Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Judgment reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

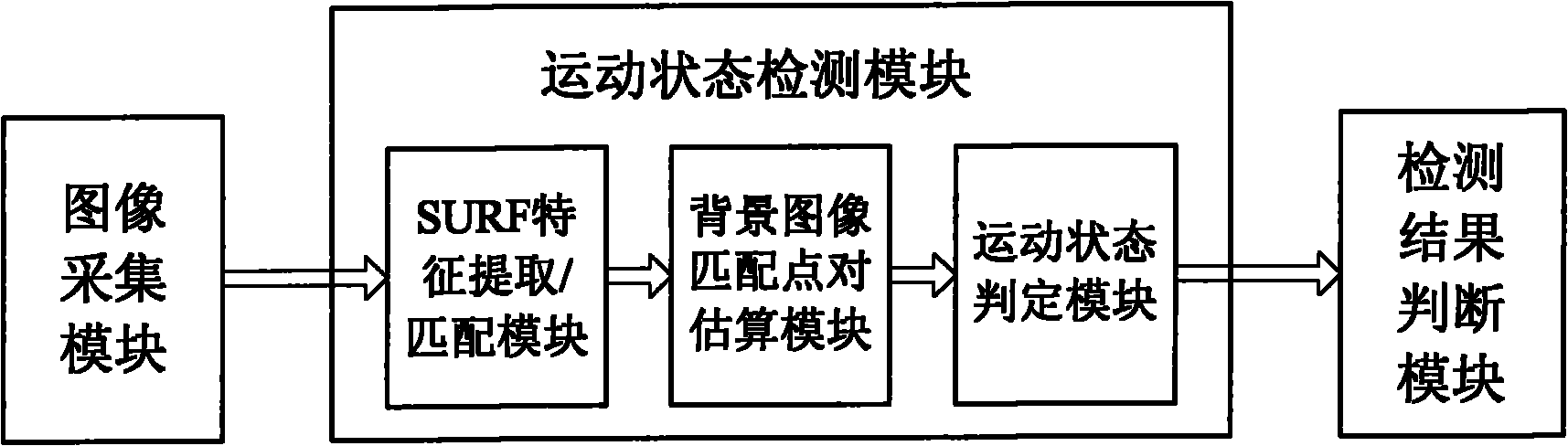

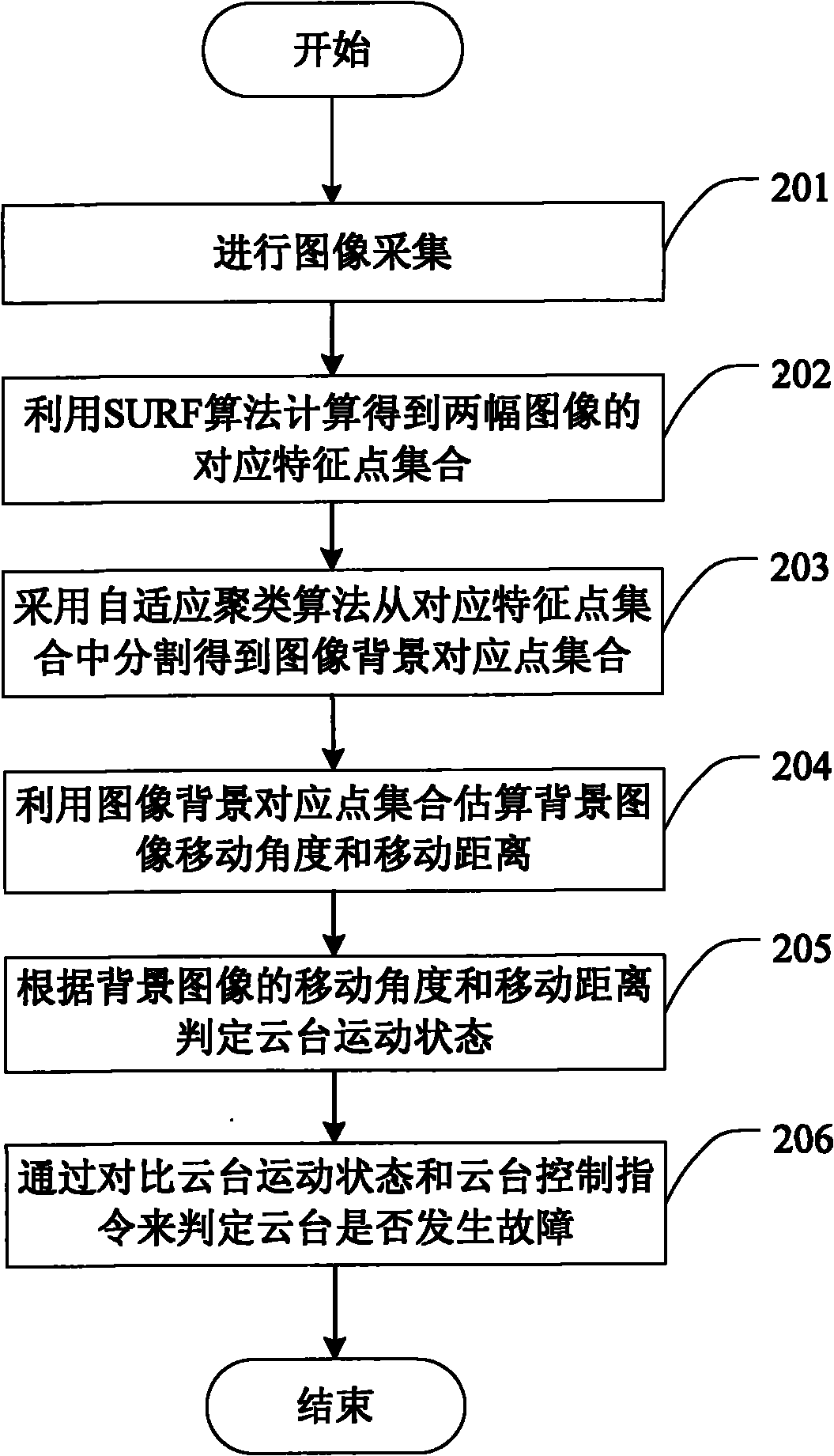

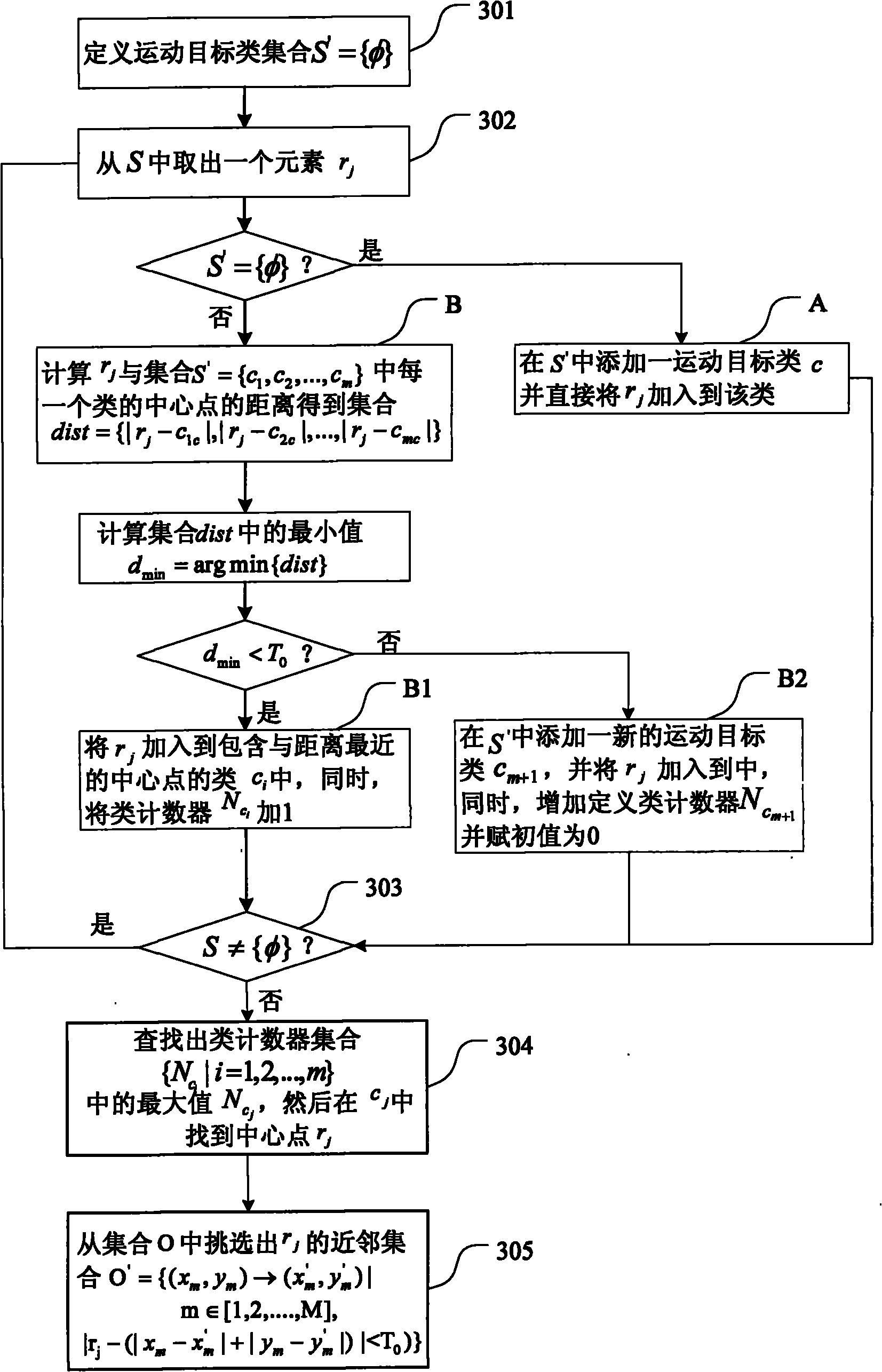

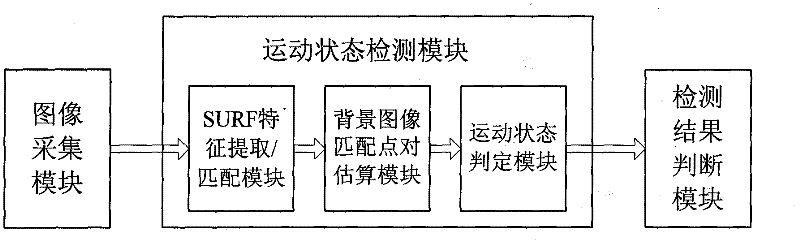

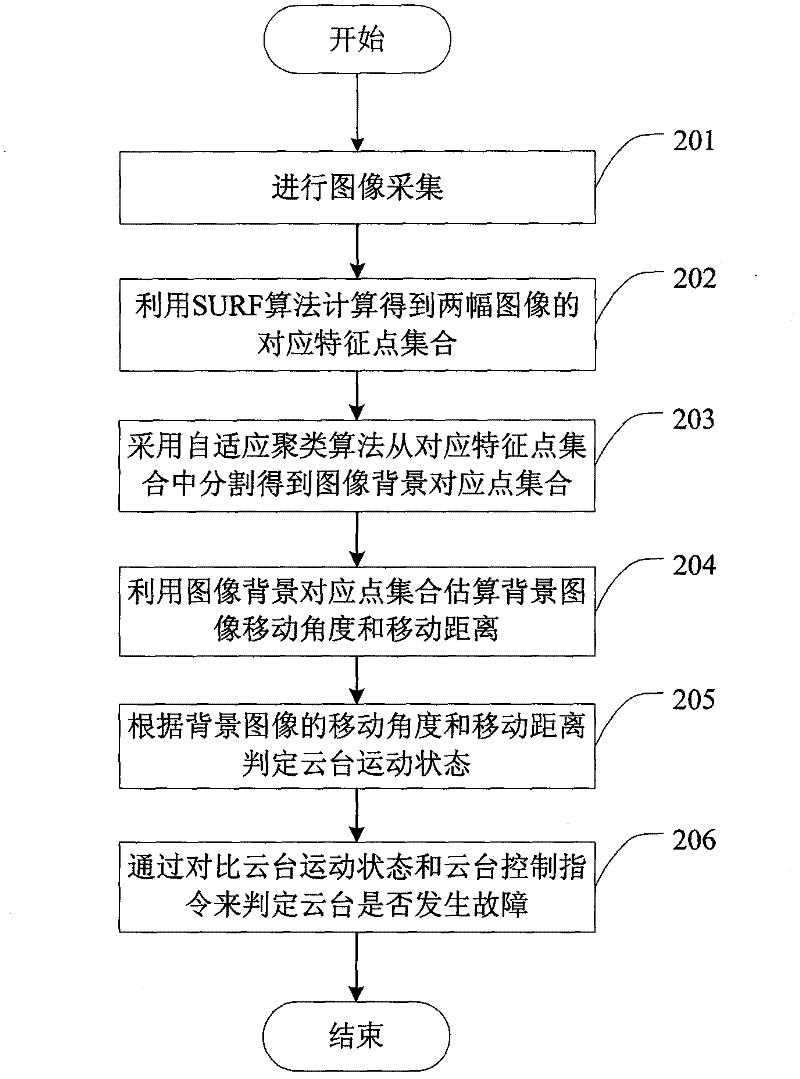

Cradle head fault detecting method and device

ActiveCN101917599AAdaptableExtended Fault Detection CapabilitiesImage analysisClosed circuit television systemsFeature extractionRandom noise

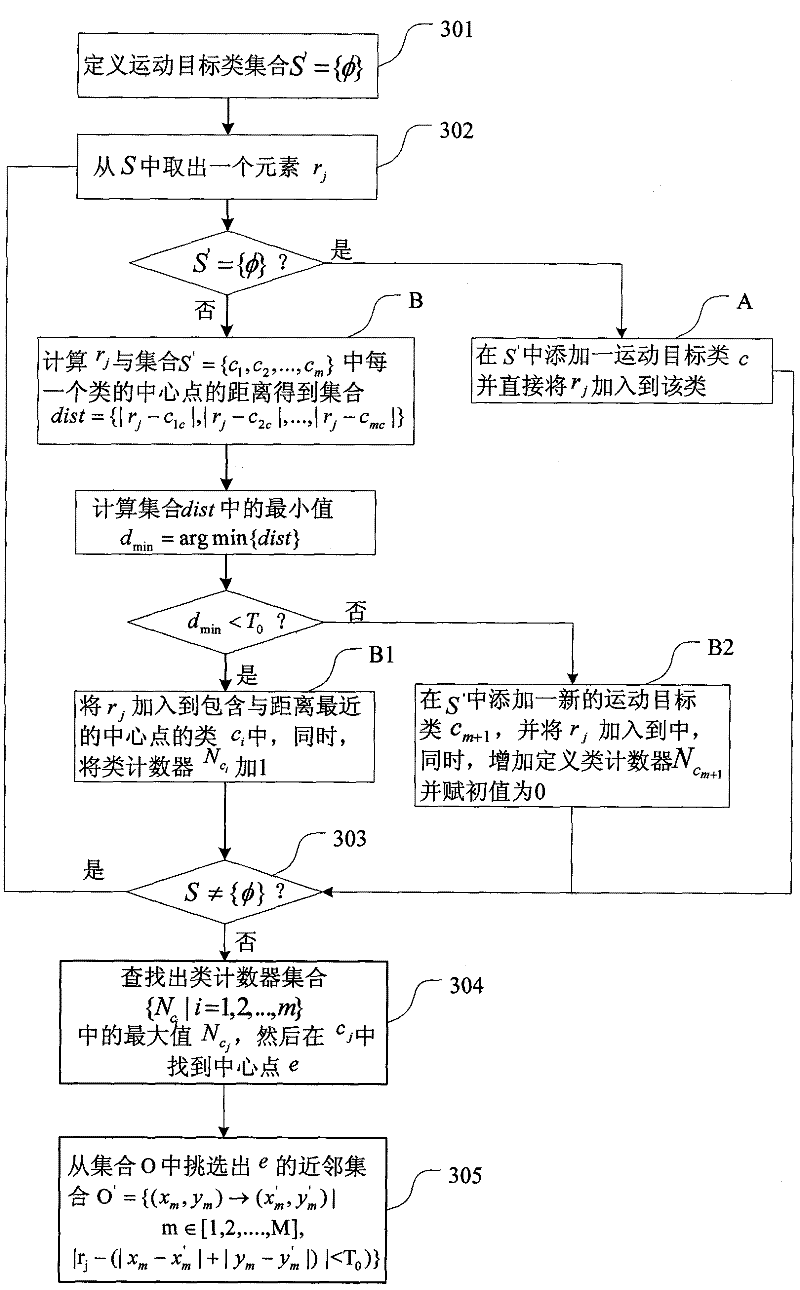

The invention discloses a cradle head fault detecting method and a cradle head fault detecting device. The method comprises the following steps: A, sending a cradle head control instruction to a cradle head to be detected and acquiring continuously collected series images as images to be analyzed; B, extracting and analyzing the characteristics of the images to be analyzed to obtain the change condition of a background image and accordingly determining the change condition of the cradle head to be detected; and C, determining if the movement condition of the background image is consistent with the cradle head control instruction, and accordingly determining if the cradle head operates normally. The fault detection method and the fault detection device have higher adaptability to light change, image foreground target movement interference and random noise interference, has an expanded cradle head fault detection function for detecting the moving or static conditions of the cradle head and the specific movement direction and distance of the moving cradle head and can further estimate the movement speed of the cradle head and more accurately determine the reliability of the cradle head.

Owner:SHENZHEN ZTE NETVIEW TECH

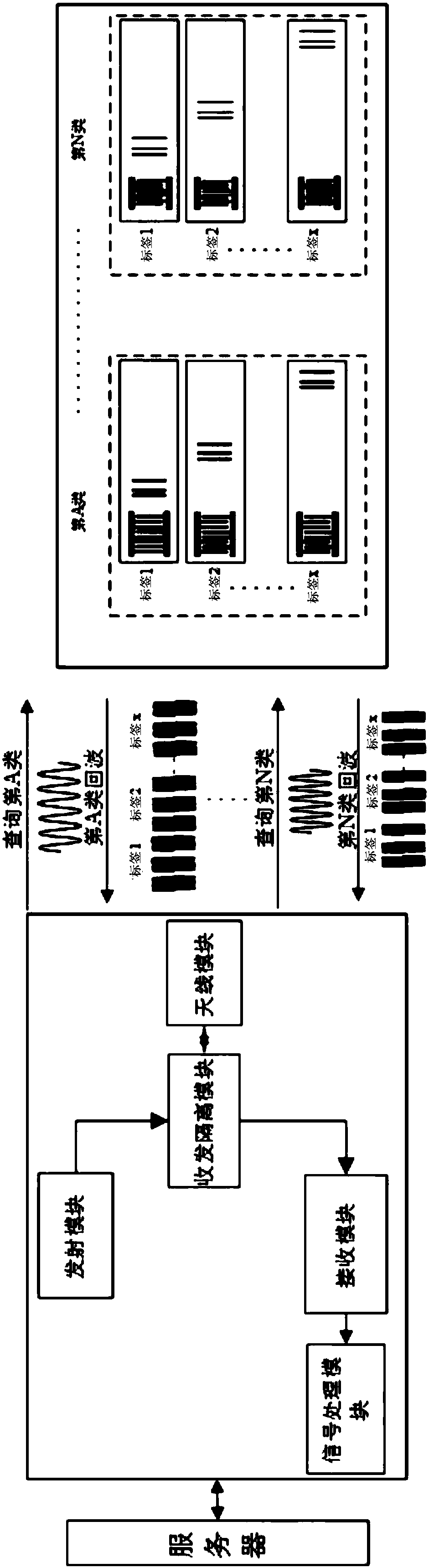

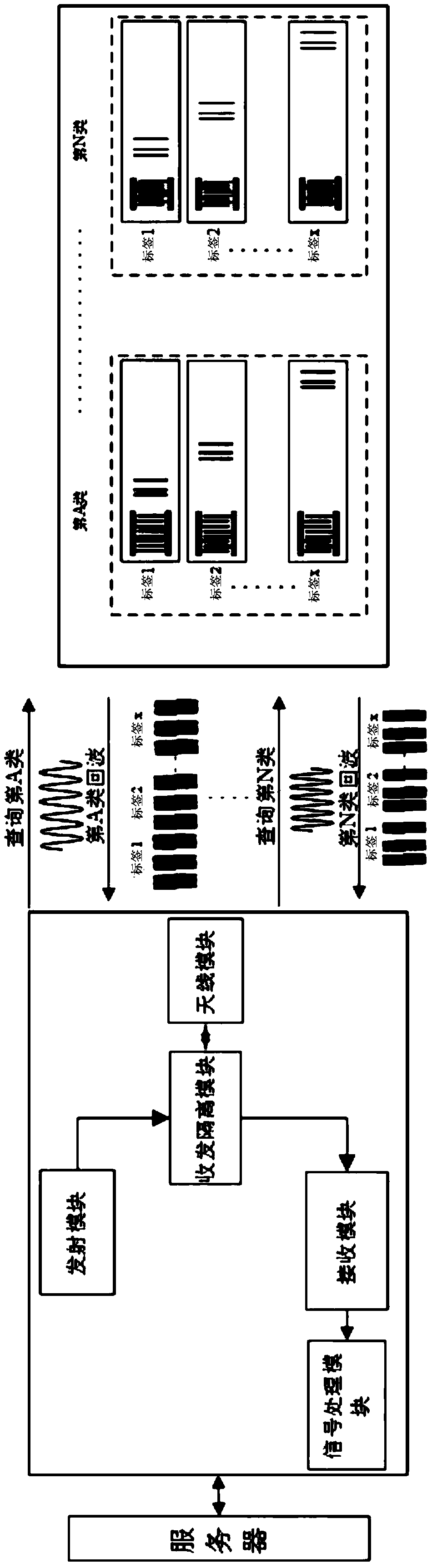

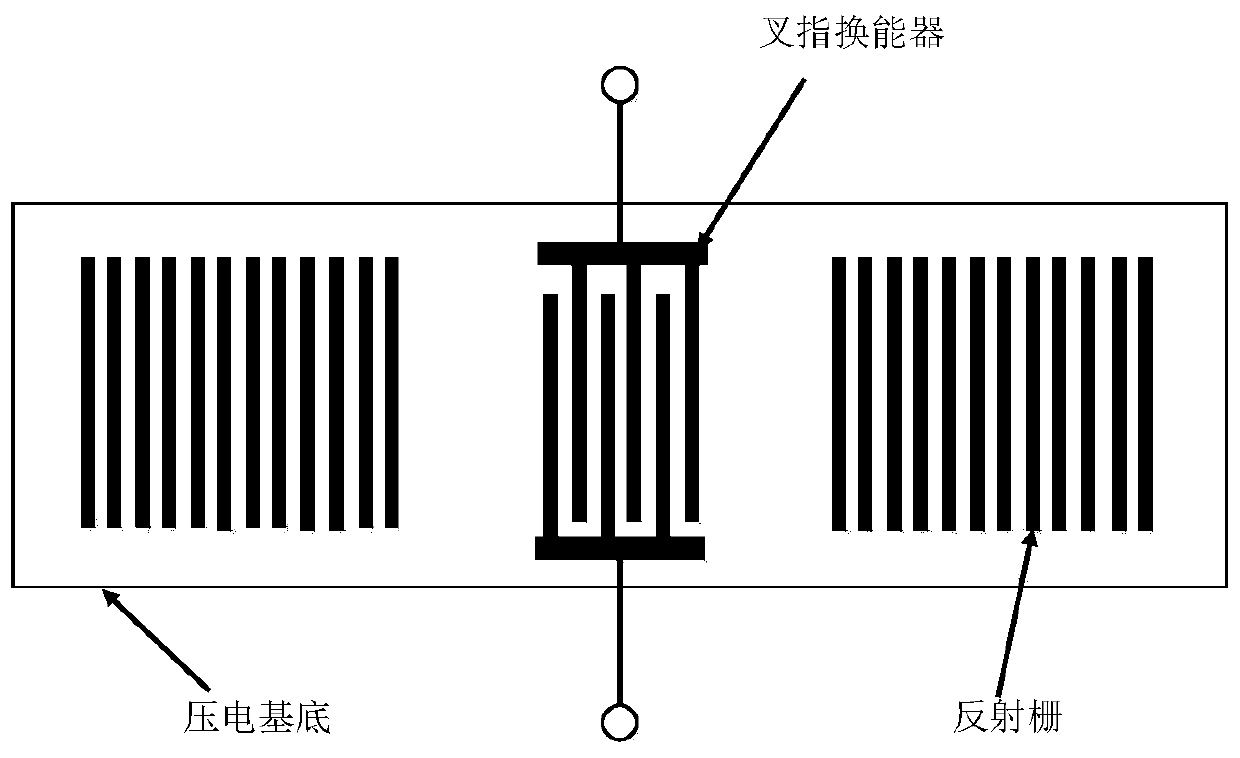

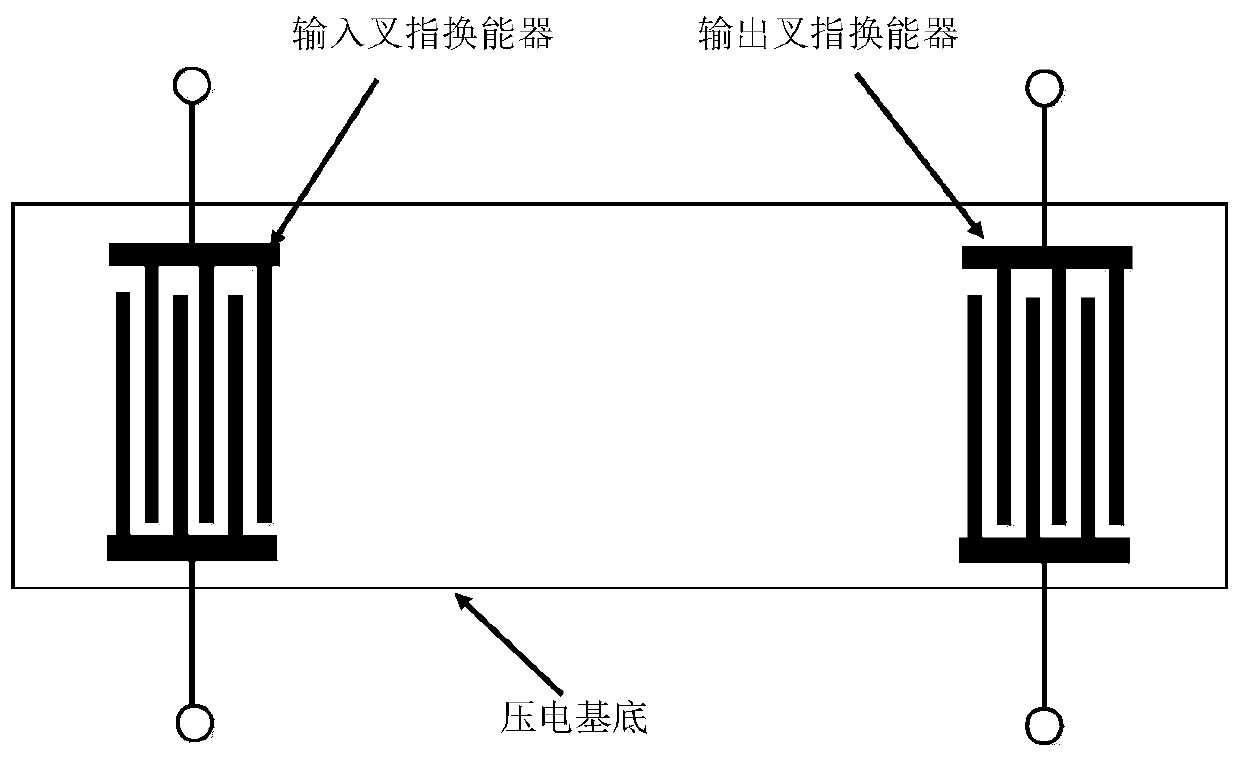

Time division, time division-frequency division, time division-code division, time division-code division-frequency division-combined sound surface wave label temperature-measurement system and method

