazes to the dried desulfurated gypsum board green body; and (7), drying the glaze-sprayed desulfurated gypsum board green body in a drying oven. The desulfurated gypsum board disclosed by the invention has the advantages of being hard in texture, green and environment-friendly, free of radioactive toxicity and the like.

Owner:朔州市润臻新技术开发有限公司

Stone slab with patterns

The invention discloses a formula of a stone slab with artificial patterns. The formula comprises raw materials as follows: unsaturated polyester resin, a curing agent, quartz, glass fiber, color paste, an accelerant, a coupling agent, alloy powder, composite powder and water serving as a hydraulic bonding agent. The stone slab is energy-saving and environment-friendly due to the fact that the quartz and the glass fiber which are low in price and easy to obtain are taken as the raw materials of the formula and belongs to a novel environment-friendly building material, and various resources can be sufficiently used; the stone slab replaces natural quartz stone to serve as a high-grade decoration, over-exploitation of the natural quartz stone is effectively restrained, and environment protection and development of recycling economy and low-carbon economy are promoted; the stone slab has the advantages of non-toxic, tastelessness, non-radiation, no microcellular structure, dirt resistance, easiness in maintenance and high processability and can has a good lighting effect by the aid of projection of common light.

Owner:ZHUHAI SESALI HEALTH STONE CO LTD

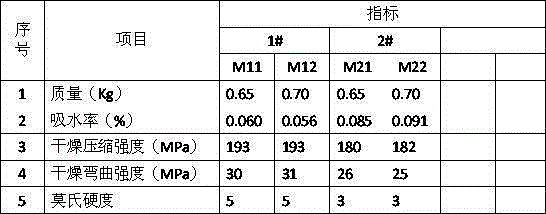

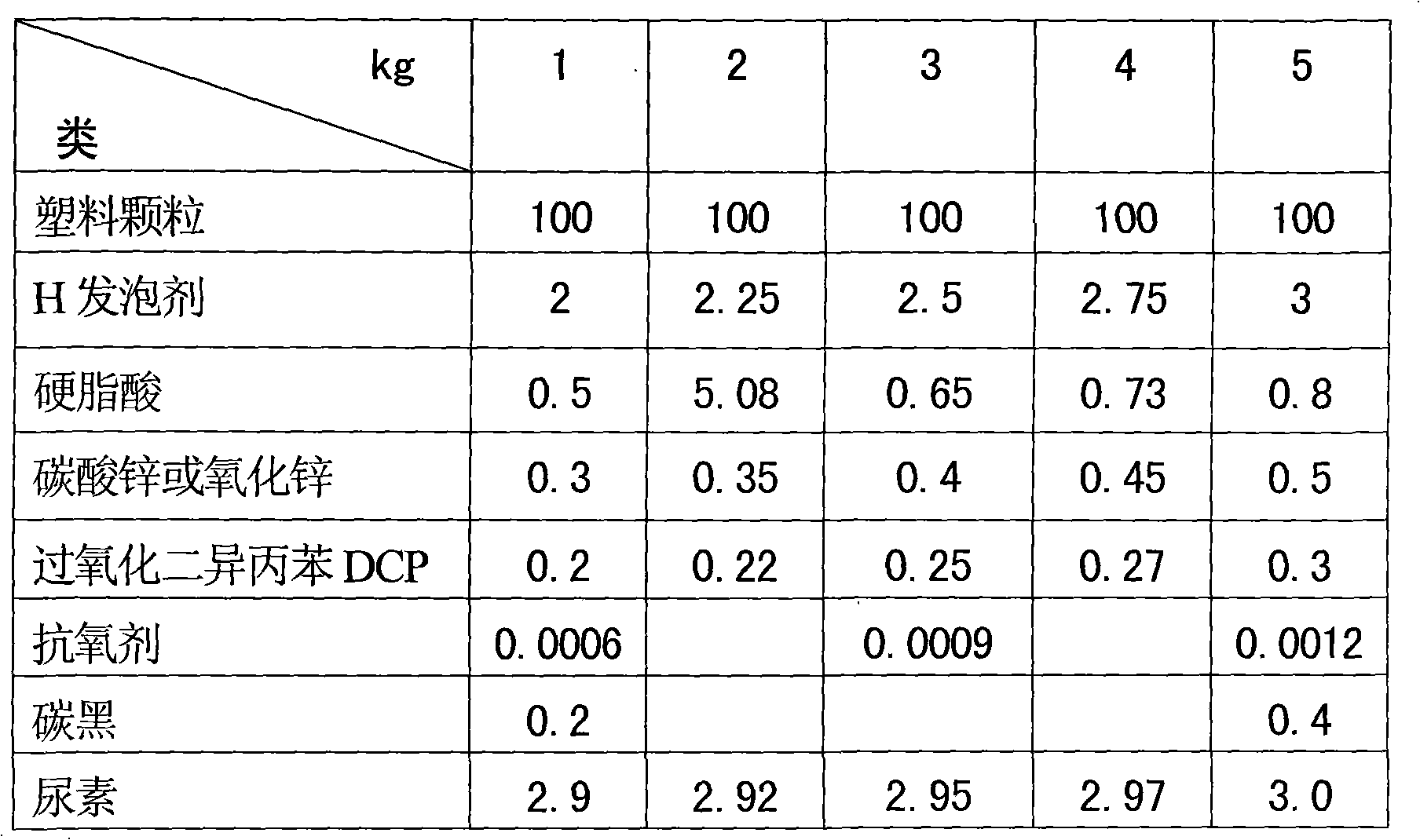

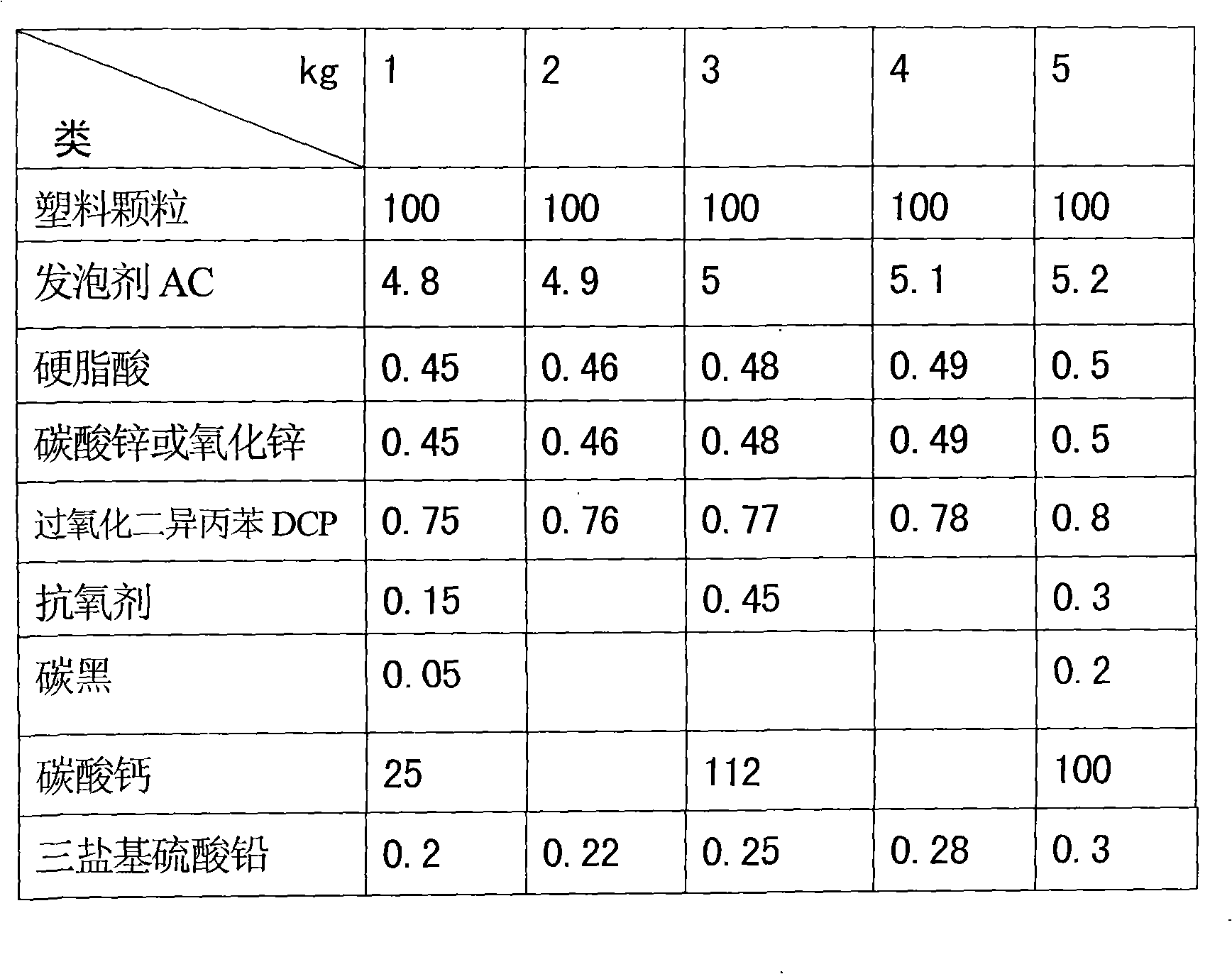

Production technique of low-density high-pressure polyethylene closed-cell foamed plastics plate

