Production technique of low-density high-pressure polyethylene closed-cell foamed plastics plate

A high-pressure polyethylene and foam plastic board technology, which is applied in applications, household utensils, flat products, etc., can solve the problems of short service life, poor impact resistance, unstable performance, etc., and achieve long service life, low surface water absorption, The effect of superior aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment L-600

[0047] Embodiment L-600 test result:

[0048] Recovery rate 97.3%, elongation rate 226 (unbroken), impermeability 5 (unpenetrated), corrosion resistance (30% hydrochloric acid, 30% sulfuric acid, 15% caustic soda, gasoline, diesel, toluene) - no change, resistance Heat resistance - no change, cold resistance - no change, erosion resistance - no change, high and low temperature resistance change - no change, density 120kg / m 3 ; Non-toxic.

Embodiment L-1100

[0049] Embodiment L-1100 test result:

[0050] The recovery rate is 95%, the bending load is 4.6N, the water absorption rate is 3.1%, the tensile strength is 0.96Mpa, the elongation at break is 125%, and the impact resistance is 6.12kg / c m 2, antifreeze 150 times weight without ℃ ℃ Solvent resistance: 30% hydrochloric acid, 28-day corrosion loss of 0.22%; 30% sulfuric acid, 28-day corrosion loss of 0.22% 15%; caustic soda 15%, 28-day corrosion loss of 0.21 %; gasoline, eclipse 28 days loss %, no change; diesel oil, eclipse 28 day loss %, no change; toluene, eclipse 28 day loss 2%, capacity 126kg / m 3 ; No change.