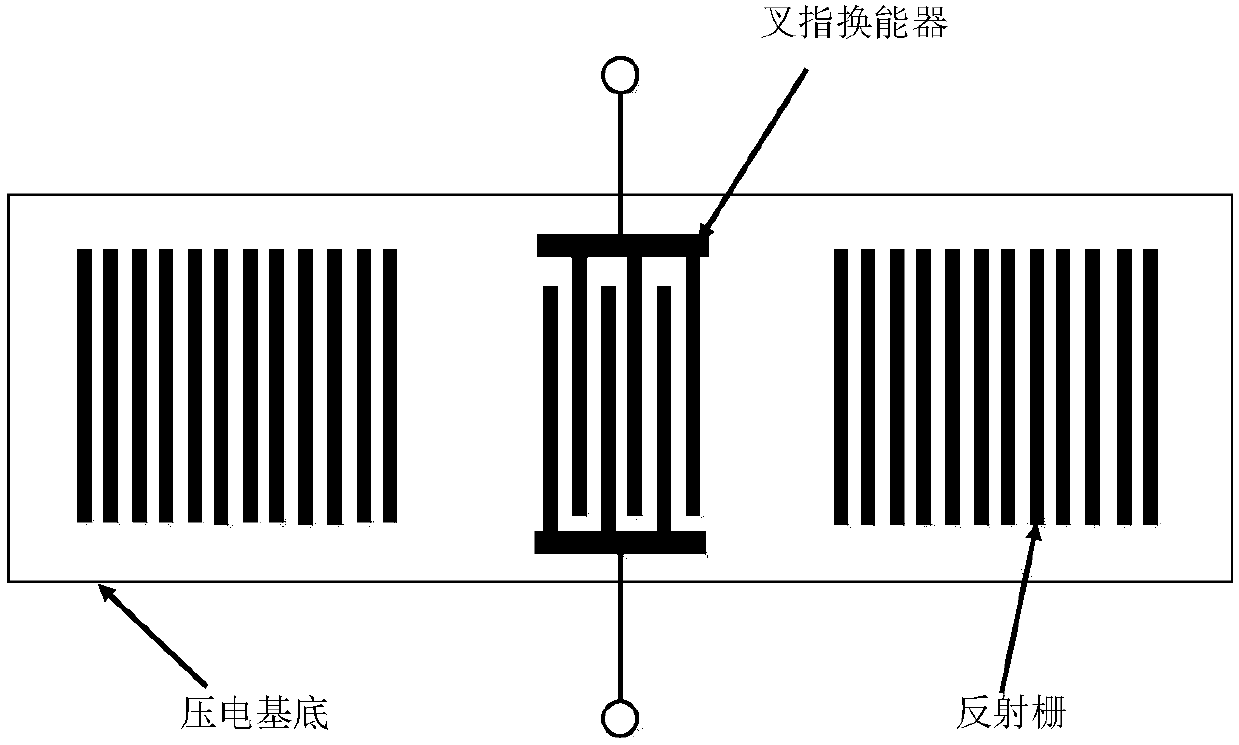

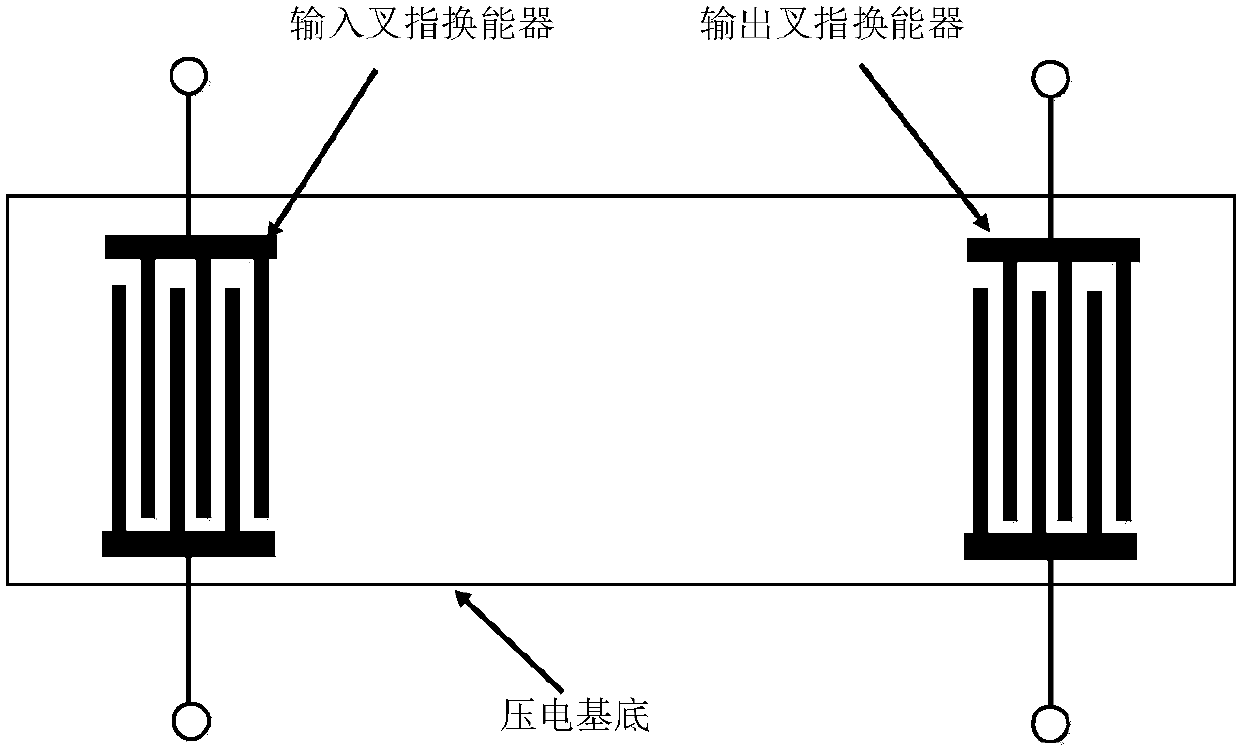

ActiveCN108020344AIncrease the number ofImprove anti-interference abilityThermometers using physical/chemical changesAnti jammingGrating

The invention discloses four surface acoustic wave label temperature measuring systems and corresponding temperature measuring methods. Based on the combination of tie division, time division-frequency division, time division-code division, and time division-code division-frequency division, the multi-node anti-collision temperature measurement is realized. The temperature measuring system is composed of a surface acoustic wave label node, a reader and a server. During the time-division method, different positions of echo pulses are divided into a plurality of surface acoustic wave label nodesaccording to different positions of the reflection gratings of labels. During the time division-frequency division method, time division labels are classified according to different resonance frequencies. During the time division-code division method, time division labels are grouped according to different phase codes of a phase modulation interdigital transducer. During the time division-code division-frequency division-combined method, time division labels are classified firstly and then are grouped. For the temperature measuring systems of different temperature measuring methods, the reader sends out different excitation signals. According to the invention, the ISM and the bandwidth allowed in the national standard are satisfied, and the number of nodes is increased. The verification function is achieved, and the anti-jamming capability is high. The real-time performance is relatively good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

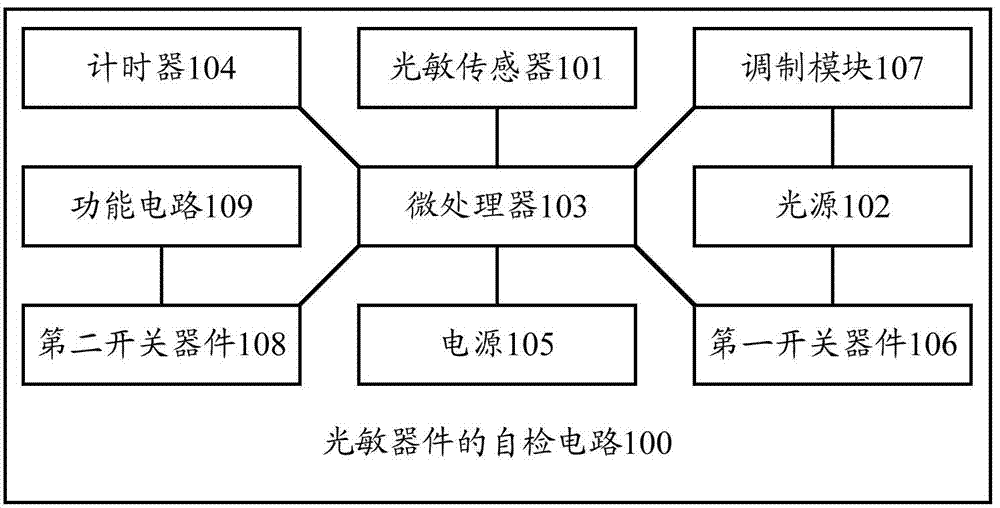

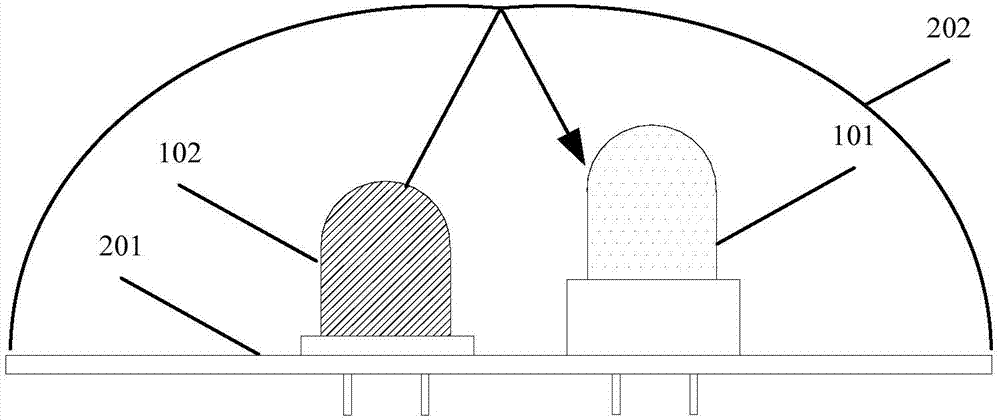

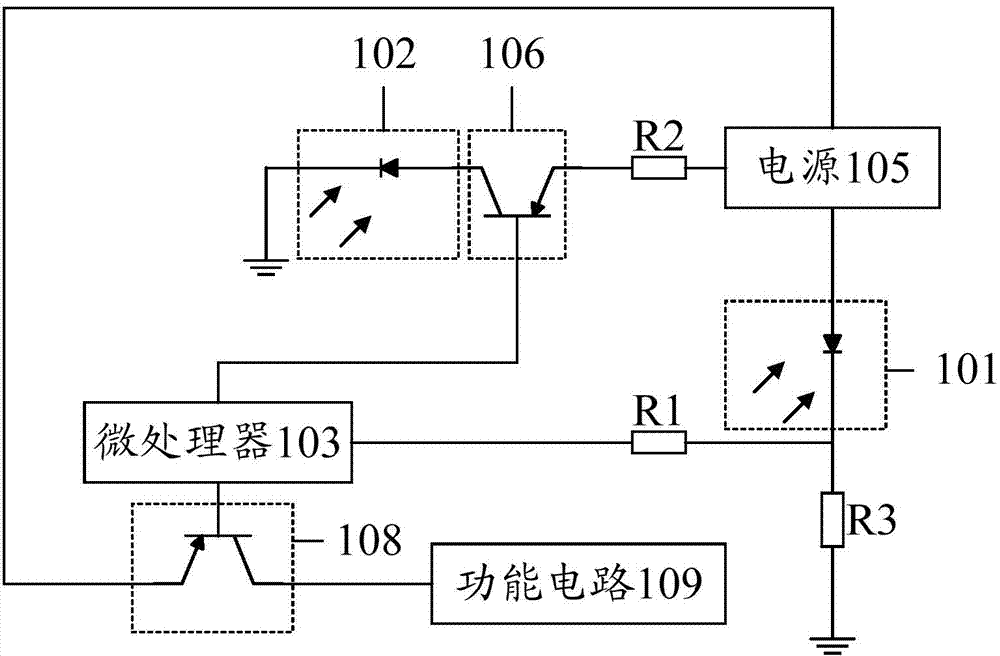

Self-checking circuit, self-checking method and self-checking system for photosensitive element as well as air conditioner

InactiveCN104501851AImplement self-testJudgment reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringSelf checking

The invention provides a self-checking circuit for a photosensitive element. The self-checking circuit comprises a photosensitive sensor, a light source and a micro processor, wherein the light source is arranged within a photosensitive range of the photosensitive sensor and used for providing a detecting light source for the photosensitive sensor in a self-checking process of the photosensitive sensor; the micro processor is connected to the light source and used for controlling the light source to switch on for realizing the self-checking process of the photosensitive element. The invention further provides a self-checking method and a self-checking system for a photosensitive element as well as an air conditioner. According to the technical scheme adopted by the invention, the self-checking process of the photosensitive element is realized so as to conveniently judge whether the photosensitive element effectively works or not; besides, the reliability of the photosensitive element is timely judged, so that the micro processor can be used for accurately obtaining a test signal of the photosensitive element and accurately controlling a functional module.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

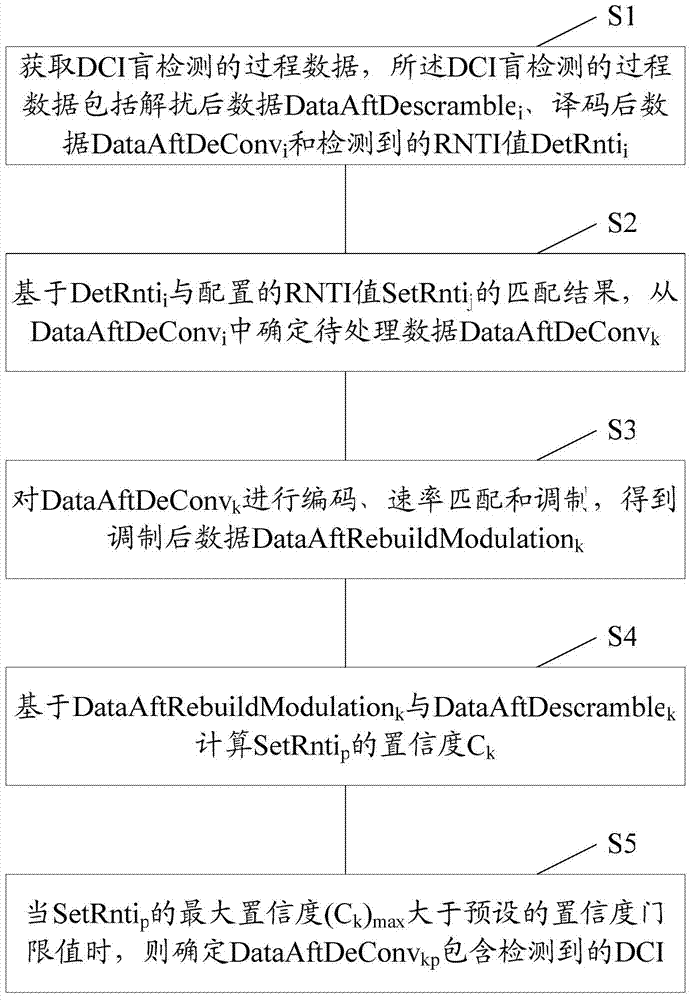

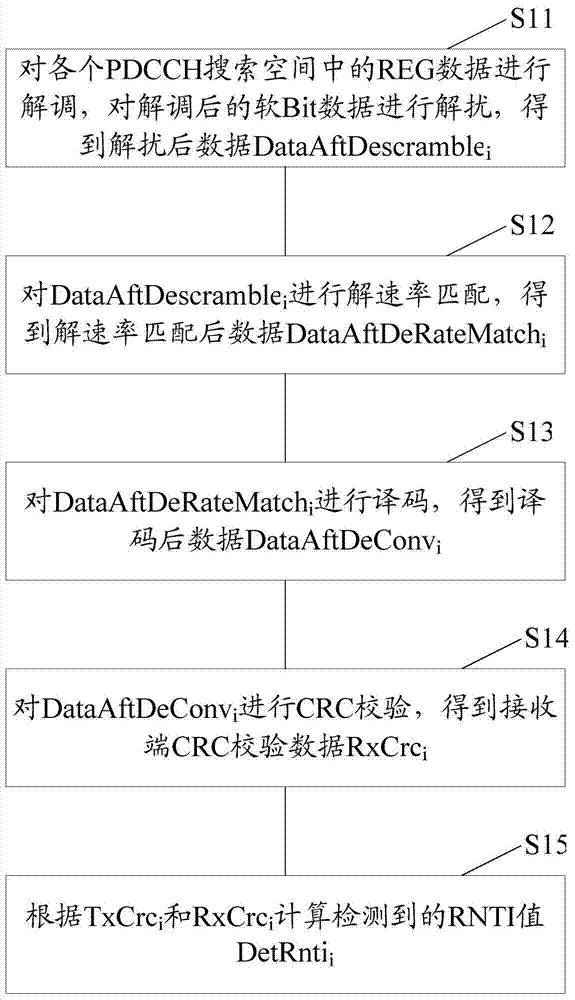

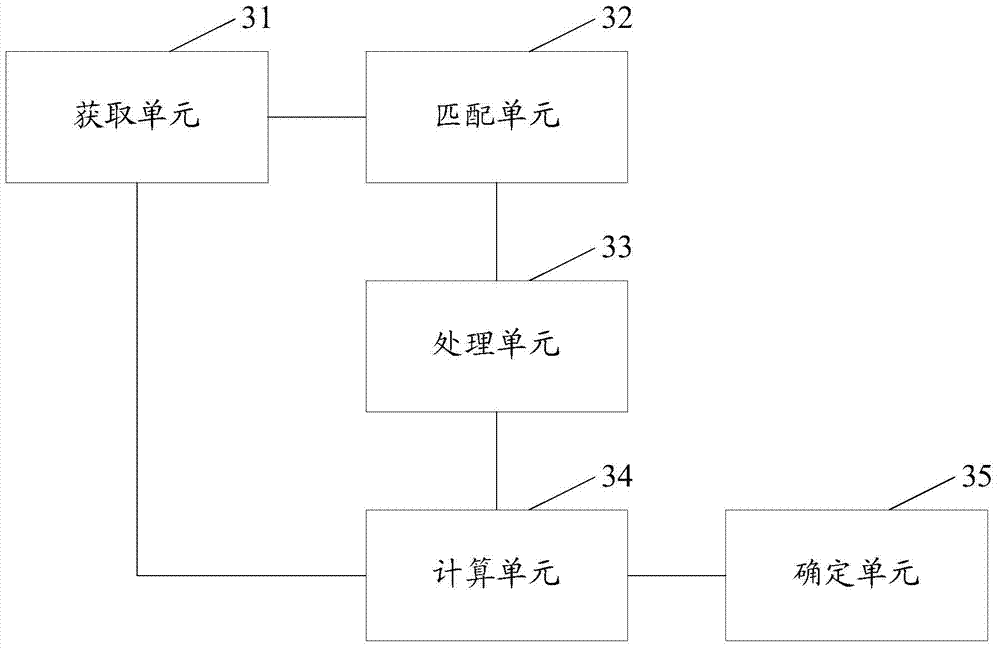

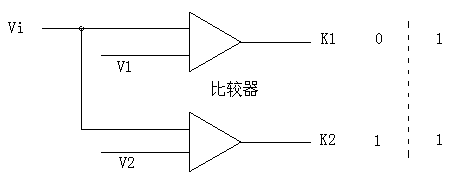

DCI (Downlink Control Information) detection method and device

ActiveCN104753634AJudgment reliabilityEffective filteringPower managementCorrect operation testingSystem stabilityComputer science

A method and device for detecting DCI are provided. The method includes: obtaining intermediate data in DCI blind detection, the intermediate data including descrambled data, decoded data and detected RNTI values; determining data to be processed from the decoded data based on a matching result of the detected RNTI values and configured RNTI values; performing encoding, rate matching and modulation on the data to be processed to obtain modulated data; calculating confidence levels of the configured RNTI values based on the modulated data and the descrambled data; and when a maximum confidence level of the configured RNTI value is greater than a predetermined threshold of confidence level, determining that the data to be processed contains detected DCI. The probability of DCI misdetection may be reduced, and further the accuracy of uplink and downlink data on a mobile terminal and system stability may be ensured.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

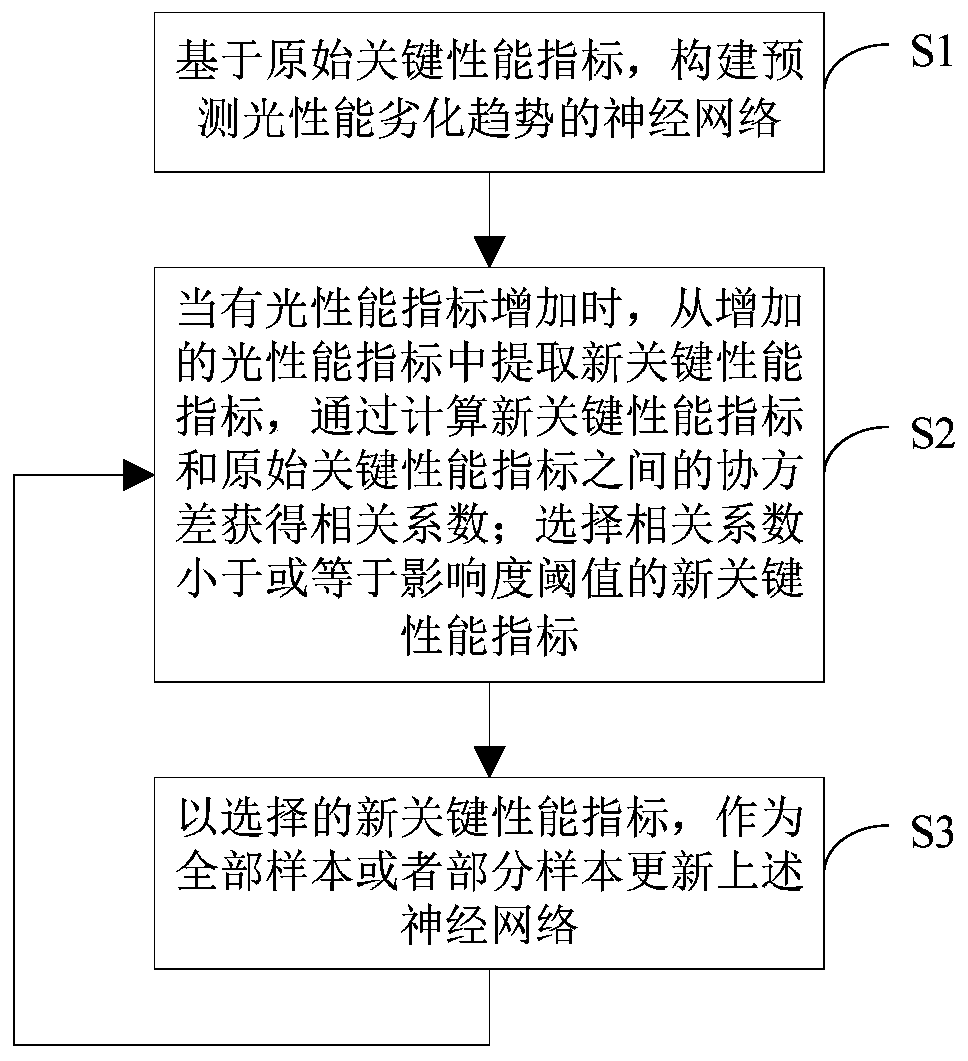

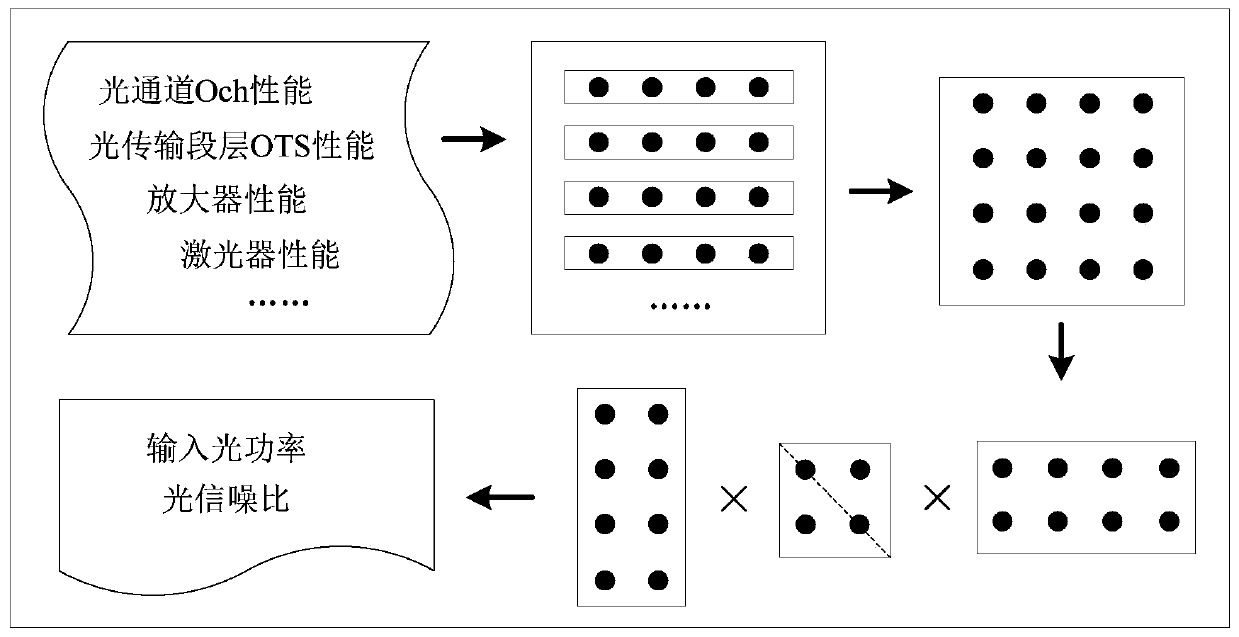

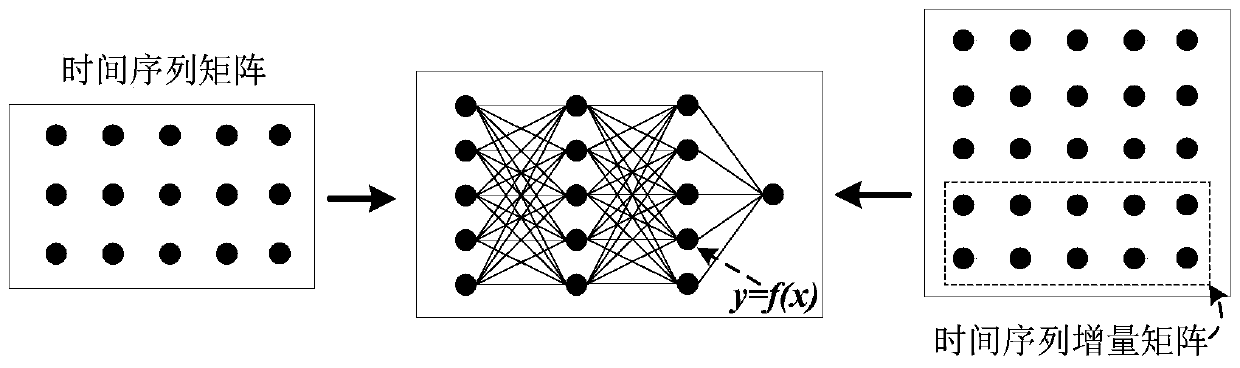

Updating method and system for optical performance degradation trend prediction

ActiveCN110555546AAccurately predict optical performance degradation trendsJudgment reliabilityForecastingNeural learning methodsCorrelation coefficientCovariance

The invention discloses an updating method and system for optical performance degradation trend prediction, and relates to the field of optical communication, and the method comprises the steps: constructing a neural network for predicting an optical performance degradation trend based on an original key performance index; and extracting a new key performance index from the added optical performance indexes, obtaining a correlation coefficient by calculating a covariance between the new key performance index and the original key performance index, and selecting the new key performance index ofwhich the correlation coefficient is less than or equal to an influence degree threshold as all or part of samples to update the neural network. According to the method, when the optical performanceindexes are increased, new key performance indexes are obtained from the optical performance indexes and serve as samples to update the neural network for predicting optical performance degradation, the optical performance degradation trend is continuously perfected, and the prediction accuracy is improved.