ActiveCN101337401AReduce the probability of reactionHigh response rateFlat articlesPolymer scienceLead sulfate

The invention provides a process for producing a low-density high-pressure polyethylene unicellular plastic foam board and relates to the technical field of concrete road and bridge building. The low-density high-pressure polyethylene unicellular plastic foam board is manufactured of the following materials according to a certain proportion by mixing, laminating, mould pressing and foaming: plastic granules, an AC or H foaming agent, a stearic acid promoting agent or a lubricant, zinc carbonate or a zinc oxide accelerant, a dicumyl peroxide DCP crosslinking agent, carbamide,a lead sulfate tribasic stabilizer, an antioxidant and carbon black. The process solves the long-term technical problem to be solved. The low density high pressure polyethylene unicellular plastic foam board has the advantages of low density, high recovery ratio, independent bubble structure, low water absorbing capacity of surface, good anti-penetrating quality, corrosion resistance to acid, alkali, salt, oil, etc., excellent ageing-resistant performance, no flow at the high temperature, no embrittlement cracking at the low temperature, high recovery ratio, long service life, easy construction, material conservation, light weight, good manufacturability, no toxicity or pollution, and broad application range.

Owner:衡水大禹工程橡塑科技开发有限公司

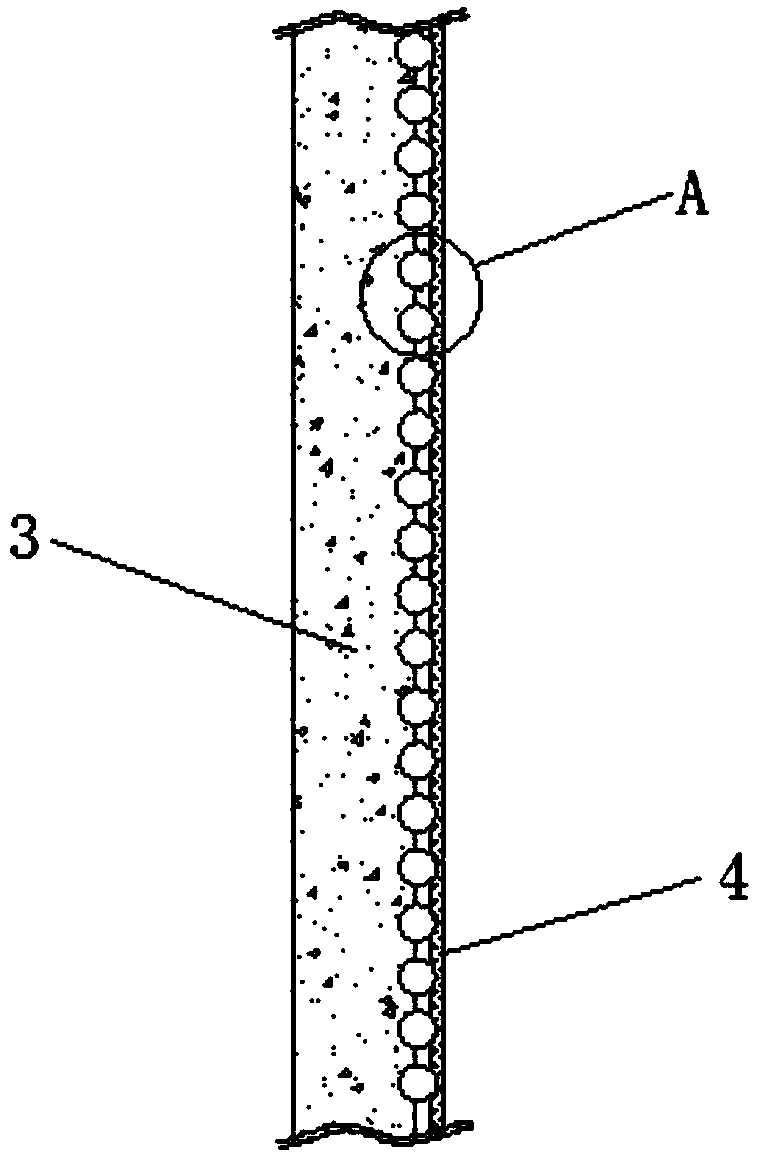

Honeycomb foam material for wall

The invention discloses a honeycomb foam material for a wall for foaming slip casting machine, which consists of the following components in part by weight: 30 to 50 parts of sulphate aluminium cement, 30 to 65 parts of flyash, 25 to 50 parts of water, 6 to 8 parts of hydrogen peroxide, 0.8 to 1.26 parts of calcium stearate and 1.2 to 2 parts of ash calcium powder. The honeycomb foam material has the advantages that: 1, a board is not cracked or stripped, does not absorb water, fire or accumulate halogen, and is soundproof, heat-insulated, shockproof, high in strength and light in weight; and 2, the board is convenient to construct, can be sawed and connected, and can be wide, narrow, thick and thin.

Owner:丹东市兄弟建材有限公司

Epoxy floor coating

InactiveCN103305091AExcellent chemical corrosion resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses an epoxy floor coating, which is characterized by comprising a host and a curing agent, wherein the mixing ratio of the host to the curing agent is 2: 1, and wherein the host comprises the following components in parts by weight: 22-50 parts of epoxy resin, 10-30 parts of filler, 1-8 parts of thickener, 4-7 parts of auxiliaries, 18-35 parts of pigment or color cream and 6-20 parts of plasticizer, and wherein the curing agent is fatty amine and / or polyamide. The epoxy floor coating provided by the invention has excellent chemical corrosion resistance, high hardness, and excellent physical characteristics such as impact resistance, scrub resistance, abrasive resistance and the like; the epoxy floor coating is simple to prepare and convenient for construction; the epoxy floor coating is prepared from environment-friendly, solvent-free good-quality epoxy resin; the epoxy floor coating is wearproof and insulating, and hard and fine in surface; the epoxy floor coating is excellent in resistance to acid, to alkali, to salt, to oil, to esters, and to drugs; the epoxy floor coating is waterproof and non-absorbent, easy to flush, and simple and easy to clean and maintain; besides, the epoxy floor coating is bright and comfortable, smooth and beautiful in appearance with mirror face effect.

Owner:杭州宝力物资再生利用有限公司

Crack-resistant plasterboard

The invention discloses a crack-resistant plasterboard. The crack-resistant plasterboard comprises, by weight, 12 parts of ore tailings, 42 parts of quicklime, 3 parts of iron oxide powder, 4 parts of fly ash, 14 parts of alumina silicate fibers, 10 parts of a silicon filling material, 4 parts of slag, 6 parts of a polymer emulsion, 6 parts of a calcium oxide expanding agent and 95 parts of water. The crack-resistant plasterboard avoids plasterboard cracking, does not contain formaldehyde, has no pollution, guarantees plasterboard strength and hardness and has good environmental protection functions.