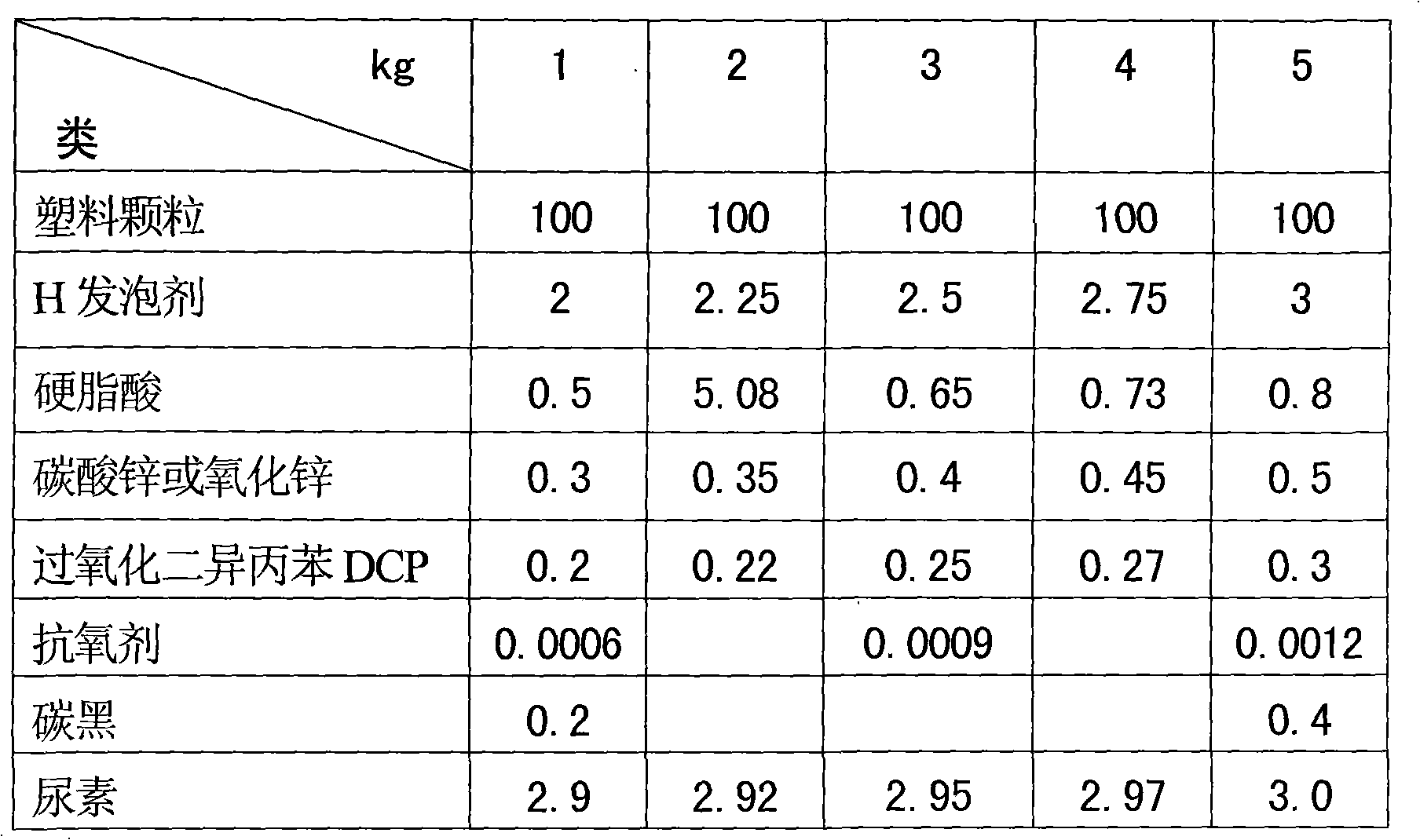

[0051] Table 1

[0052]

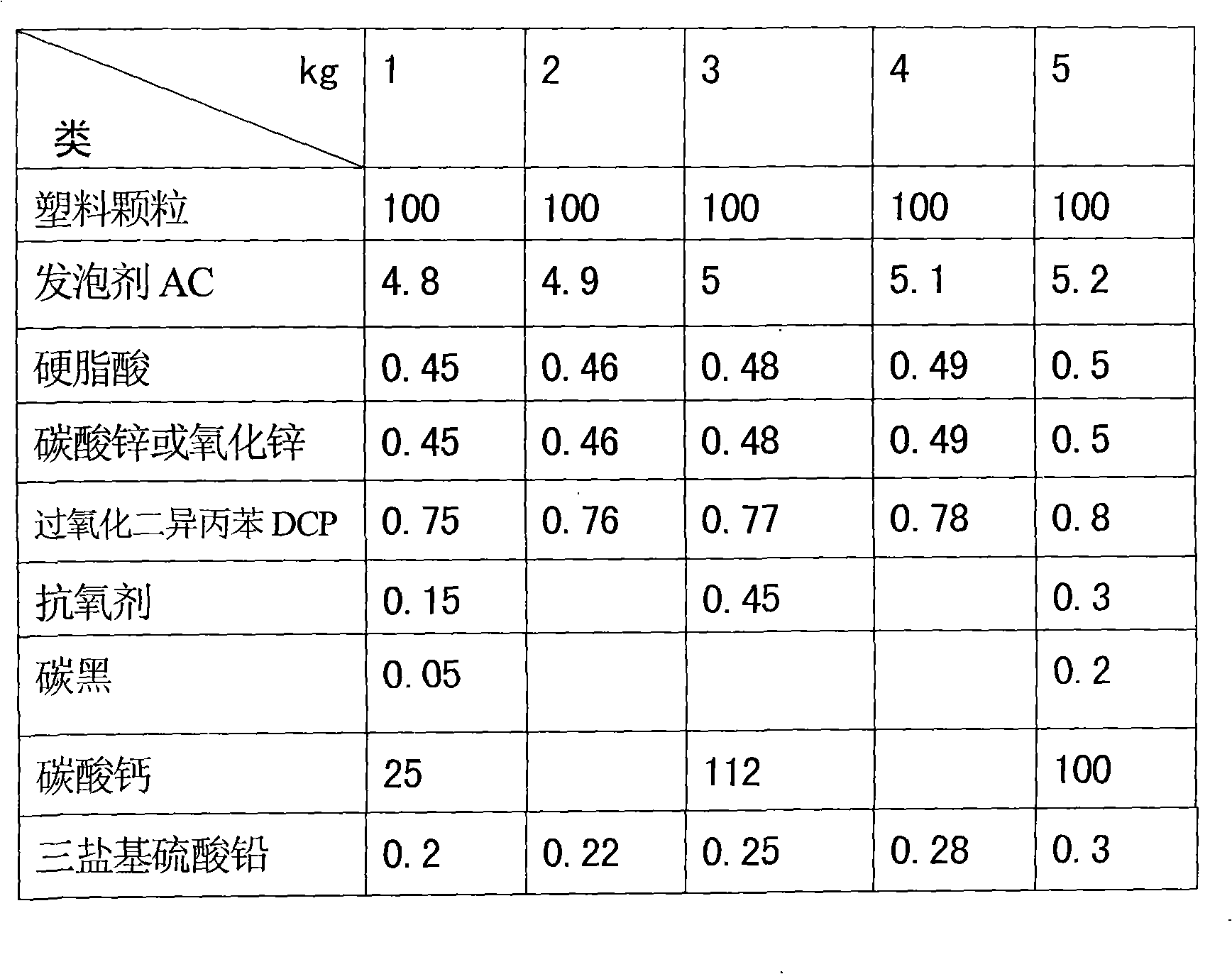

[0053] Table 2

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com