Owner:FENGHUO COMM SCI & TECH CO LTD

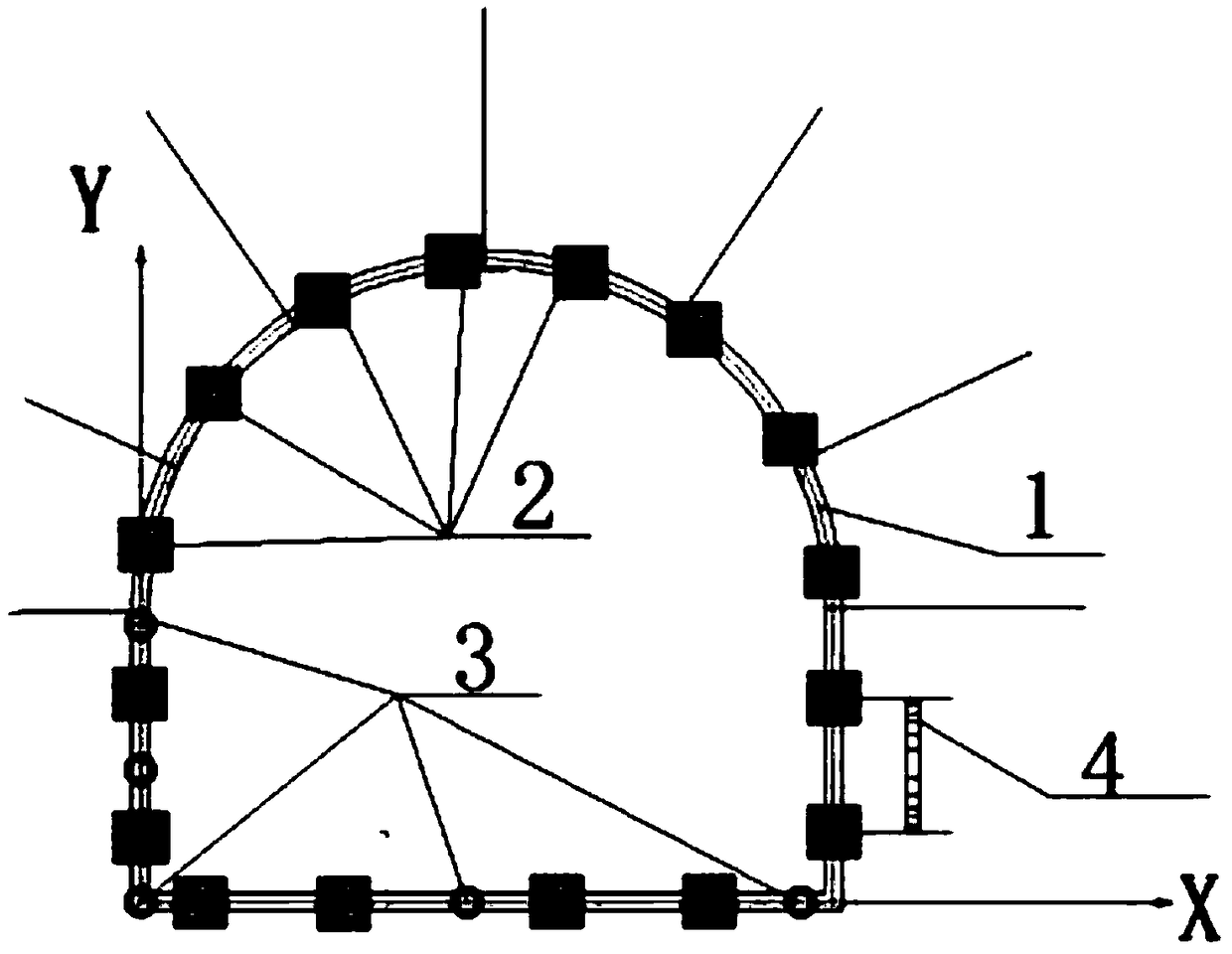

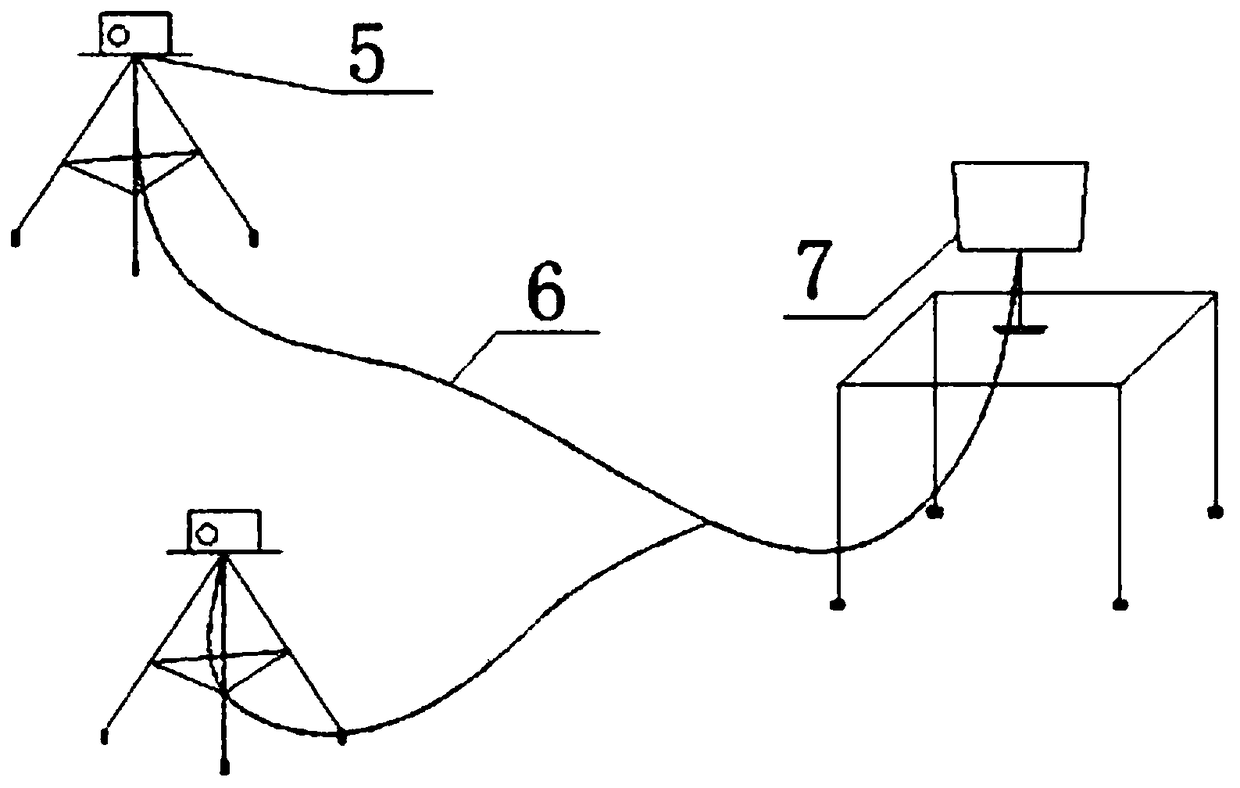

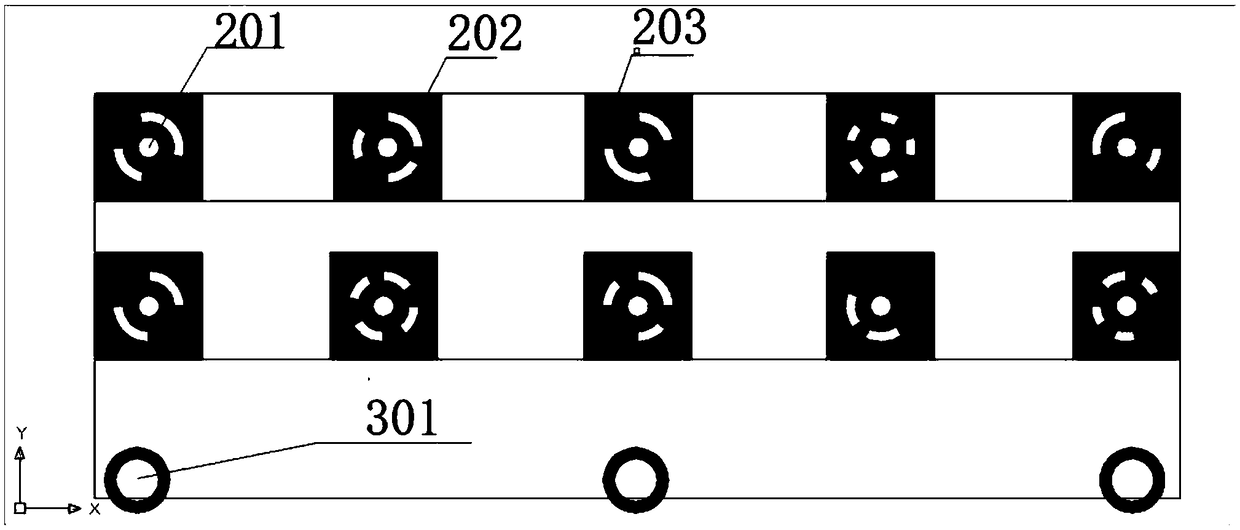

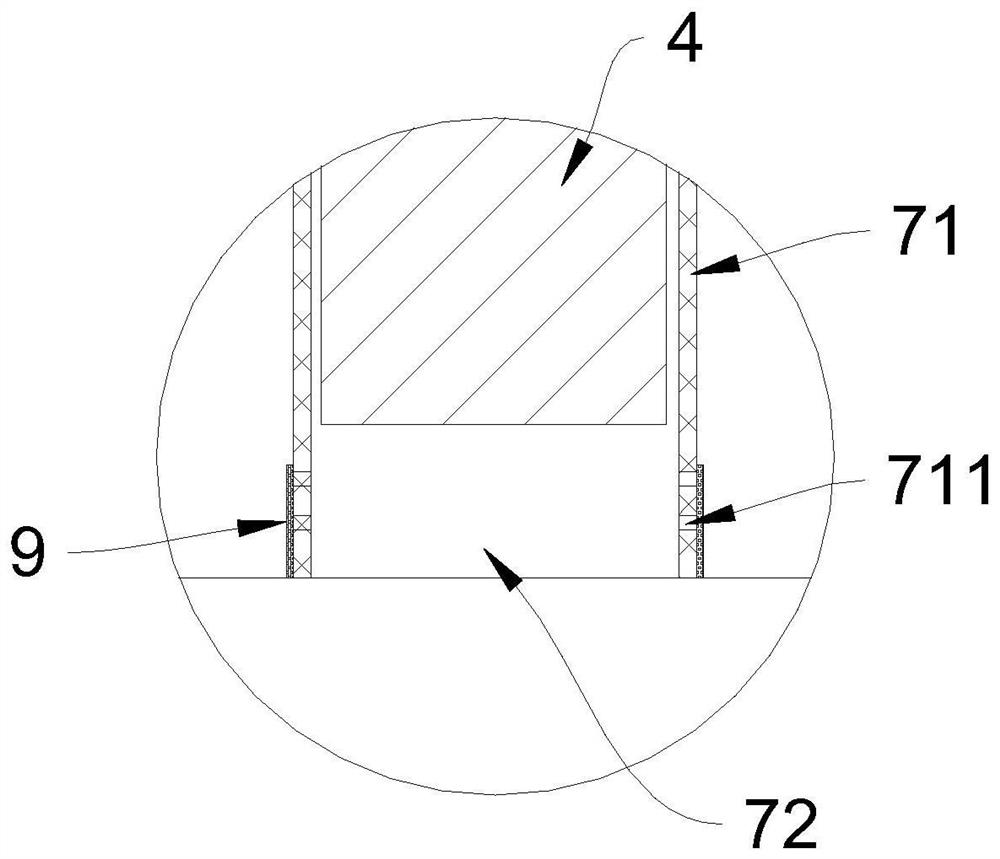

Rapid and accurate monitoring system for deformation of surrounding rock of underground roadway and monitoring method of system

InactiveCN108716891ALong transmission distanceLarge amount of informationUsing optical meansCamera lensEnvironmental geology

The invention discloses a rapid and accurate monitoring system for the deformation of surrounding rock of an underground roadway and a monitoring method of the system. The system comprises a rubber belt, code reference points, non-code reference points, a fixed scale, cameras and a computer; each non-code reference point is composed of a non-code center point, and each code reference point consists of a code center point and annular codes. The monitoring method of the system comprises the steps that S1, the rubber belt is fixed on the section of the roadway, wherein the shape of the rubber belt is identical to that of the section of the roadway; S2, the code reference points and the non-code reference points are inserted in the rubber belt at intervals, and the fixed scale is hung betweentwo code points; S3, the cameras are connected with the computer, and camera lens are aligned with the rubber belt; S4, an automatic photographing mode is adopted for recording the movement process ofthe code reference points and the non-code reference points; S5, collection is completed, and photo information is transmitted to the computer; S6, system measurement software calculates the three-dimensional coordinate changes of the code reference points and the non-code reference points; S7, the deformation of the surrounding rock of the entire roadway is analyzed.

Owner:HENAN POLYTECHNIC UNIV

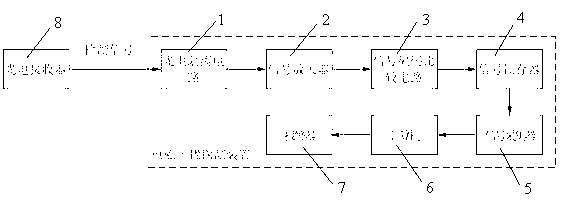

Electromagnetic interference detecting device and method for pinhole detecting equipment

ActiveCN103185843AJudgment reliabilityImprove anti-electromagnetic interference performanceElectrical testingAudio power amplifierElectromagnetic interference

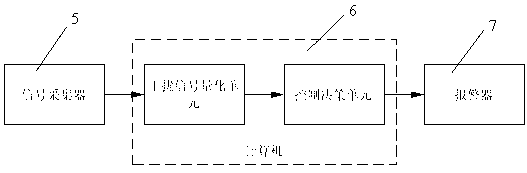

The invention discloses an electromagnetic interference detecting device and a method for pinhole detecting equipment. A detection signal is input into an interference detecting device and enters a signal amplifier (2) through an optoelectronic isolation circuit (1), an output of the signal amplifier is connected with a signal encoding comparing circuit (3), an output of the signal encoding comparing circuit is connected with a signal latch (4), the signal in the signal latch is collected by a signal collector (5) and transmitted to a computer (6), the signal is processed by the computer and output, and the output signal is connected with an alarm (7). According to the electromagnetic interference detecting device and the method for the pinhole detecting equipment, the detection signal is collected, processed, converted into a grading digital signal, sent to the computer and processed so that an interference impulse sequence chart can be displayed, an electromagnetic interference frequency can be analyzed and calculated, and the electromagnetic interference which is over large is alarmed. The electromagnetic interference detecting device and the method for the pinhole detecting equipment can conveniently achieve detection of an environmental electromagnetic interference signal and judgment of interference degree so that a working state of the detecting equipment and the reliability of detecting data can be judged.

Owner:BAOSHAN IRON & STEEL CO LTD

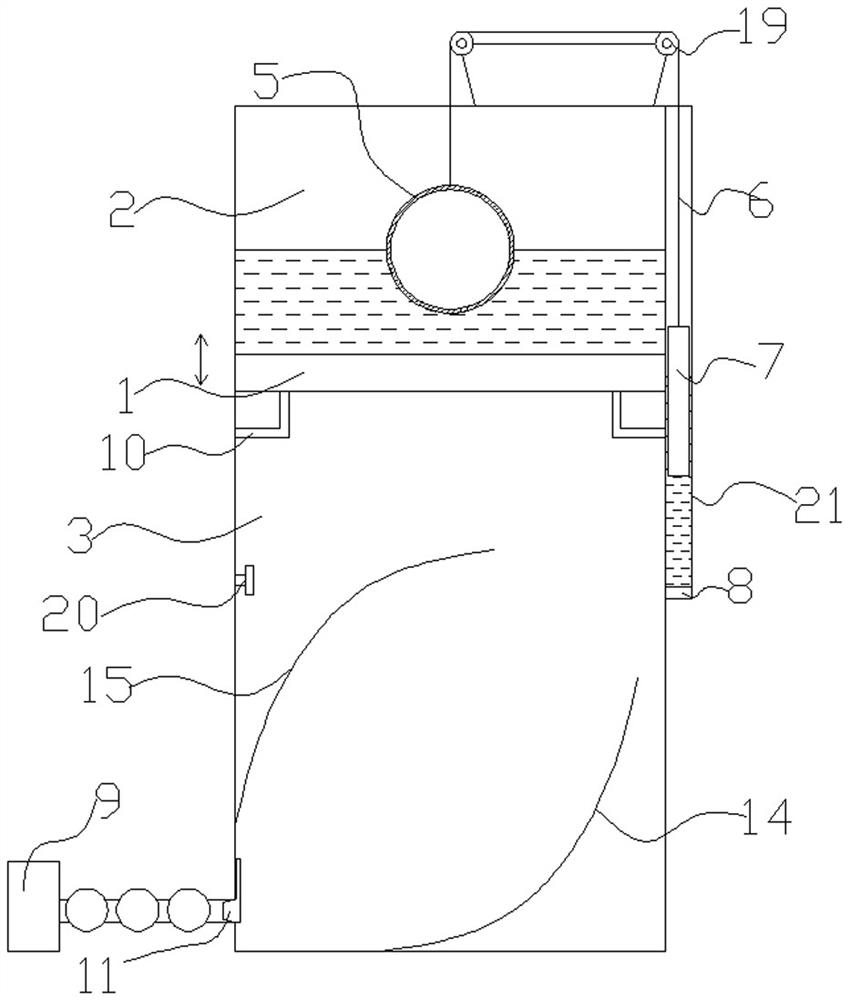

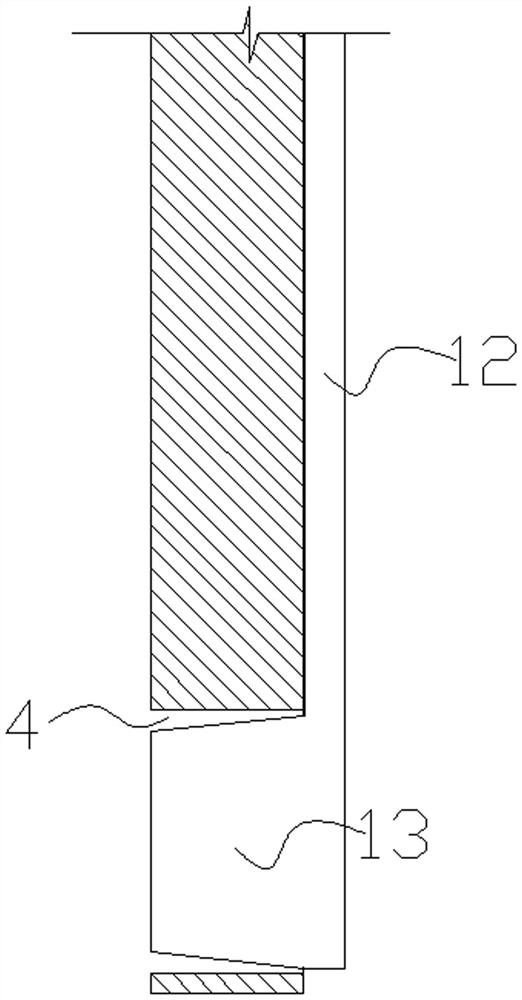

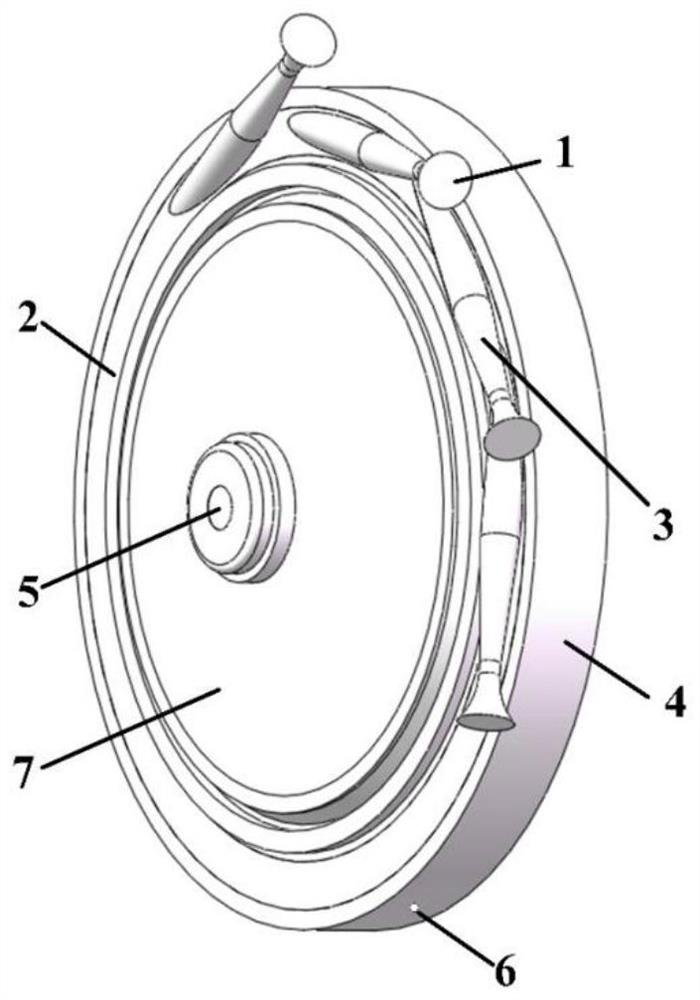

Charger mainboard test equipment for simulating Qi standard wireless charging by using real coil

PendingCN110837040AMeet voltage output requirementsGuarantee authenticityElectronic circuit testingFunctional testingReceiver coil

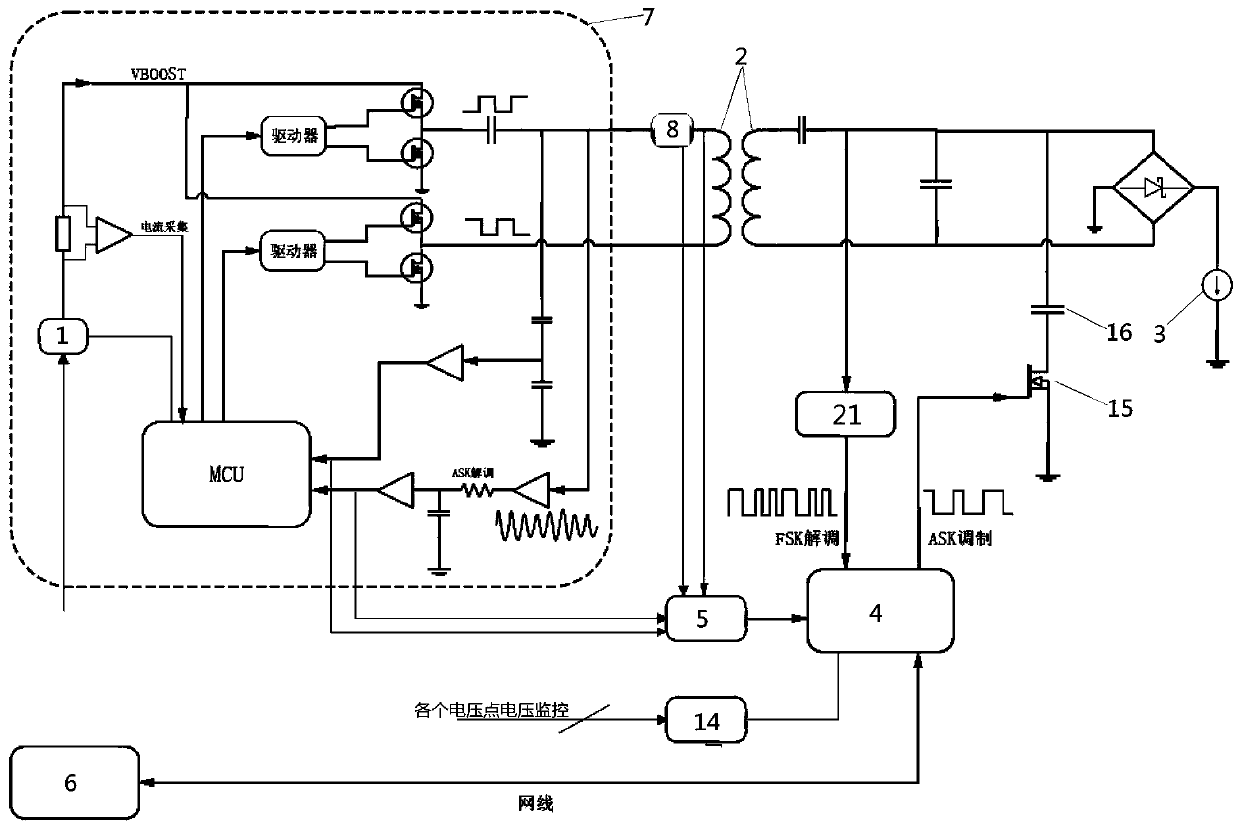

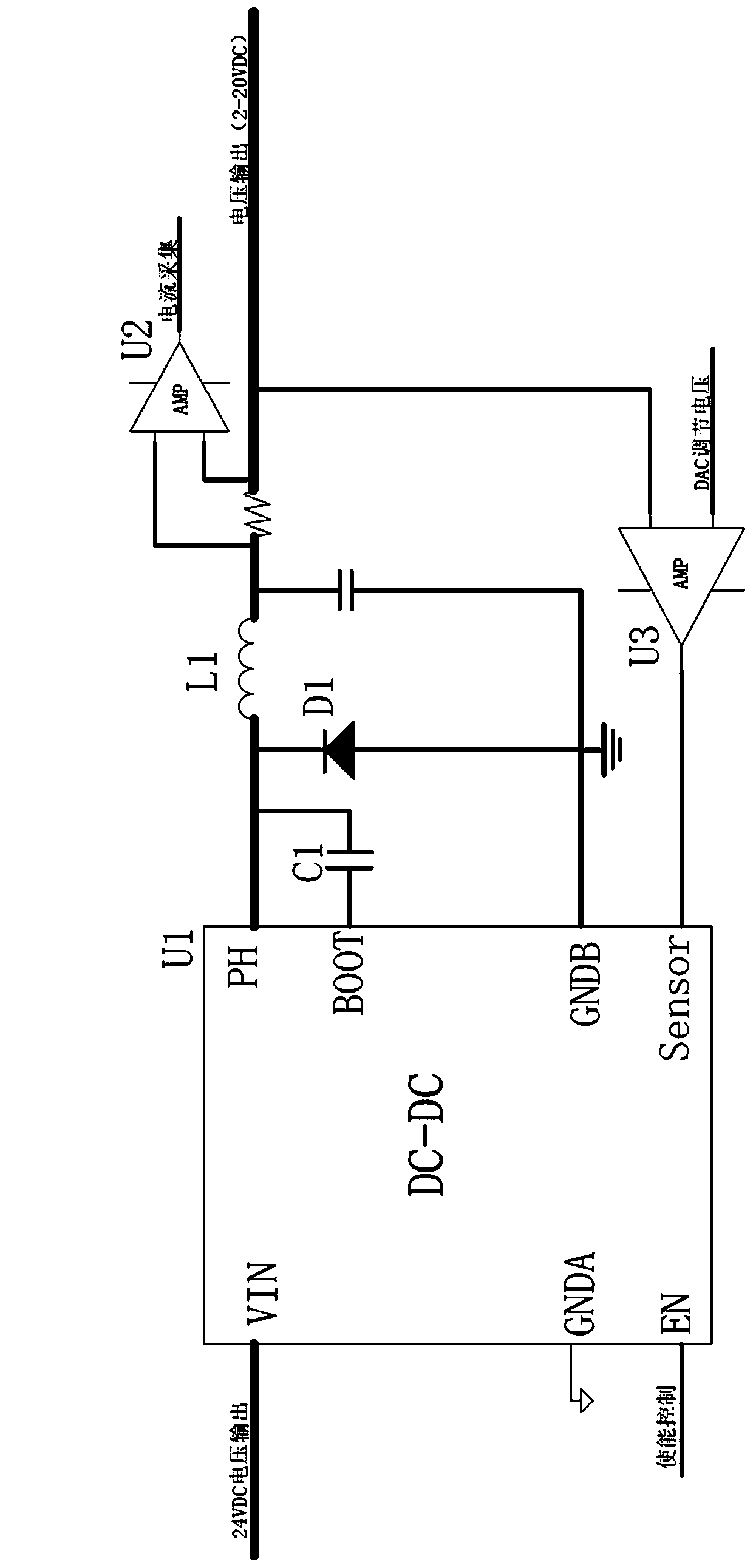

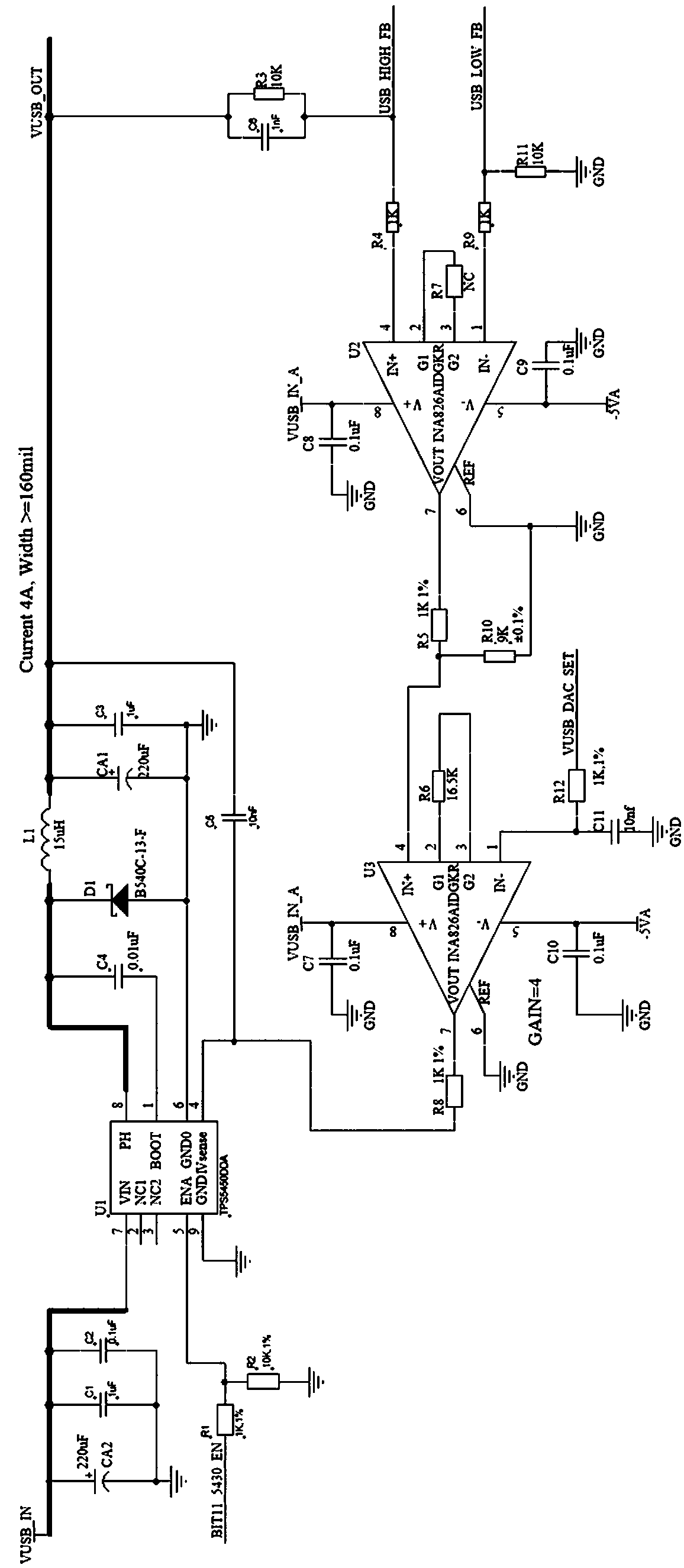

The invention provides charger mainboard test equipment for simulating Qi standard wireless charging by using a real coil, and the equipment is low in cost, high in integration level, complete in function and is suitable for a product manufacturing whole-process test. The equipment comprises a power supply module (1), a transmitting and receiving coil (2), an electronic simulation load (3), an FPGA (4), a plurality of function test modules, a high-speed ADC acquisition module (5) and a peripheral upper computer (6). The power supply module powers up the whole test equipment and a charger mainboard (7) to be tested. One side of the transmitting and receiving coil is connected with the charger mainboard to be tested, the other side is connected with the electronic simulation load, the high-speed ADC acquisition module acquires various signals of the charger mainboard to be tested and uploads the signals to the FPGA, and the function test modules perform function test on the simulated output process of the charger mainboard to be tested, output a test result to the FPGA for analysis, and upload the test result to the upper computer for background processing and storage. The equipmentis applied to the field of wireless charger testing.