Owner:平邑县富华石膏制品有限公司

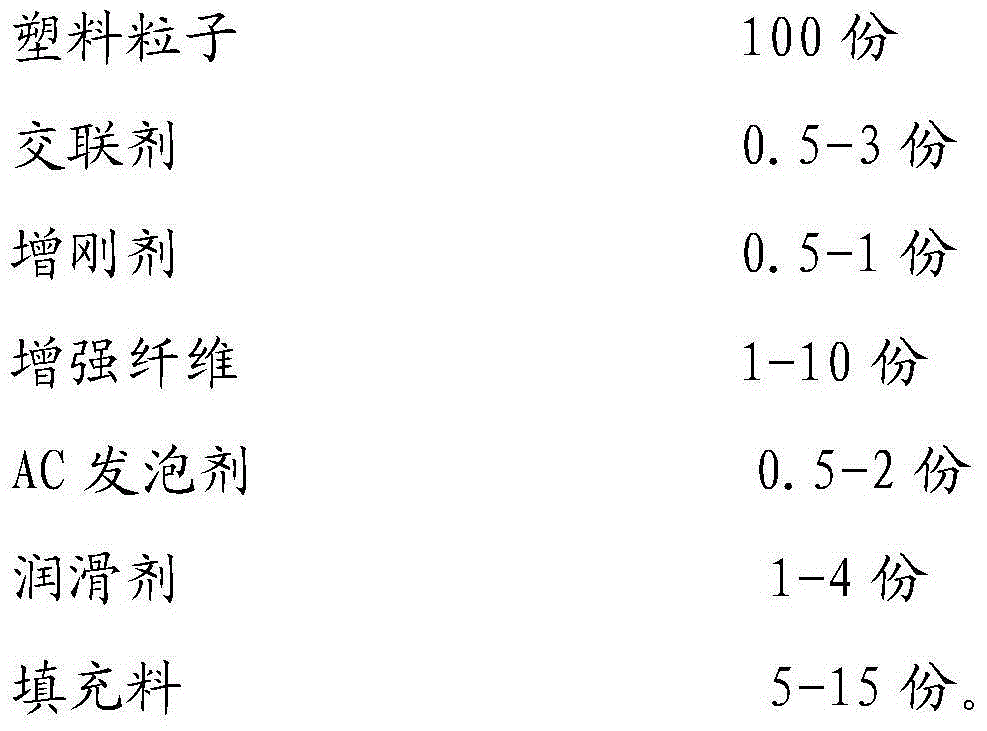

Enhanced door and window auxiliary frame and manufacturing method thereof

The invention discloses an enhanced door and window auxiliary frame. The enhanced door and window auxiliary frame is composed of a micro-foaming sheet material and a steel body embedded inside the micro-foaming sheet material; the micro-foaming sheet material comprises the following compositions: plastic particles, a cross-linking agent, a stiffening agent, reinforced fibers, an AC (Azodicarbonamide) foaming agent and a packing material. By the existence of a large number of bubbles in the micro-foaming material, the enhanced door and window auxiliary frame is low in density, light in weight and high in impact absorption loading capacity; by the steel body embedded inside the micro-foaming sheet material, the enhanced door and window auxiliary frame shows excellent cushioning capacity, and has the advantages of high heat insulation property, good sound insulation effect, acid and alkali resistance and good chemical stability.

Owner:沈建良

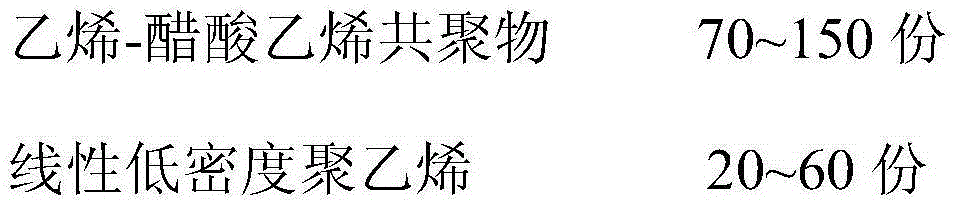

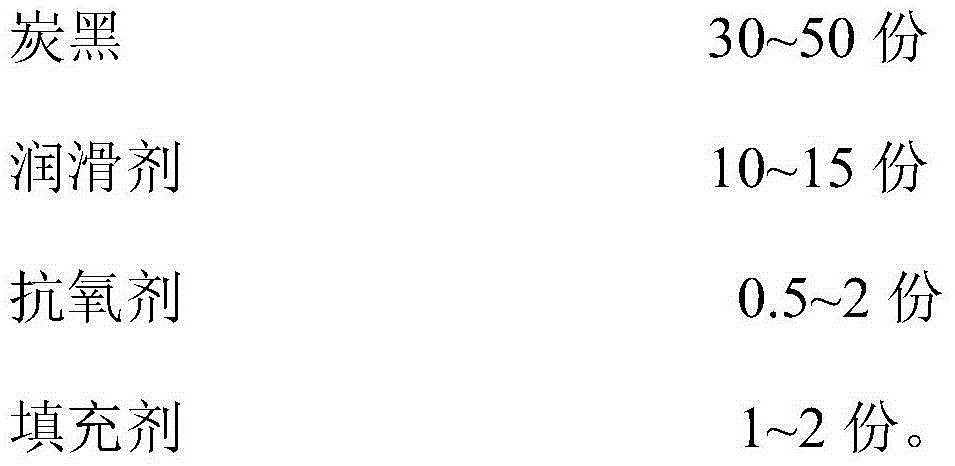

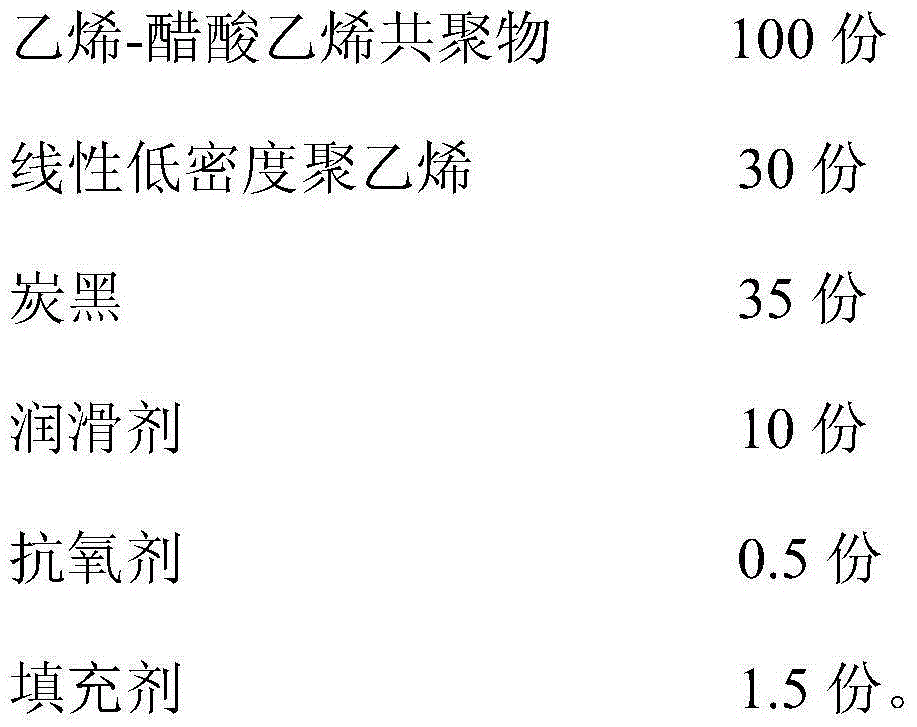

Ethylene-vinyl acetate copolymer based thermoplastic semiconductive shielding material for conductor and preparation method of thermoplastic semiconductive shielding material

ActiveCN105061879ARaise the processing temperatureDoes not affect extrudabilityThermoplasticLinear low-density polyethylene

The invention discloses an ethylene-vinyl acetate copolymer based thermoplastic semiconductive shielding material for a conductor and a preparation method of the thermoplastic semiconductive shielding material. The thermoplastic semiconductive shielding material consists of the following components in parts by weight: 70-150 parts of ethylene-vinyl acetate copolymer, 20-60 parts of linear low density polyethylene, 30-50 parts of carbon black, 10-15 parts of a lubricant, 0.5-2 parts of an antioxygen and 1-2 parts of a filling agent. The thermoplastic semiconductive shielding material is formed by adopting the specific components according to the specific content, so that under the condition of not adopting a cross linking agent, the processing temperature is increased, the extrusion property is not influenced, and the product performance meets the requirements of JB / T10738-2007.

Owner:成都鑫成鹏高分子科技股份有限公司

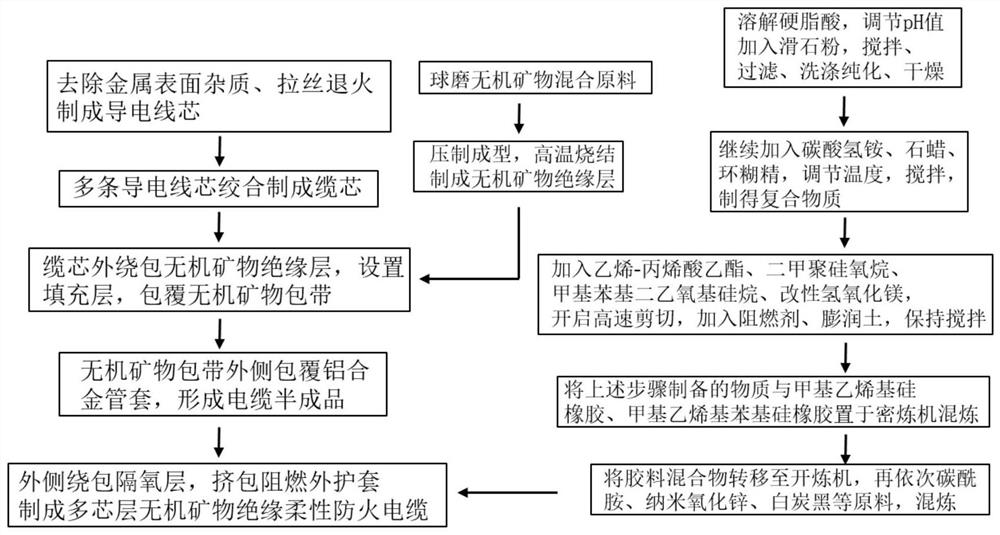

Multi-core-layer inorganic mineral insulation flexible fireproof cable and preparation method thereof

ActiveCN112599286ALarge sectionImprove overload capacityMetallic oxidesFlexible cablesPower cableInsulation layer

The invention discloses a multi-core-layer inorganic mineral insulation flexible fireproof cable and a preparation method thereof, belonging to the technical field of power cables. The multi-core-layer inorganic mineral insulation flexible fireproof cable comprises cable cores, inorganic mineral insulation layers, filling layers, inorganic mineral wrapping tapes, a metal tube composite layer, an oxygen barrier layer and a flame-retardant outer sheath, wherein each cable core is formed by twisting a plurality of groups of conductive cores, the outer side of each cable core is coated with the inorganic mineral wrapping tape, and the filling layers are arranged between the cable cores coated with the inorganic mineral insulating layers and the inorganic mineral wrapping tapes. The cable has good flexibility and flame retardance, and is excellent in mechanical shock resistance and waterproof performance under the condition of fire.

Owner:GUANGDONG NANYANG CABLE CO LTD

Wood plastic floor resistant to acid and alkali corrosion and production technology thereof

The invention discloses a wood plastic floor resistant to acid and alkali corrosion and a production technology thereof, and belongs to the technical field of construction materials. The wood plastic floor is prepared from the following raw materials in parts by weight: 20 to 40 parts of waste and old PVC aggregate, 3 to 8 parts of PVC plastic particle, 40 to 70 parts of waste and old wood powder or fiber powder, 5 to 10 parts of active calcium carbonate, 1 to 3 parts of filler, 5 to 10 parts of processing aid, 1 to 5 parts of anti-aging auxiliary agent, 0.1 to 0.15 part of copper powder, 0.01 to 0.02 part of molybdenum disulfide, and 5 to 10 parts of PTFE pellet. The raw materials mentioned above are subjected to steps of granulating, mixing, extruding, and moulding to produce the wood plastic floor. Compared with the conventional wood plastic floors, the provided wood plastic floor has the advantages of good mechanical properties, strong performance on resisting acid and alkali corrosion, and low manufacturing cost.

Owner:脱德明

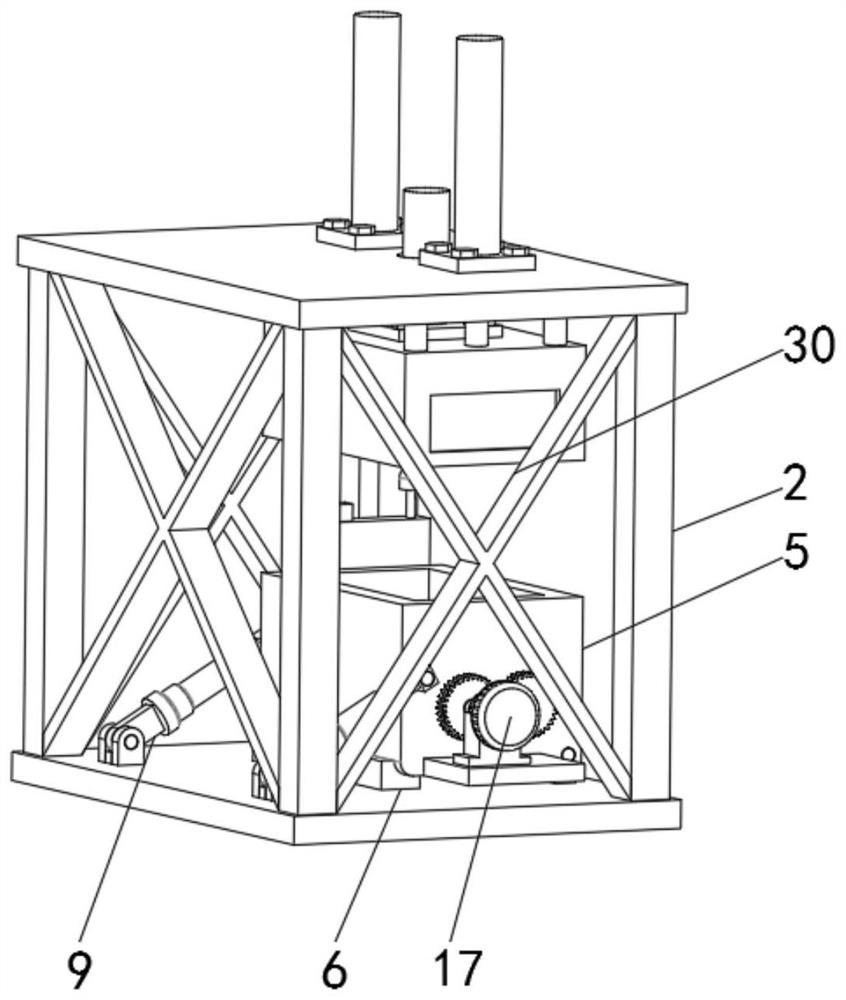

Structure design and construction process for preventing concrete cracks

ActiveCN109267751AGood warningHigh viscosityBuilding material handlingEngineeringBuilding construction

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Coal ash thermal insulating material and preparation method thereof

The invention discloses a coal ash thermal insulating material and a preparation method of the coal ash thermal insulating material, belongs to the field of building material, and relates to a thermal insulating material and a preparation method of the thermal insulating material. The coal ash thermal insulating material is prepared by expanding and sintering coal ash and soda ash serving as raw material. The preparation method comprises the following steps of: mixing and stirring the coal ash and the soda ash in proportion; preheating the mixture to 600-1000 DEG C in a rotary kiln, and introducing the preheated mixture into a temperature resistant distributor; uniformly distributing a layer of material from the upper part of a tunnel kiln to a kiln car located inside the high-temperature area of the tunnel kiln by using the distributor, sintering and expanding the material at 1200-1250 DEG C so that the material is bonded together; when the material inside the tunnel kiln is sintered and formed to the prescribed thickness, sending the material and the kiln car out of the tunnel kiln, distributing, sintering, expanding and forming the material inside next kiln car, and repeatedly carrying out the operations; and introducing the material sent out of the kiln car into an insulating kiln, carrying out thermal insulation for 24 hours, then reducing the temperature to be below 300 DEG C, and cooling, cutting and forming. The preparation method disclosed by the invention has the advantages of controllable kiln temperature, low production cost, and good thermal insulation effect; moreover, place and equipment are saved.

Owner:哈尔滨琪裕新材料科技有限公司

Waterproof fiber plasterboard

The invention discloses a waterproof fiber plasterboard. The waterproof fiber plasterboard comprises, by weight, 32-36 parts of wood fibers, 50-55 parts of dihydrate gypsum, 4-6 parts of glass fibers, 5-8 parts of an acrylic acid emulsion, 3-5 parts of an inorganic aluminum salt waterfroof agent and 50-60 parts of industrial waste water. A preparation method of the waterproof fiber plasterboard comprises the followings steps. The waterproof fiber plasterboard utilizes the wear-resistant components, guarantees plasterboard strength and hardness and has good wear resistance.