Owner:珠海市运泰利自动化设备有限公司

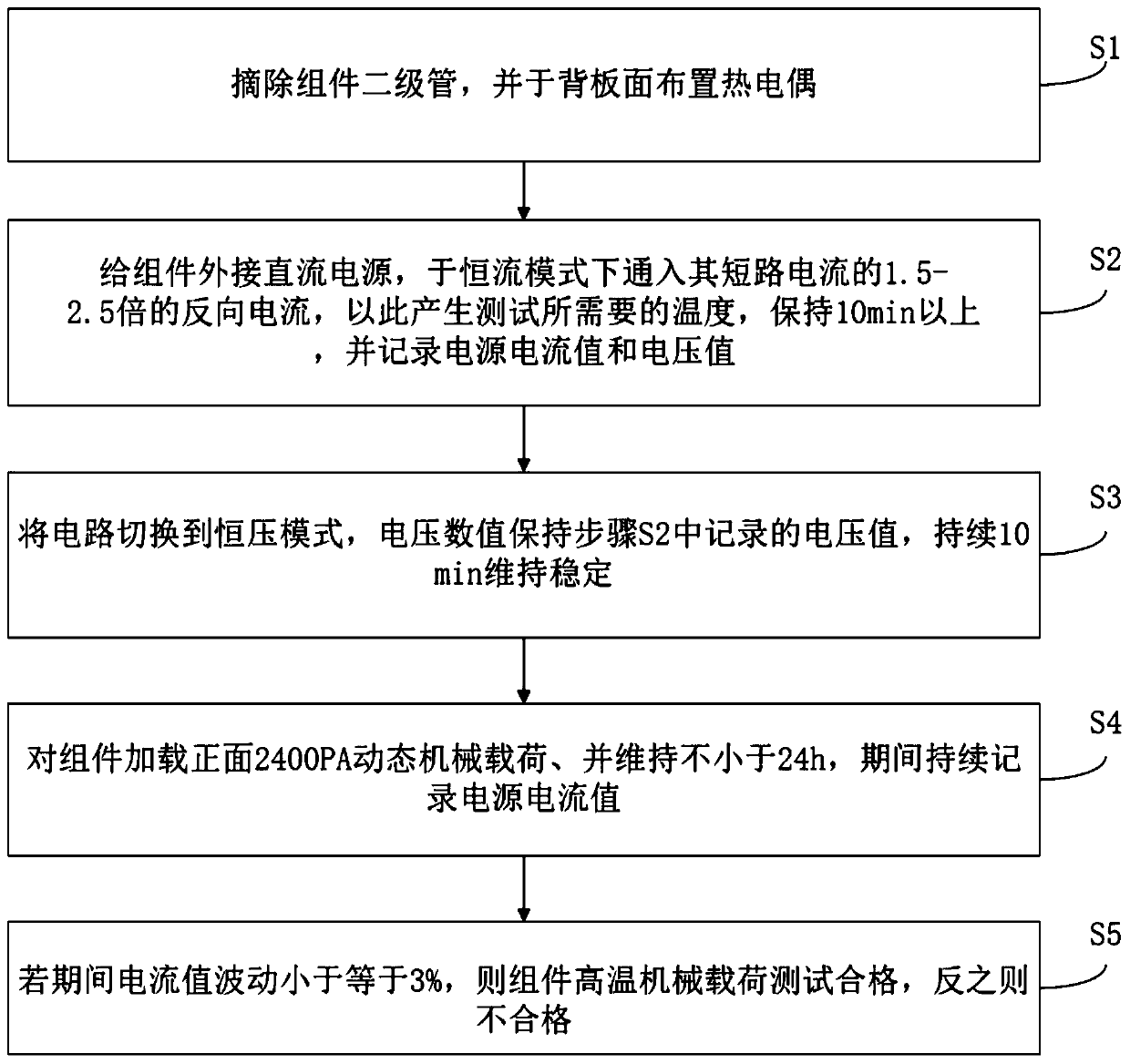

Photovoltaic module reliability detection method

ActiveCN110492844AEffectively judge long-term reliabilityLow costPhotovoltaic monitoringPhotovoltaic energy generationProcess moduleEngineering

The invention discloses a photovoltaic module reliability detection method, which comprises the following steps: S1, removing a module diode, and arranging a thermocouple on a back plate surface; s2,externally connecting a direct-current power supply to the module, introducing reverse current which is 1.5-2.5 times of short-circuit current of the module in a constant-current mode so as to generate temperature required by testing, keeping the temperature for more than 10min, and recording a current value and a voltage value of the power supply; s3, switching the circuit to a constant-voltage mode, keeping the voltage value recorded in the step S2 for 10 minutes, and keeping the voltage value stable; s4, loading a front 2400PA dynamic mechanical load to the module, maintaining the front 2400PA dynamic mechanical load for not less than 24 hours, and continuously recording a power supply current value during the period; and S5, if the current value fluctuation in the period is less than or equal to 3%, determining that a high-temperature mechanical load test of the module is qualified, otherwise, determining that the module is unqualified. According to the invention, a mode of externally applying a high-temperature mechanical load is adopted, so that the new process module is subjected to mechanical deformation at high temperature to verify the long-term reliability of outdoor useof the module, and is very worthy of popularization.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

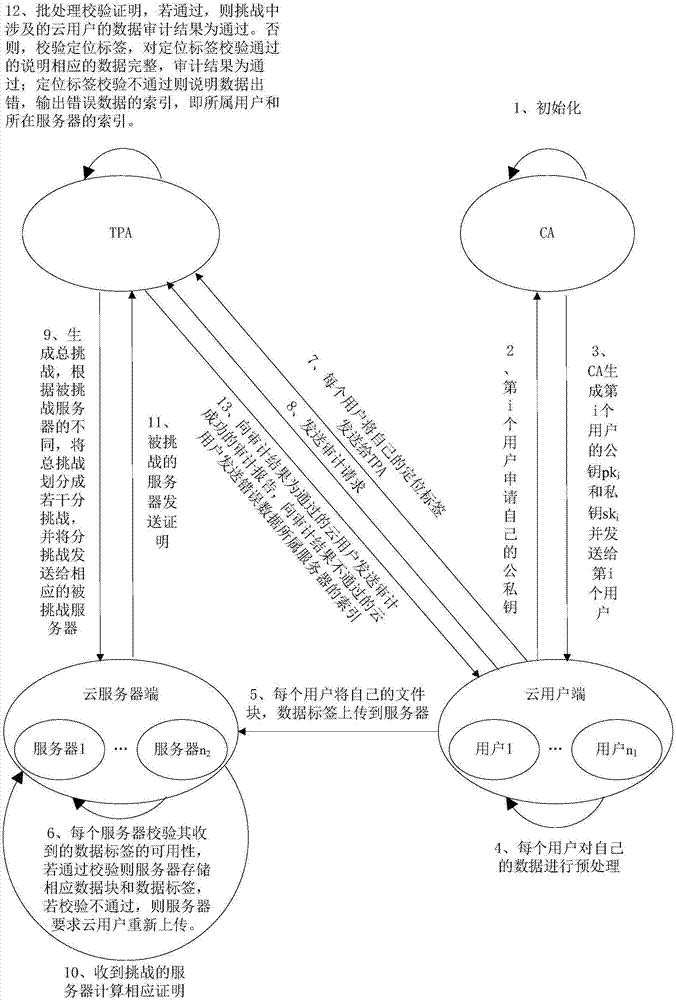

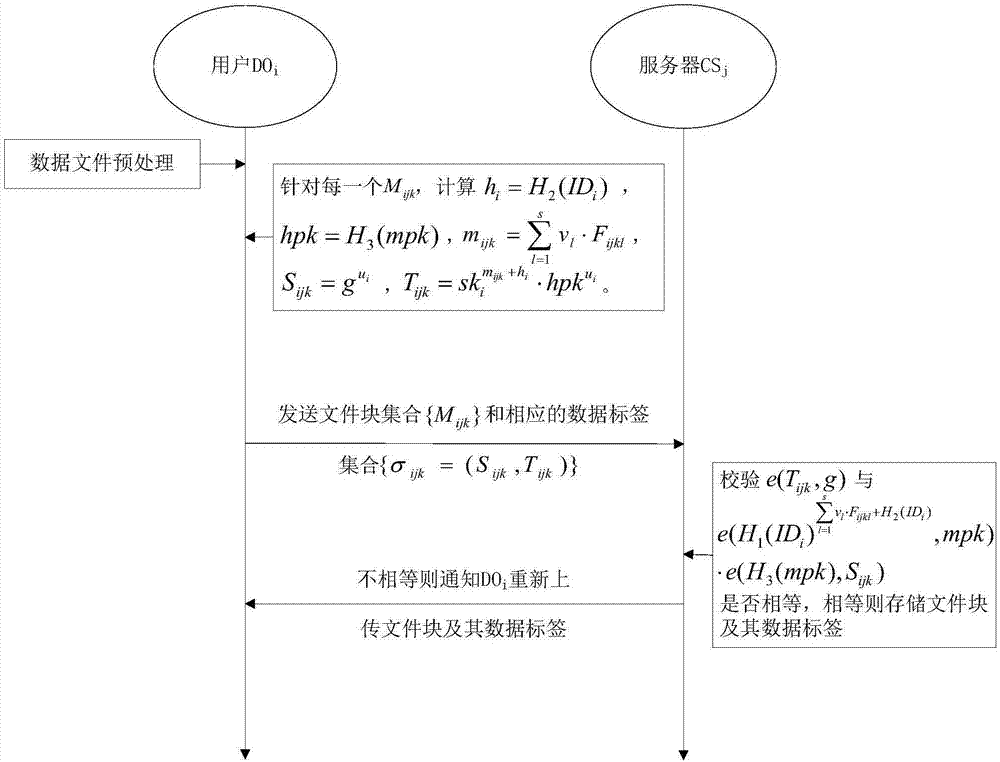

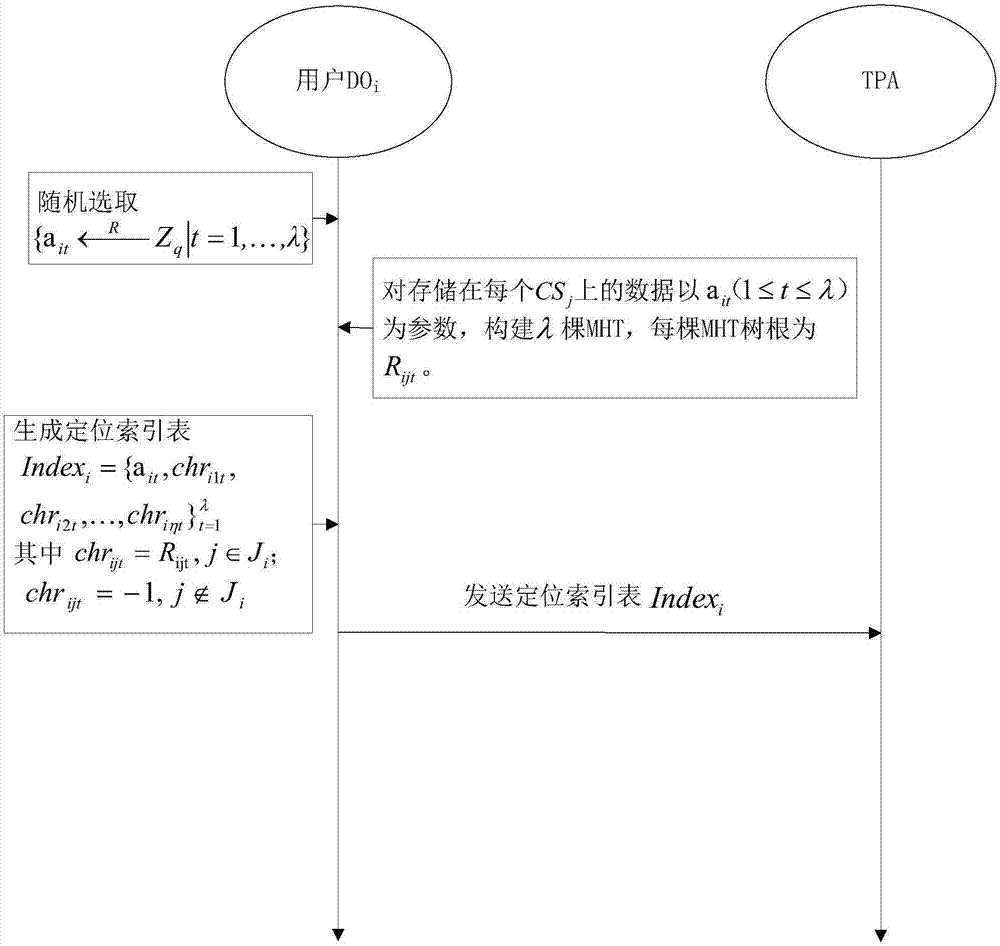

Batch verification cloud data public audit method with error data positioning function

ActiveCN106911708AShorten the timeJudgment reliabilityEncryption apparatus with shift registers/memoriesPublic key for secure communicationCloud userCloud data

The invention discloses a batch verification cloud data public audit method with an error data positioning function. The method comprises the steps that each cloud user stores the file block and data label in a cloud server, and sends the positioning label of the file block to TPA; the TPA challenges the data stored on a number of cloud servers by users after receiving the audit request of the users; after receiving a returned proof, the TPA carries out validity verification based on the sent challenge and the proof returned by of the servers; if the verification is passed, a data audit result is passed; if the verification is not passed, the TPA verifies the positioning label; if the verification of the positioning label is passed, the audit result is passed, otherwise the cloud user index of error data and the index of the server are output; and finally, the TPA sends audit success to the cloud user whose audit result is passed, and sends the index of the server of error data to the cloud user whose audit result is not passed. According to the invention, the users can conveniently and quickly locate damaged data.

Owner:ZHONGBEI UNIV

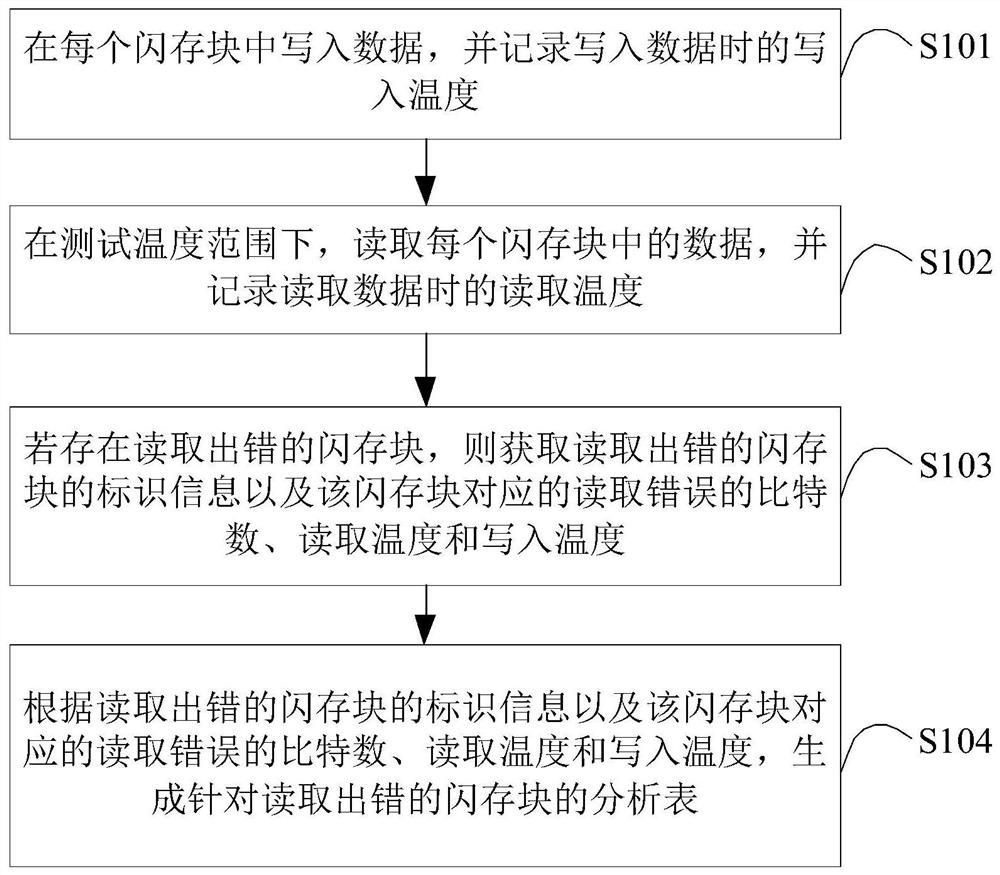

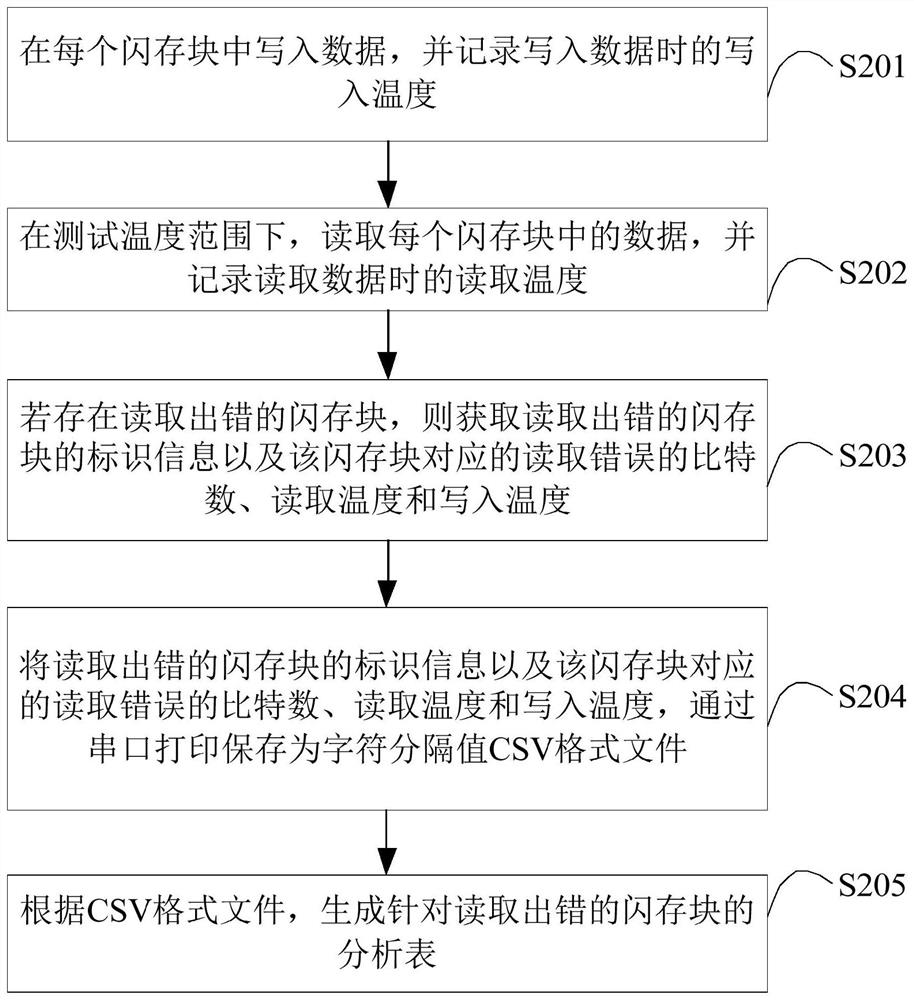

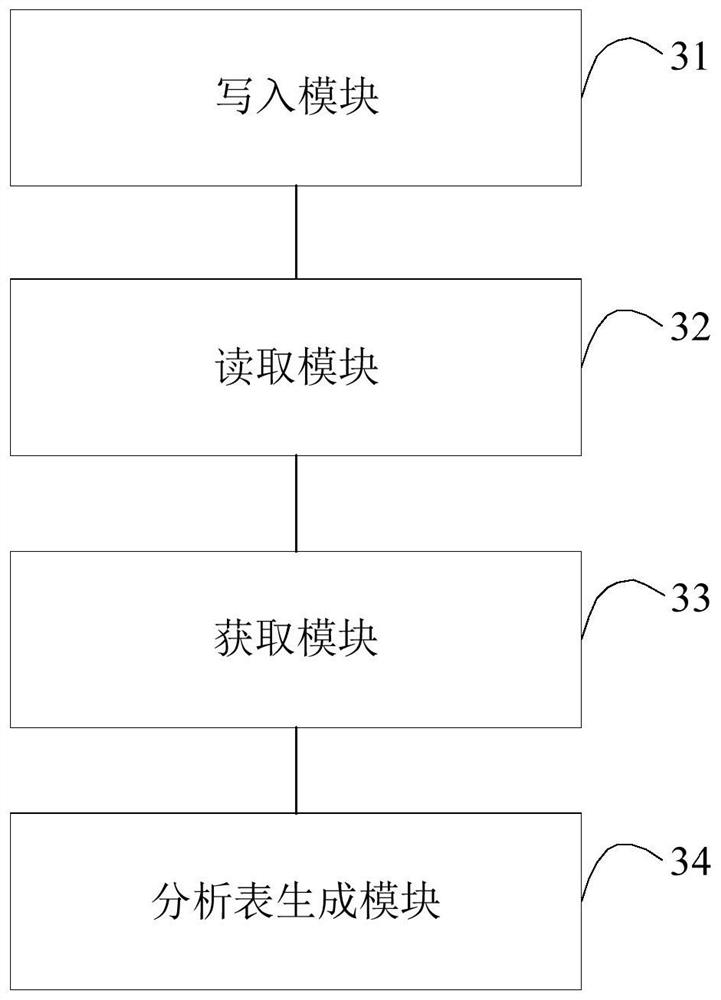

Flash memory data analysis method and device, terminal equipment and storage medium

ActiveCN113643746AImplement read and write performance testsThe test result is accurateStatic storageSoftware engineeringTerminal equipment

The invention is suitable for the technical field of flash memories, and particularly relates to a flash memory data analysis method and device, terminal equipment and a storage medium. According to the method, data writing is executed for each flash memory block in the flash memory, the writing temperature during data writing is recorded, and in a test temperature range, the data in each flash memory block is read, and the reading temperature during data reading is recorded; and the identification information of the flash memory block with the read error and the bit number, the read temperature and the write-in temperature of the read error corresponding to the flash memory block are obtained, the information of the flash memory block with the read error is used for generating an analysis table, and the read-write performance test of the flash memory is realized. According to the bit number of the read error of the flash memory block under the temperature condition, the test result of each flash memory block can be more accurately obtained in combination with the temperature condition so as to judge the reliability of the flash memory.