Owner:合肥向荣环保科技有限公司

Construction curing agent and application thereof in chromic slag building block

The invention discloses an architectural hardener and application in the chromium slag building brick, which comprises the following parts: 30-50% calcium aluminate, 30-40% silica, 10-20% bivalent ferric material, 5-10 % tourmaline and 5-7% solid water glass. The making method comprises the following steps: 1) feteching 10-20% chromium, 10-20% cement, 20-50% solid architectural rubbish, 5-15% clay and 1-5% hardener; 2) mixing these raw materials to stir evenly; adding 10-55% water; stirring; making dry hard cement clod; 3) loading the cement into specimen mold; pressing; stripping; culturing.

Owner:石一彤

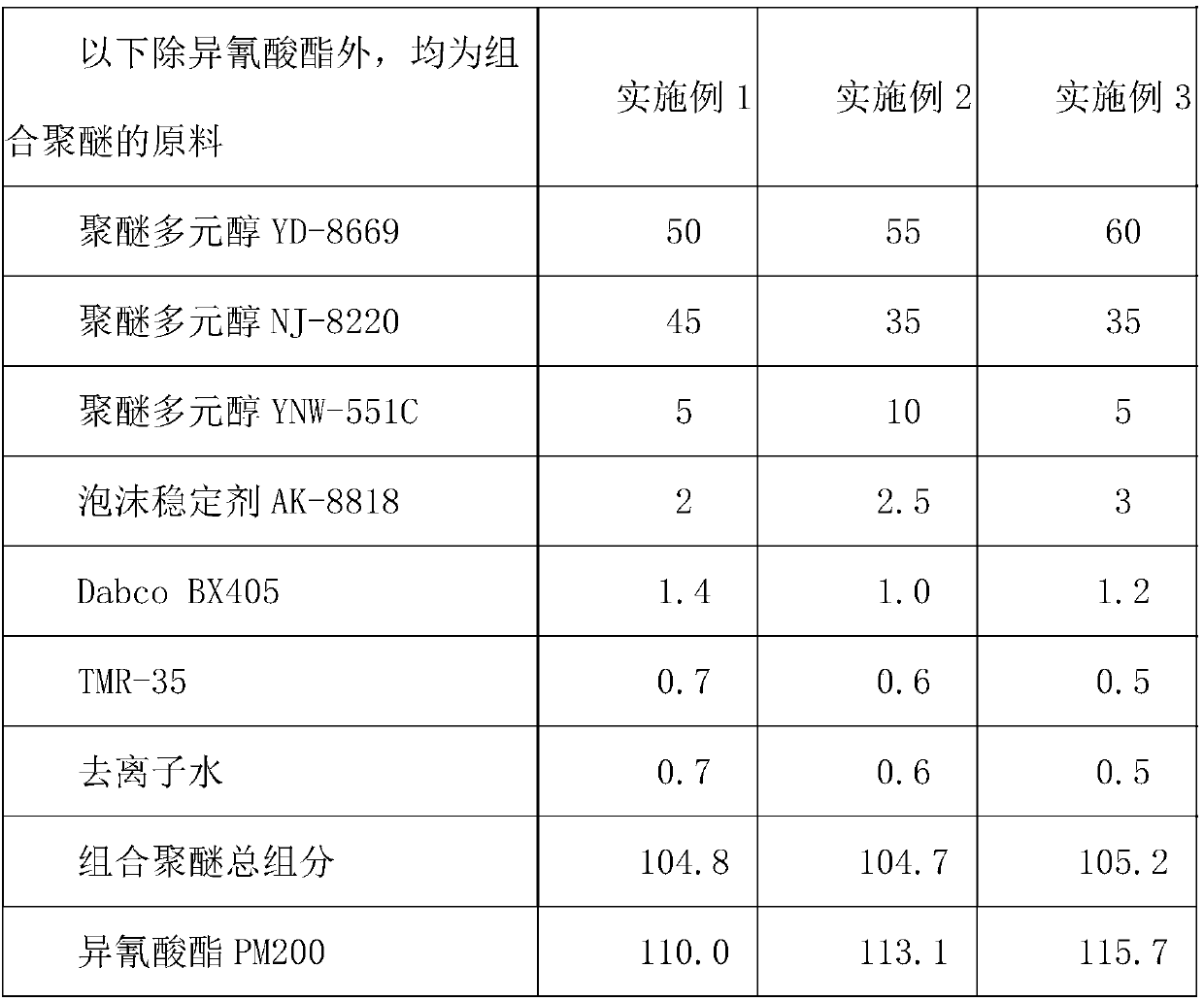

Premixed polyether polyol, polyurethane raw material composition and polyurethane foam for polyurethane imitated wood product and preparation method of polyurethane foam

The invention relates to premixed polyether polyol, polyurethane raw material composition and polyurethane foam for a polyurethane imitated wood product and a preparation method of the polyurethane foam. The premixed polyether polyol is prepared from components in parts by weight as follows: 50-60 parts of first polyether polyol, 35-45 parts of second polyether polyol, 5-10 parts of third polyether polyol, 2-3 parts of a foam stabilizer, 1.5-2.5 parts of a catalyst and 0.5-0.7 parts of a foaming agent, wherein viscosity of first polyether polyol is 3200 plus or minus 500 mPa.s and hydroxyl value is 425-455 mgKOH / g when first polyether polyol is at 25 DEG C; viscosity of second polyether polyol is 1500 plus or minus 500 mPa.s and hydroxyl value is 400-460 mgKOH / g when second polyether polyol is at 25 DEG C; viscosity of third polyether polyol is 500 plus or minus 100 mPa.s and hydroxyl value is 54.5-57.5 mgKOH / g when third polyether polyol is at 25 DEG C. The polyurethane imitated woodproduct prepared from premixed polyether polyol has the advantages of being high in toughness, bendable and suitable for dome, arc-shaped furniture / wall decoration and the like.

Owner:SHANGHAI DONGDA POLYURETHANE

Production technology for integrated tray type polyurethane heat-insulating heating tile

InactiveCN106273185AKeep warmReduce heat dissipationCovering/liningsFlooring insulationsControllabilitySurface plate

The invention discloses a production technology for an integrated tray type polyurethane heat-insulating heating tile. The production technology comprises the following steps: (1) putting a ceramic panel into a forming mold; (2) putting a tray containing a carbon fiber heating material on the back of the ceramic panel; (3) pouring a polyurethane foaming raw material into the forming mold, closing the mold, polymerizing polyurethane after 8-15min, opening the mold and taking out, thereby acquiring the integrated tray type polyurethane heat-insulating heating tile. The production technology has the advantages of simple process, high controllability and facilitation of large-scale production. The prepared floor heating tile has the advantages of long service life, convenience in mounting, high heating speed, high heat supply efficiency and attractiveness.

Owner:四川省新万兴瓷业有限公司

Environmental-friendly gypsum board

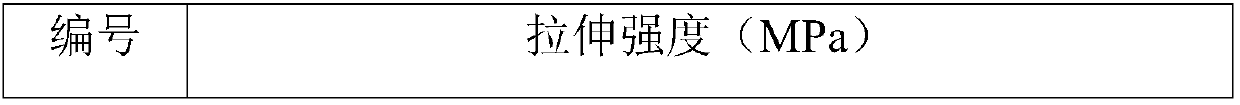

InactiveCN104355593ARealize resource reuseGuaranteed StrengthSolid waste managementSlagUltimate tensile strength

The invention discloses an environmental-friendly gypsum board. The environmental-friendly gypsum board comprises the following raw materials in parts by weight: 20-25 parts of blast furnace slag with the particle size of 80-100 microns, 30-45 parts of flue gas desulfurization gypsum, 8-10 parts of plant ash, 12-15 parts of slag wool, 9-11 parts of water glass, 3-5 parts a water reducer and 40-50 parts of water with the Ph value of 9-11. The environmental-friendly gypsum board uses the blast furnace slag, the plant ash and the slag wool as the raw materials, is formaldehyde-free and pollution-free during production, meanwhile, realizes recycling of gypsum resources, and has an excellent environmental-friendly function while ensuring the strength and the hardness of the gypsum board.