Owner:深圳市宏旺微电子有限公司

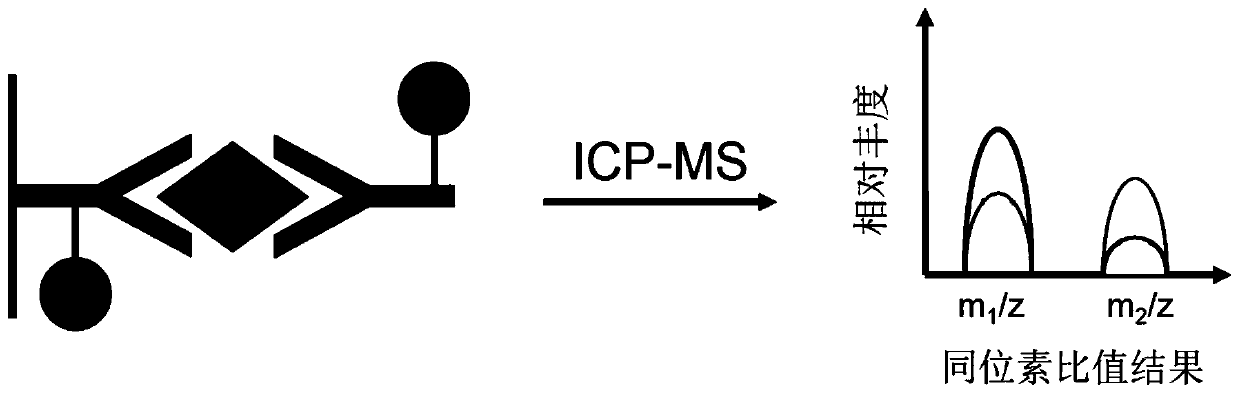

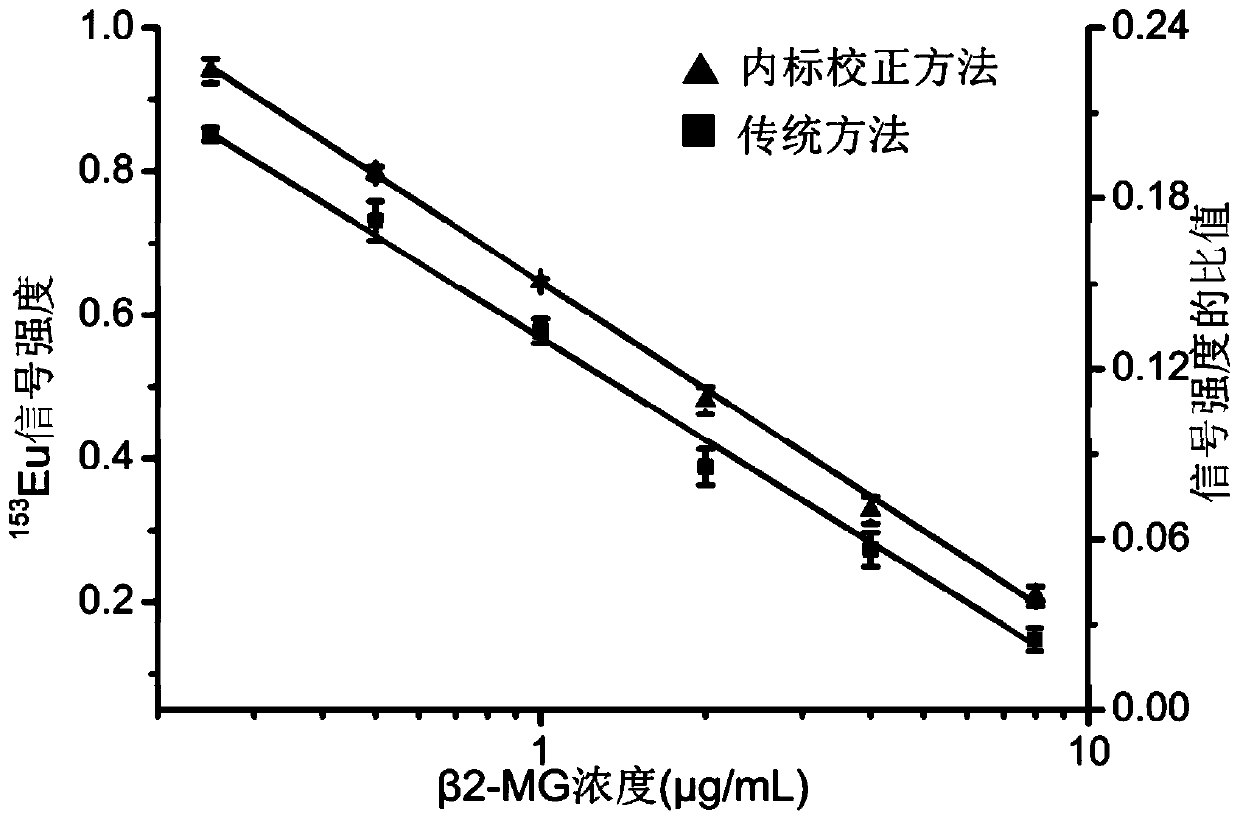

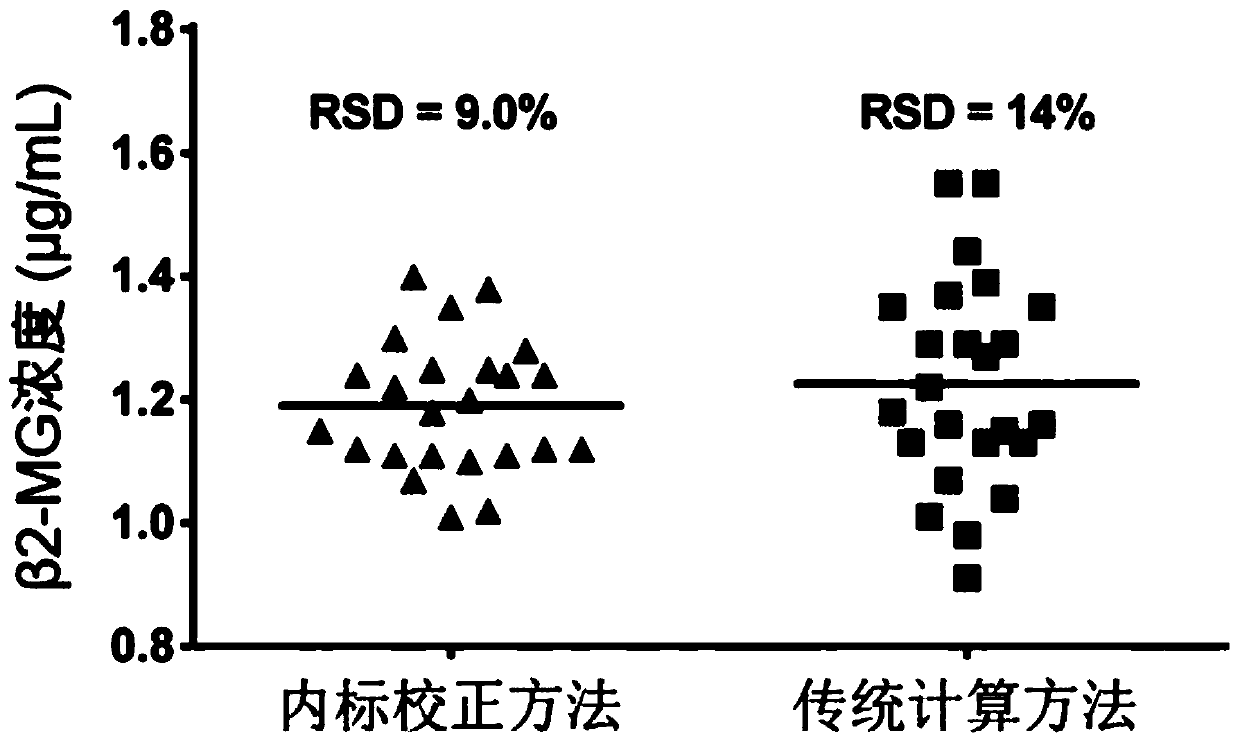

Internal standard correction-based immune precise quantitative analysis method and special kit thereof

InactiveCN111458496AJudgment reliabilityThe result is accurateMaterial analysis by electric/magnetic meansBiological testingImmune profilingIndividualized treatment

The invention discloses an internal standard correction-based immune precise quantitative analysis method and a special kit thereof. According to the method, an internal standard probe is added in animmune reaction process, simultaneous detection of multiple components can be performed by using a plasma mass spectrometer; and accurate quantitative analysis of immunity is realized by correcting random errors in the immune reaction process and an instrument detection process through the internal standard probe. The internal standard probe strategy designed by the method of the invention not only can be used for competitive immunoassay, but also can be used for non-competitive immunoassay. Therefore, the internal standard correction-based accurate immunoassay method can be used for preparingimmunoassay kits for all clinical disease markers. The method is expected to play a positive role in the fields of clinical detection, individualized treatment, precision medicine and the like.

Owner:TSINGHUA UNIV

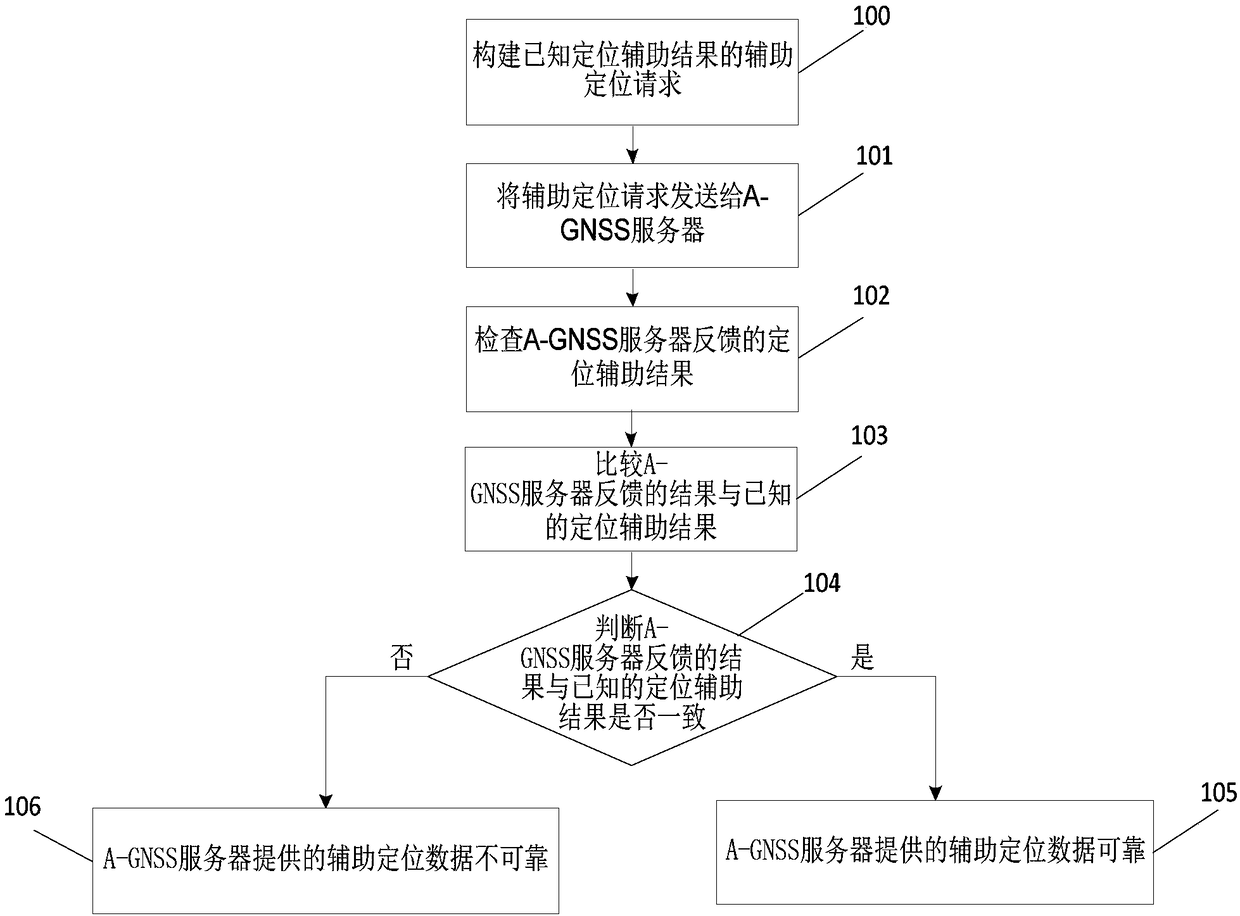

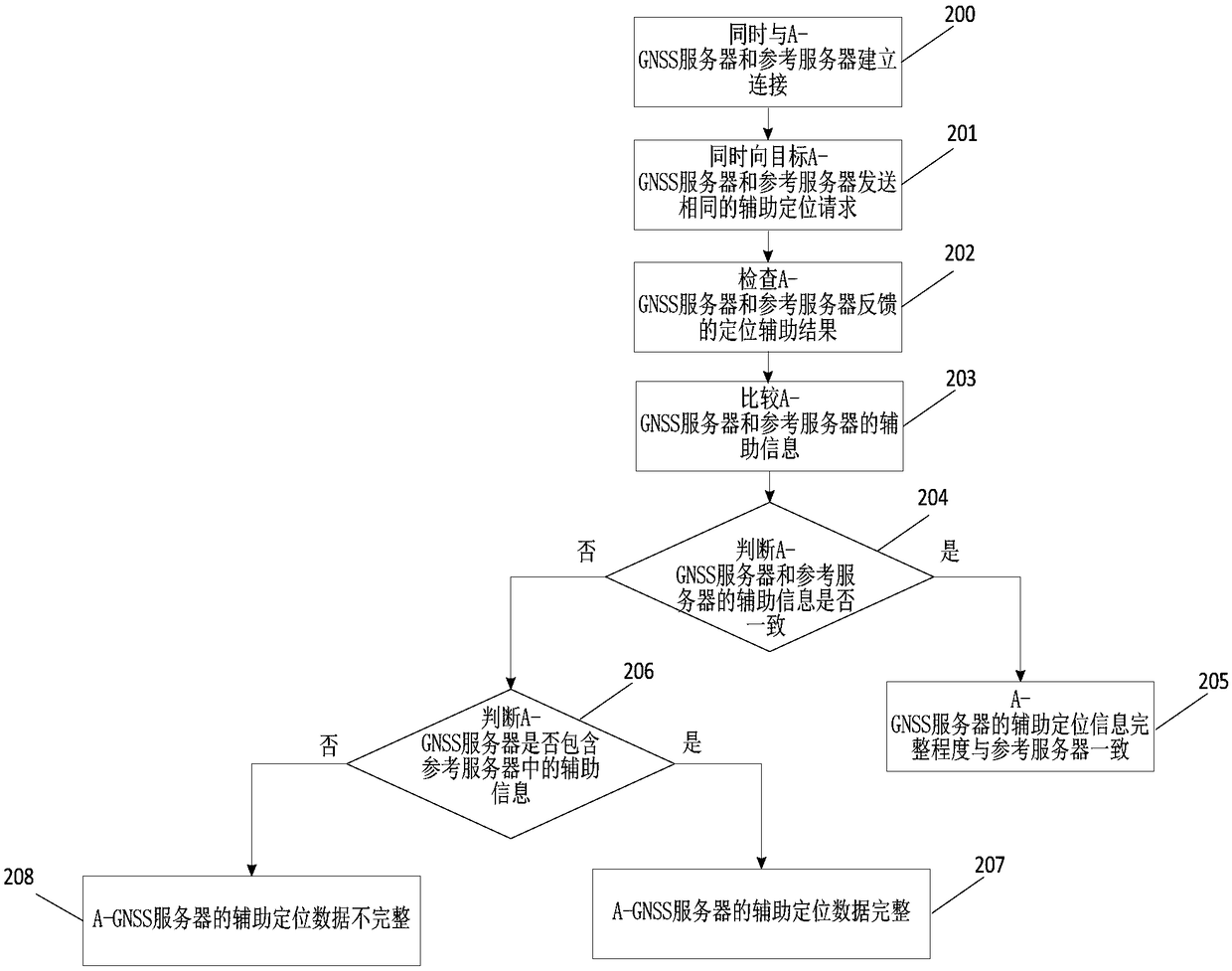

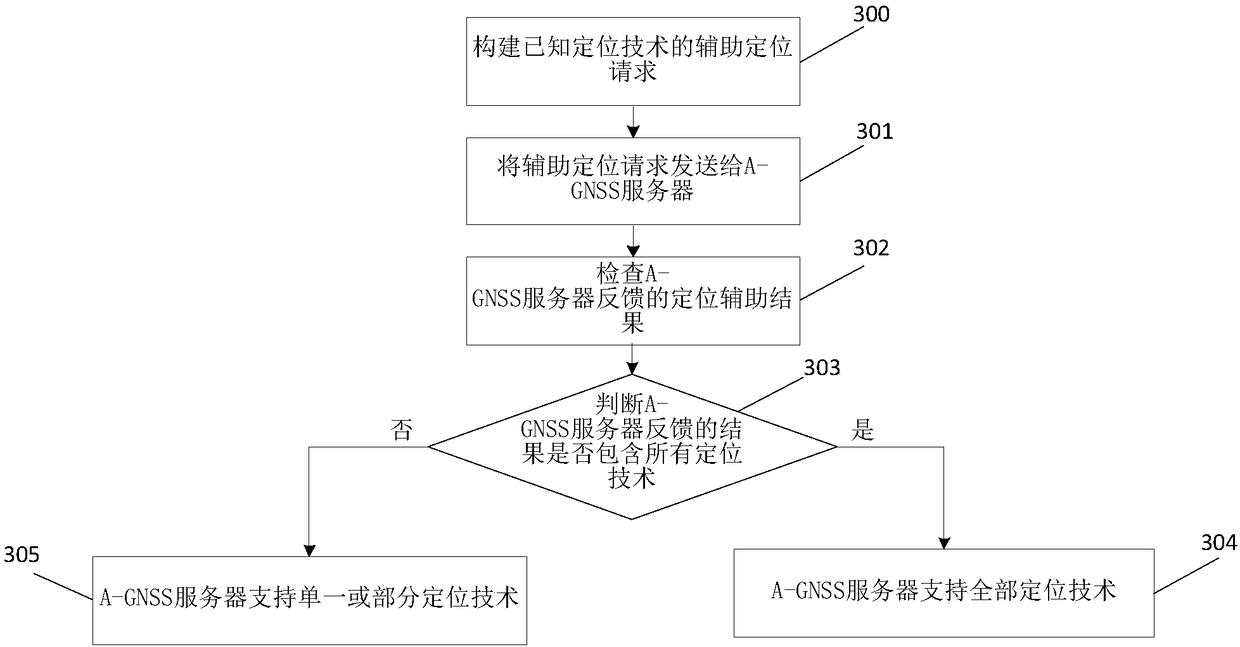

Method for assessing quality of service of A-GNSS server and system thereof

ActiveCN108075916ALong-term monitoring of service qualityJudgment reliabilityData switching networksQuality of serviceComputer terminal

The invention discloses a method for assessing quality of service of an A-GNSS server and a system thereof. The assessment is performed mainly beginning from the service availability, reliability andintegrity of the A-GNSS server, the support capacity of multiple auxiliary positioning technologies and the protocol support capacity. The method for assessing the reliability of auxiliary positioningdata of the A-GNSS server comprises the following steps: sending an auxiliary positioning request of a known positioning auxiliary result to an A-GNSS server through a positioning terminal virtual machine; judging whether a positioning auxiliary result fed back by the A-GNSS server is consistent with concerned data in the known positioning auxiliary result; and judging that the auxiliary positioning data provided by the A-GNSS server is reliable if the positioning auxiliary result fed back by the A-GNSS server is consistent with concerned data in the known positioning auxiliary result; or judging that the auxiliary positioning data provided by the A-GNSS server is unreliable if the positioning auxiliary result fed back by the A-GNSS server is inconsistent with concerned data in the knownpositioning auxiliary result. Through the method disclosed by the invention, the problem that the quality of service of the A-GNSS server cannot be intuitively judged at present is solved.

Owner:QIANXUN SPATIAL INTELLIGENCE INC

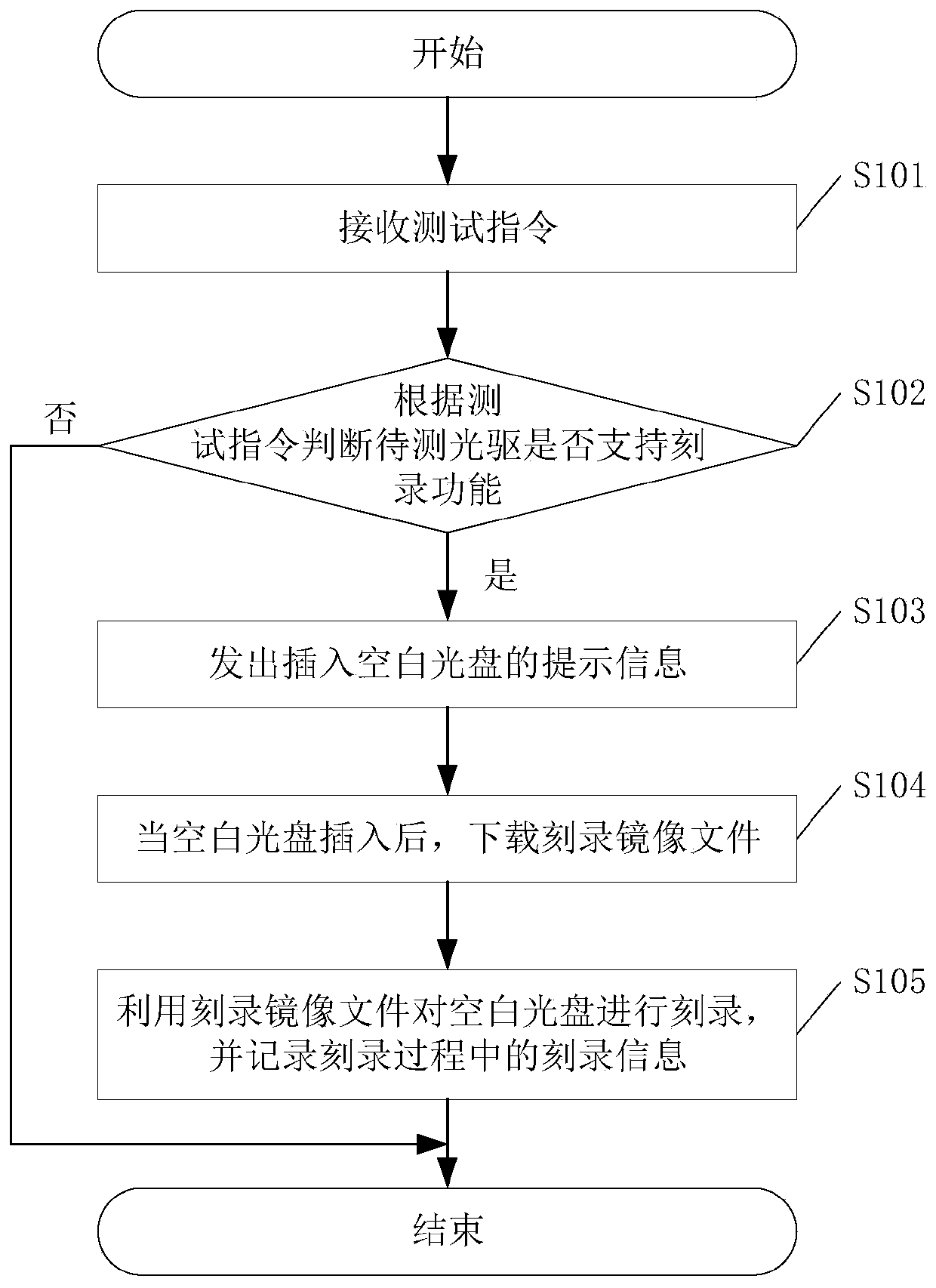

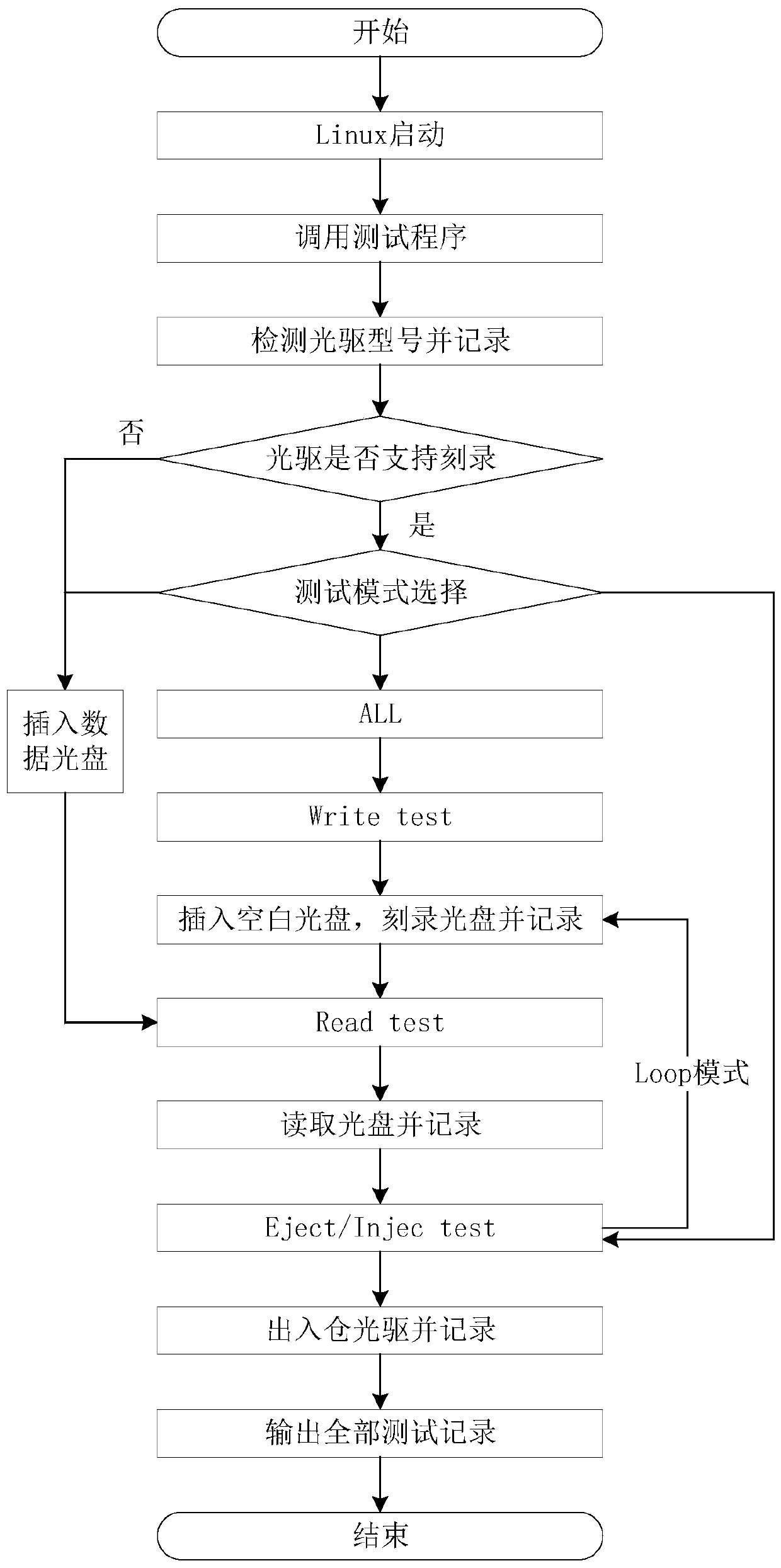

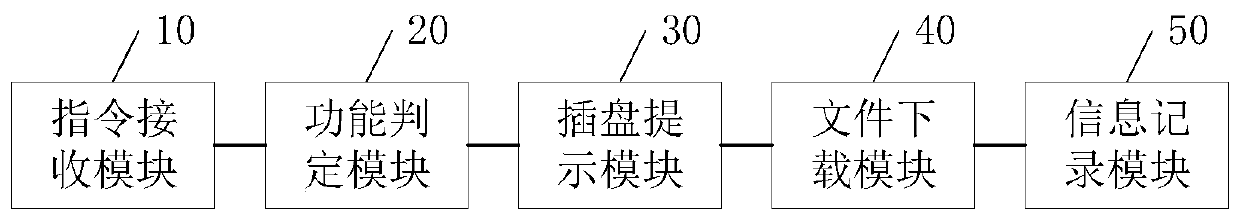

CD driver testing method, CD driver testing device and related equipment

InactiveCN111338877AImplement automated testingDetermine availabilityRecord information storageFunctional testingComputer hardwareTest efficiency

The invention discloses a CD driver test method, which is applied to a Linux system and comprises the following steps: receiving a test instruction; judging whether the CD driver to be tested supportsa burning function or not according to the test instruction; if the recording function is supported, sending prompt information for inserting a blank optical disk; after the blank optical disk is inserted, downloading a recorded mirror image file; burning the blank optical disk by using the burning mirror image file, and recording burning information in the burning process; the CD-ROM testing method is simple to operate, realizes automatic testing of the CD-ROM, and improves the testing efficiency. The invention further discloses a CD driver testing device, CD driver testing equipment and a computer readable storage medium, which all have the above beneficial effects.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

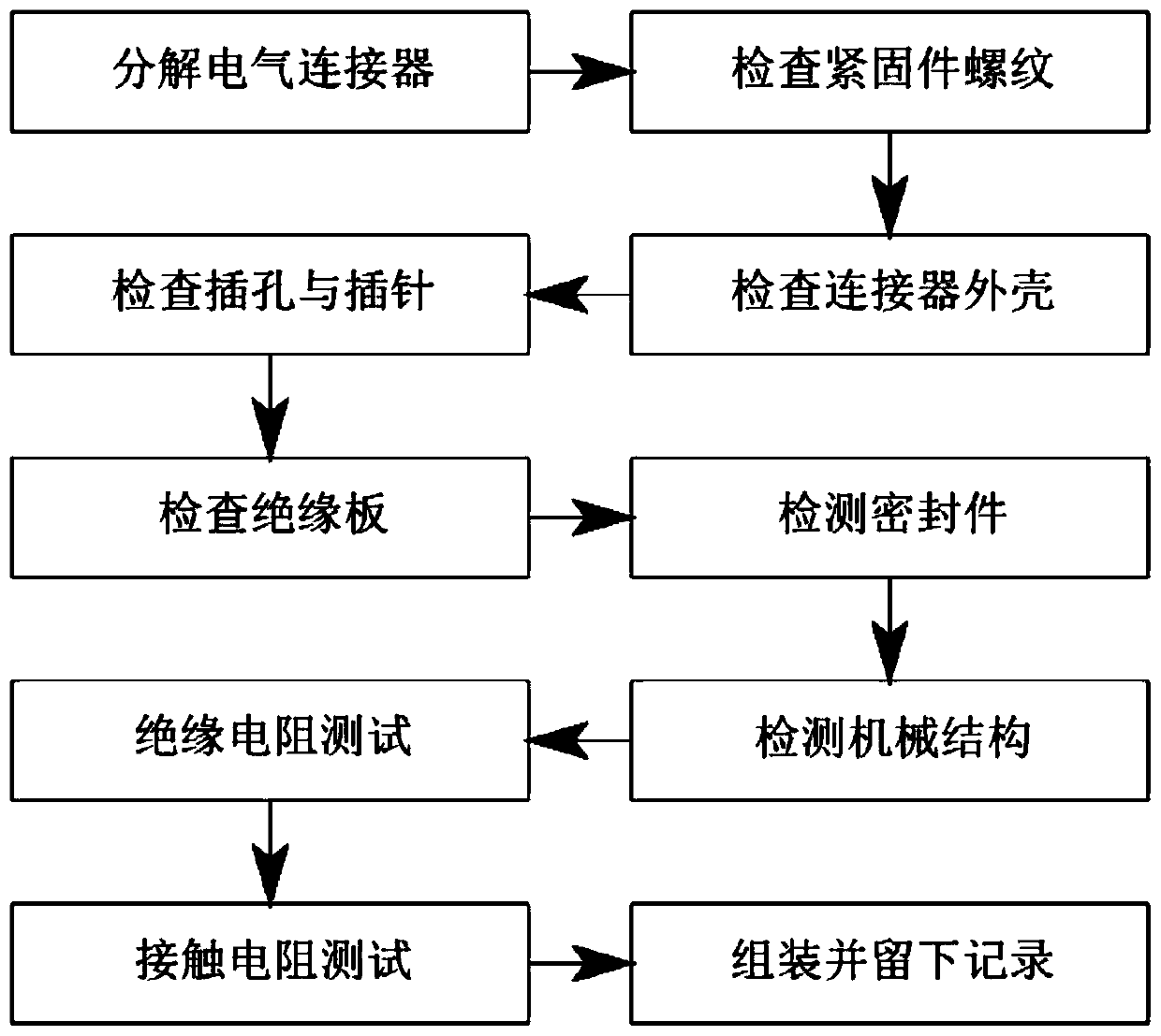

Maintenance method for electrical connector of tramcar

PendingCN111381105AStandardize the maintenance processSolve maintenance quality problemsVery high resistance measurementsEarth resistance measurementsElectrical resistance and conductanceMechanical components

The invention relates to a maintenance method for an electrical connector of a tramcar, and the method comprises the steps: S1, decomposing the electrical connector; S2, checking internal threads of athreaded hole of the fastener; S3, checking a connector shell; S4, checking a connector jack and a contact pin; S5, checking the insulating plate; S6, checking a sealing piece; S7, detecting a mechanical component; S8, carrying out an insulation resistance test on the electrical connector; S9, performing a contact resistance test on the electrical connector; S10, assembling each part of the electrical connector, sleeving a cable sheath on each part, and leaving an overhaul record. The tramcar electrical connector maintenance method is systematized, and the tramcar electrical connector maintenance process is standardized; the maintenance quality problem of the tramcar electrical connector is solved, and potential safety hazards are reduced; a detailed and reliable contact resistance testing method is provided, and the reliability of the electrical connector is effectively judged; and the maintenance cost of the tramcar operation unit on the electrical connector is reduced.

Owner:中铁轨道交通装备有限公司

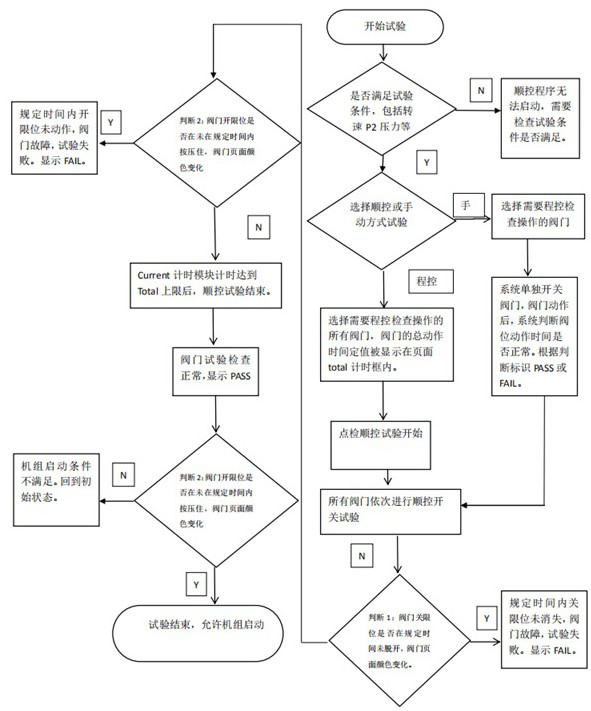

Full-automatic detection method for pneumatic valve based on gas turbine purging system

PendingCN112816207AReduce workloadShorten the timeMachine valve testingProgramme control in sequence/logic controllersProcess engineeringGas turbines

The invention discloses a full-automatic detection method for a pneumatic valve based on a gas turbine purging system. The method comprises the steps of S1, controlling the building of a logic block through a MARK Vie control system, wherein the building includes establishment of a purging system pneumatic valve needing to be detected, and visual operation is carried out on the purging system pneumatic valve; S2, combining and selecting the purging system pneumatic valve needing to be detected; S3, setting test conditions and test requirements, wherein the conditions comprise preconditions and locking conditions; and S4, judging whether the valve test is qualified or not. According to the invention, the check work of the purging system pneumatic valve is automatically completed, the workload and time of maintainers are reduced, the working efficiency is greatly improved, the check work is automatically completed through the logic module, the action time of each valve is accurately recorded, and the reliability of equipment is accurately judged.

Owner:HANGZHOU HUADIAN BANSHAN POWER GENERATION

Performance testing device for pressure sensor production

ActiveCN114061831AJudgment reliabilityJudging authenticityFluid pressure measurementEngineeringMechanical engineering

Owner:WUHAN FINEMEMS

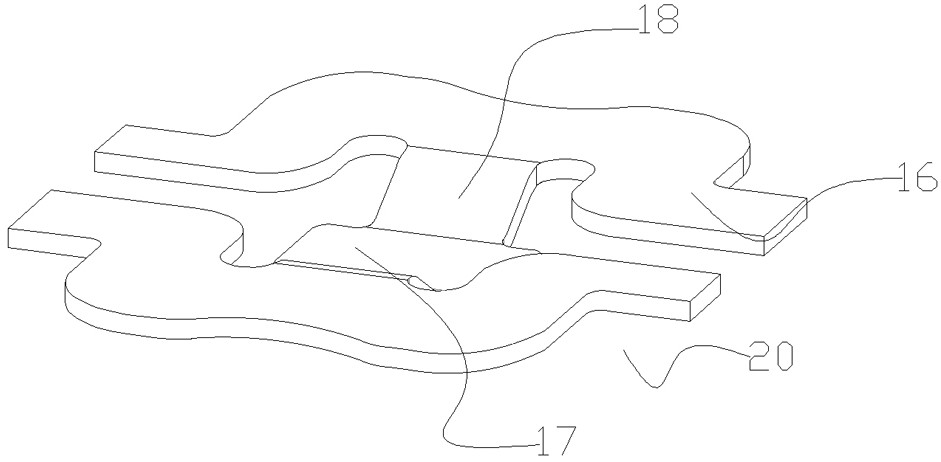

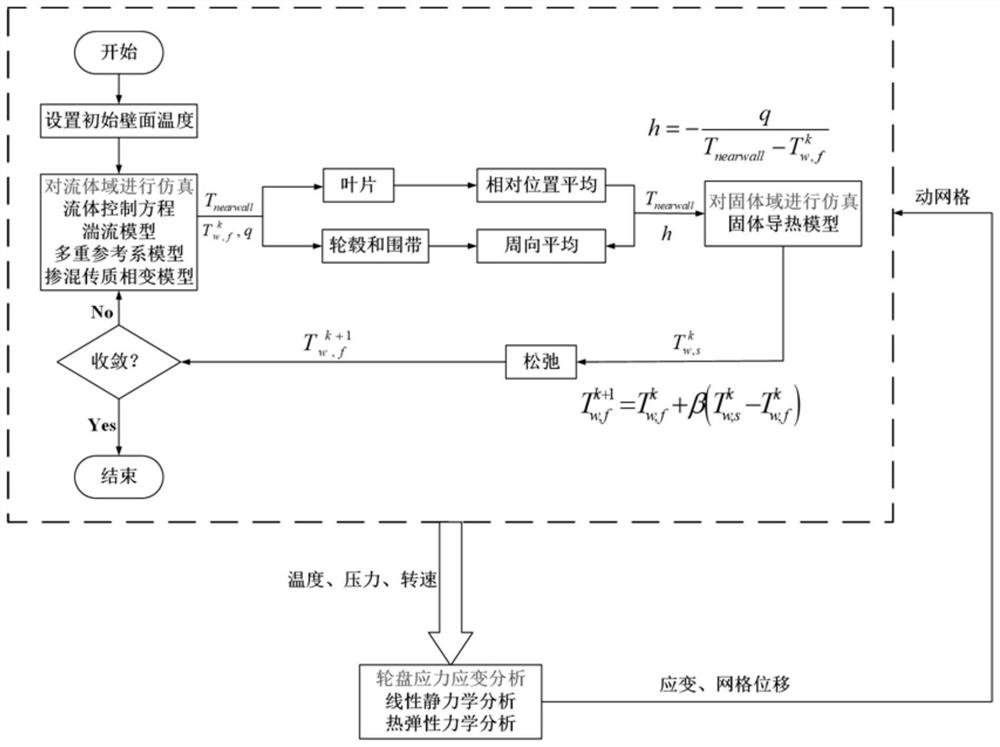

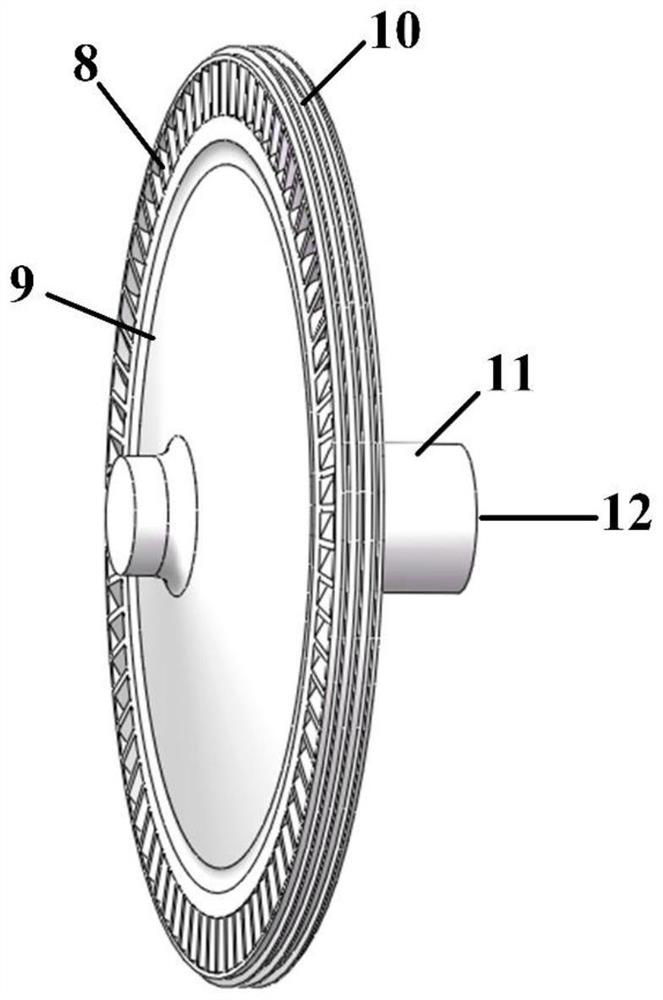

Gas-thermal-elastic coupling calculation method for water-spraying cooling axial turbine of partial air inlet structure

PendingCN114880764AJudgment reliabilityGeometric CADSustainable transportationData simulationEngineering

The invention discloses a gas thermal elastic coupling calculation method for a water spray cooling axial turbine of a partial air inlet structure, and the aerodynamic performance and stress strain of the turbine influenced by the deformation of a wheel disc are obtained through modeling, grid division of a model and data simulation analysis. Visual data support is provided for the performance of the water spray cooling turbine, the influence of an air inlet structure of an underwater turbine part on turbine gas thermal elastic coupling simulation can be well solved, and the reliability of a turbine disc under water spray cooling can be judged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

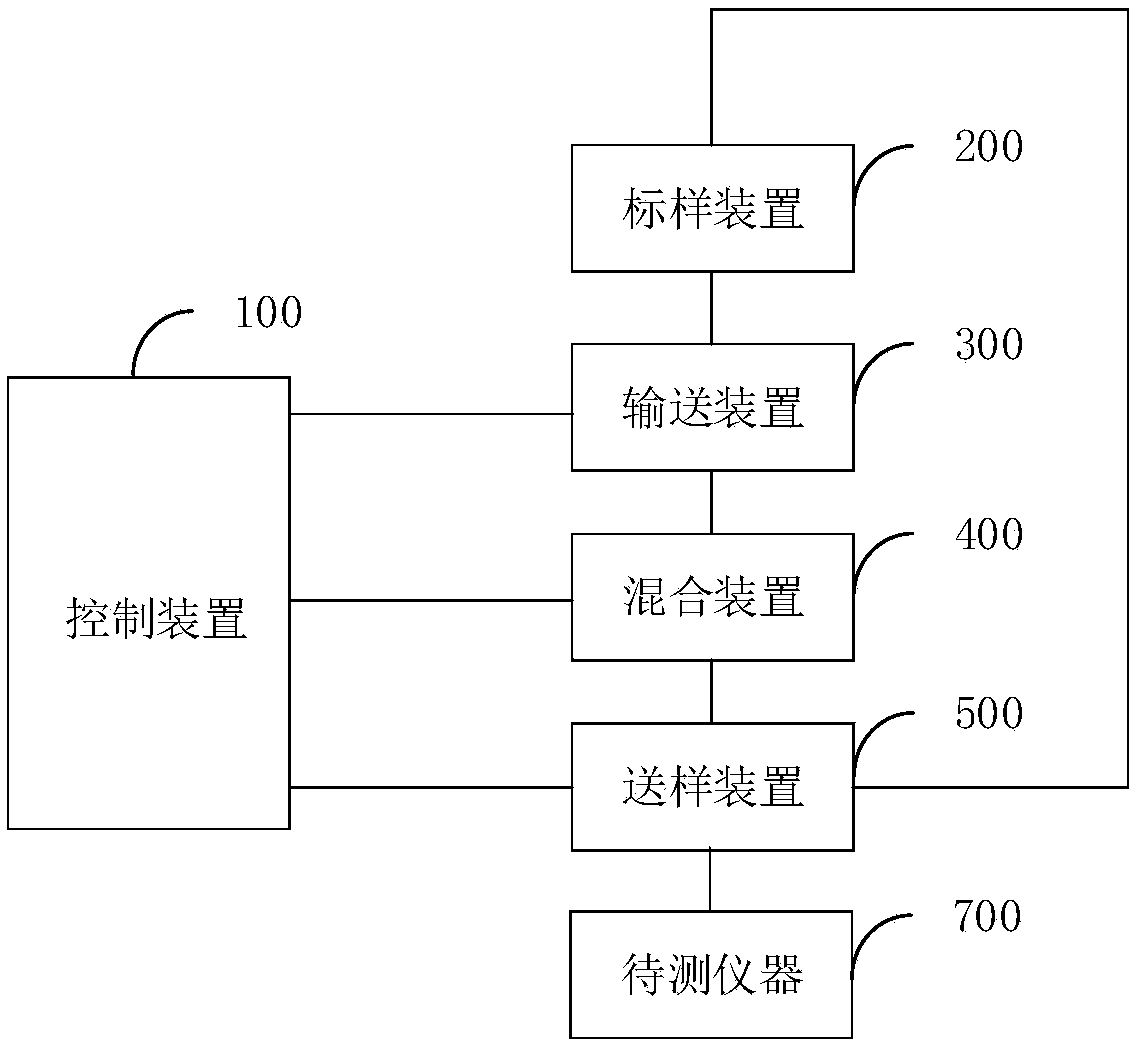

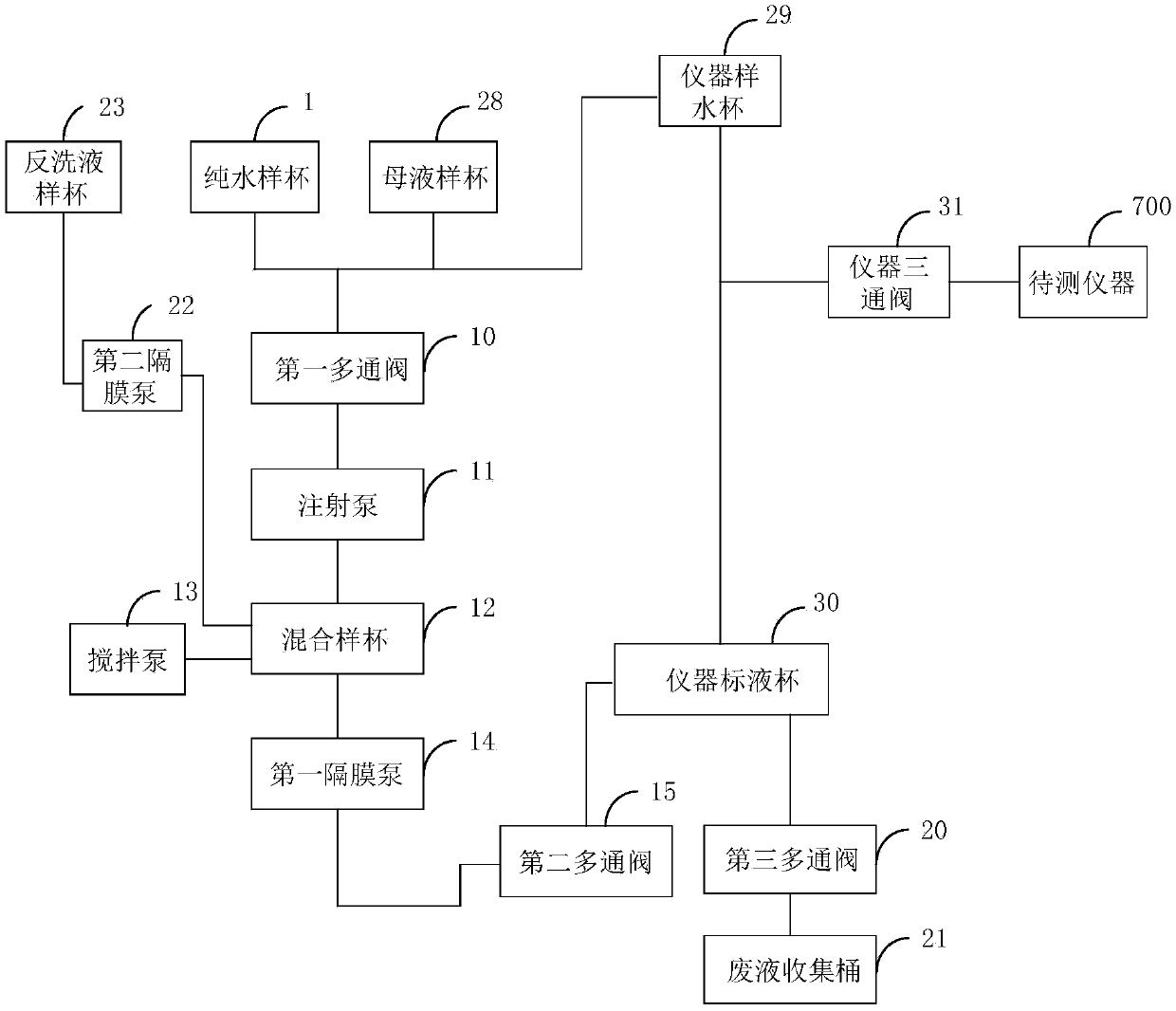

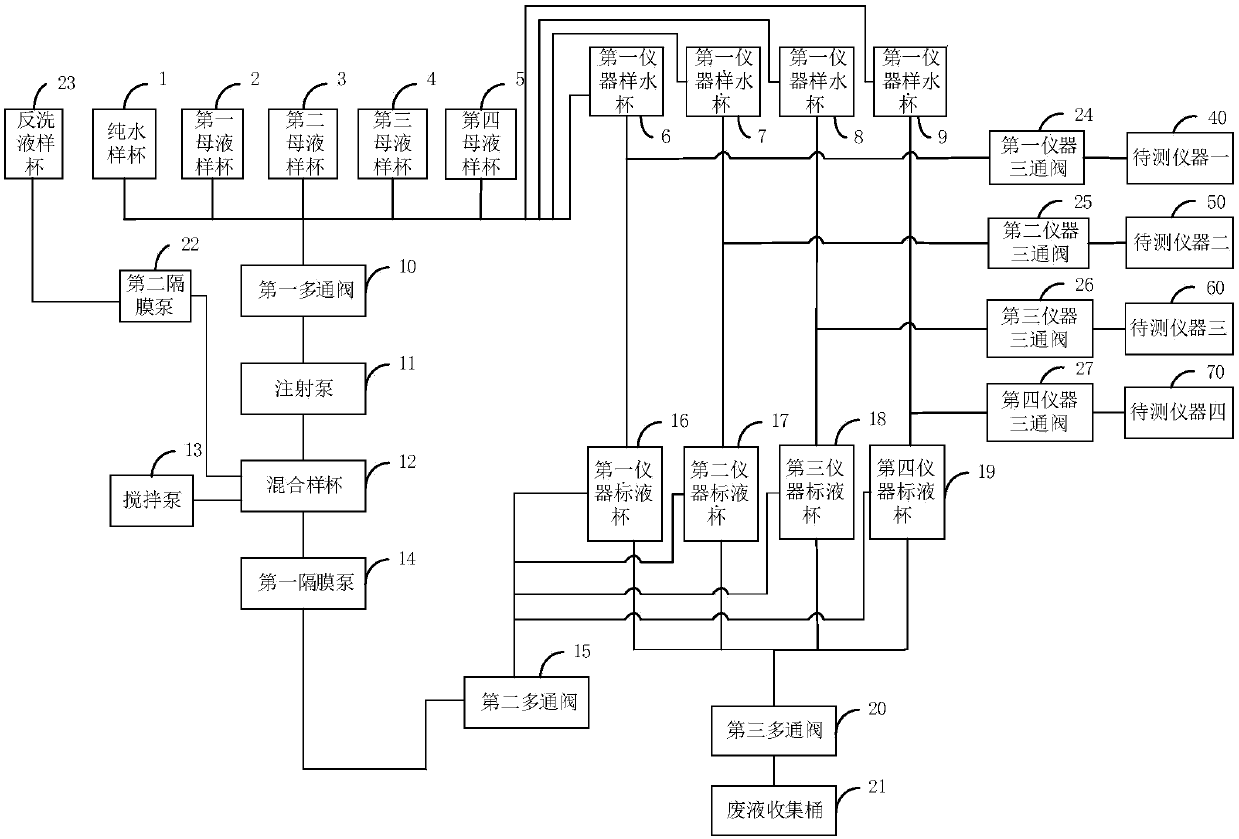

Water quality automatic quality control system, function formula method and data auditing method

InactiveCN108982890ARealize automatic calibrationJudgment reliabilityMaterial analysisQuality controlQuality control system

The invention relates to a water quality automatic quality control system, a function formula method and a data auditing method. The water quality automatic quality control system comprises a controldevice, a standard sample device, a conveying device, a mixing device and a sample sending device, wherein the control device is respectively connected to the conveying device, the mixing device and the sample sending device; the standard sample device, the conveying device, the mixing device and the sample sending device are sequentially connected with one another to form a closed loop; and the sample sending device is connected with an instrument to be detected. The water quality automatic quality control system can provide a local and remote quality control function to a monitoring instrument in a water station so as to judge the reliability and the effectiveness of monitoring data of the instrument and realize automatic calibration of the instrument.

Owner:XIAN SITAN ENVIRONMENT TECH CO LTD

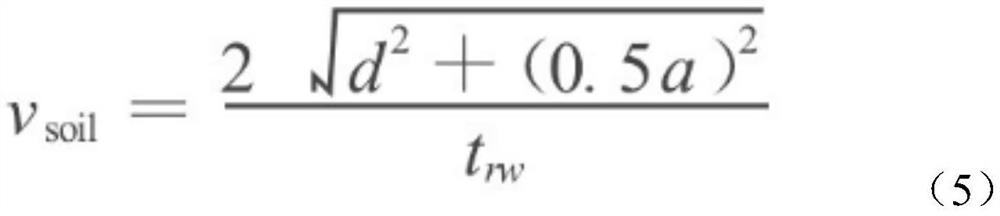

Test method for obtaining hydrogeological parameters

ActiveCN113092332AEfficient detectionJudgment reliabilityEarth material testingPermeability/surface area analysisPorositySoil science

The invention provides a test method for acquiring hydrogeological parameters, which comprises the following steps of: detecting a to-be-detected area by using a ground penetrating radar to obtain the volume water content and the unsaturated zone porosity of the to-be-detected area; dividing the to-be-detected area into a plurality of sampling areas according to the volume moisture content, and sampling soil in each sampling area to obtain a columnar soil sample; placing the columnar soil sample in a test cylinder, and carrying out permeability tests under different water temperature conditions to obtain test permeability coefficients; and according to the porosity of the unsaturated zone, obtaining an estimated permeability coefficient through a Kozeny-Carman formula, if the ratio of the test permeability coefficient to the estimated permeability coefficient is 0.9-1.1, adopting the test permeability coefficient, and otherwise, abandoning the test permeability coefficient in the test. The problem that in the prior art, a method for obtaining hydrogeological parameters is low in accuracy is solved.