Owner:合肥向荣环保科技有限公司

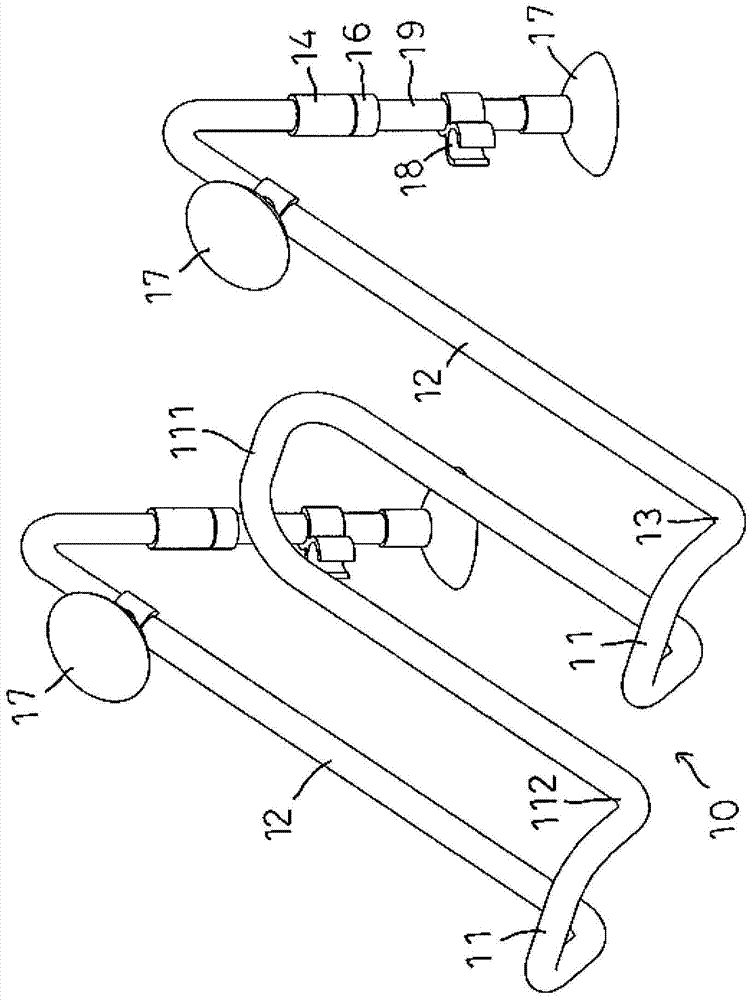

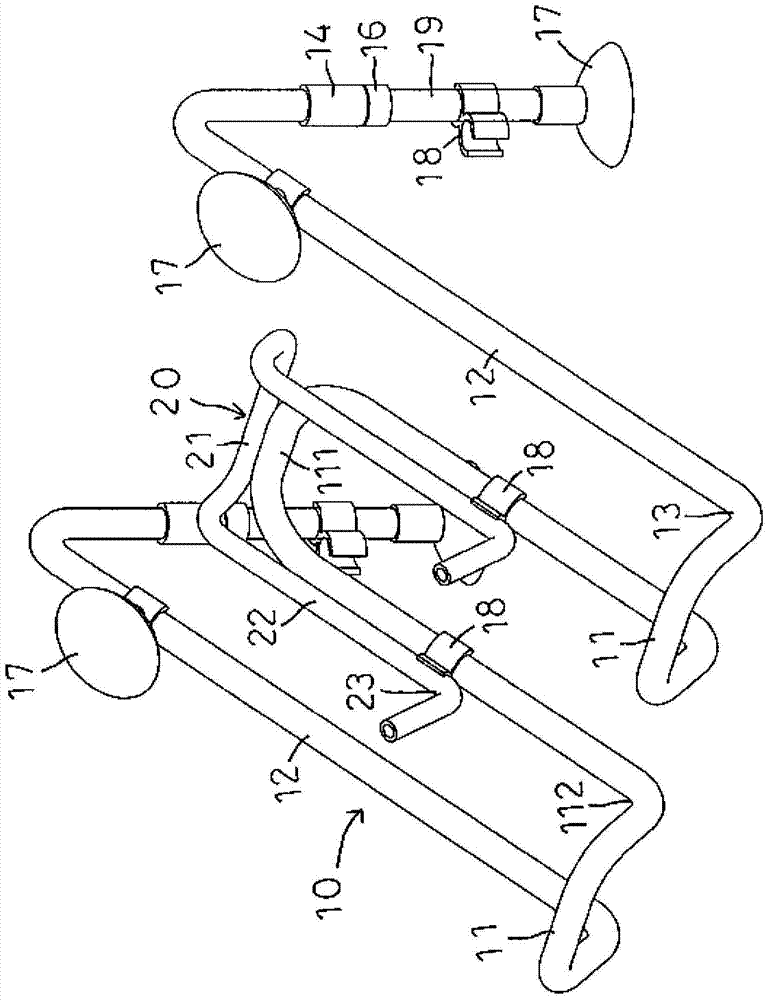

Angle-adjustable holder

InactiveCN104771022AStrong adhesionResilientDigital data processing detailsTelephone set constructionsTablet computerMobile phone

An angle-adjustable holder particularly comprises a main holder and an auxiliary holder, wherein the main holder adopts the structure that a support bar is arranged on a bottom rod; and an arc-shaped third holder is arranged at the connecting part of the support bar and the bottom rod and allows a mobile phone, a tablet computer and other related articles to be vertically and uprightly placed. The angle-adjustable holder has the characteristics that direct operation is allowed; the stability is high; and the size of the main holder as well as ascending and descending of the mobile phone, the tablet computer and the related articles can be adjusted.

Owner:周金河

Moisture-proof and high strength IC carrier tape material

Belonging to the field of material preparation, the invention specifically relates to a moisture-proof and high strength IC carrier tape material. The material is characterized by adopting the technical scheme of: mixing 55-75 parts of polystyrene, 5-15 parts of high density polyethylene, 15-30 parts of organosilicon grafted polyethylene polypropylene, 2-8 parts of an aging-resistant linear triblock copolymer, 1-5 parts of a toughening agent, and 0.3-0.8 part of an antioxidant evenly, then conducting granulation by a twin-screw extruder to obtain a granulated material, and then mixing the granulated material with 3%-5% of black masterbatch and conducting extrusion, thus obtaining the carrier tape material.

Owner:浙江三和塑料有限公司

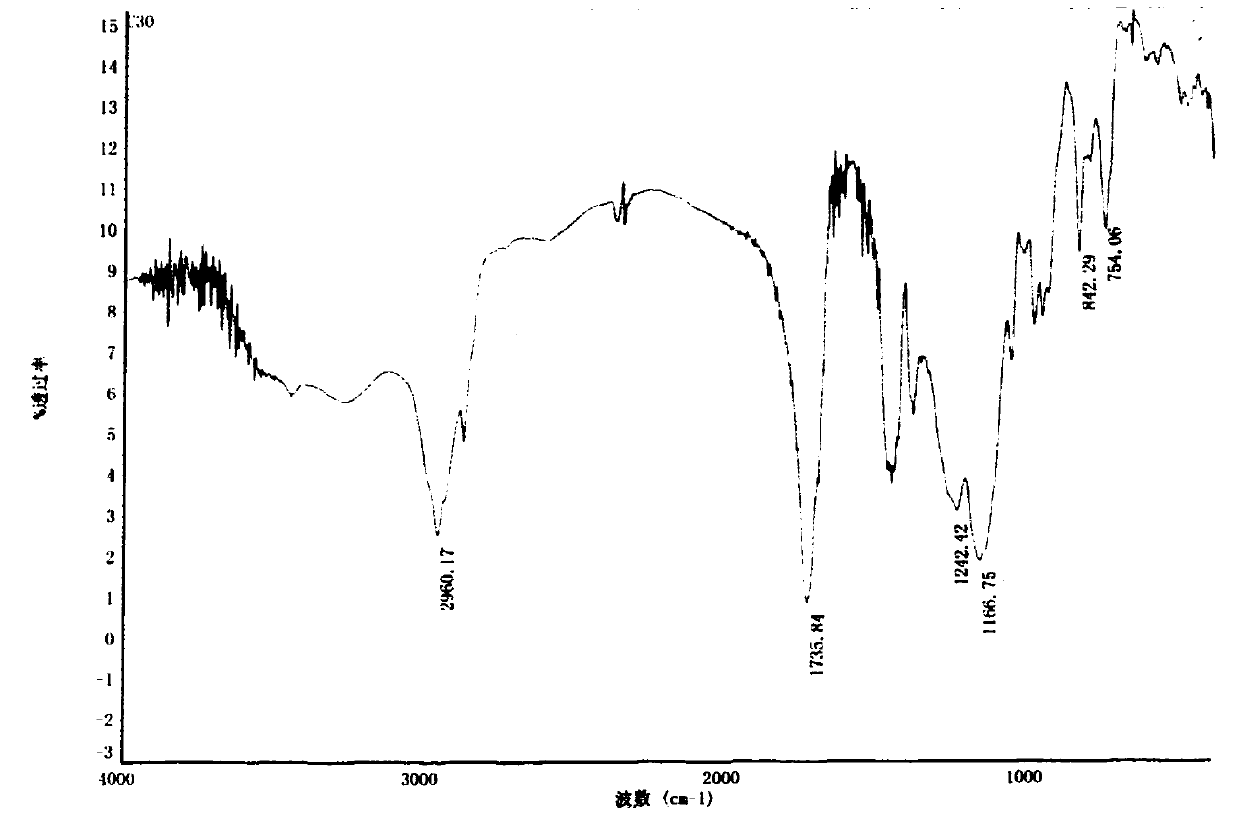

Application of nano-grade water-based narrow molecular-weight distributed acrylic copolyester

The invention discloses application of nano-grade water-based narrow molecular-weight distributed acrylic copolyester, which is used for preparing pure water-based oil ink. The pure water-based acrylic copolyester is synthesized from the following raw materials: basic monomer including methyl methacrylate, methacrylic acid and butyl acrylate, wherein the basic monomer is polymerized in a pure water system under the effect of an emulsifier and an initiator to form acrylic copolyester which has the D50 grain size of 40-65nm and the polydispersity index PDI (Mw / Mn) of less than 1.05. The invention further provides a pure water-based oil ink. According to the pure water-based oil ink, the system viscosity can be reduced without adding an organic solvent, so that independence on VOC-containingsubstances can be eliminated, and human body health is guaranteed. The acrylic copolyester has high drying speed, does not need to add organic drier to greatly reduce VOC emission, has strong adhesionand excellent water resistance without after-tack phenomenon, and has excellent color revealing, excellent strain force and excellent boiling resistance.

Owner:SHANGHAI XIANKE CHEM CO LTD

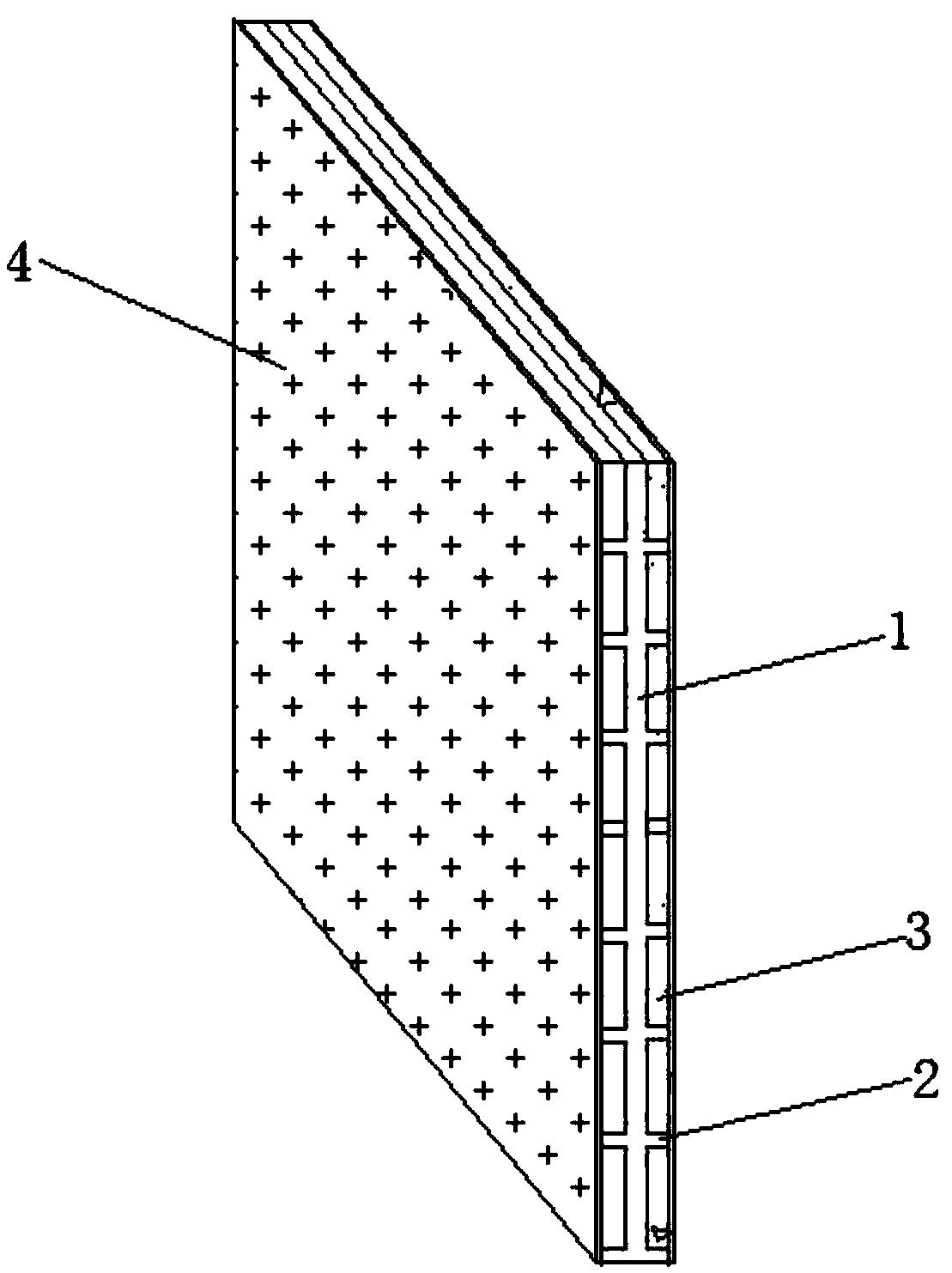