Owner:核工业西南勘察设计研究院有限公司

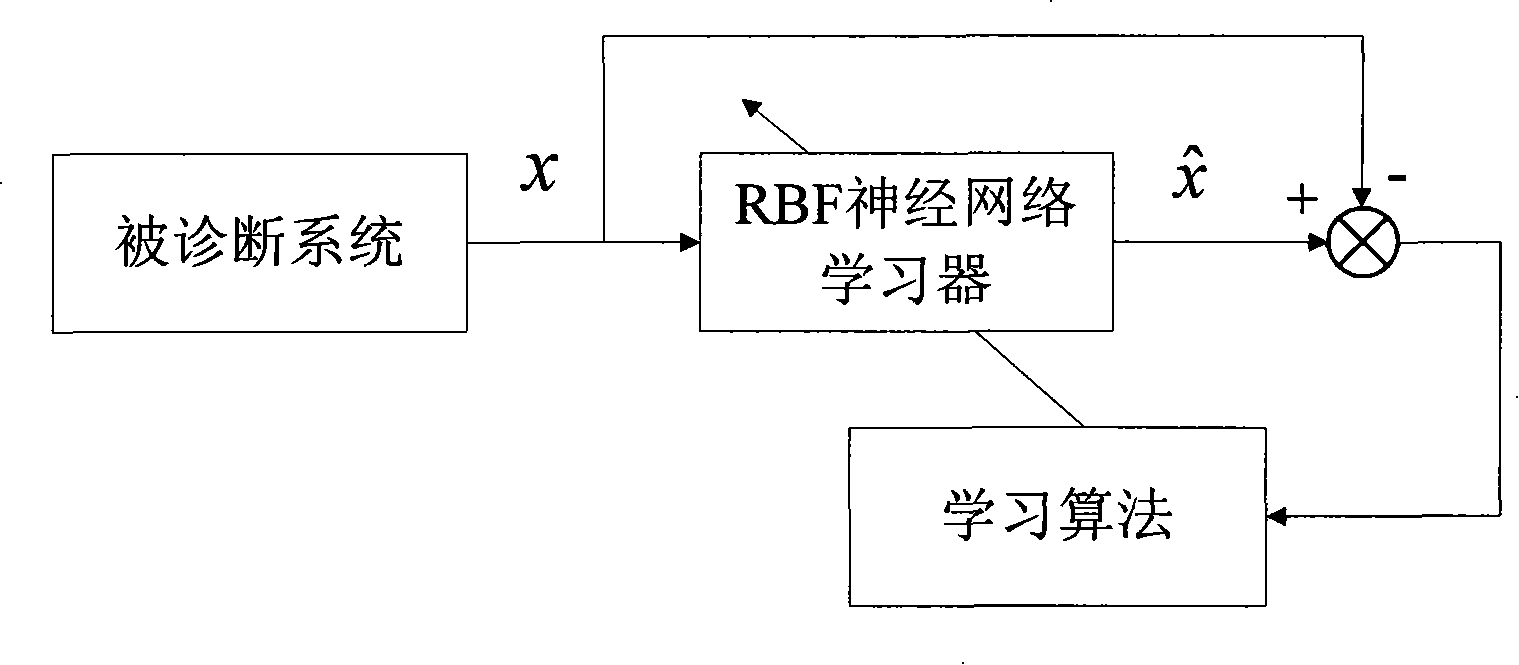

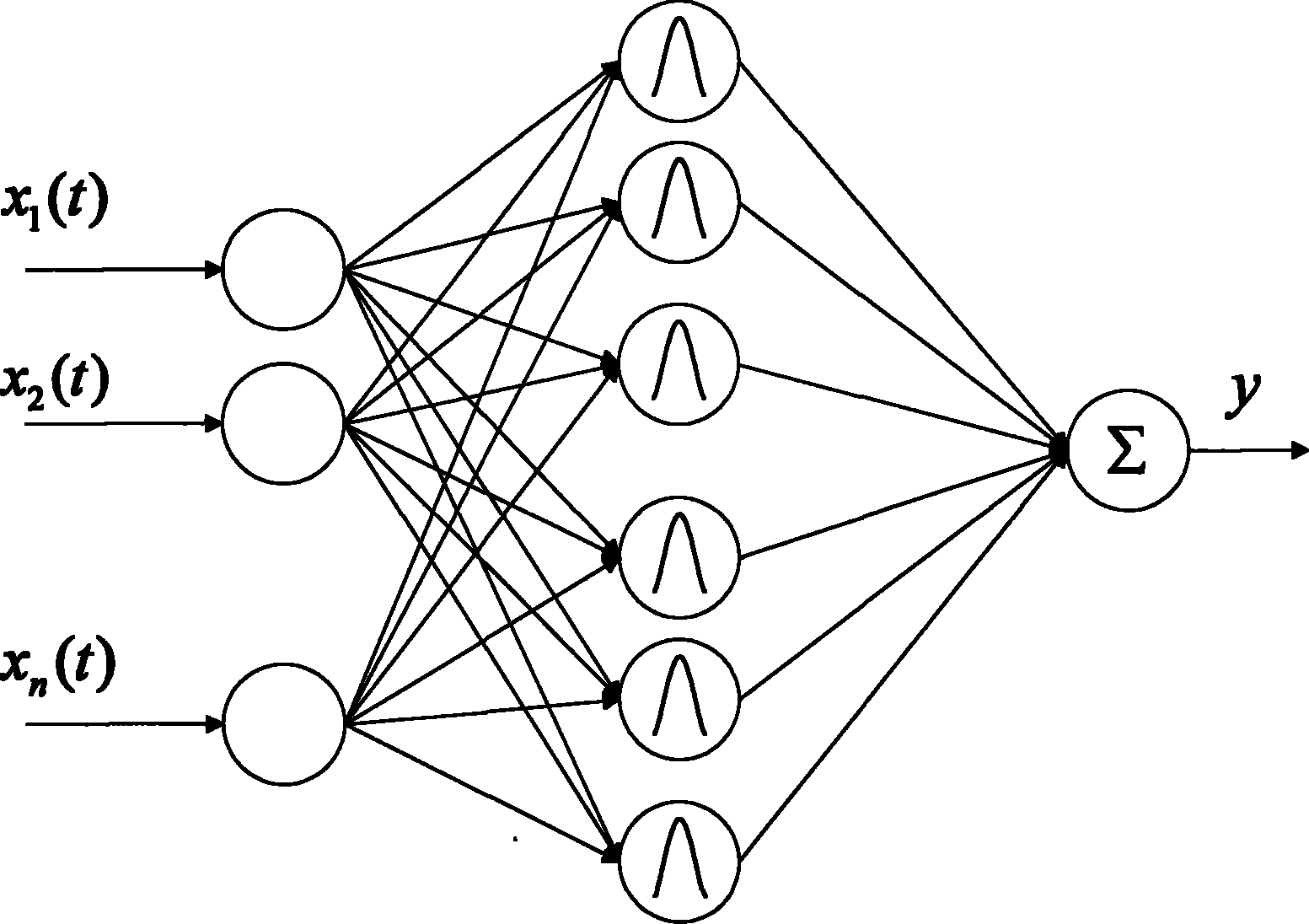

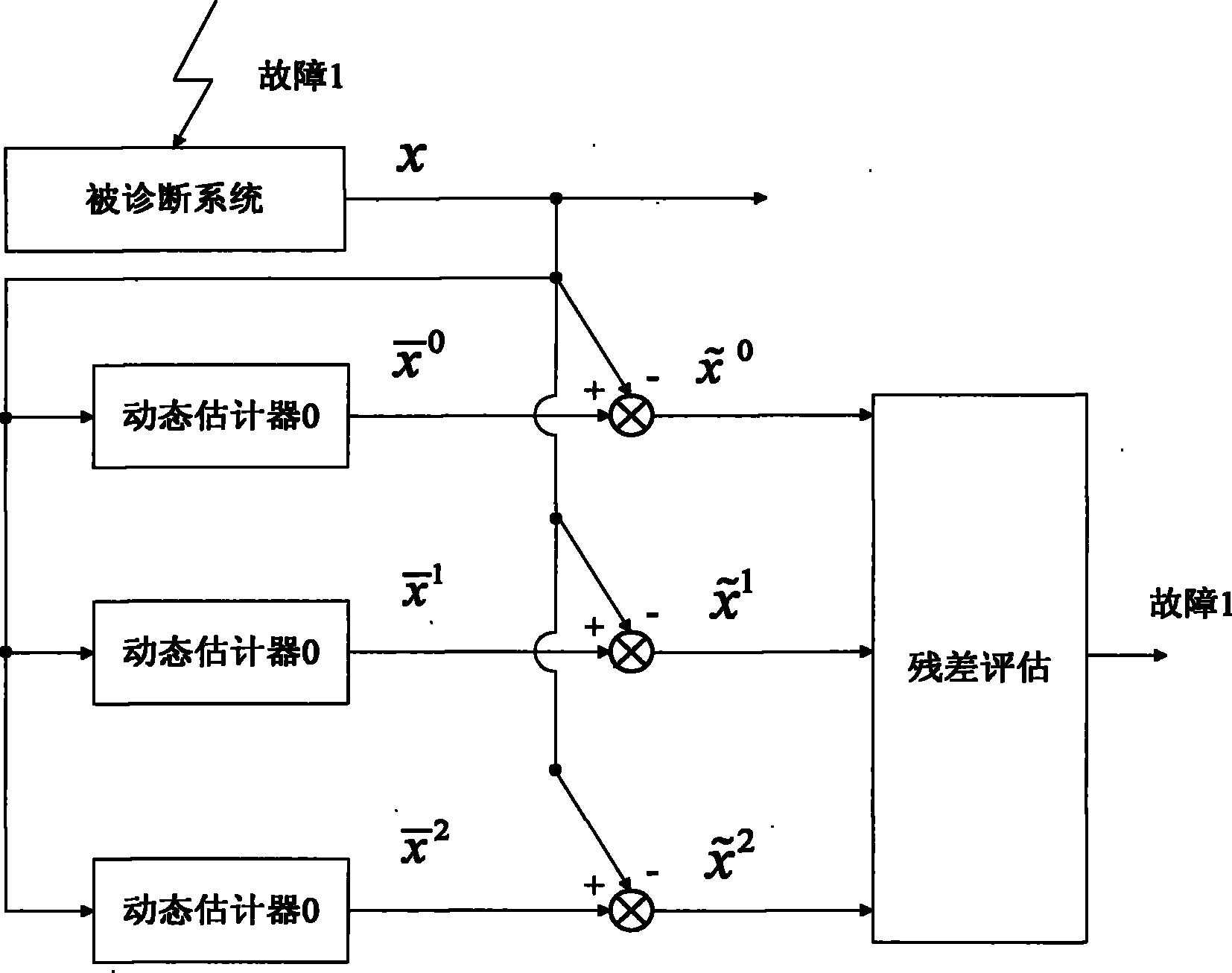

Vibrating failure diagnosis method based on determined learning theory

InactiveCN101299004BBig amount of dataFull storageVibration testingNeural learning methodsNormal modeLinear vibration

The present invention discloses a vibration fault diagnosis method based on confirming the learning theory. The method comprises the following steps: (1) executing learning exercise to the normal mode and fault mode of the diagnosed system; (2) establishing a mode database (comprising a normal mode and a fault mode); (3) establishing a dynamic estimator; (4) comparing the state of the dynamic estimator with the state of the detected system to generate a residual error; and (5) evaluating the residual error thereby discovering and eliminating the fault. The method is suitable for diagnosing the fault of complicated unknown non-linear vibration system. The unknown normal mode and fault mode can be studied to establish a mode database thereby executing fast failure discovery and elimination.

Owner:SOUTH CHINA UNIV OF TECH

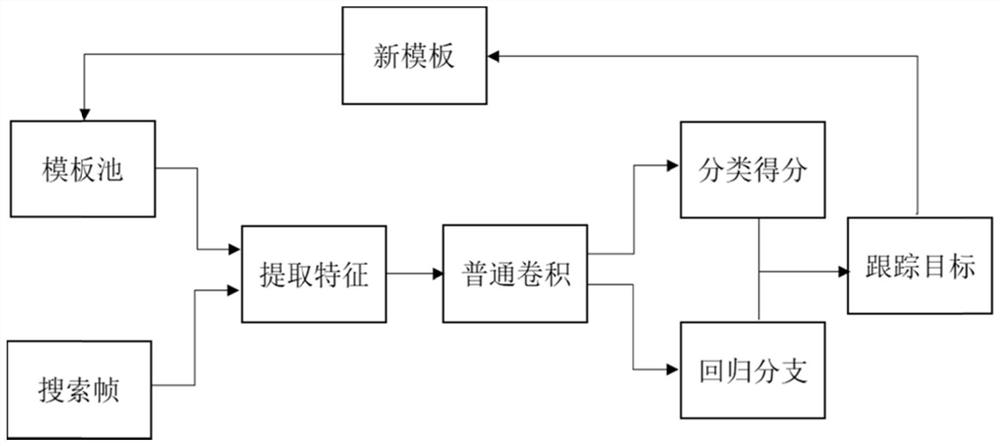

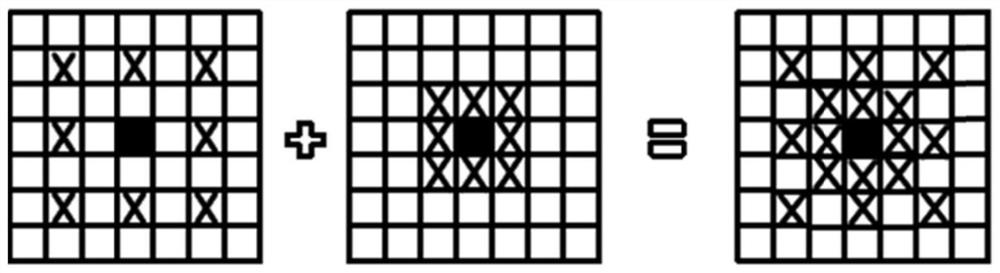

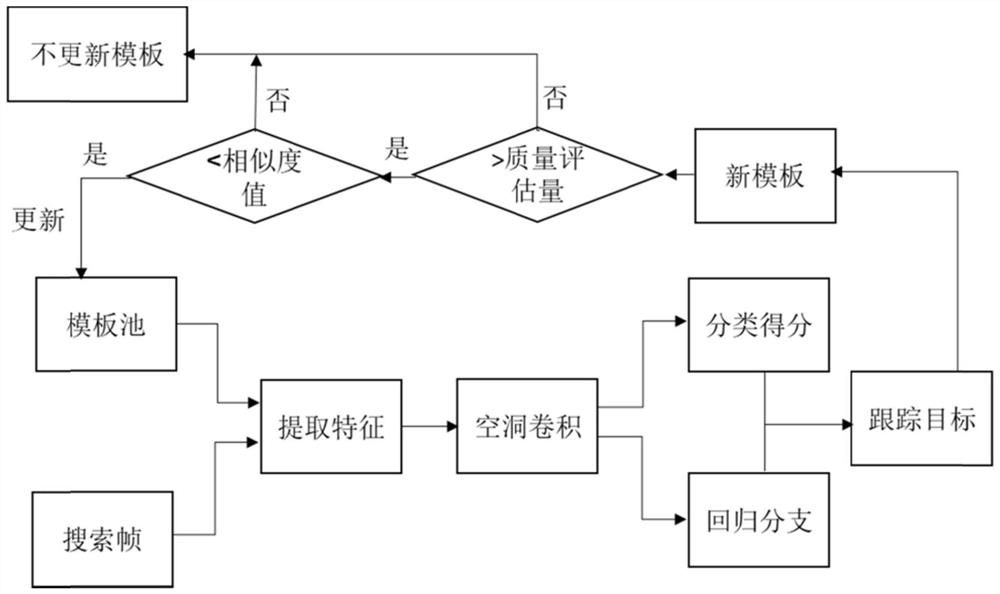

Target tracking method based on quality and similarity evaluation online template updating

PendingCN114372997AJudgment reliabilityGuaranteed reliabilityImage analysisCharacter and pattern recognitionCosine similarityAlgorithm

The invention discloses a target tracking method based on quality and similarity evaluation online template updating. The target tracking method comprises the following steps that S1, an initial template frame is augmented to generate N incremental templates, and a template pool with the size being M is established; s2, performing feature extraction on the template frame and the search frame through a target tracking module, performing convolution response to obtain a response score chart, and performing quality evaluation on a current new template according to a quality evaluation index; s3, judging the similarity between the template passing the quality evaluation and the template in the template pool through the cosine similarity, and judging whether a new template needs to be added into the template pool or not; s4, fusing the templates in the template pool through different weights of the templates to obtain a final template at the moment ti; and S5, carrying out convolution on a feature map obtained through feature extraction of the template frame and the search frame and a cavity convolution layer with different synchronization lengths and length-width ratios, and then carrying out feature fusion.

Owner:YANSHAN UNIV

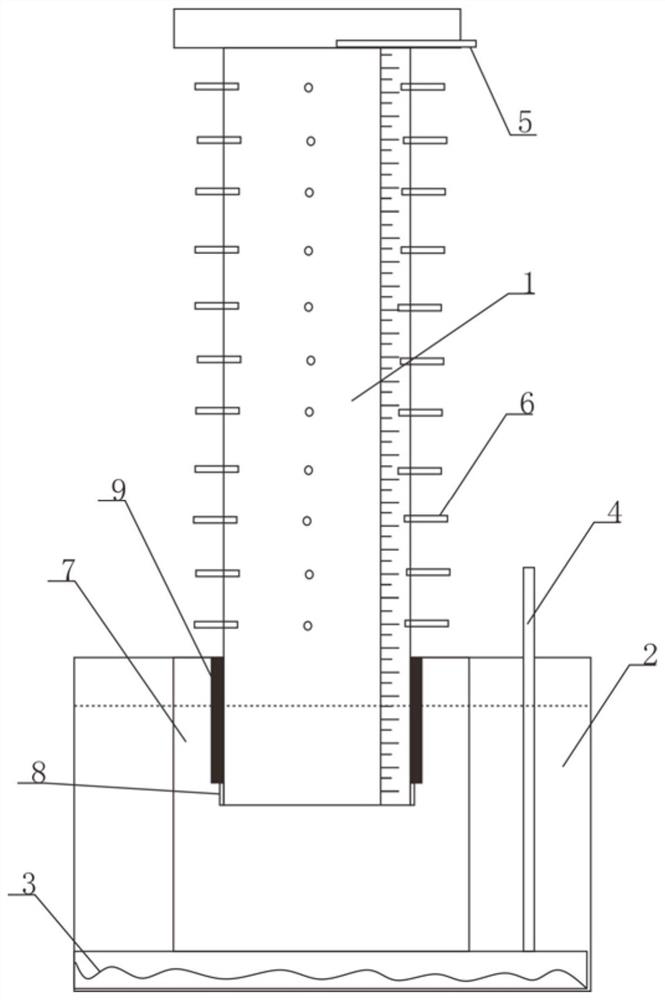

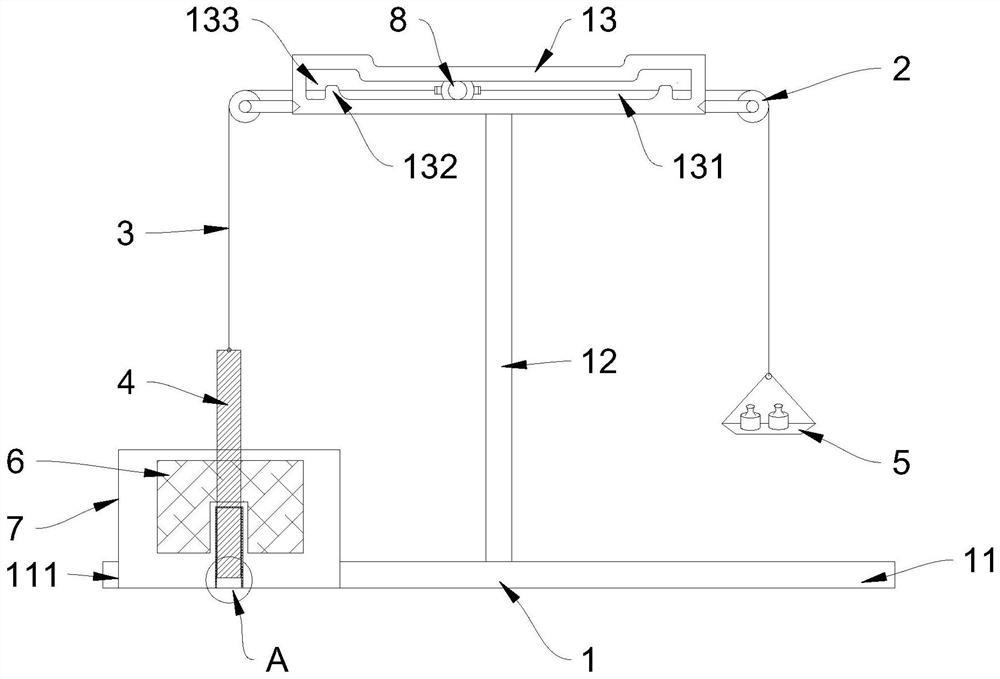

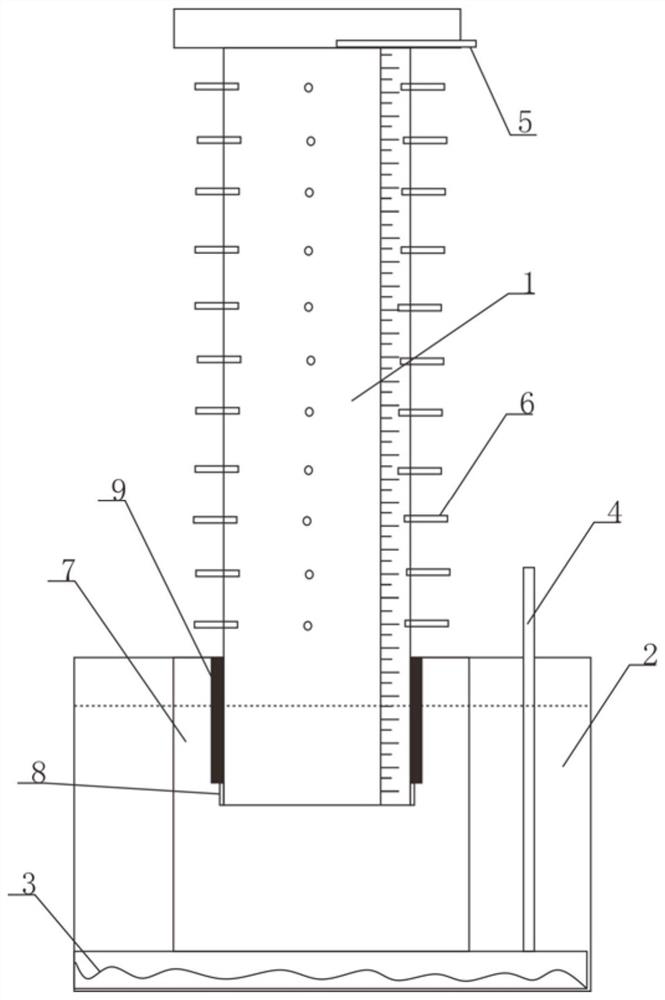

Slurry stability evaluation device and evaluation method

A slurry stability evaluation device comprises a bracket, two pulleys are fixed on two sides of the bracket; a lead is connected between the two pulleys; two ends of the lead are respectively connected with a shaft rod and a weight disc; a test rod is arranged on the shaft rod, and salient points are distributed on the surface of the test rod; a measuring cup is arranged below the shaft rod; the mass of the weight disc is equal to the sum of the masses of the shaft rod and the test rod; the gravity resultant force of the shaft rod and the testing rod is larger than the buoyancy force borne by the testing rod when the testing rod is completely immersed in the slurry. The device is simple in structure, easy to operate, extremely convenient to assemble, disassemble, replace and clean and capable of being repeatedly used; wherein the test rod structure adsorbs agglomerates or gels in the suspended slurry, the mass of the agglomerates is visually displayed by accumulating the total mass of the weights, a stability curve of the slurry can be obtained through multiple tests, then the stability of a slurry system is judged, and the test efficiency, reliability and accuracy are evaluated to meet the requirements.

Owner:江西安驰新能源科技有限公司

Time-division, time-division and frequency division, time-division and code-division, time-division and code-division and frequency-division combined surface acoustic wave tag temperature measurement system and method

ActiveCN108020344BIncrease the number ofImprove anti-interference abilityThermometers using physical/chemical changesExcitation signalComputer science

The invention discloses four surface acoustic wave label temperature measuring systems and corresponding temperature measuring methods. Based on the combination of tie division, time division-frequency division, time division-code division, and time division-code division-frequency division, the multi-node anti-collision temperature measurement is realized. The temperature measuring system is composed of a surface acoustic wave label node, a reader and a server. During the time-division method, different positions of echo pulses are divided into a plurality of surface acoustic wave label nodesaccording to different positions of the reflection gratings of labels. During the time division-frequency division method, time division labels are classified according to different resonance frequencies. During the time division-code division method, time division labels are grouped according to different phase codes of a phase modulation interdigital transducer. During the time division-code division-frequency division-combined method, time division labels are classified firstly and then are grouped. For the temperature measuring systems of different temperature measuring methods, the reader sends out different excitation signals. According to the invention, the ISM and the bandwidth allowed in the national standard are satisfied, and the number of nodes is increased. The verification function is achieved, and the anti-jamming capability is high. The real-time performance is relatively good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

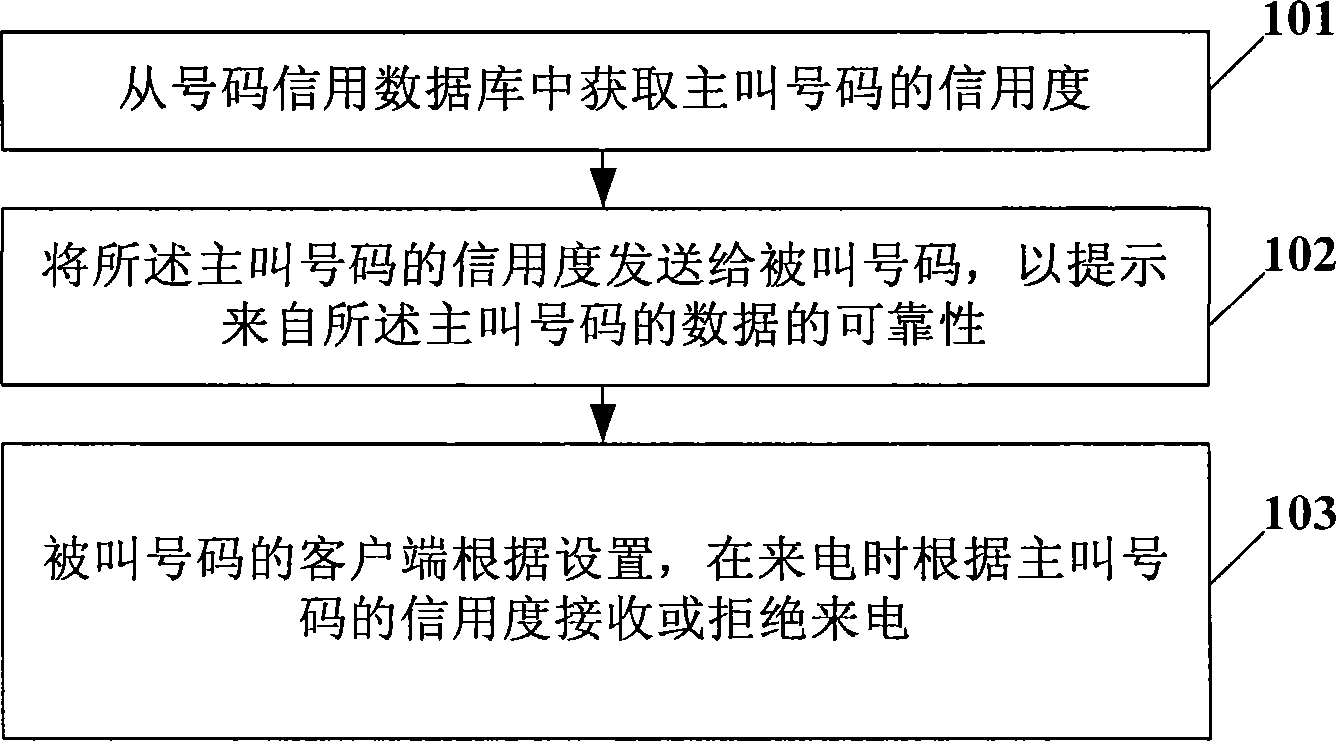

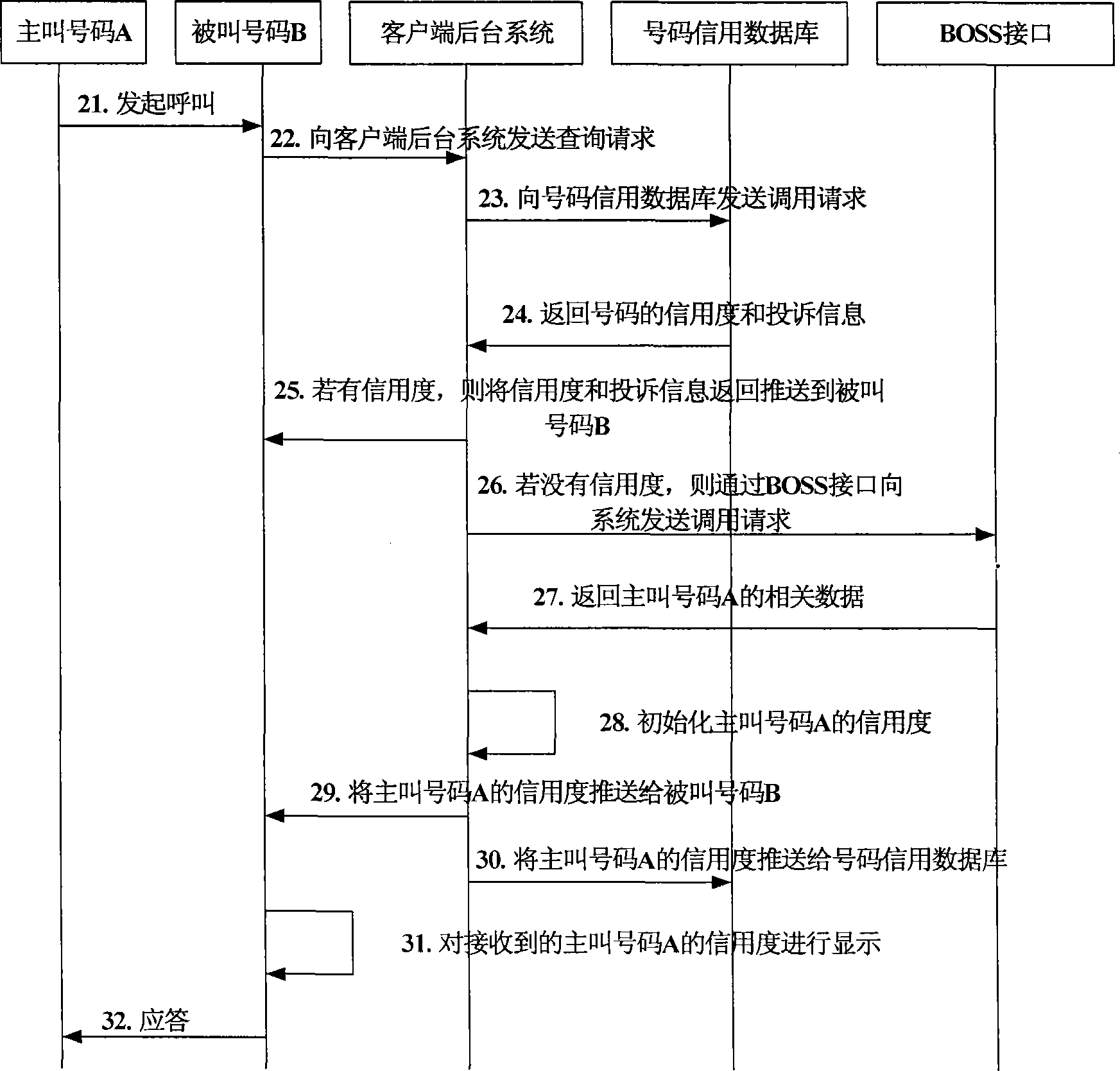

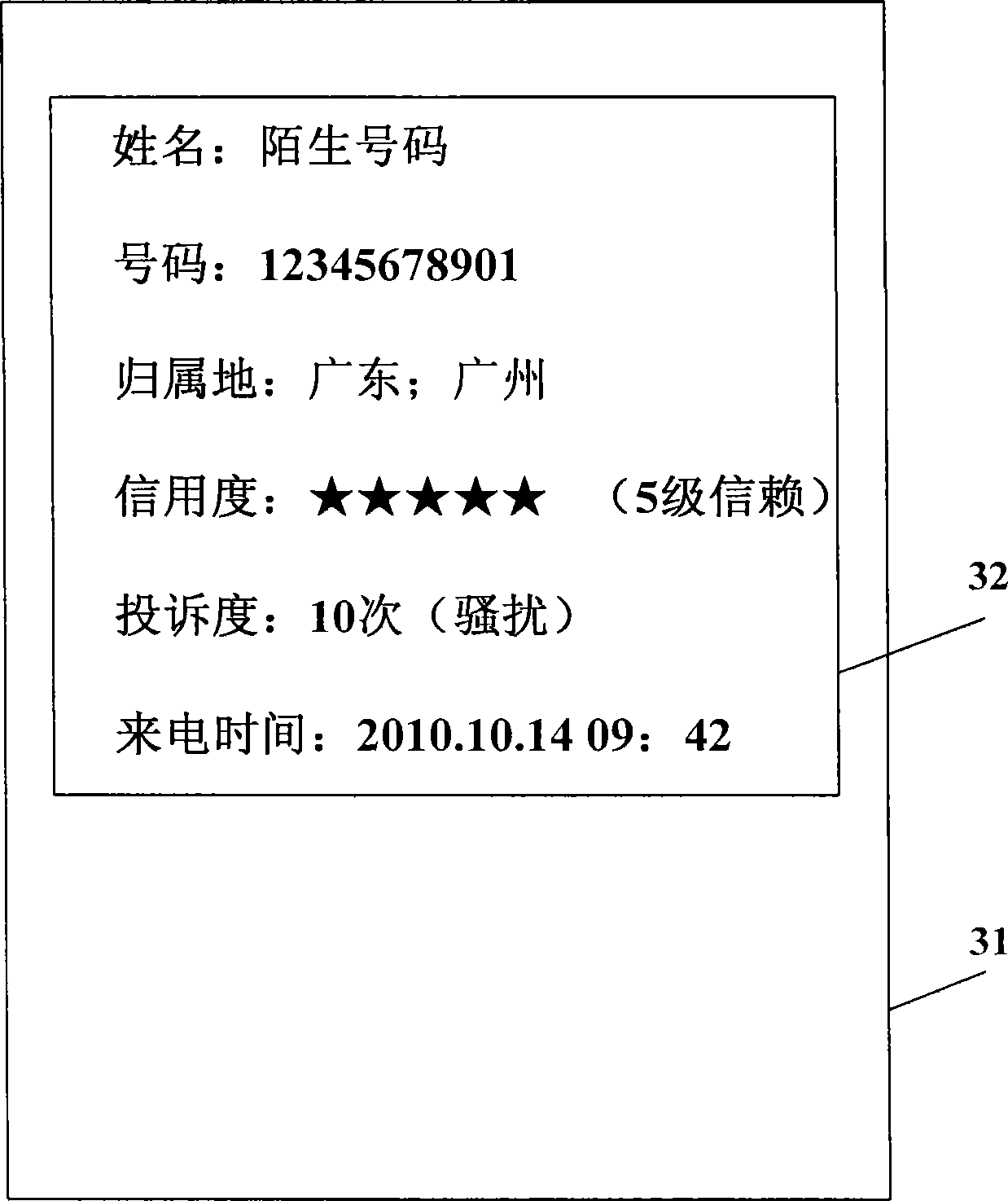

Method and system for incoming call processing

ActiveCN102572059BJudgment reliabilityCommmunication supplementary servicesSubstation equipmentData miningData reliability

The invention provides a method and a system for incoming call processing and belongs to the technical field of data service. The method provided by the invention comprises the following steps: the credit degree of a calling number is obtained from a number credit data base and then sent to a called number, thereby reminding the data reliability of the calling number; and the incoming call reliability is judged based on the credit degree of the calling number, thereby reducing the probability of receiving harassing telephone calls or harassing short messages.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

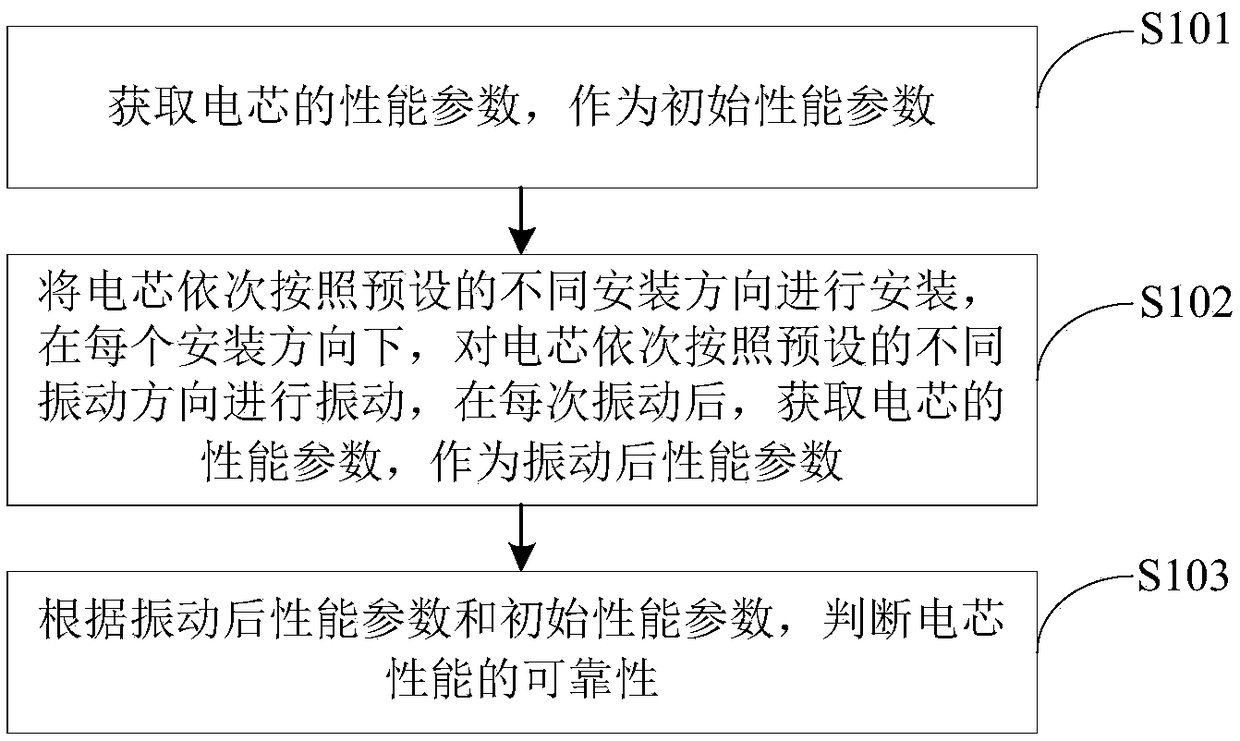

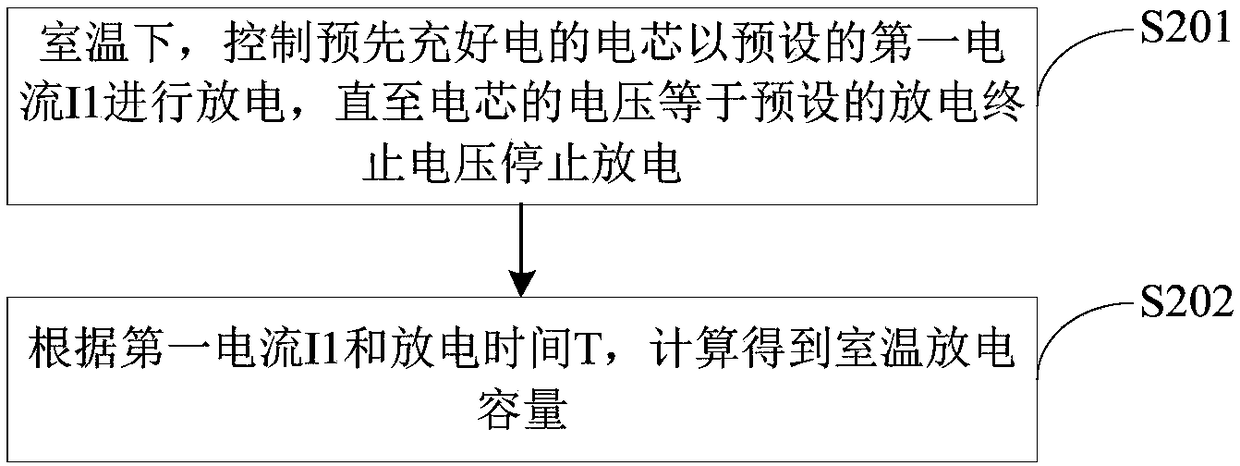

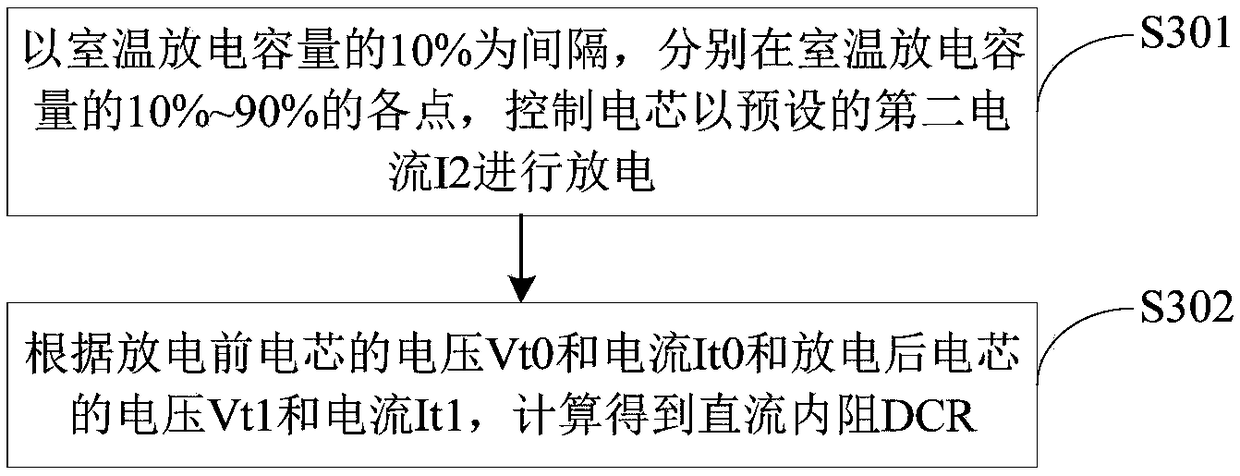

Detection method and device for battery cell performance

The invention provides a detection method and device for battery cell performance. The detection method for the battery cell performance comprises the following steps of: acquiring the performance parameters of each battery cell as initial performance parameters; sequentially installing the battery cells according to the preset different installation directions, sequentially vibrating the batterycells according to the preset different vibration directions in each installation direction, and acquiring the performance parameters of each battery cell as post-vibration performance parameters after each vibration; and judging the reliability of the battery cell performance according to the post-vibration performance parameters and the initial performance parameters. The detection method and device for the battery cell performance sequentially installs the battery cells according to the preset different installation directions, sequentially vibrates the battery cells according to the presetdifferent directions in each installation direction, acquires the post-vibration performance parameters, and judges the reliability of the battery cell performance after the vibration in different directions under the different installation directions.

Owner:CH AUTO TECH CORP CO LTD

Cradle head fault detecting method and device

ActiveCN101917599BAdaptableExtended Fault Detection CapabilitiesImage analysisClosed circuit television systemsFeature extractionRandom noise

The invention discloses a cradle head fault detecting method and a cradle head fault detecting device. The method comprises the following steps: A, sending a cradle head control instruction to a cradle head to be detected and acquiring continuously collected series images as images to be analyzed; B, extracting and analyzing the characteristics of the images to be analyzed to obtain the change condition of a background image and accordingly determining the change condition of the cradle head to be detected; and C, determining if the movement condition of the background image is consistent with the cradle head control instruction, and accordingly determining if the cradle head operates normally. The fault detection method and the fault detection device have higher adaptability to light change, image foreground target movement interference and random noise interference, has an expanded cradle head fault detection function for detecting the moving or static conditions of the cradle head and the specific movement direction and distance of the moving cradle head and can further estimate the movement speed of the cradle head and more accurately determine the reliability of the cradle head.

Owner:SHENZHEN ZTE NETVIEW TECH

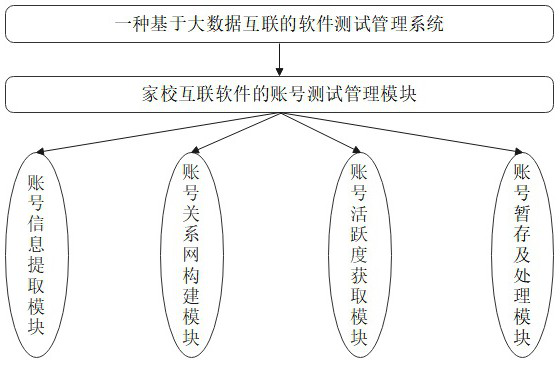

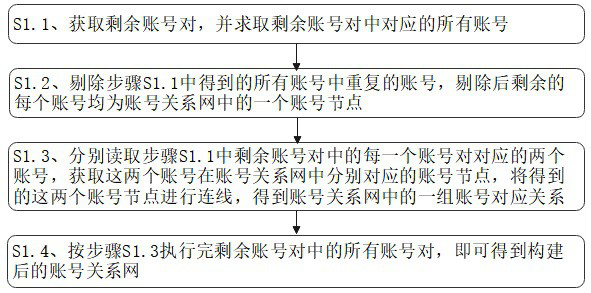

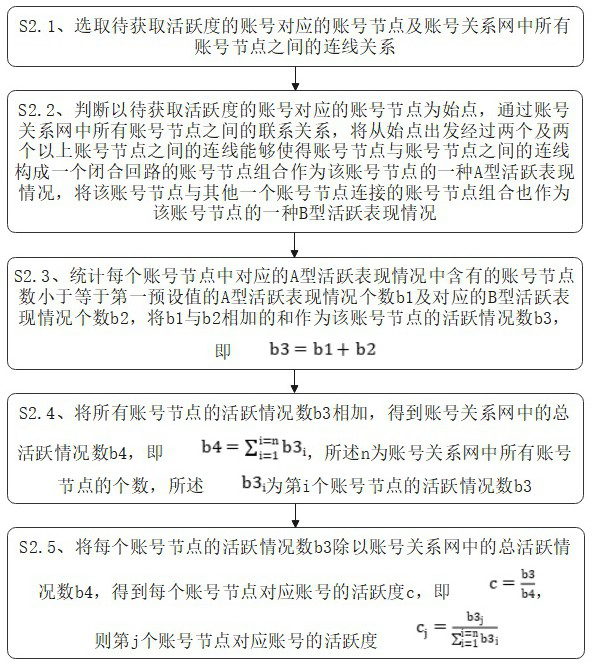

Software test management system and method based on big data interconnection

PendingCN113946501AJudgment reliabilityEfficient discriminationSoftware testing/debuggingTest managementManagement system

The invention discloses a software test management system based on big data interconnection. The system is characterized by comprising an account test management module of home-school interconnection software; the account number test management module of the home-school interconnection software comprises an account number information extraction module used for extracting account number pairs which communicate with each other in a first unit time of each account number; and the account number pairs comprise two account numbers which are the account numbers of the two parties which communicate with each other. According to the invention, testing management is carried out on interconnected software, and particularly account testing management is carried out on home-school interconnected software; according to the invention, the low-activity accounts can be effectively distinguished, and the low-activity accounts can be stored in a unified manner, so that the low-activity accounts can be cleaned conveniently; and the account management function of the home-school interconnection software is tested, and thus judging the reliability and whether the home-school interconnection software needs to be corrected or not.

Owner:广州思谋信息科技有限公司

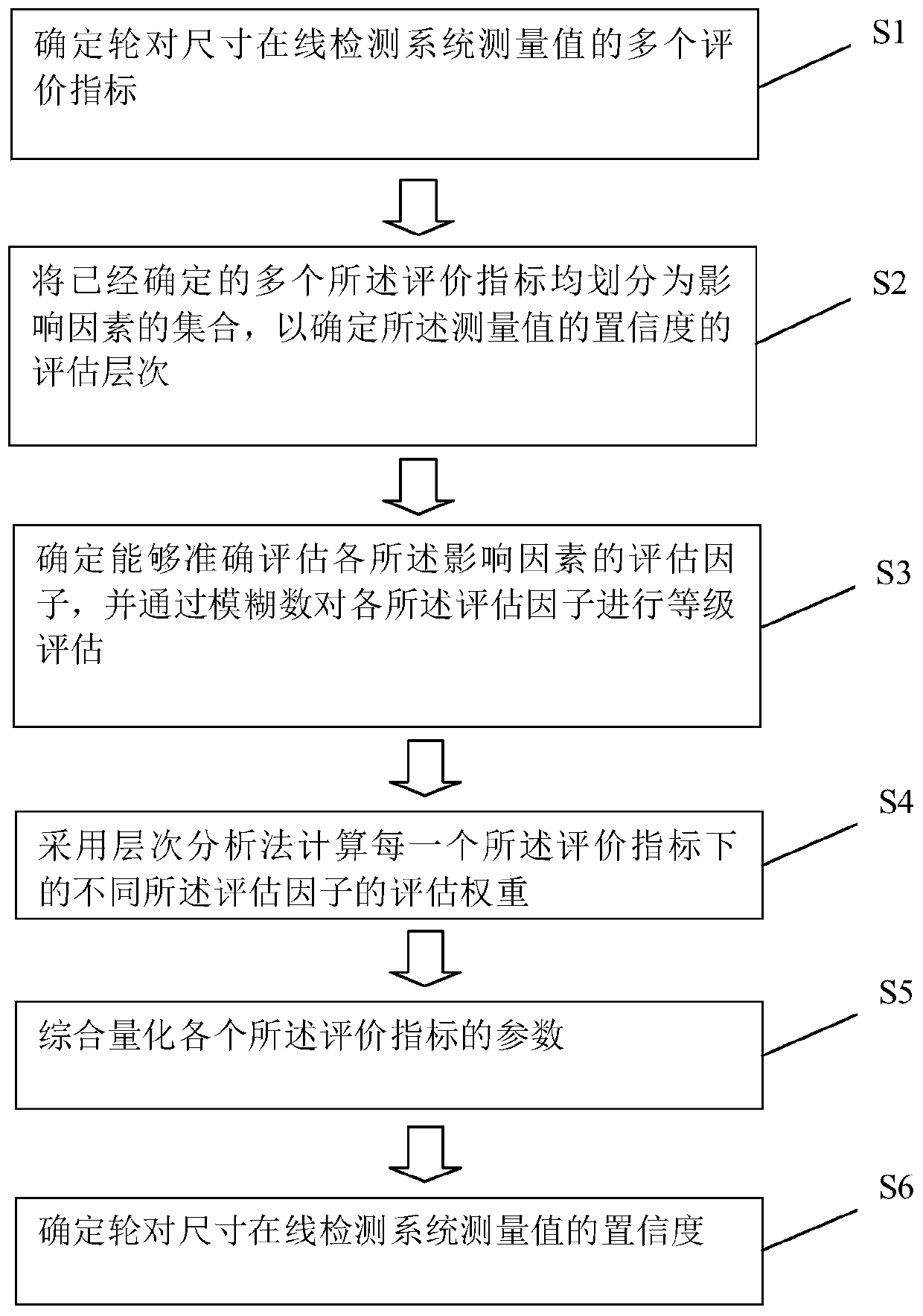

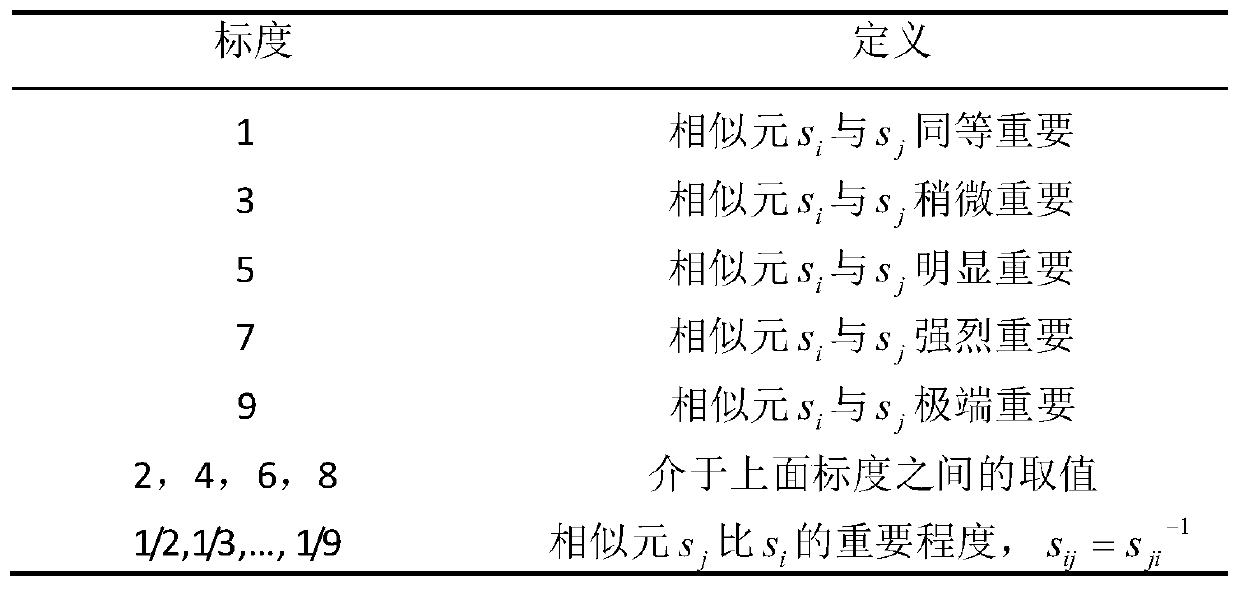

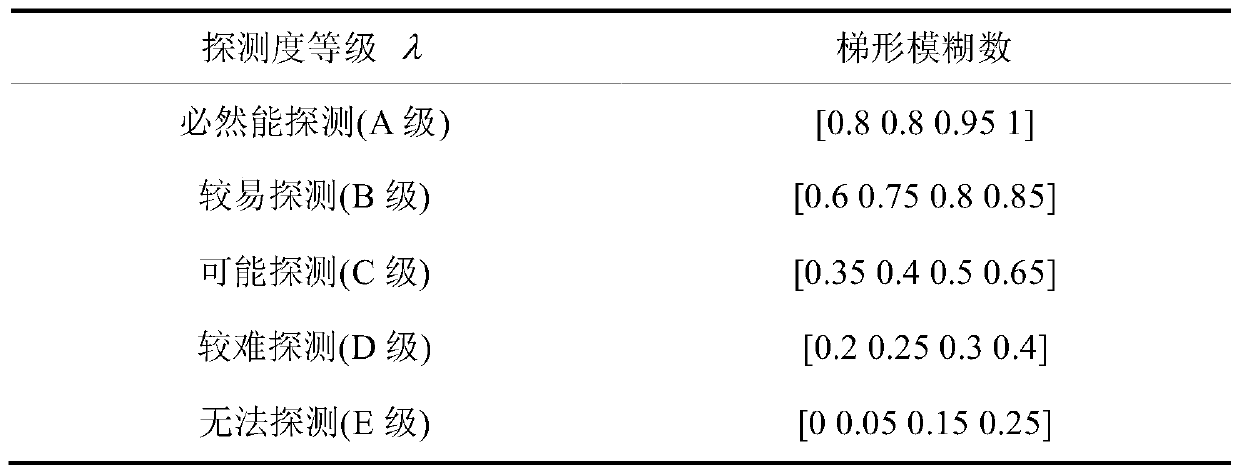

A Method for Determining Confidence Degree of Measured Value of Wheelset Size Online Detection System

The invention discloses a method for determining the confidence of a measured value of a wheel-set size online detection system. The method includes the steps of S1, determining a plurality of evaluation indicators for a measured value of a wheel-set size online detection system; S2, dividing the determined plurality of evaluation indicators into a set of influence elements to determine the evaluation hierarchy of the confidence of the measured value; S3, determining evaluation factors that can be used for accurately evaluating the influence elements, and performing grade evaluation for the evaluation factors by a fuzzy number; S4, calculating evaluation weights of other different evaluation factors under each evaluation indicator by the analytic hierarchy process; S5, quantizing parameters of the evaluation indicators comprehensively; and S6, determining the confidence of the measured value of the wheel-set size online detection system. According to the invention, the reliability degree of each measured value of the wheel-set size online detection system can be determined directly and effectively so that the confidence of each measurement result can be reasonably quantized.

Owner:GUANGZHOU METRO GRP CO LTD

A Test Method for Obtaining Hydrogeological Parameters

ActiveCN113092332BEfficient detectionJudgment reliabilityEarth material testingPermeability/surface area analysisSoil scienceEnvironmental engineering

The invention provides a test method for obtaining hydrogeological parameters, which includes using ground penetrating radar to detect the area to be measured, and obtaining the volume water content and porosity of the unsaturated zone of the area to be tested; dividing the area to be tested into Several sampling areas, soil sampling in each sampling area to obtain columnar soil samples; the columnar soil samples were placed in the test cylinder for infiltration tests at different water temperatures to obtain the test permeability coefficient; according to the porosity of the unsaturated zone obtained by the Kozeny-Carman formula Estimated permeability coefficient, if the experimental permeability coefficient / estimated permeability coefficient = 0.9 ~ 1.1, the experimental permeability coefficient is adopted, otherwise, the experimental permeability coefficient in this test is discarded. The problem of low accuracy of the method for obtaining hydrogeological parameters in the prior art is solved.

Owner:核工业西南勘察设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com