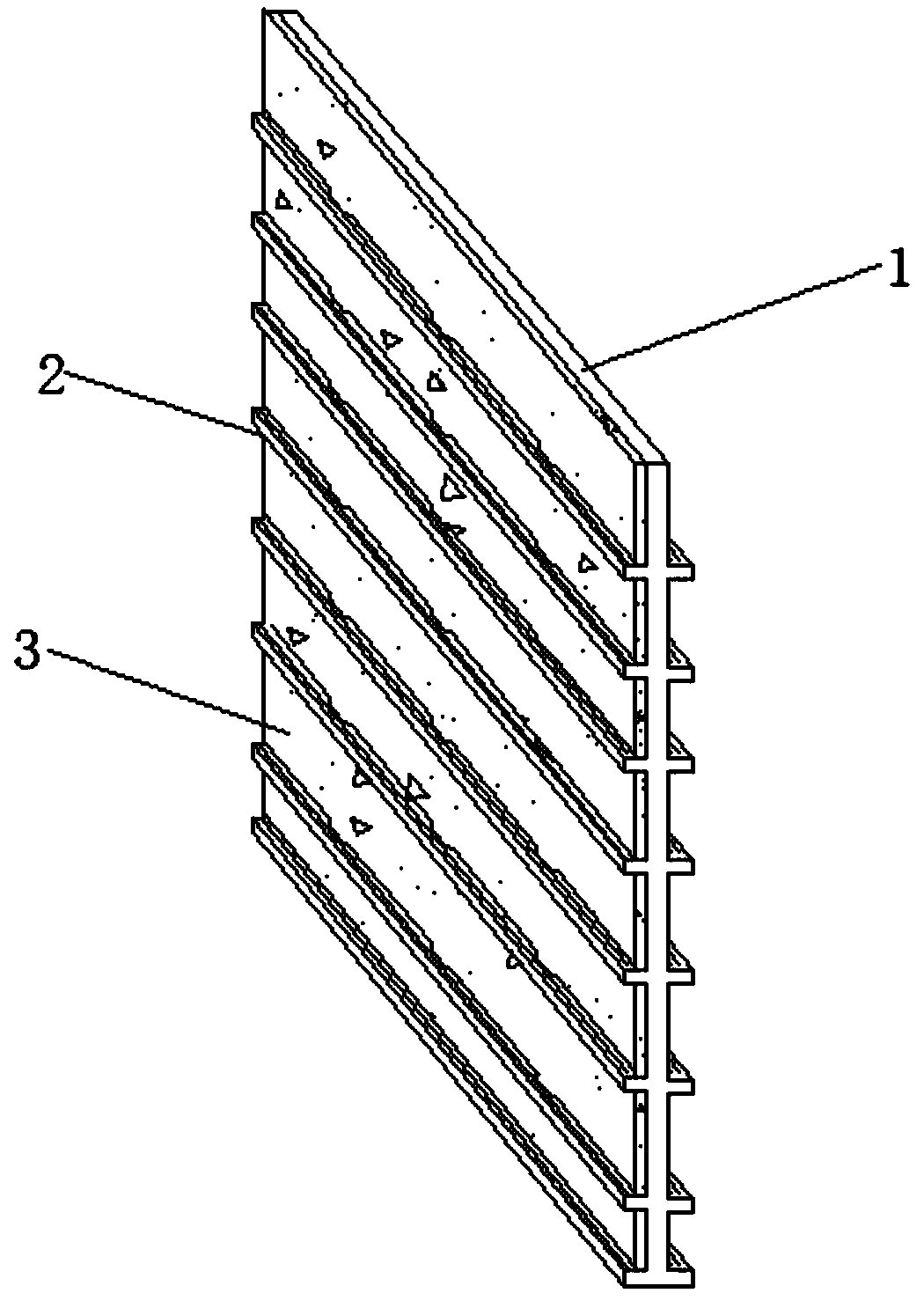

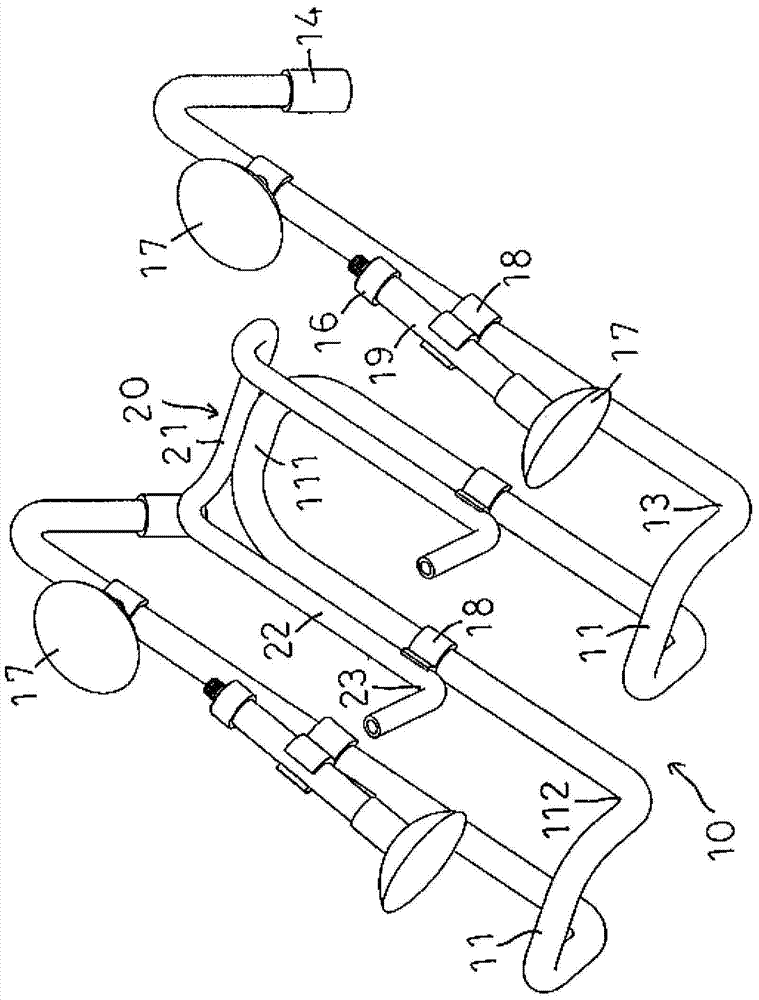

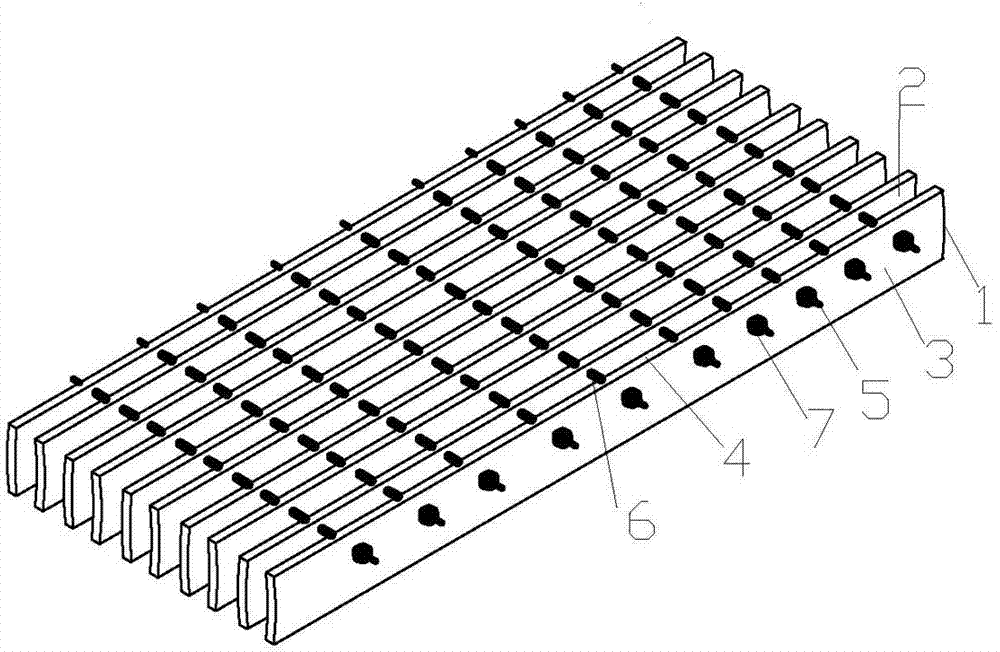

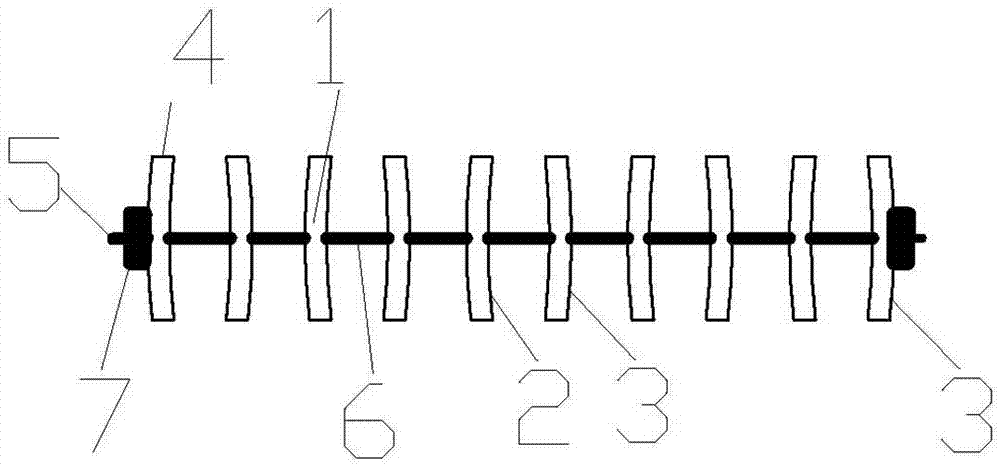

Bamboo excrement-leakage board structure

InactiveCN102919147ALeakage effect is goodConsumableBird housingsCrop livestockAgricultural engineering

The invention relates to devices of livestock raising technique, in particular to a bamboo excrement-leakage board structure. The bamboo excrement-leakage board structure comprises long-strip flat bamboo bars (1) used as supporting main bodies, the bamboo bars (1) arranged side by side are combined in series mode through connecting ribs (5), the bamboo bars (1) are provided with penetration holes used for penetration of the connecting ribs (5), locating devices used to fix positions of the bamboo bars (1) are arranged between the bamboo bars (1) arranged side by side, and locking devices used to lock the whole structure are arranged on outer ends of two bamboo bars (1) disposed at the outermost portions of two sides. The bamboo excrement-leakage board structure is simple and stable in structure, good in excrement-leakage effect and easy to clean, disinfect and install.

Owner:安吉县荣昌竹木制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com